Effect of Stress Relaxation and Annealing Treatment on the Microstructure and Mechanical Properties of Steel Wire

Abstract

1. Introduction

2. Experimental Methods

2.1. Stress Relaxation Test

2.2. Steel Wire Annealing Test

2.3. Characterization

3. Results and Discussion

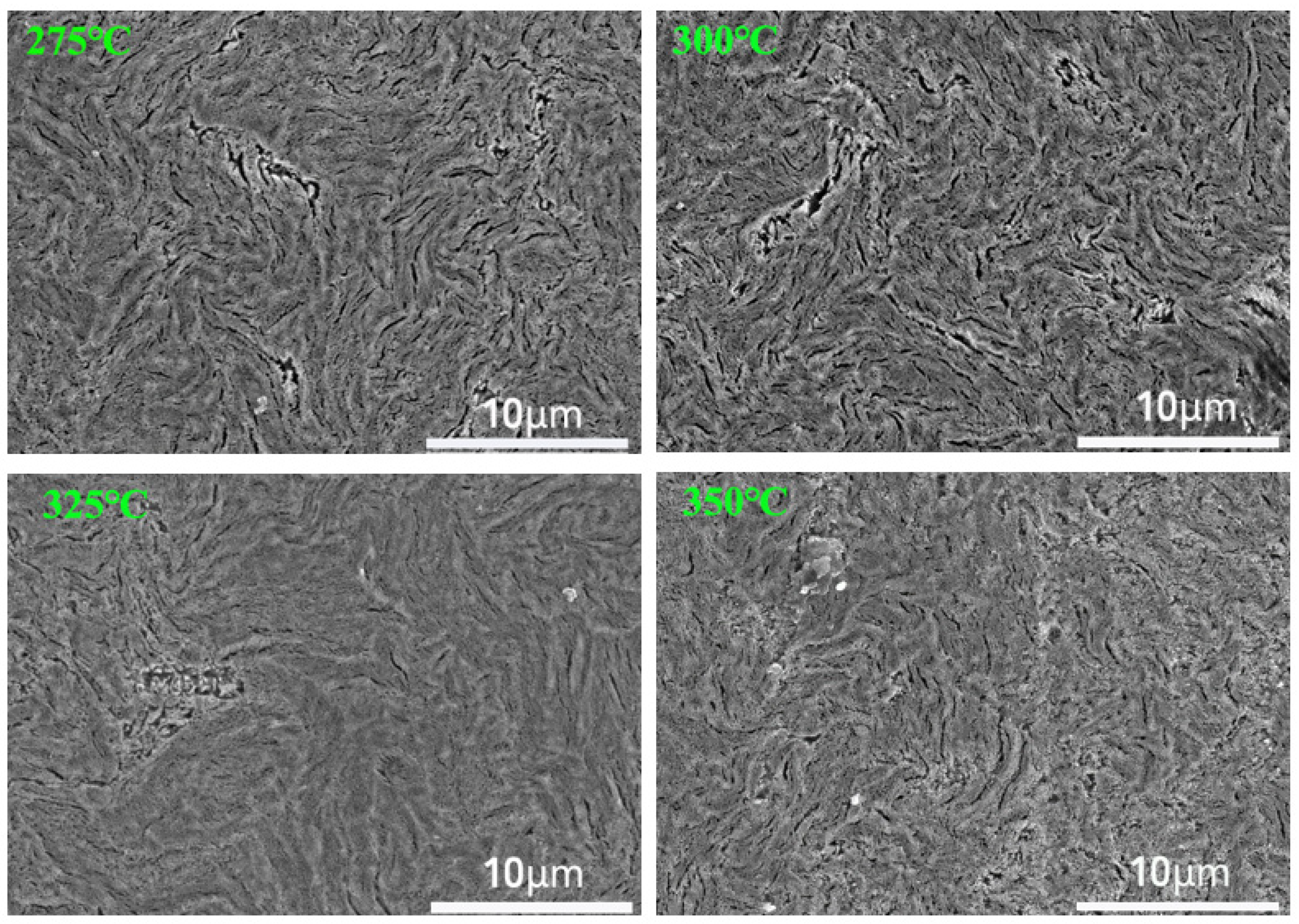

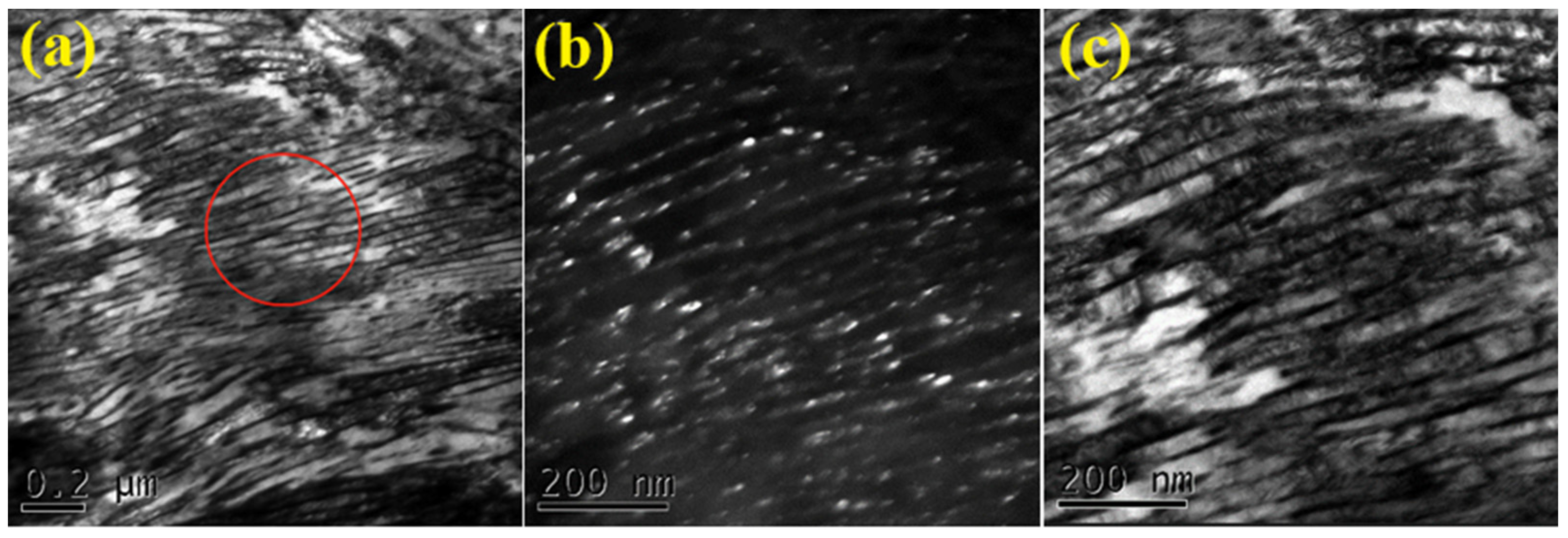

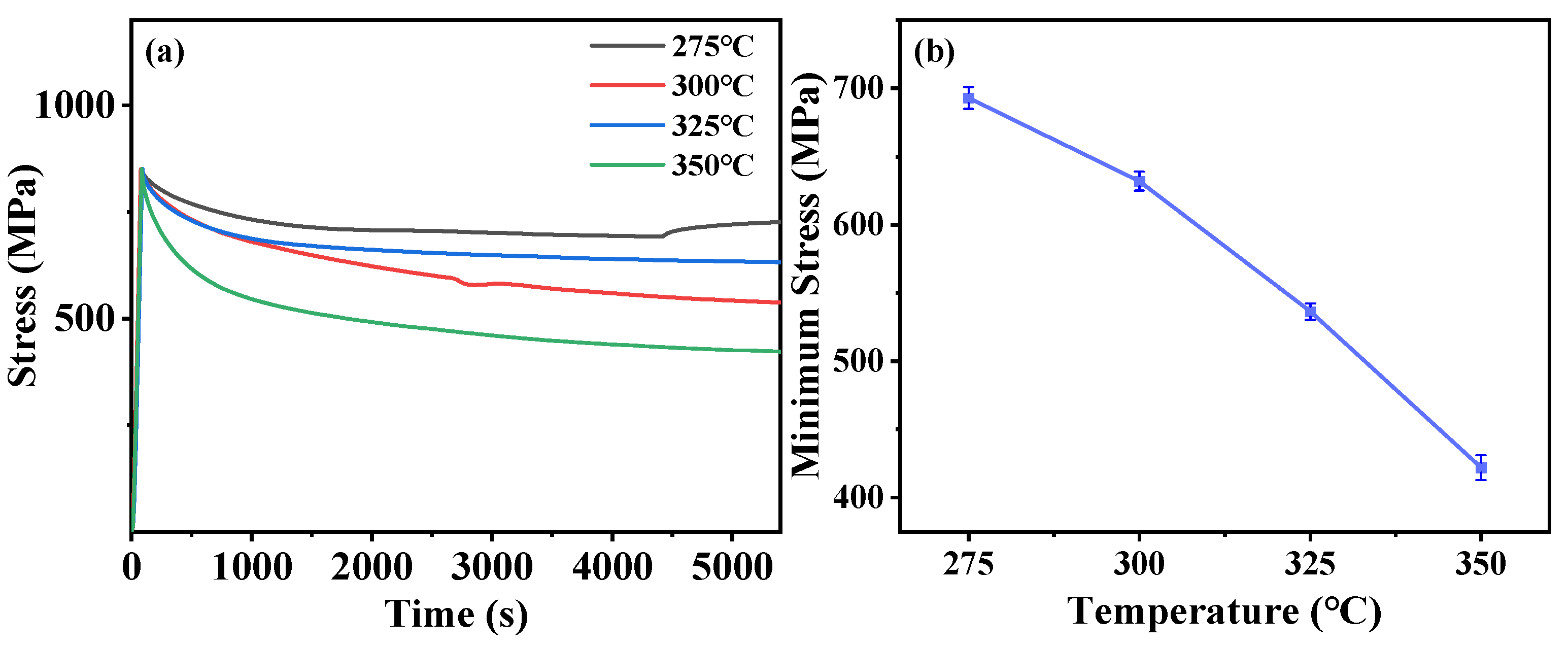

3.1. The Effect of Stress Relaxation on Microstructure and Mechanical Properties of Steel Wire

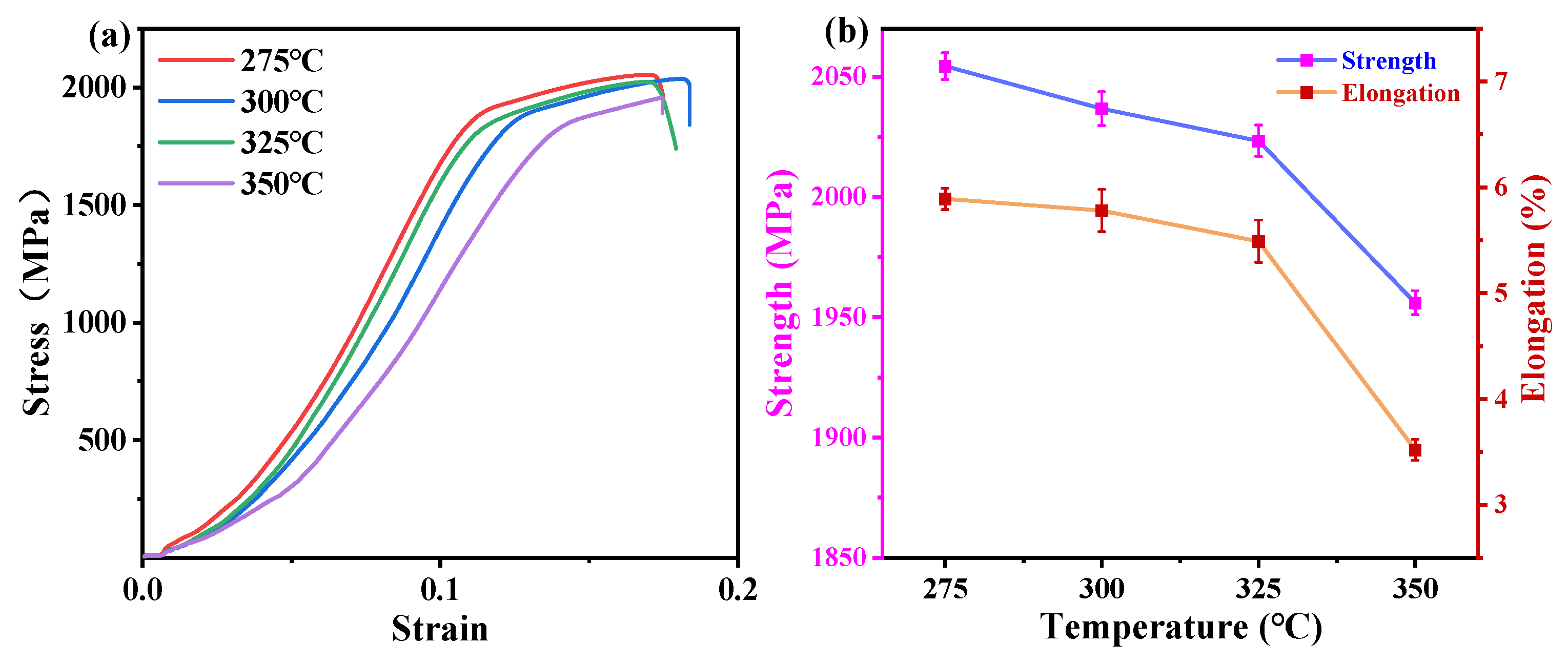

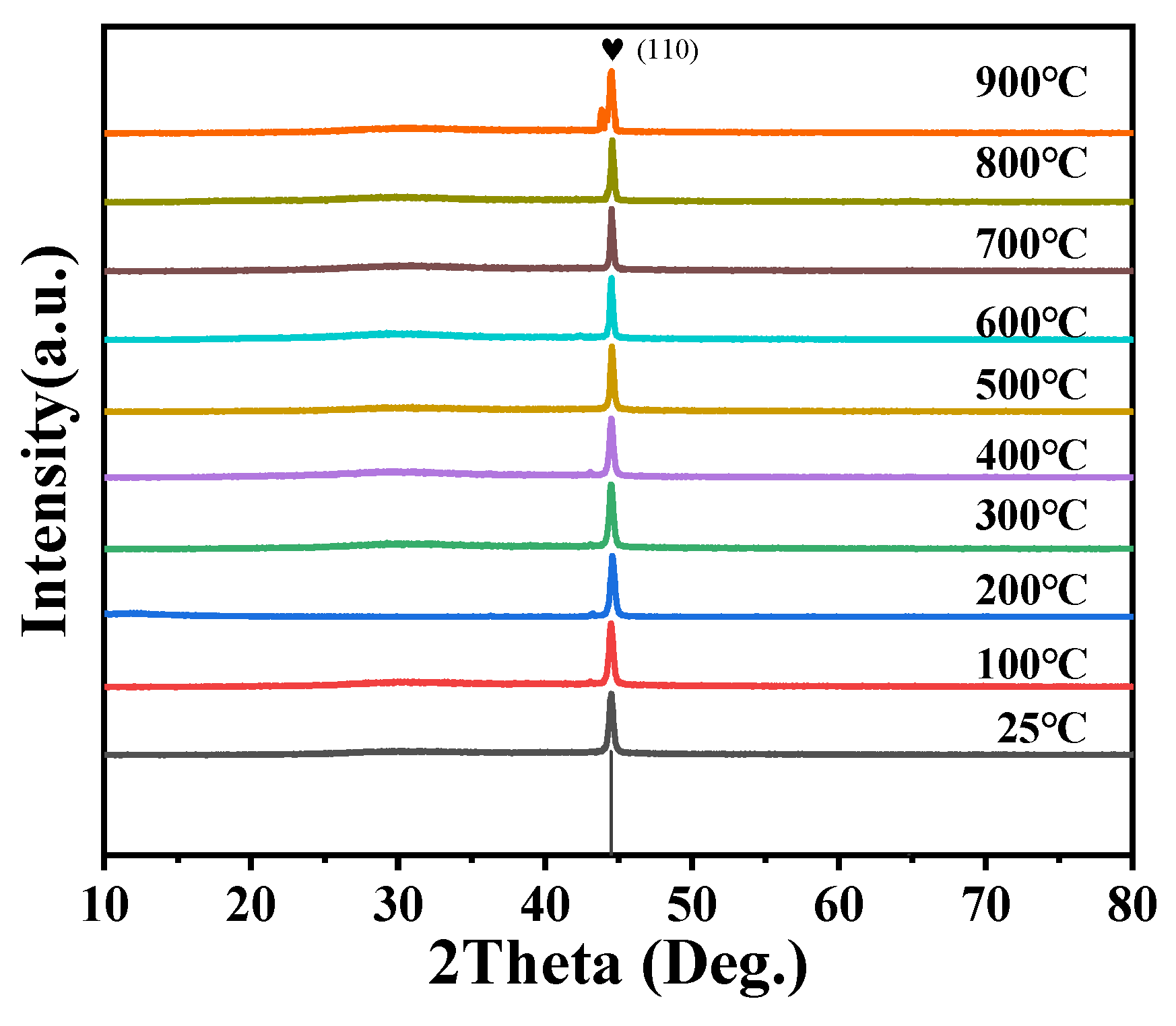

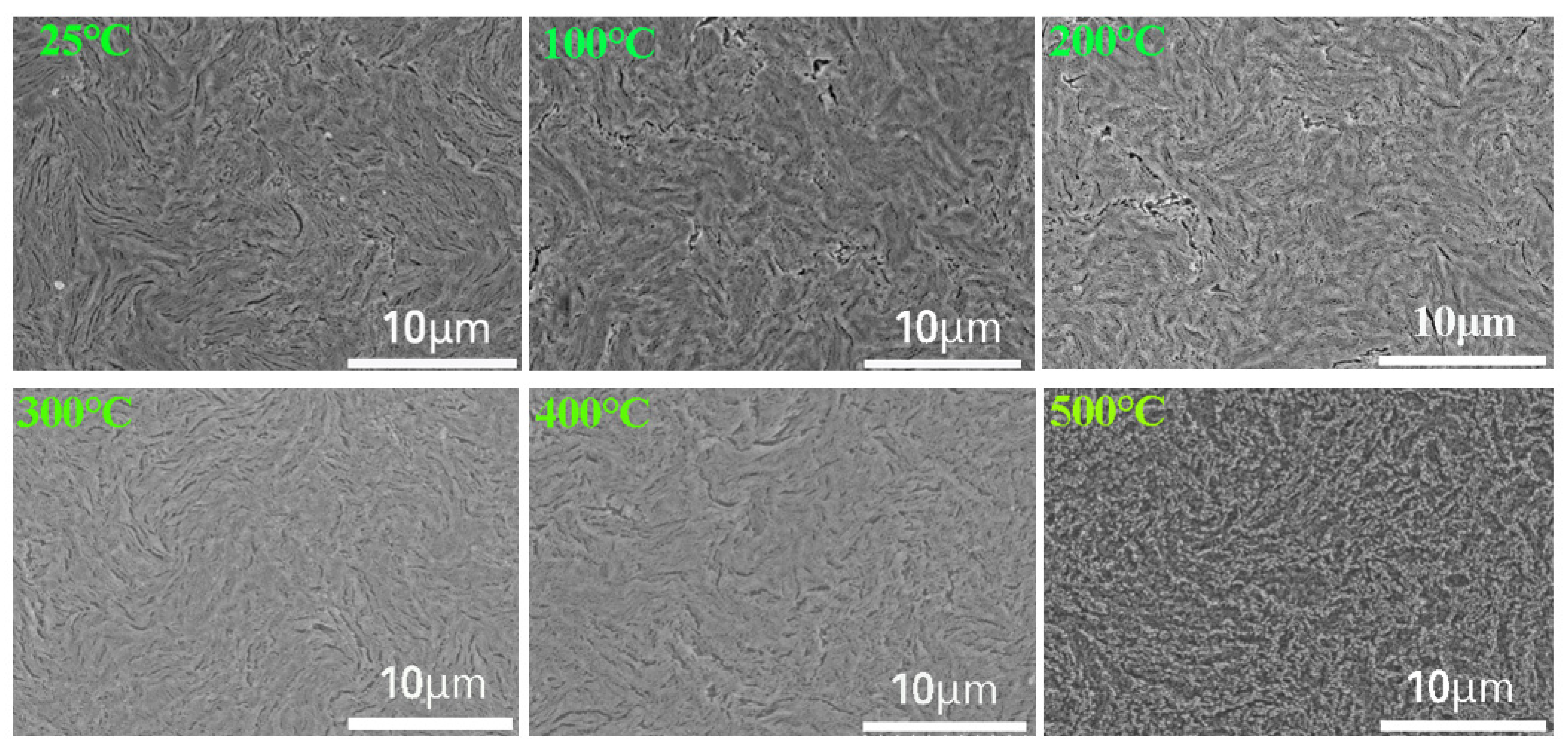

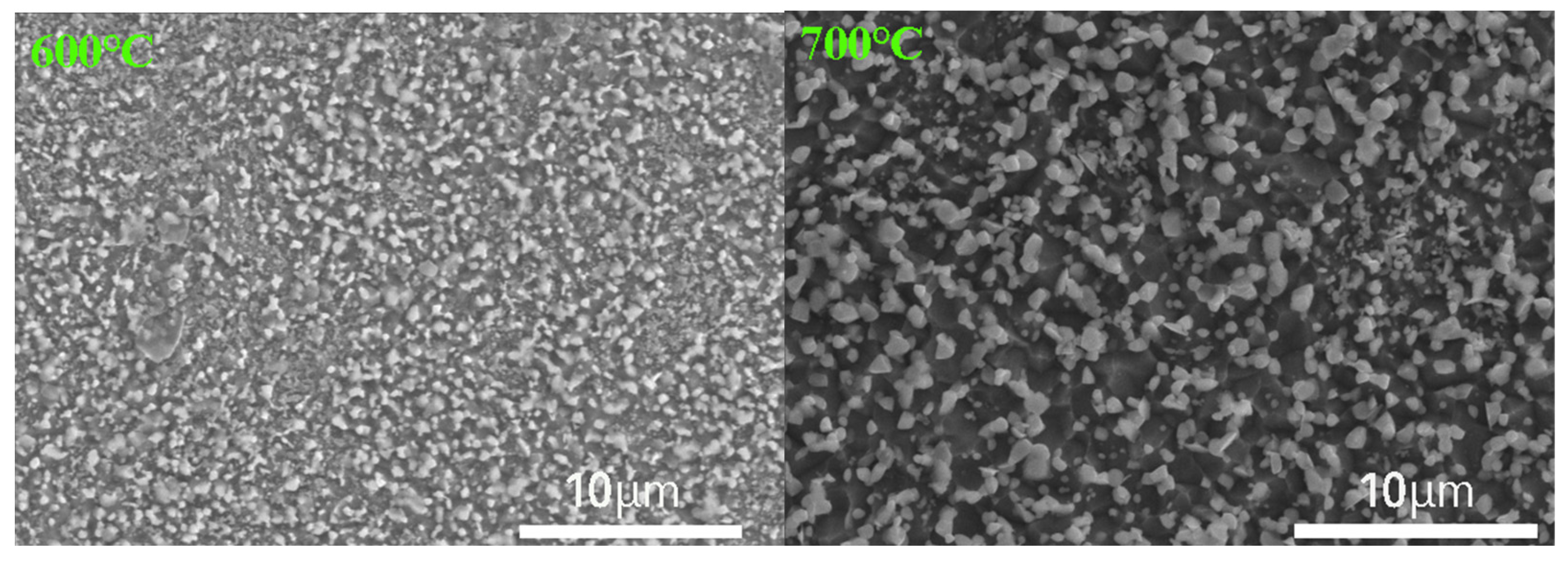

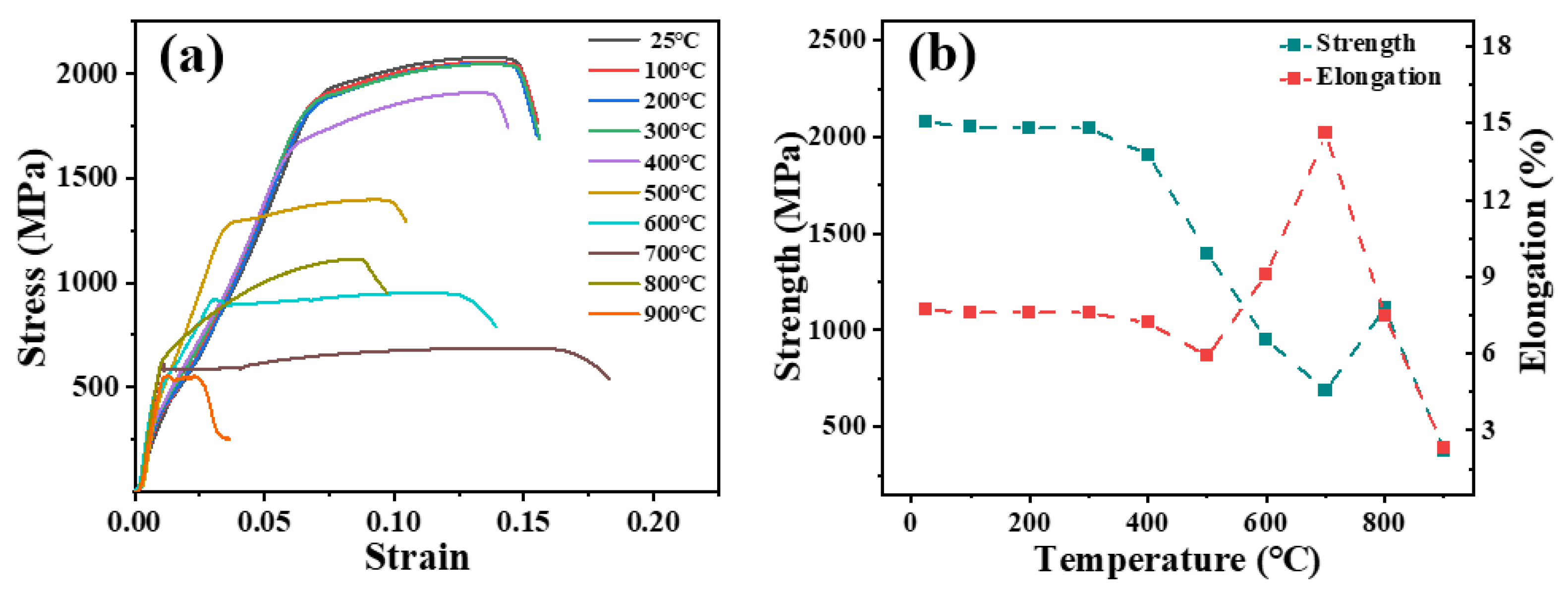

3.2. The Effect of Annealing Temperature on Microstructure and Mechanical Properties of Steel Wire

4. Conclusions

- (1)

- The spacing of the pearl sheet layers increases as the temperature increases. When the temperature is increased to 300 °C, the spacing of the pearlite lamellae is 55 nm, which is not much change from the initial value of 50 nm. However, the spacing of the pearlite sheet layers is 75 nm when the temperature is 350 °C. In the stress relaxation test, the irreversible damage occurs in the 1960 MPa wires when the temperature exceeds 300 °C.

- (2)

- The tensile strength and elongation of the steel wire after stress relaxation gradually decreases with increasing temperature. The tensile strength of the steel wire is 1957 MPa when the temperature is 300 °C, which is 5.73% lower than the room temperature.

- (3)

- The granular carbides appeared inside the wire when the annealing temperature of 500 °C. The granular carbide achieves bigger and bigger temperature increases to 700 °C. When the annealing temperature is 800 and 900 °C, the organization appeared in the network carburite, and the brittleness of the steel wires increases substantially.

- (4)

- The maximum tensile strength of the steel wire is greater than 98% of the strength of the steel wire at room temperature after annealing at 300 °C. The strength of the 1960 MPa steel wire decreases significantly when the temperature exceeds 300 °C. Tensile strength accounts for 91% of the strength at room temperature at 400 °C. The strength drops sharply when the temperature rises to 500~900 °C. The tensile strength of steel wire is only 26.7% of the strength at room temperature when the temperature is 900 °C. A fire-resistant temperature of 300 °C is recommended for cables. The fire protection temperature can be set at 275 °C if more conservative fire protection measures are considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.G.; Wang, B.; Xie, G.Z.; Li, C.C.; Zhang, D.K.; Ge, S.R. Effect of temperature on tribo-corrosion behaviors of parallel steel wires of main cable in the suspension bridge. Wear 2023, 512, 204522. [Google Scholar] [CrossRef]

- Juozapaitis, A.; Kliukas, R.; Sandovic, G.; Lukoseviciene, O.; Merkevicius, T. Analysis of modern three-span suspension bridges with stiff in bending cables. Balt. J. Road Bridge Eng. 2013, 8, 205–211. [Google Scholar] [CrossRef]

- Son, Y.; Lee, C.; Yoo, D.; Kim, J.; Choi, J. Cheon-Sa Bridge-The First Sea Crossing Multi-Span Suspension Bridge. Struct. Eng. Int. 2021, 31, 431–434. [Google Scholar] [CrossRef]

- Yegian, M.K.; Arzoumanidis, S.; Strohman, B.P.; Kishore, K.; Patel, J. Appraising the Brooklyn Bridge. Civ. Eng. 2009, 79, 38–49. [Google Scholar] [CrossRef][Green Version]

- Peris-Sayol, G.; Paya-Zaforteza, I.; Balasch-Parisi, S.; Alós-Moya, J. Detailed Analysis of the Causes of Bridge Fires and Their Associated Damage Levels. J. Perform. Constr. Facil. 2017, 31, 04016108. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Naser, M.Z. Importance factor for design of bridges against fire hazard. Eng. Struct. 2013, 54, 207–220. [Google Scholar] [CrossRef]

- Lu, J.; Liu, H.; Chen, Z.; Liao, X. Experimental investigation into the post-fire mechanical properties of hot-rolled and cold-formed steels. J. Constr. Steel Res. 2016, 121, 291–310. [Google Scholar] [CrossRef]

- Wang, H.; Nie, S.; Li, J. Reduction model of hot- and cold-rolled high-strength steels during and after fire. Fire Saf. J. 2022, 129, 103563. [Google Scholar] [CrossRef]

- Yu, Y.J.; Lan, L.F.; Ding, F.X.; Wang, L.P. Mechanical properties of hot-rolled and cold-formed steels after exposure to elevated temperature: A review. Constr. Build. Mater. 2019, 213, 360–376. [Google Scholar] [CrossRef]

- Ren, C.; Zhang, P.; Yan, S.; Dai, L. Analysis and design of cold-formed steel storage rack uprights under localised fires. Structures 2020, 27, 2082–2095. [Google Scholar] [CrossRef]

- Laím, L.; Rodrigues, J.P.C. Numerical analysis on axially-and-rotationally restrained cold-formed steel beams subjected to fire. Thin-Walled Struct. 2016, 104, 1–16. [Google Scholar] [CrossRef]

- Ye, K.; Ozaki, F.; Knobloch, M. Impact fracture energies of cold-formed steel square hollow section in and after fire. J. Constr. Steel Res. 2021, 183, 106740. [Google Scholar] [CrossRef]

- Zeng, X.; Wu, W.B.; Huo, J.S.; Elchalakani, M. Residual mechanical properties of Q890 high-strength structural steel after exposure to fire. Constr. Build. Mater. 2021, 304, 124661. [Google Scholar] [CrossRef]

- Li, G.-Q.; Wang, X.-X.; Zhang, C.; Cai, W.-Y. Creep behavior and model of high-strength steels over 500 MPa at elevated temperatures. J. Constr. Steel Res. 2020, 168, 105989. [Google Scholar] [CrossRef]

- Qiang, X.; Bijlaard, F.S.K.; Kolstein, H. Deterioration of mechanical properties of high strength structural steel S460N under transient state fire condition. Mater. Des. 2012, 40, 521–527. [Google Scholar] [CrossRef]

- Muciaccia, G. Anchorage and detailing of reinforcement under fire action. Struct. Concr. 2023, 24, 3264–3280. [Google Scholar] [CrossRef]

- Molkens, T.; Cashell, K.A.; Malaska, M.; Alanen, M.; Rossi, B. Performance of structural stainless steel following a fire. Eng. Struct. 2021, 235, 112001. [Google Scholar] [CrossRef]

- Ban, H.; Bai, R.; Chung, K.-F.; Bai, Y. Post-fire material properties of stainless-clad bimetallic steel. Fire Saf. J. 2020, 112, 102964. [Google Scholar] [CrossRef]

- Sun, R.; Xie, B.; Perera, R.; Pan, Y. Modeling of Reinforced Concrete Beams Exposed to Fire by Using a Spectral Approach. Adv. Mater. Sci. Eng. 2018, 2018, 6936371. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Y.; Huang, Z.; Li, L.; Huang, Y.; Zhang, Y.; Zhang, G.; Zhang, X.; Duan, Y. Post-fire behaviour of continuous reinforced concrete slabs under different fire conditions. Eng. Struct. 2021, 226, 111342. [Google Scholar] [CrossRef]

- Nguyen, N.V.; Vu, Q.A.; Kim, S.E. An experimental study on stress relaxation behaviour of high strength steel wire: Microstructural evolution and degradation of mechanical properties. Constr. Build. Mater. 2020, 261, 119926. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, W.; Ma, K.C.; Jiang, L.S.; Ye, J.H.; Xu, L.L. Creep and stress relaxation experiments of 1960-grade high-strength steel wire at elevated temperatures. Structures 2024, 59, 105682. [Google Scholar] [CrossRef]

- Zheng, W.Z.; Hu, Q.; Haoyu, Y. Experimental research on the mechanical property of prestressing steel wire during and after heating. Front. Struct. Civ. Eng. 2007, 1, 247–254. [Google Scholar] [CrossRef]

- Atienza, J.M.; Elices, M. Behavior of prestressing steels after a simulated fire: Fire-induced damages. Constr. Build. Mater. 2009, 23, 2932–2940. [Google Scholar] [CrossRef]

- Liu, H.; Guo, L.; Chen, Z.; Fan, Z. Study on temperature dependency of spiral strand properties. Int. J. Mech. Sci. 2019, 161, 105013. [Google Scholar] [CrossRef]

- Huang, M.; Wang, L.; Wang, C.; Li, Y.; Wang, J.; Yuan, J.; Hu, J.; Huang, M.; Xu, W. Optimizing crack initiation energy in austenitic steel via controlled martensitic transformation. J. Mater. Sci. Technol. 2024, 198, 231–242. [Google Scholar] [CrossRef]

- Zong, Z.; Jiang, D.; Zhang, J. Study of the mechanical performance of Grade 1860 steel wires at elevated temperatures. Mater. Res. Innov. 2015, 19, 1175–1181. [Google Scholar] [CrossRef]

- Jung, J.Y.; An, K.S.; Park, P.Y.; Nam, W.J. Correlation between Microstructures and Ductility Parameters of Cold Drawn Hyper-Eutectoid Steel Wires with Different Drawing Strains and Post-Deformation Annealing Conditions. Metals 2021, 11, 178. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Yu, S.; Li, M. Mechanical Properties of Steel Strands Cooled by Different Methods After High-Temperature Treatment. Int. J. Steel Struct. 2022, 22, 333–342. [Google Scholar] [CrossRef]

- Xiao, R.; Song, C.; Sun, B.; Dai, W.; Liu, J. Reliability-assisted determination of partial factors for the design of main cables considering secondary stress effect. Structures 2023, 48, 1479–1490. [Google Scholar] [CrossRef]

- Ge, S.; Ni, Y.; Zhou, F.; Yang, C.; Guo, F.; Li, J.; Shi, B. A passive fire protection method for main cables and slings of suspension bridges utilizing fiber felt/aerogel composites. Constr. Build. Mater. 2023, 408, 133822. [Google Scholar] [CrossRef]

- GB/T 10120-2013; Metallic Materials—Tensile Stress Relaxation—Method of Test. Standards Press of China: Beijing, China, 2013.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

| Elemental | C | Si | Mn | P | S | Cr | Cu | V |

|---|---|---|---|---|---|---|---|---|

| % | 0.9 | 1.1 | 0.9 | 0.02 | 0.015 | 0.35 | 0.05 | 0.02 |

| Range | 0.84~0.9 | 0.7~1.1 | 0.6~0.9 | ~0.02 | ~0.015 | 0.05~0.35 | ~0.05 | ~0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, G.; Ni, Y.; Shi, F.; Qi, J.; Xu, B. Effect of Stress Relaxation and Annealing Treatment on the Microstructure and Mechanical Properties of Steel Wire. Buildings 2024, 14, 4044. https://doi.org/10.3390/buildings14124044

Du G, Ni Y, Shi F, Qi J, Xu B. Effect of Stress Relaxation and Annealing Treatment on the Microstructure and Mechanical Properties of Steel Wire. Buildings. 2024; 14(12):4044. https://doi.org/10.3390/buildings14124044

Chicago/Turabian StyleDu, Gaoming, Ya Ni, Fangchang Shi, Jiqiu Qi, and Bolong Xu. 2024. "Effect of Stress Relaxation and Annealing Treatment on the Microstructure and Mechanical Properties of Steel Wire" Buildings 14, no. 12: 4044. https://doi.org/10.3390/buildings14124044

APA StyleDu, G., Ni, Y., Shi, F., Qi, J., & Xu, B. (2024). Effect of Stress Relaxation and Annealing Treatment on the Microstructure and Mechanical Properties of Steel Wire. Buildings, 14(12), 4044. https://doi.org/10.3390/buildings14124044