1. Introduction

Population growth, urbanization, industrialization, and the intensification of transport have generated negative externalities on the environment. The need for sustainable development is demonstrated by the dramatic climate change and international initiatives regarding the transition to a green economy, the promotion of corporate social responsibility, and the principles of the circular economy [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10]. The complexity of the sustainable development phenomenon requires technical and economically viable solutions that ensure a reduced consumption of resources and zero carbon emissions [

11,

12,

13,

14,

15,

16,

17,

18,

19].

The world population is projected to increase from 7.7 billion to 9.7 billion people by 2050. As a result of the growing population, product consumption will also increase. Estimations show that overall material use will reach around 90 billion tons by 2050, approximately twice the quantity observed in 2015 [

20,

21,

22].

The European Union (EU) is the undisputed leader, at the international level, in promoting the principles of sustainable development through complex measures that have allowed the creation of a coherent legal and institutional framework. The use of renewable energy, the decrease in energy consumption, and the increase in the energy efficiency of buildings are some of the essential points on which the European Green Deal is built. The complex measures aim at both the management of negative environmental externalities generated by human activity and the improvement of social problems determined by the energy transition such as energy poverty. High energy prices, energy inefficiency of buildings, and heating systems fuel the phenomenon of energy poverty. In addition, challenges generated by ensuring energy security oblige European authorities to find solutions for energy saving, with energy efficiency being considered the best resource.

The strategies proposed by the EU regarding the reduction in carbon footprints of building materials, especially for all products used in External Thermal Insulation Composite Systems (ETICSs), are a major challenge for all producers and members of the EAE (European Association for ETICS) [

23,

24]. Good product design from the elementary stages of the process is key in order to comply with energy policies and the life cycle analysis of these materials [

25,

26,

27]. To mitigate the climate change proposed in the Paris agreement in 2015, all participating countries will have to adjust to the global average temperature of the planet below 1.5 °C and, at most, not exceeding 2 °C. On the basis of this target, the EU has developed a Green Deal strategy, the aim of which is to decarbonize the European economy and industrial processes at least by 2050 as a preliminary part of the strategy [

28,

29,

30]. With initiatives such as Renovate2Recover through the NRRPs (National Recovery and Resilience Plans) program in conjunction with REPowerEU, the EU is aiming to provide the impetus by strengthening energy security through a reduction in energy demand and consumption, thus facilitating the transition from fossil sources to renewable energies.

The building sector is key to the fight against climate change considering that European buildings are responsible for 36% of CO

2 emissions and, at the same time, 40% of the continent’s energy demand. It offers an enormous capacity to make use of and contribute not only to environmental protection but also to health, comfort, and economic growth [

31,

32,

33,

34]. European regulations aim not only to reduce the negative externalities on the environment through the energy transition but also to ensure a fair path for consumers and local communities that will both ensure jobs and reduce the risk of energy poverty considering price fluctuations in the context of renewable energies but also the geopolitical situation on the continent [

35,

36,

37,

38,

39,

40,

41,

42,

43,

44]. What was once considered waste can be transformed into a valuable resource. The expansion of the world’s population and the personal quest for a better life and comfort go hand in hand with the expansion of energy and raw material consumption. As consumption continues to grow, the annual production of waste in the EU increases, and its composition becomes more complex year by year. In the context of the circular economy, an ambitious EU-wide action plan was adopted in 2015 to stimulate the transition towards a circular and competitive economy so that sustainable treatment and recycling methods applied at the different sources of waste origin are accelerated. Electrical and electronic waste, known as e-waste, is one of the fastest-growing waste streams, growing at a rate of 3–5% per year. In 2012, 9 million tonnes of electrical and electronic products were placed on the EU market, and in some EU countries, around 3.5 million tonnes of electrical and electronic waste were collected through the usual channels for treatment, of which around 2.5 million tonnes were subsequently recycled or reused.

The recycling of building materials, especially from demolition sites, is far from being clarified, so it remains a threat to the environment and a challenge for every EU member state. Recycling such waste involves enormous efforts, starting with its collection, transport, sorting, and reprocessing. At present, there is no European and/or national waste stream that allows for the integration of such waste, so it is necessary to implement measures that contribute to the circularity and better management of this type of waste through recovery. A large part of this waste is deposited in open fields and landfills, which increases the risks of water pollution, soil pollution due to its complex acidification and alkalinization, and the remains of highly hazardous organic material that can affect the environment.

To this end, all new buildings are required to comply with the nZEB (Nearly Zero Energy Building) standard. ETICS is a complex system consisting of numerous products and applications generating energy value, as well as the quality and sustainability of housing and buildings (Renovate Europa, 2023) [

45], the pillars and amazing benefits of which are also mentioned by the European Association for ETICS (EAE, 2022): complex benefits, numerous fields of applications, designs, and technology.

Industrial activities at the company level, waste management by authorities, and responsible and sustainable consumption by consumers represent scenarios that are in line with a circular model. In Asia, one of the continents with the highest demand for building materials, today, its growing population and high demand for housing and buildings are indicators of concern for the construction sector, as it requires greater efforts to meet this demand, and this is one of the biggest challenges for its governments. The balance between environmental sustainability through more environmentally friendly building materials, as well as highly recyclable materials, could be key to improving the quality of life of its inhabitants and the environment. It is worth remembering that the continent has the greatest imbalance between waste management and waste production. In contrast to the other continents, the challenge remains to ensure best practices in waste management, the development of more sustainable building materials from renewable energy sources, and techniques to improve their useful life through a good life cycle analysis (LCA).

The development of lighter, more sustainable materials, which means lower carbon footprints, will depend largely on the efforts of governments, using budgets earmarked for this purpose through well-established EU programs. All member states will have to ensure that the objectives of the Paris Agreement are met. All these aspects mentioned above are applicable to the ETICS-EIFS thermal insulation model based on energy efficiency. As the law of conservation of energy states: Energy is neither created nor destroyed, it is only transformed. Its transformation or the method of maintaining it in a sustainable way is through building models that can retain this energy, integrating it into a space to improve the living conditions of the residents. ETICS-EIFS systems are construction models of thermal insulation systems whose objective is to minimize the heat transmission coefficient, U(W/m2K) per m2 of surface area. This parameter is key to designing and producing materials that fit these thermal models. Minimizing thermal losses is key to the construction of sustainable homes and buildings. A large part of the responsibility falls on the manufacturers and producers of raw materials, starting with cement in all its typologies: CEM I, II, III, etc. Subsequently, this also includes the producers of HPMC-type cellulose and their derivatives, whether modified or simple. Obtaining quality indicators of the final product of the European or American thermal insulation system will depend to a large extent on all the components that make it up, so it is highly important to select materials with lower-carbon-footprint substances from their manufacturer and the design of highly balanced recipes that maintain the indicators of quality, price, and balance of emissions. The basecoat, renders-topcoat, or final coat for the entire system should be well-developed and fulfill the ETAG 004 standard for such systems.

The market for cement-based additives for the ETICS-EIFS (External Thermal Insulation Composite Systems) is a highly competitive market and it is becoming increasingly difficult to comply with European sustainability specifications. This market plays a highly important role in the construction sector, not only for the technical solutions it offers but also for the aesthetic aspects. Since 2005, this market has been growing by more than 20% per year, which makes it increasingly attractive and offers better opportunities. However, this increase has been reduced not only by the crisis of 2007–2008 but also by the pandemic of the last few years [

46,

47,

48]. Cement-based admixtures are solid mixtures that are generally characterized by their lower chemical reactivity in heterogeneous systems. The constituent components in their basic formulation, such as limestone (CaCO

3) magnesites (MgCO

3), gypsum (CaSO

4-2H

2O), dolomite (MgCa (CO

3)

2), SiO

2, etc., known as filler materials, are key to establishing the functionality of the dispersed system and the rheology of the final product in terms of application and setting times. As for cement, its introduction into these systems from the 19th century onwards has been a milestone in the construction industry, becoming a key component in any ETICS additive recipe. Historically, cement-based adhesives have been used since ancient civilizations such as the Babylonians 6000 years ago. Hydraulic joint mortars based on pozzolan were likely discovered 3000 years ago and used to a large extent by the Greeks, Phoenicians, and Romans. In terms of industrial production and recipe, the first patent for dry and cement-based adhesives was published in 1893 in Europe, while concrete appeared much later in the mid-1950s.

The modern development of the cement-based adhesives sector through dry-based chemistry in the 1960s was generally influenced by three important trends:

The substitution of plant floor mixing through pre-mixing and pre-packaging of dry adhesives.

The mechanization of applications, including bulk transport (silos), automatic mechanical systems with water for hydration, and machinery for atomized water injection.

The modification of mortars and adhesives with polymeric binders in powder form such as re-dispersible powders (RDPs) and other special additives such as cellulose ether-type Hydroxypropyl methyl cellulose (HPMC) that improve material properties in the setting chemical reaction stages.

The first appearance of cement-based dry mortar production took place during the World Wars in Germany, where the innovation and development of special cellulose ethers in solid form as simple and/or modified RDP boomed. These ethers have been the catalysts for modern construction in the 21st century. In addition, it should be noted that, after the 1973 oil crisis, thermal insulation systems became a source of interest and development since, during the crisis, many raw materials derived from downstream crude oil operations were reduced and their commercialization became more and more difficult. On top of all this, there was an environmental problem generated by products based on fossil raw materials. In this context, the ETICS system was born and introduced on all continents in the mid-1980s. The energy policies established in Europe have increasingly pushed the producers of these materials to be aware of the use and recirculation of raw materials and energy resources to maintain demand and production at stable peaks and waste management plans. In Asia, especially in China and the Middle East, there was an explosion of demand in 2000, which has led to a great deal of investment in materials science and development to improve their properties and applications. In terms of the global production of ETICS additives, 100–150 × 10

6 tonnes were produced in 2007 [

17,

18]. Europe produced approximately 49–50 × 10

6 tonnes in 2007, ahead of Asia and the Americas, and the largest European producers in ETICS are Germany, Italy, Spain, and France.

The production of cement-based adhesives requires various raw materials such as (1) mineral binders: Portland cement (CEM/OPC), High Alumina Cement (HAC), special binders (HPMC, RDPs), hydrated limestone, mineral sulphates such as gypsum, etc., and anhydrite; and (2) polymer binders: simple or modified RDPs, fillers (silicate sand, CaCO3 complex sands, dolomite, etc.), special additives (cellulose ethers, pigments, anti-foaming agents, anti-airing agents, retarding agents, accelerators, thickeners, hydrophobizing agents, and plasticizers).

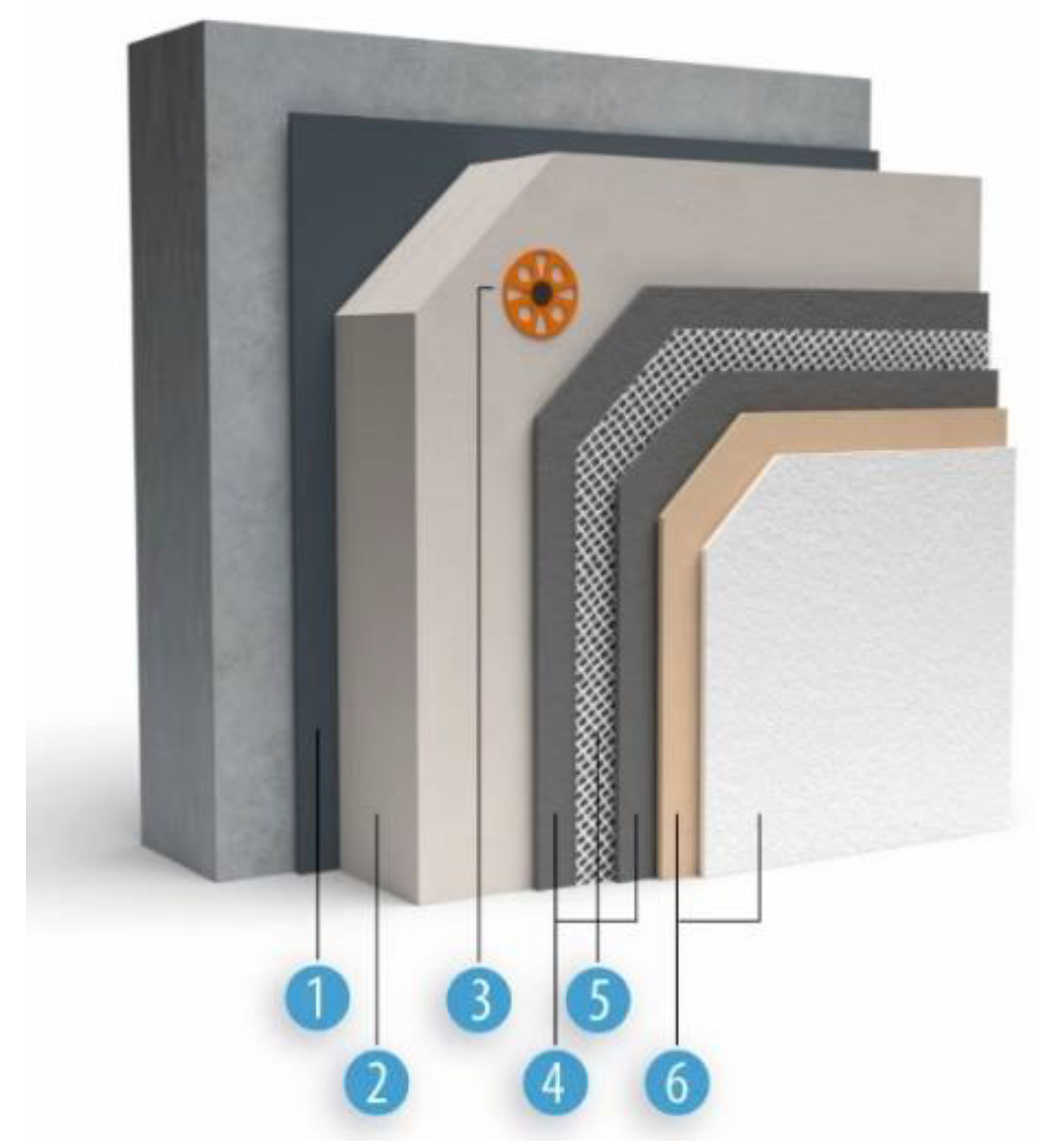

ETICS adhesives are products that conform to European quality policies by means of ETAG-004 guidelines for European technical approval with rendering. The general structure of such a system can be seen in

Figure 1.

Producing a cement-based adhesive that is sustainable and meets European energy requirements for ETICS is the objective of this research; therefore, it should be noted that the traditional formulation of adhesives is based on the use of Portland cement type CEM I 42.5R, whose Clinker content ranges between 95 and 100% and 0–5% of minority additives. The resulting products based on this formulation contain more than 85% of the CO2 footprint due to the chemical kinetics of the combustion reaction for the production of clinker. The cement type CEM II 42.5R B-LL Ecoplanet (Green Cement, Jewett, TX, USA), a new formula developed by the company Holcim Romania, was used for the experiment.

3. Results

Water absorption is an important parameter when dealing with ETICS products. The topcoat adhesive must ensure a minimum water absorption (not less than 20 min) to avoid thermal losses and subsequent aging of the system. This has been achieved by means of laboratory techniques and comparison with the standard reference product (Std). As can be seen in

Figure 4, the water absorption in both products is quite good, although the new product (Tf) presents a better hydrophobic character, and this is due to the complexity of the rheology of the mixture, the hydrophobic agents used, and the modified RDP and HMPC that provide some additional hydrophobic character to the system.

The density results of both products are quite similar. The hydration reaction kinetics of the cement is key to determining the required water content and adjusting the consistency of the product at the time of topcoat application. Both products have good density ranges as shown in

Figure 5.

Figure 5.

Comparative density representation.

Figure 5.

Comparative density representation.

One of the main conditions of the adhesive is its ability to adhere to EPS and MW. According to the results obtained from the experiment, the new adhesive shows better adhesion than the standard product, as shown in

Figure 6.

Figure 6.

Adhesion to dry concrete substrate.

Figure 6.

Adhesion to dry concrete substrate.

The adhesion to wet concrete after 2 d-2 h according to ETAG-004 of both products is quite good, although the new product shows better results, as shown in

Figure 7.

Figure 7.

Adhesion to wet concrete (2 d-2 h) substrate.

Figure 7.

Adhesion to wet concrete (2 d-2 h) substrate.

In

Figure 8 and

Figure 9, the adhesion to wet concrete substrate results after 7 days are presented. Both products perform well, although the adhesion of the new adhesive stands out.

Figure 8.

Adhesion to wet concrete (7 days) substrate.

Figure 8.

Adhesion to wet concrete (7 days) substrate.

Adhesion to dry EPS shows better results with the new adhesive. Better adhesion guarantees the durability of the ETICS system and reinforces the concept of introducing aggregates from construction demolition. The great flexibility in the granulometric curve allows better cement setting, improving the hydraulic properties and favoring the adhesion as shown in

Figure 9.

Figure 9.

Adhesion to dry EPS.

Figure 9.

Adhesion to dry EPS.

Wet adhesion on EPS boards (2 h) shows similar results as in

Figure 10. In both cases, the recycled sand aggregates improve the rheological properties, together with the binders improving the adhesion.

Figure 10.

Adhesion to wet EPS (2 h).

Figure 10.

Adhesion to wet EPS (2 h).

When the application time is prolonged by 7 days, better results are observed for both products, but the new product stands out, as shown in

Figure 11.

Figure 11.

Adhesion to wet EPS (7 days).

Figure 11.

Adhesion to wet EPS (7 days).

Mineral wool is a product with very good absorbent properties and high density, so achieving excellent adhesion is key to a good ETICS system. Tests during the experiment have shown very good results. It has been applied to 10- and 20-cm-thick wool, increasing the open time. In both thicknesses, the results have been excellent, with the Tf sample standing out as shown in

Figure 12.

Figure 12.

Adhesion to dry MW.

Figure 12.

Adhesion to dry MW.

For the calculation of CO

2 emissions, the following expression has been used:

From a standard product, the CO

2 emission from the mineral and organic binder is more than 75%. The value is relatively high due to the fact that CEM I 42.5R is used and this type of cement has a concentration of clinker of approximately 95–100%, and stoichiometrically, for every kg of this cement used, it will generate 1 kg of clinker and, consequently, 1 kg of CO

2, with ratios of 1:1 leading to high CO

2 emissions. When this calculation applied to cement is applied to the innovative product in this paper, the CO

2 footprint is 36% less than the standard product. The reason is that the CEM II 42.5R B-LL cement has a concentration of clinker of approximately 65% and contains a more than 40% smaller CO

2 footprint than CEM I 42.5R, so this makes it more sustainable from an emissions point of view. Regarding energy policies, its energetic class is A

+ (

Table 8).

The circular economy is currently a key issue for discussions and interventions aimed at transitioning systems towards greater environmental sustainability. While definitions abound, the circular economy is understood as the transformation of interconnected production and consumption systems into ones in which valuable products, materials, and resources are retained in the economy for as long as possible and waste generation is minimized. Such a transformation involves incremental changes in industrial processes and product design, as well as the reconfiguration of business models. This production and consumption model is generally based on two complementary loops inspired by biological cycles: one for biological materials and the opposite, known as the technical materials loop. In both cases, the aim is to limit resource leakage as much as possible. When a product reaches the end of its useful life, its materials are retained within the economy wherever possible. They can be used productively again and again, creating additional value. Measures leading to a circular economy include reusing, repairing, renewing, and recycling existing materials and products [

10,

51,

52,

53,

54,

55,

56,

57,

58,

59,

60,

61].

4. Conclusions

European energy policies on ETICS-EIFS construction and sustainability are measures that will have to be evaluated in the long term to see how well they are being implemented or not. A large part of thermal insulation system products is produced by linear systems that do not guarantee sustainability and circularity. Raw materials, such as renders, basecoats, and topcoats, generally still result from fossil energy production, and therefore their carbon footprint remains high. In the present research study, numerous tests have been carried out, starting from the European concept of sustainability, a cement source with high sustainable value CEM II, and with properties similar to the CEM I category, which, together with other materials such as recyclable aggregates from construction sites, modified dispersants of RDPs, have formed a stable system, providing highly comparable results with traditional formulations. Water absorption, which, according to the ETAG 004 standard, must be less than or equal to 0.5 kg/m2, has been one of the major points of focus since, being cement type CEM II 42.5R B-LL whose carbonate content reaches almost 25–23%, the absorption has been reduced due to the nature of the rheological system and the formation of films that prevent or reduce water. As for the impact resistance, values have been obtained that conform to the European parameters and their corresponding classification according to the penetration and non-penetration zones 3 and 10 Joules, as discussed at the end of the study.

The main objective of this paper has been to develop a sustainable adhesive for ETICS that complies with energy policies in terms of CO2 footprint reduction, meeting the minimum quality requirements based on the European standard ETAG-004. In this research, a unique formulation of sustainable additives based on cement and modified RDPs and HPMC derivatives has been developed to obtain special thermal properties that comply with European sustainability specifications and policies and introduced as green innovation in the construction industry. For the experiment, 25% of recycled material (demolition waste based on non-hydraulic binder but good functional filler) and 10% of environmentally friendly natural raw material and cement type CEM II 42.5R B-LL Ecoplanet type, developed by Holcim Romania, have been used. In the prelaminar phase of the experiment, several technical aspects of raw material quality and their corresponding types have been considered. Parts of these raw materials are natural, as is the case of modified HPMC, which represents the key component and binder to reinforce not only the rheology of the wet product but also to offer better bond strength in EPS and MW.

In this research, a unique formulation of sustainable additives based on cement and modified RDPs (Redispersible Polymer Powders) and cellulose derivatives has been developed to obtain special thermal properties that comply with European sustainability specifications and policies and introduced as green innovation in the construction industry. In this experiment, 25% of recycled material and 10% of environmentally friendly natural raw material and cement type CEM II 42.5R have been used, and the results show that the newly developed product has adhesion to dry concrete substrate of 0.75 N/mm2 while the minimum is 0.25 N/mm2, adhesion to the wet concrete substrate (2 h) of 1.75 N/mm2 while the minimum is 0.08, adhesion to the wet concrete substrate after 7 days of 1.8 N/mm2 while the minimum is 0.25, adhesion to dry EPS (Expanded Polystyrene board) of 0.105 N/mm2 while the minimum is 0.08, adhesion to dry mineral wool (MW) of 0.02 N/mm2 while the minimum is 0.006, and adhesion to wet EPS (2 h) of 0.114 N/mm2, while the minimum is 0.03.

In addition, this raw material offers a rather reasonable working time given by the open time, which makes it more flexible. The second aspect considered was the choice of modified RDP, a special type of organic binder dedicated for special formulations. Its fast re-dispersibility works well in any application that needs quick dissolving in water and the creation of a stable emulsion. The main polymer is a copolymer of vinyl acetate and ethylene, and it contains polyvinyl alcohol as a protective colloid and mineral and an anti-blocking agent. The results from the accredited laboratory by ISO 17025:2018, Urban Incerc shows that the new innovative and sustainable developed product has adhesion to dry concrete substrate of 0.75 N/mm2 while the minimum is 0.25 N/mm2, adhesion to wet concrete substrate (2 h) of 1.75 N/mm2 while the minimum is 0.08, adhesion to wet concrete substrate after 7 days of 1.8 N/mm2 while the minimum is 0.25, adhesion to dry EPS of 0.105 N/mm2 while the minimum is 0.08, adhesion to dry MW of 0.02 N/mm2 while the minimum is 0.006, and adhesion to wet EPS (2 h) of 0.114 N/mm2 while the minimum is 0.03. Regarding the carbon footprint, from a standard product, the CO2 emission from the mineral and organic binder is more than 75%. This value is relatively high due to the fact that CEM I 42.5R is used, and this type of cement has a concentration of clinker of approximately 95–100%, which leads to high CO2 emissions. Comparing this to the innovative product in this paper, the CO2 footprint is 36% less than the standard product. The reason is that CEM II 42.5R B-LL cement was used and it has a concentration of clinker of approximately 65% and contains a more than 40% smaller CO2 footprint than CEM I 42.5R, so this make it more sustainable from an emissions point of view. Regarding energy policies, its energetic class is A+. As can be seen, the results of this green innovation product are above the minimum values agreed by the ETICS standards and ETAG-004. In addition, this product has a 36% smaller carbon footprint in its formulation compared to any other standard adhesive in the construction market applied for ETICS systems; therefore, we are talking about a sustainable and clean product, suitable for rehabilitation and ecological construction adjusted to the European policies of carbon footprint reduction.