Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM)

Abstract

1. Introduction

2. Literature Review

2.1. Agile Project Management Approach

2.2. Lean Construction and BIM-Based Construction Project Management

2.3. Properties of BIM-Based Construction Coordination Progress

2.4. Business Process Modeling Methodology

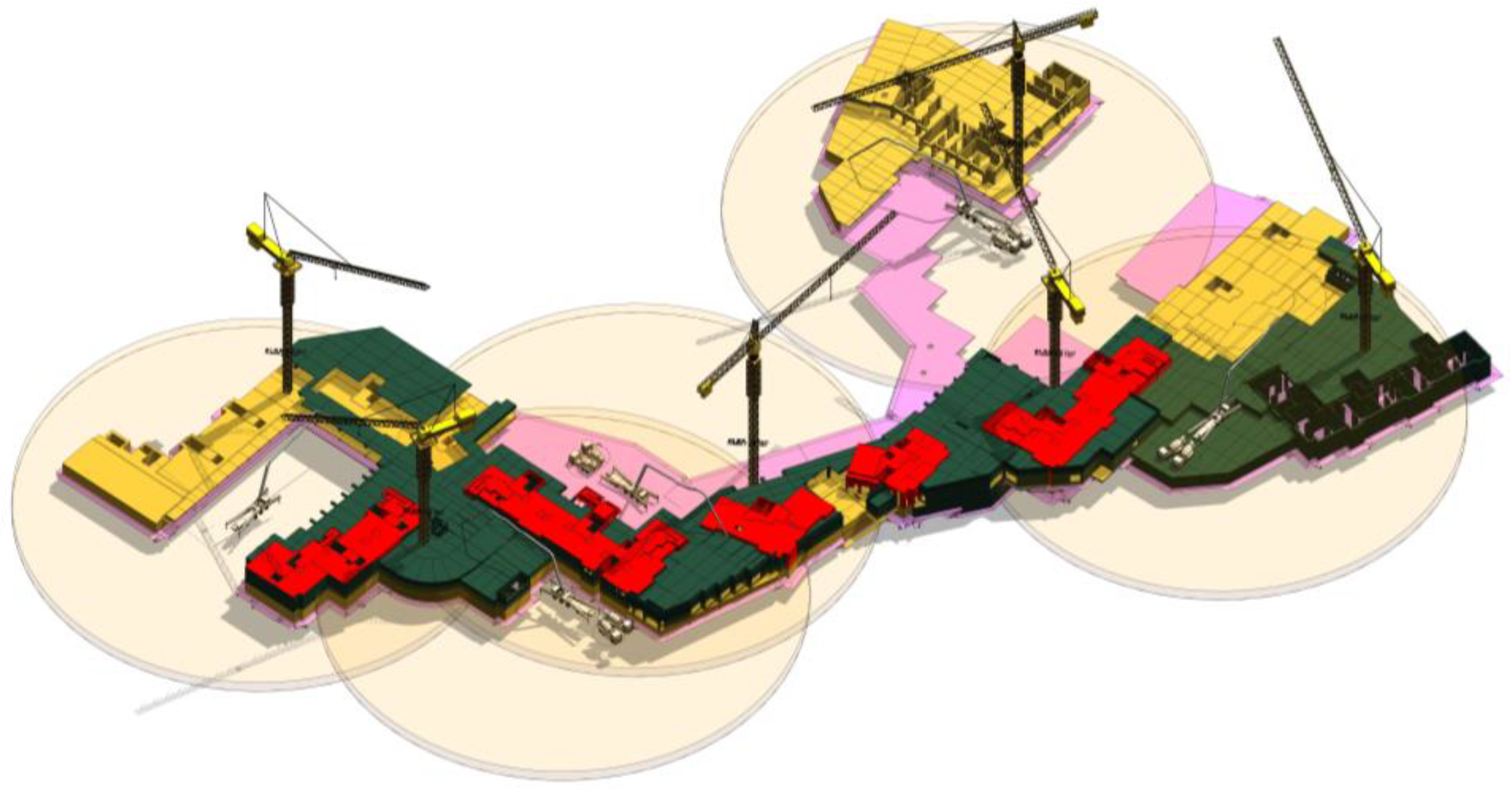

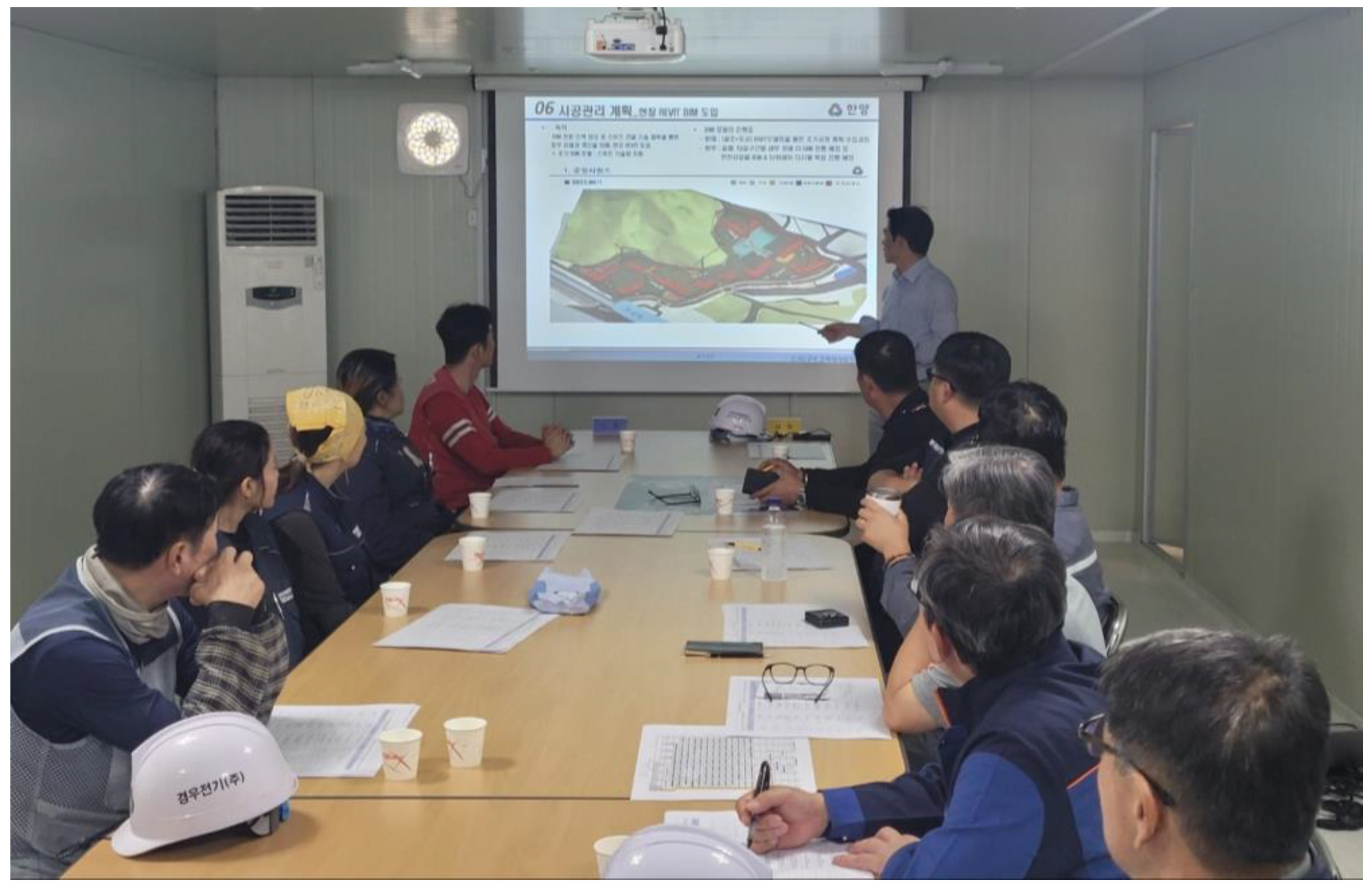

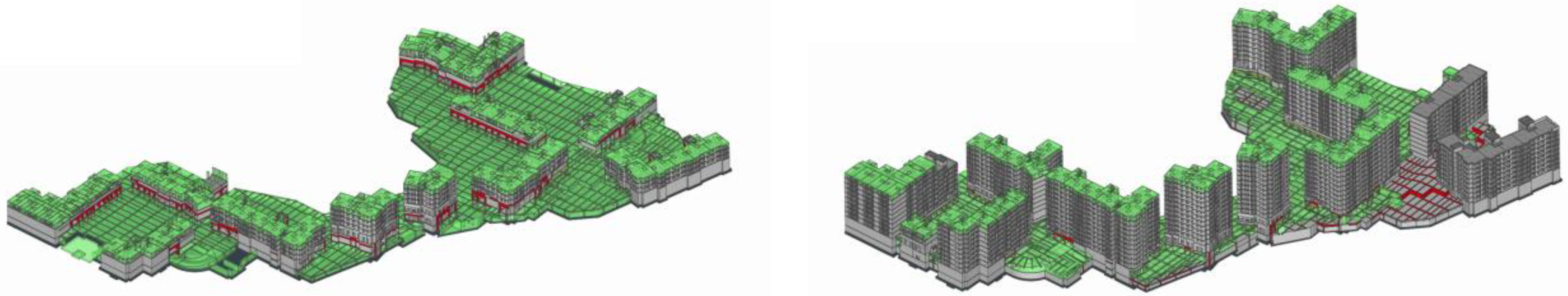

3. Problem Statements of Real-World BIM-Based Construction Project

4. Research Framework

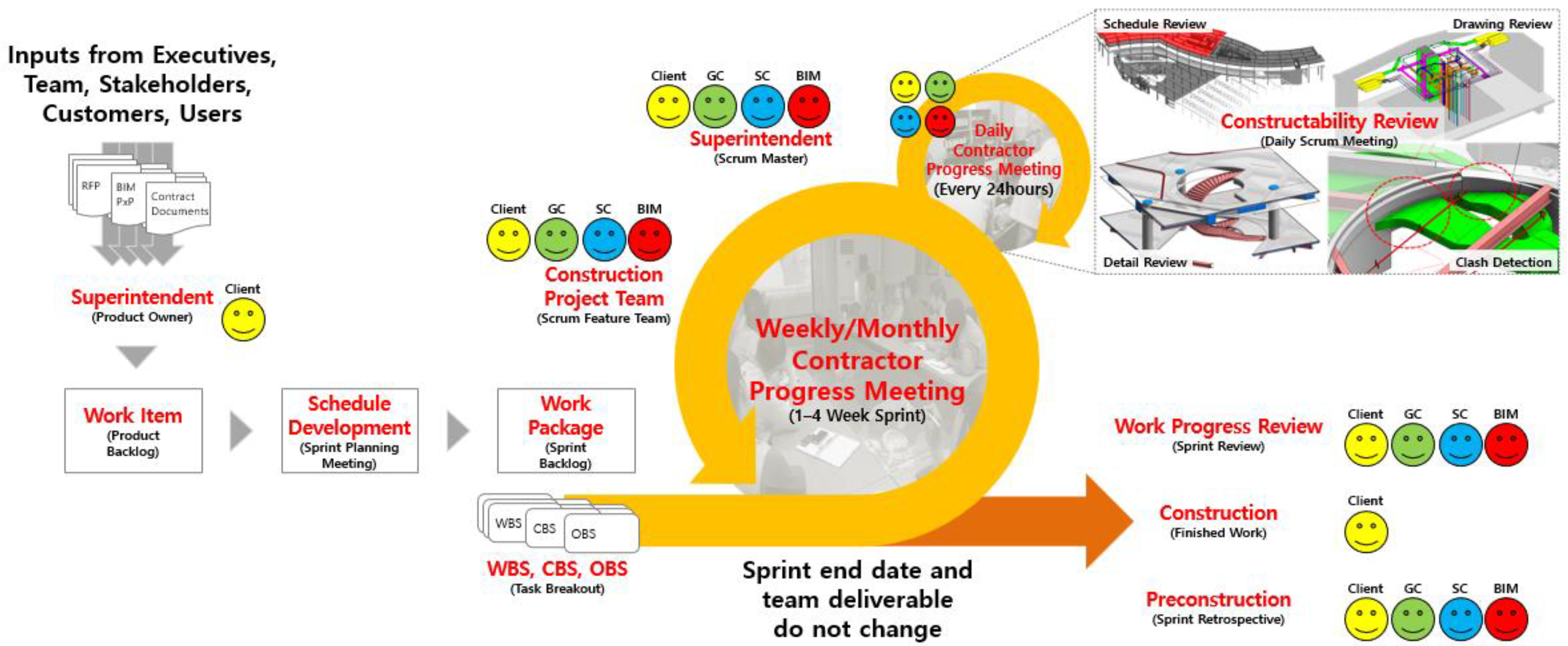

4.1. Scrum Framework of BIM-Based Constrution Coordination Progress

4.2. Application of Extended Collaborative Process Modeling (exCPM)

- ·

- Process-centric modeling methodology;

- ·

- Based on the components of CPM, there are 10 components in total;

- ·

- Color tokens allow for the representation of complex actors;

- ·

- It is easy to recognize general, internal collaboration, and external collaboration processes intuitively with separate symbols;

- ·

- Dynamic representation is possible by applying tokens from Petri-Nets, enabling the real-time monitoring of processes;

- ·

- IDEF0′s ICOM concept enables clear representation of collaborative data flows.

5. Collaborative BIM-Based Construction Coordination Progress Modeling

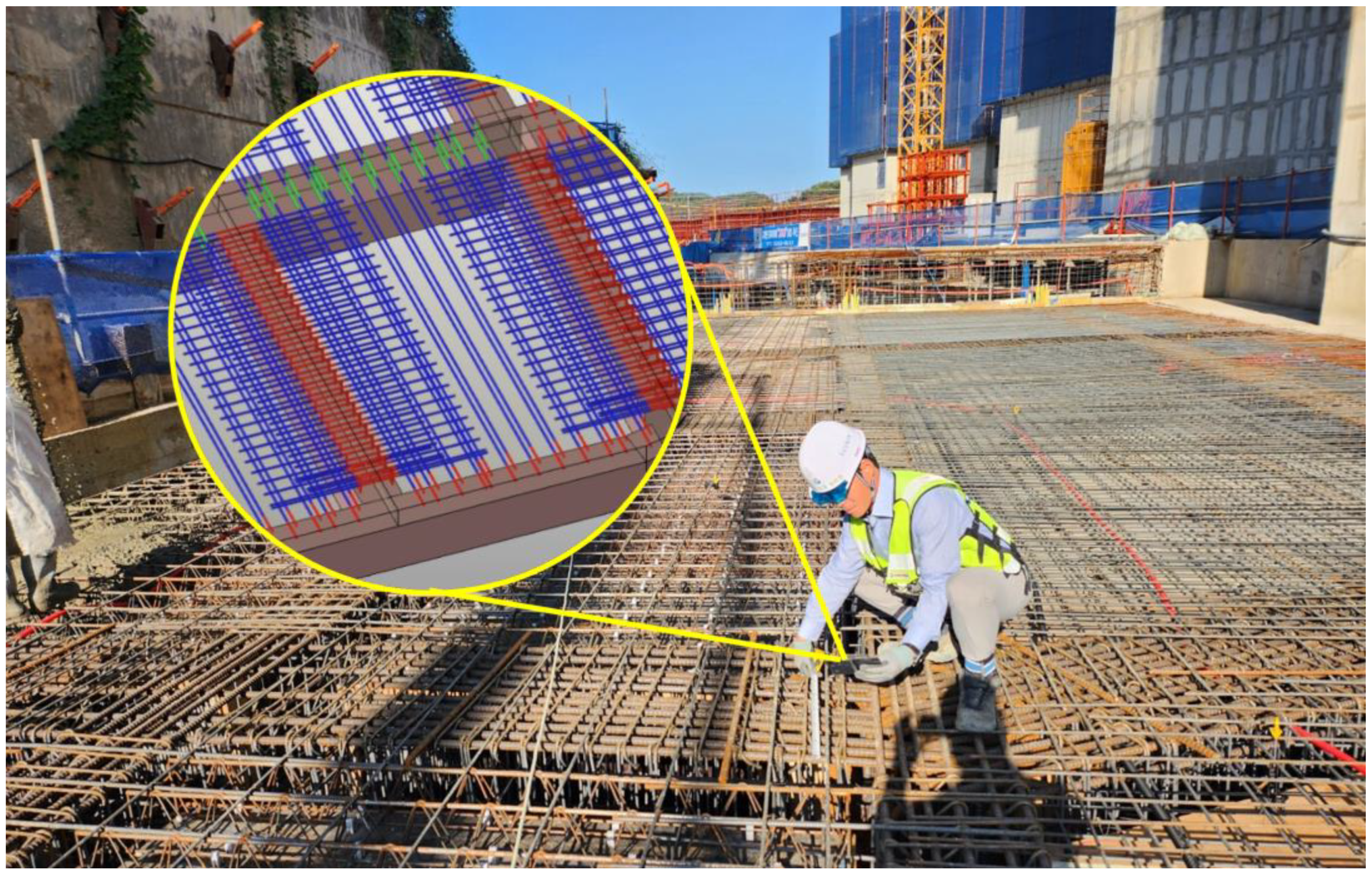

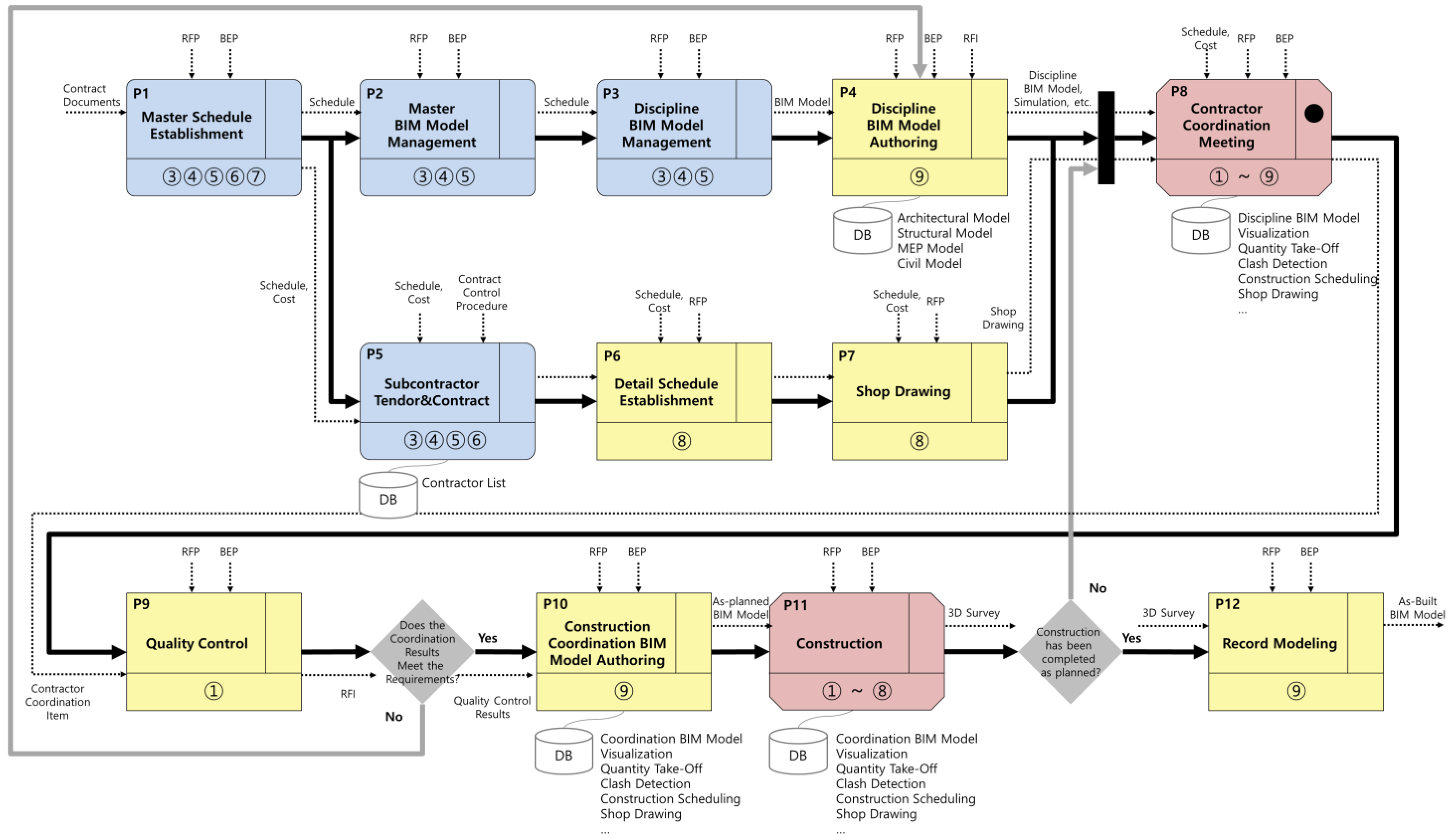

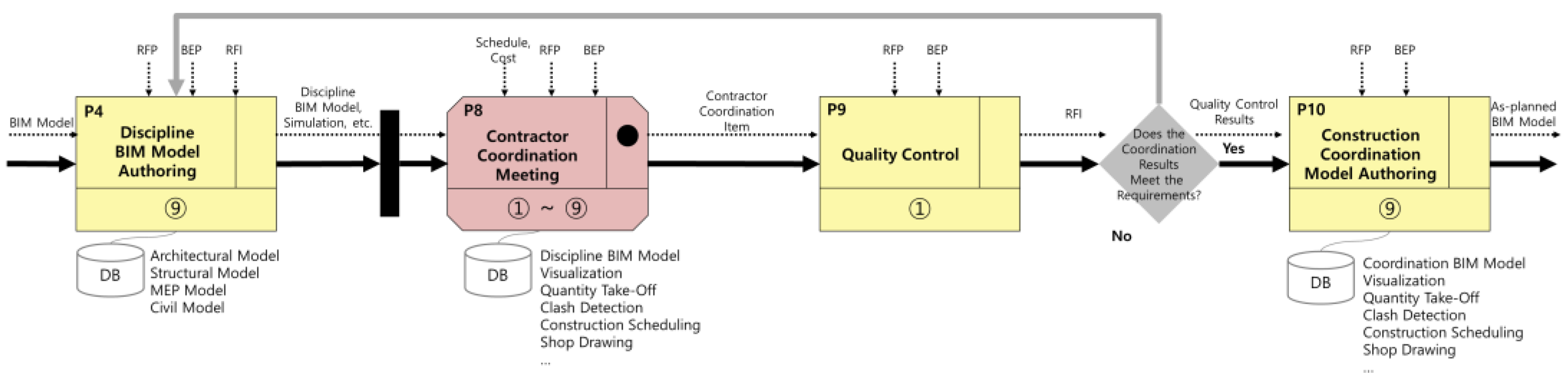

5.1. BIM-Based Construction Coordination Progress

- ·

- Revision of work set to manage large data;

- ·

- Revision of sheets/view for user interface;

- ·

- List for the entry and use of data;

- ·

- Addition of BIM model properties to enhance its application in the construction stage;

- ·

- Revision of material properties for accurate calculation;

- ·

- Addition of engineering data considering technologies available on the project site;

- ·

- Other elements to improve communication on the project site;

- ·

- System for data input/output in the construction stage.

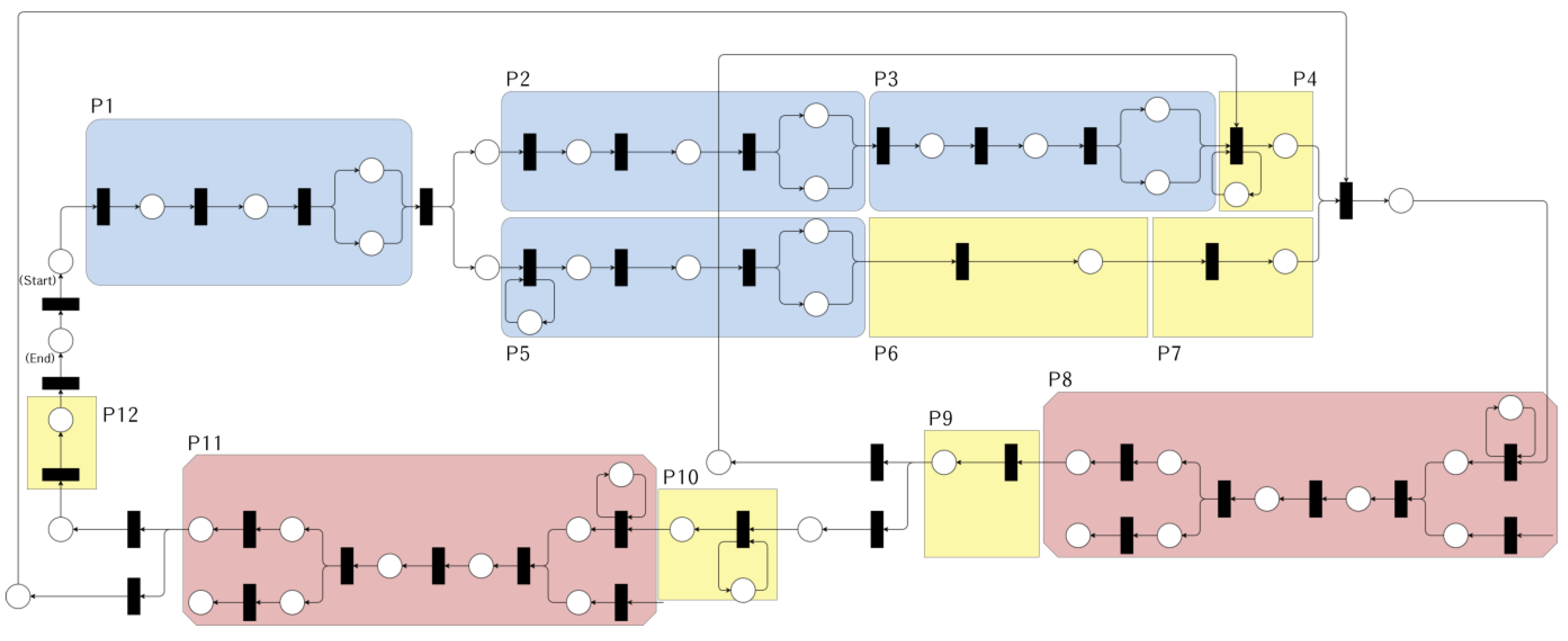

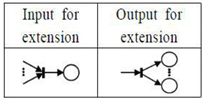

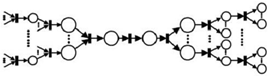

5.2. Modeling and Description

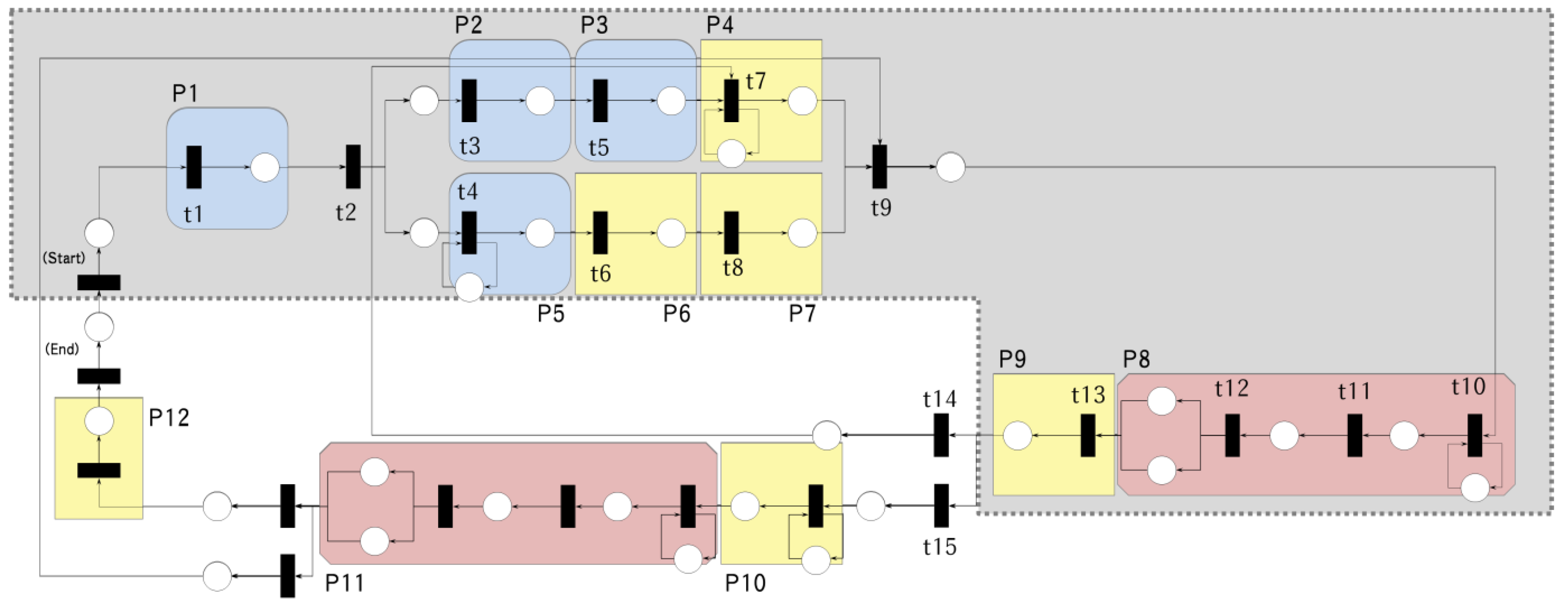

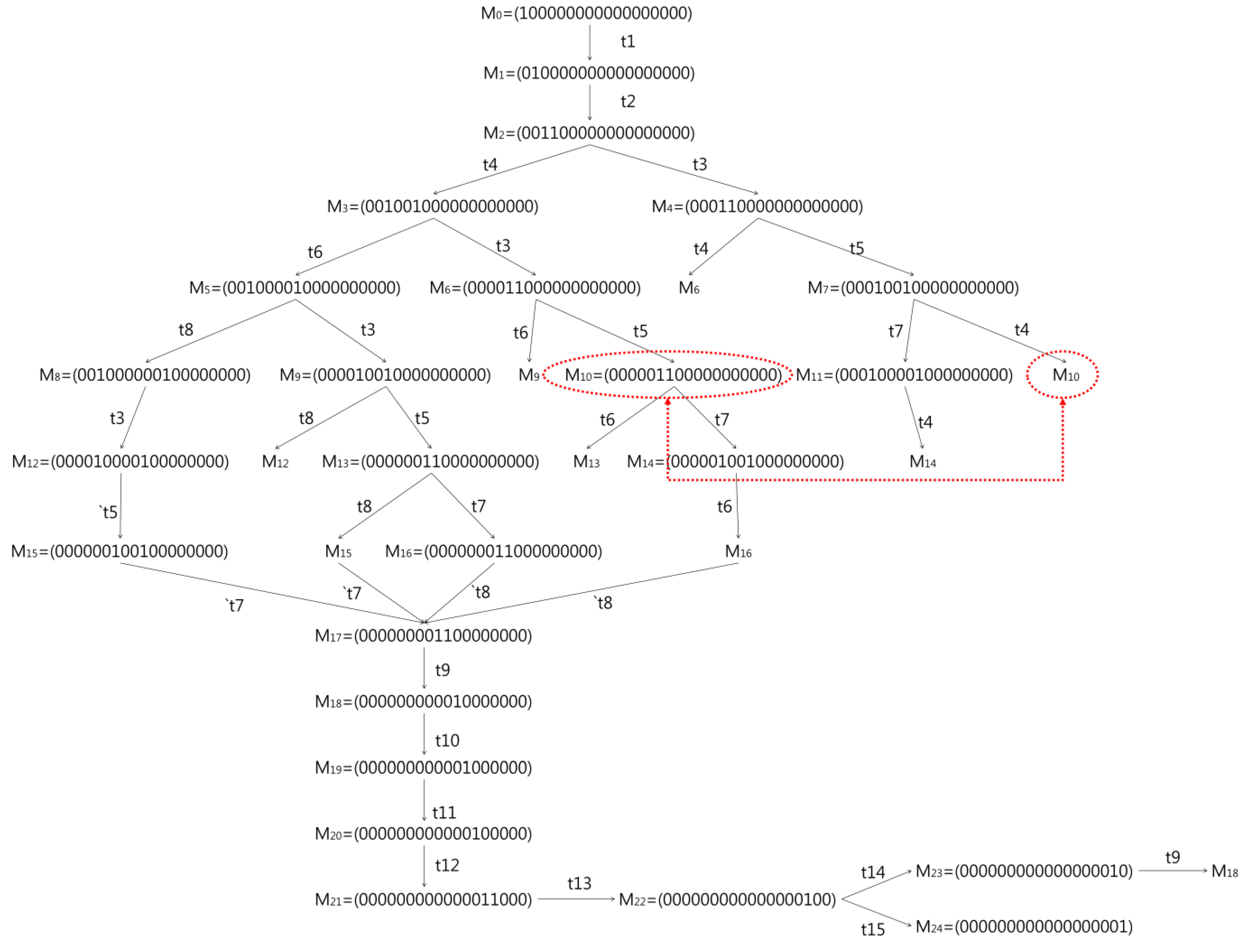

5.3. Model Validation

- ·

- Rule 1: Any input, output, and control elements in the exCPM model that are not defined as MGBBs are removed.

- ·

- Rule 2: The level of the marked graph to be converted (company, department, or individual) is determined.

- ·

- Rule 3: Each element of the exCPM model is converted to a Petri-Nets model using the defined MGBB. Here, the MGBB component selection for the process selected in Rule 2 is based on Table 3.

- ·

- Rule 4: The Petri-Nets model is completed by adding an ending mark between the place of the building block representing the last process in the converted Petri-Nets model and the transition of the building block representing the first process.

- ·

- Rule 5: If a process in an exCPM model has a state token, it places the state token in all the first appearances of the corresponding building block.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chan, A.P.; Scott, D.; Chan, A.P. Factors affecting the success of a construction project. J. Constr. Eng. Manag. 2004, 130, 153–155. [Google Scholar] [CrossRef]

- Ham, N.; Moon, S.; Kim, J.H.; Kim, J.J. Economic analysis of design errors in BIM-based high-rise construction projects: Case study of Haeundae L project. J. Constr. Eng. Manag. 2018, 144, 05018006. [Google Scholar] [CrossRef]

- Abourizk, S.; Halpin, D.; Mohamed, Y.; Hermann, U. Research in modeling and simulation for improving construction engineering operations. J. Constr. Eng. Manag. 2011, 137, 843–852. [Google Scholar] [CrossRef]

- Preidel, C.; Borrmann, A.; Oberender, C.; Tretheway, M. Seamless integration of common data environment access into BIM authoring applications: The BIM integration framework. In eWork and eBusiness in Architecture, Engineering and Construction; CRC Press: Boca Raton, FL, USA, 2017; pp. 119–128. ISBN 9781315386904. [Google Scholar]

- Singh, M.M.; Geyer, P. Information requirements for multi-level-of-development BIM using sensitivity analysis for energy performance. Adv. Eng. Inform. 2020, 43, 101026. [Google Scholar] [CrossRef]

- Eastman, C.; Sacks, R. Introducing a new methodology to develop the information delivery manual for AEC projects. In Proceedings of the CIB W78 2010: 27th International Conference, Cairo, Egypt, 16–18 November 2010. [Google Scholar]

- Beetz, J.; Borrmann, A.; Weise, M. Process-based definition of model content. In Building Information Modeling: Technology Foundations and Industry Practice; Springer: Berlin/Heidelberg, Germany, 2018; pp. 127–138. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2018; ISBN 978-1-119-28753-7. [Google Scholar]

- Charef, R.; Alaka, H.; Emmitt, S. Beyond the third dimension of BIM: A systematic review of literature and assessment of professional views. J. Build. Eng. 2018, 19, 242–257. [Google Scholar] [CrossRef]

- Jupp, J. 4D BIM for environmental planning and management. Procedia Eng. 2017, 180, 190–201. [Google Scholar] [CrossRef]

- Smith, P. Project cost management with 5D BIM. Procedia-Soc. Behav. Sci. 2016, 226, 193–200. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Zhou, Z. Sustainability-based lifecycle management for bridge infrastructure using 6D BIM. Sustainability 2020, 12, 2436. [Google Scholar] [CrossRef]

- Marta, A.; Stefano, B.; Carlo, B.; Filippo, M. 7D BIM for sustainability assessment in design processes: A case study of design of alternatives in severe climate and heavy use conditions. Archit. Eng. 2019, 4, 3–12. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Constantino, G.B.; Almeida, N.M. 8D BIM model in urban rehabilitation projects: Enhanced occupational safety for temporary construction works. Appl. Sci. 2022, 12, 10577. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the relationship between Building Information Modelling (BIM) implementation barriers, usage and awareness on building project lifecycle. Build. Environ. 2022, 207, 108556. [Google Scholar] [CrossRef]

- Mesa, H.A.; Molenaar, K.R.; Alarcón, L.F. Comparative analysis between integrated project delivery and lean project delivery. Int. J. Proj. Manag. 2019, 37, 395–409. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M. Virtual design and construction. Constr. Manag. Econ. 2020, 38, 355–363. [Google Scholar] [CrossRef]

- Wasim, M.; Vaz Serra, P.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—A review. Int. J. Constr. Manag. 2022, 22, 3014–3022. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Ogunnaike, B.A.; Ray, W.H. Process Dynamics, Modeling, and Control; Oxford University Press: Oxford, UK, 1994; p. 364. ISBN 0-19-509119-1. [Google Scholar]

- Schwaber, K. Agile Project Management with Scrum; Microsoft Press: Redmond, WA, USA, 2004; ISBN 9780735619937. [Google Scholar]

- Sacks, R.; Korb, S.; Barak, R. Building Lean, Building BIM: Improving Construction the Tidhar Way; Routledge: London, UK, 2017; ISBN 9781138237230. [Google Scholar]

- Maestas, A.; Parrish, K. Exploring the roots of lean culture at DPR Constuction: A case study in lean culture. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, IGLC 2014, Oslo, Norway, 25 June 2014; pp. 1413–1424. [Google Scholar]

- Zhang, B.; Dong, N.; Rischmoller, L. Design Thinking in action: A DPR case study to develop a sustainable digital solution for labor resource management. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–10 July 2020; pp. 6–12. [Google Scholar] [CrossRef]

- Paulk, M.; Davis, N.; Maccherone, L. On Empirical Research into Scrum; Institute for Software Research, Carnegie Mellon University: Pittsburgh, Pennsylvania, 2011. [Google Scholar]

- Fernandes, J.M.; Almeida, M. Classification and comparison of agile methods. In Proceedings of the 7th International Conference on the Quality of Information and Communications Technology, Porto, Portugal, 29 September–2 October 2010; pp. 391–396. [Google Scholar] [CrossRef]

- Dingsøyr, T.; Dybå, T.; Moe, N.B. Agile software development: An introduction and overview. In Agile Software Development: Current Research and Future Directions; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–13. [Google Scholar] [CrossRef]

- Hamed, A.M.M.; Abushama, H. Popular agile approaches in software development: Review and analysis. In Proceedings of the International Conference on Computing, Electrical and Electronic Engineering (ICCEEE), Khartoum, Sudan, 26–28 August 2013; 2013; pp. 160–166. [Google Scholar] [CrossRef]

- Larman, C.; Vodde, B. Scaling Lean & Agile Development. Organization 2009, 230. [Google Scholar]

- Han, S.; Lee, S.; Pena-Mora, F. Identification and quantification of non-value-adding effort from errors and changes in design and construction projects. J. Constr. Eng. Manag. 2012, 138, 98–109. [Google Scholar] [CrossRef]

- Liao, L.; Teo EA, L.; Chang, R.; Li, L. Investigating critical non-value adding activities and their resulting wastes in BIM-based project delivery. Sustainability 2020, 12, 355. [Google Scholar] [CrossRef]

- Jasti, N.V.K.; Kodali, R. Lean production: Literature review and trends. Int. J. Prod. Res. 2015, 53, 867–885. [Google Scholar] [CrossRef]

- Rashidian, S.; Drogemuller, R.; Omrani, S. Building information modelling, integrated project delivery, and lean construction maturity attributes: A Delphi study. Buildings 2023, 13, 281. [Google Scholar] [CrossRef]

- Salem, O.; Solomon, J.; Genaidy, A.; Minkarah, I. Lean construction: From theory to implementation. J. Manag. Eng. 2006, 22, 168–175. [Google Scholar] [CrossRef]

- Schimanski, C.P.; Pradhan, N.L.; Chaltsev, D.; Monizza, G.P.; Matt, D.T. Integrating BIM with Lean Construction approach: Functional requirements and production management software. Autom. Constr. 2021, 132, 103969. [Google Scholar] [CrossRef]

- Michalski, A.; Głodziński, E.; Böde, K. Lean construction management techniques and BIM technology–systematic literature review. Procedia Comput. Sci. 2022, 196, 1036–1043. [Google Scholar] [CrossRef]

- Tezel, A.; Taggart, M.; Koskela, L.; Tzortzopoulos, P.; Hanahoe, J.; Kelly, M. Lean construction and BIM in small and medium-sized enterprises (SMEs) in construction: A systematic literature review. Can. J. Civ. Eng. 2020, 47, 186–201. [Google Scholar] [CrossRef]

- Kim, J. Why Perform Low When You can Perform High? BIM/Lean/IPD in DPR Construction, The BIM_ The Building Information Modeling. Summer 2013, 9, 36–39. [Google Scholar]

- De Saram, D.D.; Ahmed, S.M.; Anson, M. Suitability of the critical incident technique to measure quality of construction coordination. J. Manag. Eng. 2004, 20, 97–109. [Google Scholar] [CrossRef]

- Shen, F.Y.; Chang, A.S. Exploring coordination goals of construction projects. J. Manag. Eng. 2011, 27, 90–96. [Google Scholar] [CrossRef]

- Mehrbod, S.; Staub-French, S.; Mahyar, N.; Tory, M. Beyond the clash: Investigating BIM-based building design coordination issue representation and resolution. ITcon 2019, 24, 33–57. Available online: https://www.itcon.org/2019/3 (accessed on 1 December 2023).

- Won, J.; Cheng, J.C.; Lee, G. Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef]

- Messner, J.; Anumba, C.; Dubler, C.; Goodman, S.; Kasprzak, C.; Kreider, R.; Leicht, R.; Saluja, C.; Zikic, N. BIM Project Execution Planning Guide, 3rd ed.; Computer Integrated Construction Research Program, The Pennsylvania State University: University Park, PA, USA, 2021; Available online: http://bim.psu.edu (accessed on 1 December 2023).

- Won, J.; Lee, G. How to tell if a BIM project is successful: A goal-driven approach. Autom. Constr. 2016, 69, 34–43. [Google Scholar] [CrossRef]

- Lee, G.; Park, H.K.; Won, J. D3 City project—Economic impact of BIM-assisted design validation. Autom. Constr. 2012, 22, 577–586. [Google Scholar] [CrossRef]

- Ham, N.; Moon, S.; Kim, J.H.; Kim, J.J. Optimal BIM staffing in construction projects using a queueing model. Autom. Constr. 2020, 113, 103123. [Google Scholar] [CrossRef]

- Ham, N.H.; Yuh, O.K. Performance Analysis and Assessment of BIM-Based Construction Support with Priority Queuing Policy. Buildings 2023, 13, 153. [Google Scholar] [CrossRef]

- Huh, S.H.; Ham, N.; Kim, J.H.; Kim, J.J. Quantitative impact analysis of priority policy applied to BIM-based design validation. Autom. Constr. 2023, 154, 105031. [Google Scholar] [CrossRef]

- Luo, W.; Alex, T.Y. A framework for selecting business process modeling methods. Ind. Manag. Data Syst. 1999, 99, 312–319. [Google Scholar] [CrossRef]

- Wang, W.; Ding, H.; Dong, J.; Ren, C. A comparison of business process modeling methods. In Proceedings of the IEEE International Conference on Service Operations and Logistics, and Informatics, Shanghai, China, 21–23 June 2006; pp. 1136–1141. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. From BIM to extended reality in AEC industry. Autom. Constr. 2020, 116, 103254. [Google Scholar] [CrossRef]

- Alreshidi, E.; Mourshed, M.; Rezgui, Y. Cloud-based BIM governance platform requirements and specifications: Software engineering approach using BPMN and UML. J. Comput. Civ. Eng. 2016, 30, 04015063. [Google Scholar] [CrossRef]

- Al Hattab, F.M. Hamzeh, Information Flow Comparison Between Traditional and BIM-Based Projects in the Design Phase. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, IGLC, Fortaleza, Brazil, 29 July–2 August 2013; pp. 761–770, Retrieved on 3 May 2017. [Google Scholar]

- Salimifard, K.; Wright, M. Petri net-based modelling of workflow systems: An overview. Eur. J. Oper. Res. 2001, 134, 664–676. [Google Scholar] [CrossRef]

- Ryu, K.; Yücesan, E. CPM: A collaborative process modeling for cooperative manufacturers. Adv. Eng. Inform. 2007, 21, 231–239. [Google Scholar] [CrossRef]

- Lee, S.; Ryu, K.; Lee, S.; Shin, J.; Kim, B. Extended collaboration process modeling method enabling model validation. In Proceedings of the 40th International Conference on Computers & Indutrial Engineering, Awaji City, Japan, 25–28 July 2010; 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Park, G.B.; Ham, N.H.; Kim, K.H.; Kim, J.J. Application of extended collaborative process modeling (exCPM) for multi-disciplinary collaboration and coordination in planning phase. J. Archit. Inst. Korea Plan. Des. 2014, 30, 21–30. [Google Scholar] [CrossRef]

- Eastman, C.M. Information exchange architectures for building models. Durab. Build. Mater. Compon. 1999, 8, 2139–2156. Available online: https://itc.scix.net/pdfs/w78-1999-2139.content.pdf (accessed on 9 December 2023).

- Yoo, T.; Jeong, B.; Cho, H. A Petri Nets based functional validation for services composition. Expert Syst. Appl. 2010, 37, 3768–3776. [Google Scholar] [CrossRef]

| Symbol | Description | Symbol | Description |

|---|---|---|---|

| Normal Process |  | Process transition |

| Intra-collaboration Process |  | Input/Output/ Control |

| Inter-collaboration Process |  | Synchronization |

| Decision |  | State token |

| Resource |  | Color token |

| House Type | 39 m2 | 45 m2 A | 45 m2 B | 59 m2 A | 59 m2 B | 75 m2 A | 75 m2 B | 84 m2 | Total |

|---|---|---|---|---|---|---|---|---|---|

| General sale unit | 42 | 164 | 32 | 110 | 1 | 26 | 52 | 58 | 485 |

| Union member unit | 1 | 4 | 21 | 219 | 15 | 17 | 37 | 71 | 385 |

| Rental unit | 38 | - | - | - | - | - | - | - | 38 |

| Total | 81 | 168 | 53 | 329 | 16 | 43 | 89 | 129 | 908 |

| Company | Color Token | Company/Department |

|---|---|---|

| Company A | Facility Owner | |

| ① | Client (or CM) Team | |

| ② | Facility Management Team | |

| Company B | Construction Engineering Department | |

| ③ | Design Team | |

| ④ | Construction Planning Team | |

| ⑤ | Construction Team | |

| ⑥ | Finance Team | |

| ⑦ | Safety Team | |

| Company C | Sub-Contractor | |

| ⑧ | Sub-Contractor Team | |

| Company D | BIM Consulting Company | |

| ⑨ | BIM Coordination Team |

| Symbol | Marked Graph Building Block | Symbol | Marked Graph Building Block | |

|---|---|---|---|---|

Normal Process | [P0] |  |  Synchronization |  (Split-type) (Split-type) (Join-type) (Join-type) |

[P1] |  Decision |  (linked from a place) | ||

Intra- collaboration process | [P2] |  Process transition |  (link places to transition) | |

Resource |  (link to transition) (link to transition) | |||

Inter- collaboration process | [P3] | Ending mark (additional) |  (start) (start)- link to the first transitions (end) | |

| Level | Company | Department | Individual | |

|---|---|---|---|---|

| Process | ||||

| Normal Process | [P0] | |||

| Intra-collaboration process | [P0] | [P1] | [P2] | |

| Inter-collaboration process | [P1] | [P2] | [P3] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shim, J.-H.; Ham, N.-H.; Kim, J.-J. Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM). Buildings 2024, 14, 358. https://doi.org/10.3390/buildings14020358

Shim J-H, Ham N-H, Kim J-J. Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM). Buildings. 2024; 14(2):358. https://doi.org/10.3390/buildings14020358

Chicago/Turabian StyleShim, Jae-Hyung, Nam-Hyuk Ham, and Jae-Jun Kim. 2024. "Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM)" Buildings 14, no. 2: 358. https://doi.org/10.3390/buildings14020358

APA StyleShim, J.-H., Ham, N.-H., & Kim, J.-J. (2024). Collaborative BIM-Based Construction Coordination Progress Modeling Using Extended Collaborative Process Modeling (exCPM). Buildings, 14(2), 358. https://doi.org/10.3390/buildings14020358