Abstract

In 2011, the term Digital Twin was originally introduced by Michael Grieves to define the synchronization between two realities: physical objects placed in a real space and virtual objects within in virtual space, linked through the mutual exchange of data throughout the entire lifecycle, both in real-time and asynchronously. Nowadays, Digital Twin is among the principal and emerging technological innovations of both Industry 4.0 and the emerging Industry 5.0, enabling an interaction between physical and virtual objects, Big Data, Internet of Things, and Artificial Intelligence. The construction sector, too, is now exploring the potentialities offered by the Digital Twin approach in enhancing innovative, responsible, and sustainable governance of buildings’ lifecycles. Concerning these issues, this paper proposes visualizing future challenges with a specific focus on the operation and maintenance phase and its related impact on decarbonization via a critical literature review of the current statements. The applied methodology is based on three different questions related to certain research issues performed in the Scopus database. The selected findings were filtered, classified, and discussed. Some future challenges on specific issues have been identified, defining and promoting novel research ideas.

1. Introduction

The digital transition launched at the European level has identified key enabling technologies (KETs) as one of the principal innovative and implementing factors. Their mainly digital matrix expresses the dual purpose of supporting innovation and operativity, promoting improved digital solutions for processes, products, and services. KETs combine and establish a strong integration between research and industry. Furthermore, they focus on the interdisciplinary and transdisciplinary aspects connected to Big Data and the management of related information processes, combining the following three different levels of bidirectional exchange of information: man to man; man to machine; and machine to machine. By moving away from the simple digitization phase, they are driving the digital transformation processes of the different production sectors [1].

Today, some 15 years after the promulgation of the European document, which ratified the introduction of KETs, European digital policies reaffirm and strengthen the same principles contained therein [2,3,4,5].

The strategies of Industry 4.0 first, and later, of Industry 5.0, explain the visions, methods, and operational tools dealing with both the ecological and digital transition.

Industry 4.0 has introduced the interconnection between the physical and digital world in the management of industrial processes. It has assumed the integration of cyber-physical systems, interoperability, virtualization, decentralization, and real-time monitoring strategies as founding principles [6,7].

Industry 5.0 later outlines renewed human–machine–environment interactions, which find concrete implementation in the use of cloud platforms that are able to control production services, optimizing the cost and quality of the final product. It supports the implementation of processes aimed at saving resources, reducing waste, and recycling, focusing on Artificial Intelligence (AI) and, therefore, on bots, intelligent software, and cobots programmed to interact with humans in production processes and shared workspaces [8].

In this very complex scenario, digitalization is a key element, playing the role of a macro-strategy enabling these transformations to function sustainably. This is a role stated in many principles contained in some European communications specifically addressing the various industrial sectors [9,10]. New economic and production models have arisen and become established. The Internet of Things (IoT), Big Data, 3D printing, robotics, cloud, and virtual and augmented reality (VR, AR) are just some of KETs now directly associated with today’s new technological potential. Digital Twin (DT) approaches appear alongside these. Their experimentation and widespread application constitute the most advanced frontier of innovation, referring to the general Lifecycle Management (LCM) of systems, products, and components in the whole industrial sector [11,12,13].

In the construction sector, the sustainable Lifecycle Management of buildings and related digital processes has become a crucial topic over the past decades, to face which some action has been taken. Nowadays, the following are still ongoing: the definition of new standards and new methodologies, the development of specific tools and methods, and the construction of effective databases [14,15].

The European Commission with the Renovation Wave Strategy has set these priorities, emphasizing the goals concerning existing heritage recovery, reducing greenhouse gas emissions for climate neutrality, and starting digitalization in the building sector [16]. However, there is still a lack of integrated approaches that can address all of the issues connected with the whole lifecycle of buildings. The Digital Twin approach is a research area that identifies many of the current and potential future challenges [17,18].

The paper questions the issues related to the level of transfer of DT approaches to the construction sector, their application in the operation and maintenance phase (O&M), and the type of contribution that their use can make in terms of the activation of decarbonization processes in the sector. This paper views future challenges via a critical literature review, as introduced in Paragraph 3, specifically concerning the following three questions performed in the Scopus database.

- What are the main aspects concerning the integration of Digital Twin in the Building Construction sector?

- What is the level of application of Digital Twin in the O&M phase in the Building Construction sector?

- In which way could the Digital Twin approach be applied in the O&M phase to contribute to the sustainable transformation of the Building Construction sector with regards to decarbonization and carbon emission/footprint reduction?

The selected findings were filtered, classified, and discussed. Some future challenges on specific issues have been identified, defining and promoting original research topics.

Moreover, and relevant for the growth and affirmation of studies in the specific area, the authors have included other references not directly referred to the Scopus database.

2. Background

2.1. The Growth of the Digital Twin Approach

Since the 1990′s, in different industries, the need for a holistic approach to information management throughout a product’s lifecycle has led to the definition of tools such as Product Lifecycle Management (PLM) that integrated computer-aided design solutions (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE).

The aim of PLM was to support the process of managing the lifecycle of a product starting from the optimization and rationalization of all activities, systems, and information during the product development phase, production, use, and end of life [19].

In 2006, Michael Grieves, now the Executive Director of the Digital Twin Institute at the Florida Institute of Technology, presented an innovative PLM prototype, defining it simultaneously as a dynamic virtual system and a mirror of the real system. On that occasion, he introduced the fundamental characteristics of the future Digital Twin concept. Physical objects placed in a real space and virtual objects placed in a virtual space interact with each other through the bidirectional exchange of data between the two dimensions. For this reason, he first called it the “Mirrored Spaces Model” and, subsequently, the “Information Mirroring Model”. He had defined an extremely dynamic operational tool in which the real and the virtual were connected during the entire lifecycle of the system, from design to production, to manufacturing, to use, and, finally, to its disposal at the end of life [20].

A few years later, in 2011, the new term Digital Twin was coined by Michael Grieves, defining simultaneously both the digital and virtual reality of a physical object. A set of digital information describes, in a virtual space, a real or potential object from the micro-atomic level to the macro-geometric level [21].

However, the first experimentation with a simulation process comparable to Digital Twin dates back to several decades earlier.

In 1970, for the Apollo 13 Mission, NASA experimented, for the first time, with a simulation procedure through a digital prototype, creating an adaptive and dynamic digital system. This was a virtual replica of the spacecraft and of its behavior, which was used to predict and simulate potential operating problems in a controlled context. The prototype was created to analyze and control its behavior with realistic conditions that could be activated during the use phase [22,23].

2.2. Digital Twin Development and Ongoing Implementation

Nowadays, following Grieves’s vision, through applied research in different fields of science, the Digital Twin concept is increasingly affirming its importance.

Some developments and applications are listed below.

- DT is configured as a technological evolution/revolution that affirms the transition from atoms to bits, from a material dimension to a virtual one, with a strong interconnected, informational, and immaterial character [24].

- DT is defined as a virtual representation of physical objects, associated with functional and technical outputs and with the monitoring of real-time conditions of the related processes, activities, or functioning [25].

- DT use introduces enormous development chance and opening in various production areas and, in all of those complex contexts in which a forecasting activity, implemented at the design or operational phase, can reduce the problematic unknowns connected to the occurrence risk of malfunction or delay in management and productive process. Regardless of the production sector, thanks to the availability and possibility of using DT, the design process and subsequent operational verification potentially become faster and more efficient. It is possible to perform otherwise difficult tests and simulations on real mock-ups, test the potential of alternative solutions, and evaluate different spatial articulations. The bit model can be used for durability testing and to evaluate the wear of parts. It is equally possible to carry out aging tests, artfully accelerating the passage of time to evaluate several years of operation in a very short time. Conversely, in the event of these dysfunctions or malfunctions, time can be “slowed down” to observe a representation of what could happen in intervals of seconds or even milliseconds [26,27,28,29].

- DT is based on three-dimensional digital models of complex objects and/or individual components. It enables the simulation of their functioning in ordinary conditions and/or under stress [30,31].

- The DT maturity level is expected to rapidly increase. Its technological upgrade will accelerate as its use increases in industrial areas, including the construction sector [32,33].

- The DT idea and its use could be expected to play a nodal role in facilitating and impacting sustainable transformation through widespread technological development [34,35].

A survey conducted in 2019 by Gartner Inc. in the field of information technology stated that DT is among the five emerging trends that will drive technological innovation over the next decade.

The survey stated that almost half of the companies (48%) that were working on projects related to IoT were simultaneously experimenting with DT. The same study also predicted that, in 2020, there would be 21 billion sensors connected to each other [36]. Their diffusion over recent years has confirmed further predictions connected to the experimentation and increasingly pervasive use of DT [37,38].

2.3. Digital Twin for the Built Environment: An Open Development Field

The strategies connected to the ongoing dual ecological and digital transition, as well as the challenges relating to nodal environmental issues, outline the characteristics of a true revolution. This is both ambitious and essentially no longer deferrable for landscapes, territories, cities, and communities [39,40,41,42,43].

These ineluctable urgencies may become opportunities, highlighting the potential arising from the emerging technological innovations applied to the entire construction sector, which is increasingly committed to overcoming instrumental and process gaps [44,45,46].

DT is, today, widely applied in many sectors, from aerospace to aeronautics, from complex industrial scenarios to automotive and medicine scenarios. It is equally applicable to the construction industry, and, despite its well-known atavistic slowness, represents a fundamental tool for the innovative and sustainable governance of the entire lifecycle of buildings. This is a perceived revolution, dealing with the major themes of built environment transformation [47,48].

DT can be considered as the combination of the Product Lifecycle Management (PLM) approach [19,20] with the Building Lifecycle Management (BLM) and Lean principles and approaches.

At the beginning of the 1990s, Lauri G. Koskela hypothesized the transfer of the Lean approach derived from the Toyota production chains of the 1950s to the construction sector in order to improve the predictability of projects, reducing possible critical issues in the construction and management phases. His studies are the basis of Lean Construction [49,50].

Today, alongside the consolidated dimension of Lean Construction Management, the general principles and the concept of collaborative integration, linked to the continuous exchange of information, are matched by the evolving and in-process operational features of the DT approach [51,52,53,54].

When transferring these principles, methodologies, and techniques to the construction sector, the DT approach integrates the data generation and information management process for lifecycle planning and lifecycle assessment [55,56,57].

Therefore, DT could allow and implement process optimization in the construction sector; increase the quality and productivity; stimulate interest in the integration of automatic and smart systems; combine the goals of enhancing the digital technological level of buildings; reduce waste and costs; support decision-making process functionalities; and guarantee more efficient and safe living and better customer satisfaction [58,59,60,61].

The DT concept could greatly benefit the built environment; however, the lack of appropriate methodological approaches, effective standardization actions, and capability of data management reduces the extent to which it could advantage the architecture, engineering, construction, and operation sector (AECO) [27,62,63,64,65].

3. Materials and Methods

This investigation explored the recent efforts of DT application in the built environment, identifying some dominant research topics.

The exploration for related papers was performed in the Scopus database.

It was carried out focusing on the following criteria: “Subject area:” “Engineering,” “Computer Science,” “Environmental Science,” and “Energy”.

Furthermore, the “Document Types” investigated were “Article” and “Review;” and the “Source Types” were “Journal” and “Book series”.

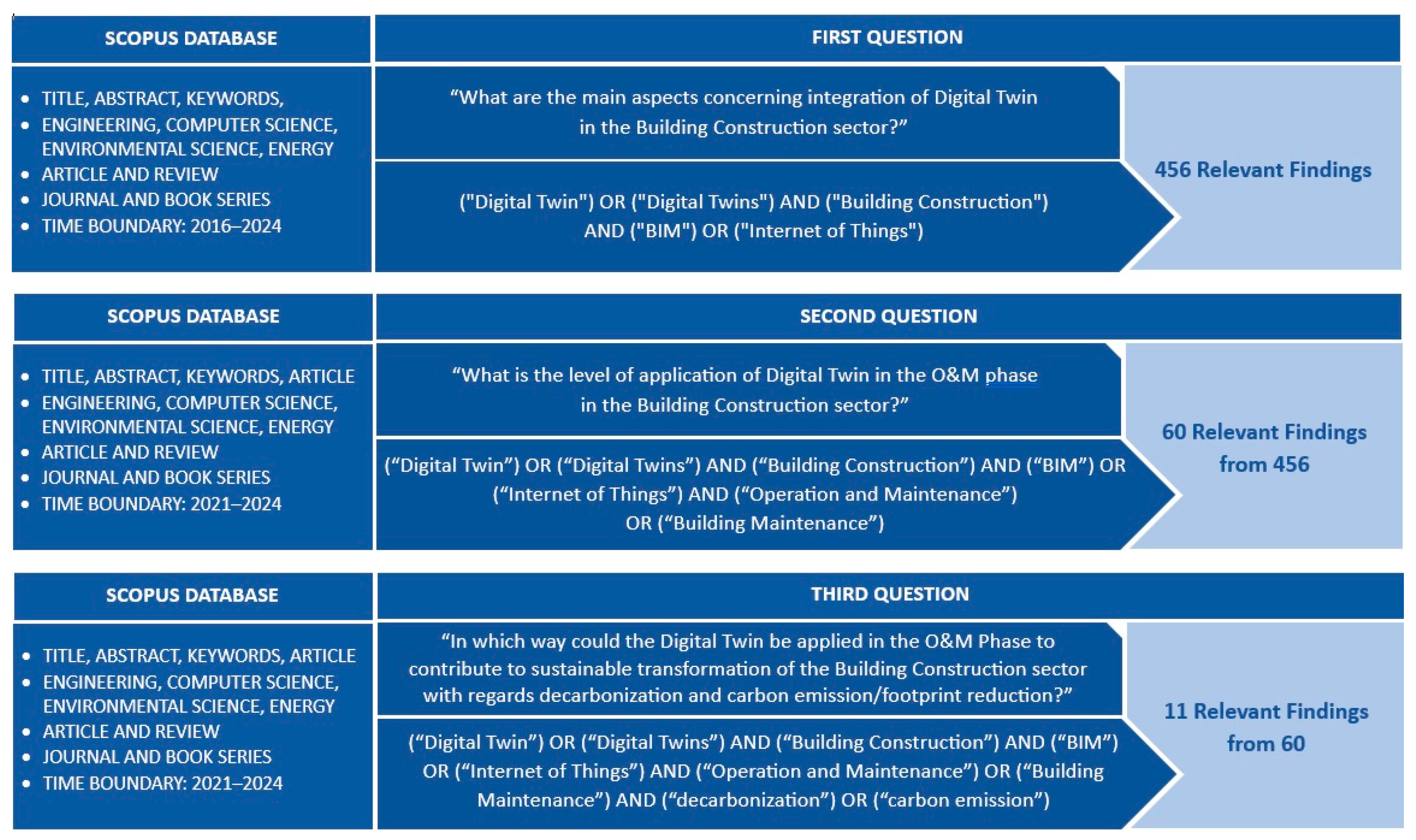

The literature review process was based on three different main research questions.

The applied methodology is described in Figure 1.

Figure 1.

Literature review process and applied methodology.

The first question was as follows: “What are the main aspects concerning integration of Digital Twin in the Building Construction sector?”

The analysis was led firstly on the title, abstract, and keywords.

A search string was defined to develop the study on the specific subjects connected to DT in the Building Construction sector, as follows:

(“Digital Twin”) OR (“Digital Twins”) AND (“Building Construction”) AND (“BIM”) OR (“Internet of Things”).

A total of 456 papers were found (Table 1).

Table 1.

First question and related research string.

Firstly, a time boundary was defined from 2016 to 2024, due to a lack of available findings prior to 2016.

Subsequently, the findings selected by the identified search criteria were filtered through a second deep and qualitative analysis of the content of both the title and abstract.

While the present work recognizes sustainability as a major goal for the Building Construction sector, it specifically focuses on those aspects also connecting DT experimental application and the O&M phase. In this phase, the lifecycle incurs the major environmental and economic costs, impacting growth exponentially.

Then, further verification was carried out on the resulting 456 relevant documents, filtered to include a new specific issue focused on DT in the O&M phase.

A second question was proposed as follows: “What is the level of application of Digital Twin in the O&M phase in the Building Construction sector?”

A new search string was created to develop the study on the refined specific studied subject, as follows:

(“Digital Twin”) OR (“Digital Twins”) AND (“Building Construction”) AND (“BIM”) OR (“Internet of Things”) AND (“Operation and Maintenance”) OR (“Building Maintenance”).

At first, the search concentrated on the title, abstract, and keywords.

The same specific filters were repeated, as follows: “Subject area:” “Engineering,” “Computer Science,” “Environmental Science,” and “Energy;” “Document Type:” “Article” and “Review;” and “Source Type:” “Journal” and “Book series”.

The time boundary was initially from 2016 to 2024, however, since all of the publications were related to the last three years, it was reduced to 2021 to 2024.

A total of 60 papers were filtered (Table 2).

Table 2.

Second question and related research string.

An in-depth qualitative content analysis was performed successively.

From this analysis, three words appear several times, both isolated and associated with each other, as follows: monitoring, virtual reality, and simulation.

Three specific strings were then created. Each string combines an initial common part with one of the three aforesaid words (Table 3).

Table 3.

Second question. Added string search and related findings.

According to these results, a different search was performed to highlight topics and potential contributions within the scope of sustainability in the built environment.

Therefore, a third specific question was defined as follows: “In which way could the Digital Twin be applied in the O&M phase to contribute to the sustainable transformation of the Building Construction sector with regards decarbonization and carbon emission/footprint reduction?”

A new search string was created by adding to the same previous common part decarbonization and carbon emission, as follows:

(“Digital Twin”) OR (“Digital Twins”) AND (“Building Construction”) AND (“BIM”) OR (“Internet of Things”) AND (“Operation and Maintenance”) OR (“Building Maintenance”) AND (“Decarbonization”) OR (“carbon emission”).

The titles, abstracts, and full texts of the 60 relevant documents were analyzed to filter the relevant documents specifically related to the third question.

A total of 11 papers were filtered (Table 4).

Table 4.

Third question and related research string.

Table 5 highlights the findings addressed by topics regarding the second and third questions. While not representing the results of traditional sensitive analysis, it does describe and evaluate the different impact of the topics.

Table 5.

Findings addressed by topics.

The analyzed findings are comparable to each other and sufficiently free from bias; moreover, they are also uniform and not too dissimilar in type and outcome.

4. Findings

The following section outlines the considerations developed from the applied methodology and concerns firstly the analysis of the 456 relevant documents. The title, abstract, and keywords were considered only.

Subsequently, the 60 specifically filtered samples were thoroughly analyzed, exploring and discussing their methodologies and relevant findings in order to identify some potential future challenges and verify some existing research gaps to fill.

The contents of the sub-paragraphs below include the results of the research and other relevant references not directly related to the Scopus database, which were added by the authors to define more precisely the research areas investigated in this paper.

4.1. Digital Twin in Building Construction Sector: BIM and IoT

Certain considerations arise from the first question: “What are the main aspects concerning integration of Digital Twin in the Building Construction sector?”

Firstly, the analysis of the 456 relevant documents highlights the following two nodal interactions as development scenarios: Digital Twin–Building Information Model (DT–BIM) and the Digital Twin–Internet of Things (DT–IoT). The double interrelation within the construction sector commonly concerns the following five areas: planning, design, construction, operations and maintenance, and decommissioning.

DT–BIM and DT–IoT are, in many ways, interrelated, dealing with some specific and emerging issues.

- DT, due to BIM, provides opportunities for defining databases concerning the built environment, facilitating the exchange of information in a common and standardized digital manner. BIM is now progressively adopted and promoted within the community regulatory framework, as well as in various national contexts, and is a key element, functional both to green transition and digital processes [66,67,68,111,112,113,114].

- DT, through BIM modeling, configures a digital representation, an instrumental modality capable of returning a three-dimensional representation, replicating geometric, structural, and performance characteristics. Simultaneously, it enables several emerging specific development areas, such as 3D visualization and geo-referencing approaches, through a Geographical Information System (GIS) [69,70].

- DT and BIM together allow for control inefficiencies and increase quality by using computational, interconnection, and interoperability capabilities of digital technologies. Furthermore, information can be shared in the cloud in a single data environment on interoperable and collaborative digital platforms [71,72,73].

- DT is deeply coupled to IoT, which describes the network that connects smart systems, software, and technologies through the Internet, as well as the communication of outgoing or incoming data.

The synchronization between physical reality and virtual reality is guaranteed by a pervasive communication infrastructure, a real-time data-sharing platform that, using sensors installed in the building, allows us to have access to the data and their analyses. In this way, information that is appropriately structured can be extrapolated, shared, and updated simultaneously for an always up-to-date representation [115,116,117].

- The DT and IoT network allow operations on digital model integrating views, virtual reality, augmented reality, and Artificial Intelligence (AI), involving operators and final users, too [74,75,118,119].

- DT, when combined with IoT, becomes a dynamic informative repository concerning construction during its lifecycle, from the design to construction, to real-time monitoring during the in-use phase [76,77].

- DT, BIM, and IoT overcome the common and critical limitations of the construction sector, such as the inability to create prototypes of buildings and manage information during the lifecycle, particularly in the in-use phase [78,79,120]. DT permits an approach based on the information available and usable from the design phase to the end of life, allowing simulation, evaluation, and the ability to check different choices in terms of technological and performance alternatives. DT concretely opens a new approach to support design and management in the lifecycle of buildings [80,81,82,83,110,121]. Thanks to interoperability and information management, it could improve productivity; reduce the impact of buildings and infrastructures on the environment; enhance sustainability, circularity, and green construction; and predict more accurate outcomes and in-use behavior, reducing waste, risk, and costs in the lifecycle [84,85,122,123,124].

4.2. Digital Twin in O&M Phase

Several considerations follow from the second question: “What is the level of application of Digital Twin in the O&M phase in the Building Construction sector?”

- DT is related to the development/exploitation of the BIM as-built model. The following is in accordance with ISO 19650-1:2018, thus the as-built dimension corresponds to the level of development of the virtualized objects [125]. The BIM as-built model holds general information and technical specifications of the existing building. It represents the specific construction systems, with the definition of the related management and maintenance interventions in the whole lifecycle. While BIM has been successfully adopted in the design and construction phases, it still presents many criticalities and a limited adoption within the O&M phase and in general in-use asset management. These are conditions that express the current inability to activate virtuous control and governance processes of the operational phase and introduce a rapidly growing research area [76,86,126,127].

- DT, due to IoT in the O&M phase, assumes devices and sensors that enable the monitoring and detection of the performance and the control of the operating conditions, faults, and malfunctions of systems and components. It limits the potential risk situations, downtime, and inefficiencies, optimizing performance and safety. It also permits the monitoring of energy, water consumption, etc. [87,88,89,90,109,128,129].

- DT ensures structured accessible data and the integration of analysis to activate long-term data management and connecting it with the structuring of a Building Logbook, which is a digital and dynamic repository of information relating to the lifecycle of buildings [91,92,93,94,130,131].

Some research areas should also be highlighted, which have already been widely covered in the literature related to the development of decision-making processes based on the widespread adoption of Digital Twins within the O&M phase. Among these are the following:

- The implementation of interoperability tools based on open standards ISO 16739-1:2018, which direct towards the progressive experimentation of data specifications of Construction Operations Building information exchange (COBie), to be used as exchange informative formats between the design and the O&M phase [95].

4.3. Digital Twin Contributing to Decarbonization of a Built Environment

The premise is useful in introducing the third question. Digital transformation could represent the path through which the construction industry implements and enhances its ability to meet climate neutrality and sustainability challenges. Then, the third question appears, as follows: “In which way could the Digital Twin be applied in the O&M phase to contribute to the sustainable transformation of the Building Construction sector with regards decarbonization and carbon emission/footprint reduction?”

The first consideration arising from the research is the increasing, yet immature, penetration and diffusion of this topic (DT, O&M, and decarbonization) in the literature.

An analysis of the texts shows the following:

- DT enhances the potentialities of smart construction, contributing to carbon emission reduction in the lifecycle of buildings and infrastructure. With regard to the in-use phase and the related O&M strategies, DT contributes to achieving goals in the energy sector, enabling sustainable energy management and optimizing building energy efficiency in order to reduce carbon emissions and the final economic and environmental costs [96,97,98,99].

- DT, through machine learning technologies and the advancement of the building energy analysis methods, could achieve more accurate predictions by exploring benchmarks. It could also optimize energy efficiency, guaranteeing a balance between user comfort and energy consumption, and implement management processes involving different stakeholders. All of these purposes, in their application to the built environment, could facilitate the transfer to clean energy, contributing lastly to reaching sustainable development goals [100,101,102,103].

- DT, in combination with virtual reality and augmented reality in the AECO sector, is still limited but increasing. Their combined use has begun to show its benefits, mainly in integrating users and operators into the cyber-physical system [104,105,106,107,108].

5. Discussions: Open and Future Challenges

DT is a key enabler in implementing both Industry 4.0 and Industry 5.0 principles, as well as in the Building Construction Sector, where its application represents, nowadays, a potentially relevant approach within the digital and ecological transition, specifically supporting the development of smart buildings, smart cities, and smart grids.

Evident critical issues remain today in the concrete and diffused application of DT to the AECO sector. However, after the findings were discussed, some open and future challenges have been highlighted within specific development scenarios, as follows:

- DT for Renovation Wave Strategy, which was already stated at the European level.

- Dt as tool for information management in the lifecycle of buildings, which is commonly recognized both at the scientific and production level.

- DT for a sustainable approach in the O&M phase, which is generally deemed important and recognized by authors as a nodal issue.

5.1. DT for Renovation Wave Strategy

The European Commission, with the Renovation Wave Strategy for Europe, has set its objective of doubling redevelopment interventions on existing assets within ten years. [16]. Some general goals have already been affirmed, despite rarely being placed so explicitly close to each other, such as the following: the recovery of the existing heritage and, at the same time, a reduction in greenhouse gas emissions, achieving climate neutrality for Europe and the improved quality of life of the people living in and using the buildings.

In line with these objectives, operational principles and indicators have been established that are capable of measuring the smart readiness of existing buildings, i.e., their ability to be included in the digital reconversion process of existing buildings. The Smart Readiness Indicator (SRI) evaluates the ability of buildings to answer the needs of users, modifying and adapting their functioning, and ultimately improving their energy efficiency and performance during the in-use phase. For effective application, the SRI makes explicit reference to the potential gains connected to the use of the digital model and DT of buildings. It considers the goals of greater energy saving, comparative analysis, and flexibility, as well as the functionality and ability to improve performance, thanks to the widespread use of interconnected and intelligent devices. It includes the assessment of the intelligence readiness of a building or unit based on key functionalities, the impact criteria, and pre-defined technical areas, also including additional information on building inclusiveness and connectivity, interoperability, cybersecurity, and data protection [132,133].

5.2. DT as a Tool for Information Management in Lifecycle of Buildings

DT is an intelligent knowledge management system seeking its own counterpoint in the application of information technologies (ICT), welcoming innovative approaches leading to new ways of using sharing data between operators, as well as between operators and end users. These are issues that, although appropriately studied and theorized, have so far been almost never actually implemented in operational practices. Likewise, from the perspective of overall quality assurance in the lifecycle, when associating the terms “costs”, “efficiency,” and “sustainability” with the design, the need to overcome the lack of sharing and updating of information emerges, as well as the difficulty in control, the lack of communication, and interoperability.

In such a context, the cognitive and informational dimension acquires more and more centrality by bringing all of the management actions of the built environment into a unitary and interconnected process, achieving positive effects in terms of planning management activities, timing the implementation of interventions, and the control of the performance of components and equipment.

These are all aspects that are equally shared and explained in the founding characteristics of Digital Twin approaches, whose basic principle is information, which becomes information capital when it can be acquired and exchanged between buildings, digital models, operators, and users. This fuels the possibility of the effective transformations of the processes, enhancing the ability to govern the information for the current ecological and digital transition.

The widespread application of DT highlights a general goal to enhance the processing capacity of advanced technologies that are already available (BIM and IoT) but not yet widely implemented together.

The use of both BIM and IoT is increasingly diffused in the construction industry, but not in combination with each other. Their combined use has not yet been sufficiently explored, although it could contribute to achieving sustainability. In particular, the potential of their combined use could be expected to be exploited for simulations, monitoring processes, and the application of virtual and augmented reality.

There is a growing awareness that the future for Building Construction will enhance smart aspects connected to the whole functionality of buildings, combining both information systems and sensors. DT, devices, and sensors installed for monitoring and Building Automation Control Systems (BACS) create smart buildings and make the potential upgrade to cognitive buildings achievable. Physical/digital (phygital) constructions, smart grid nodes, and smart cities are capable of communicating with other buildings, mobility systems, and users [108,109].

5.3. DT for a Sustainable Approach in the O&M Phase of Buildings

DT, for the in-use and O&M phases, still appears critical, nevertheless, it represents the operational area in which the most relevant conditions exist for DT’s punctual future implementation.

Various studies quantify the consequences of the global emissions of climate-altering gases, energy consumption, land consumption, and waste production directly attributable to the building stock in operation.

There is an awareness that, when related to the conservation and transformation of the built environment, can be traced back with ever greater evidence to the O&M phase and the need for responsible and sustainable predictive maintenance actions. A phase to which, today, with equally growing awareness, extra costs are attributed, which are no longer and not only of an economic nature, but also of an environmental and social nature. The latter derives from the quantity of energy necessary to heat, cool, power, and manage buildings. As is known, a large amount of energy consumption relates to the lifecycle of buildings. Therefore, sustainable energy management and control represent urgent priorities and criticalities; however, they are not yet sufficient for achieving sustainable construction.

The Chartered Institution of Building Services Engineers (CIBSE) researchers had already expressed concern about these data. In a 2012 study, they argued that buildings normally consume double what was estimated at the design stage. This is a statement that, although not recent, continues to be in line with the energy consumption data of the building stock [134].

Therefore, with reference to the macro-objective of the decarbonization of the construction sector, the emergence of a priority critical area constituted by the O&M phase is clearly stated, as highlighted by the findings explored in the present literature review.

The report of the World Green Building Council (WGBC) affirms that the construction sector is responsible for 39% of global emissions of climate-changing gases, of which approximately one third (equal to 11% overall) is attributable to the construction phase. The remaining two thirds (equal to 28% overall) concern the operation phase [135].

Similarly, in 2016, the European Commission report attributed as much as 40% of European energy consumption to the existing building stock [136].

These data have undergone exponential growth over the last decade, with a rate of increase second only to that of the transport sector.

Between 2017 and 2018, there was a 2% increase in the energy needs of buildings, with a total increase in 2019 of approximately 8 Exajoules, equal to +7% compared to 2010 [137]. Equally significant is the data offered by the United Nation Environment Program (UNEP), which provide a snapshot of the state of buildings on a global scale. The Global Status Report found that total energy consumption and CO2 emissions increased in 2021, even when compared to the pre-pandemic levels. This notwithstanding, there has been a substantial growth in investments and a consequential global reduction in buildings’ energy consumption. The same report documents how the energy demand of buildings has increased by around 4% since 2020, reaching 135 Exajoules, which is the highest value in the last 10 years. Moreover, CO2 emissions from building have reached an all-time high of around 10 GtCO2, an increase of 5% compared to 2020, and 2% compared to the previous peak in 2019 [138,139].

It seems clear that applying the Digital Twin approach to the O&M phase, as well as to the decarbonization processes of the sector, is a challenging area.

DT configures as a potential holistic tool for introducing innovative methods and opportunities supporting maintenance actions and, principally, the widespread use of predictive maintenance strategies.

According to these potentialities, it is necessary to adequately accompany the ongoing shift from hard (techniques) to soft (in-training, organization) techniques of study focus and operational aspects relating to a renewed maintenance approach. As a result, heterogeneous fields of interest are involved that presuppose multidisciplinary approaches and require an ever-increasing ability to manage structured data relating both to performance and operating values and behavioral and experiential aspects concerning the well-being of end users.

6. Conclusions

The Digital Twin concept, introduced in 2011 by Michael Grieves, has progressively and differently impacted various industrial sectors.

Closely connected to the application of ICT, DT introduces, within the Building Construction Sector, structured decision-making processes capable of producing effects on the renewal of both design statutes and construction processes, as well as in the management processes of the in-use and end-of-life phases in a potentially sustainable perspective.

Certain considerations arise that pinpoint the open and future challenges introduced in the paper, converging in the centrality of the DT approach.

DT is certainly the tool that best expresses the potential digital and technological evolutions towards which the construction industry is moving in order to implement the transformation/revolution of current operative practices in the building process, from planning, to design, construction, O&M, and decommission.

Moreover, the European strategy for the built environment recognizes DT as a tool that can play a key role both in the maintenance and the intervention strategies on existing buildings and in addressing climate change issues.

Therefore, DT plays a clear role in the specific field of O&M, which values the dual nature of DT–BIM and DT–IoT, enabling the real-time interaction and monitoring of buildings’ use and performance conditions.

The combined DT and O&M research area is not yet sufficiently mature in terms of implementation, operating practices, and related technical tools, despite specific studies of methodological approaches and general mandatory frameworks.

A profound revision is required, not only of the operating modalities, but also their diffusion in the current operative practices of all of the operators, including the end users. This transformation is possible due to DT and the ability to activate real processes of information sharing, data management, dialogue, and concrete interaction between man and machine and vice versa. The smart building and the cognitive building are tangible results of what the DT approach is and can be in concrete terms.

The present work, and the assumptions derived from it, may lead to the ability to monitor and manage the “vital functionalities” of buildings with DT in a sustainable way.

The exact reading of the relationship between DT and decarbonization, which is currently under-explored, highlights the multiple criticalities related to environmental issues, amplifying the contribution that the pervasive application of DT approaches could allow.

As discussed in this paper, the issue of decarbonization related to the different aspects that converge in O&M acquires a value that transcends the simple assessment of CO2 emissions. It not only involves the technical aspects of building envelopment and equipment efficiency, the selection of energy sources, the management of energy resources, and the procedural aspects of planning and programming maintenance operations, but also of social behavior.

Author Contributions

Conceptualization, M.L.; methodology, M.A.; validation, M.L.; formal analysis, M.L. and M.A.; investigation, M.A.; data curation, M.A.; writing—original draft preparation, M.L. and M.A.; supervision, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| AECO | Architecture, Engineering, Construction, and Operation sector |

| AI | Artificial Intelligence |

| AR | Augmented Reality |

| BACS | Building Automation Control Systems |

| BLM | Building Lifecycle Management |

| CAD | Integrated Computer-Aided Design |

| CAE | Computer-Aided Engineering |

| CAM | Computer-Aided Manufacturing |

| CIBSE | Chartered Institution of Building Services Engineers |

| COBie | Construction Operations Building information exchange |

| DT | Digital Twin |

| ICT | Information Communication Technology |

| IFC | Industry Foundation Classes |

| IoT | Internet of Things |

| KETs | Key Enabling Technologies |

| LCM | Lifecycle Management |

| O&M | Operation and Maintenance |

| PLM | Product Lifecycle Management |

| SRI | Smart Readiness Indicator |

| UNEP | United Nations Environment Program |

| VR | Virtual Reality |

| WGBC | World Green Building Council |

References

- COM(2009)512; Preparing for Our Future: Developing a Common Strategy for Key Enabling Technologies in the European Union. EU-COM: Maastricht, The Netherlands, 2009.

- COM/2010/245; A Digital Agenda for Europe. EU-COM: Maastricht, The Netherlands, 2010.

- EU. A Europe Fit for the Digital Age; EU-COM: Maastricht, The Netherlands, 2020. [Google Scholar]

- EU. Shaping Europe’s Digital Future; EU-COM: Maastricht, The Netherlands, 2020. [Google Scholar]

- COM/2021/118; Digital Compass: The European Way for the Digital Decade. EU-COM: Maastricht, The Netherlands, 2021.

- PwC-PricewaterhouseCoopers. Global Industry 4.0 Survey. Industry 4.0: Building the Digital Enterprise; PwC-PricewaterhouseCoopers: Amsterdam, The Nederlands, 2016. [Google Scholar]

- Wang, K.; Guo, F. Towards Sustainable Development through the Perspective of Construction 4.0: Systematic Literature Review and Bibliometric Analysis. Buildings 2022, 12, 1708. [Google Scholar] [CrossRef]

- EU. Industry 5.0: Towards More Sustainable, Resilient and Human-Centric Industry; EU: Maastricht, The Netherlands, 2021. [Google Scholar]

- COM/2020/102; A New Industrial Strategy for Europe. EU-COM: Maastricht, The Netherlands, 2020.

- COM/2020/103; An SME Strategy for a Sustainable and Digital Europe. EU-COM: Maastricht, The Netherlands, 2020.

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2233–2244. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Samuelson, O.; Stehn, L. Digital transformation in construction—A review. J. Inf. Technol. Constr. 2023, 28, 385–404. [Google Scholar] [CrossRef]

- Dou, Y.; Li, T.; Li, L.; Zhang, Y.; Li, Z. Tracking the Research on Ten Emerging Digital Technologies in AECO Industry. J. Constr. Eng. Manag. 2023, 149, 03123003. [Google Scholar] [CrossRef]

- COM/2020/662; A Renovation Wave for Europe. Greening Our Buildings, Creating Jobs, Improving Lives. EU-COM: Maastricht, The Netherlands, 2020.

- Su, S.; Zhong, R.Y.; Jiang, Y.; Song, J.; Fu, Y.; Cao, H. Digital twin and its potential applications in construction industry: State-of-art review and a conceptual framework. Adv. Eng. Inform. 2023, 57, 102030. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, L.; Ren, G.; Li, H.; Li, X. Special issue: Digital twin technology in the AEC industry. Adv. Civ. Eng. 2020, 2020, 8842113. [Google Scholar] [CrossRef]

- Stark, J. Product Lifecycle Management; Springer: London, UK, 2011. [Google Scholar]

- Grieves, M. Product Lifecycle Management: Driving the Next Generation of Lean Thinking; McGraw-Hill: New York, UK, USA, 2006. [Google Scholar]

- Grieves, M. Virtually Perfect: Driving Innovative and Lean Products through Product Lifecycle Management; Space Coast Press: Merritt Island, FL, USA, 2011. [Google Scholar]

- Glaessgen, E.H.; Stargel, D.S. The Digital twin paradigm for future NASA and U.S. Air Force vehicles. In Proceedings of the 53rd Structures, Structural Dynamics, and Materials Conference: Special Session on the Digital Twin, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Allen, B.D. Digital Twins and Living Models at NASA; NASA Technical Reports; NASA: Washington, DC, USA, 2021.

- Erol, T.; Mendi, A.F.; Doğan, D. Digital transformation revolution with digital twin technology. In Proceedings of the 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020. [Google Scholar]

- Catapult, H.V. Untangling the requirements of a digital Twin. AMRC 2021, 7, 1–32. [Google Scholar]

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect. Mechatronic Futures Challenges and Solutions for Mechatronic Systems and their Designers; Hehenberger, P., Bradley, D., Eds.; Springer Nature: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L. Digital Twin for the built environment: Learning from conceptual and process models in manufacturing. Adv. Eng. Inform. 2021, 49, 101332. [Google Scholar] [CrossRef]

- Adu-Amankwa, N.A.N.; Pour Rahimian, F.; Dawood, N.; Park, C. Digital Twins and Blockchain technologies for building lifecycle management. Autom. Constr. 2023, 155, 105064. [Google Scholar] [CrossRef]

- Radman, K.; Jelodar, M.B.; Lovreglio, R.; Ghazizadeh, E.; Wilkinson, S. Digital technologies and data-driven delay management process for construction projects. Front. Built Environ. 2022, 8, 1029586. [Google Scholar] [CrossRef]

- Boyes, H.; Watson, T. Digital twins: An analysis framework and open issues. Comput. Ind. 2022, 143, 103763. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating digital twin from digital shadow: Elucidating a paradigm shift to expedite a smart, sustainable built environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Hu, W.; Lim, K.Y.H.; Cai, Y. Digital Twin and Industry 4.0 Enablers in Building and Construction: A Survey. Buildings 2022, 12, 2004. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of Digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Kineber, A.F.; Singh, A.K.; Fazeli, A.; Mohandes, S.R.; Cheung, C.; Arashpour, M.; Ejohwomu, O.; Zayed, T. Modelling the relationship between digital twins implementation barriers and sustainability pillars: Insights from building and construction sector. Sustain. Cities Soc. 2023, 99, 104930. [Google Scholar] [CrossRef]

- Li, H.; Peng, X.; Zhang, J.; Ballesteros-Perez, P.; Philbin, S.P.; Li, Z.; Tang, X.; Cheng, J. Enabling the green total factor productivity of the construction industry with the prospect of digital transformation. Environ. Dev. Sustain. 2023, 1–28. [Google Scholar] [CrossRef]

- Gartner Inc. Gartner Survey Reveals Digital Twin Are Entering Mainstream Use; Gartner: Stamford, CT, USA, 2019. [Google Scholar]

- Research and Market. Digital Twin Market Size, Share & Trends Analysis. Report by End-Use (Manufacturing, Agriculture), by Solution (Component, Process, System), by Region, and Segment Forecasts, 2023–2030. 2022. Available online: https://www.gminsights.com/industry-analysis/digital-twin-market?gclid=Cj0KCQiAqsitBhDlARIsAGMR1RjnW57npaMQeag8XvoTrXi1nLA6emy_w3RXZuH5BEHheQG_7ePZQM4aApIiEALw_wcB (accessed on 13 January 2024).

- Gartner Inc. Gartner Glossary Digital Twin; Gartner: Stamford, CT, USA, 2020. [Google Scholar]

- Rodrigo, N.; Omrany, H.; Chang, R.; Zuo, J. Leveraging digital technologies for circular economy in construction industry: A way forward. Smart Sustain. Built Environ. 2023, 13, 85–116. [Google Scholar] [CrossRef]

- Dervishaj, A.; Gudmundsson, K. From LCA to circular design: A comparative study of digital tools for the built environment. Resour. Conserv. Recycl. 2024, 200, 107291. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Tetik, M.; Liu, Z.; Korhonen, P.; Holmstrom, J. Digital Twin for Safety and Security: Perspectives on Building Lifecycle. IEEE Access 2023, 11, 52339–52356. [Google Scholar] [CrossRef]

- Akbarieh, A.; Jayasinghe, L.B.; Waldmann, D.; Teferle, F.N. BIM-based end-of-lifecycle decision making and digital deconstruction: Literature review. Sustainability 2020, 12, 2670. [Google Scholar] [CrossRef]

- Liu, L.; Li, S.; Li, C.; Zhang, J. Analysis of BIM in the Whole-Process Cost Management of Construction Projects. Adv. Multimed. 2022, 2022, 5248544. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Digital twin and web-based virtual gaming technologies for online education: A case of construction management and engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Musarat, M.A.; Sadiq, A.; Alaloul, W.S.; Abdul Wahab, M.M. A Systematic Review on Enhancement in Quality of Life through Digitalization in the Construction Industry. Sustainability 2023, 15, 202. [Google Scholar] [CrossRef]

- Hakimi, O.; Liu, H.; Abudayyeh, O.; Houshyar, A.; Almatared, M.; Alhawiti, A. Data Fusion for Smart Civil Infrastructure Management: A Conceptual Digital Twin Framework. Buildings 2023, 13, 2725. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Liu, Z.; Cui, J.; Osmani, M.; Demian, P. Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building. Buildings 2023, 13, 288. [Google Scholar] [CrossRef]

- Yang, B.; Lv, Z.; Wang, F. Digital Twins for Intelligent Green Buildings. Buildings 2022, 12, 856. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Technical Report 72; CIFE Center for Integrated Facility Engineering, Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Lean Construction Institute. Lean Construction Institute Lean Construction—Leveraging Collaboration and Advanced Practices to Increase Project Efficiency; SmartMarket Report; McGraw Hill Construction: New York, NY, USA, 2014. [Google Scholar]

- Kifokeris, D.; Tezel, A. Blockchain and lean construction: An exploration of bidirectional synergies and interactions. Archit. Eng. Des. Manag. 2023, 19, 1745–2007. [Google Scholar] [CrossRef]

- Hadi, A.; Cheung, F.; Adjei, S.; Dulaimi, A. Evaluation of Lean Off-Site Construction Literature through the Lens of Industry 4.0 and 5.0. J. Constr. Eng. Manag. 2023, 149, 03123007. [Google Scholar] [CrossRef]

- Bayhan, H.G.; Demirkesen, S.; Zhang, C.; Tezel, A. A lean construction and BIM interaction model for the construction industry. Prod. Plan. Control 2023, 34, 1447–1474. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean practices using building information modeling (Bim) and digital twinning for sustainable construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Hayat, S.; Radu, D.; Khan, M.B.; Galatanu, T.F.; Almujibah, H.R.; Hadzima-Nyarko, M.; Benjeddou, O. Building Information Modeling—Empowering Construction Projects with End-to-End Life Cycle Management. Buildings 2023, 13, 2041. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Gutiérrez Moreno, J.A.; Llatas, C. Utilization of an Automatic Tool for Building Material Selection by Integrating Life Cycle Sustainability Assessment in the Early Design Stages in BIM. Sustainability 2023, 15, 2274. [Google Scholar] [CrossRef]

- Ustinovičius, L.; Rasiulis, R.; Nazarko, L.; Vilutienė, T.; Reizgevicius, M. Innovative research projects in the field of Building Lifecycle Management. Procedia Eng. 2015, 122, 166–171. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Yang, A.; Han, M.; Zeng, Q.; Sun, Y. Adopting Building Information Modeling (BIM) for the Development of Smart Buildings: A Review of Enabling Applications and Challenges. Adv. Civ. Eng. 2021, 2021, 8811476. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Almujibah, H.; Khan, M.B.; Alotaibi, S.; Elhassan, A.A.M. Factors Influencing Adoption of Digital Twin Advanced Technologies for Smart City Development: Evidence from Malaysia. Buildings 2023, 13, 775. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.P.; Chen, W.; Chen, K. Digital Twins for Construction Sites: Concepts, LoD Definition, and Applications. J. Manag. Eng. 2022, 38, 04021094. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.; Lee, J.; Hong, T.; Jeong, K. An Integrated Assessment Framework of Economic, Environmental, and Human Health Impacts Using Scan-to-BIM and Life-Cycle Assessment in Existing Buildings. J. Manag. Eng. 2023, 39, 04023034. [Google Scholar] [CrossRef]

- Armijo, A.; Elguezabal, P.; Lasarte, N.; Weise, M. A methodology for the digitalization of the residential building renovation process through openbim-based workflows. Appl. Sci. 2021, 11, 429. [Google Scholar] [CrossRef]

- Nour El-Din, M.; Pereira, P.F.; Poças Martins, J.; Ramos, N.M.M. Digital Twins for Construction Assets Using BIM Standard Specifications. Buildings 2022, 12, 2155. [Google Scholar] [CrossRef]

- Hellmuth, R. Update approaches and methods for digital building models—Literature Review. J. Inf. Technol. Constr. 2022, 27, 191–222. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Kineber, A.F.; Chileshe, N.; Edwards, D.J. Modelling the impact of building information modelling (Bim) implementation drivers and awareness on project lifecycle. Sustainability 2021, 13, 8887. [Google Scholar] [CrossRef]

- Carrasco, C.A.; Lombillo, I.; Sánchez-Espeso, J.M.; Balbás, F.J. Quantitative and Qualitative Analysis on the Integration of Geographic Information Systems and Building Information Modeling for the Generation and Management of 3D Models. Buildings 2022, 12, 1672. [Google Scholar] [CrossRef]

- Akindele, O.; Ajayi, S.; Oyegoke, A.S.; Alaka, H.A.; Omotayo, T. Application of Geographic Information System (GIS) in construction: A systematic review. Smart Sustain. Built Environ. 2023. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Radzi, A.R.; Azmi, N.F.; Kamaruzzaman, S.N.; Rahman, R.A.; Papadonikolaki, E. Relationship between digital twin and building information modeling: A systematic review and future directions. Constr. Innov. 2023. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Adhikari, S. The role of BIM in Integrating Digital Twin in Building Construction: A Literature Review. Sustainability 2023, 15, 10462. [Google Scholar] [CrossRef]

- Banerjee, A.; Nayaka, R.R. A comprehensive overview on BIM-integrated cyber physical system architectures and practices in the architecture, engineering and construction industry. Constr. Innov. 2022, 22, 727–748. [Google Scholar] [CrossRef]

- Akanmu, A.A.; Anumba, C.J.; Ogunseiju, O.O. Towards next generation cyber-physical systems and digital twins for construction. J. Inf. Technol. Constr. 2021, 26, 505–525. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, N.; Liu, Z.; Mu, E. Construction Theory for a Building Intelligent Operation and Maintenance System Based on Digital Twins and Machine Learning. Buildings 2022, 12, 87. [Google Scholar] [CrossRef]

- Menegon, J.; da Silva Filho, L.C.P. The Impact of Industry 4.0 Concepts and Technologies on Different Phases of Construction Project Lifecycle: A Literature Review. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 1293–1319. [Google Scholar] [CrossRef]

- Olanipekun, A.O.; Sutrisna, M. Facilitating Digital Transformation in Construction—A Systematic Review of the Current State of the Art. Front. Built Environ. 2021, 7, 660758. [Google Scholar] [CrossRef]

- Torrecilla-García, J.A.; Pardo-Ferreira, M.C.; Rubio-Romero, J.C. Overall Introduction to the Framework of BIM-based Digital Twinning in Decision-making in Safety Management in Building Construction Industry. Dir. Y Organ. 2022, 76, 5–12. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Costin, A.M.; Karimi, R.; Shirowzhan, S.; Abbasian, E.; Li, J. BIM and Digital Tools for State-of-the-Art Construction Cost Management. Buildings 2022, 12, 396. [Google Scholar] [CrossRef]

- Shi, G.; Liu, Z.; Meng, X.; Wang, Z. Intelligent Health Monitoring of Cable Network Structures Based on Fusion of Twin Simulation and Sensory Data. Symmetry 2023, 15, 425. [Google Scholar] [CrossRef]

- Baghalzadeh Shishehgarkhaneh, M.; Keivani, K.; Moehler, R.C.; Jelodari, N.; Roshdi Laleh, S. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in Construction Industry: A Review, Bibliometric, and Network Analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Visartsakul, B.; Damrianant, J. A review of building information modeling and simulation as virtual representations under the digital twin concept. Eng. J. 2023, 27, 11–27. [Google Scholar] [CrossRef]

- Silva, B.V.F.; Holm-Nielsen, J.B.; Sadrizadeh, S.; Teles, M.P.R.; Kiani-Moghaddam, M.; Arabkoohsar, A. Sustainable, green, or smart? Pathways for energy-efficient healthcare buildings. Sustain. Cities Soc. 2024, 100, 105013. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Saad, N.; Azab, M.; Khan, A.M. BIM in green building: Enhancing sustainability in the small construction project. Clean. Environ. Syst. 2023, 11, 100149. [Google Scholar] [CrossRef]

- Wang, T.; Ali, A.S.; Au-Yong, C.P. Exploring a body of knowledge for promoting the building information model for facility management. Ain Shams Eng. J. 2022, 13, 101717. [Google Scholar] [CrossRef]

- Duarte-Vidal, L.; Herrera, R.F.; Atencio, E.; Muñoz-La Rivera, F. Interoperability of digital tools for the monitoring and control of construction projects. Appl. Sci. 2021, 11, 370. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. Digital twin-based progress monitoring management model through reality capture to extended reality technologies (DRX). Smart Sustain. Built Environ. 2023, 12, 200–236. [Google Scholar] [CrossRef]

- Yang, B.; Yang, S.; Zhu, X.; Qi, M.; Li, H.; Lv, Z.; Cheng, X.; Wang, F. Computer Vision Technology for Monitoring of Indoor and Outdoor Environments and HVAC Equipment: A Review. Sensors 2023, 23, 6186. [Google Scholar] [CrossRef]

- Halder, S.; Afsari, K. Robots in Inspection and Monitoring of Buildings and Infrastructure: A Systematic Review. Appl. Sci. 2023, 13, 2304. [Google Scholar] [CrossRef]

- Merino, J.; Xie, X.; Moretti, N.; Chang, J.Y.; Parlikad, A. Data integration for digital twins in the built environment based on federated data models. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2023, 176, 194–211. [Google Scholar] [CrossRef]

- Rao, A.S.; Radanovic, M.; Liu, Y.; Hu, S.; Fang, Y.; Khoshelham, K.; Palaniswami, M.; Ngo, T. Real-time monitoring of construction sites: Sensors, methods, and applications. Autom. Constr. 2022, 136, 104099. [Google Scholar] [CrossRef]

- Gómez-Gil, M.; Espinosa-Fernández, A.; López-Mesa, B. Contribution of New Digital Technologies to the Digital Building Logbook. Buildings 2022, 12, 2129. [Google Scholar] [CrossRef]

- Bruckmann, T.; Boumann, R. Simulation and optimization of automated masonry construction using cable robots. Adv. Eng. Inform. 2021, 50, 101388. [Google Scholar] [CrossRef]

- ISO 16739-2018; Industry Foundation Classes (IFC) for data sharing in the construction and facility management industries. Part 1: Data schema. ISO: Geneva, Switzerland, 2018.

- Shashi, S.; Centobelli, P.; Cerchione, R.; Ertz, M.; Oropallo, E. What we learn is what we earn from sustainable and circular construction. J. Clean. Prod. 2023, 382, 135183. [Google Scholar] [CrossRef]

- Heydari, M.; Heravi, G. A BIM-based framework for optimization and assessment of buildings’ cost and carbon emissions. J. Build. Eng. 2023, 79, 107762. [Google Scholar] [CrossRef]

- Shen, K.; Ding, L.; Wang, C.C. Development of a Framework to Support Whole-Life-Cycle Net-Zero-Carbon Buildings through Integration of Building Information Modelling and Digital Twins. Buildings 2022, 12, 1747. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Lin, L.; Wu, S.; Kang, Y.; Sepasgozar, S. Exploring the Benefits and Limitations of Digital Twin Technology in Building Energy. Appl. Sci. 2023, 13, 8814. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, Z.; Xiao, J.; Tiong, R. A conceptual framework for estimating building embodied carbon based on digital twin technology and life cycle assessment. Sustainability 2021, 13, 13875. [Google Scholar] [CrossRef]

- Yang, X.; Lei, G.; Wang, X. Can the development of digital construction reduce enterprise carbon emission intensity? New evidence from Chinese construction enterprises. Front. Ecol. Evol. 2023, 11, 1250593. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Sepasgozar, S.M.E.; Kamat, V.R. Digital twin-enabled prefabrication supply chain for smart construction and carbon emissions evaluation in building projects. J. Build. Eng. 2023, 78, 107598. [Google Scholar] [CrossRef]

- Paiho, S.; Wessberg, N.; Dubovik, M.; Lavikka, R.; Naumer, S. Twin transition in the built environment—Policy mechanisms, technologies and market views from a cold climate perspective. Sustain. Cities Soc. 2023, 98, 104870. [Google Scholar] [CrossRef]

- Wang, W.; Guo, H.; Li, X.; Tang, S.; Li, Y.; Xie, L.; Lv, Z. BIM Information Integration Based VR Modeling in Digital Twins in Industry 5.0. J. Ind. Inf. Integr. 2022, 28, 100351. [Google Scholar] [CrossRef]

- Senanayake, S.M.A.H.; Gunawardana, P.A.M.; Perera, B.A.K.S.; Rajaratnam, D. Examining the potential use of augmented reality in construction cost management tools and techniques. J. Eng. Des. Technol. 2023. [Google Scholar] [CrossRef]

- Kikuchi, N.; Fukuda, T.; Yabuki, N. Future landscape visualization using a city digital twin: Integration of augmented reality and drones with implementation of 3D model-based occlusion handling. J. Comput. Des. Eng. 2022, 9, 837–856. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, P.; Li, C.; Wang, L. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput.-Integr. Manuf. 2023, 81, 102515. [Google Scholar] [CrossRef]

- Xia, H.; Liu, Z.; Efremochkina, M.; Liu, X.; Lin, C. Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic information system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Rodrigues, A.M.; Oladimeji, O.; Guedes, A.L.A.; Chinelli, C.K.; Haddad, A.N.; Soares, C.A.P. The Project Manager’s Core Competencies in Smart Building Project Management. Buildings 2023, 13, 1981. [Google Scholar] [CrossRef]

- Zhang, R.; Li, L. Research on Evolutionary Game and Simulation of Information Sharing in Prefabricated Building Supply Chain. Sustainability 2023, 15, 9885. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- EU. 2014/24/UE Directive on Public Procurement and Repealing Directive 2004/18/EC; EU: Maastricht, The Netherlands, 2014. [Google Scholar]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with Digital Twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Aengenvoort, K.; Kramer, M. BIM in the operation of buildings: Technology Foundations and Industry Practice. In Building Information Modeling; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Pasini, D.; Ventura, S.M.; Rinaldi, S.; Bellagente, P.; Flammini, A.; Ciribini, A.L.C. Exploiting Internet of Things and building information modeling framework for management of cognitive buildings. In Proceedings of the IEEE International Smart Cities Conference (ISC2), Trento, Italy, 12–15 September 2016. [Google Scholar]

- Moretti, N.; Xie, X.; Merino, J.; Brazauskas, J.; Parlikad, A.K. An openbim approach to IoT integration with incomplete as-built data. Appl. Sci. 2020, 10, 8287. [Google Scholar] [CrossRef]

- Schweigkofler, A.; Braholli, O.; Akro, S.; Siegele, D.; Penna, P.; Marcher, C.; Matt, D. Digital Twin as energy management tool through IoT and BIM data integration. In Proceedings of the CLIMA 2022 Conference, Rotterdam, The Netherlands, 22–25 May 2022. [Google Scholar]

- Alanne, K.; Sierla, S. An overview of machine learning applications for smart buildings. Sustain. Cities Soc. 2022, 76, 103445. [Google Scholar] [CrossRef]

- Sacks, R.; Girolami, M.; Brilakis, I. Building Information Modelling, Artificial Intelligence and Construction Tech. Dev. Built Environ. 2020, 4, 100011. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for Digital Twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]

- Hu, X.; Li, X.; Zuo, M.; Michalak, W. Complexity Reduction for the Architecture Design of Large-Scale Public Buildings Based on Seismic Structure Simulation Technology. Math. Probl. Eng. 2022, 2022, 3186744. [Google Scholar] [CrossRef]

- Sharma, N.; Kalbar, P.P.; Salman, M. Global review of circular economy and life cycle thinking in building Demolition Waste Management: A way ahead for India. Build. Environ. 2022, 222, 109413. [Google Scholar] [CrossRef]

- Meng, X.; Das, S.; Meng, J. Integration of Digital Twin and Circular Economy in the Construction Industry. Sustainability 2023, 15, 13186. [Google Scholar] [CrossRef]

- Wen, Q.; Li, Z.; Peng, Y.; Guo, B. Assessing the effectiveness of building information modeling in developing green buildings from a lifecycle perspective. Sustainability 2020, 12, 9988. [Google Scholar] [CrossRef]

- ISO 19650-2018; Organization and digitization of information about buildings and civil engineering works, including building information modeling (BIM)—Information management using building information modeling. Part 1: Concepts and principles. ISO: Geneva, Switzerland, 2018.

- Pärn, E.A.; Edwards, D.J.; Sing, M.C.P. The building information modelling trajectory in facilities management: A review. Autom. Constr. 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M.; Konstantinou, E. Moving from building information models to digital twins for operation and maintenance. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2020, 174, 46–56. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Fogerty, D.; Wu, L.O.; Li, Z.; Sepasgozar, S.M.E.; Zhang, K.; Sepasgozar, S.; Marroquin, F.A. Numerical analysis of the creep and shrinkage experienced in the Sydney Opera House and the rise of digital twin as future monitoring technology. Buildings 2019, 9, 137. [Google Scholar] [CrossRef]

- Lin, T.J.; Aziz, N.M. Embracing The Digital Twin for Construction Monitoring and Controlling to Mitigate the Impact of COVID-19. J. Des. Built Environ. 2022, 22, 40–59. [Google Scholar]

- Mêda, P.; Hjelseth, E.; Calvetti, D.; de Sousa, H. Data Templates and Digital Building Logbooks boosting Digital Twin in Construction. In Proceedings of the Conference CIB W78 2021, Luxembourg, 11–15 October 2021. [Google Scholar]

- EU. Study on the Development of an European Union. In Framework for Digital Building Logbooks; Final Report; EU: Maastricht, The Netherlands, 2021. [Google Scholar]

- EU. Support for Setting Up a Smart Readiness Indicator for Buildings and Related Impact Assessment—Catalogue of Smart Ready Services Technical Working Document for Stakeholder Feedback; European Commission DG Energy: Brussels, Belgium, 2017. [Google Scholar]

- EU. Final Report on the Technical Support to the Development of Smart Readiness Indicator for Buildings; EU: Maastricht, The Netherlands, 2020. [Google Scholar]

- Menezes, A.C. The Performance Gap; CIBSE, Chartered Institution of Building Services Engineers: London, UK, 2012. [Google Scholar]

- WGBC, World Green Building Council. Bringing Embodied Carbon Upfront: Coordinated Action for the Building and Construction Sector to Tackle Embodied Carbon; WGBC: London, UK, 2019. [Google Scholar]

- EU. Putting Energy Efficiency First: Consuming Better, Getting Cleaner; EU: Maastricht, The Netherlands, 2016. [Google Scholar]

- IEA, International Energy Agency. Global Status Report for Buildings and Construction; IEA: Paris, France, 2019. [Google Scholar]

- UNEP-United Nation Environment Program. Too Little, Too Slow: Climate Adaptation Failure Puts World at Risk; UNEP: Nairobi, Kenya, 2022. [Google Scholar]

- UNEP-United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a Zero Emission, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).