Shear Bearing Capacity Prediction of Steel-Fiber-Reinforced High-Strength Concrete Corbels on Modified Compression Field Theory

Abstract

1. Introduction

2. Establishment of the Proposed Model

- The shear stress and normal stress experienced by concrete micro-elements are uniformly distributed when subjected to loads.

- The stress and strain of concrete refer to the average stress and strain in the cracking zone.

- The principal stress and principal strain directions of concrete are consistent.

- There is no bond slip between steel bars and concrete, assuming ideal bond conditions.

- Shear stress in steel bars is not considered: only the axial stress in the steel bars is taken into account.

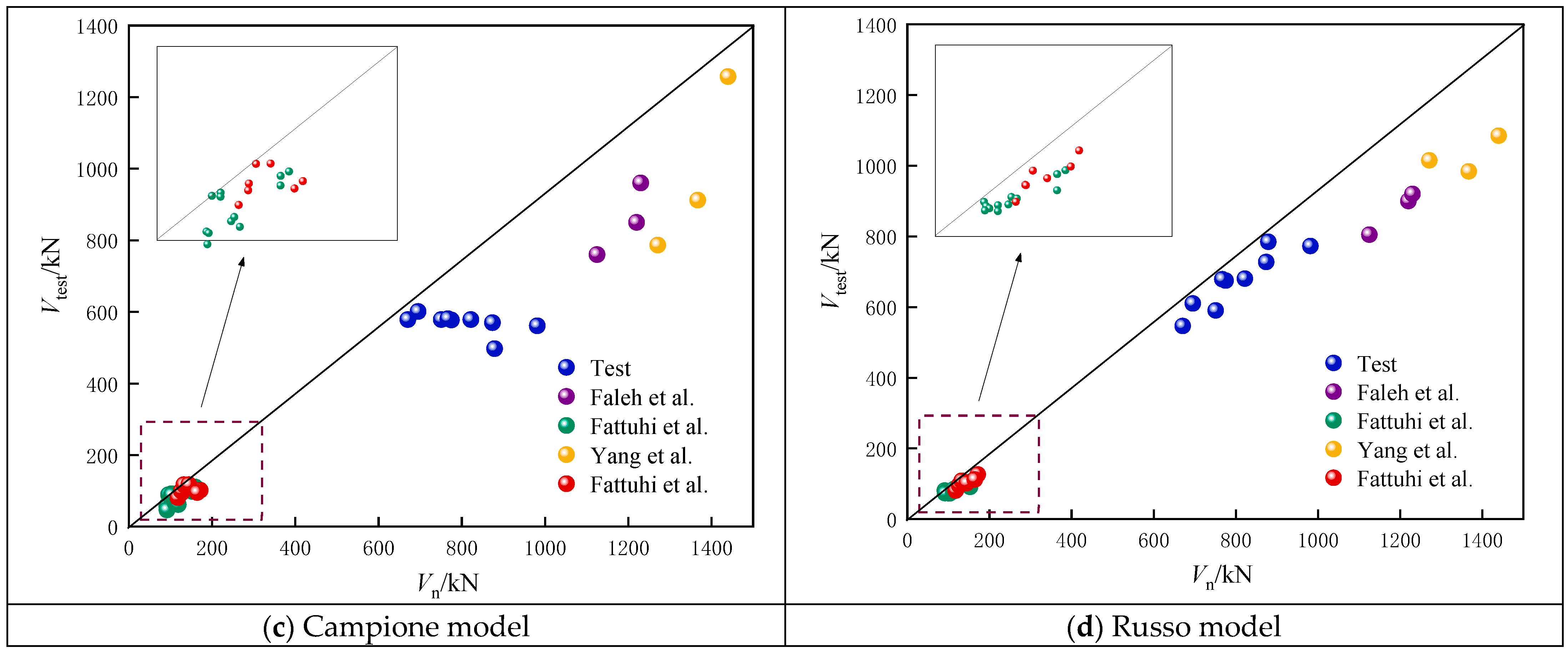

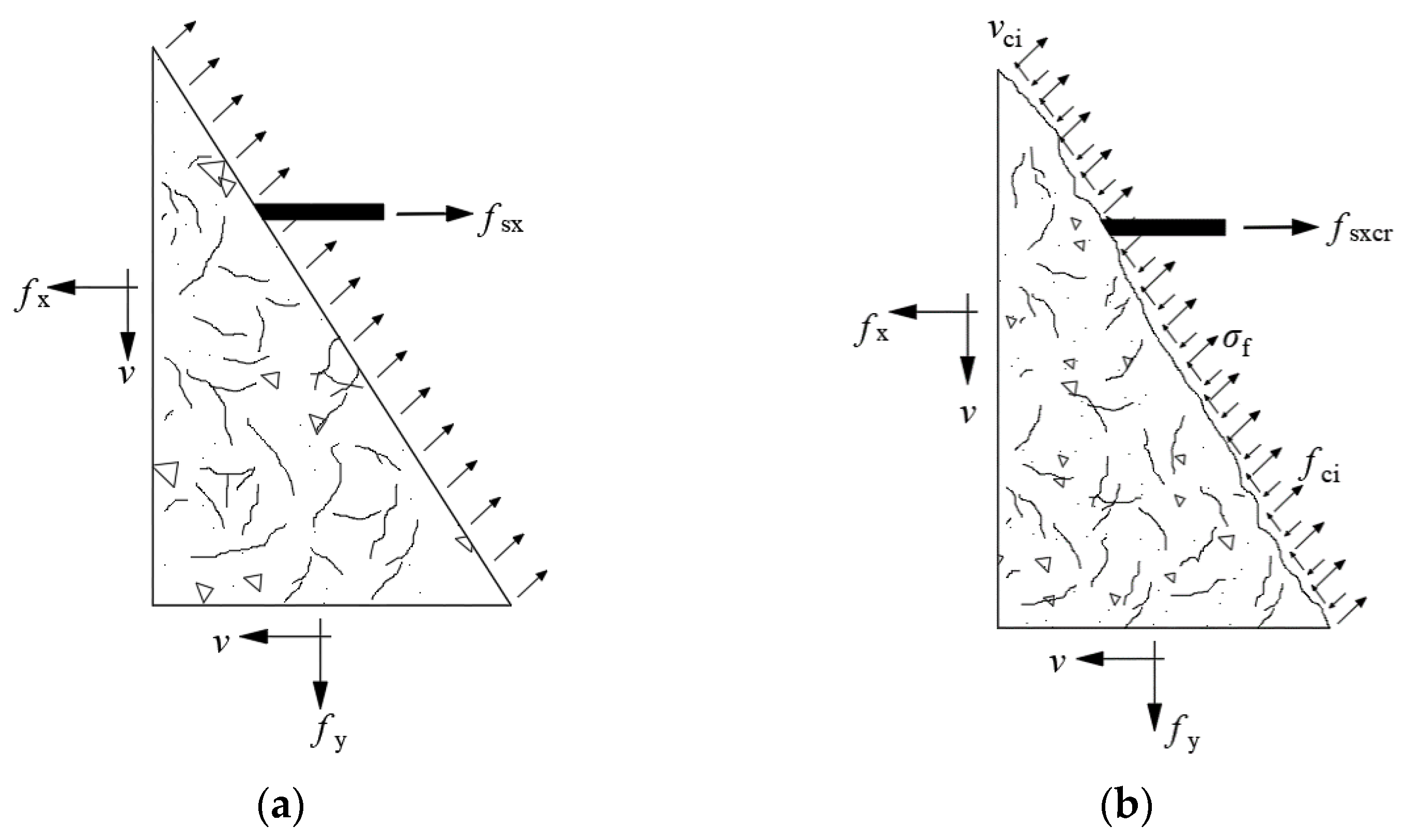

2.1. Equilibrium Conditions

2.2. Constitutive Relations

2.2.1. Stress–Strain Relationship of Concrete in Tension

2.2.2. Stress–Strain Relationship of Concrete in Compression

2.2.3. Stress–Strain Relationship of Reinforcement

2.3. Compatibility Conditions

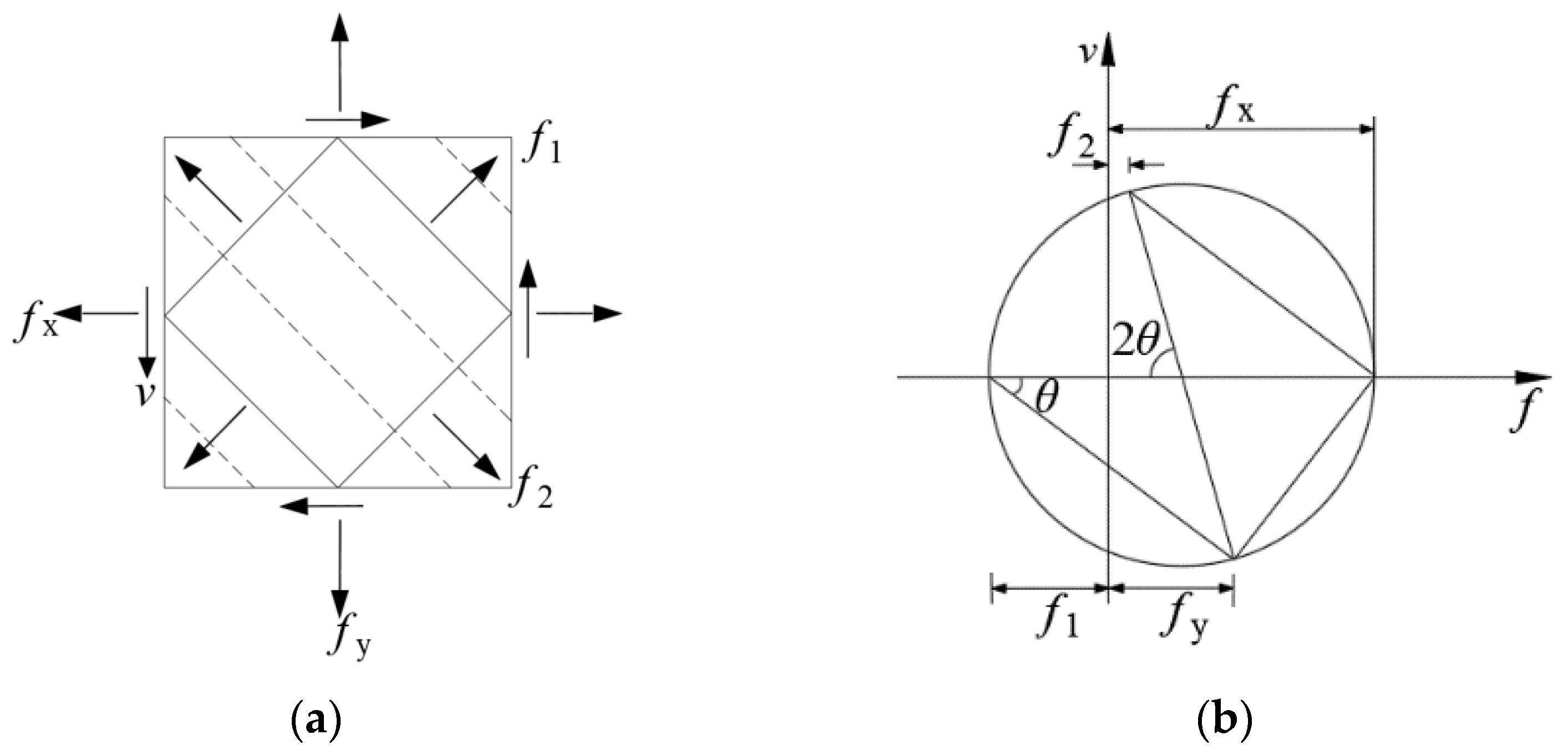

2.4. Stress Equilibrium of Steel Fibers at the Crack

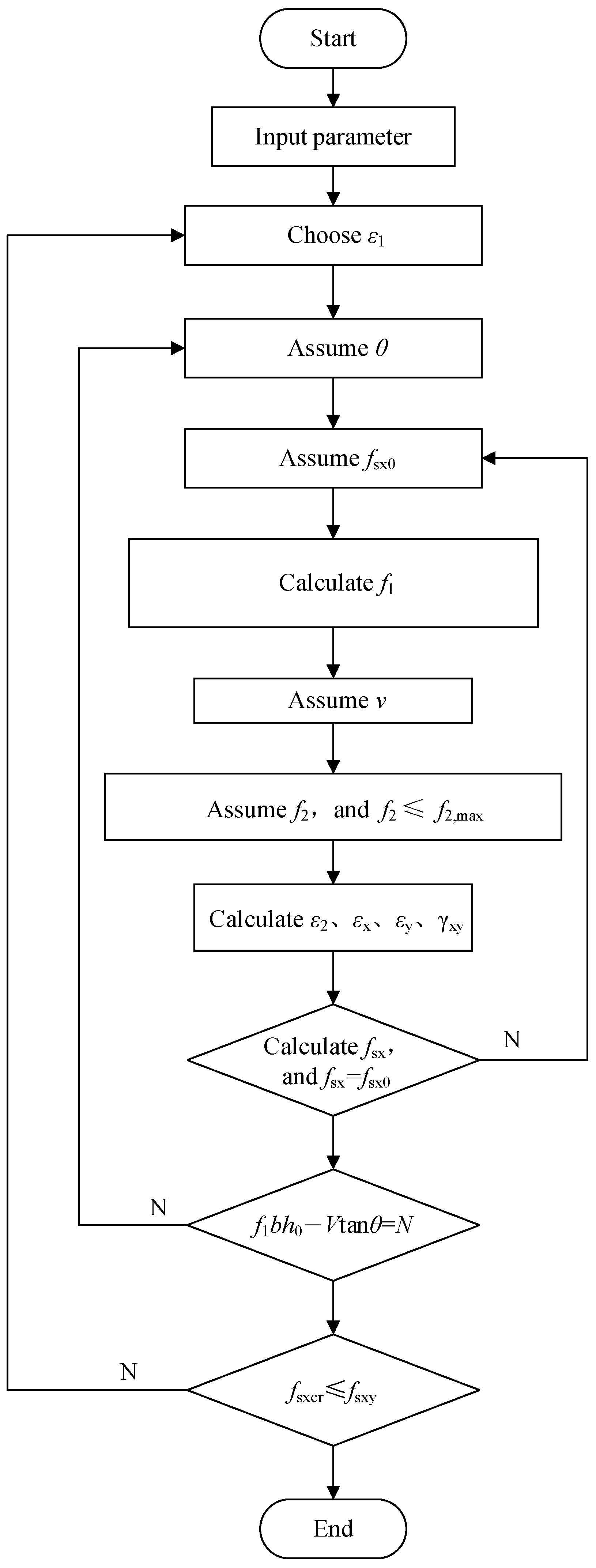

2.5. Calculation Process

- Input corbels’ geometry and material parameters.

- Assume ε1, and the increment of ε1 is 0.0001.

- Assume θ.

- Calculate vci and w using Equations (25) and (26).

- Assume fsx0.

- Calculate f1 using Equation (11), and satisfy Equation (28).

- Calculate v using Equation (30).

- Calculate f2 using Equation (3), and f2 is limited by f2,max.

- Use Equation (14) to determine whether it is equal to the assumed fsx0. If it is, continue to the next step; otherwise, return to (6) to assume the stirrup stress again.

- Calculate axial load N using Equation (8), and whether the axial force is equal to 0. If it is true, the analysis of the corresponding principal tension strain state is completed. If not, return to (4) to assume the crack inclination again until it is equal.

- Calculate fsxcr using Equation (29), if fsxcr is less than fsxy, the calculation ends. Otherwise, return to (2) to re-assume the main tensile strain of concrete.

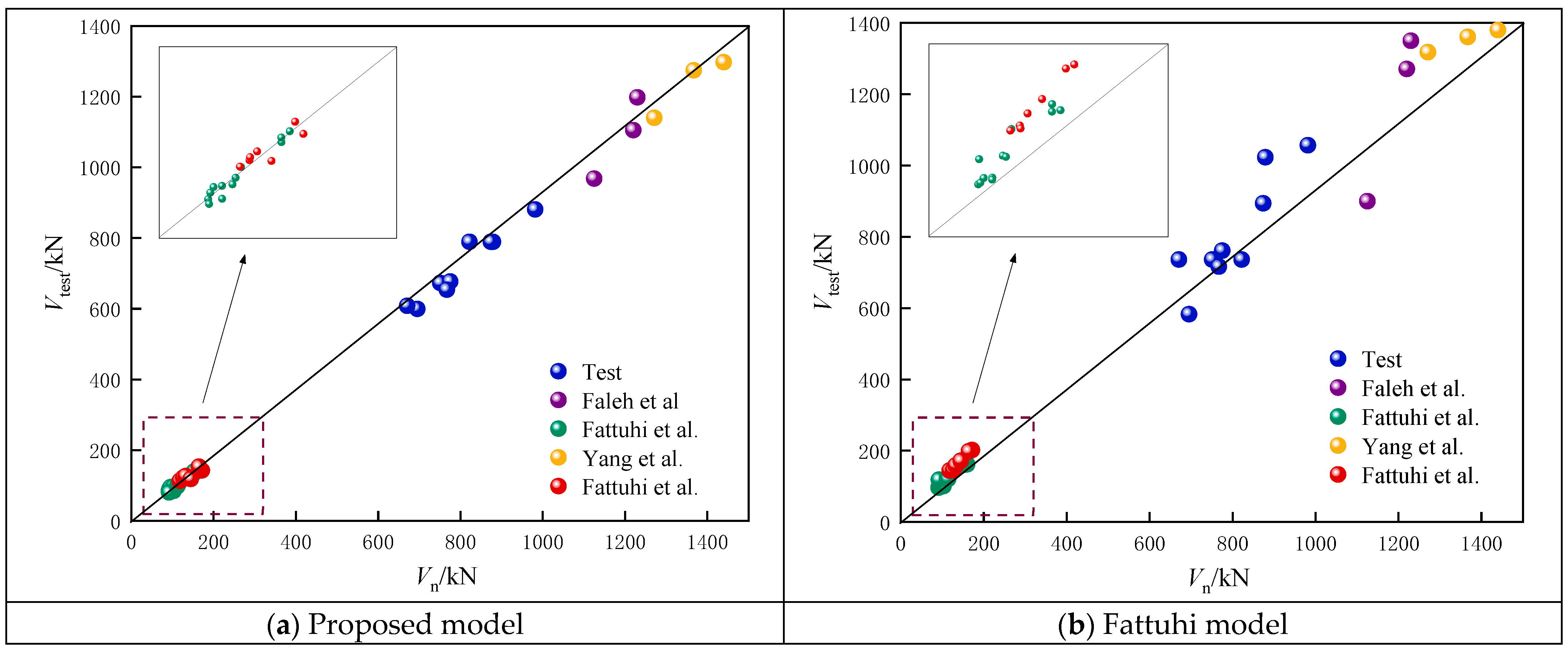

3. Model Verification

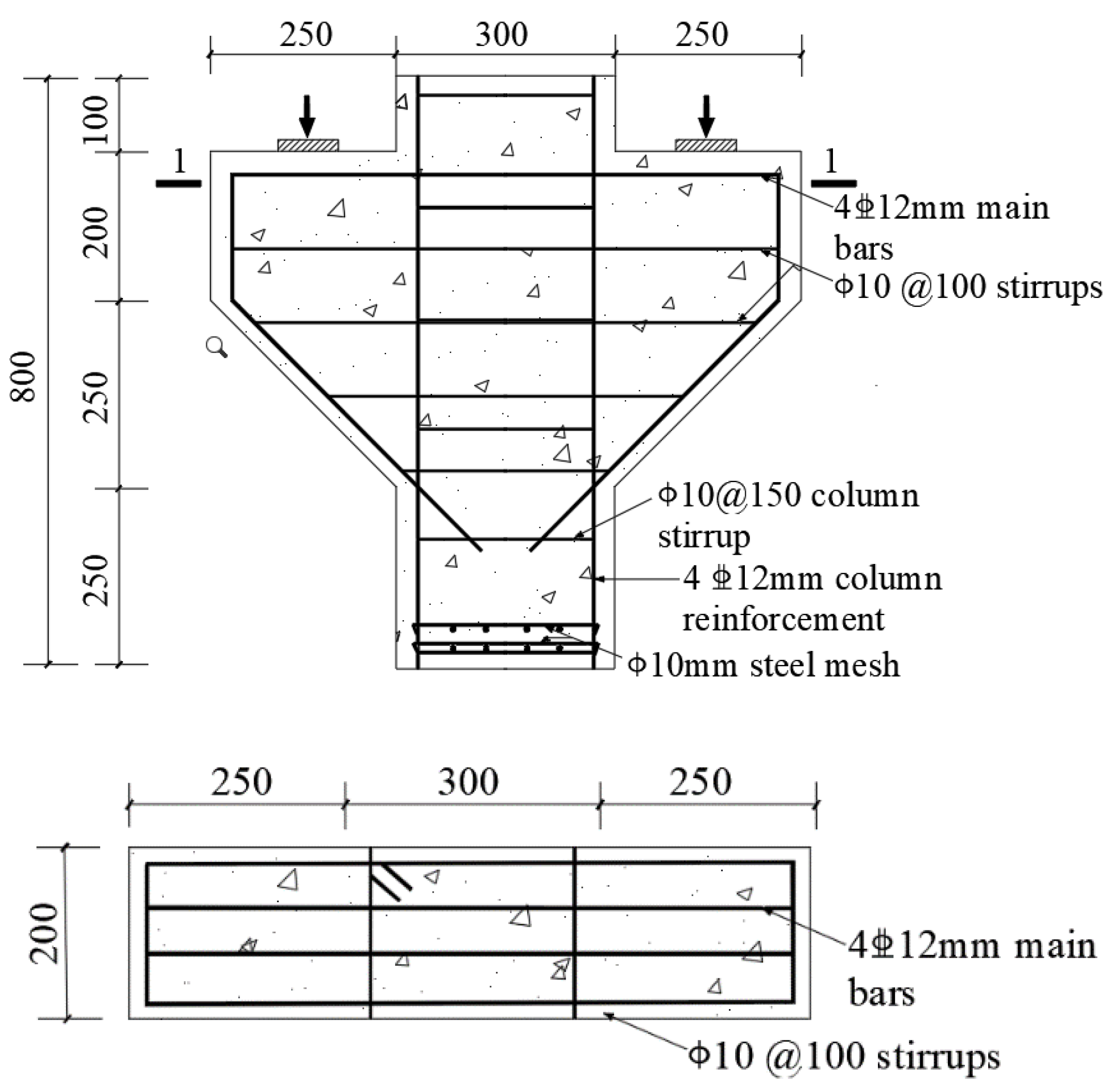

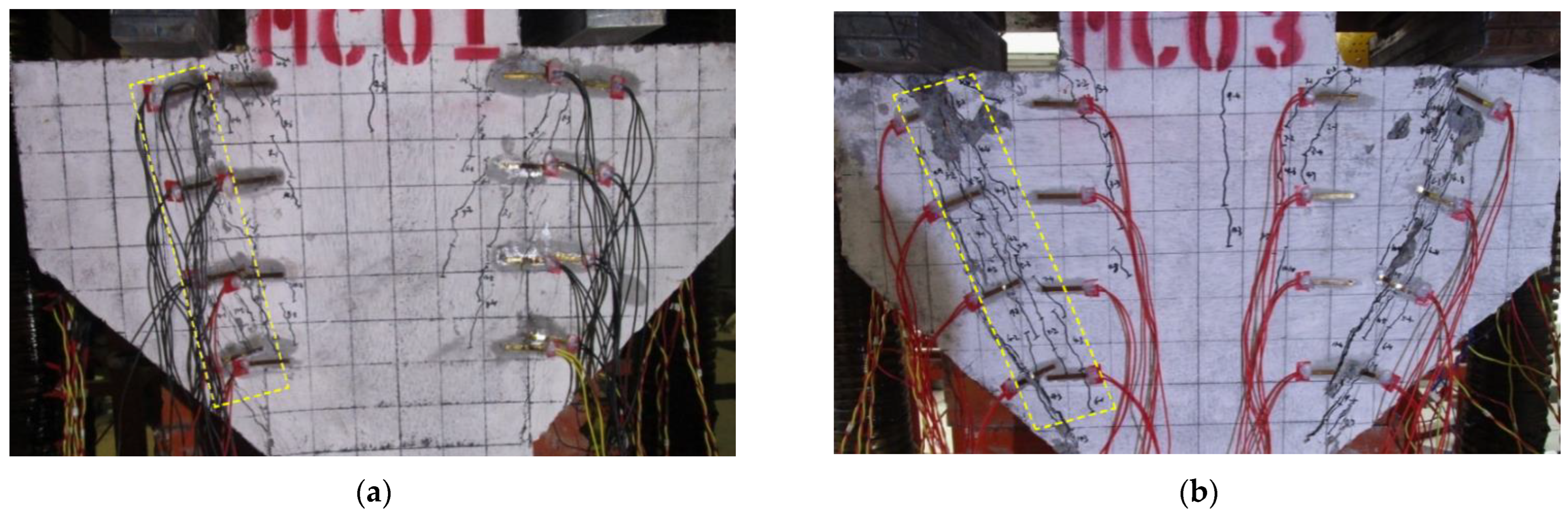

3.1. Experimental Work

3.2. Comparison with Test Results

3.2.1. Fattuhi Model [32]

3.2.2. Campione Model [33]

3.2.3. Russo Model [34]

3.2.4. Model Validity

4. Conclusions

- Based on the modified compression field theory, the contribution of steel fibers to the tensile strength of concrete at crack locations is considered. The constitutive relationship of cracked steel-fiber-reinforced concrete and the local stress equilibrium equation are modified. A calculation model for the shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels is proposed.

- Compared with other scholars’ models, the predicted value of shear capacity calculated by the proposed model is closer to the experimental value. It can be effectively utilized for predicting and analyzing the shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels, and has a clear mechanical model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Z.Q.; Liu, Z.; Ma, Z. Investigation of Load-Transfer Mechanisms in Deep Beams and Corbels. ACI Struct. J. 2012, 109, 467–476. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Thai, H.T.; Ngo, T. Effect of steel fibers on the performance of an economical ultra-high strength concrete. Struct. Concr. J. 2023, 24, 2327–2341. [Google Scholar] [CrossRef]

- Parthiban, P.; Kar, S.; Mondal, A.K. Stress–strain behaviour of (hpfrc) high-performance fibre reinforced concrete: An experimental study. Mater. Today Proc. 2023, 80, 3119–3123. [Google Scholar] [CrossRef]

- Iqbal, S.; Ali, I.; Room, S. Enhanced mechanical properties of fiber reinforced concrete using closed steel fibers. Mater. Struct. J. 2019, 52, 56. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V.L. Evaluation of crack propagation and post-cracking hinge-type behavior in the flexural response of steel fiber reinforced concrete. Int. J. Concr. Struct. Mater. 2017, 11, 365–375. [Google Scholar] [CrossRef]

- Yun, Y.M.; Lee, Y. Strengths of Struts and Nodal Zones for Strut-and-Tie Model Design of Reinforced Concrete Corbels. Civ. Eng. J. 2021, 7, 1275–1289. [Google Scholar] [CrossRef]

- Schlaich, J.; Schafer, K.; Jennewein, M. Toward a consistent design of reinforced concrete structures. PCI J. 1987, 32, 74–150. [Google Scholar] [CrossRef]

- Canha, R.M.F.; Kuchma, D.A. Numerical analysis of reinforced high strength concrete corbels. J. Eng. Struct. 2014, 74, 130–144. [Google Scholar] [CrossRef]

- Hwang, S.J.; Tsa, R.J.; Lam, W.K. Simplification of softened strut-and-tie model for strength prediction of discontinuity regions. ACI Struct. J. 2017, 114, 1569–1579. [Google Scholar] [CrossRef]

- Abdul, R.; Khattab, S. Corbel strut and tie modeling—Experimental verification. ACI Struct. 2020, 26, 327–339. [Google Scholar] [CrossRef]

- ACI 318 Committee. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Lachowicz, M.K. Experimental study of the post tensioned prestressed concrete corbels. J. Eng. Struct. 2016, 108, 1–11. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F. Shear capacity of reinforced concrete corbels using mechanism analysis. Struct. Build. 2012, 165, 111–125. [Google Scholar] [CrossRef]

- Wael, K. Strength Prediction of Corbels Using Strut-and-Tie Model Analysis. Int. J. Concr. Struct. Mater. 2015, 9, 255–266. [Google Scholar] [CrossRef]

- Perceka, W.; Liao, W.C.; Wu, Y.F. Shear Strength Prediction Equations and Experimental Study of High Strength Steel Fiber-Reinforced Concrete Beams with Different Shear Span-to-Depth Ratios. J. Appl. Sci. 2019, 9, 4790. [Google Scholar] [CrossRef]

- Jaza, H.M.; Ali, R.Y. Shear behavior of normal and high-strength concrete beams reinforced with BFRP bars and basalt macro fibers. Constr. Build. Mater. 2023, 408, 133516. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M. The modified compression field theory for reinforced concrete elements subjected to shear. ACI Struct. J. 1986, 3, 219–231. [Google Scholar] [CrossRef]

- Kaufmann, W.; Mata, F.J.; Amin, A. Compression field analysis of fiber-reinforced concrete based on cracked membrane model. ACI Struct. J. 2019, 116, 213–224. [Google Scholar] [CrossRef]

- Wagh, S.K.; Vianthi, A.; Liao, W.C. Experimental and MCFT-Based Study on Steel Fiber-Reinforced Concrete Subjected to In-Plane Shear Forces. Int. J. Concr. Struct. Mater. 2023, 17, 29. [Google Scholar] [CrossRef]

- Gao, D.Y.; Shi, K. Calculation method for shear behavior of steel fiber reinforced concrete beam-column joints based on modified compression field theory. Civ. Eng. J. 2016, 49, 41–48. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Yao, J.T.; Hu, Y.K.; Gao, J. Predicting shear strength of steel fiber reinforced concrete beam-column joints by modified compression field theory. ACI Struct. J. 2022, 41, 1432–1441. [Google Scholar] [CrossRef]

- Zhu, K.F.; Lu, J.Z.; Liu, Y.; Shao, Y.M. Shear Capacity of Hybrid Fiber Reinforced Concrete Deep Beams Based on Modified Compression Field Theory. J. Yantai Univ. 2016, 29, 216–221. [Google Scholar] [CrossRef]

- Lei, J.; Chen, Z.X.; Shi, K.; Wang, W.G. Study on shear behavior and bearing capacity calculation of steel fiber reinforced high strength concrete two-pile caps. J. Build. Struct. 2023, 44, 234–245. [Google Scholar] [CrossRef]

- Yan, X.; Shi, Q.X.; Xu, Z.D. Experimental study on bond behavior between concrete and deformed steel bar with different steel bar. J. Hunan Univ. 2020, 47, 45–52. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effect of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. J. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Huo, L.Y.; Bi, J.H.; Zhao, Y.; Wang, Z.Y. Constitutive Model of Hybrid Steel Fiber Reinforced Concrete with Different Fiber Lengths. Constr. Build. Mater. 2022, 25, 1034–1039. [Google Scholar]

- Foster, S.J. On Behavior of High-Strength Concrete Columns: Cover Spalling, Steel Fibers and Ductility. ACI Struct. J. 2001, 98, 583–589. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M.P. Predicting the response of reinforced concrete beams subjected to subjected to shear using modified compression field theory. ACI Struct. J. 1988, 85, 258–268. [Google Scholar] [CrossRef]

- Naaman, A.E.; Moavenzadeh, F.; Mcgarry, J. Probabilistic analysis of fiber reinforced concrete. J. Eng. Mech. Div. 1974, 100, 397–431. [Google Scholar] [CrossRef]

- Bentz, E.C.; Vecchio, F.J.; Collins, M.P. Simplified modified compression field theory for calculating shear strength of reinforced concrete elements. ACI Struct. J. 2006, 103, 614–624. [Google Scholar] [CrossRef]

- Collins, M.P.; Mitchell, D.; Adebar, P. A general shear design method. ACI Struct. J. 1996, 93, 36–45. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Reinforced corbels made with plain and fibrous concretes. ACI Struct. J. 1994, 91, 530–536. [Google Scholar] [CrossRef]

- Campione, G.; Lidia, L.M.; Maria, L.M. Steel Fiber-Reinforced Concrete Corbels: Experimental Behaviour and Shear Strength Prediction. ACI Struct. J. 2007, 104, 570–579. [Google Scholar] [CrossRef]

- Munez, P.R. Reinforced Concrete Corbels—Shear Strength Model and Design Formula. ACI Struct. J. 2006, 103, 904–906. [Google Scholar] [CrossRef]

- Faleh, S.K.H.; Chkheiwer, A.H.; Saleh, I.S. Structural behavior of high-strength concrete corbels involving steel fibers or closed stirrups. Period. Eng. Nat. Sci. 2022, 10, 239–252. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Column-Load Effect on Reinforced Concrete Corbels. J. Struct. Eng. 1990, 116, 188–197. [Google Scholar] [CrossRef]

- Yang, J.M.; Lee, J.H.; Yoon, Y.S. Influence of Steel Fibers and Headed Bars on the Serviceability of High-Strength Concrete Corbels. J. Struct. Eng. 2012, 138, 123–129. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Strength of SFRC Corbels Subjected to Vertical Load. J. Struct. Eng. 1990, 116, 701–718. [Google Scholar] [CrossRef]

| Specimens | Main Reinforcement | Ratio of Reinforcement | Stirrup | Stirrup Reinforcement Ratio | Shear Span Ratio | Effective Depth | Steel Fiber Dosage |

|---|---|---|---|---|---|---|---|

| MC01 | 4C12 | 0.55% | A10@100 | 0.785% | 0.2 | 400 | 1.5% |

| MC02 | 4C12 | 0.55% | A10@100 | 0.785% | 0.3 | 400 | 1.5% |

| MC03 | 4C12 | 0.55% | A10@100 | 0.785% | 0.4 | 400 | 1.5% |

| MC04 | 4C12 | 0.55% | A10@100 | 0.785% | 0.3 | 400 | 1.5% |

| MC05 | 4C12 | 0.55% | A10@100 | 0.785% | 0.3 | 400 | 1.5% |

| MC06 | 4C12 | 0.75% | A10@150 | 0.390% | 0.3 | 400 | 1.5% |

| MC07 | 4C12 | 0.98% | A10@200 | 0.520% | 0.3 | 400 | 1.5% |

| MC08 | 4C12 | 0.55% | A10@100 | 0.785% | 0.3 | 400 | 0 |

| MC09 | 4C12 | 0.55% | A10@100 | 0.785% | 0.3 | 400 | 0.75% |

| Reinforcement Type | Diameter (mm) | Cross-Sectional Area (mm2) | Yield Strength (MPa) | Elastic Modulus (GPa) | Ultimate Strength (MPa) |

|---|---|---|---|---|---|

| HPB300 | 10 | 78.5 | 333.7 | 195.95 | 535.8 |

| HRB400 | 12 | 113.1 | 425.2 | 172.6 | 541.4 |

| HRB400 | 14 | 153.9 | 467.8 | 185.0 | 582.3 |

| HRB400 | 16 | 201.1 | 427.3 | 192.5 | 587.7 |

| Specimens | /kN | /kN | Vu/kN | Failure Patterns |

|---|---|---|---|---|

| MC01 | 270 | 400 | 879 | Diagonal shear patterns |

| MC02 | 220 | 290 | 822 | Diagonal compression pattern |

| MC03 | 166.5 | 255 | 695 | Diagonal compression pattern |

| MC04 | 220 | 355 | 874 | Diagonal compression pattern |

| MC05 | 193 | 386.5 | 981.5 | Diagonal compression pattern |

| MC06 | 192 | 234.5 | 670.5 | Diagonal compression pattern |

| MC07 | 164 | 240 | 751 | Diagonal compression pattern |

| MC08 | 150 | 331 | 775 | Diagonal compression pattern |

| MC09 | 180 | 381 | 767 | Diagonal compression pattern |

| References | Specimens | b/mm | h0/mm | ρf | Vtest | Vtest/VF | Vtest/VC | Vtest/VR | Vtest/Vn |

|---|---|---|---|---|---|---|---|---|---|

| This study | MC01 | 200 | 400 | 1.50% | 879 | 0.859 | 1.768 | 1.120 | 1.113 |

| MC02 | 200 | 400 | 1.50% | 822 | 1.116 | 1.420 | 1.208 | 1.041 | |

| MC03 | 200 | 400 | 1.50% | 695 | 1.192 | 1.156 | 1.139 | 1.159 | |

| MC04 | 200 | 400 | 1.50% | 874 | 0.978 | 1.534 | 1.201 | 1.107 | |

| MC05 | 200 | 400 | 1.50% | 981.5 | 0.929 | 1.750 | 1.270 | 1.114 | |

| MC06 | 200 | 400 | 1.50% | 670.5 | 0.911 | 1.159 | 1.227 | 1.102 | |

| MC07 | 200 | 400 | 1.50% | 751 | 1.020 | 1.298 | 1.272 | 1.116 | |

| MC08 | 200 | 400 | 0% | 775 | 1.018 | 1.342 | 1.148 | 1.144 | |

| MC09 | 200 | 400 | 0.75% | 767 | 1.071 | 1.321 | 1.130 | 1.173 | |

| Faleh et al. [35] | CF3-0.5 | 200 | 250 | 0.50% | 1125 | 1.25 | 1.480 | 1.397 | 1.162 |

| CF3-1.0 | 200 | 250 | 1.00% | 1220 | 0.960 | 1.435 | 1.356 | 1.104 | |

| CF3-1.5 | 200 | 250 | 1.5% | 1230 | 0.911 | 1.281 | 1.337 | 1.027 | |

| Fattuhi et al. [36] | 1 | 150 | 125 | 1.70% | 153 | 0.917 | 1.436 | 1.453 | 1.132 |

| 2 | 150 | 125 | 1.70% | 160 | 0.990 | 1.449 | 1.470 | 1.104 | |

| 3 | 150 | 129 | 1.70% | 91.2 | 0.947 | 1.580 | 1.130 | 1.079 | |

| 4 | 150 | 127 | 1.70% | 93 | 0.952 | 1.647 | 1.208 | 1.029 | |

| 5 | 150 | 124 | 1.70% | 103 | 1.008 | 1.121 | 1.325 | 1.213 | |

| 6 | 150 | 125 | 1.70% | 95.7 | 0.940 | 1.075 | 1.276 | 1.003 | |

| 9 | 150 | 125 | 1.70% | 152.9 | 0.954 | 1.558 | 1.680 | 1.097 | |

| 10 | 150 | 124 | 1.70% | 102.9 | 1.024 | 1.166 | 1.418 | 1.068 | |

| 12 | 150 | 127 | 0.70% | 92 | 0.777 | 1.974 | 1.258 | 1.145 | |

| 13 | 150 | 125 | 1.70% | 111.7 | 0.920 | 1.674 | 1.424 | 1.143 | |

| 16 | 150 | 125 | 1.70% | 114.3 | 0.948 | 1.622 | 1.344 | 1.103 | |

| 18 | 150 | 125 | 1.00% | 119 | 0.820 | 1.921 | 1.422 | 1.052 | |

| Yang et al. [37] | CW1 | 200 | 400 | 0% | 1271 | 0.964 | 1.615 | 1.252 | 1.115 |

| CW2 | 200 | 400 | 0.50% | 1367 | 1.005 | 1.499 | 1.390 | 1.073 | |

| CW3 | 200 | 400 | 0.75% | 1440 | 1.043 | 1.145 | 1.327 | 1.110 | |

| Fattuhi et al. [38] | 20 | 153 | 124 | 1.75% | 126 | 0.851 | 1.342 | 1.313 | 1.056 |

| 21 | 156 | 122 | 1.50% | 118 | 0.821 | 1.455 | 1.460 | 1.041 | |

| 23 | 153 | 123 | 2.00% | 126.5 | 0.869 | 1.267 | 1.324 | 1.038 | |

| 27 | 153.5 | 124 | 2.50% | 171.5 | 0.850 | 1.681 | 1.358 | 1.204 | |

| 32 | 154 | 120 | 2.00% | 132.5 | 0.835 | 1.131 | 1.221 | 1.044 | |

| 39 | 153.5 | 124 | 2.25% | 144.5 | 0.843 | 1.231 | 1.420 | 1.219 | |

| 49 | 154.4 | 122 | 2.50% | 164.5 | 0.830 | 1.721 | 1.466 | 1.073 | |

| Mean | 1.453 | 0.942 | 1.311 | 1.103 | |||||

| Variance | 0.061 | 0.009 | 0.017 | 0.003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.-M.; Zheng, J.-Y.; Li, S.-S. Shear Bearing Capacity Prediction of Steel-Fiber-Reinforced High-Strength Concrete Corbels on Modified Compression Field Theory. Buildings 2024, 14, 388. https://doi.org/10.3390/buildings14020388

Li H-M, Zheng J-Y, Li S-S. Shear Bearing Capacity Prediction of Steel-Fiber-Reinforced High-Strength Concrete Corbels on Modified Compression Field Theory. Buildings. 2024; 14(2):388. https://doi.org/10.3390/buildings14020388

Chicago/Turabian StyleLi, Hong-Mei, Jin-Yan Zheng, and Shu-Shan Li. 2024. "Shear Bearing Capacity Prediction of Steel-Fiber-Reinforced High-Strength Concrete Corbels on Modified Compression Field Theory" Buildings 14, no. 2: 388. https://doi.org/10.3390/buildings14020388

APA StyleLi, H.-M., Zheng, J.-Y., & Li, S.-S. (2024). Shear Bearing Capacity Prediction of Steel-Fiber-Reinforced High-Strength Concrete Corbels on Modified Compression Field Theory. Buildings, 14(2), 388. https://doi.org/10.3390/buildings14020388