Abstract

In the practical operation of traditional landfills, compaction clay often experiences cracking, while the HDPE geomembrane may tear and bulge, resulting in a compromised performance of the landfill covering system. To address this issue, a capillary retarding covering material for landfill sites is proposed by utilizing municipal sludge and construction waste particles as substrates and incorporating a small quantity of calcium bentonite. The mechanical characteristics of the covering material were investigated using a standard consolidation test and a triaxial compression test. A permeability test and a soil water characteristic curve (SWCC) test were conducted to examine the permeability and capillary retarding effect of the covering material. Microscopic tests including SEM scanning, laser particle size analysis, and T2 NMR analysis were performed to investigate the connection mode, particle size composition, and pore structure characteristics of the covered particles. Based on the aforementioned research, the following conclusions can be drawn: The cohesion of the covering material ranged from 50 to 150 kPa, while the internal friction angle ranged from 24.23° to 31°. The cohesion was directly proportional to the content of construction waste, whereas the internal friction angle was inversely proportional to calcium bentonite content. The permeability coefficient ranged from 5.04 × 10−6 cm/s to 7.34 × 10−5 cm/s, indicating a certain level of impermeability. Both the sludge and the calcium bentonite contents jointly influenced the final permeability coefficient in a negative correlation manner, with a notable hydraulic hysteresis phenomenon observed. A higher content of construction waste leads to a more pronounced supporting force exerted by the formed skeleton structures within a load pressure range between 0 and 1600 kPa. When considering a mass ratio of municipal sludge: construction waste: calcium bentonite as 30:60:7, respectively, only a decrease in the pore ratio by approximately 13.20% was observed. This study provides valuable data support for designing and applying capillary retarding cover barrier systems in landfills.

1. Introduction

The People’s Republic of China, being a highly populous nation, generates over 400 million tons of urban solid waste annually with an annual growth rate ranging from 8% to 10%. Despite this, landfilling remains the predominant method for managing municipal waste in most Chinese cities [1]. The primary constituents of the sealing and covering system commonly employed in traditional landfill sites include a top layer that conducts water, compacted clay, and an HDPE geomembrane. During actual operation, the compacted clay is often dry and cracked, while the HDPE geomembrane frequently experiences tearing and bulging. These issues result in a failure of the landfill’s service performance for its sealing and covering system, allowing rainwater to seep into the landfill and form a liquid contaminant that pollutes the surrounding soil [2,3,4,5]. Due to numerous flaws in the conventional overlay, it is imperative to seek out a novel alternative.

The sludge is a by-product of sewage treatment technology aimed at addressing the issue of water pollution. Municipal sludge contains a significant amount of pathogenic microorganisms, organic matter, heavy metals, and other toxic and hazardous substances. If the sludge is not effectively treated, it will inevitably lead to secondary pollution in both public areas and the environment [6]. By 2020, China’s construction waste generation is expected to exceed 3 billion tons, with a recycling rate of only about 10%, despite efforts to manage engineering residue and mud [7]. Municipal sludge exhibits a high moisture content, significant volume deformation, and numerous cracks during water loss, which severely impacts the service performance of the cover layer. Incorporating construction waste into municipal sludge can not only reduce volume deformation but also provide mechanical strength to the material by using construction waste as a skeleton support. Although municipal sludge contains some clay particles, its content is minimal and has a weak capillary blocking ability; therefore, adding a small amount of bentonite improves its capillary blocking ability [8,9].

In recent years, the capillary blocking covering system has garnered significant attention from researchers. The capillary blocking cover layer typically consists of fine-grained soil in the upper portion and coarse-grained soil in the lower portion. Due to differences in pore diameter between these two types of soil, their permeability coefficients and equations also differ. When matrix suction exceeds a certain threshold, the permeability coefficient of coarse-grained soil becomes smaller than that of fine-grained soil, preventing rainwater from penetrating through to the coarse-grained layer and instead storing it within the fine-grained layer [10,11,12]. Miyazaki initially discovered the occurrence of this capillary barrier phenomenon between fine-grained and coarse-grained soils, wherein water emerges at the interface forming a capillary isolation zone during soil water flow [13]. Stormont et al. employed a soil mixture comprising silt, gravel, construction sand, and silt to conduct rainfall experiments on the cover layer. This investigation substantiated the presence of a capillary barrier effect and revealed that coarse-grained soil with large and uniform particle sizes exhibited a more robust capillary barrier effect [14]. Rahardjo et al. had proposed an innovative approach known as the dual capillary retarding mulching system, which involves strategic placement of fine and coarse-grained soil to establish two identical barriers for retarding rainwater infiltration. This study investigates the effectiveness of this dual capillary barrier in reducing rainwater infiltration at a sanitary landfill site in Singapore, with particular emphasis on its hydraulic characteristics under both saturated and unsaturated conditions. The investigation includes determining key parameters such as the soil water characteristic curve (SWCC) and permeability coefficient [15,16]. Zhang comprehensively considered the two phases of water and gas, proposed a multiphase flow model, and utilized the finite element software COMSOL to conduct simulation research. It was concluded that fine soil with low saturation exhibits a high water storage capacity, effectively mitigating water infiltration and harmful gas emission. Additionally, the presence of coarser soil enhances the capillary blocking effect and decelerates water infiltration [17].

Bizarreta et al. conducted a comprehensive analysis of the mineralogy and morphological characteristics of sludge in the leachate treatment plant, meticulously selecting sludge samples with varying moisture content for shrinkage tests. Subsequently, they investigated the potential utilization of sludge as a final cover material for specific landfills [18,19]. The study conducted by Rubinos et al. investigated the geotechnical and hydraulic characteristics, advantages, and disadvantages of various waste materials, including paper mill sludge, cement kiln dust, biochar modified clay, and red mud as constituents for landfill barriers. The findings of this study demonstrated that the modified sludge fulfilled the requirements for landfill cover materials in terms of unconfined compressive strength and permeability coefficient tests [20,21,22]. The compaction, screening, and CT scan tests were conducted by Li et al. on a renewable construction waste mixture. The study unveiled that the diverse microscopic particle morphology and interparticle contact among geomaterials played a pivotal role in determining their respective mechanical properties [23]. Ray et al. demonstrated that bentonite exhibits low permeability, a high sealing capacity, a large specific surface area, and the ability to adsorb impurities and prevent their migration. Therefore, it can be effectively utilized as a lining material in landfills [24]. The tests conducted by Wasil aimed to verify the influence of bentonite and additive quantities on material properties in compacted fly ash and fly ash–bentonite mixtures. The results demonstrated that a 15% addition of bentonite to fly ash achieved hydraulic conductivity values suitable for constructing a compacted landfill seal [25]. Liu et al. employed industrial waste slag comprising calcium, fly ash, and desulphurized gypsum for the purpose of consolidating municipal sludge into a pioneering landfill liner material. Additionally, they conducted linear shear testing, uniaxial compression testing, as well as permeability testing to evaluate the mechanical properties and permeability of the consolidated sludge material. The research results revealed that the consolidated sludge demonstrated remarkable strength and minimal water conductivity attributes, which render it an exceptional barrier substance [26]. The effect of pore size on the capillary barrier effect (CBE) was investigated through pore network modeling by Li et al. The results demonstrate that the pore diameter of both the fine and the coarse layers significantly influences the CBE. Specifically, a higher ratio of coarse-to-fine mean pore size leads to an enhanced effectiveness of the CBE [27].

However, there is a limited amount of research on the preparation of cover materials using municipal sludge (MS), construction waste (CW), and calcium bentonite (CB). Currently, most studies solely focus on direct water seepage parameters such as the soil water characteristic curve and unsaturated permeability coefficient of mulching materials. There is a significant lack of systematic studies on the micro-mechanical characteristics, macro-mechanical characteristics, and hydrological properties of these materials. Based on MS and CW, a capillary retarding covering material for landfills was developed by incorporating a small quantity of CB. Among them, MS acted as a skeleton to inhibit the shrinkage of the material CW wrapped on the surface of the coarse and fine aggregate and filled the space between the aggregate, and the capillary blocking effect of the material was increased using CB. Standard consolidation tests and triaxial compression tests were conducted to investigate the resistance to deformation and shear of this covering material. Permeability tests and SWCC (soil water characteristic curve) tests were performed to examine its permeability and capillary retarding effect. A series of microscopic examinations including SEM scanning, laser particle size analysis, and T2 NMR analysis were carried out to study the connection mode, particle size composition, and pore structure characteristics of the covered particles. The feasibility of utilizing this covering material in solid waste landfill base sealing fields was analyzed through theoretical considerations combined with experimental results. The research can offer specific data support for the design and performance evaluation of the capillary retarding cover barrier system in landfills based on the environmentally friendly treatment of MS and CW.

2. Test Materials and Methods

2.1. Test Materials

In this experiment, the covering material for solid waste-based capillary block type field sealing consisted of MS, CW, and CB. The MS used in the test was obtained from a sewage treatment plant in Wuhan, China. It appeared as a black mud-like substance with a moisture content ranging from 75% to 85% and contained lots of organic matter, which was mainly carbohydrate, protein, and fat, and was converted to humus under the action of microorganisms. The sample was collected in a chemical barrel during sampling and stored in a sealed container in the laboratory for further use. The CW was derived from a brick factory located near Wuhan, which was obtained by crushing waste materials such as bricks and concrete. After being crushed at the brick factory, the recycled fine aggregate was screened again using a 2.0 mm sieve to select fine particles within the size range of 2.0 mm to 4.75 mm as test materials. The CB used in the test was produced from a factory in Zhejiang, China. The appearance of CB was white or off-white powder, with strong hygroscopicity, which can absorb water equivalent to 8–20 times its own volume and expand 30 times, containing a small amount of feldspar, quartz, baderite, calcite, and pyroclastic materials. The depicted entity is illustrated in Figure 1.

Figure 1.

Physical drawings of raw materials.

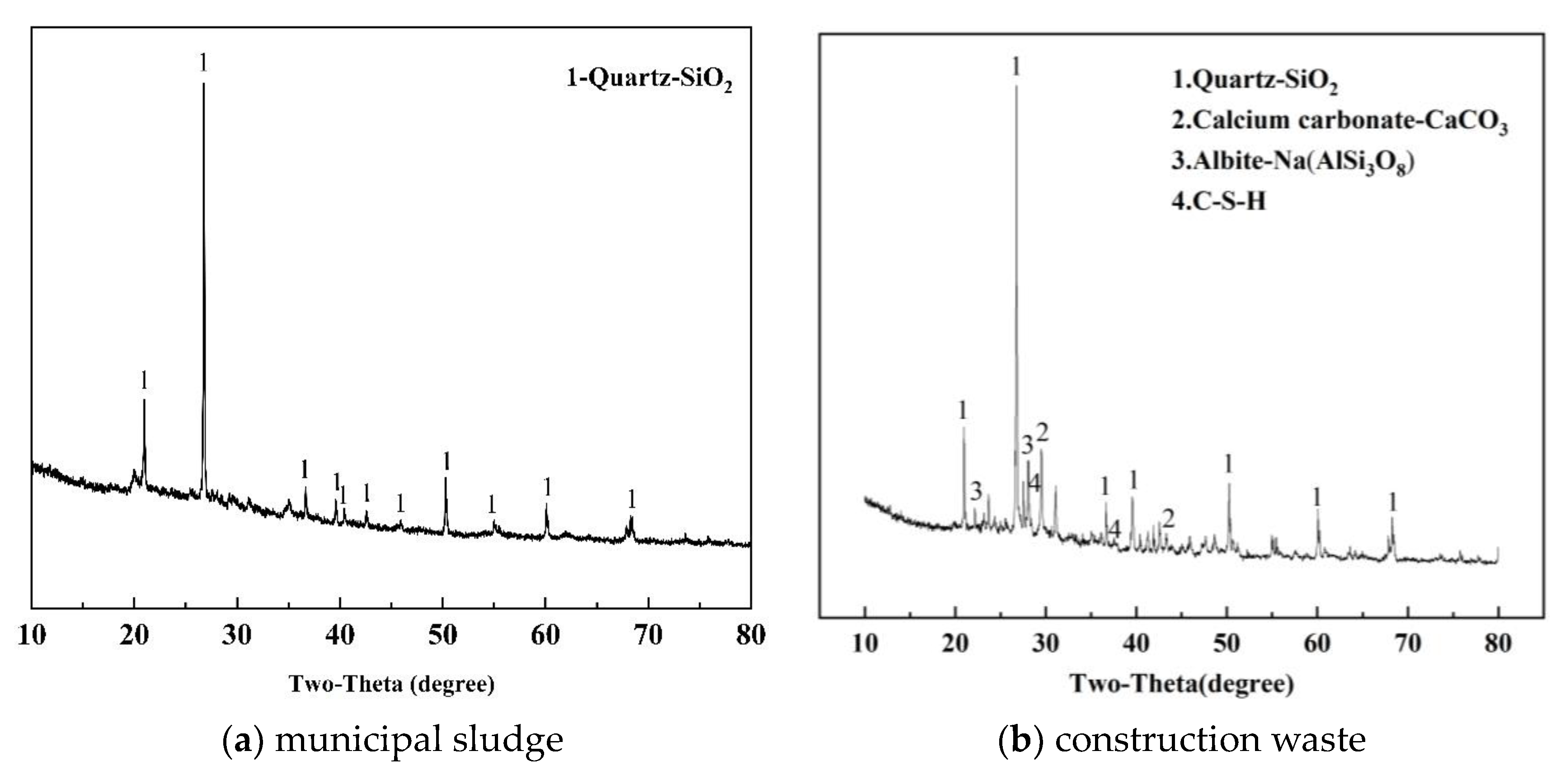

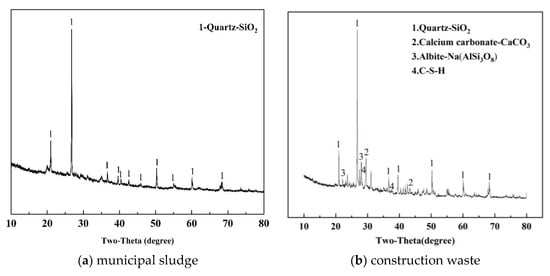

The chemical composition of MS and CW is presented in Table 1, while the mineral composition is illustrated in Figure 2. As depicted in the figure, SiO2 predominantly constitutes the mineral composition of both MS and CW. Notably, the aluminum content of MS exhibits a high concentration at 17.19%, whereas the calcium content of CW reaches a significant level of 35.07%.

Table 1.

Chemical compositions and content of MS and CW.

Figure 2.

XRD of MS and CW.

2.2. Test Methods

2.2.1. Mix Design and Sample Preparation

After conducting preliminary research, the team proposed a mass ratio range for each material as follows: MS:CW:CB = (30–45):(40–70):(5–9) [8]. Four different ratios were designed for testing purposes, as presented in Table 2.

Table 2.

Proportion of capillary retarding field covering material.

When preparing the test block, the quantitative fresh MS is initially agitated for 5 to 7 min using a JJ-5 cement mortar mixer at a speed of 100 to 400 r/min until it reaches a thick consistency. Subsequently, materials of varying quality such as CB and CW are sequentially added to the mixing pot, with CB being added in at least three separate portions followed by CW. After each addition, stir for 3 to 5 min at a speed of 100 to 400 r/min before adding the remaining materials. Once all materials have been added, rapidly stir all contents in the mixing pot for 10 to 20 min at a speed of 600 to 1000 r/min until they are thoroughly mixed. Finally, extract the mixture and utilize a designated mold size for shaping purposes. Following formation, promptly remove the test block under indoor dry conditions for maintenance. It should be noted that during the mixing process, MS may adhere to the inner wall of the mixing pot; therefore, it must be promptly scraped down in order to ensure uniform blending.

The corresponding quality of the mixture should be carefully weighed, and the appropriate size of the mold should be added. During press molding, a forming pressure of 160 kN is applied. It is important to ensure that the press line does not advance too quickly during the molding process, and maintain a speed of 5~7 kN/s. The pressed sample should be wrapped in plastic wrap and placed in a curing box under standard curing conditions (temperature: 20 ± 2 °C, relative humidity: above 90%) for a duration of 7 days.

2.2.2. Mechanical Property Test

In order to investigate the fundamental mechanical properties of capillary retarded field covering materials, consolidation tests and triaxial tests were conducted in accordance with the “Standard for Geotechnical Test Methods” (GB/T 50123-2019) [28]. The BHG vacuum saturation cylinder (Nanjing Jingke Yusheng Instrument Co., Ltd., Nanjing, China) was employed for sample pumping during the experiment.

The WG consolidation instrument (Nanjing Ningxi Soil Instrument Co., Ltd., Nanjing, China) was utilized for conducting the consolidation test. The dimensions of the sample were Φ61.8 mm × 20 mm. During the test, incremental pressures of 12.5 kPa, 25 kPa, 50 kPa, 100 kPa, 200 kPa, 300 kPa, 400 kPa, 800 kPa, and finally reaching up to a maximum pressure of 1600 kPa were applied to the sample.

The triaxial test was conducted using the CKC pneumatic full digital closed loop control and repeated loading triaxial apparatus (Global Digital Systems., Ltd., Hampshire, UK.) under consolidated undrained (CU) conditions. The sample size measured Φ70 mm × 140 mm, while the confining pressure was set at 100 kPa, 200 kPa, and 300 kPa, respectively with a shear rate of 0.1%/min.

2.2.3. Soil and Water Characteristic Test

The soil and water characteristic tests consist of the soil water characteristic curve test and flexible arm penetration test. The pressure plate method was used to conduct the soil water characteristic curve test with a Fredlund SWCC instrument (Beijing Shuangjet Technology Co., Ltd., Beijing, China) on a mixture packed into a Φ61.8 mm × 20 mm ring cutter and saturated. Measurements were taken at target pressures of 0 kPa, 5 kPa, 10 kPa, 20 kPa, 50 kPa, 100 kPa, 200 kPa, and 400 kPa for both dehumidification and hygrometric curves. Fitting was performed using the Van Genuchten model [29].

where the mass moisture content is represented by , %; the residual mass moisture content is represented by , %; the saturated mass moisture content is represented by , %; the soil matric suction is represented by , kPa; is the parameter related to the intake air value; is the parameter related to the soil dewatering rate; and is the fitting parameter.

According to the American test standards (ASTM D5084, ASTM D7100), the PN3230M environmental rock and soil flexible wall triple penetrator (GEOEQUIP, USA) was used as the testing instrument. The mixture was placed into a mold with dimensions of Φ50 mm × 100 mm, and the test specimen was immediately removed from the mold and kept under natural conditions. After 7 days of curing, the confining pressure was set at 20 kPa, the lower back pressure at 30 kPa, and the upper back pressure at 20 kPa.

2.2.4. Microstructure Characteristics

The SEM tests were conducted in accordance with the specifications outlined in “Analytical Method for the Analysis of Rock Samples by Scanning Electron Microscopy” (SY/T 5162-2014) [30]. The scanning equipment used was Zeiss Gemini 300. The test sample for SEM analysis was a block measuring less than 1 cm3, and a larger sample was prepared beforehand and dried at 105 °C. From this larger sample, a solid block was then cut to meet the required volume. Prior to testing, gold coating was applied on the surface of the sample to prevent charge accumulation that could potentially affect the test results. Additionally, vacuum treatment was performed before scanning.

The average particle size of the sample was determined by conducting a particle size separation test using a laser particle size analyzer (Dandong Better Instrument Co., Ltd., Dandong, China, 9300ST). The detection range for the sample was 0.01–1000 µm, with a resolution of 0.15 and a relative error of less than 3%. Ultrasonic treatment was performed for 0.5 min, and the wet method (using ethanol as the dispersion liquid) was employed to analyze the sample.

The nuclear magnetic resonance test was conducted in accordance with the “Measurement Specification for Nuclear Magnetic Resonance Parameters Laboratory of Rock Samples”. The PQ-001 Mini NMR analyzer was utilized as the testing instrument. The magnetic field intensity of the permanent magnet was set at 0.52 T, while the temperature within the magnetic field was maintained at 32 °C.

3. Results and Discussions

3.1. Macroscopic Mechanical Properties of Field Covering Materials

3.1.1. Consolidation Characteristic

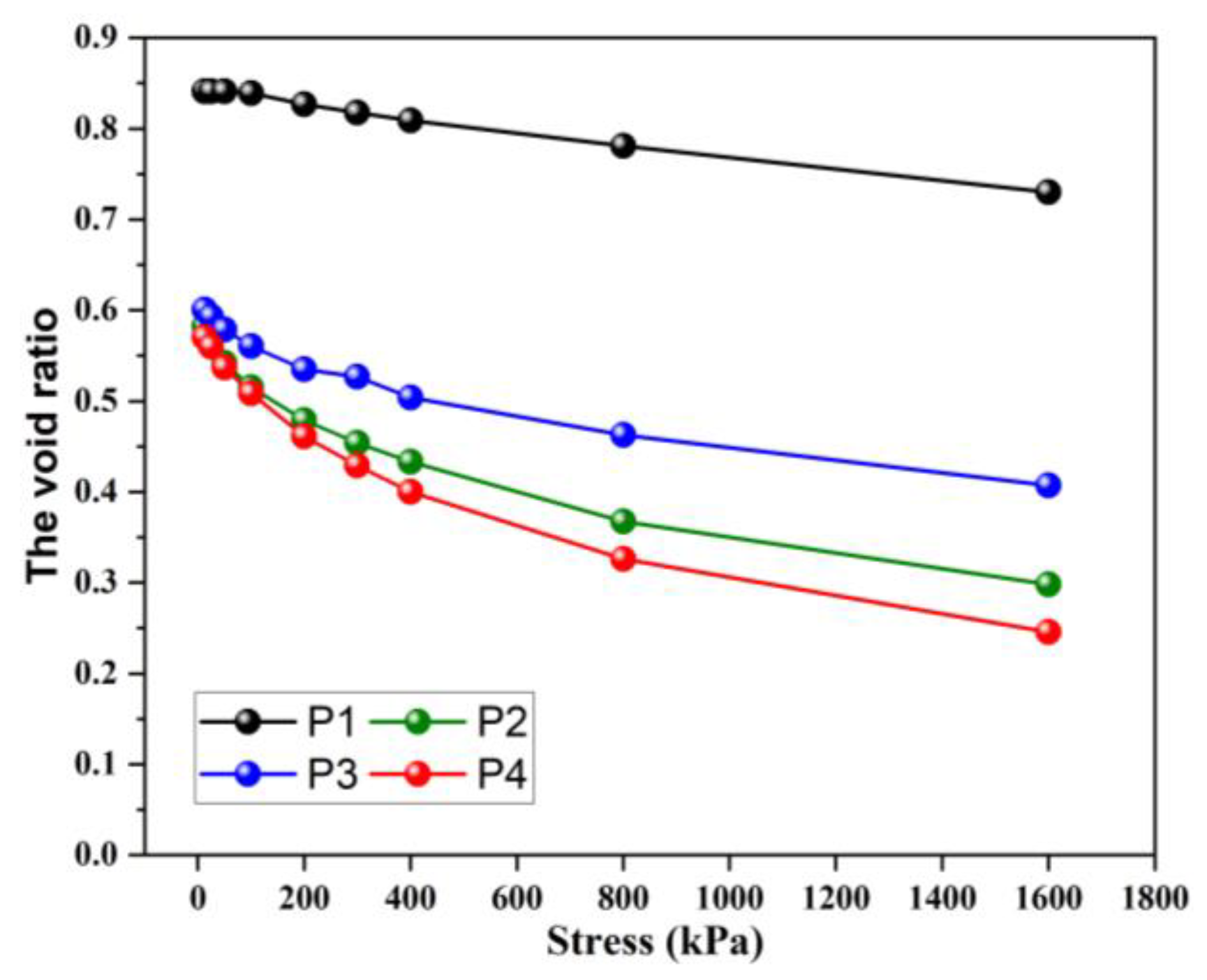

As a covering material, it should have strong deformation resistance. The pore ratio of the solid waste base capillary retarded field covering material varied with the applied pressure load, as illustrated in Figure 3. It can be seen from the figure that the initial pore ratio of P1 to P4 was 0.841, 0.628, 0.625, and 0.589, respectively. When the load pressure was 12.5 kPa, the values of P1 to P4 were 0.841, 0.583, 0.601, and 0.570, respectively. With the increase in load pressure, the load–pore ratio curve shows a downward trend. When the load pressure was 1600 kPa, the final pore ratio was 0.730, 0.297, 0.407, and 0.245, respectively, which decreased by 13.20%, 52.71%, 34.88%, and 58.40% compared with the initial state. Compared with other proportioning samples, P2 and P4 exhibited a higher compressibility.

Figure 3.

Consolidation stress–porosity ratio diagram.

It can be observed that, under the same load pressure, an increase in the particle content of CW results in a higher pore ratio. The particles of CW possess high strength and when mixed with MS they form a supportive framework within the gap between the MS and the CB. When subjected to lateral constraints, they exhibit greater resistance against longitudinal pressure without experiencing damage. As the content of CW increased, the supporting force exerted by this framework became more pronounced, resulting in reduced longitudinal deformation and changes in porosity. Under low load pressures, this framework directly counteracted deformation by providing support. However, as the load pressure intensified, both MS and CB experienced volume compression which caused a dislocation among CW particles leading to increased longitudinal deformation and decreased porosity.

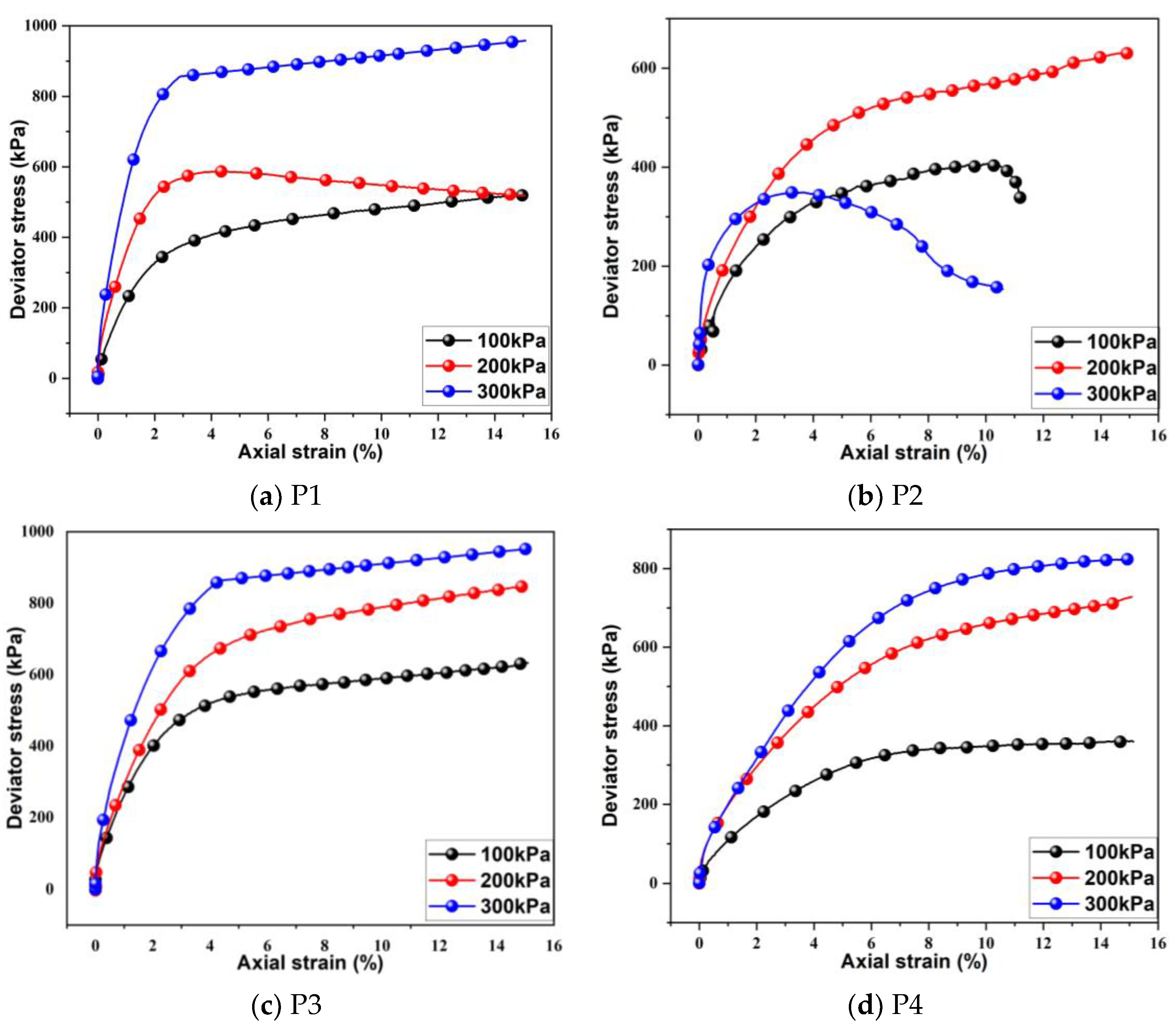

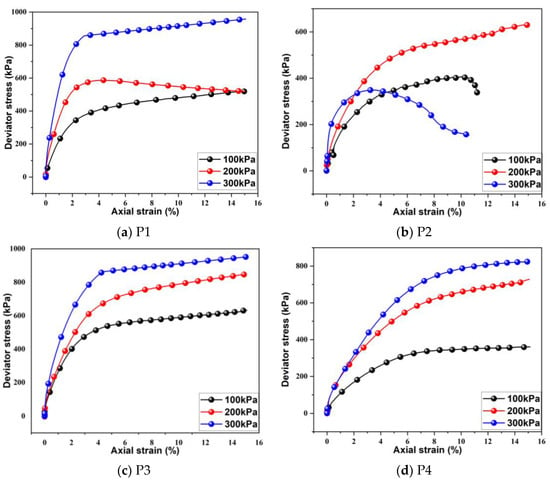

3.1.2. Triaxial Shear Strength

A landfill is an unstable disaster body, and it can result in a landslide phenomenon; once a landfill’s instability slips, it will lead to a lot of landfill leachate and landfill gas overflow. It is necessary to test the triaxial shear strength of this material [31]. The triaxial test shear results of the solid waste base capillary retarded field covering material are presented in Figure 4. The cohesive forces for P1–P4 were 100 kPa, 70 kPa, 50 kPa, and 150 kPa, respectively, while the internal friction angles were measured as 30.11°, 24.23°, 31°, and 26.1°, respectively. Three distinct stress–strain curves can be observed for the solid waste base capillary retarded field covering material: strong strain softening, weak strain softening, and strain hardening phenomena. It is evident from the figure that the sample exhibited an increasingly pronounced strain hardening behavior with increasing confining pressure. Specifically, P1 and P2 initially demonstrated a strain softening response followed by a transition to a strain hardening behavior, whereas P3 and P4 consistently exhibited a strain hardening response throughout. The stress required for P1 and P3 to achieve the same strain under identical confining pressure was higher compared to that for P2 and P4, which aligns with the findings from consolidation tests. The content of CW played a significant role, exhibiting a positive correlation with stress levels.

Figure 4.

Stress–strain curve of triaxial compression test.

With the increase in CW content, there was a decrease in cohesion and an increase in the internal friction angle. However, as the total amount of MS and CB increased, the opposite trend was observed for cohesion and the internal friction angle. The presence of CW enhanced the surface friction force and interlocking between particles, leading to an increase in the internal friction angle. Simultaneously, the contact tightness between MS and CB viscous particles weakened, resulting in reduced van der Waals forces and cementation among these particles, thereby reducing cohesion. Similarly, increased MS and CB content reduced the spacing between viscous particles while increasing the van der Waals forces between them. The filling of pores between CW particles by MS and CB viscous particles decreased the friction among CW particles, ultimately enhancing cohesion while reducing the internal friction angle [32,33].

3.2. Water Seepage Characteristics of Field Covering Materials

3.2.1. Soil Water Characteristic Curve (SWCC)

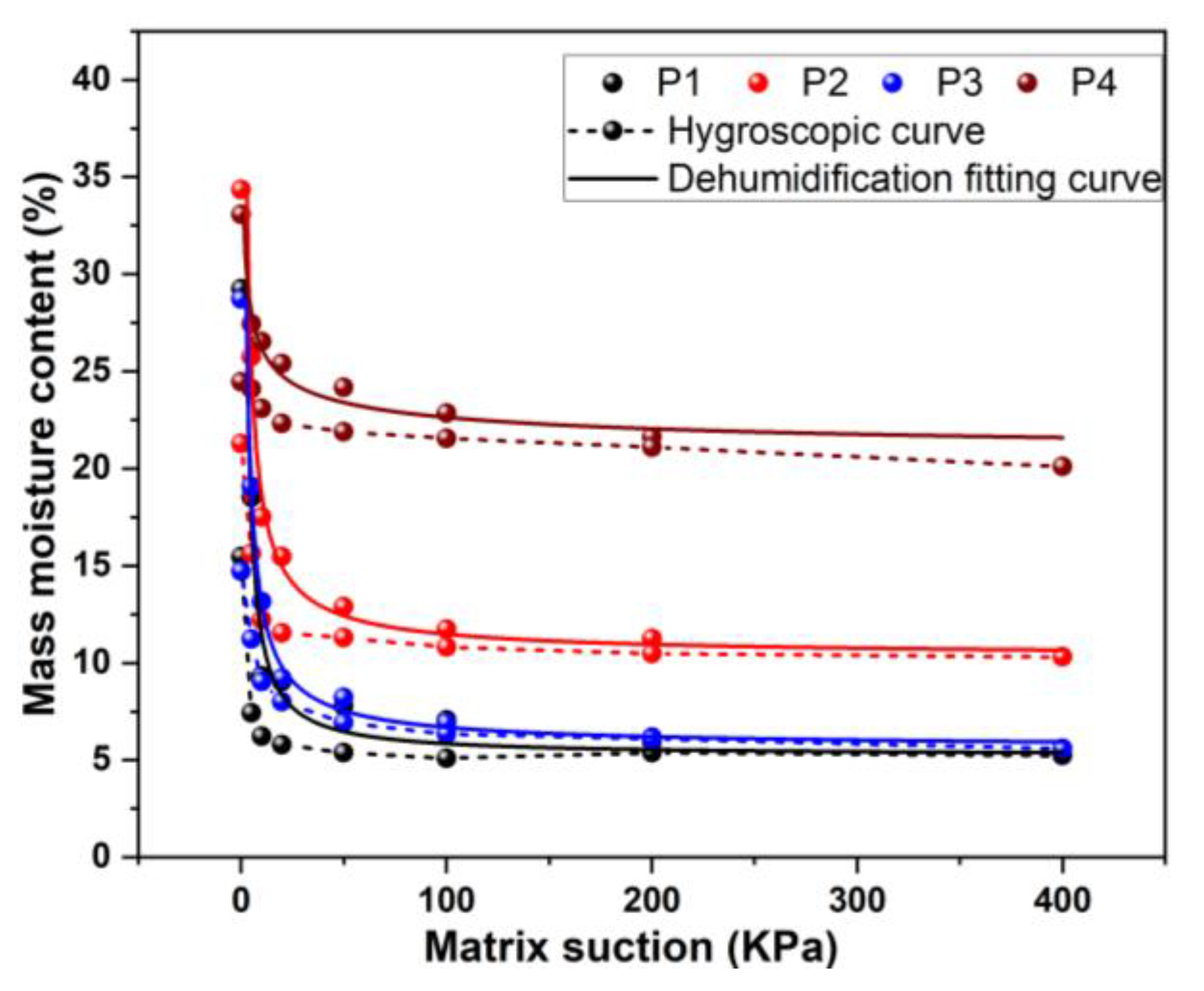

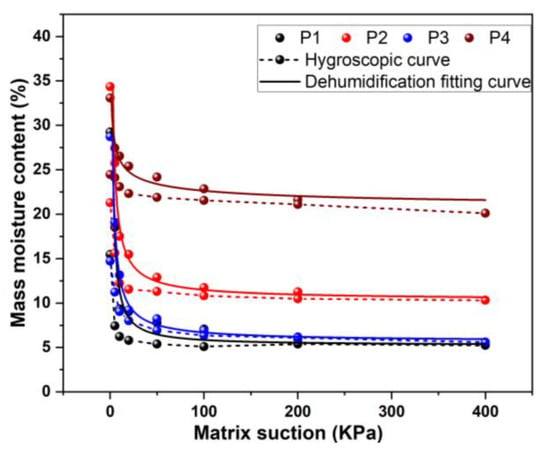

The soil water characteristic curves of the capillary block field covering material for solid waste during the dehumidification and hygroscopic process are illustrated in Figure 5, which can effectively show the capillary retarding effect of materials. The dehumidification process of the sample was fitted using the Van Genuchten model, with the fitting parameters presented in Table 3.

Figure 5.

Soil water characteristic curve.

Table 3.

Parameters fitted using Van Genuchten model.

The overall performance of the sample indicates that as the CW content increased, the soil water characteristic curve shifted downwards, resulting in a decrease in the intake value point and residual matrix suction. Consequently, the water holding capacity of the sample decreased while the hydraulic hysteresis phenomenon gradually weakened. Under low suction conditions, the capillary effect mainly affected the material’s water holding capacity, with pore structure development between particles being a key factor influencing its strength. When small and medium pores occupied more space in the mixture, the capillary effect was strong and the hydraulic hysteresis phenomenon was evident, whereas a high proportion of large pores resulted in a weak capillary effect and an insignificant hydraulic hysteresis phenomenon. As matric suction increases, larger pores discharge water first, leaving only small ones to retain it. After saturation, pore water exists on soil particle surfaces as film which can be affected by montmorillonite attraction to water molecules and the intermolecular van der Waals force [34,35]. The presence of organic matter in MS leads to a decrease in the water absorption capacity of CB. Consequently, the capillary properties of the covering material for capillary blocking field can be described as follows: an increase in the amount of CB enhances its affinity towards water molecules, resulting in a denser sample with more small- and medium-sized pores and stronger van der Waals forces between molecules, thereby increasing the intake value. However, incorporating MS reduces a portion of this intake value [36].

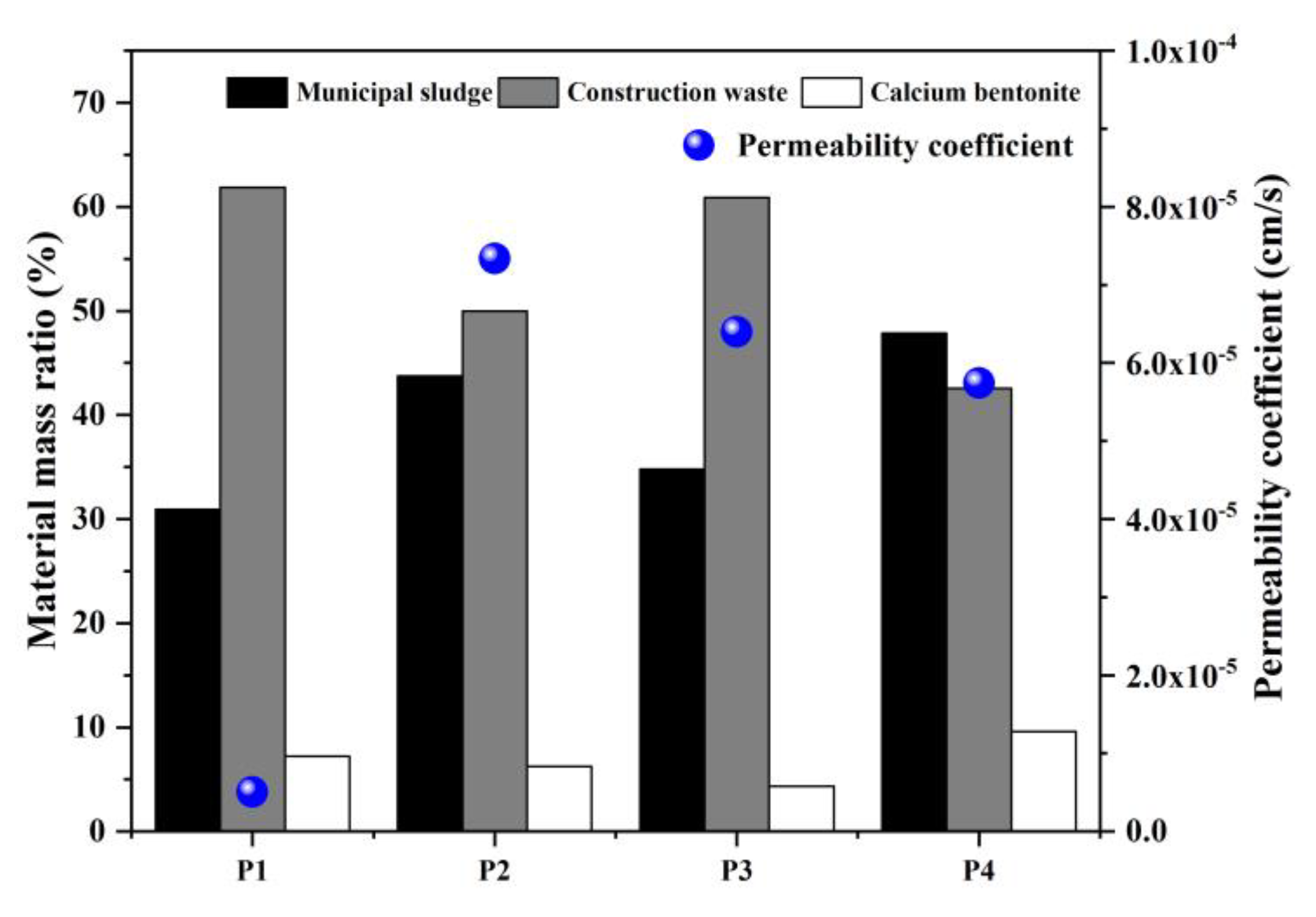

3.2.2. Permeability Coefficient

The infiltration of leachate into the soil of landfill will cause pollution, so it is necessary to research the permeability coefficient of materials. The final permeability coefficients of samples with different ratios of materials are presented in Figure 6, with P1 to P4 exhibiting values of 5.04 × 10−6 cm/s, 7.34 × 10−5 cm/s, 6.4 × 10−5 cm/s, and 5.74 × 10−5 cm/s, respectively. It can be observed from the figure that when the content of CW was high, CB played a dominant role and significantly influenced the final permeability coefficient of the field sealing material in a negative manner. Conversely, when the content of CW was low, both MS and CB jointly impacted the final permeability coefficient in a negative manner.

Figure 6.

Permeability coefficient of materials with different proportions.

When CB absorbs water and expands to saturation, it compresses the pore structure of the permeability test sample, resulting in a decrease in the pore diameter and reduced fluidity of the pore water. As a result, the overall permeability coefficient of the sample is reduced [37]. Under long-term immersion conditions, organic matter in the MS continues to decompose. The decomposition products adsorb suspended matter as well as calcium and magnesium ions from rainwater to form colloids. These colloids are transported under osmotic pressure below the test block and eventually settle and clog in the pores between CW. This continuous process leads to a gradual reduction in the permeability coefficient until equilibrium is reached with the decomposition reaction of organic matter in MS [38]. During actual testing, the rainwater that permeated through cylindrical samples was observed to be black and odorous, confirming the continuous decomposition of MS while saturated.

3.3. Microstructure Characteristics of Field Covering Materials

The microstructure of different material proportions was qualitatively and quantitatively analyzed using scanning electron microscopy (SEM) and laser particle size test (LPS), which also provided information on microstructure parameters such as the particle size, specific surface area, and median particle size. Additionally, nuclear magnetic resonance (NMR) was employed to determine the pore size of soil samples.

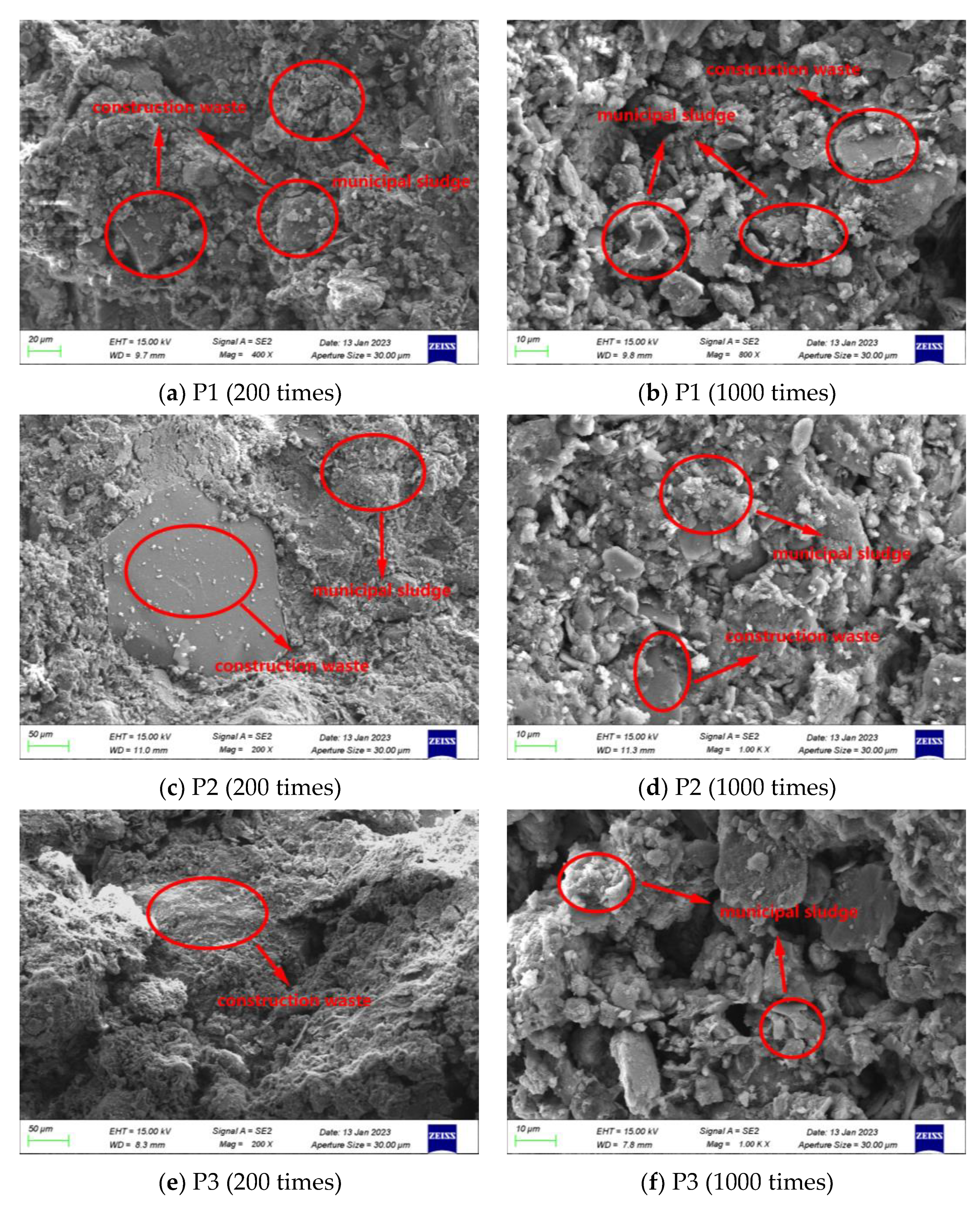

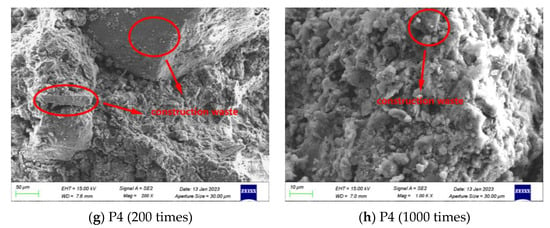

3.3.1. Micromorphology

The SEM results of samples P1–P4 are presented in Figure 7. The images clearly depict the close association between CW, which exhibited regular shapes and varying sizes, with MS and CB. The distribution of CW was uneven and its shape appears chaotic, with larger particles displaying a sheet-like structure and sharp edges. MS primarily exhibited a cluster-like polymer structure, with clusters arranged in a regular pattern and non-penetrating pores present between them, forming an integrated whole. When magnified by 200 times, the microstructure of the field sealing material sample appeared to be relatively dense, with more uniform filling between particles mainly in flake or agglomerate form. Upon further magnification to 1000 times, non-penetrating pores became visible and the predominant structural form consisted of clastic clay mineral particles that were highly dispersed. However, there was weak connectivity among these particles [39].

Figure 7.

SEM scanning electron microscope results.

The electron microscope scanning results of P1 and P3 can clearly show the overlap between CW, which can effectively improve its strength and resistance to deformation. The gaps between CW are tightly filled with an MS and CB mixture, and there are basically no large gaps, so the volume shrinkage rate is low. The scanning electron microscope results of P2 and P4 show that the particles of CW in them were alone, and did not bond with each other to form an effective skeleton network, but were only wrapped in MS and CB. The mixture of MS and CB has low strength and can easily lose water and shrink, so the structure itself has a large shrinkage. The surface pores of materials are primarily influenced by the content of MS and CB. A decrease in the MS content leads to a reduction in the formation of cementing material within the material, resulting in an increase in the number of surface pores. Similarly, a decrease in the CB content reduces the pore space filled after water absorption and expansion, leading to an increase in the surface pore volume.

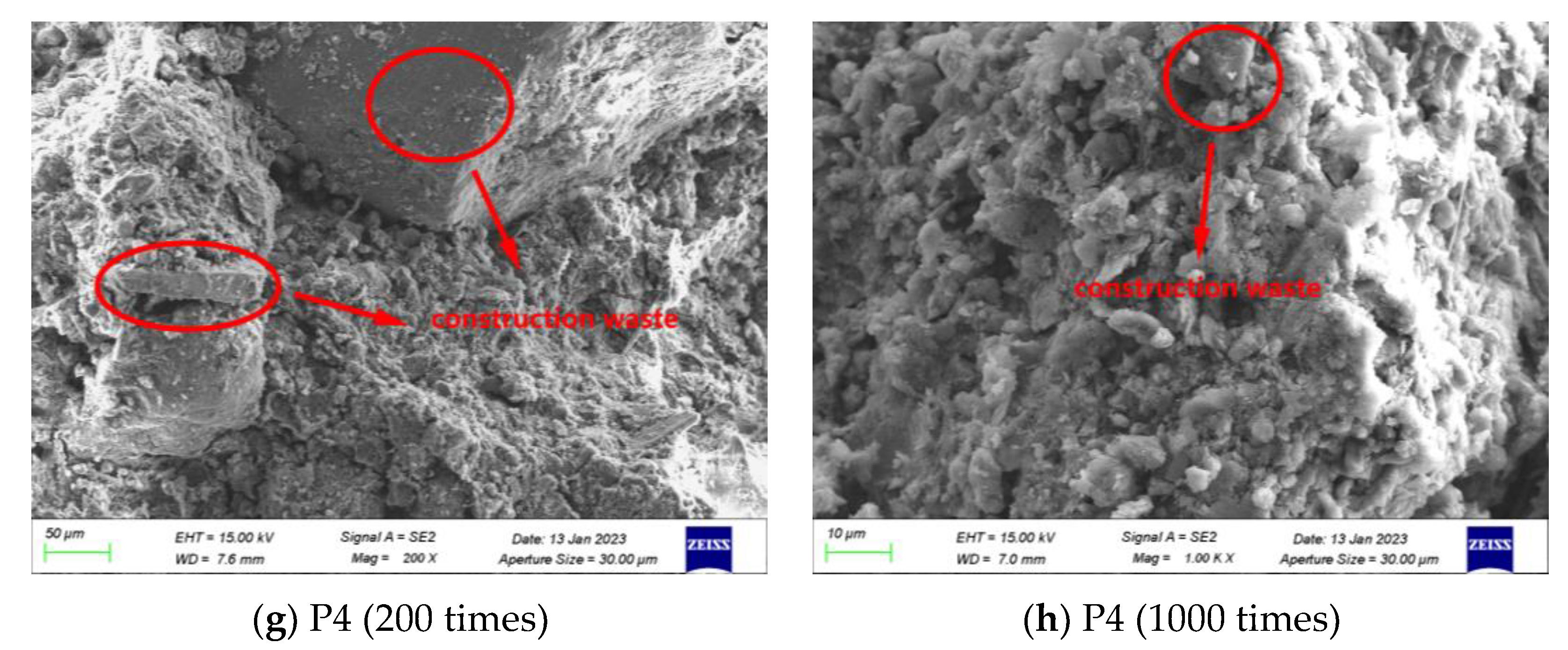

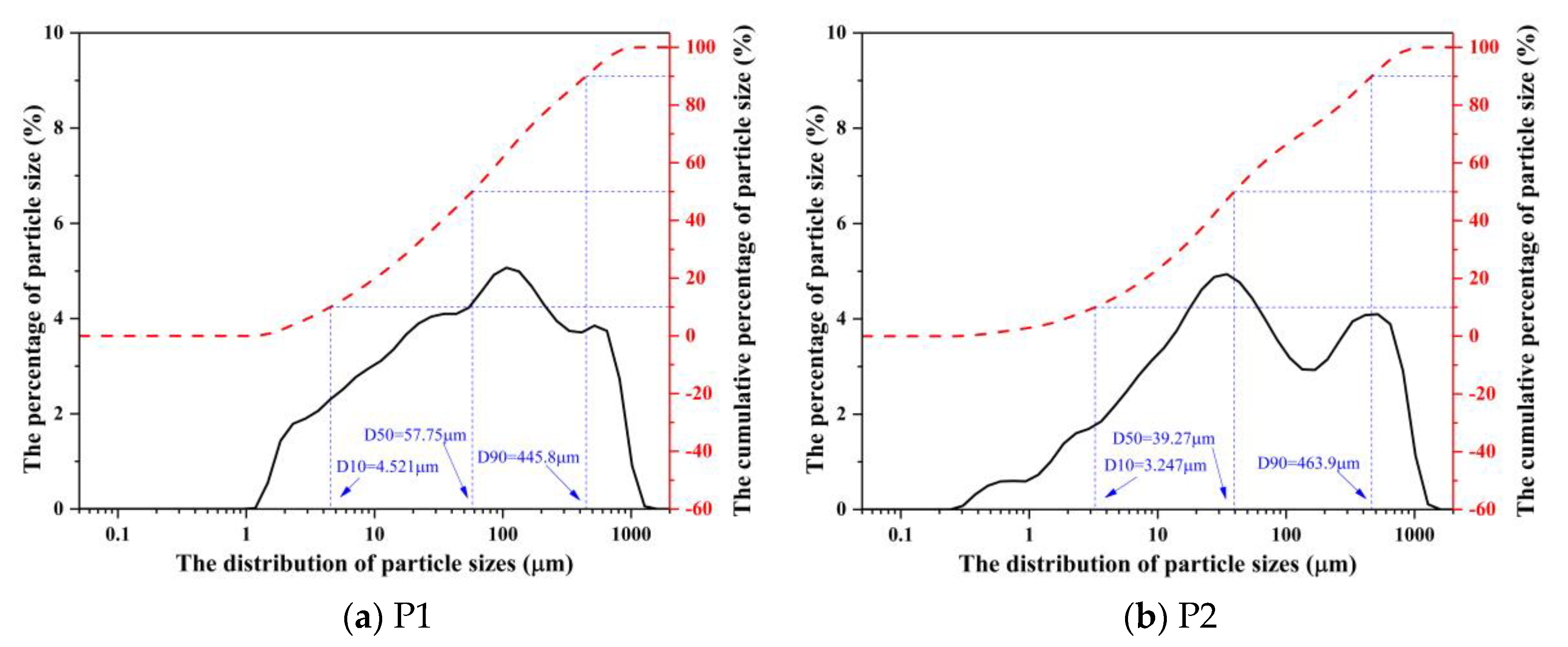

3.3.2. Granular Fabric

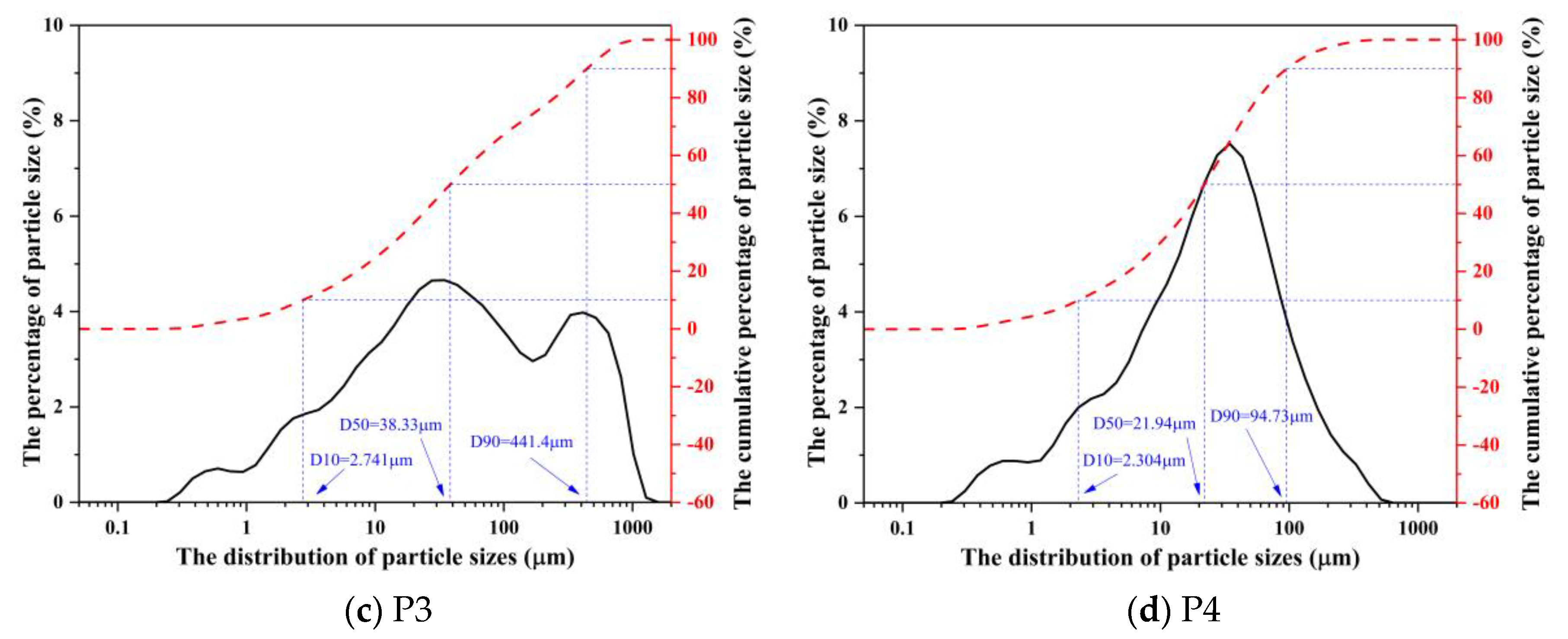

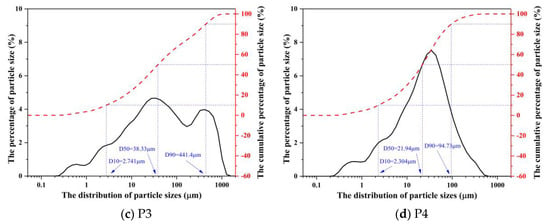

The particle size separation curve of P1–P4 is presented in Figure 8. It can be observed from the figure that the particle size distribution of P1 is predominantly within the range of 1–1000 µm and exhibits a relatively uniform pattern. The overall shape of the particle size separation curve appears unimodal, devoid of any abrupt increases or decreases. Similarly, for P2, the particle size distribution mainly ranges from 0.2 to 1000 µm with a relatively uniform profile, while exhibiting a bimodal shape throughout the curve. Likewise, for P3, the particle size distribution primarily falls within the range of 0.2–1000 µm and displays a relatively uniform pattern; however, it also demonstrates a bimodal shape across its entirety. As for P4, most particles were distributed between 0.2 and 500 µm with only a small fraction extending into the range of 500–1000 µm; moreover, their mass fraction approaches zero. Consequently, the particle size separation curve manifests as unimodal.

Figure 8.

Particle size distribution and accumulation curve.

The relevant microstructure parameters are presented in Table 4. Notably, The relevant parameters of P4 and P1–P3 exhibit significant differences. The average particle size of P4 measured 35.01 µm with a D90 value of 94.73 µm, whereas the average particle size of P1–P3 ranged from 118.9 to 126.5 µm, with a corresponding D90 range of 441.4 to 463.9 µm. By comparing the specific surface area to the average particle size, it can be observed that the content of MS had a pronounced impact on the particle size distribution for each sample; a higher MS content resulted in larger specific surface areas due to the abundant organic matter, free oxides, and soluble salts presence within it [40]. The polar carried by the suspended organic matter was attracted to the montmorillonite cells in the free state in CB, leading to agglomeration and the formation of larger particles with a greater surface area. Organic matter that is not attracted by montmorillonite cells will aggregate during collision processes. As the particle size of organic matter aggregates increases, its surface smoothness also improves due to the fluid impact. At this point, the aggregation of organic matter particles begins to cease and the aggregate particle size gradually stabilizes. When the MS content is low, most suspended organic matter will be attracted by montmorillonite crystal cells, making it difficult for organic aggregates to form. Soil particles and CW powder separated from CW particles will remain suspended in a dispersed state within the solution, resulting in a relatively smooth particle size separation curve without distinct peaks. However, when the MS content is too high, numerous aggregates formed by organic particles are present in the dispersion solution, which explains why P4’s particle size curve exhibits an obvious unimodal phenomenon with relatively large-sized particles ranging from 30 to 50 µm [41].

Table 4.

Microstructure parameters of capillary retarded field covering material.

3.3.3. Characterization of Pore Structure

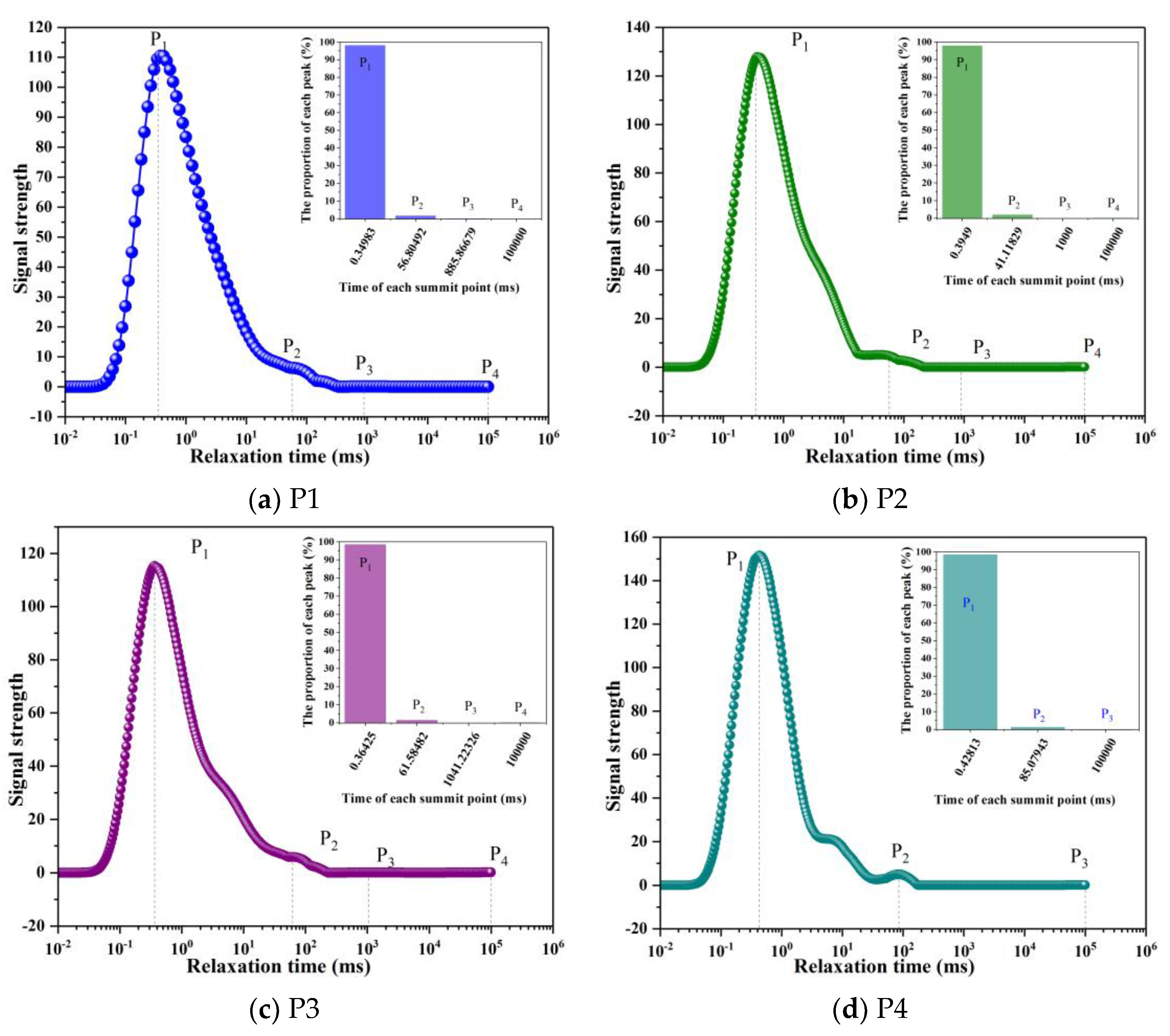

The NMR T2 inversion map effectively reflects the distribution of pore proportions with different sizes in the sample, and a higher peak signal intensity indicates a higher proportion. Additionally, longer relaxation times corresponding to peak values indicate larger pore diameters [42]. According to the comprehensive comparison Figure 9a–d in Figure 9, although the amplitude peaks differed for samples with different proportions, the overall distribution shape of transverse relaxation time T2 remained similar. Based on the test results, when the transverse relaxation time was less than 0.04 ms, the amplitude of transverse magnetic resonance signal was essentially zero and remained unchanged, indicating no detection of hydrogen nuclei or presence of pore water in this section. When the transverse relaxation time increased to 0.4–0.5 ms, all specimens with different proportions exhibited their first and largest peak value during the entire testing process, suggesting that this stage detects a greater number of hydrogen atoms and pore water. The distribution of this type of pore is the most extensive and widely spread throughout the entire specimen. As the NMR relaxation time continues to increase, there is a significant decrease in the amplitude of NMR signals. At this stage, the NMR curves for different samples start to differentiate, with some samples exhibiting a resurgence between 2 and 400 ms.

Figure 9.

NMR T2 inversion map.

The comprehensive analysis demonstrates that the incorporation of MS and CB enhances the abundance of small- and medium-sized pores in the sample, while the addition of CW promotes the development of larger pore sizes within the sample. This phenomenon can be attributed to the fact that MS contains a substantial amount of organic matter, which results in a compact structure with smaller pore sizes due to interlocking cementation. Conversely, introducing CW and CB disrupts the original pore structure of MS, leading to the formation of larger pores with a more uniform size distribution within the capillary block field covering material. In saturated conditions, water absorption and expansion by CB fill some large-pore spaces in the specimen while reducing their proportion.

3.4. Summary of Various Test Results

A variety of representative test data are summarized in Table 5.

Table 5.

The summary of various test results.

4. Conclusions

The capillary block type field covering material was prepared using municipal sludge (MS), construction waste (CW), and calcium bentonite (CB). Through testing and analysis of its macroscopic mechanical properties, soil and water characteristics, as well as microstructure, the following conclusions were drawn:

- (1)

- This material exhibits a cohesive force ranging from 50 to 150 kPa and an internal friction angle between 24.23° and 31°, demonstrating a certain shear strength. The cohesion showed a positive correlation with the particle content of CW, while the internal friction angle displayed a negative correlation with the CB content. CW possesses high strength and can establish a supportive framework within the gap between MS and CB. As the CW content increases, the supporting force exerted by this framework becomes more pronounced, resulting in reduced longitudinal deformation and changes in porosity.

- (2)

- The permeability coefficient of this material ranges from 5.04 × 10−6 to 7.34 × 10−5 cm/s, indicating excellent impermeability. The final permeability coefficient is influenced by both MS and CB, exhibiting a negative correlation. CB absorbs water and undergoes expansion, resulting in compression of the pore structure within the sample and a reduction in the pore diameter. On the other hand, MS organic matter decomposes and adsorbs suspended matter as well as calcium and magnesium ions present in rainwater, forming colloidal particles that fill the pores between CW particles. Consequently, there is an abundance of small- and medium-sized pores in the material with a strong capillary effect, leading to noticeable hydraulic hysteresis.

- (3)

- The gaps between particles of CW are densely filled with a mixture of MS and CB, thereby enhancing the material’s strength and resistance to deformation. The higher the content of MS, the greater the specific surface area of the material. The incorporation of MS and CB can increase the quantity of small- and medium-sized pores in the sample, while adding CW particles facilitates the development of larger pores in the sample.

- (4)

- By comparing the macroscopic and microscopic test results, it can be found that the optimal mass ratio of MS:CW:CB is 30:60:7. This ratio has the best impermeability, and its mechanical strength and capillary effect are similar to others.

- (5)

- This research can offer specific data support for the design and performance evaluation of the capillary retarding cover barrier system in landfills. The application of this not only addresses the issue of MS and CW disposal, but also effectively reduces landfill costs.This research is not comprehensive, and in the future, we will use model experiments to explore the service performance of this material from different rainfall intensities, dry and wet cycles, freeze–thaw cycles, and other aspects.

Author Contributions

Y.H.: conceptualization, methodology, data curation, and writing-original draft. Y.D.: conceptualization, methodology, data curation. J.L. and M.L.: methodology, writing-review and editing, and investigation. J.M.: methodology and investigation. H.L.: funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. U20A20320) and the Natural Science Foundation of Hubei Province of China (Grant No. 2022CFA011; 2023AFD214).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Sun, X.J.; Wang, C.L.; Li, Q.; Zhang, H.X.; Ye, Y.H. Development and evolution of China’s domestic waste classification policy system. Environ. Eng. 2020, 38, 6. [Google Scholar]

- Rowe, R.K.; Yu, Y. Tensile Strains in Geomembrane Landfill Liners. In Proceedings of the Geo Shanghai 2018 International Conference Ground Improvement and Geosynthetics, Shanghai, China, 27–30 May 2018; Springer: Singapore, 2018; pp. 1–10. [Google Scholar]

- Li, M.; Zhao, R.; Ma, S.; Yang, T. Scale deposition inhibiting composites by hdpe/silicified acrylate polymer/nano-silica for landfill leachate piping. Materials 2020, 13, 3497. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Bajar, S.; Hemraj; Rohilla, R. Assessment of groundwater quality near municipal solid waste landfill by using multivariate statistical technique and GIS: A case study of Bandhwari (Gurugram) landfill site, Haryana, India. Sustain. Water Resour. Manag. 2023, 9, 174. [Google Scholar] [CrossRef]

- Xia, L.; Chen, J.; Yang, Y.; Zhao, H.; Zhan, L.; Bate, B. Hydrogeochemical Responses of MTMS-Coated Capillary Cover under Heavy Rainfalls. Sustainability 2023, 15, 6667. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, X.; Xu, T.; Wang, C. A novel sludge acidification combined multistage elutriation (ame) pretreatment strategy for sludge dewaterability improvement, inorganic components separation and heavy metals removal. Resour. Conserv. Recycl. 2022, 185, 106498. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, L. Evolutionary game analysis of construction waste recycling management in China. Resour. Conserv. Recycl. 2020, 161, 104863. [Google Scholar] [CrossRef]

- Liu, M.; Lu, H.; Deng, Q.; Ji, S.; Qin, L.; Wan, Y. Shear strength, water permeability and microstructure of modified municipal sludge based on industrial solid waste containing calcium used as landfill cover materials. Waste Manag. 2022, 145, 20–28. [Google Scholar] [CrossRef]

- Biju, M.S.; Arnepalli, D.N. Effect of biopolymers on permeability of sand-bentonite mixtures. Chin. J. Rock Mech. Geotech. Eng. Engl. 2020, 12, 10. [Google Scholar] [CrossRef]

- Boral, S.; Das, S.; Sahoo, T.; Meylan, M.H. Blocking dynamics of capillary-gravity waves in a two-layer fluid in the presence of surface and interfacial tensions. J. Ital. Assoc. Theor. Appl. Mech. 2022, 57, 1307–1335. [Google Scholar] [CrossRef]

- Bochen, J.; Somka-Supik, B.; Lusarek, J. Experimental study on salt crystallization in plasters subjected to simulate groundwater capillary rise. Constr. Build. Mater. 2021, 308, 125039. [Google Scholar] [CrossRef]

- Harimi, B.; Masihi, M.; Ghazanfari, M.H. An insight into the formation of liquid bridge and its role on fracture capillary pressure during gravity drainage in fractured porous media. Can. J. Chem. Eng. 2023, 99, 212–231. [Google Scholar] [CrossRef]

- Miyazaki, T. Water flow in unsaturated soil in layered slopes. J. Hydrol. 1988, 102, 201–214. [Google Scholar] [CrossRef]

- Stormont, J.C.; Anderson, C.E. Capillary barrier effect from underlying coarser soil layer. J. Geotech. Geoenviron. Eng. 1999, 125, 641–648. [Google Scholar] [CrossRef]

- Rahardjo, H.; Satyanaga, A.; Harnas, F.R.; Leong, E.C.; Yuan, W.J. Capillary Barrier System for Landfill Capping. In Coupled Phenomena in Environmental Geotechnics: Form Theoretical and Experimental Rsesarch to Practical Applications; CRC Press: London, UK, 2013; pp. 425–433. [Google Scholar]

- Rahardjo, H.; Satyanaga, A.; Harnas, F.R.; Leong, E.C. Use of dual capillary barrier as cover system for a sanitary landfill in Singapore. Indian Geotech. J. 2016, 46, 228–238. [Google Scholar] [CrossRef]

- Zhang, L.; Ke, Y.Q. Combinations of Soil Materials for Granular Capillary Barriers for Minimizing Rainfall Infiltration and Gas Emission. Can. Geotech. J. 2017, 54, 1580–1591. [Google Scholar] [CrossRef]

- Bizarreta, J.; Campos, T. Water Retention Curve and Shrinkage of Sludge from a Leachate Treatment Plant. In Unsaturated Soils: Research and Applications; Springer: Berlin/Heidelberg, Germany, 2012; pp. 409–414. [Google Scholar]

- Marchiori, L.; Albuquerque, A.; Cavaleiro, V. Water Treatment Sludge as Geotechnical Liner Material: State-of-Art. In Sustainable Earth and Beyond, Proceedings of the EGRWSE 2022, Izmir, Türkiye, 15–17 September 2022; Springer: Singapore, 2023; Volume 370, pp. 529–547. [Google Scholar]

- Rubinos, D.A.; Spagnoli, G. Utilization of waste products as alternative landfill liner and cover materials—A critical review. Crit. Rev. Environ. Sci. Technol. 2018, 48, 376–438. [Google Scholar] [CrossRef]

- Franus, W. Hydraulic and swell–shrink characteristics of clay and recycled zeolite mixtures for liner construction in sustainable waste landfill. Sustainability 2021, 13, 7301. [Google Scholar] [CrossRef]

- Oh, S.; Shin, W.S. Applicability of solidified/stabilized dye sludge char as a landfill cover material. KSCE J. Civ. Eng. 2017, 21, 2573–2583. [Google Scholar] [CrossRef]

- Li, Z.; Liu, L.; Yan, S.; Zhang, M.; Xie, Y. Properties of microscopic particle morphology and particle contact of renewable construction waste mixtures. Constr. Build. Mater. 2019, 207, 190–205. [Google Scholar] [CrossRef]

- Ray, S.; Mishra, A.K.; Kalamdhad, A.S. Hydraulic performance, consolidation characteristics and shear strength analysis of bentonites in the presence of fly-ash, sewage sludge and paper-mill leachates for landfill application. J. Environ. Manag. 2022, 302 Pt A, 113977. [Google Scholar] [CrossRef]

- Wasil, M. Effect of bentonite addition on the properties of fly ash as a material for landfill sealing layers. Appl. Sci. 2020, 10, 1488. [Google Scholar] [CrossRef]

- Liu, Y.J.; Lu, H.J.; Wang, C.F. Mechanical strength, water seepage and microstructure of a novel landfill solidified sludge liner material. Processes 2022, 10, 1641. [Google Scholar] [CrossRef]

- Li, G.Y.; Zhan, L.T.; Zhang, Z.H.; Zhang, S.; Feng, S. Pore network modeling of capillary barrier effects: Impact of pore sizes. Can. Geotech. J. 2024, 61, 174–182. [Google Scholar] [CrossRef]

- Liu, X.Q.; Zhang, J.G.; Liu, M.L. Analysis on relevant test methods of GB/T 50123-2019 "Standard for Geotechnical Test Methods". Tianjin Constr. Technol. 2020, 30, 4. [Google Scholar]

- Kuang, J.Y.Z. A modification to the van genuchten model for improved prediction of relative hydraulic conductivity of unsaturated soils. Eur. J. Soil Sci. 2021, 72, 1354–1372. [Google Scholar] [CrossRef]

- SY/T 5162-2014; Analytical Method for the Analysis of Rock Samples by Scanning Electron Microscopy. National Energy Administration: Beijing, China, 2015.

- Hu, D.L.; Zhang, Z.Y. Numerical simulation and analysis of the stability of a municipal solid waste landfill. Model. Simul. 2023, 12, 3864–3873. [Google Scholar] [CrossRef]

- Louati, H.; Bednarek, X.; Martin, S.; Ndiaye, A.; Bonnefoy, O. Qualitative and quantitative dem analysis of cohesive granular material behaviour in ft4 shear tester. Chem. Eng. Res. Des. 2019, 148, 155–163. [Google Scholar] [CrossRef]

- Ming, Z.; Hu, D.; Pan, S.; Chen, G. Experimental study on impermeability of loess liner mixed with bentonite-hdtma. Sci. Rep. 2023, 13, 8740. [Google Scholar] [CrossRef]

- Scarfone, R.; Wheeler, S.J.; Lloret-Cabot, M. A hysteretic hydraulic constitutive model for unsaturated soils and application to capillary barrier systems. Geomech. Energy Environ. 2020, 30, 100224. [Google Scholar] [CrossRef]

- Lajmiri, A.; Bagherieh, A.R.; Azizi, F. The simultaneous effect of void ratio and hydraulic hysteresis on effective stress parameter in unsaturated soils. Eur. J. Environ. Civ. Eng. 2020, 26, 1415–1432. [Google Scholar] [CrossRef]

- Chen, W.; Song, J.; Jiang, S.; He, Q.; Ma, J.; Huangfu, X. Influence of extracellular polymeric substances from activated sludge on the aggregation kinetics of silver and silver sulfide nanoparticles. Front. Environ. Sci. Eng. 2022, 16, 16. [Google Scholar] [CrossRef]

- Huang, Y. Influence of calcium bentonite addition on the compressive strength, efflorescence extent and drying shrinkage of fly-ash based geopolymer mortar. Trans. Indian Ceram. Soc. 2020, 79, 77–82. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Liu, T. Instights into the respective role of oxidation and flocculation conditioning for enhancing paper sludge dewaterability. Chem. Eng. Res. Des. Trans. Inst. Chem. Eng. 2022, 184, 392–401. [Google Scholar] [CrossRef]

- Tummala, S.K.; Priyadarshini, T.I. Morphological operations and histogram analysis of sem images using python. Indian J. Eng. Mater. Sci. 2022, 29, 794–798. [Google Scholar]

- Nakonechny, F.; Avisar, D.; Ludmer, Z.; Brauner, N.; Ullmann, A. Application of partially miscible solvent system for an efficient extraction of organic pollutants from contaminated sludge. Water Air Soil Pollut. 2019, 230, 86. [Google Scholar] [CrossRef]

- Peng, G.L.; Lu, Y.; You, W.Q.; Yin, Z.Y.; Li, Y.L.; Gao, Y. Analysis of five bisphenol compounds in sewage sludge by dispersive solid-phase extraction with magnetic montmorillonite. Microchem. J. 2020, 157, 105040. [Google Scholar] [CrossRef]

- Gao, Y.B.B. Analysis of three-site T2-T2 exchange NMR. J. Magn. Reson. 2020, 315, 106740. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).