Prediction of Wet Area of Underwater Tunnel Lining

Abstract

:1. Introduction

2. Theoretical Basis

3. Research Methods

3.1. Indoor Test

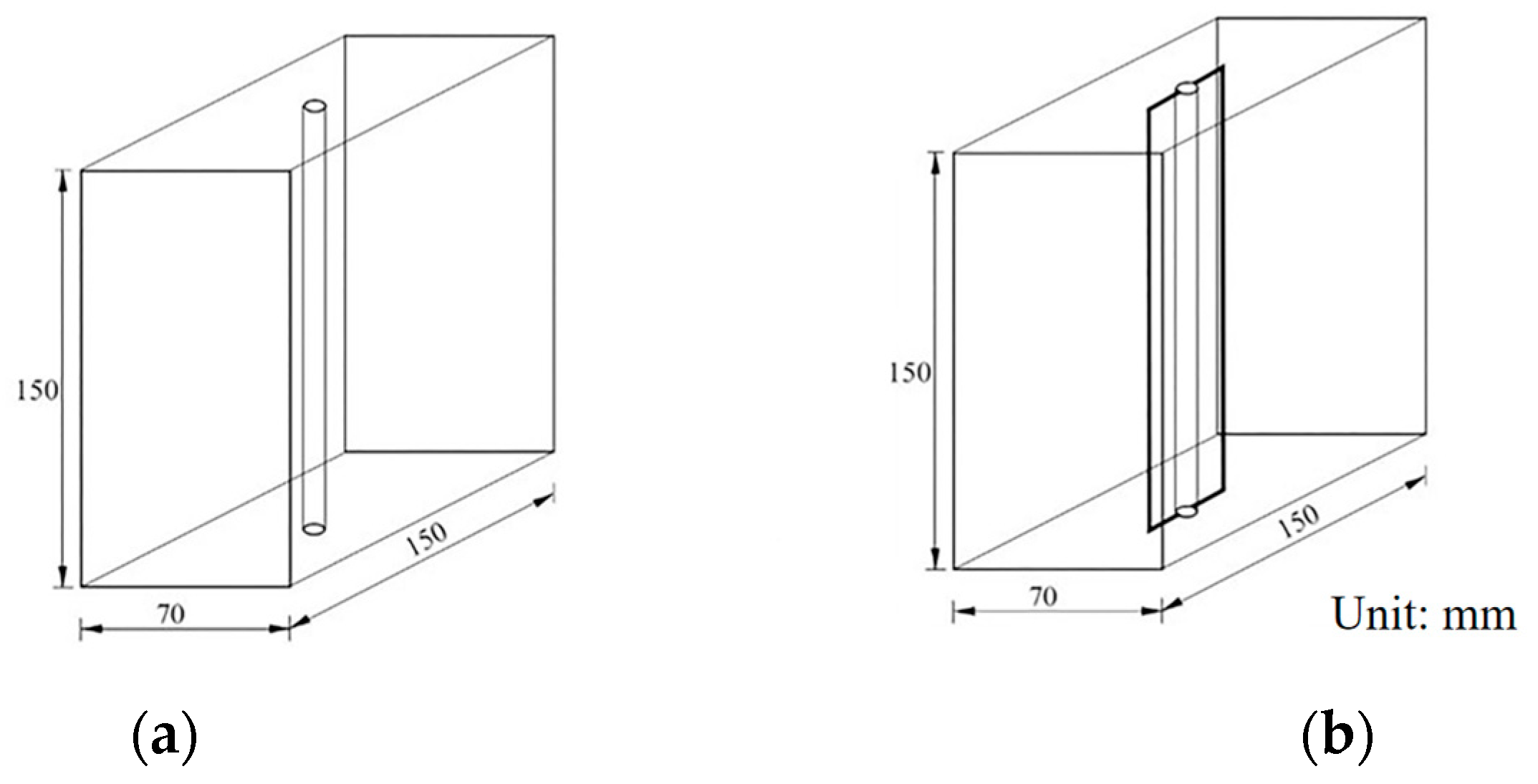

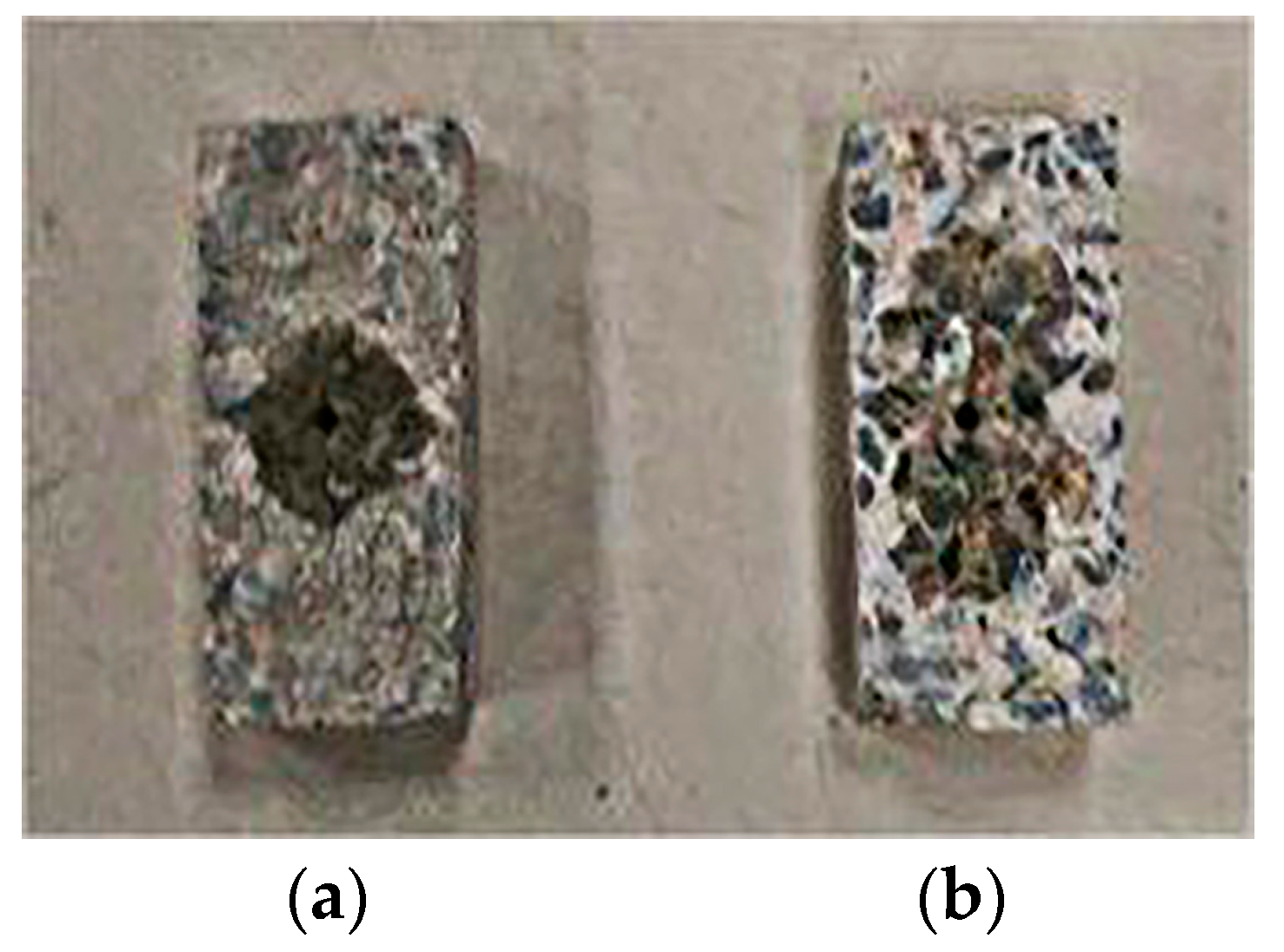

3.1.1. Test Specimens Preparation

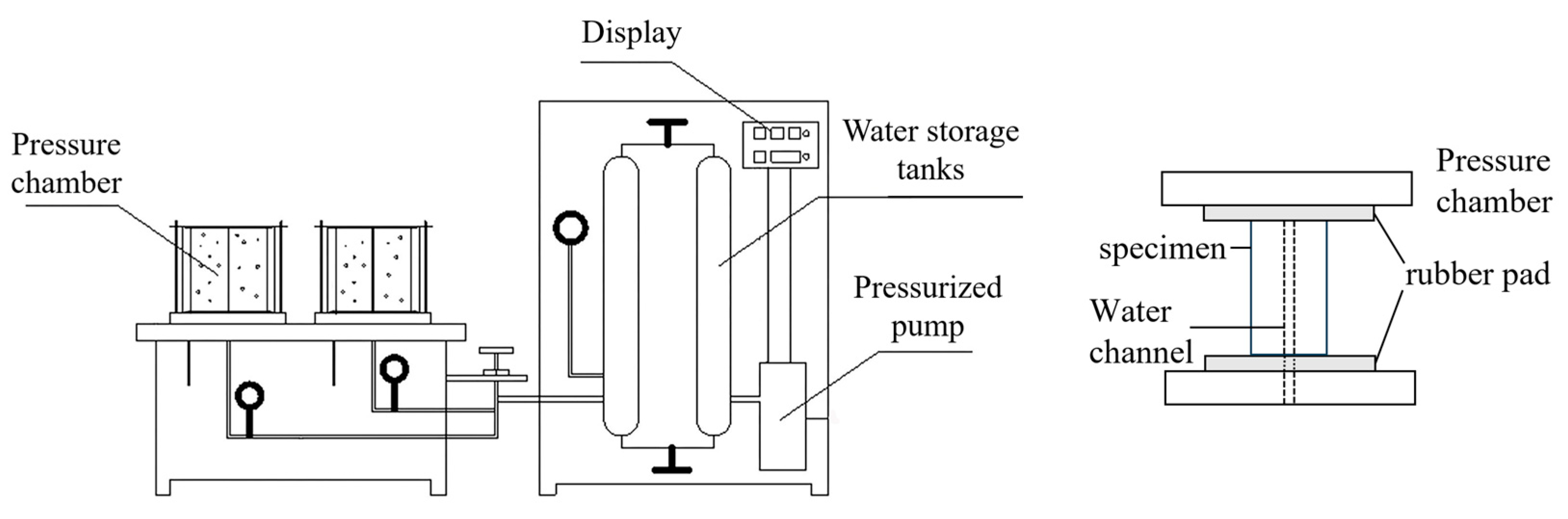

3.1.2. Test Methods

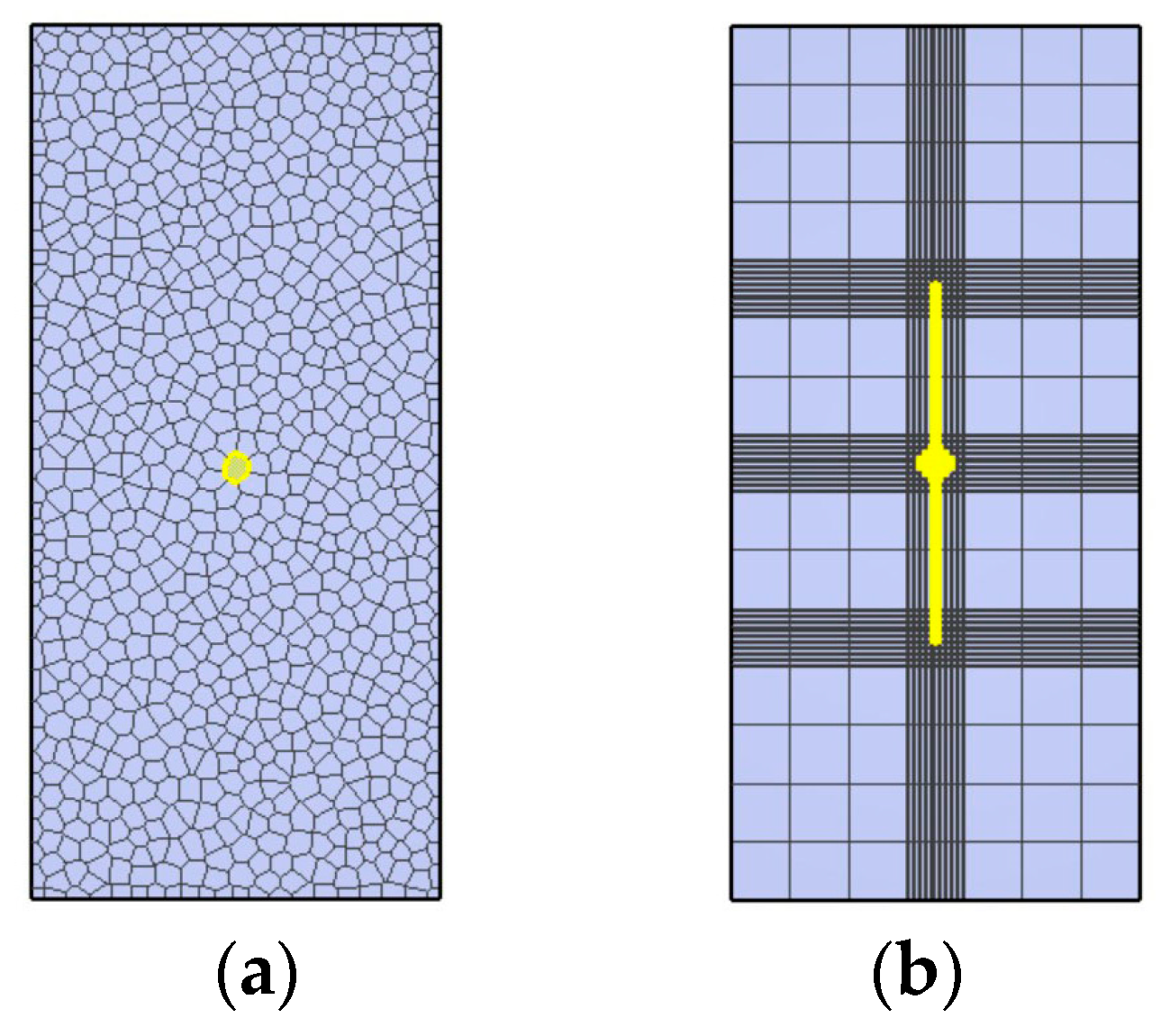

3.2. Numerical Simulation

4. Results and Discussion

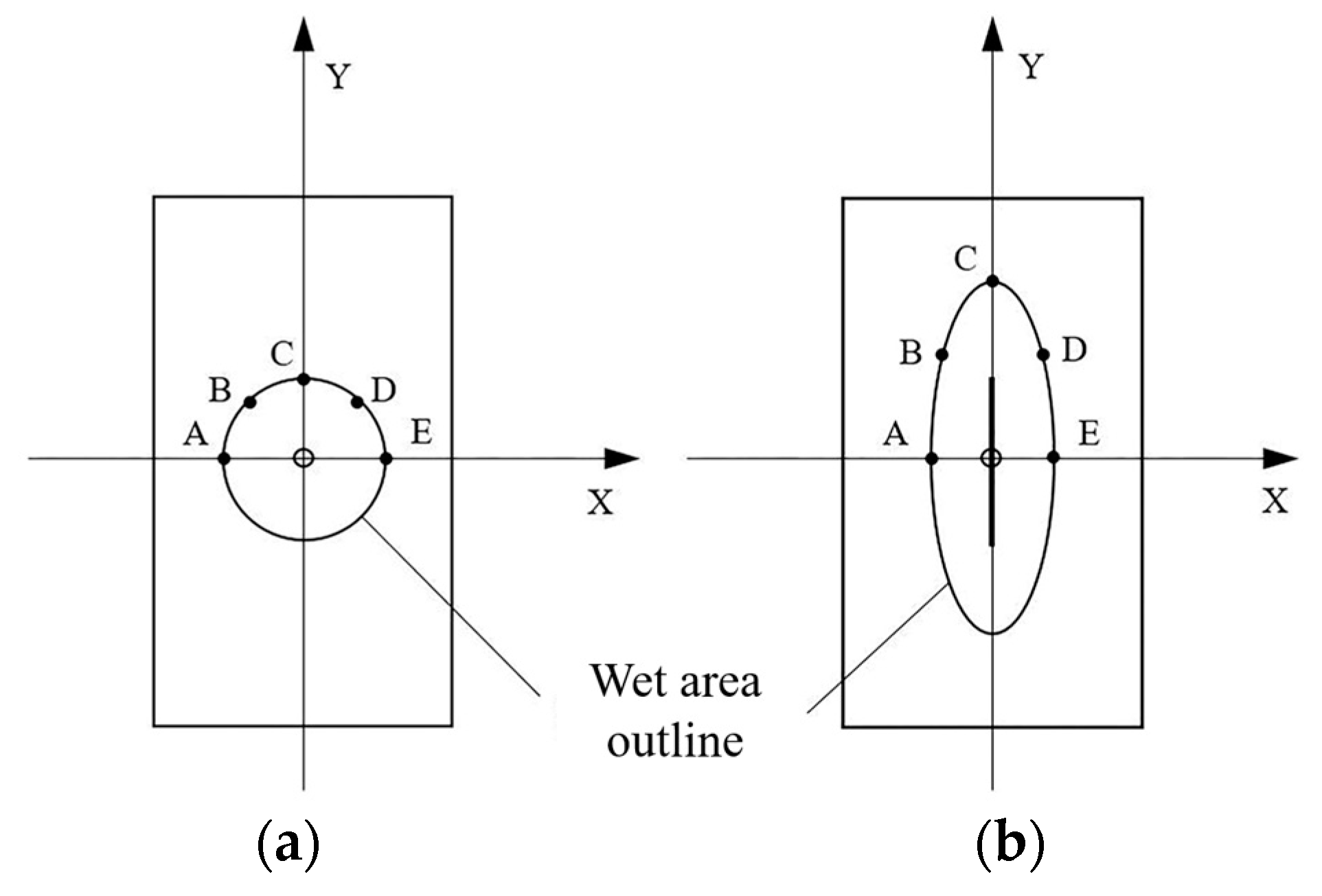

4.1. Geometry of Wet Area

4.2. Wet Area

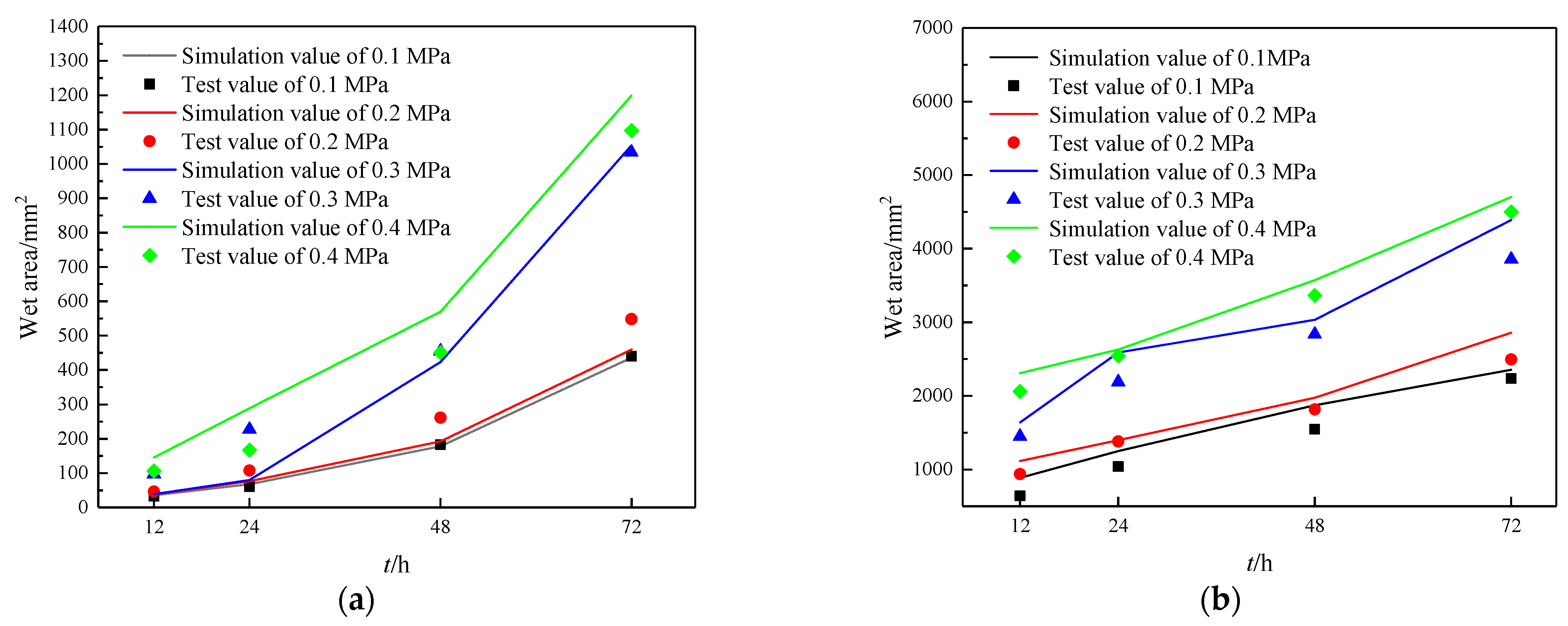

4.2.1. Influence of External Water Pressure on Wet Area

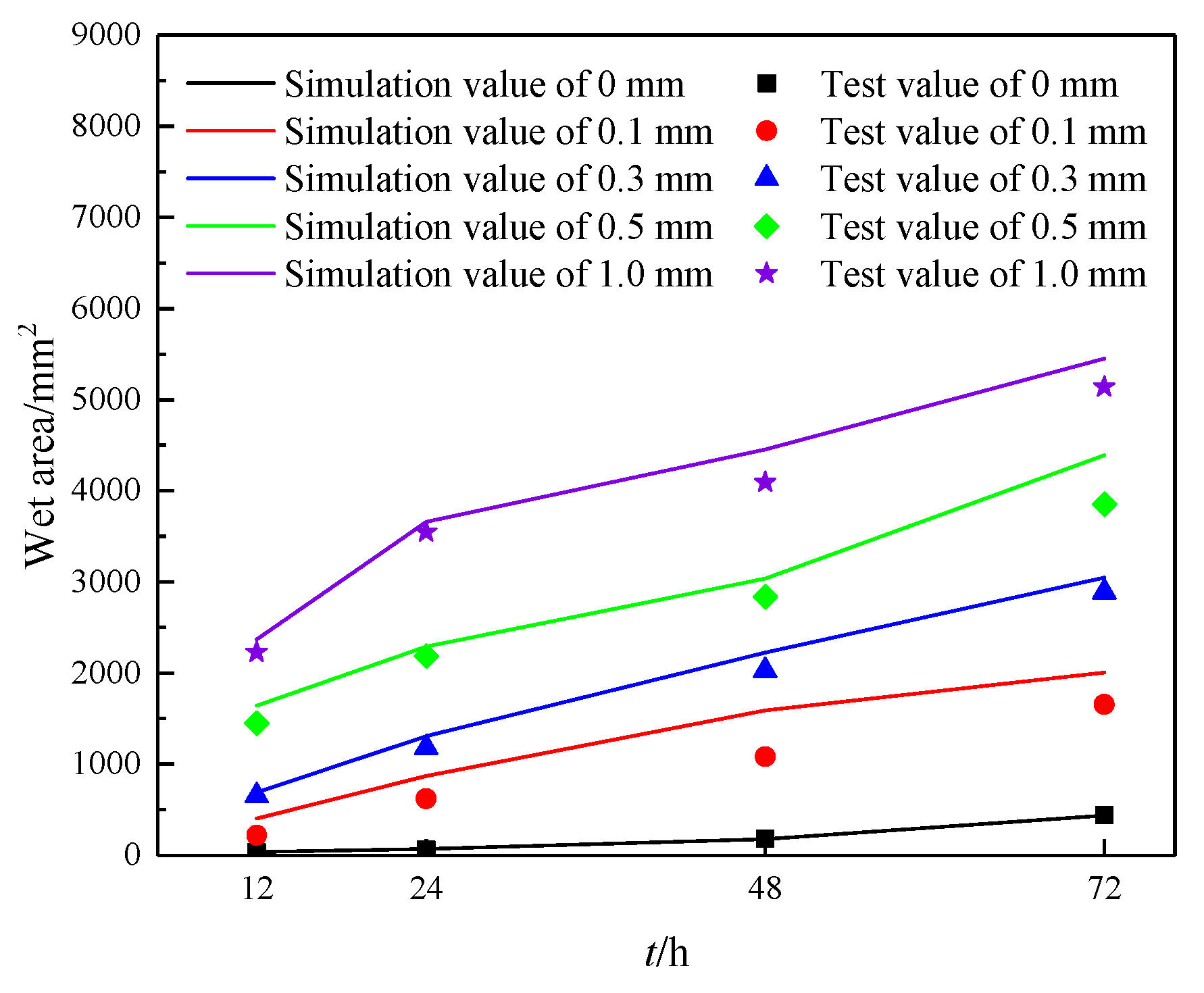

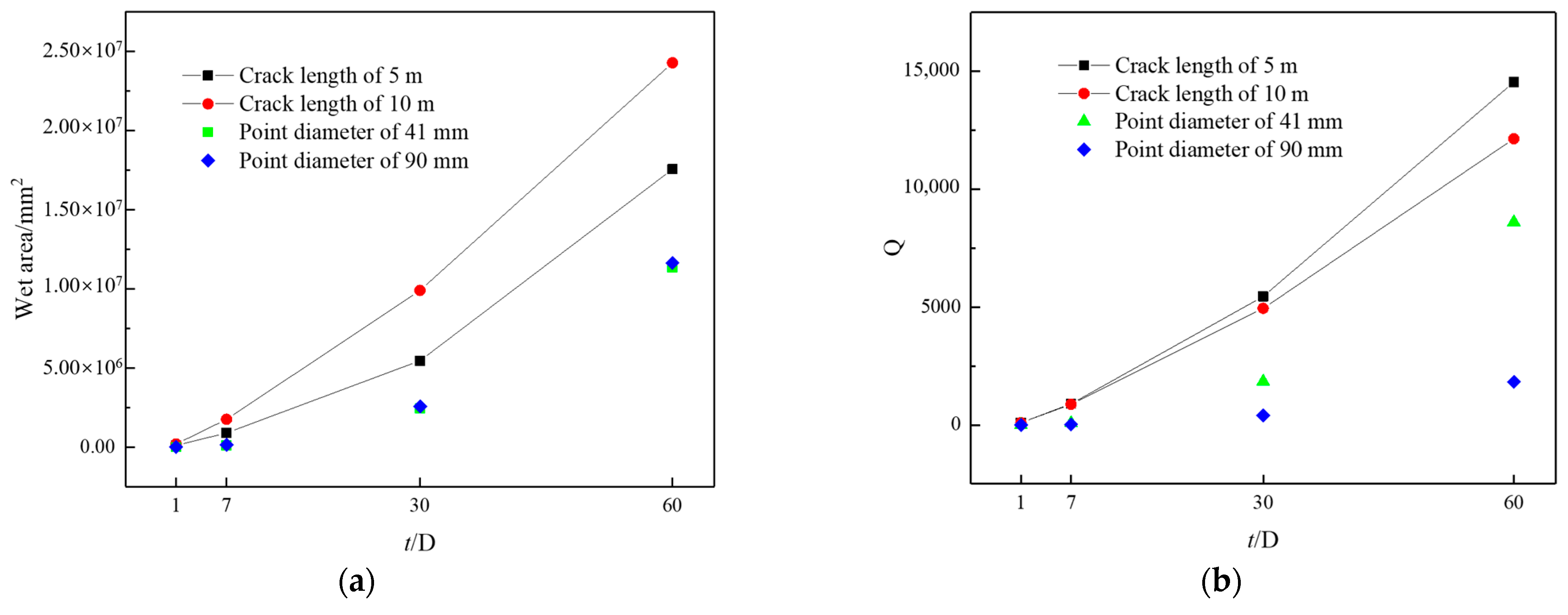

4.2.2. Influence of Defects on Wet Area

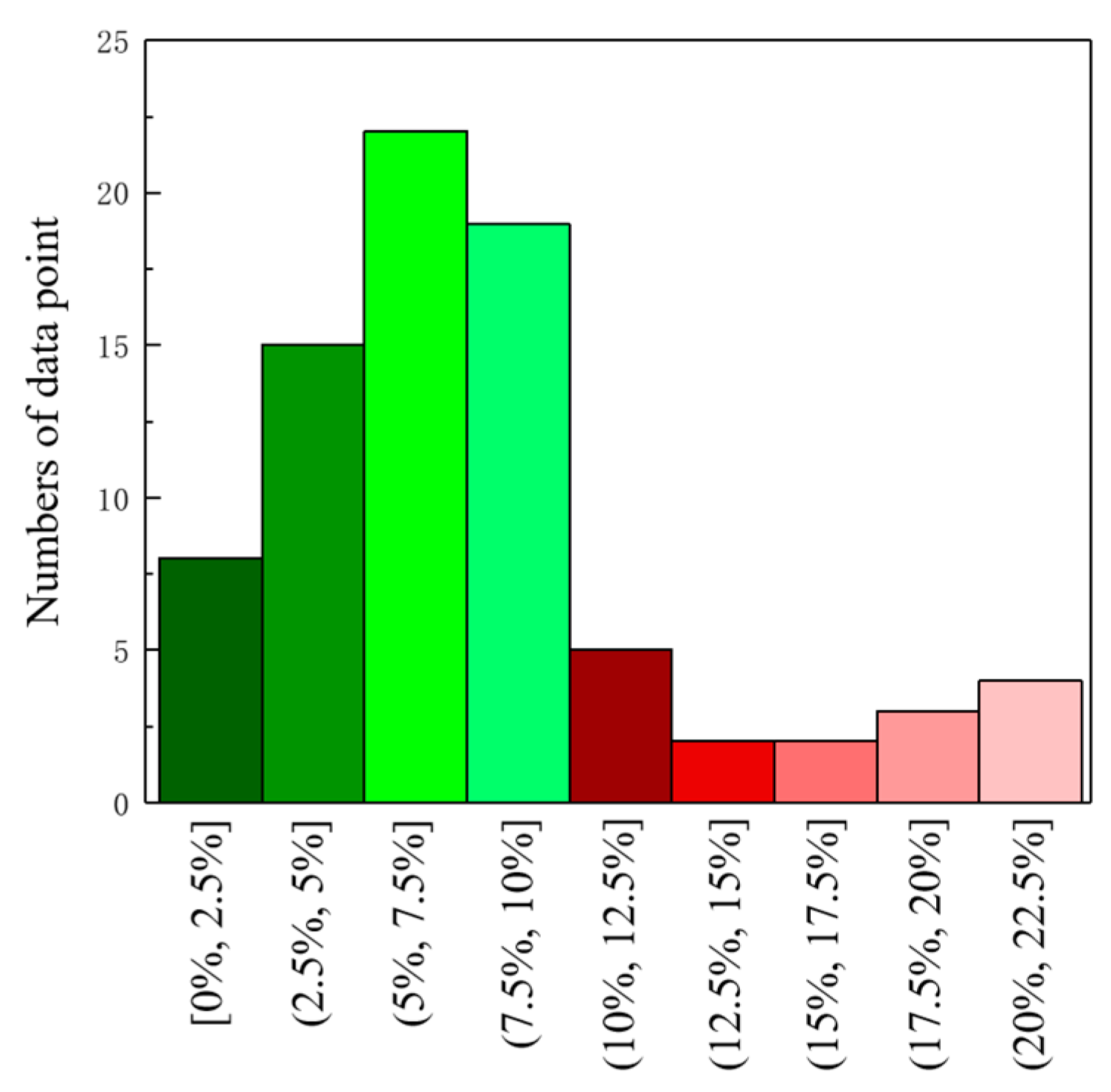

4.3. Discussion

4.3.1. Leakage Depth Fitting

4.3.2. Fitting of Wet Area

5. Engineering Cases

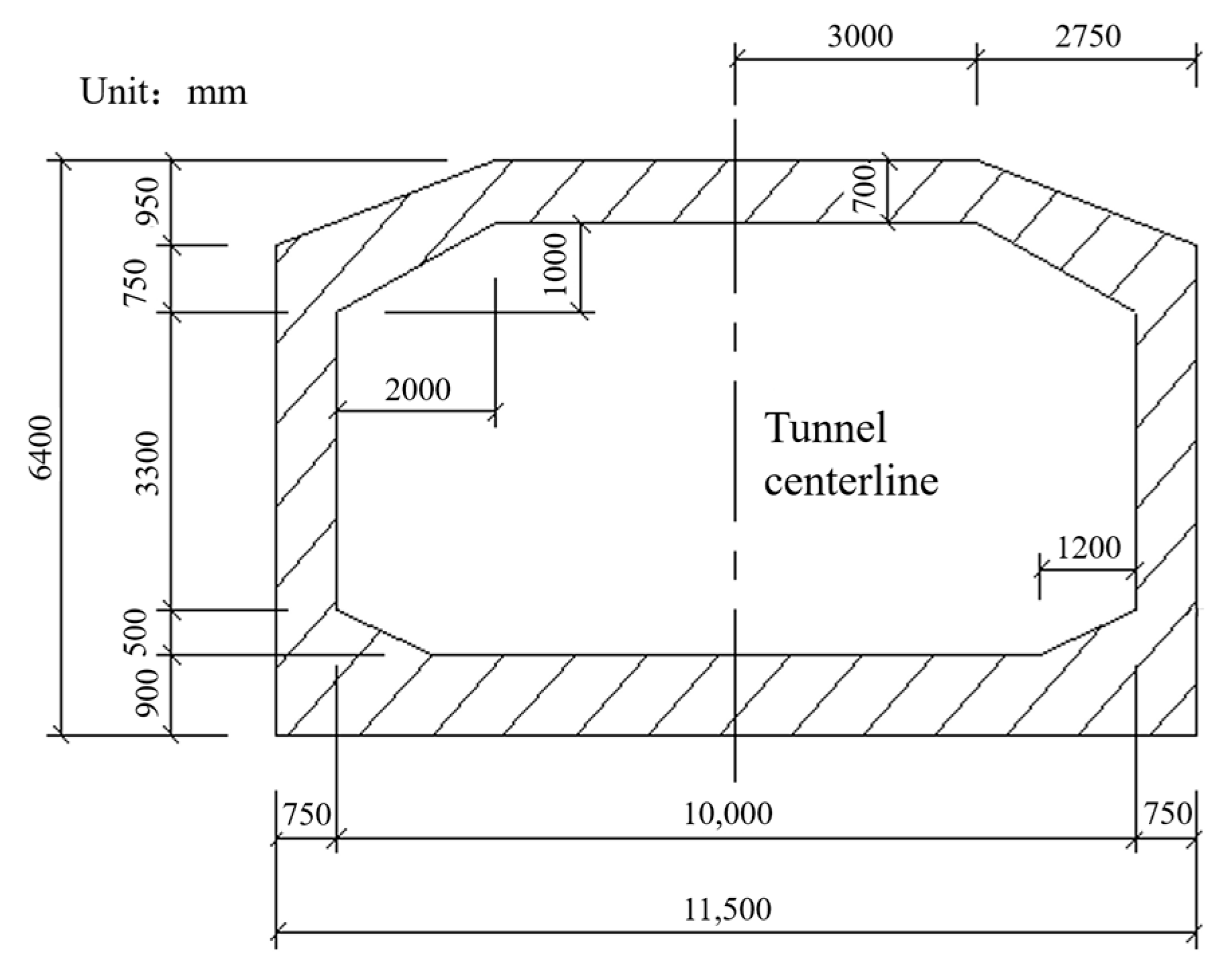

5.1. Engineering Condition

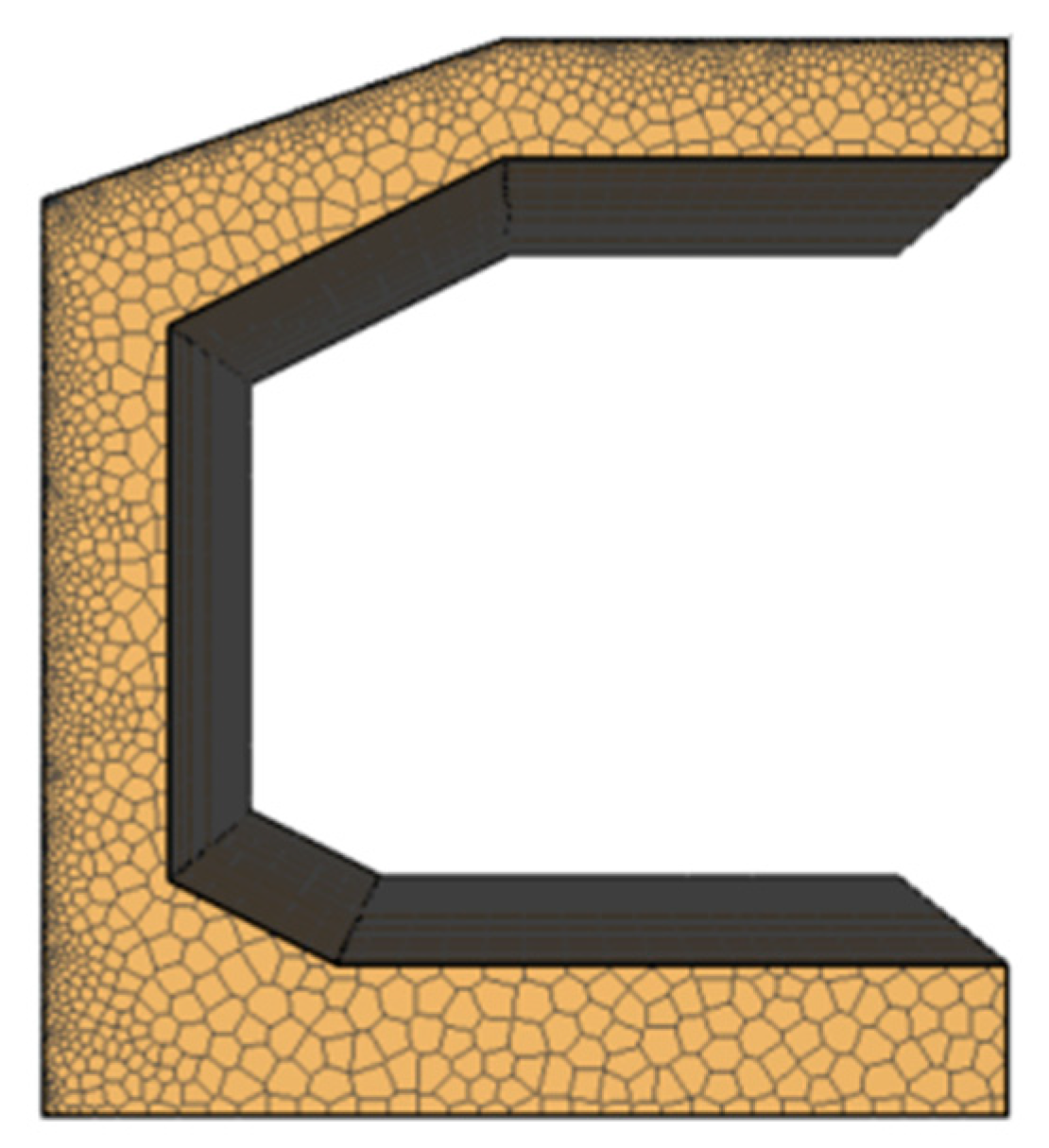

5.2. Numerical Simulation

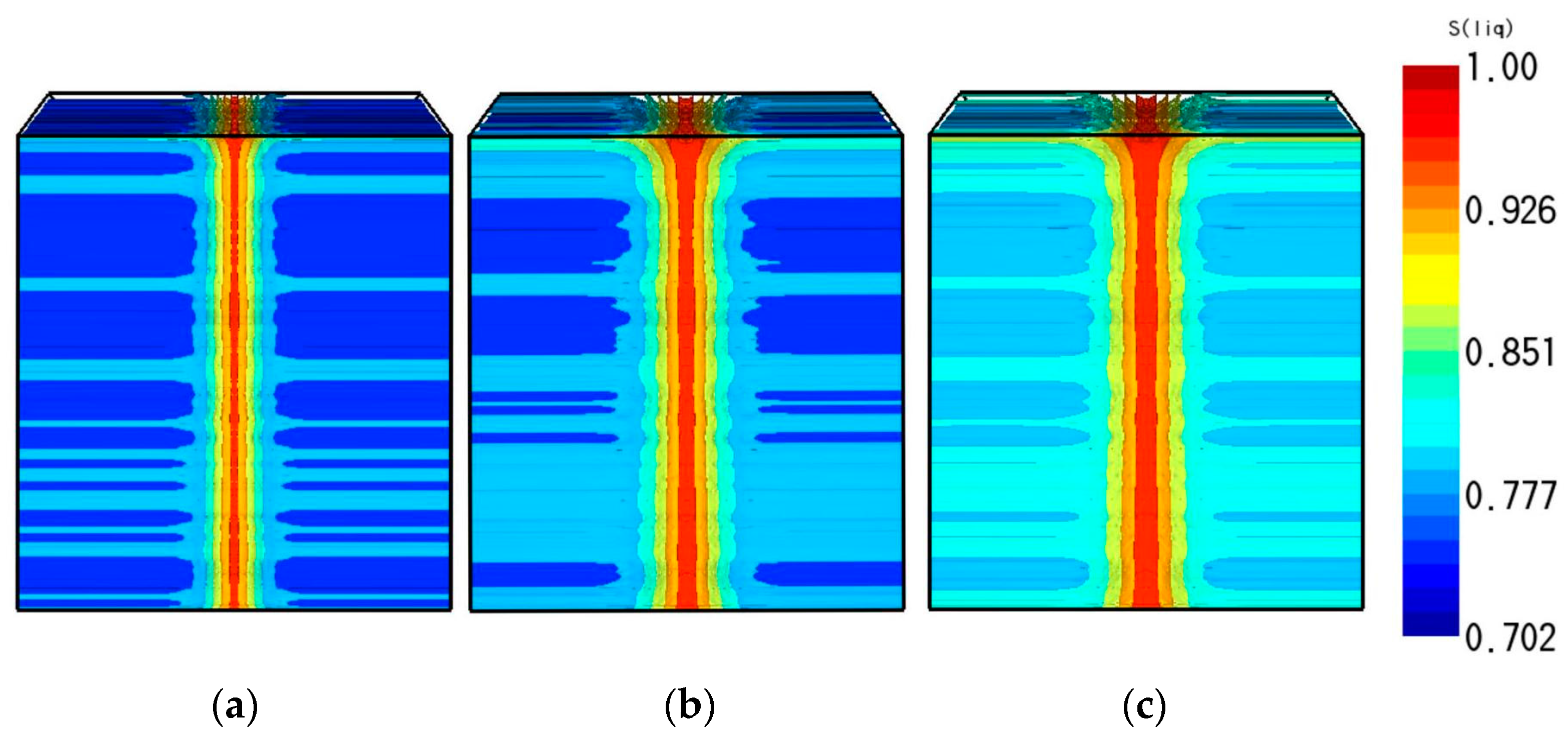

5.3. Result Analysis

6. Conclusions

- (1)

- The geometric shape of water seepage is influenced by the form of defects. Both point leaks and line leaks have symmetric distributions, with the former approximating a circular shape and the latter approximating an elliptical shape. Compared to point leakage, the permeability coefficient at the crack is larger, manifested by a higher initial water flow rate at the ends of the crack. Therefore, the wet area of line leakage is larger than that of point leakage in the same time period.

- (2)

- Indoor experiments have shown that both external water pressure and crack width increase the permeability of concrete and the wet area of the lining. Under similar conditions, an increase in external water pressure from 0.1 MPa to 0.4 MPa can result in a 2–3 times increase in wet area, while an increase in crack width from 0.1 mm to 1 mm can lead to a 3–5 times increase in wetted area. Within 72 h, the growth of wet area over time shows a linear relationship with water pressure and follows the cubic law with crack width. The numerical model of unsaturated concrete established using TOUGH2 shows consistent trends with experimental results in terms of wetted area variation with water infiltration time, external water pressure, and crack width. Additionally, the numerical values of wet area are also close to the experimental results. Therefore, TOUGH2 numerical simulation can be used for predicting the wetted area of tunnel linings, providing assistance in assessing their durability.

- (3)

- The harm caused by line leakage is greater than that of point leakage. Using TOUGH2 to predict the time for the wet area of the Shenjiamen Port Subsea Tunnel project to reach critical value after cracks within engineering specifications occur, it takes about 110 days for a 0.1 mm crack width and about 95 days for a 0.2 mm crack width. Once the limit value is exceeded, remedial measures are necessary. For now, this approach is limited. The scope of water leakage prediction is limited to the defect that the evaluation system based on the wet area has a relatively regular shape under constant water pressure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, C.; Zhang, D.; Zhang, S. Characteristics and treatment measures of lining damage: A case study on a mountain tunnel. Eng. Fail. Anal. 2021, 128, 105595. [Google Scholar] [CrossRef]

- Chun-Qing, L.; Hassan, B.; Shangtong, Y. Probabilistic study on hydraulic conductivity of concrete at meso-scale. ACI Mater. J. 2018, 115, 717–725. [Google Scholar]

- Chen, J.; Zhou, M.; Zhang, D.; Huang, H.W. Quantification of water inflow in rock tunnel faces via convolutional neural network approach. Autom. Constr. 2021, 123, 103526. [Google Scholar] [CrossRef]

- Li, Z.; Huang, H.; Zhou, M.; Zhang, D. Failure responses of rock tunnel faces during excavation through the fault-fracture zone. Undergr. Space 2023, 10, 166–181. [Google Scholar] [CrossRef]

- Wang, X.; Fan, F.; Lai, J.; Xie, Y. Steel fiber reinforced concrete: A review of its material properties and usage in tunnel lining. Structures 2021, 34, 1080–1098. [Google Scholar] [CrossRef]

- Gong, C.; Wang, Y.; Peng, Y.; Ding, W.; Lei, M.; Da, Z.; Shi, C. Three-dimensional coupled hydromechanical analysis of localized joint leakage in segmental tunnel linings. Tunn. Undergr. Space Technol. 2022, 130, 104726. [Google Scholar] [CrossRef]

- Liu, D.; Wang, F.; Hu, Q.; Huang, H.; Zuo, J.; Tian, C.; Zhang, D. Structural responses and treatments of shield tunnel due to leakage: A case study. Tunn. Undergr. Space Technol. 2020, 103, 103471. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, Z.; Yang, W.; Lin, C.-J. Model test and numerical simulation research of water leakage in operating tunnels passing through intersecting faults. Tunn. Undergr. Space Technol. 2019, 94, 103134. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Z.; Wang, J.; Cohn, A.G. Defect segmentation: Mapping tunnel lining internal defects with ground penetrating radar data using a convolutional neural network. Constr. Build. Mater. 2022, 319, 125658. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Li, C.C.; Huang, B. Case studies of groundwater flow into tunnels and an innovative water-gathering system for water drainage. Tunn. Undergr. Space Technol. 2009, 24, 260–268. [Google Scholar] [CrossRef]

- Jiang, Y.; Lai, W.; Bo, Z.; Dai, X.; Ye, J.; Sun, B.; Liu, N.; Wang, Z.; Zhao, Y. Tunnel lining detection and retrofitting. Autom. Constr. 2023, 152, 104881. [Google Scholar] [CrossRef]

- GB50108-2008; Technical Specifications for Waterproofing of Underground Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Plan Press: Beijing, China, 2008.

- Wu, C.; Huang, H.; Zhang, L.; Chen, J.; Zhou, M.; Tong, Y. Towards automated 3D evaluation of water leakage on a tunnel face via improved GAN and self-attention DL model. Tunn. Undergr. Space Technol. 2023, 142, 105432. [Google Scholar] [CrossRef]

- Tan, L.; Hu, X.; Tang, T.; Yuan, D. A lightweight metro tunnel water leakage identification algorithm via machine vision. Eng. Fail. Anal. 2023, 150, 107327. [Google Scholar] [CrossRef]

- Huang, H.; Sun, Y.; Xue, Y.; Wang, F. Inspection equipment study for subway tunnel defects by grey-scale image processing. Adv. Eng. Inform. 2017, 32, 188–201. [Google Scholar] [CrossRef]

- Xue, Y.; Cai, X.; Shadabfar, M.; Shao, H. Deep learning-based automatic recognition of water leakage area in shield tunnel lining. Tunn. Undergr. Space Technol. 2020, 104, 103524. [Google Scholar] [CrossRef]

- Feng, S.J.; Feng, Y.; Zhang, X.L.; Chen, Y.H. Deep learning with visual explanations for leakage defect segmentation of metro shield tunnel. Tunn. Undergr. Space Technol. 2023, 136, 105107. [Google Scholar] [CrossRef]

- Zheng, A.C.; He, Z.Y.; Li, J.Q.; Zhang, R.L.; Tan, B.X.; Huang, F. Experimental study on infrared characteristic recognition for water leakage of tunnel cracked lining. J. Southeast Univ. Nat. Sci. Ed. 2022, 52, 109–116. [Google Scholar]

- Fahmy, M.; Moselhi, O. Automated Detection and Location of Leaks in Water Mains Using Infrared Photography. J. Perform. Constr. Facil. 2010, 24, 242–248. [Google Scholar] [CrossRef]

- Han, L.; Chen, J.; Li, H.; Liu, G.; Leng, B.; Ahmed, A.; Zhang, Z. Multispectral water leakage detection based on a one-stage anchor-free modality fusion network for metro tunnels. Autom. Constr. 2022, 140, 104345. [Google Scholar] [CrossRef]

- Yang, W.; Li, C.; Baji, H. Design for service life of underground space based on water seepage criterion. Tunn. Undergr. Space Technol. 2019, 93, 103066. [Google Scholar] [CrossRef]

- Li, X.Z.; Zhang, Y.Z. Study on the chloride permeability in non-saturated concrete of subsea tunnel. Bull. Chin. Ceram. Soc. 2014, 33, 1929–1934. [Google Scholar]

- Edvardsen, C.K. Deterioration Modelling Model Verification Through In-Situ Tests Great Belt Link Tunnel (Demark); International Tunnelling and Underground Space Association: Prague, Czech Republic, 2004. [Google Scholar]

- Wang, K.; Jansen, D.C.; Shan, S.P. Permeability study of cracked concrete. Cem. Concr. Res. 1997, 27, 381–393. [Google Scholar] [CrossRef]

- Wang, L.; Bao, J.; Ueda, T. Prediction of mass transport in cracked-unsaturated concrete by mesoscale lattice model. Ocean. Eng. 2016, 127, 144–157. [Google Scholar] [CrossRef]

- Kong, X.Y. Advanced Seepage Mechanics; University of Science and Technology of China: Hefei, China, 2020; pp. 368–369. [Google Scholar]

- Zhang, Y.; Zhang, S.; Wei, G.; Wei, X. Water Transport in Unsaturated Cracked Concrete under Pressure. Adv. Civ. Eng. 2019, 2019, 4504892. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Test Methods for Mechanical Properties of Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Building Industry Press: Beijing, China, 2019.

- GB/T 50107-2010; Standard for Assessment of Compressive Strength of Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China; China Building Industry Press: Beijing, China, 2010.

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide, Version 2.0; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1999. [Google Scholar]

- Tran, A.P.; Dafflon, B.; Hubbard, S. iMatTOUGH: An open-source Matlab-based graphical user interface for pre- and post-processing of TOUGH2 and iTOUGH2 models. Comput. Geosci. 2016, 89, 132–143. [Google Scholar] [CrossRef]

- Moradllo, M.K.; Qiao, C.; Keys, M.; Becker, H.H. Quantifying Fluid Absorption in Air-Entrained Concrete Using Neutron Radiography. ACI Mater. J. 2019, 116, 213–226. [Google Scholar] [CrossRef]

- Tsuchiya, N.; Kanematsu, M.; Noguchi, T. Quick water movement around concrete cracks under unsaturated conditions. Constr. Build. Mater. 2014, 67, 95–99. [Google Scholar] [CrossRef]

- JTG H12-2015; Technical Specifications for Highway Tunnel Maintenance. Ministry of Transport of the People’s Republic of China: Beijing, China; China Communications Press: Beijing, China, 2015.

| Material | Gel Material | Sand | Gravel | Water | Water Reducing Agent | |

|---|---|---|---|---|---|---|

| Specifications | P.O 52.5 | Fly ash Grade-II | Middle sand | 5~10 mm (35%) | Tap water | Acid type |

| 10~25 mm (65%) | ||||||

| Dosage (kg/m3) | 456 | 44 | 640 | 1253 | 163 | 4.6 |

| Type | Specimen | P (MPa) | w (mm) | t (h) |

|---|---|---|---|---|

| Point leakage | BI | 0.1, 0.2, 0.3, 0.4 | 0 | 12, 24, 48, 72 |

| Line leakage | BII | 0.1, 0.2, 0.3, 0.4 | 0.1, 0.3, 0.5, 1.0 | 12, 24, 48, 72 |

| Parameter | Concrete | Leakage | |

|---|---|---|---|

| Triaxial permeability coefficient (m−3) | 1.0 × 10−19 | 1.00 × 10−13 (point leakage) | |

| 1.48 × 10−14 (w = 0.1 mm) | |||

| 1.33 × 10−13 (w = 0.3 mm) | |||

| 3.70 × 10−13 (w = 0.5 mm) | |||

| 1.48 × 10−12 (w = 1.0 mm) | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, L.; Zhang, Y.; Xu, K. Prediction of Wet Area of Underwater Tunnel Lining. Buildings 2024, 14, 408. https://doi.org/10.3390/buildings14020408

Lai L, Zhang Y, Xu K. Prediction of Wet Area of Underwater Tunnel Lining. Buildings. 2024; 14(2):408. https://doi.org/10.3390/buildings14020408

Chicago/Turabian StyleLai, Leyi, Yuanzhu Zhang, and Kuixin Xu. 2024. "Prediction of Wet Area of Underwater Tunnel Lining" Buildings 14, no. 2: 408. https://doi.org/10.3390/buildings14020408

APA StyleLai, L., Zhang, Y., & Xu, K. (2024). Prediction of Wet Area of Underwater Tunnel Lining. Buildings, 14(2), 408. https://doi.org/10.3390/buildings14020408