Full Size Two-Layer Steel Frame–Exterior Wall Panel Shaking-Table Test

Abstract

1. Introduction

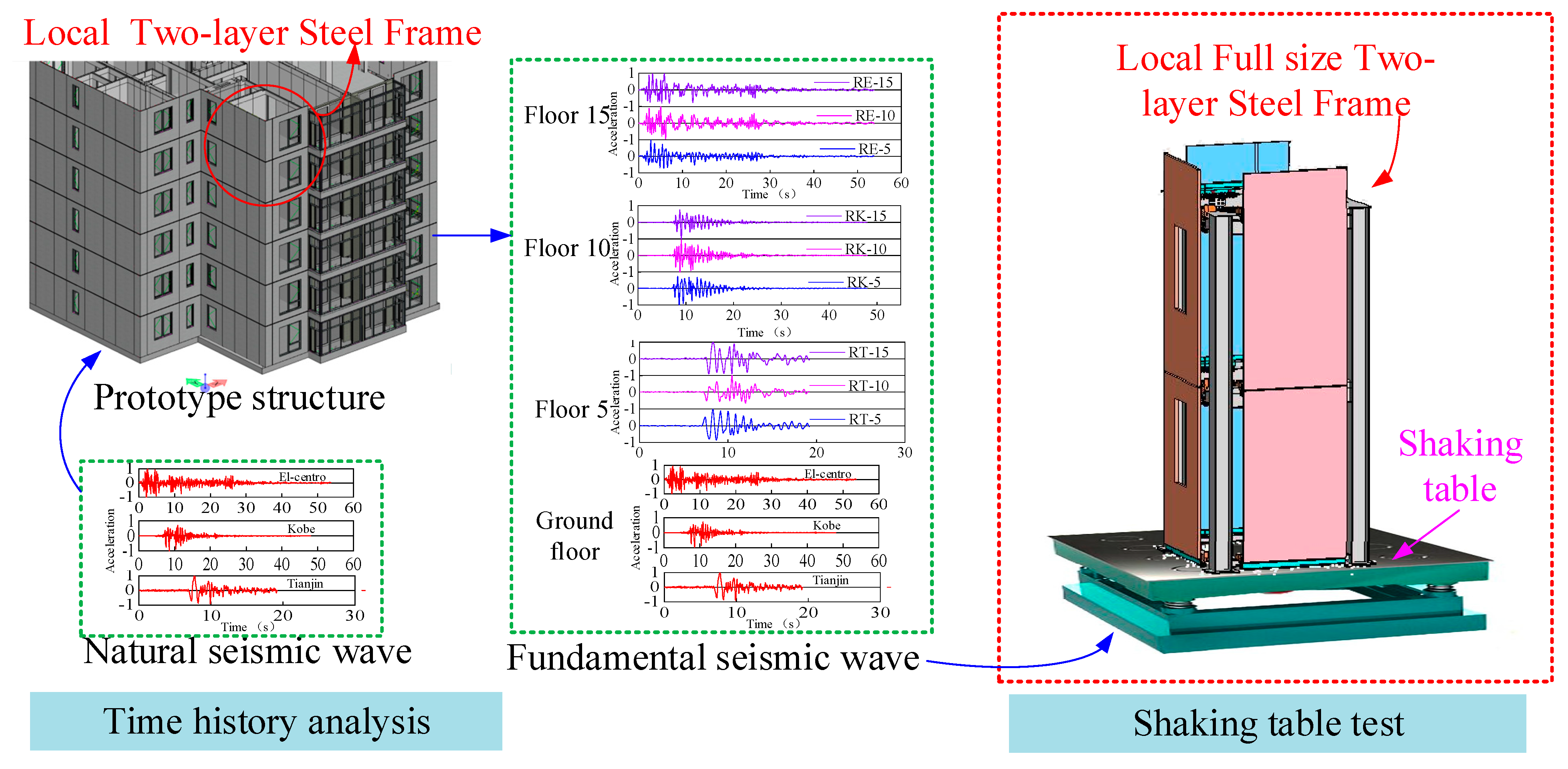

2. Materials and Methods

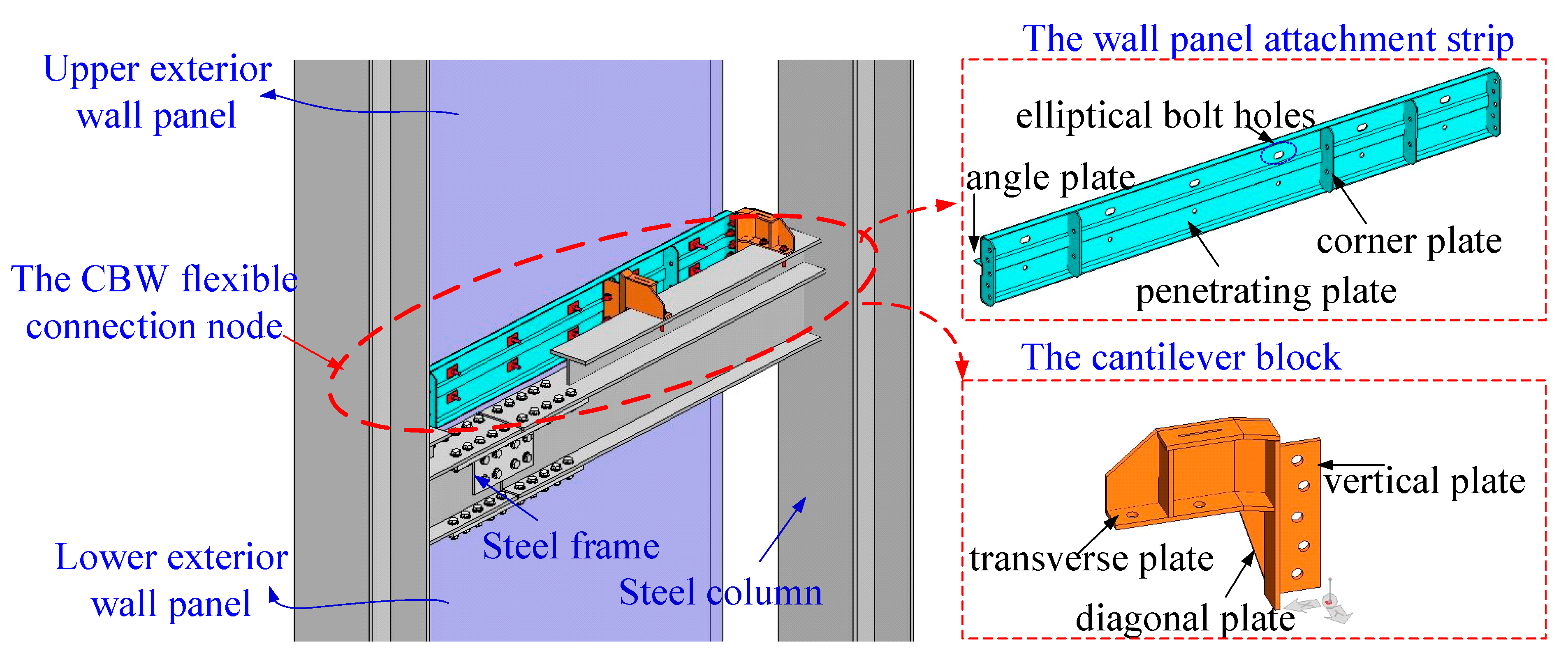

2.1. CBW Flexible Connection Node

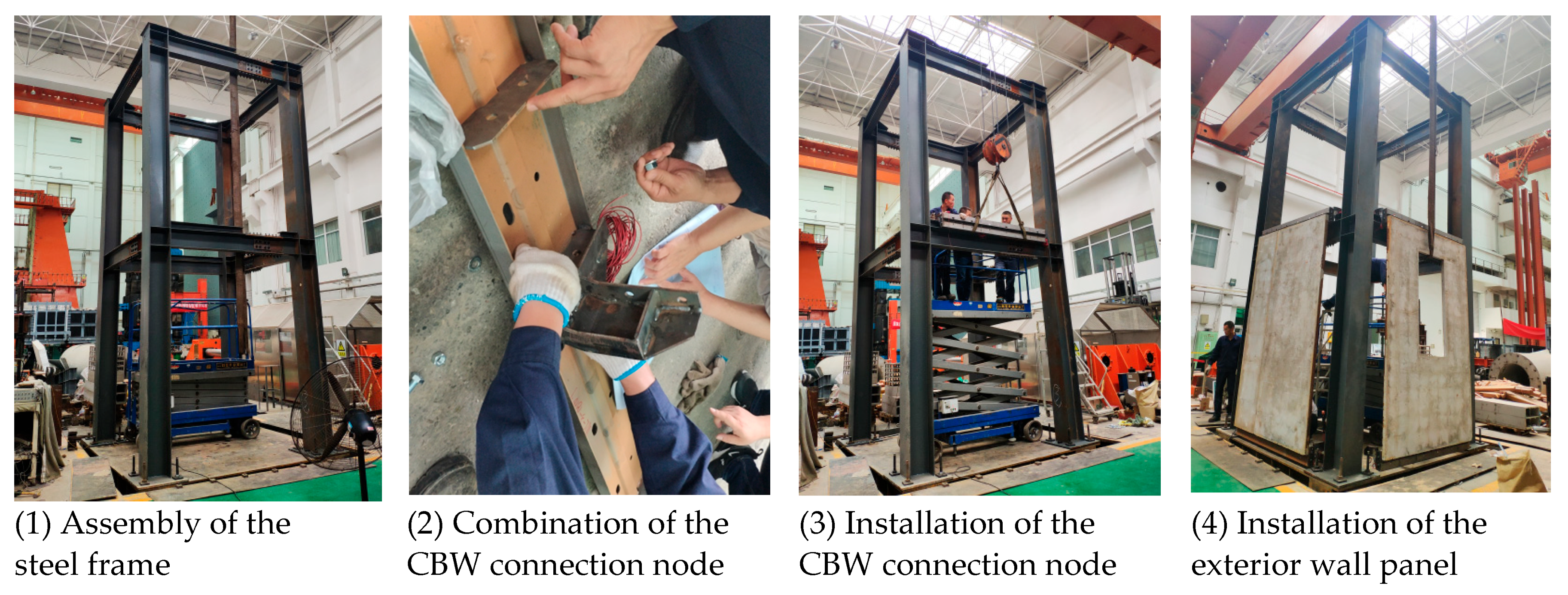

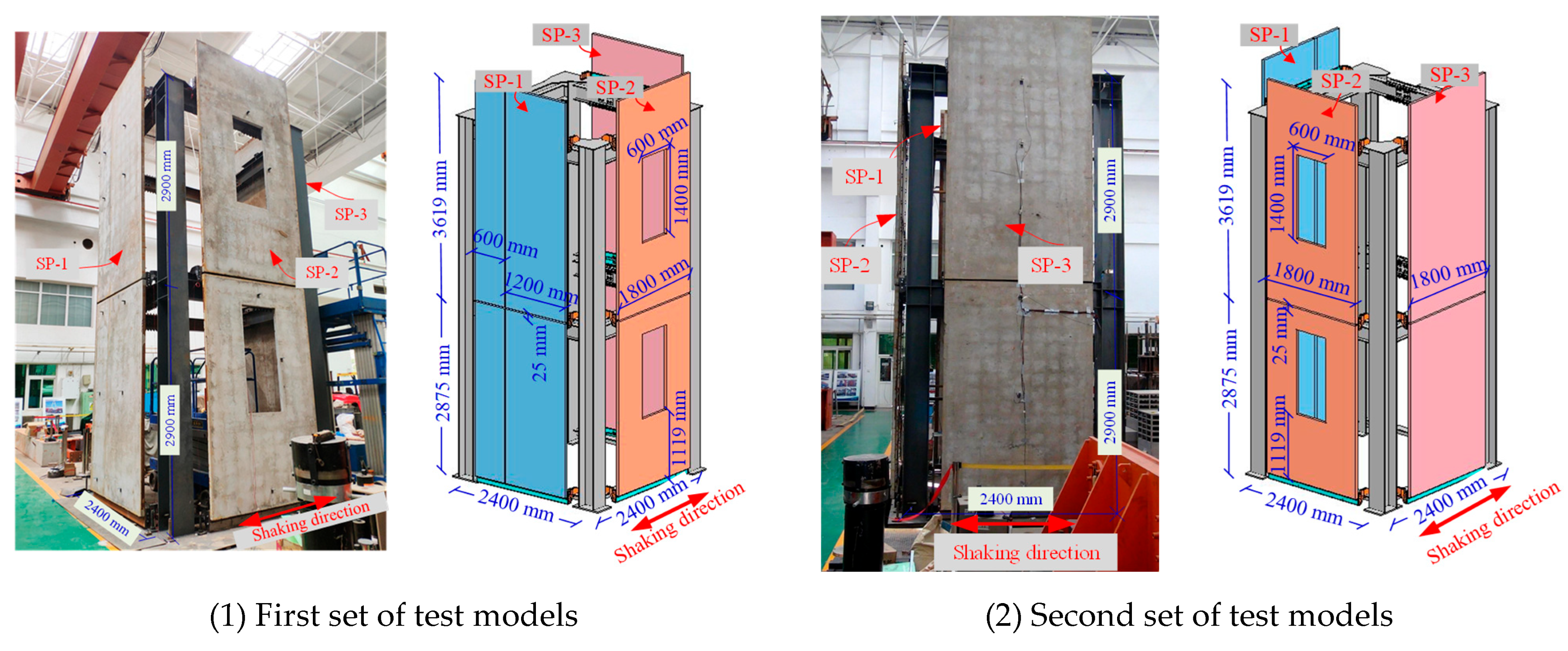

2.2. Test Specimen

2.3. Material Properties

2.4. Test Setup and Instrumentation

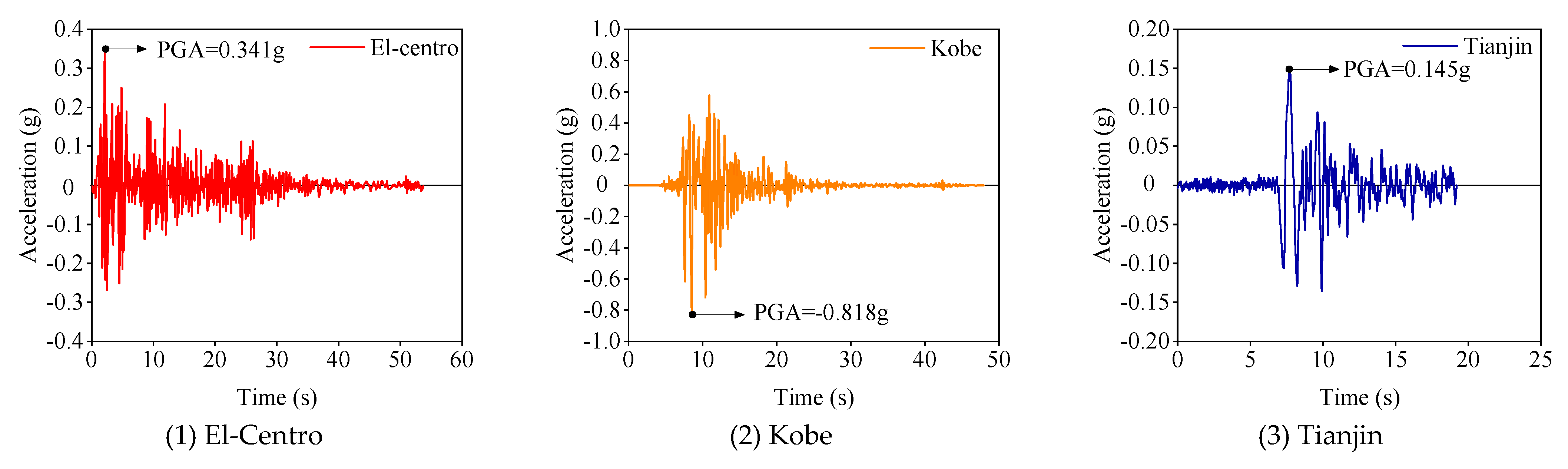

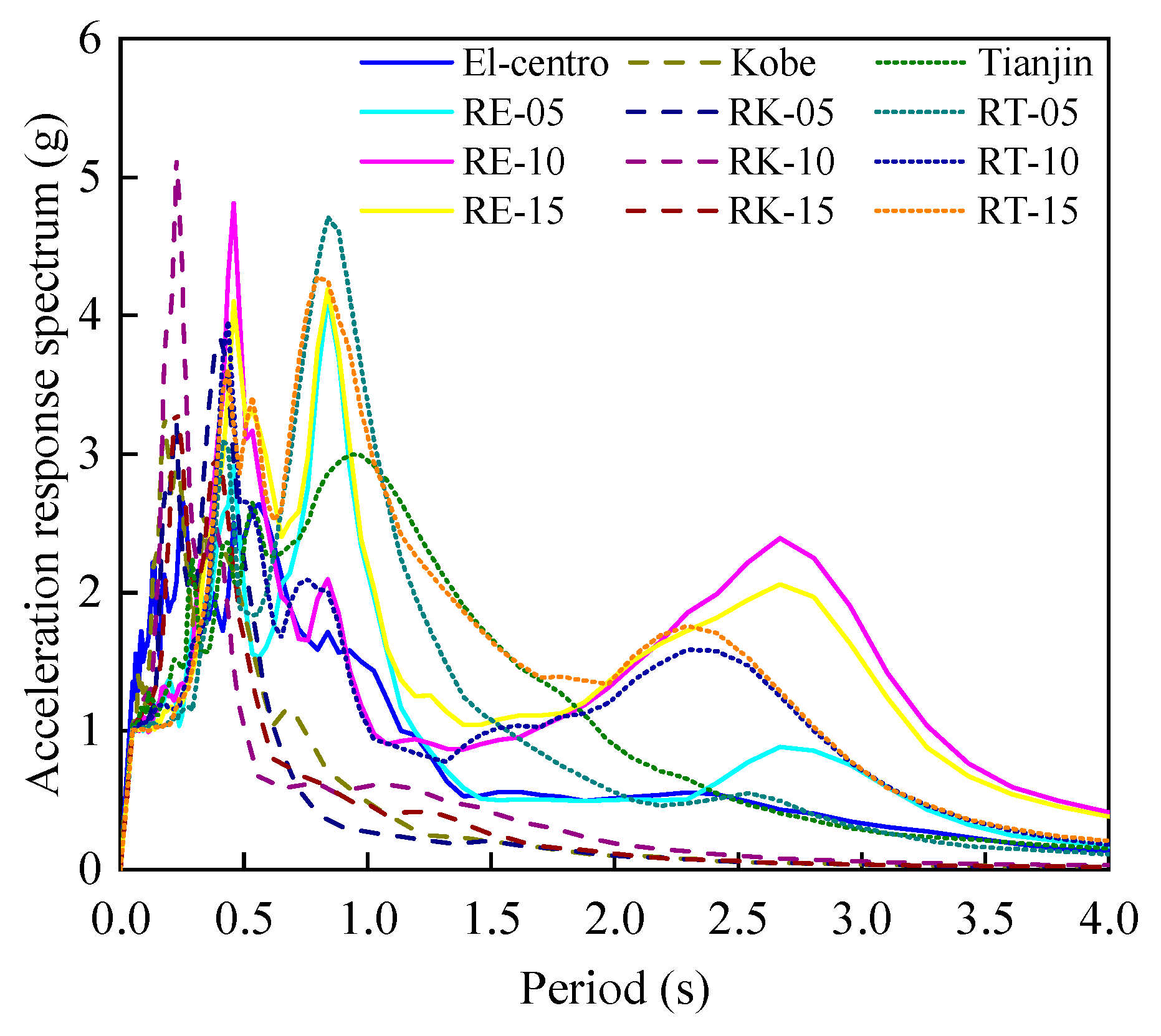

3. Inputs

4. Results and Discussion

4.1. Experimental Observations

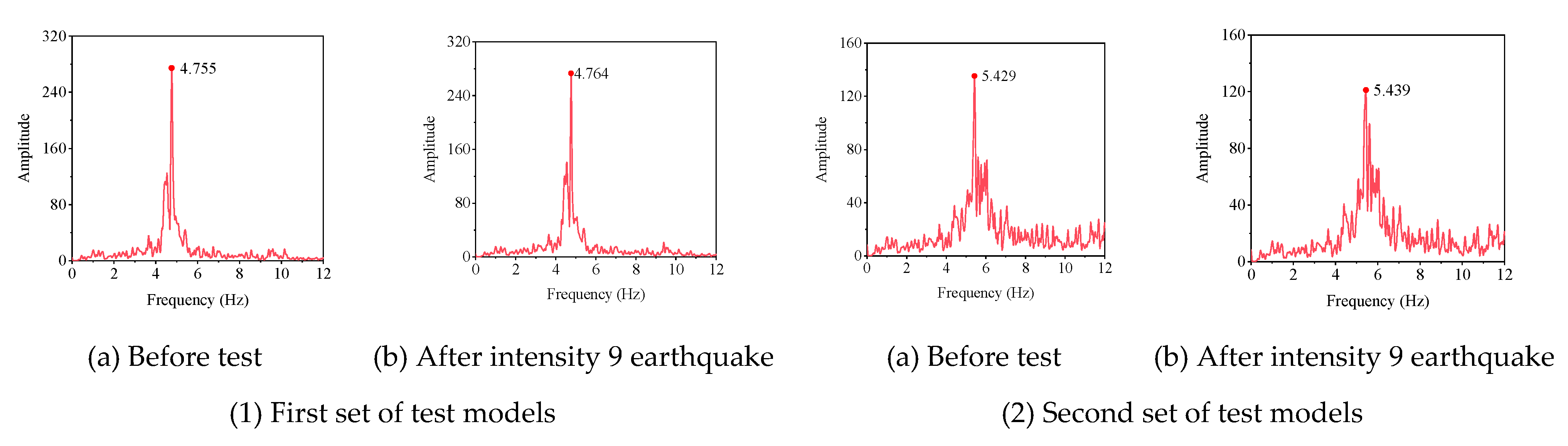

4.2. Dynamic Characteristics

4.3. Acceleration Response

- (1)

- In the in-plane direction, the acceleration amplification factors of the composite wall panel SP-1, open window wall panel SP-2, and integral wall panel SP-3 were found to be in the ranges of 0.881–1.304, 0.994–1.400, and 0.753–1.330, respectively, which were less than the code values (2.0 for prefabricated building elements) [21]. This indicated that the CBW flexible connection nodes had a good cushioning effect on the PC exterior wall panels.

- (2)

- For the out-of-plane direction, the acceleration amplification factors of the composite wall panel SP-1, open window wall panel SP-2, and integral wall panel SP-3 were found to be in the ranges of 0.998–2.094, 1.379–2.199, and 1.056–2.074, respectively.

- (3)

- For the exterior wall panels of the same types, the acceleration amplification factor of the exterior wall panels in the out-of-plane direction was larger than that in the in-plane direction. For the different types of exterior wall panels, the in-plane and out-of-plane acceleration amplification coefficients of the open window panel SP-2 were the largest, primarily because the in-plane and out-of-plane stiffnesses of the window panels weakened after opening the holes.

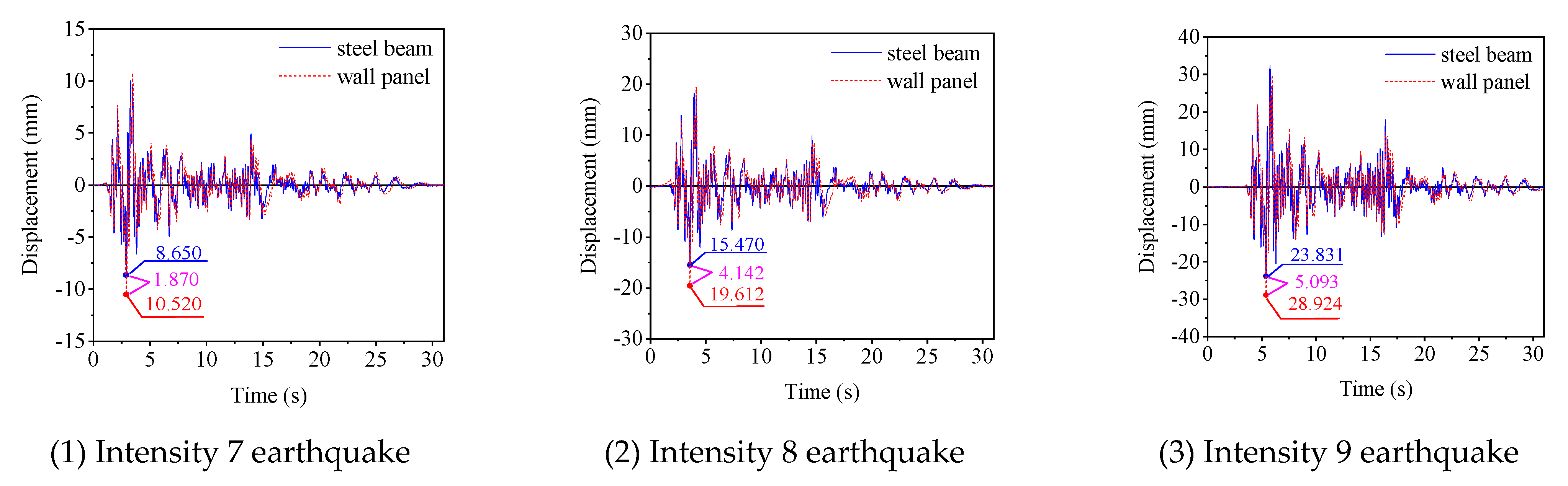

4.4. Displacement Response

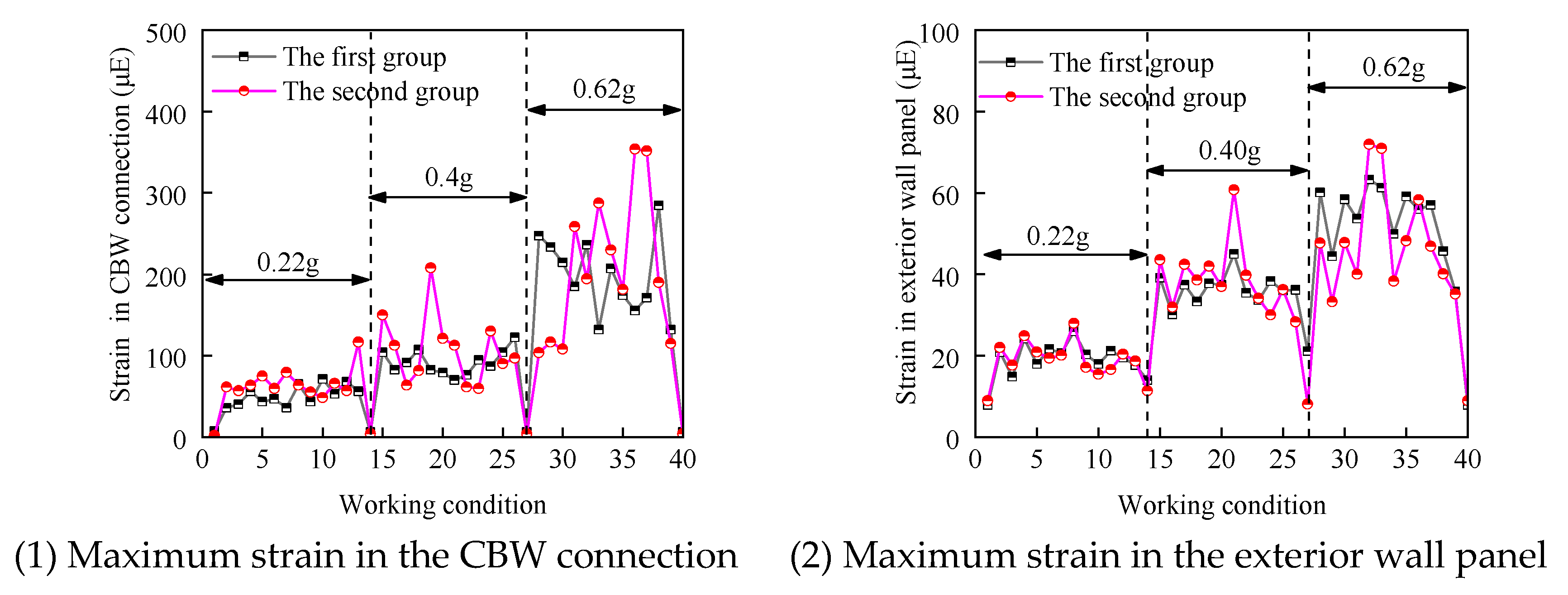

4.5. Strain Response

5. Conclusions

- (1)

- The flexible CBW connection nodes and the surfaces of the composite panel SP-1, open window panel SP-2, and integral panel SP-3 remained intact after intensity 7, 8, and 9 earthquakes. Only the exterior wall panels showed slight damage at the corners.

- (2)

- The in-plane and out-of-plane acceleration amplification coefficients of the three types of PC exterior wall panels with CBW flexible connection nodes were obtained under twelve seismic waves and three seismic intensity levels, as were the displacement amplification coefficients.

- (3)

- The CBW flexible connection node had a good deformation capacity that allowed it to coordinate the deformation of the exterior wall panels both in-plane and out-of-plane. This was useful for the design of other connection nodes in the project.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Li, Z.; Wang, W.; Li, Z.; Wang, H. A Review on the Seismic Performance of Assembled Steel Frame-Precast Concrete Facade Panels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 690, 012003. [Google Scholar] [CrossRef]

- Baek, J.-W.; Hwang, H.-J.; Kang, S.-M.; Park, H.-G. Shaking Table Test for Dimension Stone Cladding with Dowel Pin Connection. J. Build. Eng. 2023, 70, 106390. [Google Scholar] [CrossRef]

- Lee, H.-S.; Oh, M.-H.; Kim, W.-S. Structural Performance of Curtain Wall Using Separate Interstorey Modules and Three-Axis Mobile Fasteners. J. Korean Soc. Adv. Comp. Struct. 2020, 11, 34–45. [Google Scholar] [CrossRef]

- Huang, B.; Lu, W.; Günay, S. Shaking Table Tests of Granite Cladding with Dowel Pin Connection. Bull. Earthq. Eng. 2020, 18, 1081–1105. [Google Scholar] [CrossRef]

- Ding, K.; Zong, D.; Liu, Y.; He, S.; Shen, W. Experimental and Finite Element Analysis of External ALC Panel Steel Frames with New Semi-Rigid Connector. Appl. Sci. 2021, 11, 10990. [Google Scholar] [CrossRef]

- Song, Z.; Zhou, Y.; Lu, Y. Shaking table test of a 10-storey self-centering tube building. Earthq. Eng. Struct. Dyn. 2023, 52, 1511–1535. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, Z.; Huang, D.; Chui, Y.-H. Cyclic Loading Behavior of an Innovative Semi-Rigid Connection for Engineered Bamboo-Steel Hybrid Frames. J. Build. Eng. 2019, 24, 100754. [Google Scholar] [CrossRef]

- Li, Y.; Gao, C.; Yan, Y.; Ning, Z. Experimental Study on the Seismic Performance of Steel Frames with Infill ALC Wall Panels. J. Build. Eng. 2023, 65, 105739. [Google Scholar] [CrossRef]

- Wang, J.; Shen, Q.; Li, B. Seismic Behavior Investigation on Blind Bolted CFST Frames with Precast SCWPs. Int. J. Steel Struct. 2018, 18, 1666–1683. [Google Scholar] [CrossRef]

- Wang, J.; Li, B. Cyclic Testing of Square CFST Frames with ALC Panel or Block Walls. J. Constr. Steel Res. 2017, 130, 264–279. [Google Scholar] [CrossRef]

- De Matteis, G. Effect of Lightweight Cladding Panels on the Seismic Performance of Moment Resisting Steel Frames. Eng. Struct. 2005, 27, 1662–1676. [Google Scholar] [CrossRef]

- Zhenggang, C.; Peng, D.; Feng, F.; Ming, F. Cyclic Testing and Parametric Analyses of the Fabricated Steel Frames Infilled with Autoclaved Aerated Concrete Panels. Adv. Struct. Eng. 2017, 20, 629–640. [Google Scholar] [CrossRef]

- Gokmen, F.; Binici, B.; Taghipour, A.; Canbay, E. Seismic Behavior of Autoclaved Aerated Concrete Low Rise Buildings with Reinforced Wall Panels. Bull. Earthq. Eng. 2019, 17, 3933–3957. [Google Scholar] [CrossRef]

- Wang, B.; Wang, J.; Gong, X.; Liu, B. Experimental Studies on Circular CFST Frames with ALC Walls under Cyclic Loadings. Int. J. Steel Struct. 2014, 14, 755–768. [Google Scholar] [CrossRef]

- Vaghei, R.; Hejazi, F.; Firoozi, A.A. Analytical Model for Precast Wall Equipped with U-Shaped Steel Channel Connection. Structures 2021, 32, 406–432. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, K.; Tao, M. Test Study on Slipping Performance of the Flexible Nodes of the Precast Concrete Exterior Wall Cladding Panel. Adv. Mater. Res. 2014, 940, 284–288. [Google Scholar] [CrossRef]

- Du, D.; Wang, S.; Li, W.; Xu, F.; Liu, W. Seismic Performance of the Pre-Fabricated Steel Frame Infilled with AAC Wall Panels and Their Joint Connection: Full-Scale Shaking Table Test. J. Earthq. Tsunami 2019, 13, 1940004. [Google Scholar] [CrossRef]

- Cui, J.; He, S.; Ding, K.; Zhang, Y.; Kong, X. Cyclic Behavior of Autoclaved Aerated Concrete External Panel with New Connector. Materials 2022, 15, 8778. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.-J.; Wang, J.-F.; Li, G.-Q. Shaking Table Test of Steel Frame with ALC External Wall Panels. J. Constr. Steel Res. 2013, 80, 278–286. [Google Scholar] [CrossRef]

- GB/T 51232-2016; Technical Standard for Assembled Buildings with Steel-Structure. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016. (In Chinese)

- GB 50010-2010; Code for Design of Concrete Structures. China Building Industry Press: Beijing, China, 2015. (In Chinese)

- JGJ/T 458—2018; Application Technical Standard of Precast Concrete External Wall Panel. China Building Standards Design and Research Institute Co., Ltd.: Beijing, China; China Resources Land Co., Ltd.: Hong Kong, China; China Architecture and Building Press: Beijing, China, 2018. (In Chinese)

- GB50017–2017; Standard for Design of Steel Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017. (In Chinese)

- GB/T 228.1-2010; Metallic Materials-Tensile Testing—Part 1: Method of Test at Room Temperature. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Building Industry Press: Beijing, China, 2019. (In Chinese)

- GB/T 3098.1–2010; Mechanical Properties of Fasteners Bolts, Screws and Studs. State Administration for Market Regulation: Beijing, China, 2010. (In Chinese)

| Es or Ec (MPa) | fy (MPa) | fu (MPa) | fcu (MPa) | fc (MPa) | ft (MPa) | |

|---|---|---|---|---|---|---|

| Q345 steel | 206,000 | 360.96 | 487.66 | — | — | — |

| Q235 steel | 205,000 | 323.14 | 460.25 | — | — | — |

| Concrete | 32,105 | — | — | 37.93 | 25.37 | 2.57 |

| Sensors | Location | Number (Quantity) | No. |

|---|---|---|---|

| Acceleration sensors | Shaking table | 2 | A-1, A-2 |

| Each storey’s steel-frame beam | 6 | AK-1, AK-2, AK-3, ..., AK-6 | |

| Exterior wall panel at the height of the storey | 9 | AC-1, AC-3, AC-5, AW-1, AW-3, AW-5, AI-1, AI-3, AI-5 | |

| The centre of the exterior wall panel | 8 | AC-2, AC-4, AC-6, AC-7, AW-2, AW-4, AI-2, AI-4 | |

| Displacement sensors | Between the exterior wall panel and the steel beam | 9 | DC-1, DC-2, DC-3, DW-1, DW-2, DW-3, DI-1, DI-2, DI-3 |

| Strain gauges | The centre of the exterior wall panel | 6 | SC-1, SC-2, SW-1, SW-2, SI-1, SI-2 |

| The cantilever block | 27 | SN-1, SN-2, SN-3, ..., SN-27 |

| Order | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Numbering | El-Centro | RE-05 | RE-10 | RE-15 | Kobe | RK-05 | RK-10 | RK-15 | Tianjin | RT-05 | RT-10 | RT-15 |

| Seismic Intensity | During Test | After Test |

|---|---|---|

| 7 (0.22 g) | The exterior wall panels followed the movement of the steel frame. | The exterior wall panels were in good surface condition. |

| 8 (0.4 g) | The centre of the exterior wall panel (out-of-plane movement) protruded, with sound when the wall panel collided with the steel frame. | The concrete surface at the connection between the exterior wall panel and the CBW flexible connection node cracked (Figure 9). |

| 9 (0.62 g) | The centre of the exterior wall panel (out-of-plane movement) protruded significantly (Figure 9), and the sound was louder. | The surface of the exterior wall panel was largely intact, with slightly broken concrete at the corners. The CBW flexible connection node remained intact. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Li, Z.; Liu, P.; Ma, H.; Yang, J.; Kang, Z. Full Size Two-Layer Steel Frame–Exterior Wall Panel Shaking-Table Test. Buildings 2024, 14, 634. https://doi.org/10.3390/buildings14030634

Yang B, Li Z, Liu P, Ma H, Yang J, Kang Z. Full Size Two-Layer Steel Frame–Exterior Wall Panel Shaking-Table Test. Buildings. 2024; 14(3):634. https://doi.org/10.3390/buildings14030634

Chicago/Turabian StyleYang, Beibei, Zhenbao Li, Ping Liu, Hua Ma, Jiulong Yang, and Zhicheng Kang. 2024. "Full Size Two-Layer Steel Frame–Exterior Wall Panel Shaking-Table Test" Buildings 14, no. 3: 634. https://doi.org/10.3390/buildings14030634

APA StyleYang, B., Li, Z., Liu, P., Ma, H., Yang, J., & Kang, Z. (2024). Full Size Two-Layer Steel Frame–Exterior Wall Panel Shaking-Table Test. Buildings, 14(3), 634. https://doi.org/10.3390/buildings14030634