Abstract

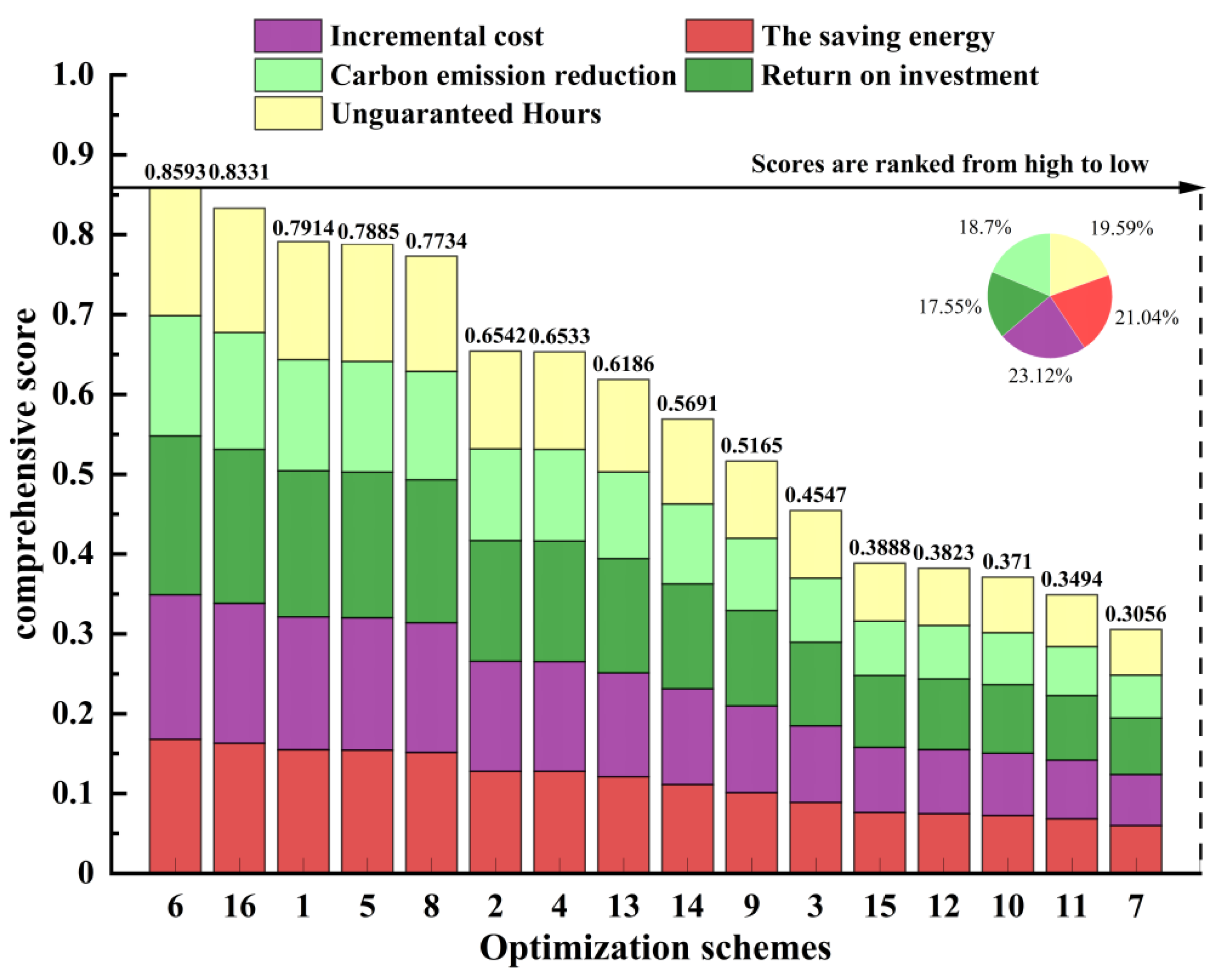

In the cold regions of China, the existing rural houses are widely distributed and in large numbers. There are widespread problems such as low thermal performance of building envelopes, high building energy consumption, and poor indoor thermal environments. Reducing the energy consumption of building heating by reforming the envelope structure can reduce the environmental pollution caused by heating. In this paper, the existing rural houses in Tongchuan City, Shaanxi Province are taken as the research object, and EnergyPlus software is used to calculate building heating energy consumption, and the schemes are compared and selected via the entropy value method. Based on a comprehensive benefit evaluation, the best scheme for the renovation of building envelopes of rural houses in Tongchuan City is put forward. The research results show that the energy saving rate of buildings can reach more than 50% after renovation. In the evaluation of energy saving, incremental cost, return on investment, carbon emission reduction and unguaranteed hours, the weights are 0.1915, 0.2104, 0.2312, 1755, and 0.187, respectively. The best renovation scheme for rural housing is as follows: the thickness of the XPS board is 90 mm for exterior wall insulation; the thickness of the XPS board is 80 mm for roof insulation; the window-to-wall ratio of additional sunspace is 0.6; and the type of exterior windows is a broken-bridge hollow aluminum window of 6 + 12A + 6 (mm).

1. Introduction

Buildings, especially those located in cold regions, are the main source of energy consumption and environmental pollution in the world, accounting for about 40% of total global energy consumption and at least 30% of greenhouse gas emissions [1]. In cold rural regions of China, due to the low thermal performance of building envelope structures, residents use a large amount of coal for heating during the heating season, resulting in serious environmental pollution and carbon emissions [2]. The existing rural houses are self built by residents and have a long history. During the construction process, economic costs are considered, resulting in poor insulation performance of rural houses’ envelope structures and the exacerbation of energy waste during the heating season. Therefore, it is necessary and urgent to conduct a comprehensive evaluation study on the trade-off between carbon emissions and indoor thermal comfort and cost-effectiveness. In order to reduce the environmental pollution and energy consumption in the heating season in rural areas, the building envelopes of rural houses must be modified [3,4].

In many countries, building energy-saving renovation has received high attention, as it can reduce energy consumption and greenhouse gas emissions and to some extent, reduce the impact of adverse weather conditions [5]. Many scholars have studied the energy-saving renovation of rural houses and have achieved certain results [6]. Jianen Huang et al. [7] established a thermal performance optimization model for building envelope structures using existing residential buildings as an example and determined that the energy-saving rate of insulation materials ranges from 0.53% to 73.59%. Xinxin Zhang et al. [8] conducted a renovation of old city buildings in Beijing and calculated and analyzed the energy consumption of winter heating and domestic hot water supply before and after the renovation. The results showed that the insulation performance of building envelope structures was a key factor affecting the energy consumption of old city buildings, and the energy-saving rate of the renovated buildings could reach 65.53%. Semperini G et al. [9] calculated the energy consumption of a large number of existing residential buildings in Bologna, analyzed a large number of possible ways to renovate enclosure structures, and provided feasible solutions for achieving near zero energy building technology. A large amount of literature has proven that renovating existing buildings can improve building energy efficiency and reduce energy waste [10,11,12]. Through the renovation of existing buildings, the thermal insulation and heat insulation performance of buildings can be improved and the energy consumption of buildings can be reduced, thus reducing the dependence on fossil fuels and reducing carbon dioxide emissions, which not only help to reduce energy costs but also have a positive impact on the environment in line with the concept of sustainable development.

A commonly used renovation method is to improve the material properties of the building envelope (external walls [13], roofs [14], windows [15], etc.) to reduce heat transfer to achieve the effect of indoor thermal insulation. This construction process is short, simple, and effective. Compared with other renovation methods such as demolition and reconstruction, it does not need a large-scale construction team and equipment, which can not only shorten the transformation time and reduce the transformation cost but also reduce the impact on the surrounding environment and residents. Lili Zhang et al. [16] studied the significant impact of adding insulation materials to the envelope structures of external walls on the cumulative annual heat load. Compared to not using insulation materials, the heat load per unit area can be reduced by about 30%, and the total load can be reduced by 5%. Daouas N [17] studied the climate characteristics of Tunisia and pointed out that one of the most effective measures for retrofitting the envelope structure is roof insulation. The most economical retrofit method is the hollow clay-based roof with rock wool insulation, which saves 58.06% of energy consumption. In the renovation of envelope structures, the methods of external wall and roof renovation are similar and involve mostly adding insulation materials to improve the insulation effect. The thickness of insulation materials also affects the insulation effect, and many scholars have also studied the optimal thickness of insulation materials. Pengfei Jie et al. [18] established an optimization model for the optimal thermal insulation thickness of existing building walls and roofs and optimized the optimal thickness of thermal insulation materials for walls and roofs in the process of building envelope renovation according to primary energy consumption, global costs, and pollutant emissions. Jinghua Yu et al. [19] studied the renovation methods of different residential roofs in hot summer and cold winter cities in China based on life cycle cost analyses of four typical cities. They analyzed the optimal thickness of four insulation materials, including expanded polystyrene, extruded polystyrene, foamed polyurethane, and foamed polyvinyl chloride. For the renovation of external windows, it is generally recommended to directly replace the window type and choose windows with better functions and high insulation performance [20]. Regarding the two renovation methods of applying insulation film to external windows and adding insulation curtains, the former is prone to cracking in summer due to high temperatures and falling off in rainy seasons due to high humidity; the latter method using insulation curtains is prone to getting dirty during use, and each cleaning reduces the insulation performance of the insulation curtains. Yuan Li et al. [21] proposed a novel three-layer vacuum glass water-flow window that combines the advantages of windows with water as a medium and vacuum glass. Based on research, the application of vacuum gaps is very effective in reducing heat flow through windows. In cities with typical cold and hot summers and warm winter climates, the indoor heat obtained through windows can be reduced by 43%, 44%, and 42% during refrigeration operation. In climates with low ambient temperatures and high heating demands, the benefits of using warm water and vacuum gap insulation for active heating are more significant. Marina Aburas et al. [22] found that the energy performances of thermochromic windows in different cities using the same film type varies greatly—up to 73.4%; But the differences between different film types used in the same city are much smaller—up to 21.6%. Dong Li et al. [23] added phase change materials to glass units, which can absorb some solar radiation for thermal energy storage, thereby reducing temperature fluctuations and improving the thermal comfort of indoor occupants.

Another effective renovation method is to use passive solar energy technology [24,25,26]. Passive solar energy technology has three forms of utilization, which can be divided into direct benefit type [27], Trombe wall type [28], and additional sunshine room type [29,30]. Additional sunshine rooms are the most suitable choice for rural residential buildings because they are easy to build and low cost [31,32]. Additional sunshine room refers to adding the light structure of the sunshine room to the south side of farm houses. It takes advantage of the region’s abundant solar energy resources to help reduce greenhouse gas emissions and thus reduce environmental pollution. And some scholars have investigated it and verified its feasibility [33,34]. By separating outdoor and indoor spaces through additional sunshine rooms, the lower outdoor temperature is buffered through the additional sunshine room. The additional sunshine room refers to an auxiliary space constructed on the outside of a building using transparent materials such as glass [35]. This space is equivalent to adding buffer space between indoors and outdoors, reducing the direct heat exchange between the external climate environment and the building body, reducing indoor heat dissipation, and achieving the insulation effect [36]. Lili Zhang et al. [37] analyzed a representative Tibetan Buddhist house with solar space in Gannan, assessed the thermal comfort of the building, and ranked the impact of building orientation, additional sunspace depth, glass type, external wall and roof insulation type and thickness, and wall and roof thickness in terms of thermal comfort and energy consumption through sensitivity analysis and numerical simulation, providing suggestions for the design of additional sunspace in this area. Lingyong Ma et al. [38] proposed an additional sunspace for rural residential buildings that uses PCM walls and silica gel aerogel glass to reduce indoor temperature fluctuations in cold regions. The results show that when the thickness of silica aerogel is 9 mm, it has the best performance in terms of the minimum energy saving rate and maximum indoor average temperature. Ana Vukadinović et al. [39] discussed the use of non-dominant sorting genetic algorithms to optimize the structure and building parameters of independent passive buildings with additional sunspace. The results indicate that when designing independent passive solar buildings with additional sunspace, the window-to-wall ratio is the most significant factor affecting energy performance in passive solar design. The opaque elements of the building envelope structures require appropriate insulation with thicker concrete or brick walls to achieve better solar gain. In order to find the optimal additional sunspace configuration, Murat Çağrı Uludaş et al. [40] integrated phase change materials into the partition wall between the additional sunspace and independent residential rooms. The results indicate that the optimal phase change material is located in the front of the partition wall, Compared to the situation without additional sunspace, the optimal configuration reduces CO2 emissions by 98 kg. The additional sunspace has the function of collecting and storing heat, which can effectively ensure heat storage. As an indoor and outdoor buffer zone, it effectively reduces the direct heat loss caused by the opening and closing of doors and windows. It provides space for air drying clothes and additional activity and is more suitable for rural housing.

However, most researchers consider renovation schemes to only change the insulation performance of the exterior wall and roof, and there are few comprehensive renovations to the building envelope and the use of passive solar technology. In recent years, the economic situation of residents has also affected the decision-making related to schemes, which thus has strong subjectivity and limitations. Especially for existing rural houses, residents are not willing to temporarily move during the renovation and do not want their normal life to be affected because of the renovation. So, when residents choose the best renovation scheme based on a single index (such as economic cost), there is a lack of comprehensive benefit evaluation of multiple indexes (such as energy saving, environmental protection, and comfort, etc.). It is difficult to reflect the comprehensive benefits of a renovation plan, and it cannot be regarded as the optimal solution for energy conservation and emission reduction. Few studies have considered the comprehensive benefits in the decision-making stage, especially for the combination of the building envelope and the use of passive solar technology. This combination scheme itself may become a difficulty and obstacle to an energy-saving design, so the comprehensive benefits cannot be optimally presented. Therefore, in order to overcome the subjective influence in the decision stage of the building envelope structure renovation scheme and evaluate the renovation scheme with a single index, this paper constructs a multi-index evaluation system based on comprehensive benefits to study the influence of each index on the renovation scheme. By determining the weight of each index, the best scheme is scientifically selected. This is to complement the current work and the shortcomings in the existing literature.

In this paper, a rural house in Tongchuan City, Shaanxi Province is taken as the research object. A variety of energy-saving renovation schemes for building envelopes based on the actual situation in rural areas is then designed. The EnergyPlus (V8-9-0) energy consumption software is selected to analyze the influence of material type and thickness of the exterior wall and roof insulation panels, different types of exterior windows, and window-to-wall ratio of additional sunspace on the building energy consumption. A comprehensive benefit evaluation of the economic benefits, energy saving benefits, environmental benefits, and comfort benefits is undertaken, and the best renovation scheme for existing rural houses in Tongchuan City is put forward.

2. Building Description and Research Methods

2.1. Natural Geographical Environment

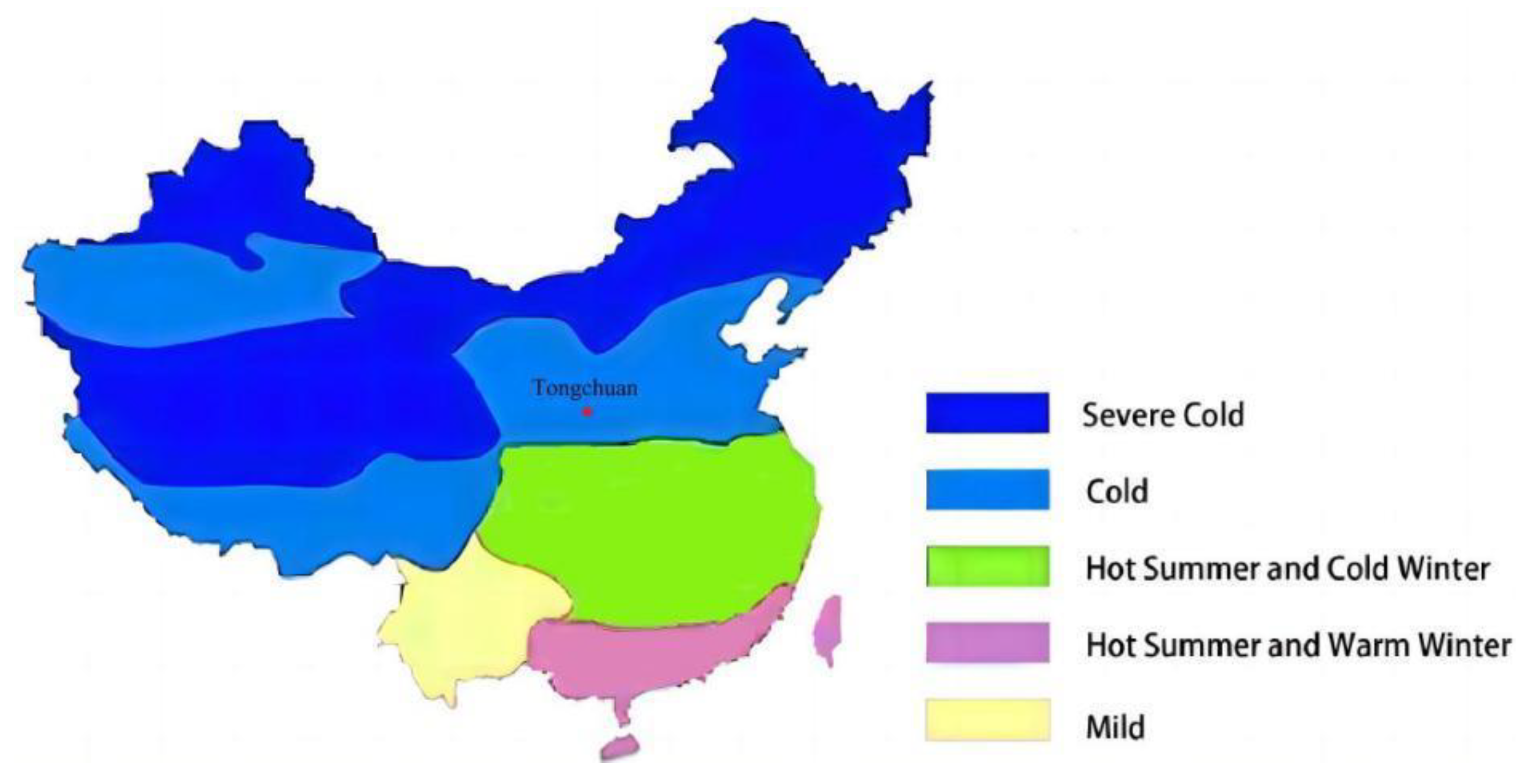

Tongchuan, Shaanxi Province, is located in a cold region with a longitude of 108.93 and a latitude of 34.90. The location of Tongchuan City on the climate map of China is shown in Figure 1, and it has warm temperate continental monsoon climate with four distinct seasons, long winters and short summers, obvious regional differences, and frequent disasters. Tongchuan has an average annual temperature of 8.9 °C, and the winter lasts from November to March. The countryside is located in a mountainous area with high terrain. The average temperature in winter is −7 to 6 °C, and the average temperature of the cold month of the year (January) is lower than −7 °C. The day and night temperature difference is large. The average winter solar radiation is 125.8 kcal/cm2.

Figure 1.

Climate regions map of China.

2.2. Heating Situation

The winter heating period in Tongchuan City is from November 15 to March 15 of the following year. There is no central heating in rural houses, and self-heating is mainly used. Due to limited conditions and in order to save, room heating is usually undertaken. The main heating rooms are bedrooms and living rooms. Based on actual research and visits to residents, it was found that local heating is mainly based on coal stoves and fire kang. Coal stoves are generally located in the living room. Due to the limited range of thermal radiation, only the temperature around the coal stove is high, and if not fully burned, it produces a lot of harmful gases. Although the fire kang in the bedroom can only maintain the temperature on the kang, it is still the main heating method in the winter. The heating sources being used are still dominated by cheap and burnable bituminous coal, but it is mostly reformed later in a heating source treatment. According to the requirements of clean heating, an electric blanket is used instead, while the heating source in the living room is mostly changed to clean coal, electric heating plate, electric heater, air conditioning, etc. Although the local government has given clean coal subsidies, the villagers are not enthusiastic about using it because the burning resistance is not as good as bituminous coal. In addition, the power consumption of heating appliances is too high, and the villagers rarely use it. Therefore, the effect of heating source renovation on the local winter heating situation is not good. Poor heating effects are still the biggest problem of rural house heating in winter, and they have a certain impact on the quality of life of villagers in winter [41,42].

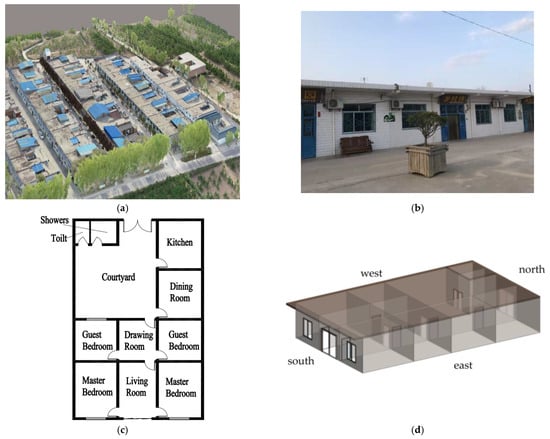

2.3. Benchmark Building Model

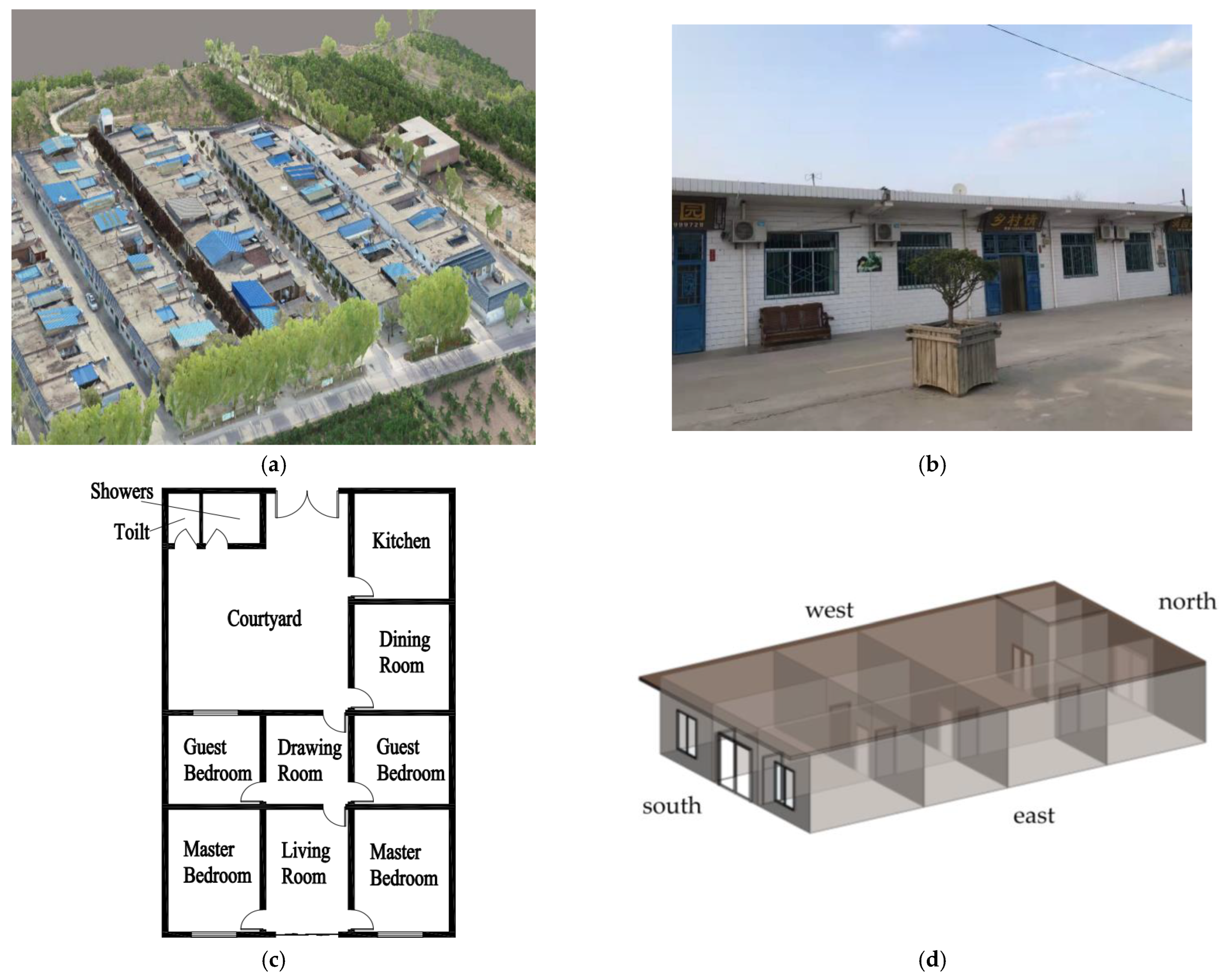

According to the field visit and investigation, the countryside is the new immigrant village in Tongchuan city in 2006, and the row bungalow building is one of the main architectural forms, with simple construction and well-defined in function. It mainly has a brick masonry structure, and more than 97% of the building exterior walls and the roof has no thermal insulation measures. Based on this, in this study, according to “Design standard for energy efficiency of rural residential buildings” (GB/T50824-2013) [43] and the current situation of existing farm houses in Tongchuan City, single farm houses were selected as the base building model; each house covers an area of 230 m2 with nine buildings in each row. There are eight town buildings with a total area of 16,560 m2. the renovation area of each main house is 115 m2, and the total renovation area of the main house in the village is 8280 m2. The aerial view of the aerial survey is shown in Figure 2a, the diagram showing the current state of the building is shown in Figure 2b, the benchmark building plan is shown in Figure 2c, and the benchmark building model is shown in Figure 2d.

Figure 2.

Aerial view of aerial survey (a), diagram showing the current state of the building (b), the benchmark building plan, (c) and the benchmark building model (d).

2.4. Rural House Envelope Situation and Building Load Statistics

According to the field visit and investigation, the construction method of the building envelope structure was obtained. According to the Standard Specification for “Design standards for energy efficiency of residential buildings in severe cold and cold zones” (JGJ26-2018) [44], the parameters of various materials are queried, and the corresponding heat transfer coefficients were calculated as shown in Table 1.

Table 1.

Construction method and corresponding heat transfer coefficients of envelope structure.

The winter heating rooms are the living room, drawing room, master bedroom, and guest bedroom. The heating time for the drawing room and the living room is 8:00–18:00 from Monday to Friday, and the rest of the time, they are closed. There is no heating of the master bedroom and guest bedroom from Monday to the weekend from 8:00 to 18:00, and the remaining time, they are heated.

2.5. Research Methods

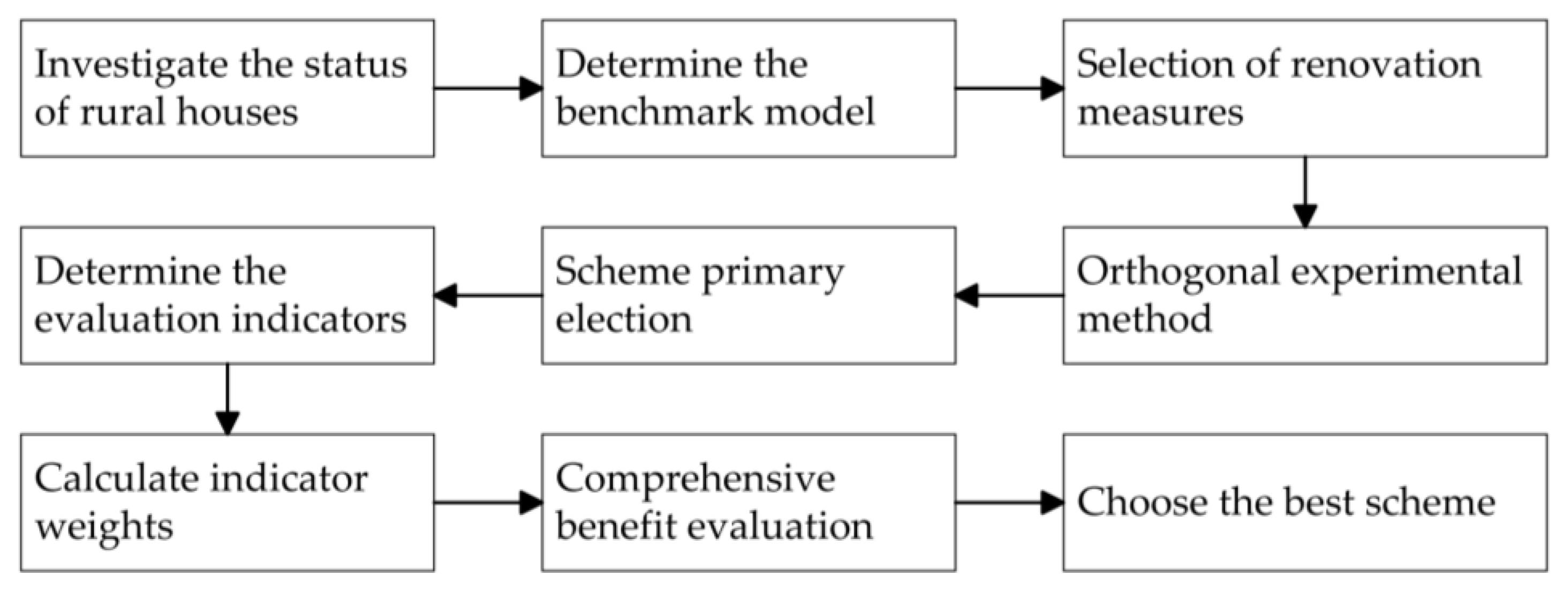

In order to study the relationship between the energy-saving renovation scheme of the envelope structure and the heating energy consumption of rural houses and to optimize the energy-saving renovation scheme under the influence of multiple indexes, the research in this paper is carried out from the following three aspects. (1) The typical building benchmark model is selected to study four kinds of single envelope structure renovation schemes: external wall insulation, roof insulation, replacement of external windows and window-to-wall ratio of additional sunspace. External wall insulation and roof insulation selection of commonly used insulation materials and insulation board thickness. The exterior window size of a rural house is difficult to change, and only replacing the exterior window structure type is possible without changing the size. Additional sunspace selection of commonly used insulation materials and window-to-wall ratio is undertaken. (2) The orthogonal test of four factors and four levels is carried out to form 16 kinds of alternatives for the renovation of the rural house envelope structure, and the primary selection of various renovation schemes of the envelope structure is carried out, using the EnergyPlus software to simulate the energy consumption. (3) With full consideration of the comprehensive benefits, the energy saving, incremental cost, return on investment, carbon emission reduction, and unguaranteed hours are selected as the evaluation indexes. The weights of different evaluation indexes are determined, the comprehensive score of each scheme is calculated, the comprehensive benefit evaluation by entropy method is applied, and the best renovation scheme is selected. The steps of the research method are shown in Figure 3.

Figure 3.

Process of the study methods.

2.5.1. Simulation Study Tools

This paper uses EnergyPlus energy consumption software, which can simulate room temperatures in the natural state of a building, the building thermal characteristics index, and the heat load of a building during the heating period. So far, a large number of case studies and theoretical validations have been carried out. Therefore, EnergyPlus has become a widely used platform for calculating building thermal processes and dynamically simulating building energy distribution [45,46].

According to the actual state of the building, the geometric size of the building, material properties, and other information to build the model are inputted. In the simulation process, local meteorological data, including outdoor temperature, solar radiation, etc. are inputted. According to the use requirements and load characteristics of the building, the load parameters of the building, such as personnel density, equipment power, etc. are set. When the simulation program is run, the software will calculate the building energy consumption, room temperature, and other data based on the input parameters and models. The simulation results to obtain the farm house heating heat load statistics are shown in Table 2.

Table 2.

Building heating heat load simulation statistical table.

As seen from the results in Table 2, the heat load index for the heating season for a rural house in winter is 50.25 W/m2. The limit value of the heating consumption index of residential buildings in Tongchuan City is 13.4 W/m2 (≤3 floors) in the engineering construction standards of “Design standard for energy saving of residential buildings” (DB61/T 5033-2022) [47], and the over standard rate is as high as 73.33%. It can be seen that compared with the current energy consumption index of urban residential buildings, the existing rural residential buildings in Tongchuan City have higher energy efficiency improvement potential and renovation value.

2.5.2. Orthogonal Experiment and Design

The orthogonal test uses a neatly arranged orthogonal table to carry out overall design, comprehensive comparison, and statistical analysis of a test and to study the effect of multiple factors and levels on a test [48,49]. Orthogonal tables can balance sampling in a range of factor changes, thus reducing the number of experiments and making each trial more representative, which are often better or better in terms of achieving the purpose of the trials.

2.5.3. Entropy Value Method

The entropy value method is an objective weighting method, and its biggest feature is to directly use the information given by the decision matrix to calculate the weight. The deviation caused by subjective factors is not introduced, which makes the evaluation results more scientific and reasonable, and it has guiding significance for multi-scheme comparison and selection [50]. In the process of determining the weight coefficient, the entropy value method avoids the interference of human factors and can objectively reflect the importance of each evaluation index in the comprehensive evaluation index system. Therefore, the entropy value method is widely used in various disciplines [51]. The mathematical model of the entropy value method is as follows:

For the renovation of the envelope structure of the Tongchuan rural house, n (1, 2, …, i) renovation schemes and m (1, 2, …, j) evaluation indexes were determined.

- (1)

- Data standardization, that is, the absolute value of the index, is converted into relative values, as shown in Formulas (1) and (2).After data standardization, the original data matrix is constructed, as shown in Formula (3).

- (2)

- The ratio of each index under each scheme is shown in Formula (4).

- (3)

- The information entropy of each index is shown in Formula (5).

- (4)

- Information entropy redundancy is determined as shown in Formula (6).

- (5)

- The weight of each index is determined as shown in Formula (7).

- (6)

- The composite score is calculated as shown in Formula (8).

In this paper, according to the characteristics of 16 kinds of renovation schemes, the indexes of each scheme are calculated, and the entropy value method is used to objectively find weight. The comprehensive scores of each scheme are calculated respectively, and the best renovation scheme for envelope structures is selected.

3. Optimization Analysis of Retrofit Scheme

3.1. Renovation Method and Calculation Method

Rural house renovation methods are usually exterior insulation, roof insulation, replacement of exterior windows, and the use of solar energy additional sunspace. According to the field visit and investigation, the deficiencies of Tongchuan rural houses in terms of building energy efficiency improvement are mainly reflected in the lack of necessary energy-saving design for envelope structures, and the failure of thermal performance to meet the requirements of relevant standards and specifications, which is also the main reason for serious indoor heat loss in winter. The technical focus of energy efficiency improvement of rural houses in Tongchuan City lies in the energy-saving design of building envelopes and additional sunspace.

The calculation of the building energy saving rate is mainly based on energy consumption simulation. The heating energy consumption of the building after renovation is simulated by software and then compared with the original heating energy consumption calculation. The calculation formula of the energy saving rate is as follows:

where is the energy saving rate (%), is the heating energy consumption of the original buildings (kW·h), and is the heating energy consumption of the building after the renovation (kW·h).

There are many kinds of thermal insulation materials. In addition to thermal insulation performance, thermal insulation materials used in rural areas should also take into account the characteristics of local materials, ecological environmental protection, and a mature thermal insulation technology system. The selection of exterior wall and roof insulation materials needs to consider not only the above factors but also the market price. The common thermal insulation material properties and prices are shown in Table 3.

Table 3.

The common thermal insulation material properties and prices.

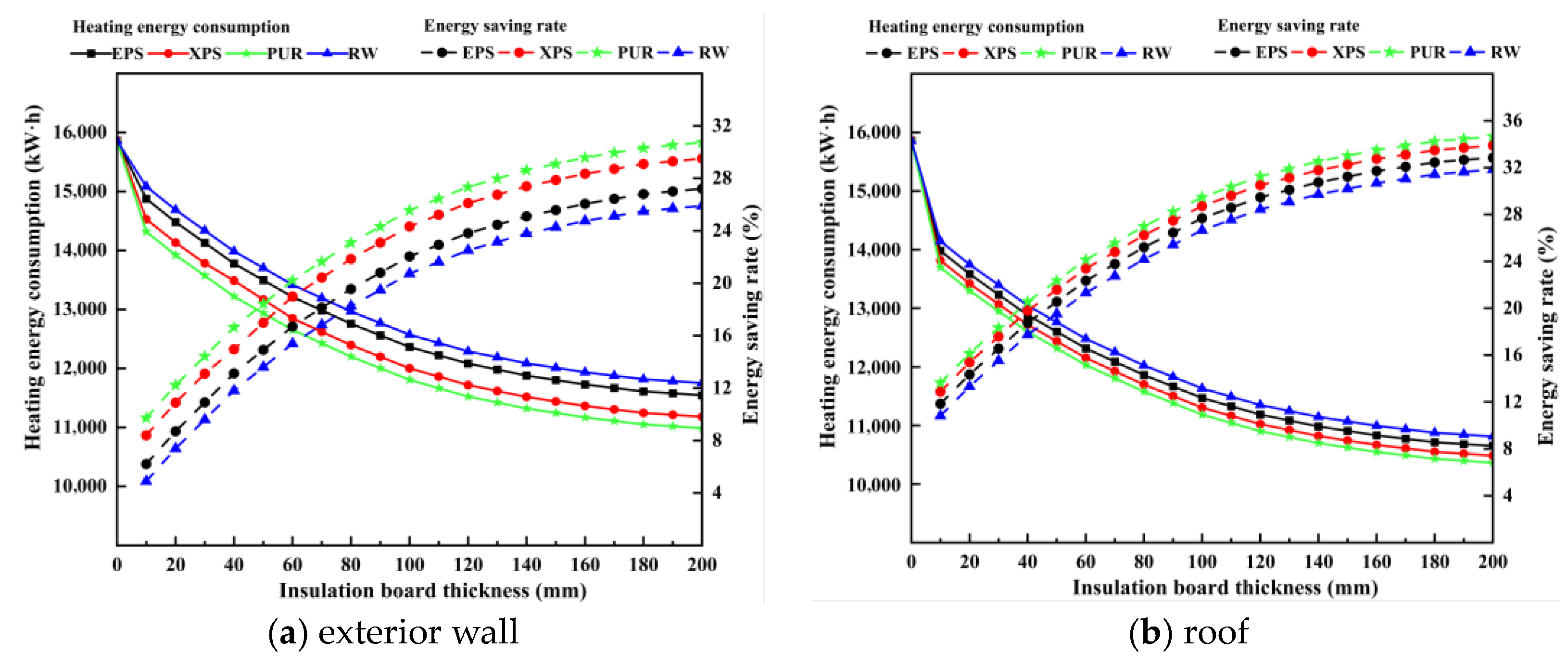

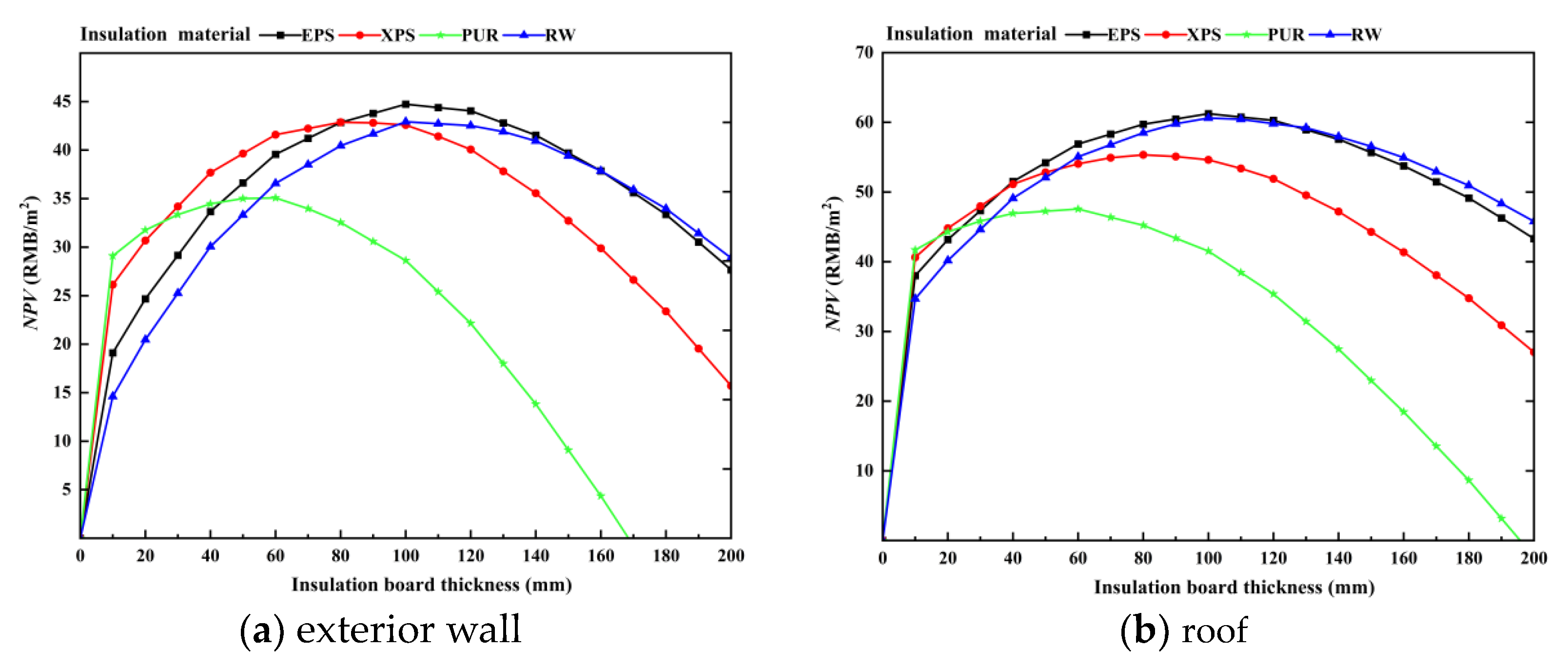

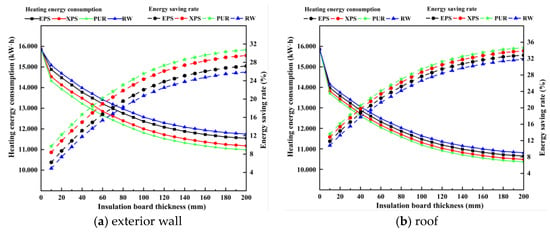

A single variable method is adopted to change the thickness of external wall and roof insulation materials, from 10 mm to 200 mm, with 10 mm as the spacing length, and 20 groups of schemes are set. The EnergyPlus energy consumption software is used to simulate the change of heating energy consumption and energy saving rate of the exterior wall and roof with different materials and thicknesses, as shown in Figure 4.

Figure 4.

Changes in the heating energy consumption and energy saving rate of external walls and roofs of different materials and thicknesses.

It can be seen from Figure 4 that the four kinds of thermal insulation materials can significantly reduce the heat transfer coefficient of the exterior wall and roof after renovation, indicating that the renovation can significantly improve the thermal performance and reduce the heat transfer of the wall and roof. The thickness of the insulation board is proportional to the energy saving rate. Among the insulation materials of the same thickness, the insulation effect ranges from superior to inferior as follows: PUR > XPS > EPS > RW. With the increase of the thickness of thermal insulation material, the energy consumption of building heating is greatly reduced first, then the reduction of building heating energy consumption tends to be flat, and the energy saving effect on the building is gradually weakened. When the exterior wall insulation material thickness is 10–100 mm, as the thickness increases, the energy saving rate increment gradually decreases. When the insulation material thickness is over 100 mm, the energy saving rate increment is less than 1% and the curve gradually tends to level, illustrating that the thickness of the exterior wall and roof insulation material on building heating energy consumption has a certain limit in terms of energy saving. Renovation should not simply improve the building energy saving rate, and when the insulation board reaches the optimal thickness, if you want to continue to reduce energy consumption, the other building envelope should be considered.

With the increase of the thickness of the insulation material, the cost of the corresponding investment will gradually increase, and the energy saving income will be lower than the thickness investment increment, resulting in the income not being proportional to the investment of the renovation capital. Therefore, selecting an appropriate insulation material thickness can give full play to the material properties while reducing the excessive cost input. The net present value (NPV) in the economic model is used to optimize the thickness of each insulation material of the external wall and roof, and the cost performance of each insulation material is studied. The net present value method indicates the return capacity of the renovation. By calculating the difference between the energy saving benefit and the investment cost of energy saving renovation after investment, the greater the net present value, the better the return of the renovation. The calculation formula is as follows:

where NPV is the net present value (RMB/m2), SCt is the building energy saving benefit in the t year of building renovation (RMB/m2), and IC represents the energy-saving renovation investment costs (RMB/m2). In this paper, the cost of thermal insulation material itself is set as the cost of the energy saving investment without considering the maintenance cost and construction cost. i is the social discount rate with a value of 5%, t indicates life years with the value of 25 years, is the saving energy for the heating energy consumption in the t-year of the building kW·h, Hc is the coal calorific value with a value of 8.14 kW·h/kg, n1 is the thermal efficiency of pipe network with a value of 0.92, n2 is the boiler operation efficiency with a value of 0.68, S is the thermal insulation project area (m2), h is the heat preservation material thickness, m, Pt is the unit price of standard coal with a value of 920 RMB/t, and Ci is the unit volume of thermal insulation material price (RMB/m3).

The NPV value of each insulation material is calculated according to the formula, and the results are shown in Figure 5.

Figure 5.

Changes in the net present values of external walls and roofs of different materials and thicknesses.

Since the energy consumption simulated by the EnergyPlus software is a discrete dispersion point, the curve fitting is performed by Matlab (r2019a), and Matlab is used to solve the optimal thickness h(op). The following formula is obtained from the relationship between the thickness and net present value of four insulation materials for the wall and roof, as shown in Table 4:

Table 4.

Net present value formulas of different thermal insulation materials.

As can be seen from Figure 4, the net present value grows rapidly in the early stage and decreases slowly in the later stage, mainly because the net present value is mainly affected by energy saving in the early period, the later net present value is mainly dominated by material prices, while the net present value in the middle is relatively flat, which is affected by both. In terms of comprehensive material price, it is recommended to choose 100 mm EPS, 90 mm XPS, 50 mm PUR, and 110 mm RW for external wall insulation materials, and 100 mm EPS, 80 mm XPS, 60 mm PUR, and 100 mm RW for roof insulation materials.

The EnergyPlus software is used to simulate changing the window-to-wall ratio of the additional sunspace and exterior window type, and the corresponding heating energy consumption and energy saving rate are shown in Table 5.

Table 5.

Material unit price and energy saving effect of different window-to-wall ratios of additional sunspace and exterior window type.

As can be seen from Table 5, the difference in the heating energy consumption of different external window types is small, but the heating energy consumption of different air layer thicknesses is large. After replacing the original aluminum alloy single-layer outer window, the heating energy consumption of the building is effectively reduced. As the window-to-wall ratio of additional sunspace increases, the heating energy consumption of rural house decreases, and the energy saving rate increases. But it is not the window-to-wall ratio that is the bigger the better, the range of needs of residents in the sun to be considered by taking into account the corridor, balcony, entertainment, and other functions. After the external window and the additional sunspace are structurally coupled, the renovation should be combined with other renovation measures. To sum up, the order of energy efficiency improvement effects of a single renovation scheme is roof renovation > external wall insulation > external window replacement > additional sunspace.

3.2. Analysis of Orthogonal Array Test Results

To improve the efficiency of scheme optimization, the orthogonal test method was used to initially select the scheme, and the analysis obtained the trend of influence, the secondary relationship, and the best collocation of the test results. The orthogonal test of four factors and four levels L16 (44) was performed a total of 16 times, among which the influence elements are as follows: select 100 mm EPS (A1), 90 mm XPS (A2), 50 mm PUR (A3), and 110 mm RW (A4) for the external wall insulation; select 100 mm EPS (B1), 80 mm XPS (B2), 60 mm PUR (B3), and 100 mm RW (B4) for the roof insulation; select 0.6 (C1), 0.7 (C2), 0.8 (C3), and 0.9 (C4) for the window-to-wall ratio of additional sunspace, select plastic steel hollow window 6 + 9A + 6 (mm) (D1) and 6 + 12A + 6 (mm) (D2) and broken bridge aluminum hollow window 6 + 9A + 6 (mm) (D3) and 6 + 12A + 6 (mm) (D4) for the external window type. The orthogonal combination tests based on the selected factors and levels are shown in Table 6.

Table 6.

Combination schemes of orthogonal test.

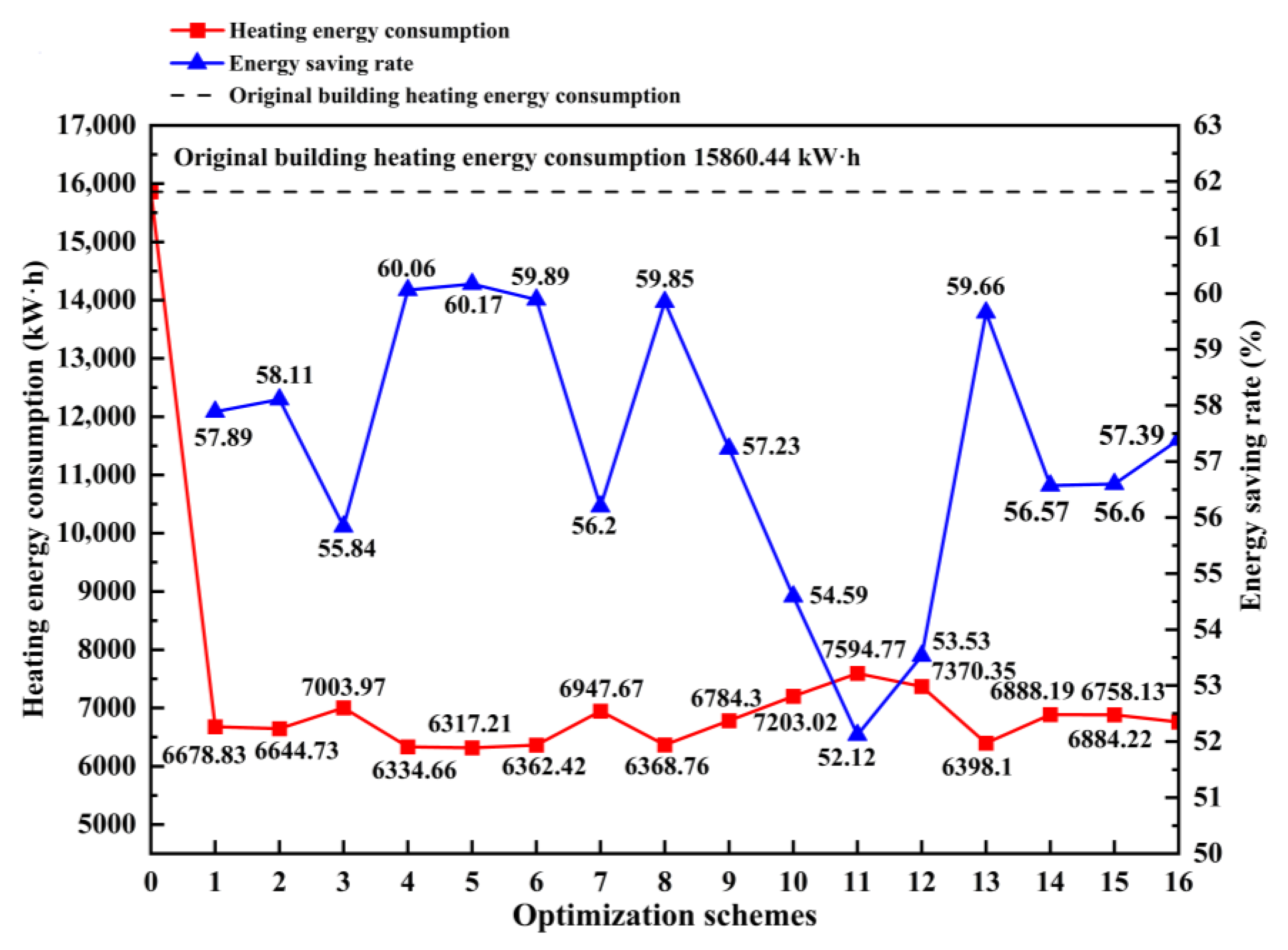

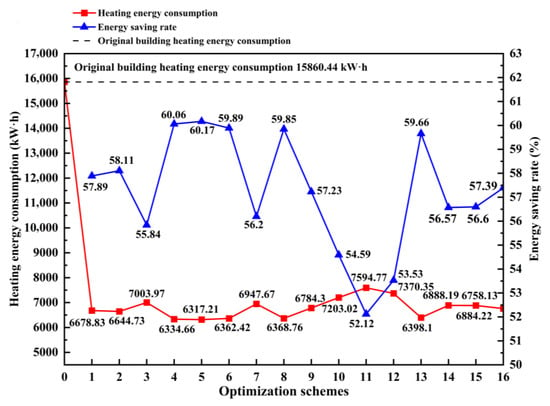

The heating energy consumption and energy saving rate of 16 schemes are obtained through the EnergyPlus software simulation, as shown in Figure 6.

Figure 6.

Heating energy consumption and energy saving rate of 16 schemes.

It can be seen from the calculation results in Figure 6 that the building energy saving rate of each combined energy-saving renovation scheme can reach more than 50%, indicating that the combined energy-saving renovation scheme can significantly reduce the heating energy consumption of rural houses and solve the problem of poor indoor thermal environments for residents. Among the 16 combined schemes, the maximum and minimum heating energy consumptions are 7594.77 kW·h for scheme 11 and 6317.21 kW·h for scheme 5, respectively, and the corresponding energy saving rates are 52.12% and 60.17%, respectively.

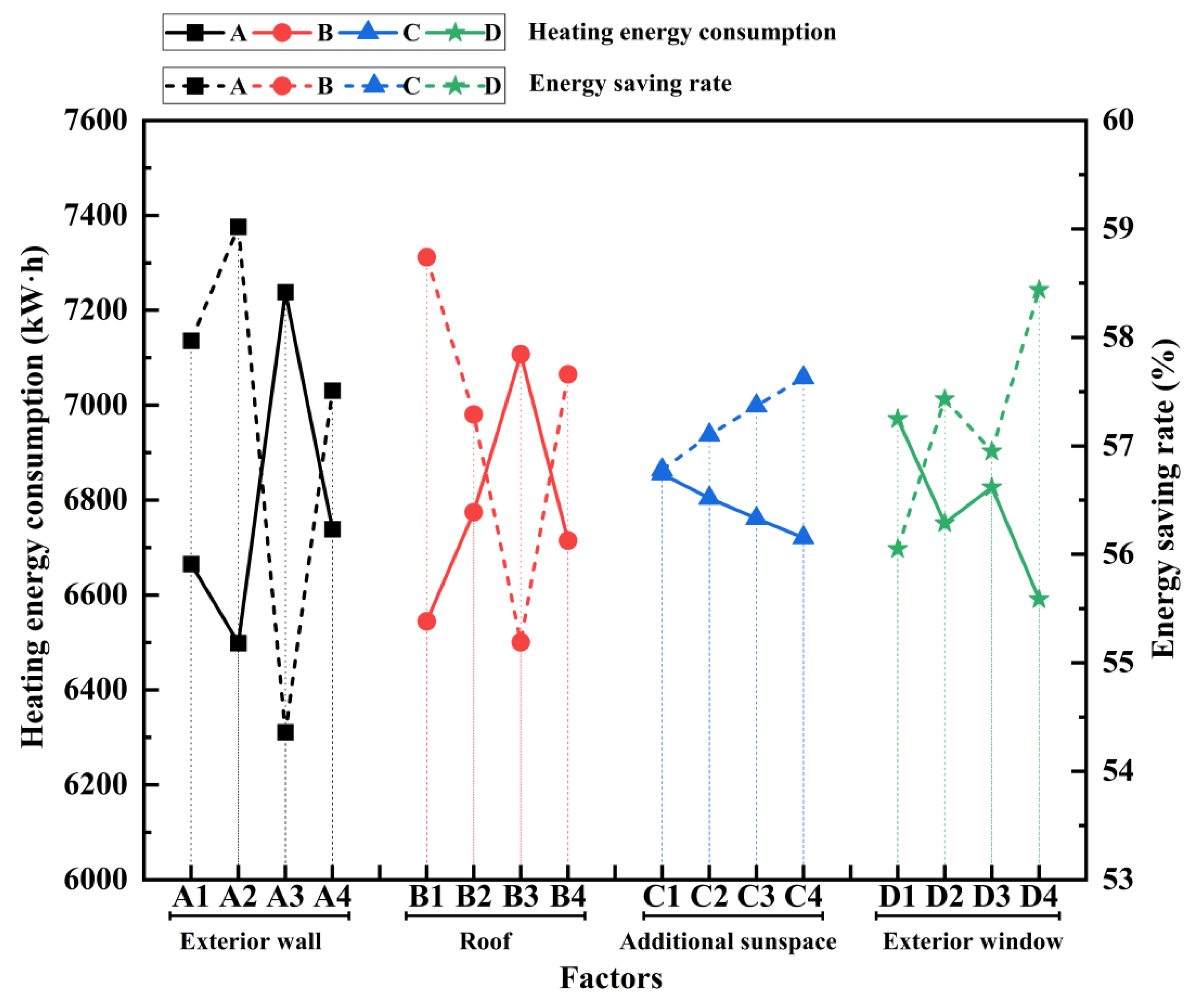

In order to measure the influence of various factors on the energy saving rate, considering the priority of each factor, a variance analysis is used to calculate the building energy consumption of the structural parameters of specific factors at different levels, and the calculated range, R, is used to analyze the influence degree of each factor weight. The impacts of factors A, B, C, and D on the energy saving rate are calculated and listed in Table 7.

Table 7.

Variance analysis of influence of different factors on building energy consumption.

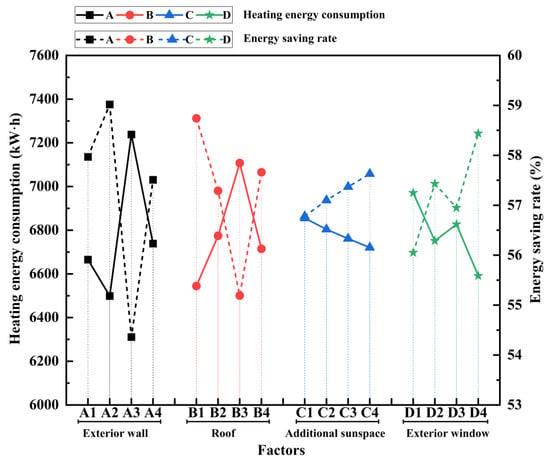

The influence of different factors on the heating energy consumption and energy saving rate is shown in Figure 7.

Figure 7.

The influence of different factors on heating energy consumption and energy saving rate.

According to Table 7 and Figure 7, the following can be seen from the heating energy consumption of the building: KA3 > KA4 > KA1 > KA2, which indicates that A2 (the thickness of the external wall insulation XPS board is 90 mm) is the optimal value of factor A; KB3 > KB2 > KB4 > KB1, which indicates that B1 (the thickness of roof insulation EPS board is 100 mm) is the optimal value of factor B; KC1 > KC2 > KC3 > KC4, which indicates that C4 (the additional sunspace window-to-wall ratio is 0.9) is the optimal value of factor C; KD1 > KD3 > KD2 > KD4, which indicates that D3 (external window is the broken bridge aluminum hollow window 6 + 12A + 6 (mm)) is the optimal value of factor D.

By comparing the range of heating energy consumption of the four factors, the optimal combination is A2B1C4D4 (that is, the thickness of the external wall insulation XPS board is 90 mm, the thickness of the roof insulation EPS board is 100 mm, the additional sunspace window-to-wall ratio is 0.9, and the external window is the broken bridge aluminum hollow window 6 + 12A + 6 (mm)). The results were obtained after the EnergyPlus software simulation: the heating energy consumption of this combined scheme is 6004.76 kW·h, and the energy saving rate is 62.14%.

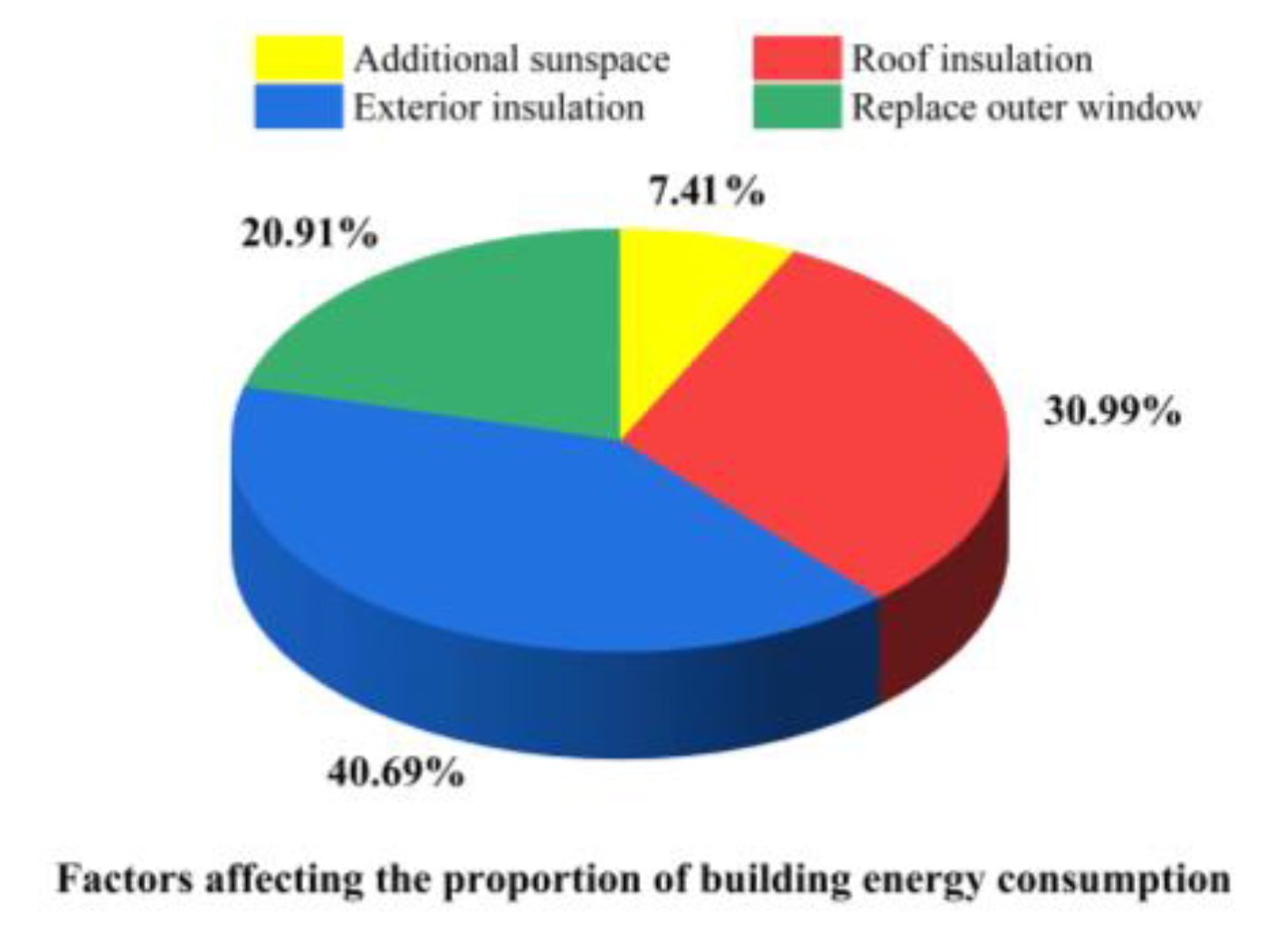

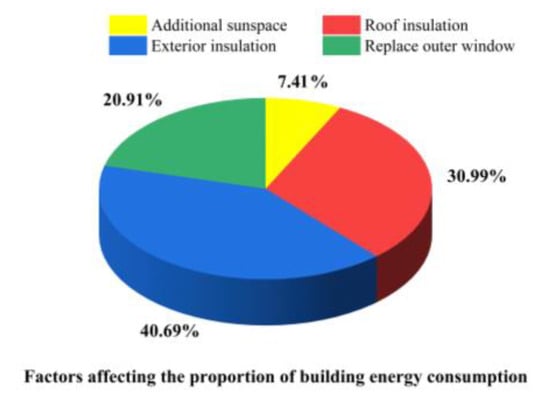

For the influencing factors of the heating energy consumption of rural houses, the range of the external wall is the largest, which is 739.19 kW·h, and the range of additional sunspace is the smallest, which is 134.458 kW·h. The order of range is as follows: R(A) > R(B) > R(D) > R(C), which indicates that when energy saving renovation of rural houses is carried out, first of all, we should consider insulation for the external wall and reduce the indoor heat transfer from the external wall. Secondly, we should consider insulation for the roof and replace the external window, and finally consider the impact of the window-to-wall ratio when replacing outer windows, as shown in Figure 8.

Figure 8.

The proportion of the significance of factors on building energy consumption.

The combination scheme with the highest energy saving rate was obtained via the orthogonal test, and the influence and proportion of 16 groups of schemes and various factors on the energy consumption of rural house buildings were compared, but the related indexes such as economy, environmental protection and comfort were ignored. Therefore, the combination scheme with the highest energy saving rate may not meet the requirements of other decision factors, meaning that considering only the energy saving rate factor is incomplete and inappropriate. In order to evaluate the comprehensive benefit evaluation of the building renovation schemes, this study aims to construct an evaluation system. The EnergyPlus software is used to simulate the energy consumption, and the materials with the best energy saving incomes are calculated through the net present value, so as to reduce the input costs of residents. The schemes affected by different factors are combined by orthogonal tests. First, the scheme with the highest energy saving rate in the combination scheme is evaluated, the influence of different renovation methods on the energy saving rate is compared, and then the comprehensive benefits of economic benefits, environmental protection benefits, energy saving benefits, and comfort benefits are evaluated using the entropy method—instead of just considering the highest energy saving rate to obtain an optimal renovation scheme. The comprehensive benefit evaluation process is described below.

3.3. Optimization Schemes Comparison

3.3.1. Optimum Indexes

In full consideration of economy, energy saving, environmental protection, and comfort, this paper selects five indexes including energy saving, incremental cost, return on investment, carbon emission reduction, and unguaranteed hours as the evaluation indicators for the optimization of the renovation schemes. The entropy value method is used to scientifically quantify the weight of each index in the decision-making of the building envelope renovation scheme, highlight the main contradictions of renovations, comprehensively evaluate different renovation schemes, and select the best renovation scheme suitable for the Tongchuan rural house. The calculation method for each evaluation index is as follows:

- (1)

- The amount of energy saving corresponding to the envelope structure renovation schemes is (kW·h), as shown in Formula (13).where Ea is the original building heating energy consumption, (kW·h), and Eb is the building heating energy consumption after renovation, (kW·h).

- (2)

- The incremental cost, C (RMB), of the building energy-saving renovation scheme includes the cost of thermal insulation material, labor cost, and mechanical cost. This paper determines the investment cost of the building envelope renovation and additional sunspace based on the national unified basic quota for building engineering and the consumption quota for building decoration engineering in Shaanxi Province, without considering the regional price difference. The incremental cost can intuitively show the specific costs of residents in the renovation process. Through the analysis of incremental cost, residents can understand the cost composition of the renovation project, including labor, material, equipment, etc. This helps residents to better understand the actual cost of the renovation project and assess its economic feasibility. When formulating comprehensive renovation plans for energy saving, residents can reasonably allocate funds according to the results of incremental cost analyses and give priority to the transformation of high-cost and low-energy saving projects, so as to obtain better energy saving effects. The prices of the selected materials are shown in Table 3 and Table 5.

- (3)

- Return on investment is the ratio of the incremental cost (C) to energy saving (). In the renovation scheme, the return on investment can be used to evaluate the cost effectiveness and cost performance of the scheme. If the return on investment of a renovation scheme is higher, it means that the investment benefit of the scheme is good, the investment cost can be recovered in a short time, and it can bring greater profits for investors. On the contrary, if the return on investment of a renovation scheme is low, it means that the investment benefit of the scheme is poor, it may take a long time to recover the investment cost, and it may not bring large profits for investors. Therefore, the return on investment can be used as an important basis to judge whether a renovation plan has feasibility and economic benefits. It can be used to judge the cost-effectiveness of a renovation scheme, indicating the cost performance of the scheme, as expressed by R (RMB/kW·h) in Formula (14).

- (4)

- For CO2 emission reduction—m (kg), see Formula (15).where m is the CO2 emission reduction (kg). After the renovation, residents reduced their carbon dioxide emissions from using coal for heating. Qa is the heat saved from the standard coal after the energy-saving renovation (MJ), Qb is the low heating value of standard coal with a value of 29,307.6 KJ/kg, is the boiler operation efficiency with a value of 0.68, and is the carbon dioxide emission factor with a value of 2.85.

- (5)

- Unguaranteed hours, UH (h)—indoor comfort is measured by the sum of unguaranteed hours, for which the annual indoor temperature is 14 degrees below the calculated temperature and above 30 degrees and is screened through the analysis results of the EnergyPlus software. It is unguaranteed that the smaller the hour value is, the better the renovation effect is.

3.3.2. Comprehensive Evaluation of Optimization Scheme

According to the Formulas (13)–(15), the indexes of 16 energy-saving retrofit schemes are calculated, and the calculation results are shown in Table 8.

Table 8.

Composite score table.

It can be seen from Table 8 that the maximum energy saving is 9543.23 kW·h, and the minimum is 8265.67 kW·h. The maximum incremental cost is 15,644.61 RMB, and the minimum is 12,766.31 RMB. The maximum carbon emission reduction is 4874.18 kg, and the minimum is 4221.67 kg. The maximum return on investment is 1.76, and the minimum is 1.4. The maximum unguaranteed hours is 4072 h, and the minimum is 3936 h. The maximum incremental cost of scheme 7 is 15,644.61 RMB, but the energy saving, return on investment, carbon emission reduction, and unguaranteed hours are ranked eleventh, first, fifth and ninth, respectively. This means that investing more incremental costs in the process of energy-saving renovations of building envelopes does not mean that it can bring greater energy saving and carbon emission reduction.

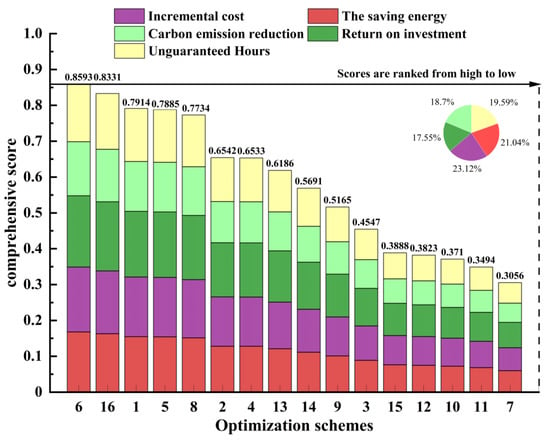

Therefore, using the entropy value method to study the weights of different indicators is of great significance for the analysis and comparison of optimization schemes. The comprehensive scores of different schemes are shown in Figure 9.

Figure 9.

Comprehensive score and ranking of optimization schemes.

4. Results and Discussion

By analysis with the entropy method, the weight of the return on investment index is the largest, which is 0.2312, followed by the weight of the incremental cost index at 0.2104, and the weights of the energy saving and unguaranteed hours indexes at 0.1959 and 0.187, respectively, while the CO2 emission reduction on investment index is the smallest, which is 0.1755. Therefore, in the energy-saving renovation decision-making stage, return on investment is the primary consideration. From the comprehensive score and ranking of the scheme, it can be seen that the score of scheme 6 is the highest, which is 0.8593. After the energy-saving renovation, energy saving is 9484.02 kW·h, CO2 emission reduction is 4851.09 kg, renovation cost is 13,778.26 RMB, the return on investment is 1.45, and unguaranteed hours is 3952 h. This scheme is most suitable for promotion. Scheme 7 had the lowest score of 0.3056. Synthesizing the data calculated by the entropy value method, scheme 6 is the optimal scheme for the energy-saving renovation of existing rural houses. Therefore, the impact of scheme 6 on building heating energy consumption will be discussed in detail.

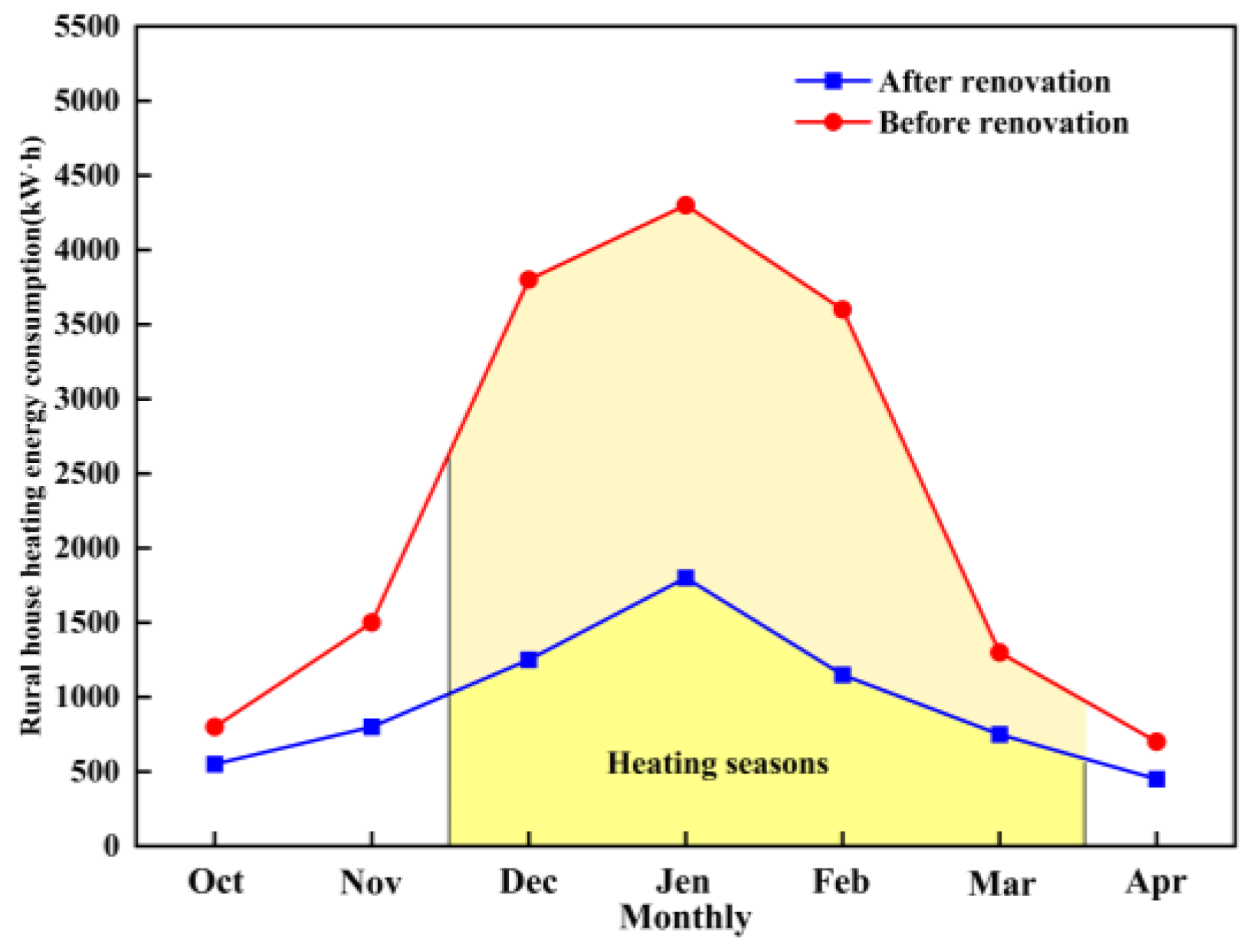

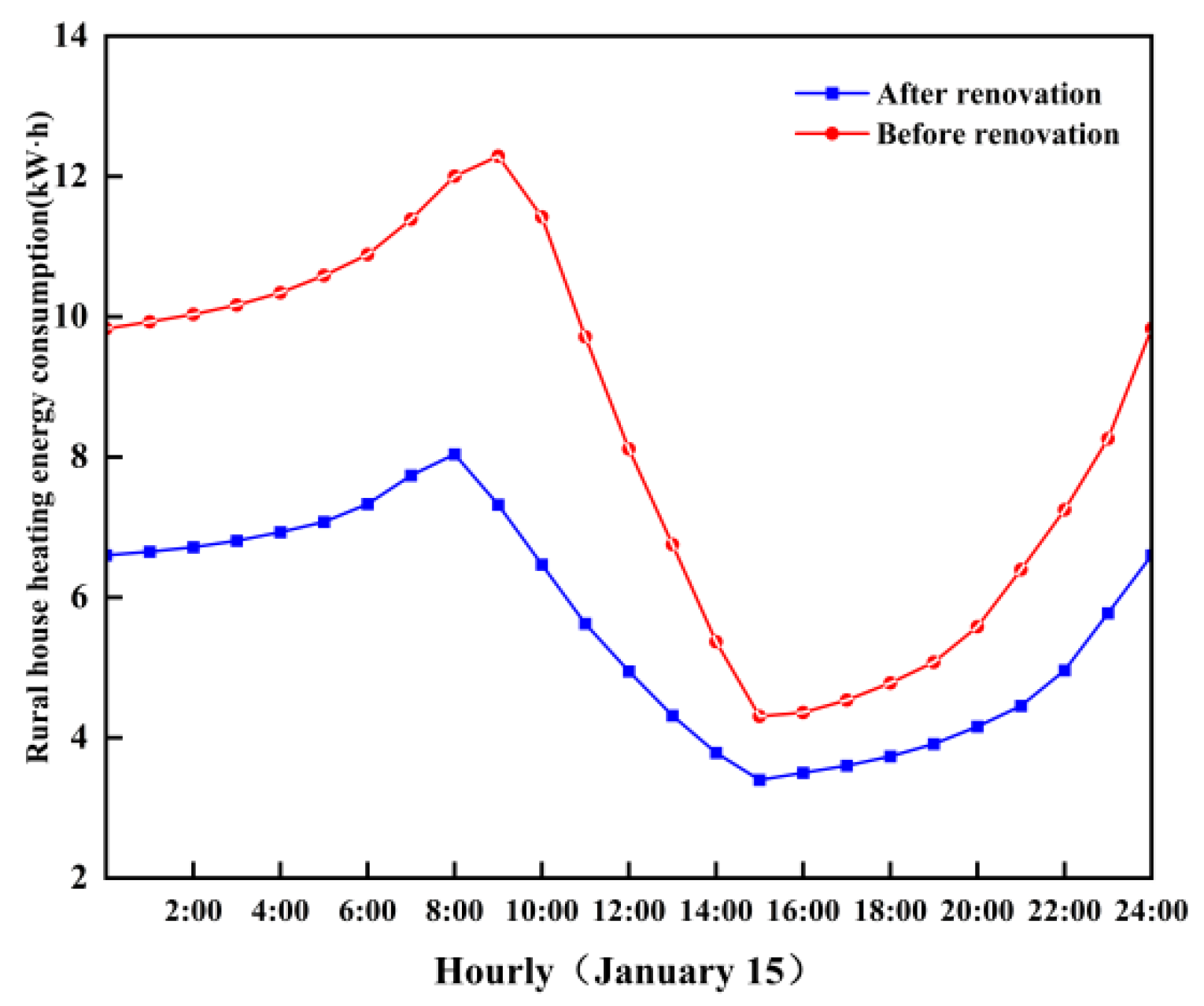

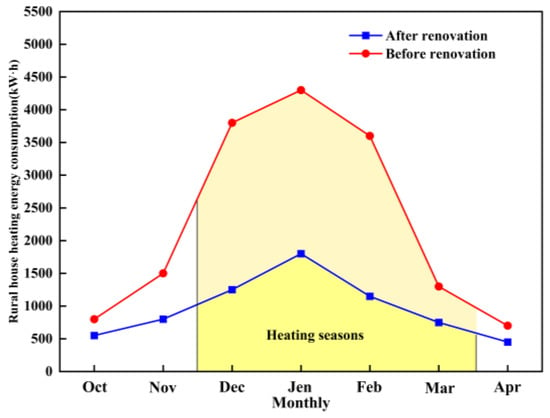

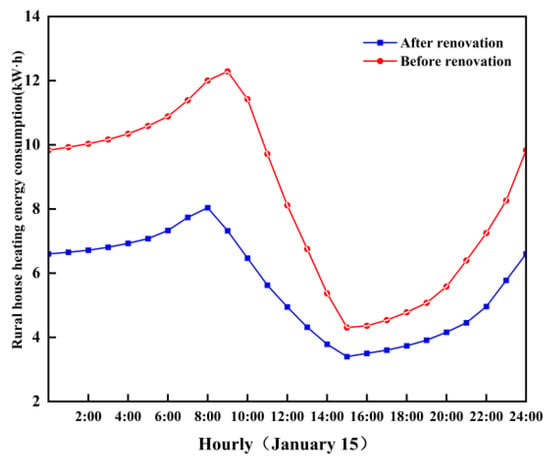

After the renovation of scheme 6, the heating energy consumption during the heating period is calculated using a simulation as shown in Figure 10. It can be seen that the monthly heating energy consumption of the rural house is significantly reduced compared with that before the renovation, and the maximum value is 1935.22 kW·h with a difference of 2397.09 kW·h. Due to the small difference between indoor and outdoor temperature in the non-heating period, the environmental heat transfer is not obvious, and the improvement range is not large, so it is concluded that the effect is the best in the low temperature season. Tongchuan City has the lowest outdoor temperature in January every year. The heating energy consumption per hour on January 15 is shown in Figure 11. Compared with before the renovation, the hourly heating energy consumption changes slowly after renovation. The maximum heating energy consumption is 8.03 kW·h, with a difference of 3.82 kW·h, and the minimum heating energy consumption is 4.32 kW·h, with a difference of 2.21 kW·h. However, the cumulative heating energy consumption in the heating season decreased by 9498.02 kW·h, and the energy saving rate reached 59.89%.

Figure 10.

Heating energy consumption during the heating period.

Figure 11.

Hourly heating energy consumption on January 15.

To sum up, scheme 6 is the optimal scheme for the energy-saving renovation of the existing rural houses in Tongchuan city, considering the comprehensive benefits.

5. Conclusions

This study proposes a multi-index optimization analysis for energy-saving renovation schemes of the envelope structures of existing rural houses. The renovation method of the envelope structure and the optimal thickness of insulation materials were provided, and the impact of energy saving, incremental cost, return on investment, carbon emission reduction, and unguaranteed hours on the plan was evaluated. The main conclusions are as follows:

- When a single renovation scheme is adopted for the renovation of building envelope structures, the order of energy saving effects is roof renovation > external wall insulation > replace external windows > additional sunspace. For the combined renovation scheme, we should consider the insulation of the external wall, thus reducing the indoor heat transfer from the external wall. Secondly, we should consider the insulation of the roof and replacing the external window, and finally, consider the impact of the window-to-wall ratio when replacing outer windows. The energy saving rate of the combined renovation scheme is much higher than that of any single renovation scheme.

- The weights of energy saving, incremental cost, return on investment, and carbon emission reduction are 0.1915, 0.2104, 0.2312, 0.1755 and 0.187, respectively. The analysis of the comprehensive score obtained the best renovation scheme for the rural house: the thickness of the XPS board is 100 mm for external wall insulation; the thickness of the XPS board is 80 mm for roof insulation; the window-to-wall ratio of additional sunspace is 0.6; and a broken bridge aluminum hollow window 6 + 12A + 6 (mm) is selected for external window type. After using this scheme, the heating energy consumption of the rural house is significantly reduced during the heating period, and the energy saving effect is the best in January with the lowest average temperature. The heating energy consumption is 1935.22 kW·h, which is 2397.09 kW·h lower than that before the renovation.

- The renovation of the building envelope structures of existing rural houses is a necessary measure to reduce building energy consumption, but its influencing factors are numerous, involving economic, social, and environmental factors as well as residents and other benefits of different subjects. The application of the entropy value method can avoid the blind use of recommended values and experience values in energy-saving design, overcome the randomness of subjective weighting, and select the best energy-saving renovation scheme scientifically, which has certain reference significance for future energy-saving constructions in Tongchuan City.

This article proposes a scientific and objective optimization analysis of energy-saving renovation plans for building envelope structures taking Tongchuan City, Shaanxi Province, which is located in a cold region, as an example. A comprehensive benefit evaluation of economic benefits, environmental protection benefits, energy saving benefits, and comfort benefits was undertaking using the entropy method to construct an evaluation system, and the best renovation scheme suitable for existing rural houses in Tongchuan City was proposed. This method provides theoretical support for the promotion of the energy-saving renovation of rural houses in Tongchuan area, and it is recommended to promote it to other regions. It also provides a research basis for the “dual carbon” goal in reducing carbon emissions in rural areas.

Due to the limited research level and practical experience of the authors, there are still some shortcomings in this paper that require further research. This paper studies the optimization scheme of energy saving renovation of the existing envelope structure of a farm house and constructs a multi-index evaluation system based on the comprehensive benefits. However, due to the lack of sufficient practical experience, the evaluation system is only applicable for promotion in existing rural areas in China. The evaluation system can also add more indicators according to local government policies for a comprehensive analysis and continuously verify and improve the evaluation system through more practical cases.

Author Contributions

Conceptualization, P.C. and Q.S.; Methodology, P.C. and Y.J.; Software, H.L. and Q.S.; Validation, P.C., H.L. and Q.S.; Formal analysis, P.C. and Q.S.; Investigation, Q.S., H.L. and Q.S.; Data curation, P.C., H.L. and Q.S.; Writing—original draft, P.C.; Writing—review & editing, P.C.; Visualization, P.C., H.L. and Q.S.; Supervision, P.C. and Y.J.; Project administration, P.C. and Q.S.; Funding acquisition, P.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external fundings.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Acknowledgments

The project is part of the Tongchuan winter clean energy heating project. The authors thank the support of Tongchuan Finance Bureau and the organizing committee of the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Research Center for Building Energy Efficiency, Tsinghua University. Annual Development Report on Building Energy Efficiency in China; China Building Industry Press: Beijing, China, 2020; pp. 18–19. (In Chinese) [Google Scholar]

- Shan, M.; Wang, P.; Li, J.; Yue, G.; Yang, X. Energy and environment in Chinese rural buildings: Situations, challenges, and intervention strategies. J. Affect. Disord. 2015, 91, 271–282. [Google Scholar] [CrossRef]

- Kınay, U.; Laukkarinen, A.; Vinha, J. Renovation wave of the residential building stock targets for the carbon-neutral: Evaluation by Finland and Türkiye case studies for energy demand. Energy Sustain. Dev. 2023, 75, 1–24. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, C.; Qian, Q.K.; Huang, R.; You, K.; Visscher, H.; Zhang, G. Incentive initiatives on energy-efficient renovation of existing buildings towards carbon–neutral blueprints in China: Advancements, challenges and prospects. Energy Build. 2023, 296, 113343. [Google Scholar] [CrossRef]

- Jensen, P.A.; Maslesa, E.; Berg, J.B.; Thuesen, C. 10 questions concerning sustainable building renovation. J. Affect. Disord. 2018, 143, 130–137. [Google Scholar] [CrossRef]

- Kang, Y.; Xu, W.; Wu, J.; Li, H.; Liu, R.; Lu, S.; Rong, X.; Xu, X.; Pang, F. Study on comprehensive whole life carbon emission reduction potential and economic feasibility impact based on progressive energy-saving targets: A typical renovated ultra-low energy office. J. Build. Eng. 2022, 58, 105029. [Google Scholar] [CrossRef]

- Huang, J.; Wang, S.; Teng, F.; Feng, W. Thermal performance optimization of envelope in the energy-saving renovation of existing residential buildings. Energy Build. 2021, 247, 111103. [Google Scholar] [CrossRef]

- Zhang, X.; Nie, S.; He, M.; Wang, J. Energy-saving renovation of old urban buildings: A case study of Beijing. Case Stud. Therm. Eng. 2021, 28, 101632. [Google Scholar] [CrossRef]

- Semprini, G.; Gulli, R.; Ferrante, A. Deep regeneration vs shallow renovation to achieve nearly Zero Energy in existing buildings: Energy saving and economic impact of design solutions in the housing stock of Bologna. Energy Build. 2017, 156, 327–342. [Google Scholar] [CrossRef]

- Kass, K.; Blumberga, A.; Blumberga, D.; Zogla, G.; Kamenders, A.; Kamendere, E. Pre-assessment Method for Historic Building Stock Renovation Evaluation. Energy Procedia 2017, 113, 346–353. [Google Scholar] [CrossRef]

- Jradi, M.; Veje, C.; Jørgensen, B. A dynamic energy performance-driven approach for assessment of buildings energy Renovation—Danish case studies. Energy Build. 2018, 158, 62–76. [Google Scholar] [CrossRef]

- Yang, H.; Liu, L.; Li, X.; Liu, C.; Jones, P. Tailored domestic retrofit decision making towards integrated performance targets in Tianjin, China. Energy Build. 2017, 140, 480–500. [Google Scholar] [CrossRef]

- Li, H.X.; Li, Y.; Jiang, B.; Zhang, L.; Wu, X.; Lin, J. Energy performance optimisation of building envelope retrofit through integrated orthogonal arrays with data envelopment analysis. Renew. Energy 2020, 149, 1414–1423. [Google Scholar] [CrossRef]

- Feng, Y.-H.; Yu, Z.-T.; Lu, J. Hygrothermal performance of a self-insulated exterior wall with various exterior/interior insulation thicknesses in two climate zones in China: A novel moisture-energy-environment-economic (M3E) method in insulation thickness optimization. Appl. Therm. Eng. 2023, 228, 120463. [Google Scholar] [CrossRef]

- Verma, R.; Rakshit, D. Comparison of reflective coating with other passive strategies: A climate based design and optimization study of building envelope. Energy Build. 2023, 287, 112973. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Hou, C.; Hou, J.; Wei, D.; Hou, Y. Optimization analysis of thermal insulation layer attributes of building envelope exterior wall based on DeST and life cycle economic evaluation. Case Stud. Therm. Eng. 2019, 14, 100410. [Google Scholar] [CrossRef]

- Daouas, N. Impact of external longwave radiation on optimum insulation thickness in Tunisian building roofs based on a dynamic analytical model. Appl. Energy 2016, 177, 136–148. [Google Scholar] [CrossRef]

- Jie, P.; Zhang, F.; Fang, Z.; Wang, H.; Zhao, Y. Optimizing the insulation thickness of walls and roofs of existing buildings based on primary energy consumption, global cost and pollutant emissions. Energy 2018, 159, 1132–1147. [Google Scholar] [CrossRef]

- Yu, J.; Tian, L.; Yang, C.; Xu, X.; Wang, J. Optimum insulation thickness of residential roof with respect to solar-air degree-hours in hot summer and cold winter zone of China. Energy Build. 2011, 43, 2304–2313. [Google Scholar] [CrossRef]

- Pan, L.; Xu, Q.; Nie, Y.; Qiu, T. Analysis of climate adaptive energy-saving technology approaches to residential building envelope in Shanghai. J. Build. Eng. 2018, 19, 266–272. [Google Scholar] [CrossRef]

- Lyu, Y.-L.; Liu, W.-J.; Su, H.; Wu, X. Numerical analysis on the advantages of evacuated gap insulation of vacuum-water flow window in building energy saving under various climates. Energy 2019, 175, 353–364. [Google Scholar] [CrossRef]

- Aburas, M.; Soebarto, V.; Williamson, T.; Liang, R.; Ebendorff-Heidepriem, H.; Wu, Y. Thermochromic smart window technologies for building application: A review. Appl. Energy 2019, 255, 113522. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Wang, B.; Liu, C.; Arıcı, M. Optical and thermal performance of glazing units containing PCM in buildings: A review. Constr. Build. Mater. 2020, 233, 117327. [Google Scholar] [CrossRef]

- Sivaram, P.; Premalatha, M.; Arunagiri, A. Computational studies on the airflow developed by the building-integrated passive solar energy system. J. Build. Eng. 2021, 39, 102250. [Google Scholar] [CrossRef]

- Bosu, I.; Mahmoud, H.; Ookawara, S.; Hassan, H. Applied single and hybrid solar energy techniques for building energy consumption and thermal comfort: A comprehensive review. Sol. Energy 2023, 259, 188–228. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Wang, D.; Liu, Y.; Zhang, Y.; Liu, Y.; Zhao, Y.; Gao, M.; Fan, J. Co-optimization of passive building and active solar heating system based on the objective of minimum carbon emissions. Energy 2023, 275, 127401. [Google Scholar] [CrossRef]

- Wang, X.; Lei, B.; Bi, H.; Yu, T. Study on the Thermal Performance of a Hybrid Heat Collecting Facade Used for Passive Solar Buildings in Cold Region. Energies 2019, 12, 1038. [Google Scholar] [CrossRef]

- Zhang, L.; Hou, Y.; Liu, Z.; Du, J.; Xu, L.; Zhang, G.; Shi, L. Trombe wall for a residential building in Sichuan-Tibet alpine valley—A case study. Renew. Energy 2020, 156, 31–46. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, D.; Lu, S. Research on the Indoor Thermal Environment of Attached Sunspace Passive Solar Heating System Based on Zero-State Response Control Strategy. Appl. Sci. 2022, 12, 855. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Ma, L.; Arıcı, M.; Li, D.; Yıldız, Ç.; Zhu, Y. Effect of sunspace and PCM louver combination on the energy saving of rural residences: Case study in a severe cold region of China. Sustain. Energy Technol. Assess. 2021, 45, 101126. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, X.; Li, D.; Arıcı, M.; Yıldız, Ç.; Li, Q.; Zhang, S.; Jiang, W. Influence of sunspace on energy consumption of rural residential buildings. Sol. Energy 2020, 211, 336–344. [Google Scholar] [CrossRef]

- Zhao, J.; Li, H.; Liu, D. Local thermal comfort-based optimal design of attached sunspace with breathing window for farmhouses in North China. J. Affect. Disord. 2022, 219, 109251. [Google Scholar] [CrossRef]

- Long, L.; Ye, H.; Liu, M. A new insight into opaque envelopes in a passive solar house: Properties and roles. Appl. Energy 2016, 183, 685–699. [Google Scholar] [CrossRef]

- Gainza-Barrencua, J.; Odriozola-Maritorena, M.; Hernandez_Minguillon, R.; Gomez-Arriaran, I. Energy savings using sunspaces to preheat ventilation intake air: Experimental and simulation study. J. Build. Eng. 2021, 40, 102343. [Google Scholar] [CrossRef]

- Amoako-Attah, J.; B-Jahromi, A. Impact of conservatory as a passive solar design of UK dwellings. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2015; Volume 169, pp. 198–213. [Google Scholar] [CrossRef]

- Chang, H.; Liu, Y.; Shen, J.; Xiang, C.; He, S.; Wan, Z.; Jiang, M.; Duan, C.; Shu, S. Experimental study on comprehensive utilization of solar energy and energy balance in an integrated solar house. Energy Convers. Manag. 2015, 105, 967–976. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, Z.; Liu, F.; Li, H.; Zhang, X.; Wang, K.; Chen, C.; Tian, C. Passive solar sunspace in a Tibetan buddhist house in Gannan cold areas: Sensitivity analysis. J. Build. Eng. 2023, 67, 105960. [Google Scholar] [CrossRef]

- Ma, L.; Luo, D.; Hu, H.; Li, Q.; Yang, R.; Zhang, S.; Li, D. Energy performance of a rural residential building with PCM-silica aerogel sunspace in severe cold regions. Energy Build. 2023, 280, 112719. [Google Scholar] [CrossRef]

- Vukadinović, A.; Radosavljević, J.; Đorđević, A.; Protić, M.; Petrović, N. Multi-objective optimization of energy performance for a detached residential building with a sunspace using the NSGA-II genetic algorithm. Sol. Energy 2021, 224, 1426–1444. [Google Scholar] [CrossRef]

- Uludaş, M.Ç.; Tunçbilek, E.; Yıldız, Ç.; Arıcı, M.; Li, D.; Krajčík, M. PCM-enhanced sunspace for energy efficiency and CO2 mitigation in a house in mediterranean climate. J. Build. Eng. 2022, 57, 104856. [Google Scholar] [CrossRef]

- Deng, M.; Ma, R.; Lu, F.; Nie, Y.; Li, P.; Ding, X.; Yuan, Y.; Shan, M.; Yang, X. Techno-economic performances of clean heating solutions to replace raw coal for heating in Northern rural China. Energy Build. 2021, 240, 110881. [Google Scholar] [CrossRef]

- Chen, S.-Y.; Xue, M.-T.; Wang, Z.-H.; Tian, X.; Zhang, B. Exploring pathways of phasing out clean heating subsidies for rural residential buildings in China. Energy Econ. 2022, 116, 106411. [Google Scholar] [CrossRef]

- GB/T50824-2013; Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Design Standard for Energy Efficiency of Rural Residential Buildings. China Building Industry Press: Beijing, China, 2012. (In Chinese)

- JGJ26-2018; Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Design Standards for Energy Efficiency of Residential Buildings in Severe Cold and Cold Zones. China Building Industry Press: Beijing, China, 2018. (In Chinese)

- Porsani, G.B.; Casquero-Modrego, N.; Trueba, J.B.E.; Bandera, C.F. Empirical evaluation of EnergyPlus infiltration model for a case study in a high-rise residential building. Energy Build. 2023, 296, 113322. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, Z.; Peng, Z.; Yang, J.; Chen, Z.; Deng, Z. Impacts of climate change and building energy efficiency improvement on city-scale building energy consumption. J. Build. Eng. 2023, 78, 107646. [Google Scholar] [CrossRef]

- DB61/T 5033-2022; Shaanxi Provincial Department of Housing and Urban-Rural Development. Design Standard for Energy Saving of Residential Buildings. China Building Industry Press: Beijing, China, 2022. (In Chinese)

- Zhang, S.; Mao, Y.; Liu, F.; Xu, H.; Qu, Z.; Liao, X. Multi-objective optimization and evaluation of PEMFC performance based on orthogonal experiment and entropy weight method. Energy Convers. Manag. 2023, 291, 117310. [Google Scholar] [CrossRef]

- Yang, S.; Zhou, D.; Wang, Y.; Li, P. Comparing impact of multi-factor planning layouts in residential areas on summer thermal comfort based on orthogonal design of experiments (ODOE). J. Affect. Disord. 2020, 182, 107145. [Google Scholar] [CrossRef]

- Ma, G.; Liu, T.; Shang, S. Improving the climate adaptability of building green retrofitting in different regions: A weight correction system for Chinese national standard. Sustain. Cities Soc. 2021, 69, 102843. [Google Scholar] [CrossRef]

- Lu, H.; Sheng, X.; Du, F. Economic Benefit Evaluation System of Green Building Energy Saving Building Technology Based on Entropy Weight Method. Processes 2022, 10, 382. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).