Influence of Petroleum-Based and Bio-Derived Recycling Agents on High-RAP Asphalt Mixtures Performance

Abstract

1. Introduction

2. Objectives and Scope

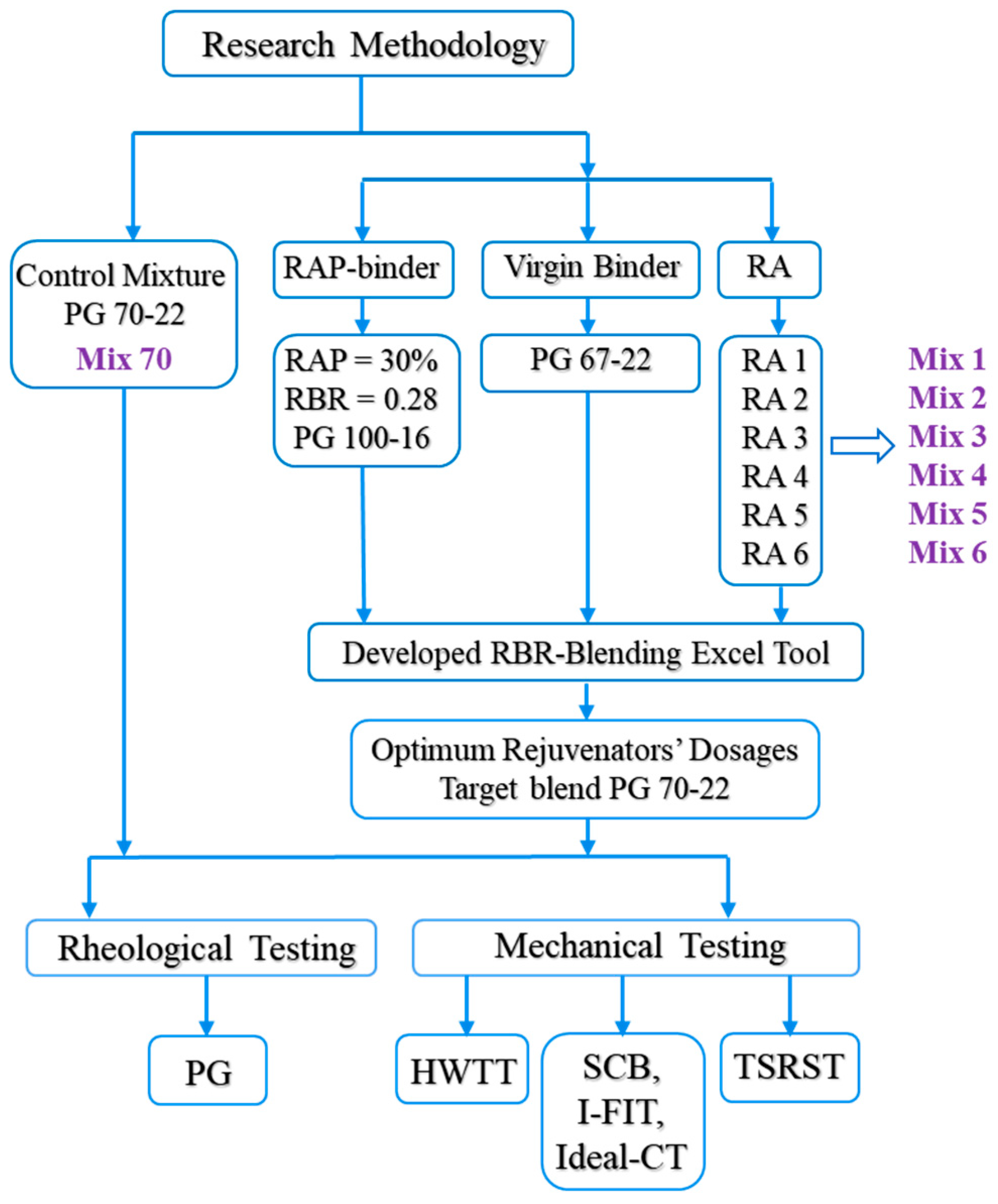

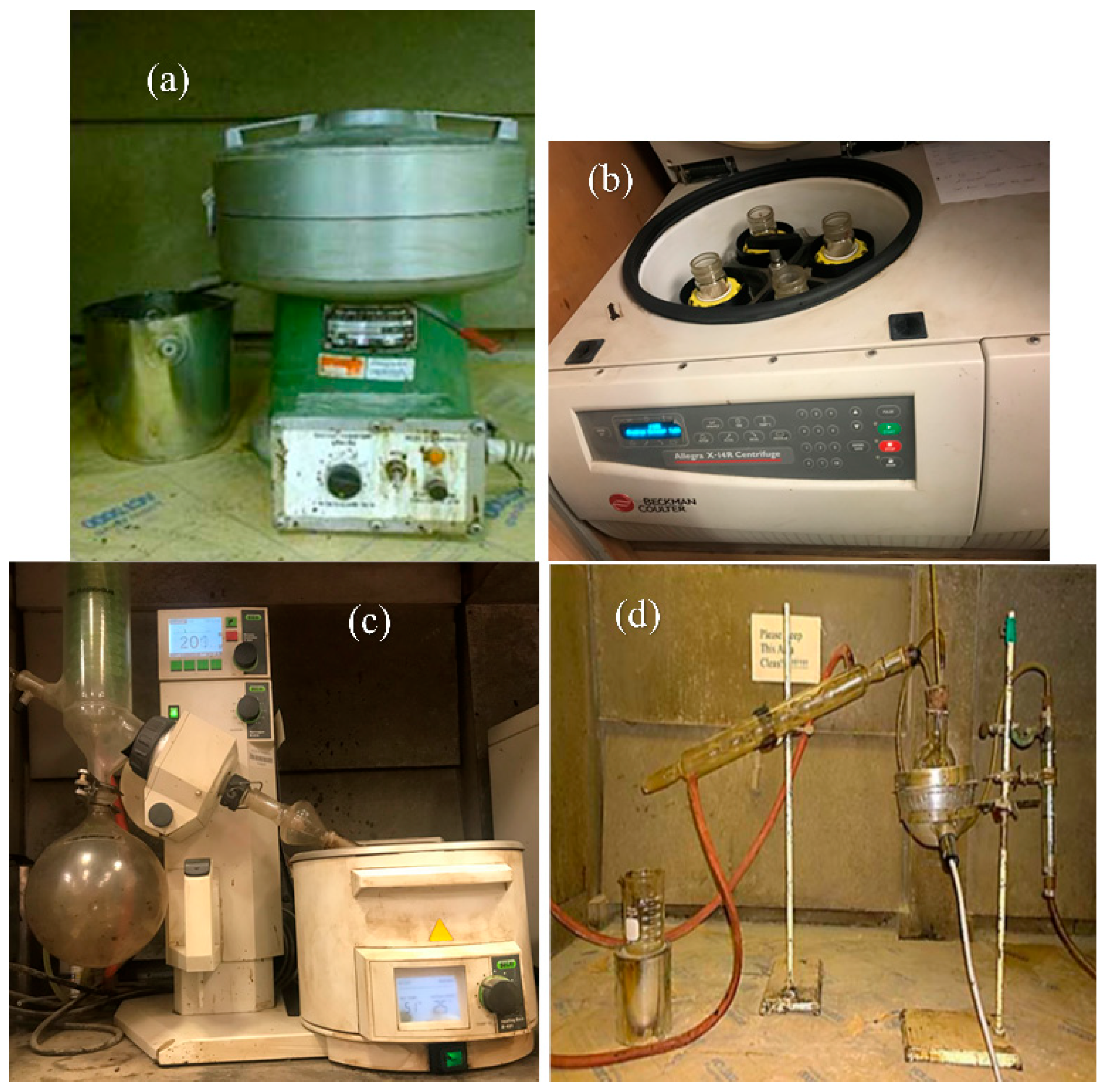

3. Materials

- G* = complex shear modulus;

- δ = phase angle;

- Tc (high) = high-critical temperature;

- G1 = value of G*/sin (δ) at temperature T1;

- T1 = recommended to be the closest temperature to the criteria;

- a = slope of stiffness-temperature curve = Δ log (G*/sin (δ))/ΔT.

- Tc (Intermediate) = intermediate-critical temperature;

- G1 = value of G*. Sin (δ) at temperature T1;

- a = slope of stiffness-temperature curve = Δ log (G*. Sin (δ))/ΔT.

- Tc (S) = critical low-temperature obtained at stiffness;

- Tc (m) = critical low-temperature obtained from m-value;

- S1 = the S-value at temperature T1;

- m1 = the m-value at temperature T1;

- T1 = recommended to be the closest temperature to the criteria;

- aS = slope of stiffness-temperature curve = Δ log (S)/ΔT;

- am = slope of m-value-temperature curve = Δm-value/ΔT.

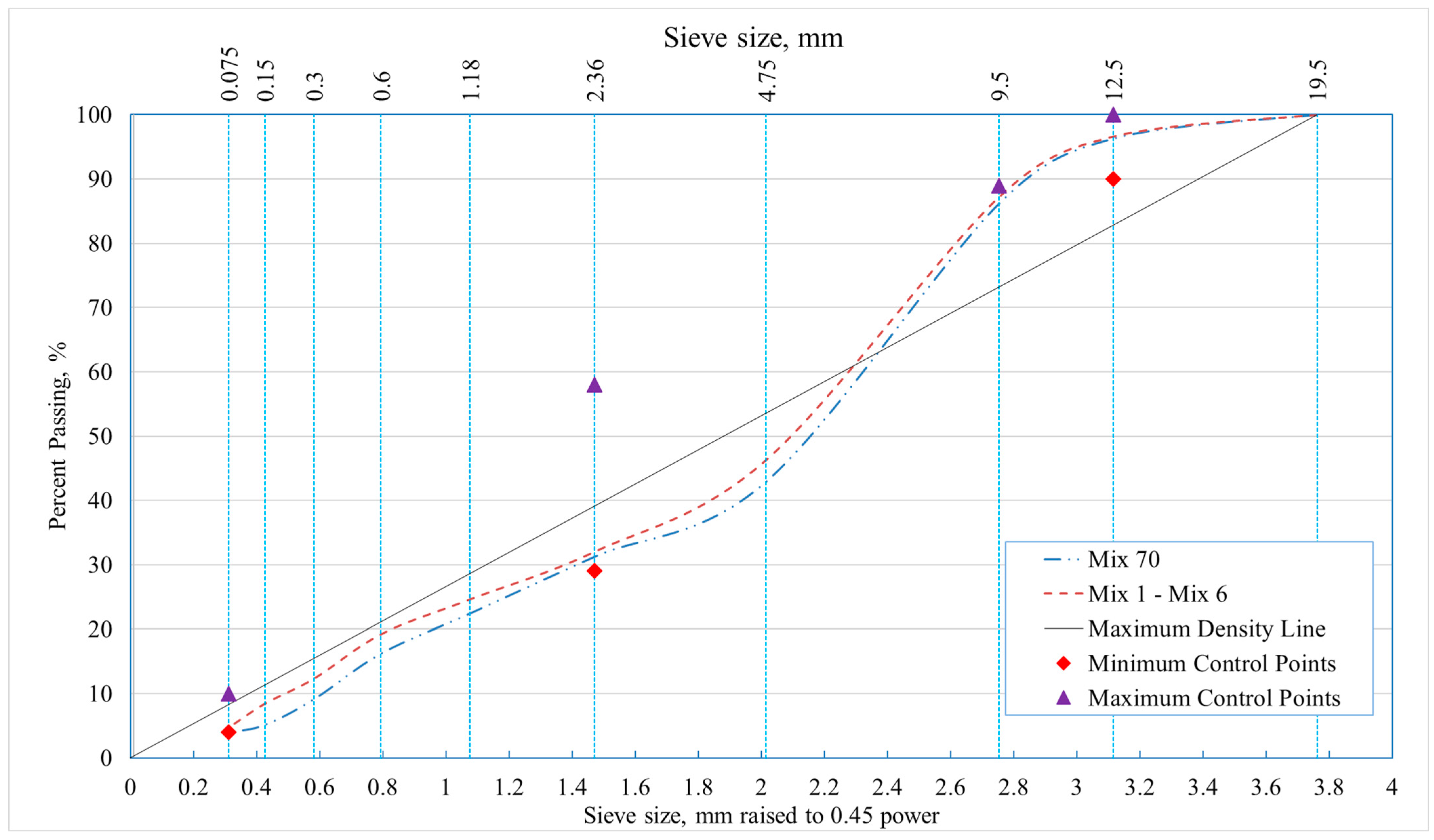

4. Mixture Design

- After preparing the RAP materials in a separate pan, 5% water by weight to the RAP materials was added to the RAP pan and stirred for five minutes to ensure water was not collected at the bottom of the pan. Then, the pan was covered with aluminum paper and soaked overnight.

- The modified PG 58-28 asphalt binder was heated at the mixing temperature of 325 °F (163 °C) along with the mixing bucket and tools. Virgin aggregates were heated at 383 °F (195 °C) for 3 h.

- First, wet RAP materials were placed in the heated mixing bucket at room temperature. Then, superheated virgin aggregates were added on top of the wet RAP materials. Subsequently, mechanical mixing was initiated and continued until there was no steam and the dark color of the RAP materials disappeared. At this point, the virgin aggregates and RAP materials were homogeneous, with no observed separation between them.

- The mixing bucket containing the aggregates and RAP was placed in an oven until a mixing temperature of 325 °F (163 °C) was reached. The modified PG 58-28 asphalt binder was added to the mixing bucket containing the aggregates mixed with RAP materials and mixed thoroughly for four minutes.

- After the mixing process, short- and long-term aging procedures were followed as per the AASHTO R 30 standard [26]. Cylindrical specimens of the asphalt mixtures were then compacted to the specified specimen dimensions of mechanical tests considered, using a Superpave gyratory compactor (SGC)

5. Testing Methods

6. Laboratory Test Results and Discussion

7. Permanent Deformation

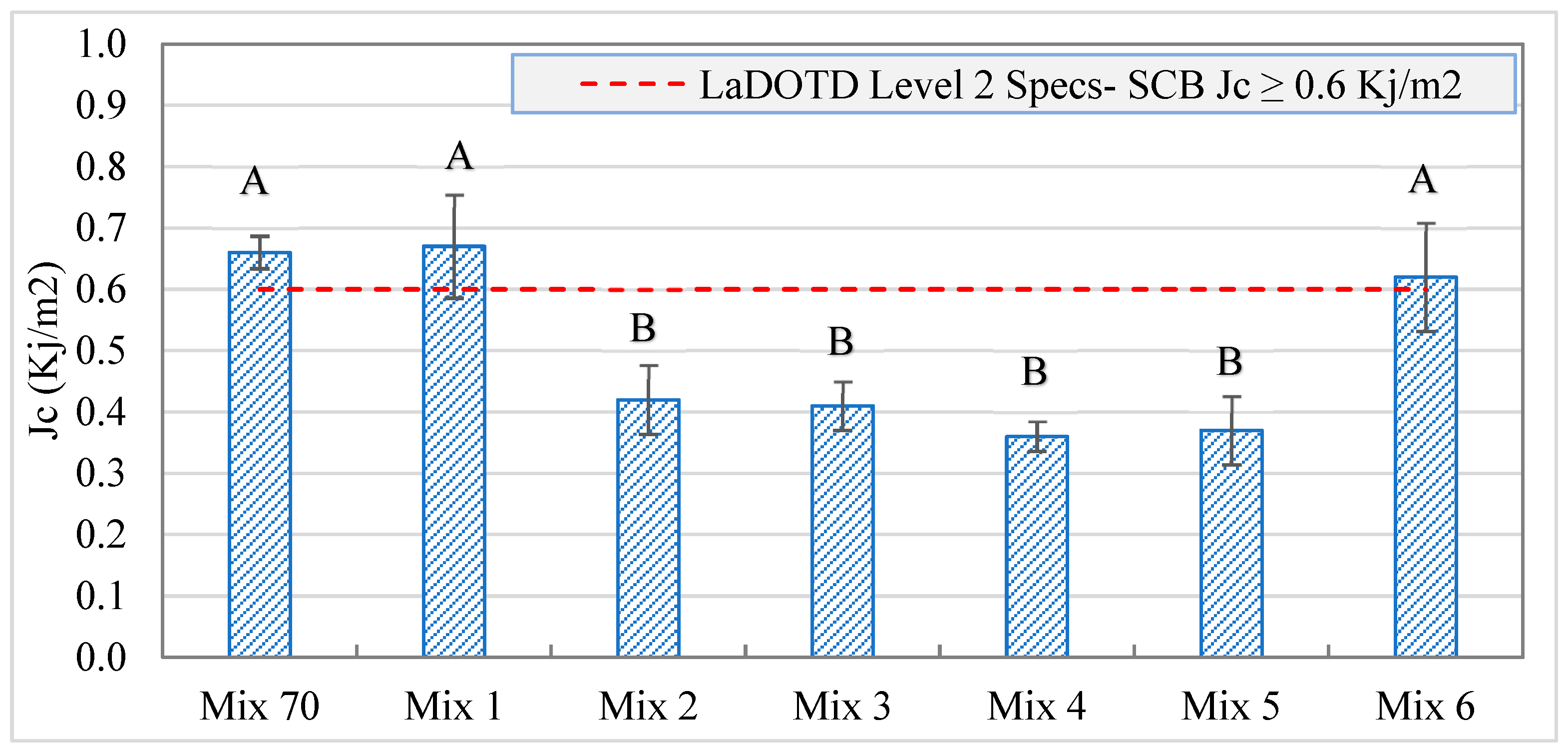

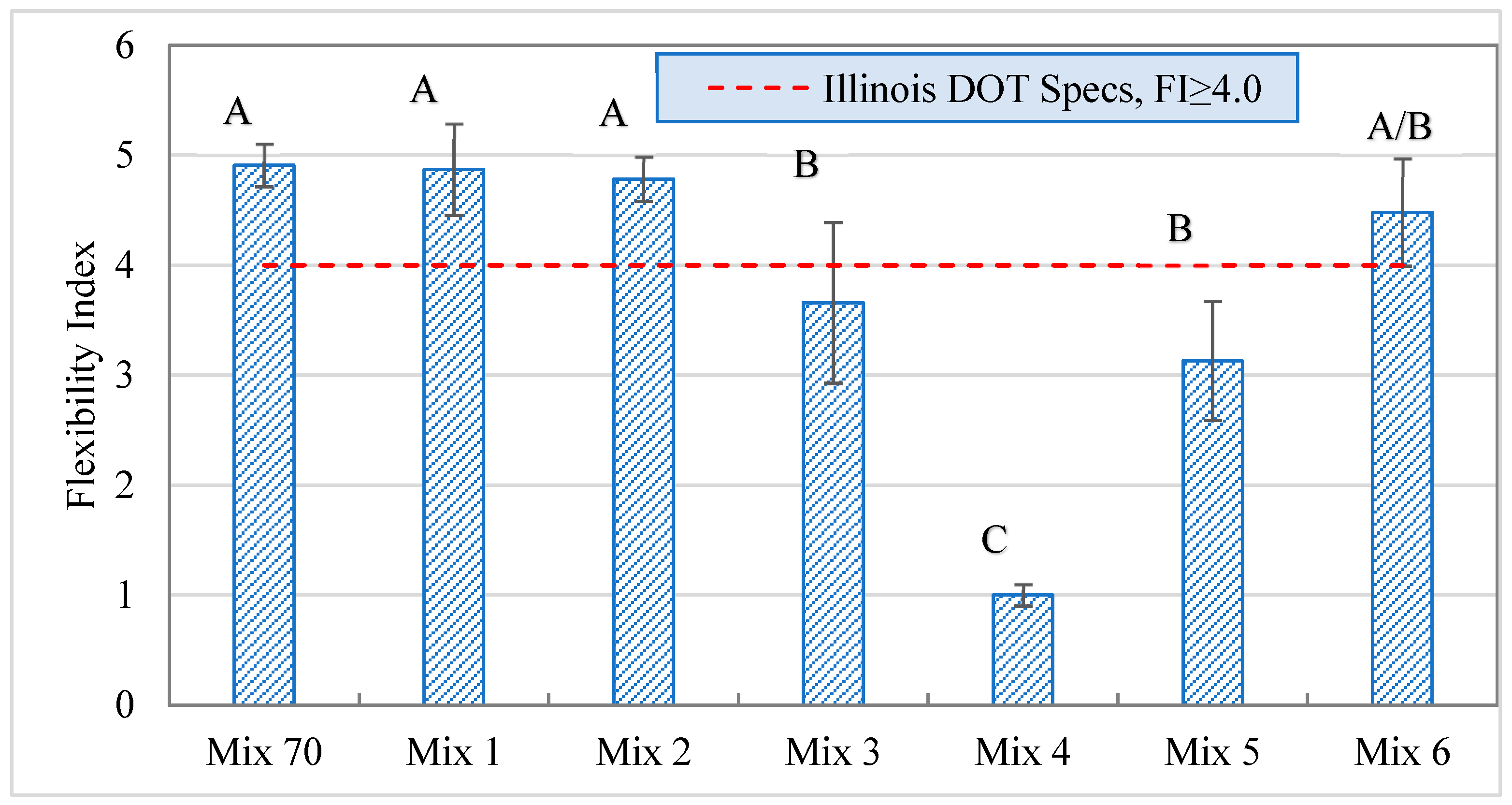

8. Cracking and Fracture Resistance

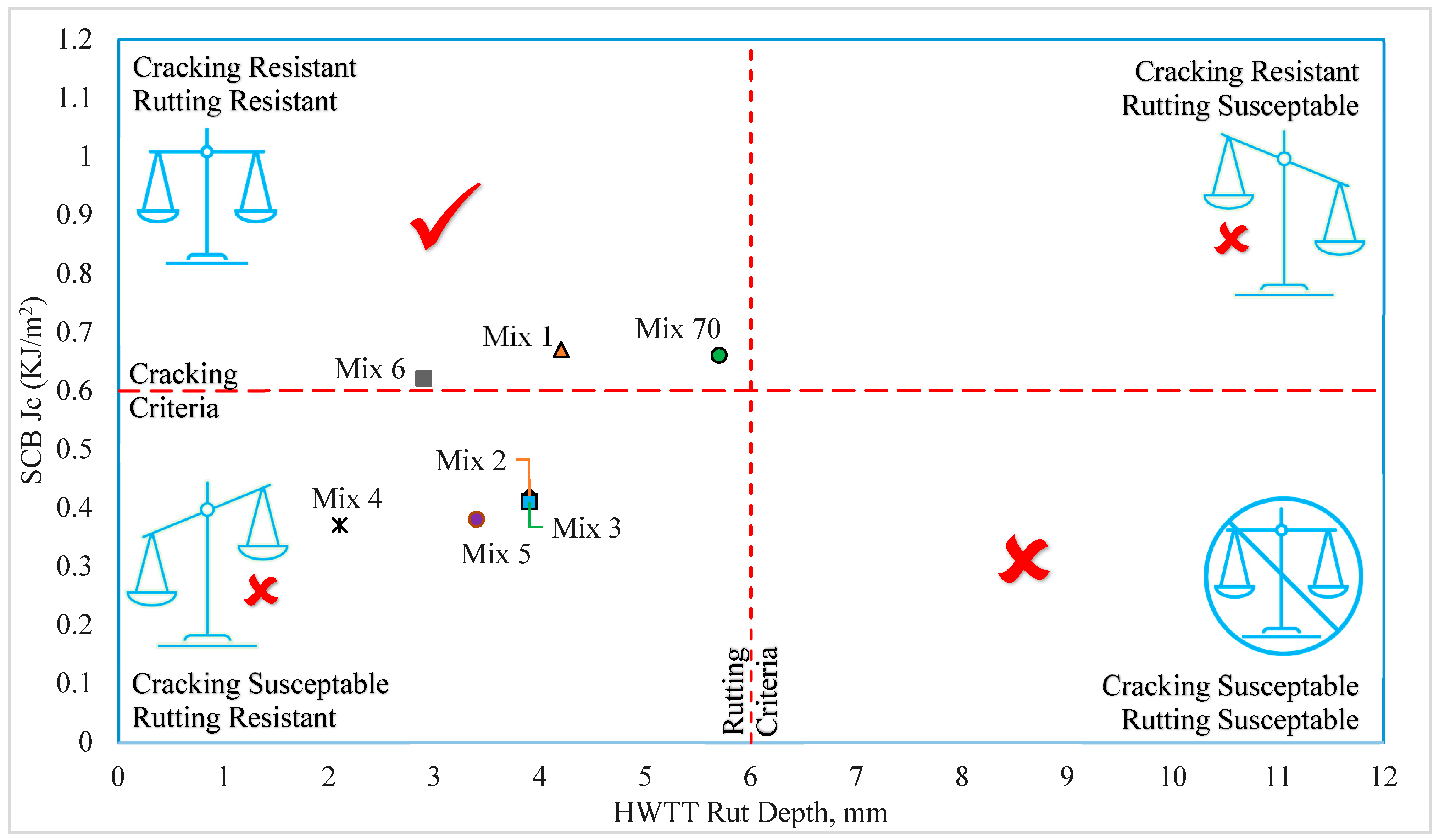

9. Louisiana DOTD Balance Mixture Design

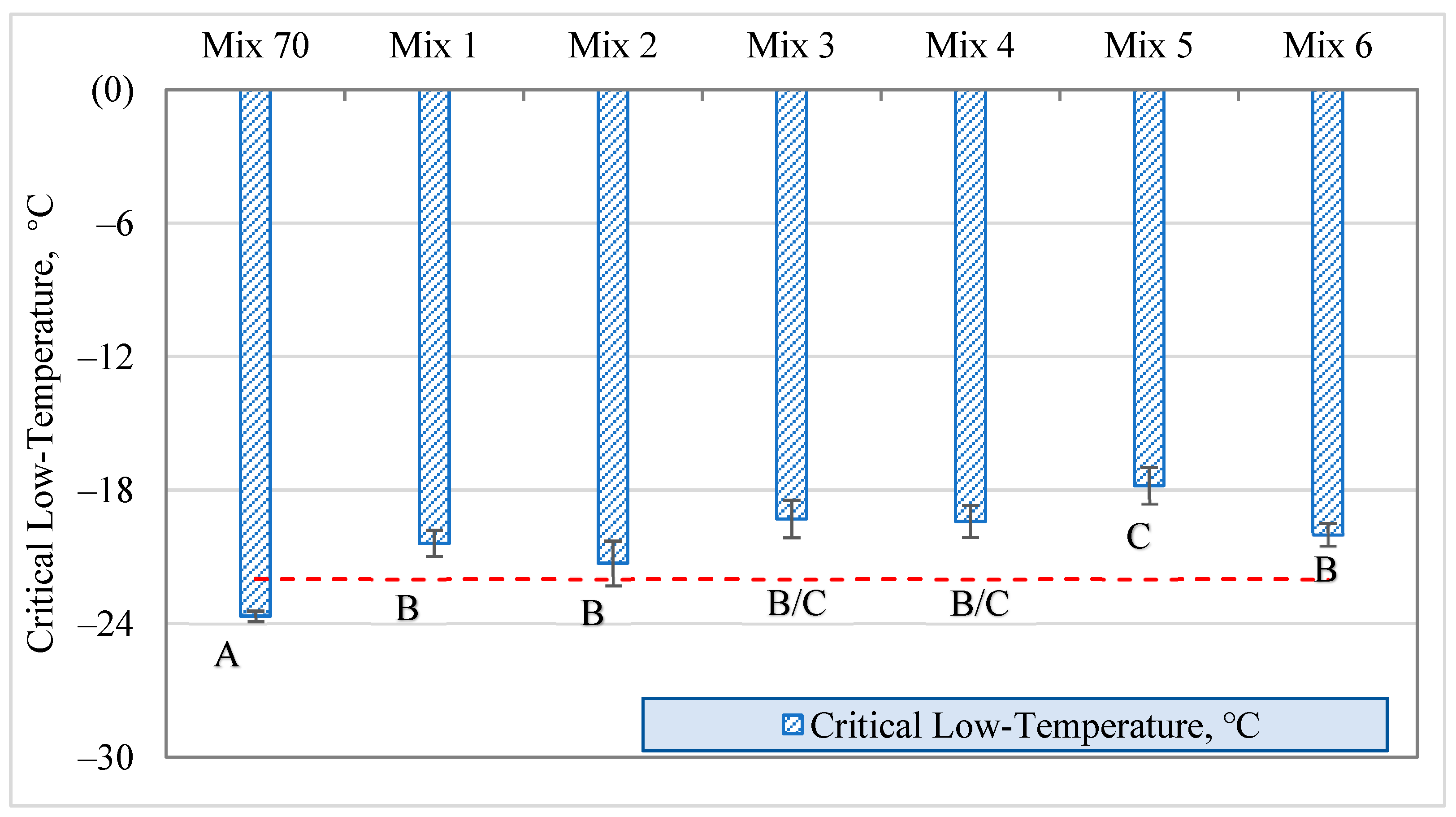

10. Low-Temperature Cracking Resistance

11. Summary and Conclusions

- The mixtures evaluated complied with the LaDOTD maximum HWTT rut depth requirement of 6.0 mm at 20,000 passes. The use of RAs did not negatively impact permanent deformation.

- Mixtures containing 30% RAP and RAs exhibited, as expected, lower rut depth than the control mixture due to the aged RAP-binder.

- Amongst RAs evaluated, RA1 (petroleum-crude-oil-derived aromatic oil) and RA6 (tall-oil-derived fatty-acid-based oil) were effective in mitigating cracking in asphalt mixtures containing 30% RAP as measured by the considered cracking tests.

- Asphalt mixtures containing 30% RAP and RAs showed slightly warmer critical low-temperature cracking values than −22 °C. All asphalt mixtures containing 30% RAP and RAs were considered to have statistically similar critical low-temperature values except for Mix 5, which showed a slightly warmer value.

- The RAs in 30%-RAP asphalt mixtures were optimized to have the same final target asphalt binder (PG 70-22); however, the results showed those RAs did not exhibit similar asphalt mixtures performances.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Howard, I.L.; Cooley, L.A.; Doyle, J.D. Laboratory Testing and Economic Analysis of High RAP Warm Mixed Asphalt; Report No FHWA/MS-DOT-RD-09-200; Mississippi State University, Dept. of Civil Engineering: Starkville, MI, USA, 2009. [Google Scholar]

- Hansen, K.R.; Newcomb, D.E. Asphalt pavement mix production survey on reclaimed asphalt pavement, reclaimed asphalt shingles, and warm-mix asphalt usage: 2009–2010. Inf. Ser. 2011, 138, 21. [Google Scholar]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review; 0197-9191; Report No: FHWA-ICT-07-001; Illinois Center for Transportation: Urbana, IL, USA, 2007. [Google Scholar]

- Elnaml, I.; Mousa, M.; Hassan, M.M.; Idris, I.; Mohammad, L. Development of Cost-Effective High-Modulus Asphalt Concrete Mixtures Using Crumb Rubber and Local Construction Materials in Louisiana. Transp. Res. Rec. 2022, 2676, 274–286. [Google Scholar] [CrossRef]

- West, R.C.; Willis, J.R.; Marasteanu, M.O. Improved Mix Design, Evaluation, and Materials Management Practices for Hot Mix Asphalt with High Reclaimed Asphalt Pavement Content; 0309259134; Transportation Research Board: Washington, DC, USA, 2013. [Google Scholar]

- Martin, A.E.; Kaseer, F.; Arámbula-Mercado, E.; Bajaj, A.; Cucalon, L.G.; Yin, F.; Chowdhury, A.; Epps, J.; Glover, C.; Hajj, E.Y. Evaluating the Effects of Recycling Agents on Asphalt Mixtures with High RAS and RAP Binder Ratios; NCHRP Research Report 927; Transportation Research Board: Washington, DC, USA, 2020. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Cooper, S.B., Jr.; Kim, M. Sustainable Materials for Pavement Infrastructure: Design and Performance of Asphalt Mixtures Containing Recycled Asphalt Shingles; Report No: FHWA/LA.17/594; Louisiana State University: Baton Rouge, LA, USA; Transportation Research Center: Baton Rouge, LA, USA, 2019. [Google Scholar]

- Ongel, A.; Hugener, M. Impact of rejuvenators on aging properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; Santos, S.D.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Im, S.; Karki, P.; Zhou, F. Development of new mix design method for asphalt mixtures containing RAP and rejuvenators. Constr. Build. Mater. 2016, 115, 727–734. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the effect of rejuvenators on the degree of blending and performance of high RAP, RAS, and RAP/RAS mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Use of the Iron Chloride Type of Lewis Acid Catalyst in High Reclaimed Asphalt Pavement Content Asphalt Mixtures. Transp. Res. Rec. 2023, 2678, 430–440. [Google Scholar] [CrossRef]

- Louisiana Department of Transportation and Development. Louisiana Standard Specifications for Roads and Bridges; Louisiana Department of Transportation and Development location: Baton Rouge, LA, USA, 2018. [Google Scholar]

- Seidel, J.C.; Haddock, J.E. Soy fatty acids as a sustainable modifier for asphalt binders. In Proceedings of the Alternative Binders for Sustainable Asphalt Pavements, Washington, DC, USA, 22 January 2012. [Google Scholar]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary examination of soybean oil derived material as a potential rejuvenator through Superpave criteria and asphalt bitumen rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Portugal, A.C.X.; Lucena, L.C.d.F.L.; Lucena, A.E.d.F.L.; Beserra da Costa, D. Rheological performance of soybean in asphalt binder modification. Road Mater. Pavement Des. 2018, 19, 768–782. [Google Scholar] [CrossRef]

- AASHTO T 164; Standard Method of Test for Quantitative Extraction of Asphalt Binder from Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO R 59; Standard Practice for Recovery of Asphalt Binder from Solution by Abson Method. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- McDaniel, R.S.; Soleymani, H.; Anderson, R.M.; Turner, P.; Peterson, R. Recommended use of reclaimed asphalt pavement in the Superpave mix design method. NCHRP Web Doc. 2000, 30, 15417. [Google Scholar]

- AASHTO M 320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2023.

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO R 35; Standard Practice for Superpave Volumetric Design for Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- Cooper, S.B., Jr. Characterization of HMA Mixtures Containing High Recycled Asphalt Pavement Content with Crumb Rubber Additives; Louisiana State University and Agricultural & Mechanical College: Baton Rouge, LA, USA, 2008. [Google Scholar]

- AASHTO R 30; Standard Practice for Laboratory Conditioning of Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2023.

- ASTM D 8044; Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance Using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2016.

- ASTM D 8225; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2019.

- AASHTO T 393; Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using the Illinois Flexibility Index Test (I-FIT). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- AASHTO TP 10; Standard Test Method for Thermal Stress Restrained Specimen Tensile Strength. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 1996.

- SAS Institute. Base SAS 9.4 Procedures Guide: Statistical Procedures; SAS Institute Inc.: Cary, NC, USA, 2013. [Google Scholar]

- Illinois Center for Transportation. Illinois Flexibility Index Test (I-FIT). Available online: https://ict.illinois.edu/research/tools/ifit-software (accessed on 15 July 2023).

- Al-Qadi, I.L.; Ozer, H.; Lambros, J. Development of the Illinois flexibility index test. Asphalt Mixtures 2019, 31, 01722468. [Google Scholar]

- Illinois department of transportation. Standard Specifications for Road and Bridge Construction; Illinois department of transportation: Springfield, IL, USA, 2022. [Google Scholar]

- Zhou, F.; Hu, S.; Newcomb, D. Development of a performance-related framework for production quality control with ideal cracking and rutting tests. Constr. Build. Mater. 2020, 261, 120549. [Google Scholar] [CrossRef]

- Mallick, R.B.; Tao, M.; O’Sullivan, K.A.; Frank, R. Use of 100% reclaimed asphalt pavement (RAP) material in asphalt pavement construction. In Proceedings of the 89th Conference of International Society of Asphalt Pavement, Nagoya, Japan, 1 August 2009. [Google Scholar]

- Neto, O.d.M.M.; Silva, I.M.; Lucena, L.C.d.F.L.; Lucena, L.d.F.L.; Mendonça, A.M.G.D.; de Lima, R.K.B. Viability of recycled asphalt mixtures with soybean oil sludge fatty acid. Constr. Build. Mater. 2022, 349, 128728. [Google Scholar] [CrossRef]

- Zhou, F. Balanced RAP–RAS–Recycling Agent Mix Design for Project-Specific Conditions. Innov. Asph. Mix. Des. Proced. 2018, 44, 01687983. [Google Scholar]

| RA Type and Components | Tests Performed | Findings |

|---|---|---|

| Resin extracted from cashew nut shells Vegetable oil, naphthenic oils | softening point, penetration, DSR, FTIR | RAs were effective in decreasing RAP asphalt binder grading [10]. RAs expedited the aging process when they added to virgin asphalt binder [10] |

| Aromatic extract (petroleum refined) Polar Waste vegetable oil (bio-based) non-polar | DSR, BBR, AFM, SARA | RAs were effective in decreasing RAP asphalt binder grading [11]. |

| Hydrogen Road Science rejuvenator Arizona Chemical | HWTT, OT | Enhanced cracking resistance Concerns with rutting resistance [12]. |

| Waste Vegetable Grease Organic Oil Aromatic Extract | DSR, BBR, RV, RTFO, HWTT, IDT, CAST | All enhanced rutting, moisture, and fatigue cracking resistance. Only the Aromatic one enhanced low-temperature cracking resistance [8]. |

| Waste Vegetable Oil | Enhanced fatigue, and rutting performance [8]. Concerns with moisture susceptibility. | |

| Distilled Tall Oil | Enhanced fatigue, and rutting performance; Concerns with low-temperature cracking performance [8]. | |

| Waste Engine Oil | Enhanced permanent deformation resistance and reduced cracking performance [8]. | |

| BituTech SonneWarmix RJT SonneWarmix RJ | DSR, BBR, LAS, MSCR, OT, TSRST | Enhancing intermediate- and low-temperature cracking resistance, especially BituTech [13]. Concerns were related to rutting and moisture susceptibility [13]. |

| Iron Chloride | DSR, HWTT, SCB, I-FIT, IDEAL-CT, S-VECD, IDT | Enhancing intermediate- and low-temperature cracking resistance without compromising rutting resistance [14]. |

| Hydrogen, Cyclogen-L Asphalt Flux, Soft binder PG58-28 | DSR, BBR, LAS, MSCR, HWTT, SCB, TSRST | Additives showed negative effects on the asphalt mixture performance and failed to improve mixture cracking resistance [11] |

| RA Number | RA Materials | Dosage Rate, % | RAs Classification |

|---|---|---|---|

| RA 1 | Petroleum crude oil derived aromatic oil using maltene blend | 12.0 | Petroleum-based oil |

| RA 2 | Modified soy-based oil | 4.0 | Bio-derived oils |

| RA 3 | Blend of RA 2 + tall oil-derived phytosterol containing industrial by-product | RA 2 = 2.5; Tall oil = 10 | |

| RA 4 | Blend of RA 2 + tall oil-derived phytosterol intermediate | RA 2 = 4.0; Tall oil = 7.5 | |

| RA 5 | Blend of RA 2 + purified phytosterol | RA 2 = 3.0; Tall oil = 5.0 | |

| RA 6 | Tall oil-derived fatty acid-based oil | 4.0 |

| Mix 70 | Mix 1 | Mix 2 | Mix 3 | Mix 4 | Mix 5 | Mix 6 | LaDOTD Specs [15] | ||

|---|---|---|---|---|---|---|---|---|---|

| Virgin Asphalt Binder | PG 70-22 | PG 67-22 | |||||||

| Aggregate Blend, % | LS#78 | 60.0 | 45.3 | ||||||

| LS#11 | 32.0 | 20.6 | |||||||

| CS | 8.0 | 4.1 | |||||||

| RAP Content, % | 0.0 | 30.0 | |||||||

| RBR | 0.0 | 0.28 | |||||||

| Total Asphalt binder, % | 5.3 | 5.3 | |||||||

| Asphalt binder from RAP, % | 0.0 | 1.5 | |||||||

| Number of Gyrations in SGC | Ni | 7 | 7 | 7 | |||||

| Nd | 65 | 65 | 65 | ||||||

| Nf | 105 | 105 | 105 | ||||||

| Gse | 2.644 | 2.635 | Na | ||||||

| Gmm | 2.453 | 2.460 | 2.461 | 2.461 | 2.463 | 2.465 | 2.459 | Na | |

| Design volumetric properties | %Gmm, Ni | 86.1 | 87.1 | 87.1 | 87.1 | 87.0 | 87.0 | 87.2 | <89 |

| %Gmm, Nf | 98.0 | 97.8 | 97.7 | 97.7 | 97.7 | 97.6 | 97.8 | <98 | |

| AV, % | 3.9 | 4.0 | 4.0 | 4.0 | 4.1 | 4.1 | 3.9 | 2.5–4.5 | |

| VMA, % | 15.5 | 15.1 | 15.1 | 15.1 | 15.1 | 15.1 | 15.1 | ≥13.5 | |

| VFA, % | 75.1 | 73.8 | 73.5 | 73.5 | 73.0 | 72.5 | 74.0 | 69–80 | |

| Effective Asphalt Binder, % | 4.70 | 4.83 | 4.82 | 4.81 | 4.86 | 4.69 | 4.85 | ±0.2 | |

| Effective Asphalt Binder after aging, % | 4.65 | 4.79 | 4.69 | 4.69 | 4.65 | 4.61 | 4.81 | ||

| D:B | 0.8 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 0.6–1.6 | |

| Test Designation | Testing Temperatures (°C) | No. of Replicates/Sample Size, mm: Dia. (D), Height (H), Thick (T), Width (W) | Engineering Properties | Protocols/Standards |

|---|---|---|---|---|

| HWTT | 50 | 4/D150 × H60 | High-Temperature Rutting resistance | AASHTO T 324 [27] |

| SCB | 25 | 4/D150 × H57 | Intermediate-Temperature Cracking resistance | ASTM D8044 [28] |

| IDEAL-CT | 25 | 3/D150 × H62 | ASTM D8225 [29] | |

| I-FIT | 25 | 2/D150 × H50 | AASHTO T 393 [30] | |

| TSRST | 5 and −10/h | 3/T50 × W50 × H250 | Low-Temperature Cracking resistance | AASHTTO TP 10 [31] |

| SCB-Jc | FI | CTindex | Summation | Rank | |

|---|---|---|---|---|---|

| Mix 70 | 1 | 1 | 1 | 3 | 1 |

| Mix 1 | 1 | 2 | 2 | 5 | 2 |

| Mix 2 | 2 | 2 | 2.5 | 6.5 | 3 |

| Mix 3 | 2 | 2.5 | 2.5 | 7 | 4 |

| Mix 4 | 2 | 4 | 3 | 9 | 5 |

| Mix 5 | 2 | 2.5 | 2.5 | 7 | 4 |

| Mix 6 | 1 | 2 | 2 | 5 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elnaml, I.; Mohammad, L.N.; Baumgardner, G.L.; Liu, J.; Cooper, S., III; Cooper, S., Jr. Influence of Petroleum-Based and Bio-Derived Recycling Agents on High-RAP Asphalt Mixtures Performance. Buildings 2024, 14, 567. https://doi.org/10.3390/buildings14030567

Elnaml I, Mohammad LN, Baumgardner GL, Liu J, Cooper S III, Cooper S Jr. Influence of Petroleum-Based and Bio-Derived Recycling Agents on High-RAP Asphalt Mixtures Performance. Buildings. 2024; 14(3):567. https://doi.org/10.3390/buildings14030567

Chicago/Turabian StyleElnaml, Ibrahim, Louay N. Mohammad, Gaylon L. Baumgardner, Jun Liu, Samuel Cooper, III, and Samuel Cooper, Jr. 2024. "Influence of Petroleum-Based and Bio-Derived Recycling Agents on High-RAP Asphalt Mixtures Performance" Buildings 14, no. 3: 567. https://doi.org/10.3390/buildings14030567

APA StyleElnaml, I., Mohammad, L. N., Baumgardner, G. L., Liu, J., Cooper, S., III, & Cooper, S., Jr. (2024). Influence of Petroleum-Based and Bio-Derived Recycling Agents on High-RAP Asphalt Mixtures Performance. Buildings, 14(3), 567. https://doi.org/10.3390/buildings14030567