Abstract

The construction business environment is becoming competitive and intense, and Business Models (BMs) are receiving considerable attention as potential sources of sustainable survival and growth. Converse to the Linear Economy (LE) model that industry follows, the Circular Economy (CE) model has the potential to create a sustainable construction industry while also creating a sustainable business environment in construction organisations. Nevertheless, in traditional BMs, value is often concentrated on the financial value for the stakeholders; in the Circular Economy Business Model (CEBM), value is seen more broadly by considering a comprehensive range of value chain partners, the environment, and society. Hence, implementing the CE in the construction industry requires reforms in each value chain. Thus, the aim of this paper is to develop a conceptual model for construction organisations’ adoption of CEBM for their organisations. To accomplish this aim, the objectives of this paper are twofold: (i) to define the concept of CEBM and (ii) to map a conceptual Circular Economy Business Model Canvas (CEBMC) that is applicable in the construction organisational context. This research adopted a systematic document review, including a content analysis of selected papers. This study contributes significantly by proposing a CEBMC where construction organisations can successfully transform their businesses from linear to circular environments.

1. Introduction

A Business Model (BM) is a sustainable method of conducting a business [1]. The BM concept is constructed based on fundamental notions in business strategy and related theoretical frameworks [2,3]. However, while this strategy emphasises competition, BMs are built more on creating value for customers [3]. The existing BM literature views the concept as an essential element for thriving organisations, as its main objective is to distinguish an organisation from others and provide it with a competitive advantage. [3,4]. The first author to discuss the BM concept was Timmers [5], who recognised several evolving internet-driven BMs and categorised them based on their level of innovation and the degree of functional integration [6]. In addition, the author explained that BMs have been frequently employed to formulate and express strategies for generating profits through innovations or particular technologies.

In addition to strategic relevance, the BM concept also relates to the concept of value chains [7] and expanded ideas for value systems, including choice of value configuration [6]. According to Ahmed and Zhang [8], value is the additional financial advantages offered to customers, such as lowering costs or enhancing productivity over a specific period. For instance, there are cases where certain businesses within the same industry are more profitable than others despite implementing identical strategies [1]. This implies that the BM concept differs from a competitive strategy, and the reason could be the additional focus on value. BMs are always discussed by utilising the value chain concept, and the ultimate goal of a BM is to generate value for the value chain partners. Foss and Saebi [9] defined a BM as a network of interconnected and interdependent activities that shape the method by which an organisation conducts business with its clients, partners, and vendors. However, there is no generally acknowledged definition of BMs. Many of the contributors to the literature focus on an organisation’s value proposition and market segments, the value chain structure required to realise the value proposition, the value capture mechanisms employed by the organisation, how these elements interrelate, and how these elements are linked together in an architecture.

As the construction industry becomes more competitive and challenging, BMs are gaining significant attention as potential means for sustainable survival and expansion [10]. However, the value chain of the industry rigidly adheres to the linear model. The construction industry’s conventional linear BM of “take, make, and dispose” faces practical challenges because of heightened market demands and a political agenda promoting sustainable and circular practices [11]. This entails the extraction of materials without consideration for regeneration, the processing of these materials into construction products, and their subsequent assembly at the construction site in a manner that does not promote regenerative or restorative practices [12]. This process often results in the generation of significant waste [13] and the emission of pollutants throughout the entire value chain [14]. The Circular Economy (CE) model provides a step change towards a sustainable construction industry by enhancing resource efficacy and efficiency, cutting waste and resource consumption, and minimising environmental impacts [15]. The CE is a regenerative system that minimises resource inputs, waste generation, emissions, and energy leakage by decelerating, closing, and refining material and energy cycles [16]. While this notion of the CE concept is new to the construction industry, which often follows the conventional Linear Economy (LE), “circular value” should be understood more comprehensively as encompassing a broader array of stakeholders participating in the value chain, particularly concerning environmental and social aspects [17]. The successful implementation of the CE in the construction industry requires reforms in each value chain, starting from the design of the BM to developing new customer values and habits [18].

In construction, the main contractors (referred to as construction organisations in this study) manage one or several phases of a construction project while also handling complex supply chain processes and directly engaging with multiple stakeholders. Hence, construction organisations have a significant role in implementing circularity in the industry by implementing suitable BMs in their organisations. Further, the BMs applicable to construction organisations differ from organisations in other sectors, as the construction industry is unique because of its project-based nature. Therefore, adopting the CE in construction organisations takes a different perspective from other organisations. This necessitates defining the Circular Economy Business Model (CEBM) and mapping a conceptual model applicable to the construction organisational context. Hence, this study aims to develop a conceptual model for construction organisations’ adoption of CEBM for their organisations by first defining the concept of CEBM in construction and, next, by developing a Conceptual Circular Economy Business Model Canvas (CEBMC) applicable to the construction organisational context. The existing studies on CE in the construction context have focused on different subject areas, for instance, resource reuse [19,20,21,22], construction and demolition waste management [23,24,25,26], construction supply chain management [27], the integration of digital technologies [28,29,30,31], stakeholder collaboration and management [32], and offsite construction [19,33]. A few studies have discussed CEBM in the context of construction [34,35]. Nevertheless, these studies have identified CEBM in the construction context, and none of these studies have properly defined or elaborated on the practical applicability of the model. Further, considering the value chain context, Dewagoda et al. [36] adopted Porter’s value chain (PVC) concept to create a “design for circularity” approach to establish and maintain circular value throughout the entire building lifecycle. Drawing inspiration from PVC, Ding et al. [37] established a circular value chain framework for construction and demolition waste recycling enterprises to analyse internal resources and capabilities, summarise the challenges they currently face, and propose strategies for their development. Moreover, Dewagoda et al. [14] developed a CE value chain for the construction industry, building upon the deficiencies of generic circular value chains proposed in the existing literature based on PVC. However, none of the studies have attempted to define CEBM in a construction context or define the architecture of CEBMC. Therefore, these studies have yet to identify CEBM in the construction organisational perspective to transform organisations from linear to circular while also achieving circularity value to gain a competitive advantage. Therefore, this study defines CEBM and identifies them from a construction organisational perspective. This paper consists of several sections: an introduction to CEBM; materials and methods; analysis; and discussion; three sections conceptualising the applicability of CE in a construction organisational context, defining CEBM, and mapping a conceptual CEBMC for construction organisations; a conclusion; and references.

2. Materials and Methods

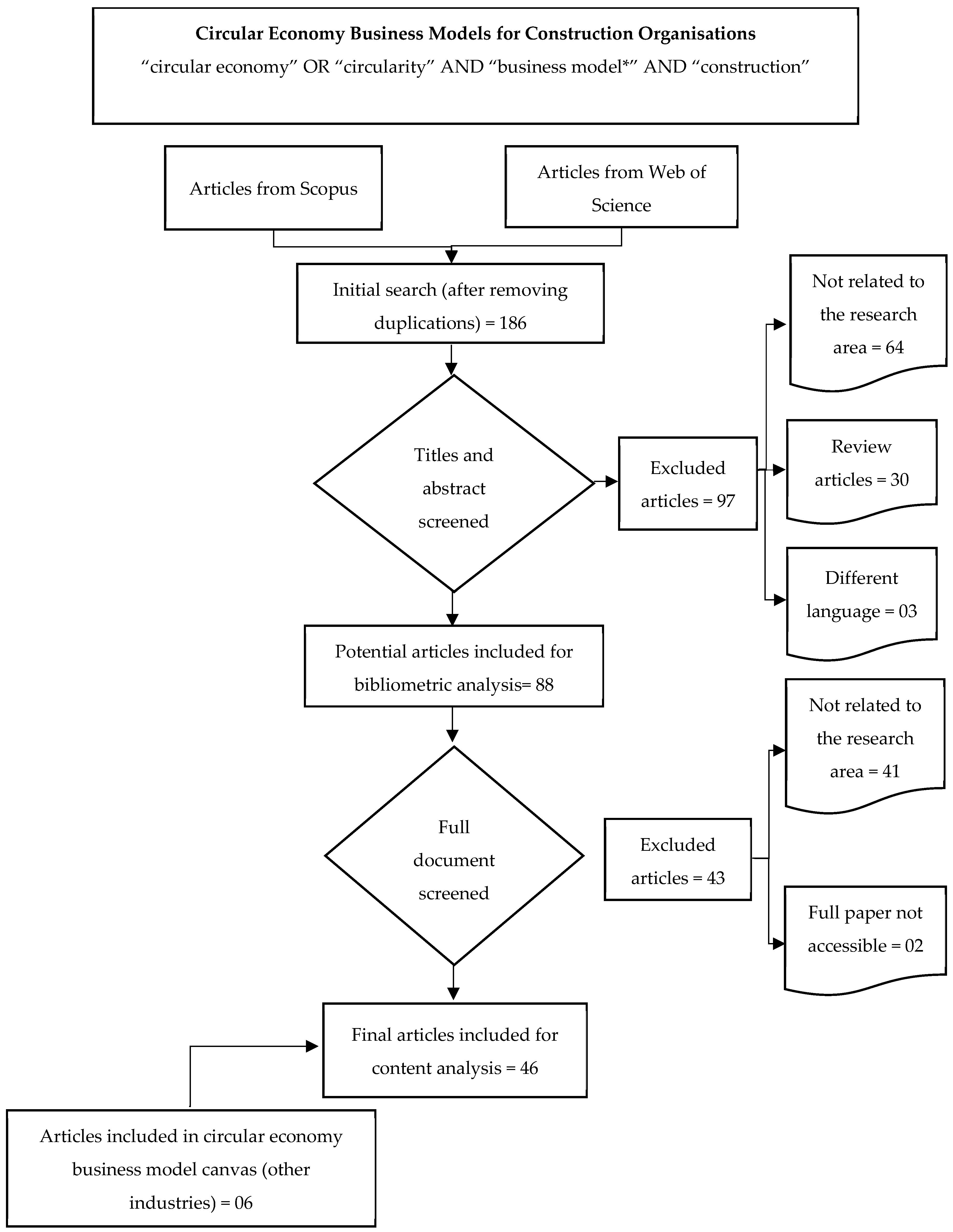

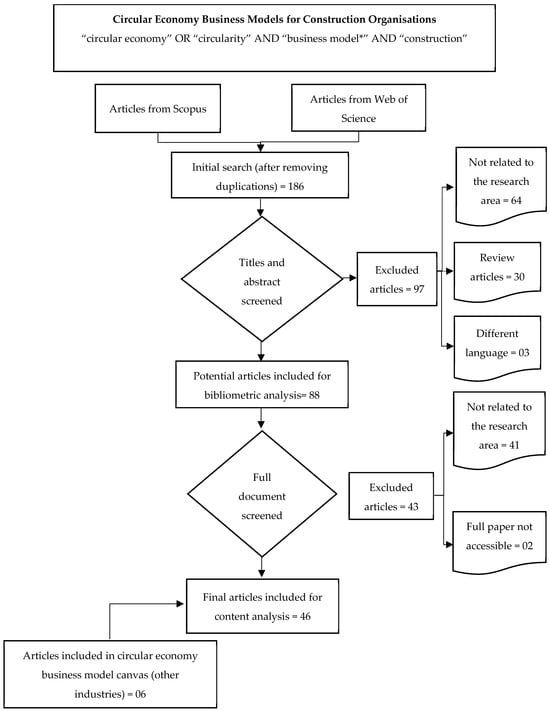

This paper focuses on defining CEBM for construction organisations and mapping a CEBMC for construction organisations. To fulfil this, a broad review of the existing studies on the subject area is required, which a Systematic Literature Review (SLR) serve the purpose. Using a structured methodology, an SLR constitutes a research approach for systematically gathering, identifying, and critically examining existing research studies, encompassing articles, conference proceedings, books, and dissertations [38]. Using an SLR necessitates following a protocol that comprehensively achieves its aim. The first stage in conducting an SLR is to define the protocol, which serves as a log of the tasks to be completed and specifies the techniques involved in the review [39]. The Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) 2020 protocol was followed to conduct the SLR. Enhancing the transparency and scientific value of a reported SLR or meta-analysis is the main objective of the PRISMA protocol [40].

For this systematic literature review, the main search strings used were “circular economy” OR “circularity” AND “business model*” AND “construction”. The CE and circularity were identified as synonyms through the literature findings, and for BMs, synonyms were not identified. Even though value chains could be considered a synonym, some studies have denied the similarity between the two concepts. When searching the articles, it was not limited to “construction organisations”. The word construction was used, as most studies have not explicitly focused on the construction organisational context when defining BMs.

An initial search using the Scopus and Web of Science databases was performed for titles, abstracts, and keywords from articles (journal papers, conference proceedings, book chapters, and books) published from 2004 to 2023. Evidence for the SLR came from journal literature and abstracts, conference proceedings, books, and book chapters [41]. The first comprehensive paper on the CE was identified in 2004, which was the reason for limiting the duration to start in 2004. After removing duplications, 186 studies were identified. Subsequently, after initial screening processes (excluding irrelevant articles after abstract reading, review articles, and articles published not in English), 88 articles were considered for bibliometric analysis. Subsequently, after applying screening criteria, 46 articles were considered for content analysis. In total, 6 of these 46 articles were further short-listed as directly relevant to developing a conceptual CEBMC for construction organisations, as shown in Figure 1. The snowball sampling technique was used to expand the search from these initial six papers and offer a critical discussion on the proposed model. Since these were based on other industries, modifications were proposed based on construction-based BM literature. The step-by-step process of this SLR is depicted in Figure 1.

Figure 1.

Systematic literature review process.

3. Results and Discussion

This section comprises two sections: bibliometric analysis and content analysis.

3.1. Bibliometric Analysis

3.1.1. Analysis of Publication (by Country)

The minimum threshold for the number of documents and citations required for a country was set at “two” and “two”, respectively. Out of 63 countries, only 23 (36.5%) met these criteria. Among these 23 countries, only 20 were found to be connected, as depicted in Figure 2. In Figure 2, the size of the nodes corresponds to the number of publications, with larger nodes indicating a more significant contribution from that country. Six distinct scientific clusters are identified and represented by different colours. The clusters represent the collaborative countries. Countries such as the United Kingdom (UK), Denmark, Spain, the Netherlands, Belgium, Italy, and Australia show a relatively higher number of publications (more than five). Regarding co-authorship, the UK, Spain, Turkey, Italy, Belgium, Denmark, the Netherlands, Switzerland, Austria, Sweden, and Australia exhibit some collaboration. The UK and Denmark are the most active countries in publication output and collaboration. This was confirmed by the study conducted by [42] on the CE and construction industry research trends. The study by [42] also confirmed that Europe leads in CE and construction-related research, followed by Asia, Oceania, and North America.

Figure 2.

Analysis of publications (by country).

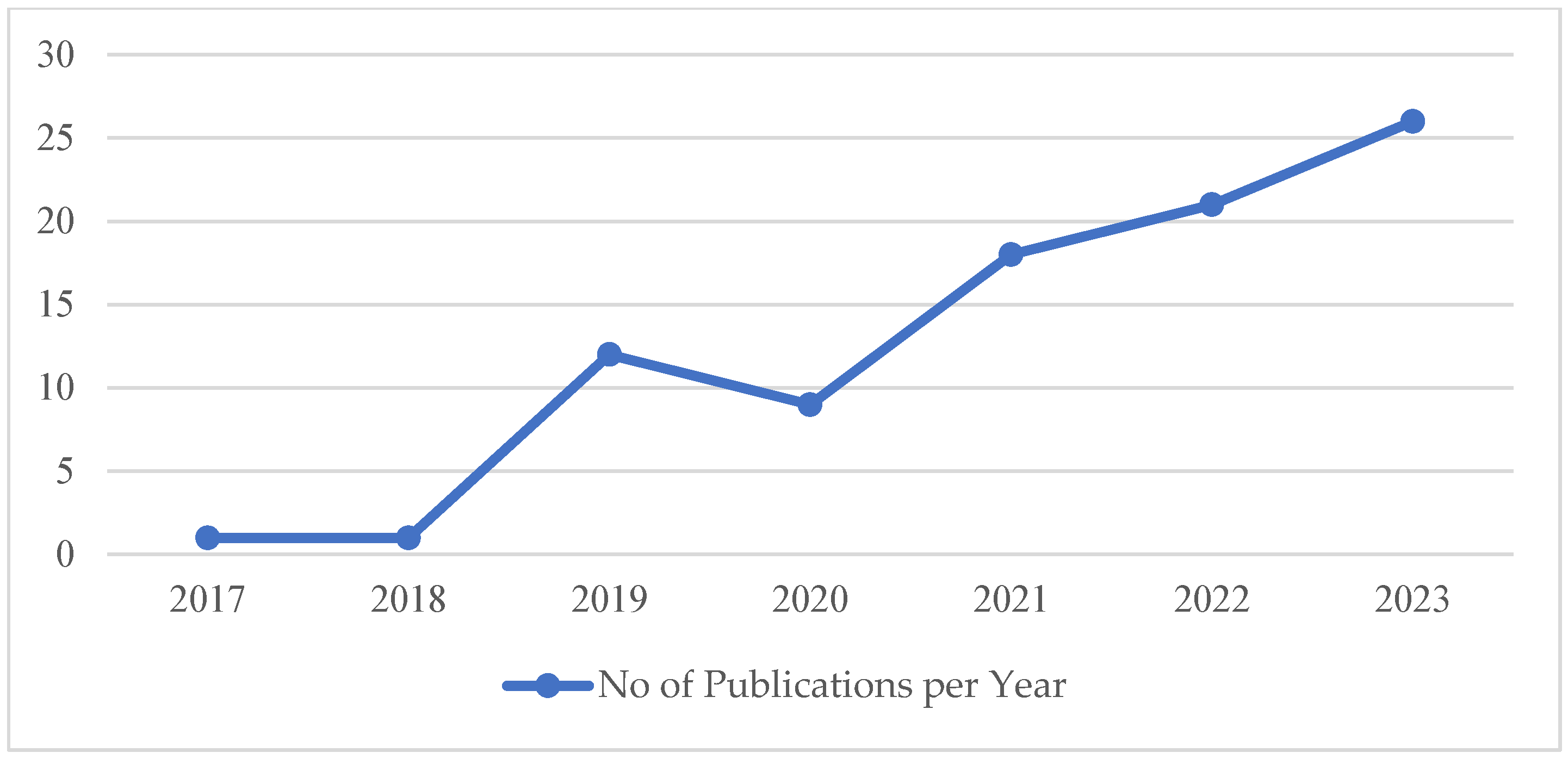

3.1.2. Evolution of the Number of Publications (per Year)

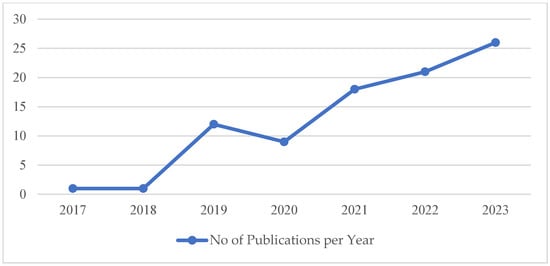

This study considered articles published from 2004 to 2023. However, the articles relevant to CEBM in the construction context were only evident in 2017. During the period considered, the total number of articles published was 88. Figure 3 depicts the evolution of the articles over the years. Until 2020, there was little progress in articles published on CEBM in construction, and the trend reflects that the number of published articles dramatically increased after 2020. A study developed on the CE in the construction context by [23] also emphasised that the number of articles on the CE in the construction context, in general, has increased during the last four years, showing the growing interest of the industry to move towards the CE.

Figure 3.

No of publications per year.

3.2. Content Analysis

3.2.1. Application of Circular Economy in the Construction Organisational Context

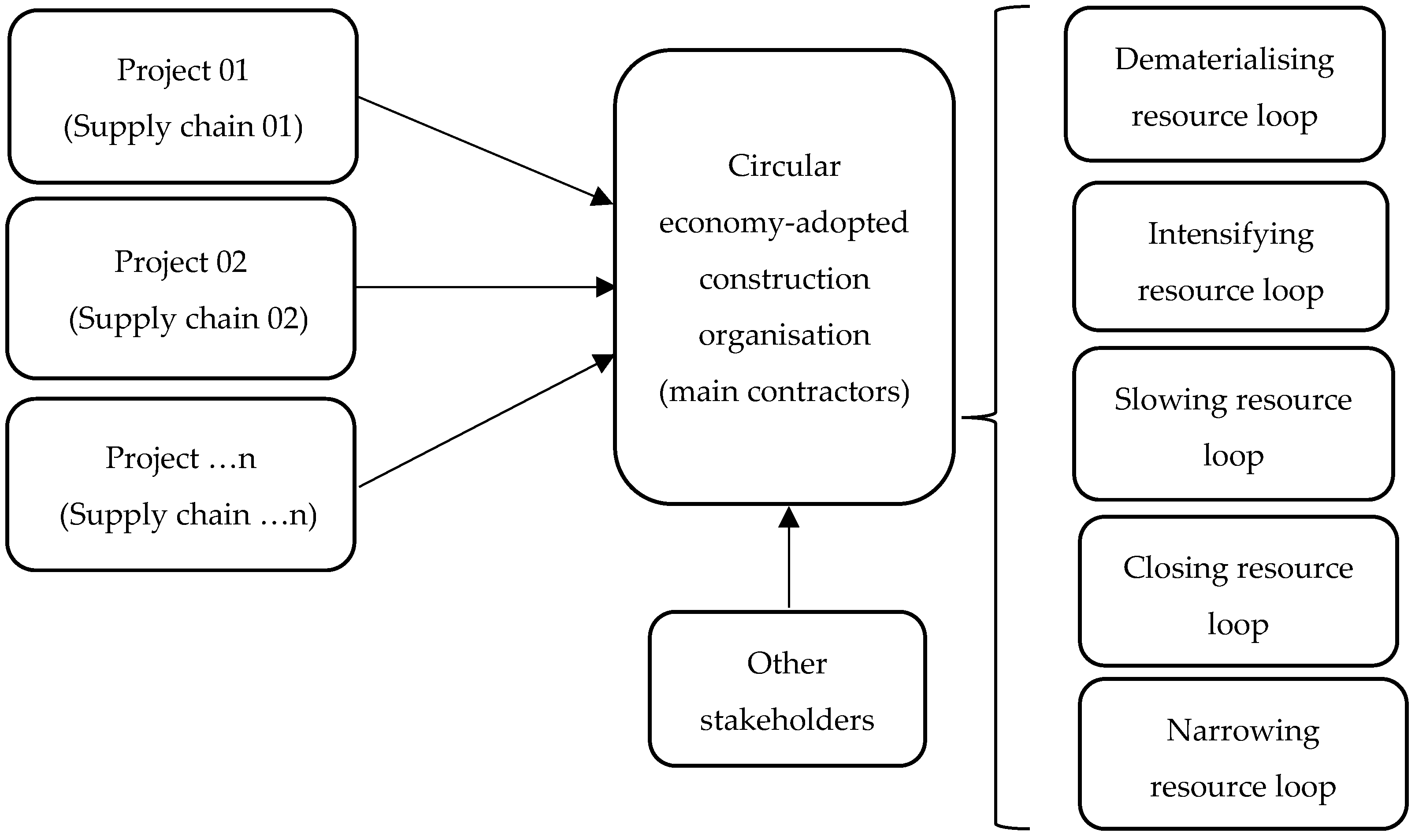

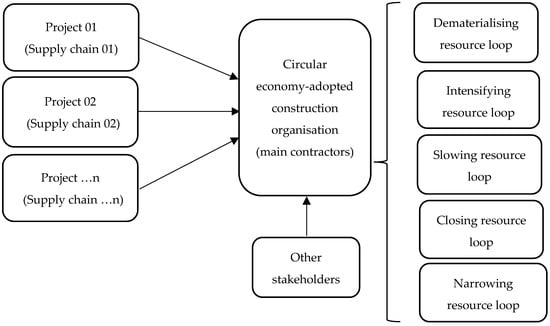

The construction industry, particularly construction organisations, is characterised by its business mainly running through construction projects [43]. One claim is that the construction industry inherently differs from other industries because its factories move around and hardly ever develop the same product twice. The principal approach of its management is based on a one-off production philosophy [43]. This explains the uniqueness of construction organisations compared with other sectoral organisations. Gorecki [44] demonstrated that two types of construction organisation CE maturity complement each other and are interdependent: organisational routine processes and construction projects. Therefore, two levels were identified for construction organisations: the organisational level (repeatable and routine processes) and the project level (non-repeatable and unique processes/collection of series of projects), which should be covered when implementing a CEBM. In particular, the organisational level is required to ensure that the CE is adopted throughout the construction supply chain processes. According to Leising et al. [26], designing circular buildings requires a new process design incorporating several supply chains disciplines up front. The distinctions in supply chains between traditional BMs and CEBM arise from the essential processes of closing, slowing, and streamlining material and energy flows [45]. In addition, Huovila and Westerholm [46] explained that CEBM in the supply chain should intensify and dematerialise the material loops given the significance of a BM’s value chain and the requirement for all of its components to be aligned for optimal sustainability performance, which could show that a circular supply chain model that aims to promote sustainable development should include elements of a sustainable BM [16]. Generally, construction supply chains are only operational throughout a project [47]. If maintenance services are included in the agreement, the supply chain has the potential to persist for the entire lifespan of the building. However, construction organisations significantly handle complex supply chain processes and directly engage with different stakeholders. Therefore, from the supply chain perspective, construction supply chains can be considered integrated construction organisations or their value chains. Consequently, this study conceptualises the application of the CE in the construction organisational context from a supply chain and project perspective, as depicted in Figure 4.

Figure 4.

Conceptual circular economy adoption in the construction organisation.

3.2.2. Defining the Concept of Circular Economy Business Model in Construction

By completing resource loops, a CEBM offers a solution to achieve sustainability on the social, economic, and environmental fronts [48]. Value in a conventional BM is frequently focused on the financial benefit to investors and clients. In a CEBM, value is viewed more broadly, considering the environment, society, and a more comprehensive range of value chain partners [46]. Therefore, embracing the CE necessitates the development of novel CEBMs, a design approach emphasising circularity, enhanced reverse cycles, and a supportive system [49]. Despite the construction industry’s high levels of value creation and employment, the environmental impact must be minimised by applying the CE model at every stage, from planning and design through construction, to ensure better construction practices that result in fewer pollution issues [50].

In addition to defining BMs, several authors have attempted to determine and classify the elements constituting BMs. For instance, Shafer et al. [51] examined twelve criteria and found forty-two elements categorised as strategic decisions, value networks, and creating and capturing value. Hamel [52] developed a framework that includes a customer interface, core strategy, strategic resources, and value network. Guerra and Shahi [34] categorised existing CEBM into nine categories: product life extension, product as a service, waste as a resource, circular supplies, resource recovery, resell, remanufacture, sharing platforms, and repair. Mackenbach et al. [35] identified four CEBMs, refurbishment and reuse, repair and maintenance, product as a service, and upcycling, considering their adaptability, applicability, and usability in modular construction. It is necessary to reconsider ownership by embracing novel ideas like product leasing or product-as-a-service [53,54] and to support supply-chain models that encourage stakeholder collaboration and value co-creation [42,55]. In a circular value chain, it is essential for every stakeholder to actively participate in achieving an outcome that maximises value for all involved parties. This involves utilising components that maintain their highest values throughout their lifecycles and minimising losses from the system [56].

Given the increasing emphasis on the value-centric approach of CE, there has been a persistent discourse regarding the imperative of integrating a value chain perspective into the implementation of CE, notwithstanding the perception of some distortion in this regard [14]. It has been found that the circular value chain is “a set of primary and support practices implemented by companies to enhance the regeneration and circularity of supply chain resources by developing resource value retention options” [57]. In the CE context, a CEBM combines value propositions, interrelationships between elements, and strategies to find circular solutions based on intensification, dematerialisation, and closing, narrowing or slowing resource flows [58]. Similarly, a CEBM emanates from creating, diversifying, acquiring, or transforming a BM that delivers value proposition, value creation, value capture, and value delivery solutions while aligning with CE principles [16,59]. Munaro and Tavares [60] referred to the need for new CEBMs that support material prolonged life through maintenance. Research has demonstrated that the most effective way to build and execute a CEBM is to work collaboratively with the value chain to maximise opportunities for value creation and proposition [61]. In line with the three-value concept proposed by Richardson [62], a CEBM seeks to maximise value capture opportunities, discover potential for circular value propositions, and grasp opportunities for circular value creation [45]. John et al. [63] argue that adopting the CE becomes significant for organisations when they recognise that transitioning to a CEBM can tangibly lead to growth and competitiveness driven by value.

According to Pekuri et al. [6], BMs in the construction industry have to be researched and developed at the operational field level. Additionally, this would help to comprehend how value is created in various construction projects and create BMs that would provide construction companies with a competitive edge while also better meeting the needs of particular clients or market groups. According to Carra and Magdani [56], the construction industry needs to focus on systemic thinking, which allows for an understanding of the whole lifecycle of buildings and the construction value chain. As such, a model that explains the various potential connections, push effects, and chain reactions among multidimensional drivers and enablers can be helpful for an integrated policy strategy in promoting the CE in the construction industry [64]. According to Kjerulf [65], larger contractor organisations’ perspectives on CEBM is likely to incorporate aspects of BMs such as ”orchestrators” and “inclusive value creation”. This adaptation is driven by the growing necessity for coordination and early engagement in projects involving multiple stakeholders within the value chain. The goal is to collaboratively develop long-term and valuable partnerships, along with active participation in novel procurement approaches. The study conducted by Munaro et al. [60] introduced a proposal for a CEBM framework that contributes to the CE theory by proposing different BMs according to building lifecycle stages for different stakeholders. Carra and Magdani [56] found that maximising value in the CEBMs of the construction industry should involve design requirements, information, and collaboration among stakeholders. Further, the authors explored CEBMs by relating their benefits to the construction value chain and grouped them according to the stages of a building’s lifecycle. The articulation of the concept of CEBM, innovation, resource recovery, and value generation for businesses is precisely in line with the logic of circular transition via the systematic transformation of production and consumption, in which value is created for businesses by changing how resources are used [66]. However, BMs are innovative and evolve from time to time. Thus, the literature has often noted the need for innovative CEBMs in light of the BMs used in the construction industry [13,60].

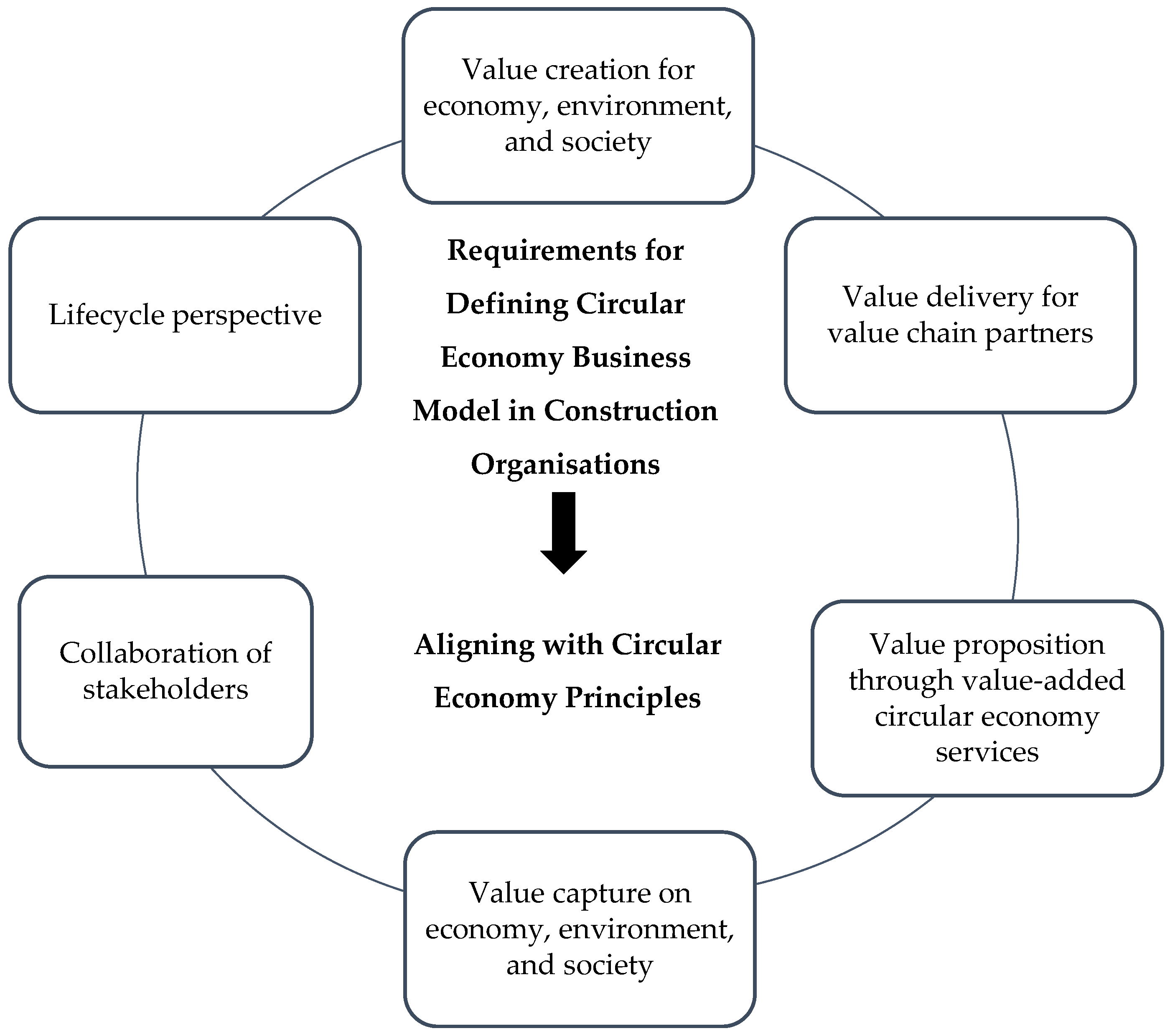

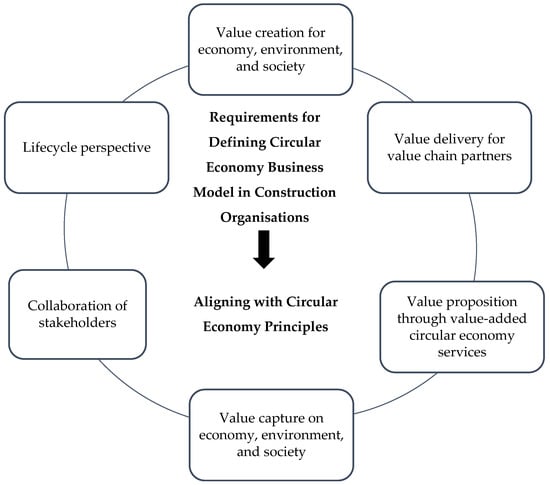

Johnson et al. [67] stated that a BM consists of four interlocking elements: value delivery, value capture, value proposition, and value creation. Considering the preceding definitions and explanations, it was observed that none of the explanations have broadly explained CEBM in the construction context utilising the value chain concept, as some definitions define only one or a few elements of it. Further, six elements were identified when explaining CEBM in a construction context: value creation, value delivery, value proposition, value capture, the collaboration of stakeholders, and the lifecycle perspective. The elements were identified through the qualitative content analysis technique based on the existing literature on CEBM. Based on the preceding discussions from the selected literature review, Figure 5 depicts the elements defining CEBM in the construction context.

Figure 5.

Requirements for defining circular economy business model in construction organisations.

- Value Creation

BMs are less discussed and studied in the construction industry; they are currently frequently employed in other sectors of the economy for designing, comparing, and assessing an organisation’s value creation logic [68]. According to recent business management literature, this idea is crucial to a successful business since it sets a company apart from other businesses and provides a competitive edge [3,4]. The value creation of construction organisations mainly focuses on the value creation of the economy, environment, and society through construction projects. Construction organisations are mainly involved in the design and construction phases of construction projects. Therefore, designing for circularity and utilising novel circular construction technologies create value for the organisation.

- Value proposition

The value proposition outlines how valuable items, such as products and services and additional value-added services, are bundled and presented to meet customers’ requirements [69]. Ibáñez-Forés et al. [70] identified circular services provided for the organisation, for instance, reverse logistics and promoting/offering shared facilities or equipment, as organisational indicators used to assess the CE. End-of-life strategies, after-sale services strategies in the design stage, after-handing, and product as a service are key performance indicators used to assess the CE in a construction project [71].

- Value delivery

Value delivery refers to outlines of the architecture of revenue costs and profit associated with the business enterprise delivering that value. Value delivery in the construction industry differs in terms of customer segments compared with other industries, as they typically represent the role of an order or investor and are, therefore, cost-intensive, few, and repeatable [65]. Therefore, value delivery is considered financial value and economic and environmental value for value chain partners involved in value chain processes.

- Value capture

The ability to capture value lies at the heart of BM design [72]. Nevertheless, value capture is never assured; value creation and value capture are necessary to obtain a circular competitive advantage. The sources generating increased value from a specific task, product, service, or activity may not necessarily secure a significant portion of it over time. Alternatively, a considerable portion of the potential value creation might be lost or diminished because of a lack of integration with the other components of the BM [72]. Adopting the CE in construction organisations adds financial, economic, and social value. Hence, several techniques need to be adopted to capture value.

- Collaboration of stakeholders

Stakeholder collaboration is essential from the outset of a construction project. According to the explanation of Huovila and Westerholm [46], when designing for disassembly, cooperation between the designer and other value chain partners is crucial to ensuring that the value of the materials will be retained, and this needs to be assessed. The collaboration will lead to effectively implementing the CEBM in an organisational context to gain maximum output.

- Lifecycle perspective

Construction organisations are not involved in the whole lifecycle of a building or infrastructure development. In the construction industry, among diversified organisations, the main contractors manage one or several phases of the lifecycle of construction projects [73]. However, the design and construction stages are crucial for the other lifecycle stages of construction development.

Overall, CEBM in construction organisations can be defined as creating economic, social, and environmental value for the whole lifecycle of a construction development by enabling collaboration with construction stakeholders while also value delivering for value chain partners, rendering value-added services for clients, and capturing value utilising suitable techniques.

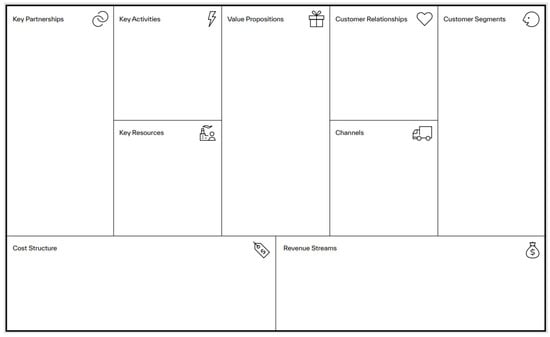

3.2.3. Mapping a Conceptual Circular Economy Business Model Canvas for a Construction Organisation

Researchers and practitioners have explored and illustrated the architecture of CEBM from different perspectives [74]. The most commonly used classification approaches are the ReSOLVE framework [75], CEBM strategies [45], and CEBM scan [76]. While the theoretical importance of CEBM to the CE transition is well recognised, more understanding of their applications is required [61]. Further, various alternative frameworks could be chosen to define the value chain of the CE, such as McKinsey’s 7S framework, the Business Model Canvas (BMC), and the Strategy Diamond [77,78,79]. Among the different approaches/frameworks, researchers have widely used the BMC, a tool developed by [78]. The BMC captures the complexity of how businesses operate while making the BM clear and easy to understand. As a result, it is a valuable instrument for undertaking BM innovation and comprehending an enterprise’s BM [80]. The components of a BM and any relationships or effects on value generation can be visually represented by users using a BMC. The BMC is a visual tool that can help debate, discuss, and investigate possible changes to the underlying BM. Users gain a more comprehensive understanding of an organisation and emphasise its effects that add value [81]. Authors have further explained that the BMC developed by Osterwalder and Pigneur [78] has been widely adopted by practitioners, as depicted in Figure 6. This BMC includes nine building blocks: key partners, key activities, value proposition, customer relationships, customer segments, essential resources, channels, cost structure, and revenue streams.

Figure 6.

Traditional business model canvas. Source: Osterwalder and Pigneur [78].

While the BMC provides a structure for what the business is expected to do at a given point in time, it is often reduced to a checklist and does not build a story of “how” an organisation can transform its operations, processes, and capabilities [82,83]. Coes [82] stated that the BMC does not aid in understanding organisational capabilities, which is a significant aspect of business transformation. While the BMC effectively understands the transformation of a BM, it cannot guide the organisation to transform from an initial state into a desired state.

It has been suggested that a typical BMC’s organisation-centric structure cannot adequately meet the systemic context of a CEBM [84]. Despite its limitations, several researchers have suggested alterations to the BMC structure and its essential elements, leading to various depictions of the CEBMC. Lewandowski [85] adapted its components and extended it by adding two further aspects: “adoption factor” and “take-back-system”. Hina et al. [86] developed a framework based on actor–network theory to move towards CEBM implementation by emphasising the importance of value propositions. Equally, Braun et al. [87] explored the concept of value creation from a cascading hierarchy of resource cycles by incorporating recovery cycles into the CEBMC and providing new components related to recovery and value. Daou et al. [88] proposed new elements for the BMC structure to account for foresight into external factors that may influence a business’s operating environment and future scenarios. Relatedly, Pollard and Osmani [89] positioned the development of a CEBMC for electrical and electronic product manufacturers as one layer of a larger framework related to internal and external factors, including CEBM opportunities and barriers. Islam and Iyer-Raniga [90] introduced a canvas for the value dimensions of CEBM. To comprehend and revamp the fundamental elements and structure of a CEBM, this canvas needs adaptation by integrating CEBM and sustainability concepts, strategies, archetypes, and value dimensions [90]. For instance, a more pronounced emphasis on the reverse logistics perspective is necessary for a conventional BMC, which predominantly concentrates on the forward supply chain, neglecting the recovery aspects within the building block of distribution channel.

According to Salvador et al. [91], the conventional BMC was designed for something other than CEBM visualisation. The authors of the study argued that there is a need to develop a framework for business modelling that can influence CE strategies in businesses as opposed to the traditional BMC, as it mainly depicts a linear BM. To understand and redesign the core elements and structure of a conceptual CEBM, such a canvas must be modified by including a conceptual CEBM and sustainability concepts, strategies, archetypes, and value dimensions [90]. Further, Islam and Iyer-Raniga [90] argued that value dimensions are used in this connection as part of BM innovation. The transformation can affect the entire BM or individuals or a combination of its value propositions, value creation and delivery, value capture elements, interrelations between elements, and the value network.

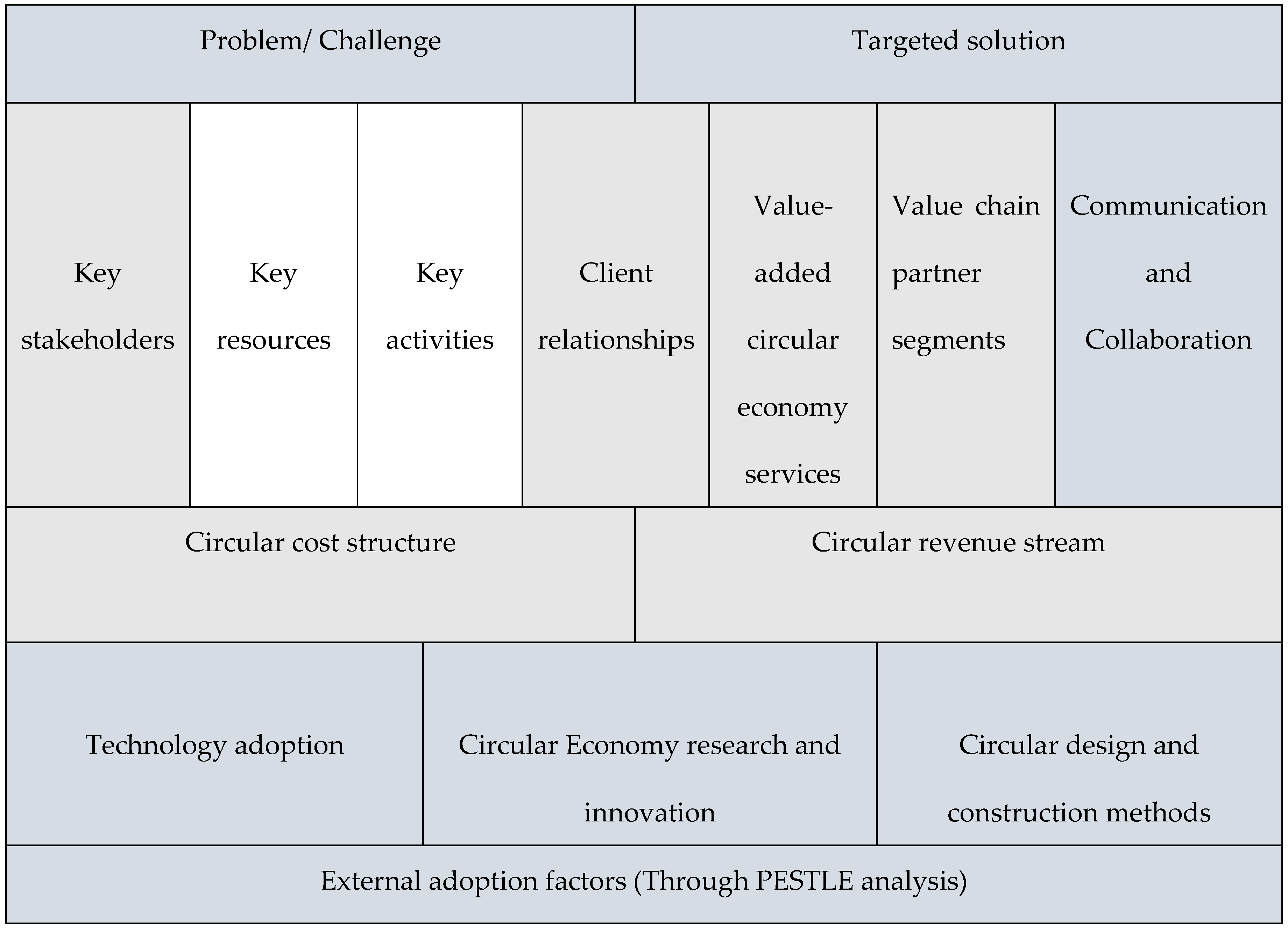

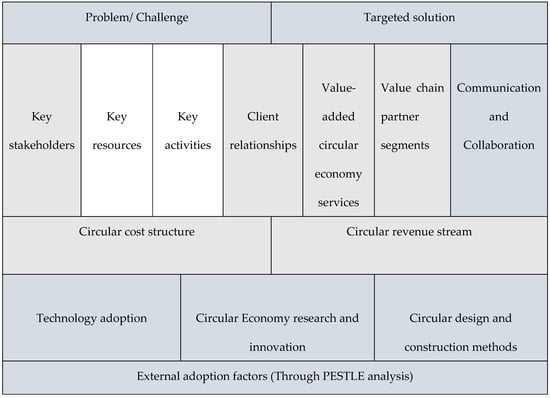

By comparing and contrasting the developed conceptual CEBMC in the existing six studies [85,86,87,88,89,90], this study has mapped a conceptual CEBMC for construction organisations, including 15 building blocks, as illustrated in Figure 7. In Figure 7, the legend indicates the unchanged building blocks, modified building blocks, and newly added building blocks compared with the conventional BMC [78]. The explanation of each building block of the conceptual CEBMC for construction organisations is given below.

Figure 7.

Conceptual circular economy business model canvas for construction organisations.

- Problem/Challenge: Organisations face problems due to adopting LE practices. The construction industry traditionally follows an LE model. According to this concept, construction projects start by extracting virgin raw materials, which are eventually converted into construction materials and assembled on construction sites in ways that leave them non-reusable during the end-of-life stage, entailing disposal as waste [92]. Further, Mangialardo and Micelli [92] found that the LE model in construction hinders economic progress and causes social and environmental consequences. Gorecki [44] explained that the construction industry has highly advanced relationships with environmental problems. Therefore, this further highlights that the CE problem in a construction organisation should be recognised within the entire organisational structure.

- Targeted Solution: The level of circularity organisations are expected to achieve needs to be identify with the problem or challenge. Lieder and Rashid [93] pointed out that the concept of the CE is increasingly seen as a multifaceted solution to various challenges, including waste generation, resource scarcity, and sustaining economic benefits. Hence, organisations are required to identify the targeted solutions in terms of different aspects, such as waste generation, material consumption, and supply chain management. By completing resource loops, a CEBM offers a solution to achieve sustainability on the social, economic, and environmental fronts [48].

- Key Stakeholders: Key stakeholders cover the different parties involved in the construction process and their collaboration to achieve circularity. Considering the construction context, the implementation of the CE in the main contractor organisations can significantly influence the overall CE implementation in the industry, as they are involved in one or several phases of a construction project while working directly with key stakeholders. Moving the construction industry towards circularity requires creating comprehensive networks that include all stakeholders in the supply chain, from design and raw material suppliers to users, including service providers, recyclers, and related information flows [94]. In the CE context, stakeholder engagement through relationship development, communication, and learning practices may promote the adoption and development of circular innovations, circular-oriented decision making, circular value capture models, co-creation, and the diffusion of sustainability culture via marketing, and educational activities are crucial [95].

- Value Chain Partner Segments: Value chain partners expect different values from organisations. Hence, segmentation needs to be performed appropriately for value delivery.

- Key Resources: Key resources cover the supply chain process, from the eco-supplier and material selection and utilisation to the construction process. The CE aims to establish a closed flow of materials throughout the economic system [96]. Nevertheless, a construction organisation is only involved in one or a few phases of a construction project. Therefore, it is required to consider the impact on the other lifecycle stages, especially the use/maintenance and demolition phases. Huovila and Westerholm [46] found that efficiently reusing construction materials can offer significant environmental benefits. However, the extent of these positive effects varies depending on the chosen materials and products [17].

- Client Relationship: Client acceptability, interest, and complaints regarding circularity are critical aspects of a CEBMC. Client management is one of the major indicators in the CE [30]. In addition, clients can encourage CE innovation in projects and create demand for circularity in the construction and real estate sectors [97].

- Communication and Collaboration: Communication and collaboration cover the circularity adoption of society and community engagement in organisational CE activities. From a social point of view, the accountancy of circularity requires a slightly different approach because social circularity is not directly related to a physical flow compared with energy, water, and material usage [98]. Published environmental reports (corporate social responsibility communications) and information about product sustainability characteristics (communicating sustainable characteristics in labelling) need to be considered CE aspects in an organisational context [70].

- Value-Added CE Services: Value-added CE services constitute services such as reverse logistics, sharing economy, dematerialisation, product as a service, and product life extension, which show that CE services are offered by organisations [70]. For instance, reverse logistics and promoting/offering shared facilities or equipment are organisational indicators of CE. Value-added services provided by the organisation create a competitive advantage among organisations.

- Key Activities: Key activities cover value chain processes such as the organisations’ main, supportive, and management activities regarding the CE. The identification of key, supporting, and management activities in CEBM is crucial for construction organisations.

- Circular Cost Structure/Revenue Stream: Circularity cost and revenue cover an organisation’s economic, social, and economic costs and revenues. Hence, appropriate financial analysis techniques are recommended, as the cost is not limited to the direct initial cost. Such techniques include net present value investment appraisals, cost-benefit analysis, and lifecycle costing [99]. Further, circular revenues, the secondary material market, supply chain risks, and material price valuations need to be assessed [99].

- Technology Adoption: Technology adoption comprises technologies adopted to achieve organisational circularity. Creating and incorporating new CE-friendly technologies into the construction industry is a promising way of pushing the industry towards sustainability [100]. Access to new technologies and smart devices for staff, building information modelling-based construction, augmented reality techniques for reuse and recycling, additive manufacturing (for instance, 3D printing), advanced robotics, construction site control via IoT, and material passports need to be considered under technologies [99].

- CE Research and Innovation: To achieve higher circularity, research and development are fundamental ways of finding a systematic approach regarding CE implementation in construction projects and organisations [100]. Janik and Szafraniec [101] argue that organisations are obliged to continuously improve, which fosters eco-innovation.

- Circular Design and Construction: Circular design and construction cover the adoption of novel building/infrastructure design techniques to achieve higher circularity. Additionally, more people and broader expertise must be involved in the design stage compared with linear construction. Further, Lewandowski [85] explained the design for circularity with varied related concepts such as design for deconstruction, maintenance, product life extension design, and remanufacturing. In addition, prefabricated elements, modular construction, open building, and other innovative construction methods need to be adopted to achieve circularity [100].

- External Adoption Factors: External adoption factors cover any factor beyond the organisational level, impacting the organisation’s CE adoption process. Several studies have emphasised that external processes that impact the CE in an organisational context need to be carefully determined using the Political, Economic, Social, Technological, Legal, and Environmental (PESTLE) perspective [88].

4. Conclusions

Construction organisations are unique because of their project-based nature compared with organisations in other sectors. Further, BMs in these organisations adhere to LE model. To achieve the aim of this study, the objectives accomplished were (i) to define the concept of CEBM in the construction organisational context and (ii) to map a conceptual CEBMC applicable to the construction organisational context through a systematic literature review. As the first step, a bibliometric analysis was conducted, comparing the analysis of publications (by country) and publication trends per year. The publication analysis by country shows that the UK and Denmark have the most published articles in the world. Considering this publication trend, 26 articles were spotted in 2023, the peak year compared with the other years.

As the subsequent step, a content analysis was carried out to define the concept of CEBM in a construction organisational context and to map a conceptual CEBMC for construction organisations. Value creation for the economy, environment, and society; value delivery for value chain partners; value proposition through value-added CE services; value capture on economy, environment, and society; the collaboration of stakeholders; and lifecycle perspective were identified as the requirements for defining CEBM in a construction organisational context. Based on these requirements, the study proposes a comprehensive definition. Finally, a conceptual CEBMC was developed for construction organisations comprising 15 building blocks. This was developed based on CEBMC developed for other industries originating from traditional BMs and by linking existing literature findings on CEBM in a construction context.

Overall, this study provides significant knowledge for construction industry practitioners to adapt CEBMC for their organisations to transform from a linear to a circular model. CEBMC is the architecture of CEBM applicable in the context of construction organisations. Visualising a conceptual CEBM, as in Figure 7, will help construction organisations to practically apply the model in an organisational context. The model starts with identifying the problem of the existing LE model adopted by the organisation with a targeted solution that the organisation plans to achieve by implementing a CE model. To achieve the target solution, the organisation or industry practitioners are required to identify all components in the second layer of the proposed model, namely, the key stakeholders, essential resources, key activities, client relationships, value-added CE services provided by the organisation, value chain partner segmentation, and communication and collaboration. In the next stage, identifying the circular cost structure and revenue stream in terms of economic, environmental, and social aspects helps organisations measure the success and effectiveness of CE implementations. Organisations can effectively consider digital technologies, research and innovation, and new circular design and construction methods to enhance and continuously improve CE implementations. Finally, organisations need to identify external forces using a PESTLE analysis to align their CE practices with the external environment and proactively respond to external forces.

The developed conceptual CEBMC for construction organisations focused more on solving the challenges of organisations adopting LE aspects. Compared with the traditional BMC by Osterwalder and Pigneur [78], in this conceptual CEBMC, some building blocks have been modified or newly added. However, compared with the other organisational canvases, such as lean canvas, which is mainly focused on evaluating a BM and products planned to be built and marketed by minimising or eliminating the concept of waste. However, the traditional BMC and lean canvas both focus on economic value creation, while the developed conceptual CEBMC focuses on economic, social, and environmental value creation.

The next stage of this research will be to confirm the developed CEBMC with industry experts to build a comprehensive CEBMC for construction organisations. This research will contribute to transforming the construction industry into a CE and minimising its adverse effects on society, the economy, and the environment while also reaching several of the United Nations’ Sustainability Goals (UNSDGs).

Author Contributions

Conceptualization, S.J. and S.S.; methodology, S.J.; software, S.J.; validation, S.S. and S.P.; formal analysis, S.J., and S.S.; investigation, S.J.; resources, S.S. and S.P.; data curation, S.J. and S.S.; writing—original draft preparation, S.J.; writing—review and editing, S.S.; visualization, S.J.; supervision, S.S. and S.P.; project administration, S.S.; funding acquisition, S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nielsen, C.; Lund, M. An introduction to business models. In The Basics of Business Models; Ventus: Copenhagen, Denmark, 2014; pp. 8–20. [Google Scholar]

- Hedman, J.; Kalling, T. The business model concept: Theoretical underpinnings and empirical illustrations. Eur. J. Inf. Syst. 2003, 12, 49–59. [Google Scholar] [CrossRef]

- Morris, M.; Schindehutte, M.; Allen, J. The entrepreneur’s business model: Toward a unified perspective. J. Bus. Res. 2005, 58, 726–735. [Google Scholar] [CrossRef]

- Teece, D.J. Business models, business strategy and innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Timmers, P. Business models for electronic markets. Electron. Mark. 1998, 8, 3–8. [Google Scholar] [CrossRef]

- Pekuri, A.; Pekuri, L.; Haapasalo, H. The role of business models in Finnish construction companies. Australas. J. Constr. Econ. Build. 2013, 13, 13–23. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage of Nations: Creating and Sustaining Superior Performance; Simon and Schuster: New York, NY, USA, 1985. [Google Scholar]

- Ahmed, R.R.; Zhang, X. Multi-layer value stream assessment of the reverse logistics network for inert construction waste management. Resour. Conserv. Recycl. 2021, 170, 105574. [Google Scholar] [CrossRef]

- Foss, N.J.; Saebi, T. Fifteen years of research on business model innovation: How far have we come, and where should we go? J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef]

- Jang, Y.; Ahn, Y.; Park, M.; Lee, H.-S.; Kwon, N. Business models and performance of international construction companies. Sustainability 2019, 11, 2575. [Google Scholar] [CrossRef]

- Kjerulf, L.; Haugbølle, K. Theoretical Framework of Circular Business Model Innovation for Building Contractors. In Nordic Conference on Construction Economics and Organization; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Bocken, N.M.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy; Wiley Online Library: Hoboken, NJ, USA, 2017; pp. 476–482. [Google Scholar]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Dewagoda, K.G.; Ng, S.T.; Chen, J. Driving systematic circular economy implementation in the construction industry: A construction value chain perspective. J. Clean. Prod. 2022, 381, 135197. [Google Scholar] [CrossRef]

- Jansen, B.W.; van Stijn, A.; Gruis, V.; van Bortel, G. A circular economy life cycle costing model (CE-LCC) for building components. Resour. Conserv. Recycl. 2020, 161, 104857. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Nußholz, J.L.; Rasmussen, F.N.; Whalen, K.; Plepys, A. Material reuse in buildings: Implications of a circular business model for sustainable value creation. J. Clean. Prod. 2020, 245, 118546. [Google Scholar] [CrossRef]

- Tomaszewska, J. Polish transition towards circular economy: Materials management and implications for the construction sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- Osobajo, O.A.; Oke, A.; Omotayo, T.; Obi, L.I. A systematic review of circular economy research in the construction industry. Smart Sustain. Built Environ. 2022, 11, 39–64. [Google Scholar] [CrossRef]

- Huang, X. An analysis of the selection of project contractor in the construction management process. Int. J. Bus. Manag. 2011, 6, 184. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Delgado, M.D.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Tong, X.; Tao, D. The rise and fall of a “waste city” in the construction of an “urban circular economic system”: The changing landscape of waste in Beijing. Resour. Conserv. Recycl. 2016, 107, 10–17. [Google Scholar] [CrossRef]

- Hossain, M.A.; Nadeem, A. Towards digitizing the construction industry: State of the art of construction 4.0. In Proceedings of the ISEC, Pune, India, 14–16 February 2019. [Google Scholar]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Jayakodi, S.; Senaratne, S.; Perera, S.; Bamdad, K. Digital technology enabled circularity in the construction industry: A bibliometric study. In Proceedings of the 11th World Construction Symposium, Colombo, Sri Lanka, 21–22 July 2023. [Google Scholar]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Mustafa, M.; Karaca, F. Circular economy: Challenges and opportunities in the construction sector of Kazakhstan. Buildings 2021, 11, 501. [Google Scholar] [CrossRef]

- O’Grady, T.M.; Brajkovich, N.; Minunno, R.; Chong, H.-Y.; Morrison, G.M. Circular economy and virtual reality in advanced BIM-based prefabricated construction. Energies 2021, 14, 4065. [Google Scholar] [CrossRef]

- Senaratne, S.; Rodrigo, N.; Almeida, L.M.; Perera, S.; Jin, X. Systematic review on stakeholder collaboration for a circular built environment: Current research trends, gaps and future directions. Resour. Conserv. Recycl. Adv. 2023, 19, 200169. [Google Scholar] [CrossRef]

- Maury-Ramírez, A.; Illera-Perozo, D.; Mesa, J.A. Circular economy in the construction sector: A case study of Santiago de Cali (Colombia). Sustainability 2022, 14, 1923. [Google Scholar] [CrossRef]

- Guerra, B.C.; Shahi, S.; Mollaei, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular economy applications in the construction industry: A global scan of trends and opportunities. J. Clean. Prod. 2021, 324, 129125. [Google Scholar] [CrossRef]

- Mackenbach, S.; Zeller, J.; Osebold, R. A roadmap towards circularity-modular construction as a tool for circular economy in the built environment. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Dewagoda, K.G.; Ng, S.T.; Kumaraswamy, M.M. Design for Circularity: The Case of the Building Construction Industry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022. [Google Scholar]

- Ding, Z.; Wang, X.; Zou, P.X. Barriers and countermeasures of construction and demolition waste recycling enterprises under circular economy. J. Clean. Prod. 2023, 420, 138235. [Google Scholar] [CrossRef]

- Carrera-Rivera, A.; Ochoa, W.; Larrinaga, F.; Lasa, G. How-to conduct a systematic literature review: A quick guide for computer science research. MethodsX 2022, 9, 101895. [Google Scholar] [CrossRef]

- Kitchenham, B.; Brereton, O.P.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- Sohrabi, C.; Franchi, T.; Mathew, G.; Kerwan, A.; Nicola, M.; Griffin, M.; Agha, M.; Agha, R. PRISMA 2020 Statement: What’s New and the Importance of Reporting Guidelines; Elsevier: Amsterdam, The Netherlands, 2021; p. 105918. [Google Scholar]

- Sampson, M.; Daniel, R.; Cogo, E.; Dingwall, O. Sources of evidence to support systematic reviews in librarianship. J. Med. Libr. Assoc. JMLA 2008, 96, 66. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Mahdiputra, S. Organisational Learning in UK Construction Companies; Northumbria University: Newcastle upon Tyne, UK, 2007. [Google Scholar]

- Gorecki, J. Circular Economy maturity in construction companies. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Bocken, N.M.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Huovila, P.; Westerholm, N. Circularity and sustainability in the construction value chain. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022. [Google Scholar]

- Briscoe, G.; Dainty, A. Construction supply chain integration: An elusive goal? Supply Chain Manag. Int. J. 2005, 10, 319–326. [Google Scholar] [CrossRef]

- Piispanen, V.-V.; Suokas, S.-T.; Henttonen, K.; Lehtimäki, H. Sustainable Circular Economy in the Wood Construction Industry: A Business Opportunity Perspective. South Asian J. Bus. Manag. Cases 2022, 11, 27–34. [Google Scholar] [CrossRef]

- Pollard, J.; Osmani, M.; Grubnic, S.; Díaz, A.I.; Grobe, K.; Kaba, A.; Ünlüer, Ö.; Panchal, R. Implementing a circular economy business model canvas in the electrical and electronic manufacturing sector: A case study approach. Sustain. Prod. Consum. 2023, 36, 17–31. [Google Scholar] [CrossRef]

- Poolsawad, N.; Chom-in, T.; Samneangngam, J.; Suksatit, P.; Songma, K.; Thamnawat, S.; Kanoksirirath, S.; Mungcharoen, T. Material circularity indicator for accelerating low-carbon circular economy in Thailand’s building and construction sector. Environ. Prog. Sustain. Energy 2023, 42, e14105. [Google Scholar] [CrossRef]

- Shafer, S.M.; Smith, H.J.; Linder, J.C. The power of business models. Bus. Horiz. 2005, 48, 199–207. [Google Scholar] [CrossRef]

- Hamel, G. Leading the revolution: An interview with Gary Hamel. Strategy Leadersh. 2001, 29, 4–10. [Google Scholar] [CrossRef]

- Hartwell, R.; Macmillan, S.; Overend, M. Circular economy of façades: Real-world challenges and opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of modularity to the circular economy: A systematic review of literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Carra, G.; Magdani, N. Circular business models for the built environment. Arup BAM 2017, 1–44. [Google Scholar]

- Muller, L.N.P.e.S.; Delai, I.; Alcantara, R.L.C. Circular value chain practices for developing resource value retention options. J. Clean. Prod. 2022, 359, 131925. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular business model innovation: Inherent uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Urbinati, A.; Rosa, P.; Sassanelli, C.; Chiaroni, D.; Terzi, S. Circular business models in the European manufacturing industry: A multiple case study analysis. J. Clean. Prod. 2020, 274, 122964. [Google Scholar] [CrossRef]

- Richardson, J.E. The business model: An integrative framework for strategy execution. SSRN Electron. J. 2005. [Google Scholar] [CrossRef]

- John, I.B.; Adekunle, S.A.; Aigbavboa, C.O. Adoption of Circular Economy by Construction Industry SMEs: Organisational Growth Transition Study. Sustainability 2023, 15, 5929. [Google Scholar] [CrossRef]

- Wuni, I.Y. Drivers of circular economy adoption in the construction industry: A systematic review and conceptual model. Build. Res. Inf. 2023, 51, 816–833. [Google Scholar] [CrossRef]

- Kjerulf, L. Theoretical Framework of Circular Business Model Innovation for Building Contractors Lin Kjerulf and Kim Haugbølle. In SDGs in Construction Economics and Organization: The 11th Nordic Conference on Construction Economics and Organisation (CREON), 18–20 May 2022; Springer Nature: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Kuzma, E.; Sehnem, S. Validation of the Measurement Scale for the Circular Economy: A proposal based on the precepts of innovation. Int. J. Prof. Bus. Rev. 2021, 7, e0278. [Google Scholar]

- Johnson, M.W.; Christensen, C.M.; Kagermann, H. Reinventing your business model. Harv. Bus. Rev. 2008, 86, 50–59. [Google Scholar]

- Pekuri, A.; Pekuri, L.; Haapasalo, H. Business models in construction companies–construction managers’ viewpoint. In Proceedings of the Technology Innovation and Industrial Management Conference, Phuket, Thailand, 29–31 May 2013. [Google Scholar]

- Osterwalder, A.; Pigneur, Y. Modeling value propositions in e-Business. In Proceedings of the 5th International Conference on Electronic Commerce, New York, NY, USA, 30 September–3 October 2003. [Google Scholar]

- Ibáñez-Forés, V.; Alejandrino, C.; Bovea, M.D.; Mercante, I. Prioritising organisational circular economy strategies by applying the partial order set theory: Tool and case study. J. Clean. Prod. 2023, 406, 136727. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Chen, J.; Oluleye, B.I.; Antwi-Afari, M.F.; Ababio, B.K. Enhancing life cycle assessment for circular economy measurement of different case scenarios of modular steel slab. Build. Environ. 2023, 239, 110411. [Google Scholar] [CrossRef]

- Hopkinson, P.; De Angelis, R.; Zils, M. Systemic building blocks for creating and capturing value from circular economy. Resour. Conserv. Recycl. 2020, 155, 104672. [Google Scholar] [CrossRef]

- Núñez-Cacho, U.P.; Górecki, J.; Maqueira, J.M. Simulation-Based Management of Construction Companies under the Circular Economy Concept—Case Study. Buildings 2020, 10, 94. [Google Scholar] [CrossRef]

- Woldeyes, T.D.; Muffatto, M.; Ferrati, F. Archetypes of Business Models for Circular Economy: A Classification Approach and Value Perspective. In International Conference on Sustainable Design and Manufacturing; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Foundation, E.M. Delivering the Circular Economy: A Toolkit for Policymakers; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Renswoude, K.V.; Woldeyes, A.T.; Joustra, D.J. Circular Business Models—Part 1: An Introduction to IMSA’s Circular Business Model Scan; IMSA: Aurora, IL, USA, 2015. [Google Scholar]

- Hambrick, D.C.; Fredrickson, J.W. Are you sure you have a strategy? Acad. Manag. Perspect. 2005, 19, 51–62. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 1. [Google Scholar]

- Peters, T.J.; Waterman, R.H. In search of excellence. Nurs. Adm. Q. 1984, 8, 85–86. [Google Scholar] [CrossRef]

- Qastharin, A.R. Business model canvas for social enterprise. J. Bus. Econ. 2016, 7, 627–637. [Google Scholar]

- Joyce, A.; Paquin, R.L. The triple layered business model canvas: A tool to design more sustainable business models. J. Clean. Prod. 2016, 135, 1474–1486. [Google Scholar] [CrossRef]

- Coes, D. Critically Assessing the Strengths and Limitations of the Business Model Canvas; University of Twente: Twente, The Netherlands, 2014. [Google Scholar]

- Widmer, T. Assessing the Strengths and Limitations of Business Model Frameworks for Product Service Systems in the Circular Economy: Why Canvas and co. Are Not Enough. Master’s Thesis, KTH, Stockholm, Sweden, 2016. [Google Scholar]

- Fehrer, J.A.; Wieland, H. A systemic logic for circular business models. J. Bus. Res. 2021, 125, 609–620. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and barriers of circular economy business models: Where we are now, and where we are heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Braun, A.-T.; Schöllhammer, O.; Rosenkranz, B. Adaptation of the business model canvas template to develop business models for the circular economy. Procedia Cirp 2021, 99, 698–702. [Google Scholar] [CrossRef]

- Daou, A.; Mallat, C.; Chammas, G.; Cerantola, N.; Kayed, S.; Saliba, N.A. The Ecocanvas as a business model canvas for a circular economy. J. Clean. Prod. 2020, 258, 120938. [Google Scholar] [CrossRef]

- Pollard, J.; Osmani, M.; Cole, C.; Grubnic, S.; Colwill, J. A circular economy business model innovation process for the electrical and electronic equipment sector. J. Clean. Prod. 2021, 305, 127211. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U. Circular Business Model Value Dimension Canvas: Tool Redesign for Innovation and Validation through an Australian Case Study. Sustainability 2023, 15, 11553. [Google Scholar] [CrossRef]

- Salvador, R.; Søberg, P.V.; Jørgensen, M.S.; Schmidt-Kallesøe, L.-L.; Larsen, S.B. Explaining sustainability performance and maturity in SMEs–Learnings from a 100-participant sustainability innovation project. J. Clean. Prod. 2023, 419, 138248. [Google Scholar] [CrossRef]

- Mangialardo, A.; Micelli, E. Rethinking the construction industry under the circular economy: Principles and case studies. In Smart and Sustainable Planning for Cities and Regions: Results of SSPCR 2017 2; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Marinelli, S.; Butturi, M.A.; Rimini, B.; Gamberini, R.; Sellitto, M.A. Estimating the circularity performance of an emerging industrial symbiosis network: The case of recycled plastic fibers in reinforced concrete. Sustainability 2021, 13, 10257. [Google Scholar] [CrossRef]

- Kaipainen, J.; Uusikartano, J.; Aarikka-Stenroos, L.; Harala, L.; Alakerttula, J.; Pohls, E.-L. How to Engage Stakeholders in Circular Economy Ecosystems: The Process. In Stakeholder Engagement in a Sustainable Circular Economy: Theoretical and Practical Perspectives; Springer: Berlin/Heidelberg, Germany, 2023; pp. 193–231. [Google Scholar]

- Geng, Y.; Doberstein, B. Developing the circular economy in China: Challenges and opportunities for achieving’leapfrog development’. Int. J. Sustain. Dev. World Ecol. 2008, 15, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Majava, J.; Aaltonen, K. Implementation of circular economy in construction projects: A procurement strategy approach. Constr. Innov. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- González, A.; Sendra, C.; Herena, A.; Rosquillas, M.; Vaz, D. Methodology to assess the circularity in building construction and refurbishment activities. Resour. Conserv. Recycl. Adv. 2021, 12, 200051. [Google Scholar] [CrossRef] [PubMed]

- Piñones, P.; Derpich, I.; Venegas, R. Circular Economy 4.0 Evaluation Model for Urban Road Infrastructure Projects, CIROAD. Sustainability 2023, 15, 3205. [Google Scholar] [CrossRef]

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

- Janik, A.; Szafraniec, M. Circular economy performance of EMAS organizations in Poland based on an analysis of environmental statements. Multidiscip. Asp. Prod. Eng. 2019, 2, 536–547. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).