Reduced Volume Approach to Evaluate Biaxial Bubbled Slabs’ Resistance to Punching Shear

Abstract

:1. Introduction

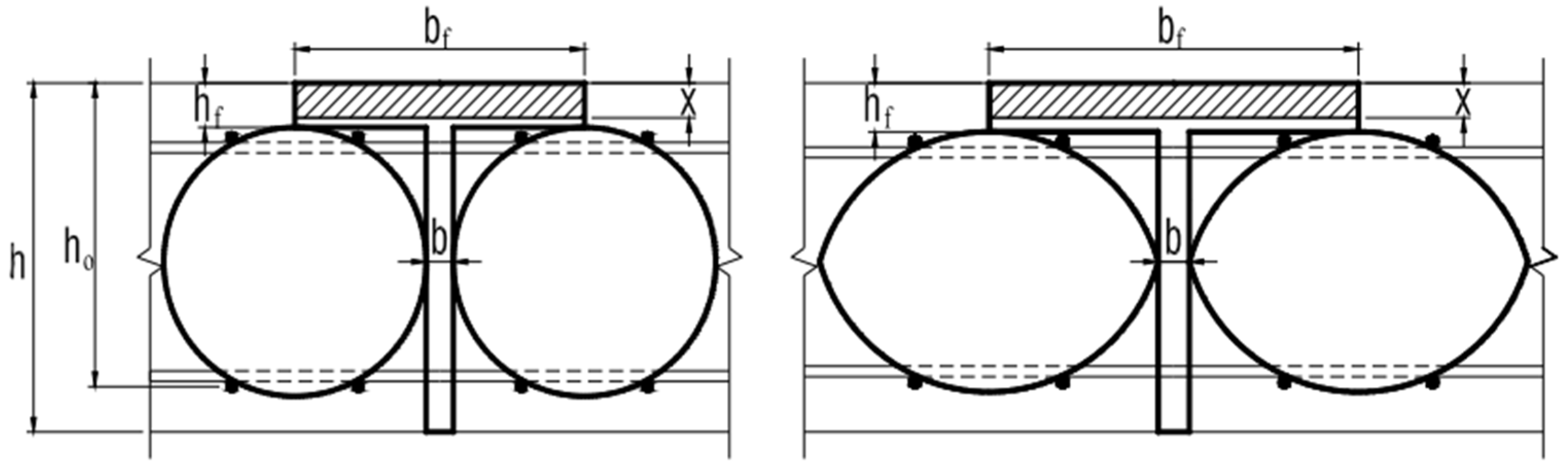

2. Literature Review on the Strength of Biaxial Voided Slabs

2.1. Punching Shear Strength of Biaxial Voided Slabs

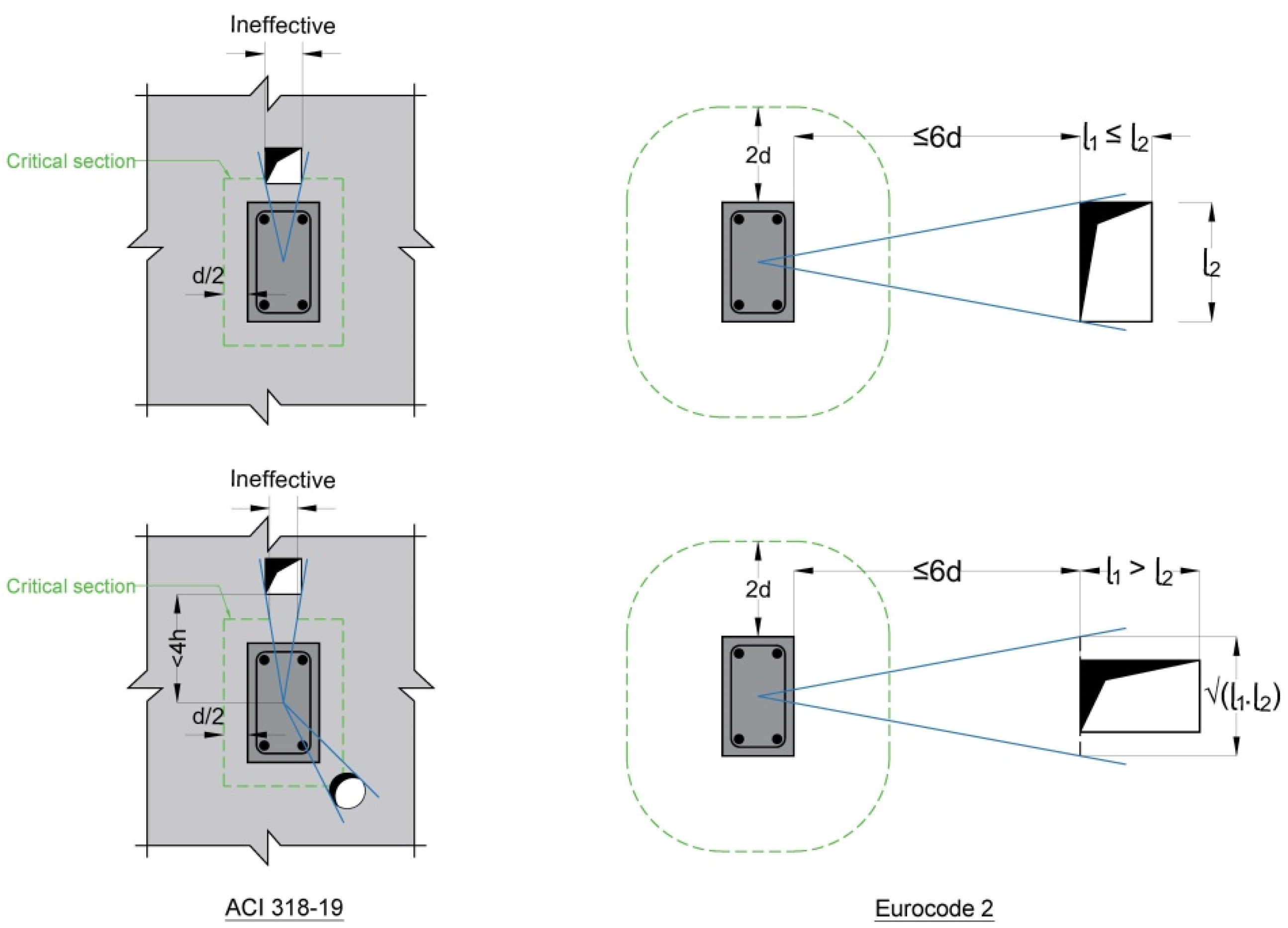

2.2. Impact of Opening on Strength of Flat Slabs

2.3. Investigated Parameters and Objectives of the Present Work

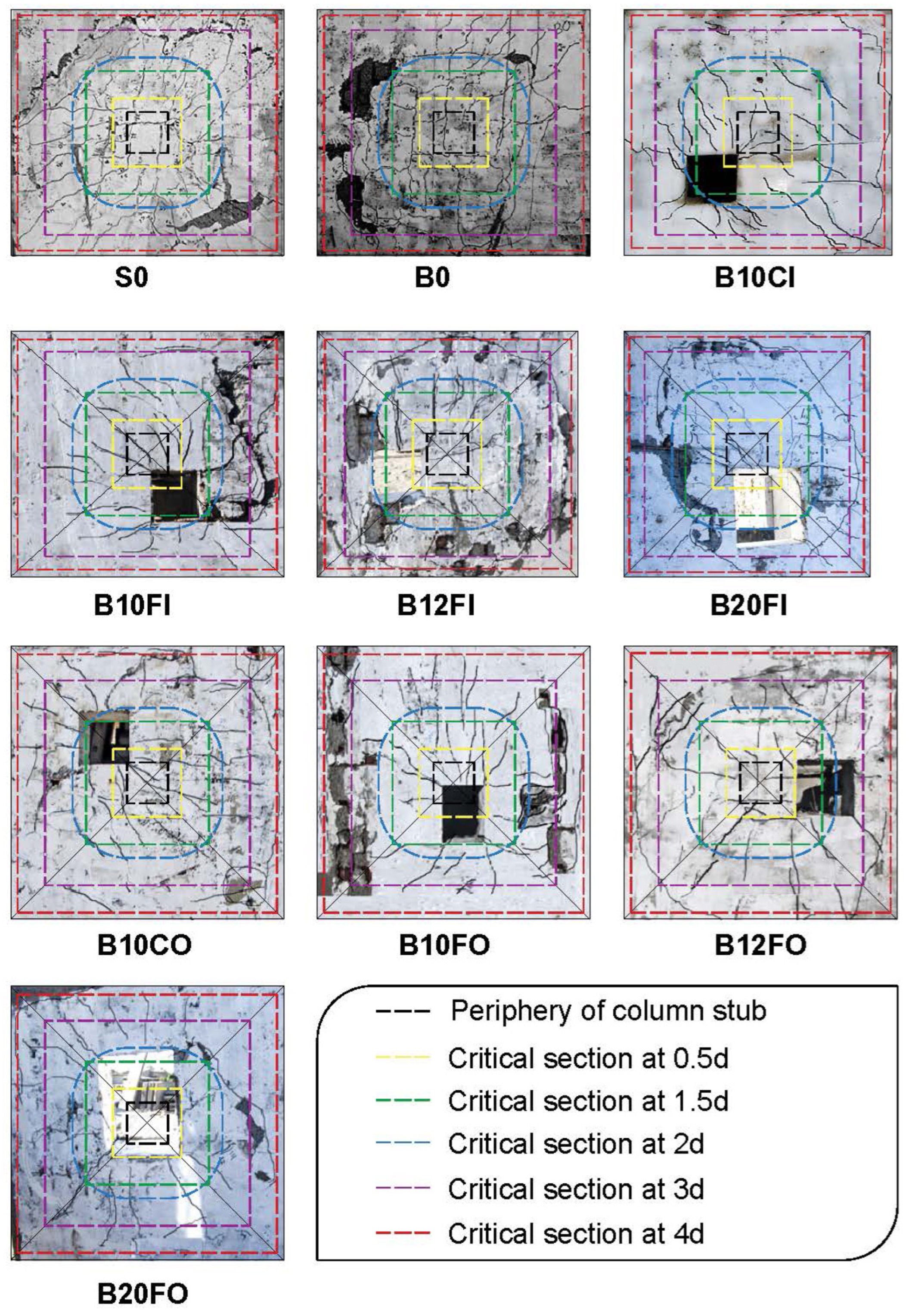

3. Experimental Program and Test Matrix

3.1. Description of Tested Specimens, Test Setup, and Instrumentation

- The type of slab specimen [biaxial voided (B) or solid (S)];

- The dimensions of the opening that was created [300 × 300 mm (1) or 450 × 450 mm (2)];

- The opening-to-column-stub-face distance [0 mm (0) or 200 mm (2)];

- The placement of the opening with respect to the column stub [in front of (F) or in the column’s corner (C)]; and

- The arrangement of voiding formers in relation to the control shear perimeter [voiding formers across all regions (I) or only outside the critical section (O)].

3.2. Concrete and Reinforcement Materials

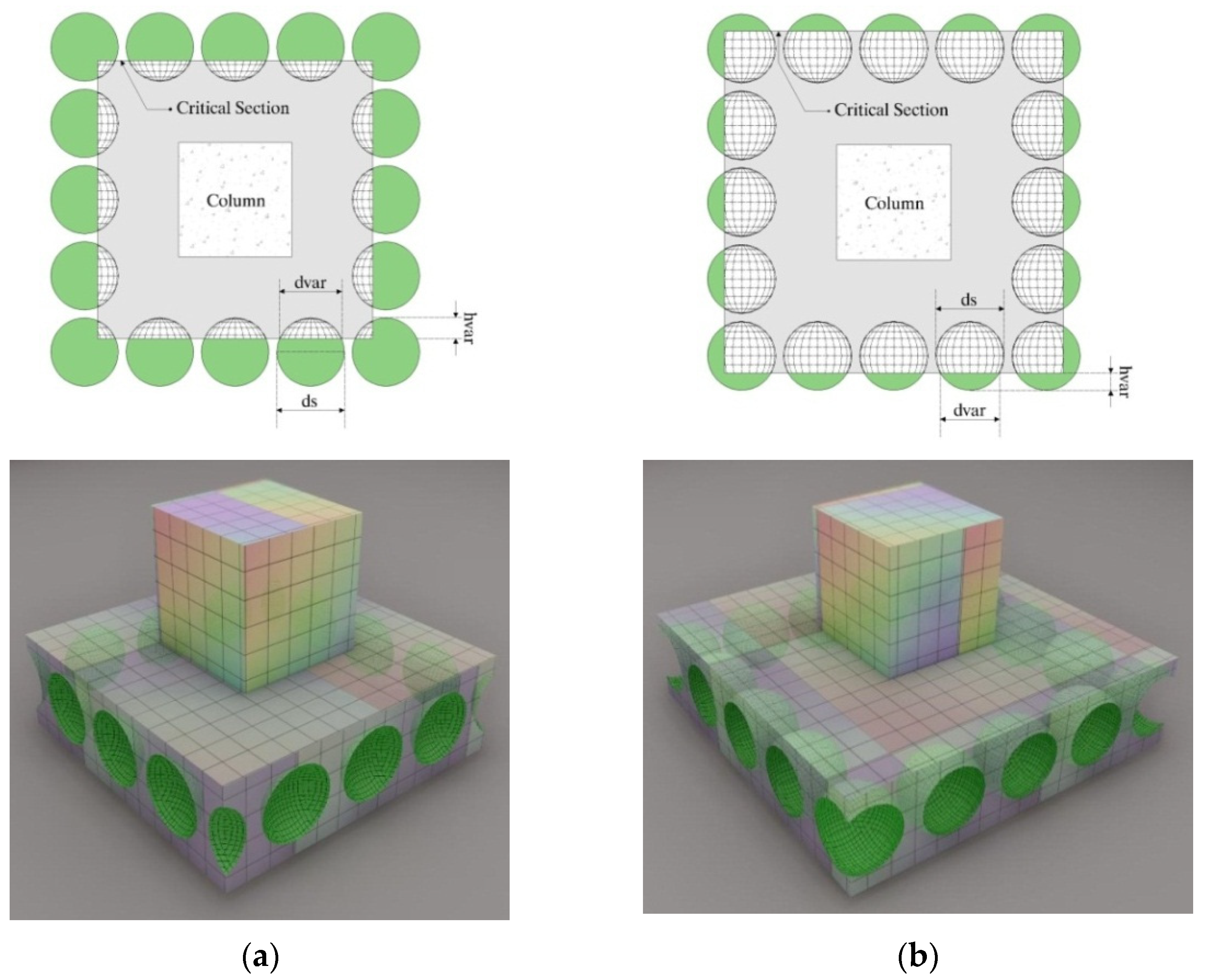

4. Theoretical Evaluation of the Critical Shear Perimeter in Biaxial Voided Slabs

4.1. General

4.2. Modification of the Critical Shear Perimeter to Consider Cavities

4.3. Design Recommendations

5. American and European Standards for the Punching Shear Resistance of Concrete Slabs

6. Adopted Treatments for Critical Openings in Concrete Slabs

7. Outcomes of This Study

7.1. Experimental Results and Discussion

7.2. Analytical Results and Discussion

8. Conclusions

- This article presents novel equations, which demonstrate substantial agreement with experimental findings, for computing the effective punching shear perimeter based on a reduced-volume concept.

- This article draws attention to the fact that, when voids are taken into account, the traditional approaches of the ACI 318-19 and Eurocode 2 design codes may overestimate or underestimate the punching shear capabilities of biaxial voided slabs. When the hollow plastic spheres were arranged throughout the entire specimen, with the exception of the area beneath the column, the estimated punching shear strength according to the ACI 318-19 was 32% to 51% less than what the tested value was; when the spheres were arranged outside the critical shear perimeter of (2d), the calculated punching shear resistance was 28% to 34% higher than the test value. According to the Eurocode 2, these values were found to be 16% to 38% lower than the test values for the first group and 23% to 27% higher than the test values for the second group.

- Our suggested approach provides increased precision and consistency for estimating the shear capacity of biaxial voided slabs. It was found that the biggest differences observed between the test results and the calculated shear strength were below 8% and 11%, respectively, as per the ACI 318-19 and Eurocode 2 methodologies.

- It is important to accurately account for the presence and location of voiding formers in these analysis calculations to ensure the accurate prediction of punching shear resistance. Given that the coefficient of variation of the proposed expressions for the slabs investigated in the current study is not greater than 0.057, our recommended treatment of the influence of voiding formers in biaxial hollow slabs on the slabs’ shear capacity was found to be quite reasonable.

- The suggested approach had the lowest coefficient of variation when compared to other approaches that had previously been advised by the aforementioned practice codes. This fact demonstrates that our proposed approach is trustworthy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Midkiff, C.J. Plastic Voided Slab Systems: Applications and Design. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2013. [Google Scholar]

- Marais, C.C. Design Adjustment Factors and the Economical Application of Concrete Flat-Slabs with Internal Spherical Voids in South Africa. Master’s Dissertation, University of Pretoria, Hatfield, South Africa, 2008. Available online: http://hdl.handle.net/2263/27476 (accessed on 2 October 2023).

- Marais, C.C.; Robberts, J.M.; van Rensburg, B.W.J. Spherical void formers in concrete slabs. J. S. Afr. Inst. Civ. Eng. 2010, 52, 2–11. [Google Scholar]

- Khouzani, M.A.; Zeynalian, M.; Hashemi, M.; Mostofinejad, D.; Farahbod, F.; Shahadifar, M. A numerical study on flexural behavior of biaxial voided slabs containing steel cages. J. Build. Eng. 2021, 44, 103382. [Google Scholar] [CrossRef]

- Hai, L.V.; Hung, V.D.; Thi, T.M.; Nguyen-Thoi, T.; Phuoc, N.T. The Experimental Analysis of BubbleDecK Slab Using Modified Elliptical Balls. In Proceedings of the Thirteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-13), Sapporo, Japan, 11–13 September 2013. G-6-1. [Google Scholar]

- Churakov, A. Biaxial hollow slab with innovative types of voids. Constr. Unique Build. Struct. 2014, 21, 70–88. [Google Scholar]

- Adil, A.I.; Hejazi, F.; Rashid, R.S.M. Voided Biaxial Slabs—State of Art. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012004. [Google Scholar] [CrossRef]

- Gamal, M.; Heiza, K.; Hekal, G.M.; Nabil, A. Voided Slabs As A New Construction Technology-A Review. In Proceedings of the International Conference on Advances in Structural and Geotechnical Engineering, ICASGE’23, Hurghada, Egypt, 6–9 March 2023; 22p. [Google Scholar]

- Nasvik, J. On the bubble: Placing concrete around plastic voids increase efficiency and reduces costs. Concr. Constr.-World Concr. 2011, 56, 20–22. [Google Scholar]

- Wesley, N. Viscoelastic Analysis of Biaxial Hollow Deck Balls. Int. J. Comput. Aided Eng. 2013, 23, 1103–1110. [Google Scholar]

- Schnellenbach-Held, M.; Pfeffer, K. Punching Behavior of Biaxial Hollow Slabs. Cem. Concr. Compos. 2002, 24, 551–556. [Google Scholar] [CrossRef]

- Broms, C.E. Elimination of flat plate punching failure mode. ACI Struct. J. 2000, 97, 94–101. [Google Scholar] [CrossRef]

- Hegger, J.; Ricker, M.; Sherif, A.G. Punching Strength of Reinforced Concrete Footings. ACI Struct. J. 2009, 106, 706–716. [Google Scholar]

- Siburg, C.; Ricker, M.; Hegger, J. Punching Shear Design of Footings: Critical Review of Different Code Provisions. Struct. Concr. 2014, 15, 497–508. [Google Scholar] [CrossRef]

- Bhagat, S.; Parikh, K.B. Parametric Study of R.C.C Voided and Solid Flat Plate Slab using SAP 2000. IOSR J. Mech. Civ. Eng. 2014, 11, 12–16. [Google Scholar] [CrossRef]

- Arslan, G.; Polat, Z. Contribution of Concrete to Shear Strength of RC Beams Failing in Shear. J. Civ. Eng. Manag. 2013, 19, 400–408. [Google Scholar] [CrossRef]

- Birkle, G.; Dilger, W.H. Shear Strength of Slabs with Double-Headed Shear Studs in Radial and Orthogonal Layouts. Int. Concr. Abstr. Portal 2009, 265, 499–510. [Google Scholar]

- Borges, L.L.J.; Melo, G.S.; Gomes, R.B. Punching shear of reinforced concrete flat plates with openings. ACI Struct. J. 2013, 110, 547–556. [Google Scholar] [CrossRef]

- Vainiṹnas, P.; Popovas, V.; Jarmolajev, A. Punching Shear Behaviour Analysis of RC Flat Floor Slab-to-Column Connection. J. Civ. Eng. Manag. 2002, 8, 77–82. [Google Scholar] [CrossRef]

- AL-Mohammadi, A.; AL-Bayati, A. Punching Shear Strength of Voided Slab: Literature Review and Evaluation of Design Codes. Wasit J. Eng. Sci. 2022, 10, 131–145. [Google Scholar] [CrossRef]

- Valivonis, J.; Šneideris, A.; Šalna, R.; Popov, V.; Daugevicius, M.; Jonaitis, B. Punching Strength of Biaxial Voided Slabs. ACI Struct. J. 2017, 114, 1373–1383. [Google Scholar] [CrossRef]

- Valivonis, J.; Skuturna, T.; Daugevičius, M.; Sneideris, A. Punching shear strength of reinforced concrete slabs with plastic void formers. Constr. Build. Mater. 2017, 145, 518–527. [Google Scholar] [CrossRef]

- Valivonis, J.; Jonaitis, B.; Zavalis, R.; Skuturna, T.; Šneideris, A. Flexural Capacity and Stiffness of Monolithic Biaxial Hollow Slabs. J. Civ. Eng. Manag. 2014, 20, 693–701. [Google Scholar] [CrossRef]

- Albrecht, C.; Albert, A.; Pfeffer, K.; Schnell, J. Design and Construction of Two-Way Spanning Reinforced Concrete Slabs with Flattened Rotationally Symmetrical Void Formers. Concr. Reinf. Concr. Constr. 2012, 107, 2–12. [Google Scholar]

- Han, S.W.; Lee, C.S. Evaluation of Punching Shear Strength of Voided Transfer Slabs. Mag. Concr. Res. 2014, 66, 1116–1128. [Google Scholar] [CrossRef]

- Sakin, S.T. Punching Shear in Voided Slab. Civ. Environ. Res. 2014, 6, 36–43. [Google Scholar]

- Oukaili, N.K.; Husain, L.F. Punching Shear Strength of BubbleDecks under Eccentric Loads. In Proceedings of the Second International Conference on Science, Engineering & Environment, Osaka, Japan, 21–23 November 2016; pp. 222–227. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318–19) and Commentary (ACI 318R–19); American Concrete Institute: Farmington Hills, MI, USA, 2019; p. 623. [Google Scholar]

- EN 1992-1-1; Eurocode 2—Design of Concrete Structures—Part 1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004; p. 225.

- Shaaban, I.G.; Hosni, A.H.; Montaser, W.M.; El-Sayed, M.M. Effect of premature loading on punching resistance of reinforced concrete flat slabs. Case Stud. Constr. Mater. 2020, 12, e00320. [Google Scholar] [CrossRef]

- Chung, J.H.; Choi, H.K.; Lee, S.C.; Choi, C.S. Punching Shear Strength of Biaxial Hollow Slab with Donut Type Hollow Sphere. Key Eng. Mater. 2011, 452–453, 777–780. [Google Scholar] [CrossRef]

- Sagadevan, R.; Rao, B.N. Experimental and analytical investigation of punching shear capacity of biaxial voided slabs. Structures 2019, 20, 340–352. [Google Scholar] [CrossRef]

- Sagadevan, R.; Rao, B.N. Punching shear capacity of RC biaxial voided slab—prediction by critical shear crack theory. In Proceedings of the 12th Structural Engineering Convention (SEC 2022), NCDMM, MNIT, Jaipur, India, 19–22 December 2022; pp. 411–415. [Google Scholar] [CrossRef]

- Ibrahim, A.; Ismael, M.; Abdul Hussein, H. The Effect of Balls Shapes and Spacing on Structural Behaviour of Reinforced Concrete Bubbled Slabs. J. Eng. Sustain. Dev. 2019, 23, 56–65. [Google Scholar] [CrossRef]

- Oukaili, N.; Hussein, L. Experimental and Analytical Study on Punching Shear Strength of BubbleDecks. ACI Struct. J. 2020, 117, 17–31. [Google Scholar] [CrossRef]

- Gajewski, T.; Staszak, N.; Garbowski, T. Optimal Design of Bubble Deck Concrete Slabs: Serviceability Limit State. Materials 2023, 16, 4897. [Google Scholar] [CrossRef] [PubMed]

- Hognestad, E.; Elstner, R.C.; Hanson, J.A. Shear Strength of Reinforced Structural Lightweight Aggregate Concrete Slabs. ACI J. Proc. 1964, 61, 643–656. [Google Scholar]

- Broms, C.E. Punching of Flat Plates—A Question of Concrete Properties in Biaxial Compression and Size Effect. ACI Struct. J. 1990, 87, 292–304. [Google Scholar] [CrossRef]

- El-Salakawy, E.F.; Polak, M.A.; Soliman, M.H. Reinforced Concrete Slab-Column Edge Connections with Openings. ACI Struct. J. 1999, 96, 79–87. [Google Scholar]

- Teng, S.; Cheong, H.K.; Kuang, K.L.; Geng, J.Z. Punching Shear Strength of Slabs with Openings and Supported on Rectangular Columns. ACI Struct. J. 2004, 101, 678–687. [Google Scholar]

- Oukaili, N.K.A.; Salman, T.S. Punching Shear Strength of Reinforced Concrete Flat Plates with Openings. J. Eng. Univ. Baghdad 2014, 20, 1–20. [Google Scholar] [CrossRef]

- Gomes, R.B.; Andrade, M.A.S. Punching in Reinforced Concrete Flat Slabs with Openings. Developments in Computer Aided Design and Modelling for Structural Engineering; Civil-Comp Press: Edinburgh, UK, 1995; pp. 185–193. [Google Scholar]

- Regan, P.E. Shear Reinforcement of Flat Slabs; TRITA-BKN Bulletin 57. In International Workshop Punching Shear Capacity of RC Slabs; Royal Institute of Technology: Stockholm, Sweden, 2000; pp. 97–107. [Google Scholar]

- Kuang, L.; Teng, S. Punching Shear Strength of Slabs with Openings and Supported on Rectangular Columns; School of Civil Engineering, Nanyang Technological University: Singapore, 2001; p. 298. [Google Scholar]

- El-Shafiey, T.F.; Atta, A.M.; Hassan, A.; Elnasharty, M. Effect of Opening Shape, Size and Location on the Punching Shear Behaviour of RC Flat Slabs. Structures 2022, 44, 1138–1151. [Google Scholar] [CrossRef]

- Al-Rousan, R.Z.; Alnemrawi, B.R. Punching Shear Code Provisions Examination Against the Creation of an Opening in Existed RC Flat Slab of Various Sizes and Locations. Structures 2023, 49, 875–888. [Google Scholar] [CrossRef]

- Hammood, H.J.; Esfandiari, J.; Movahednia, M.; Roudsari, M.T. Openings Effects on the Structural Behavior of Interior Voided Slab-Column Connections: An Experimental Study. Case Stud. Constr. Mater. 2023, 18, e01998. [Google Scholar] [CrossRef]

- Oukaili, N.; Merie, H. Reduced Area Approach for Predicting Punching Shear Resistance of Biaxial Hollow Slabs with Openings. Results Eng. 2023, 19, 101261. [Google Scholar] [CrossRef]

- Oukaili, N.; Merie, H. CFRP Strengthening Efficiency on Enhancement Punching Shear Resistance of RC Bubbled Slabs with Openings. Case Stud. Constr. Mater. 2021, 15, e00641. [Google Scholar] [CrossRef]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM 615/A615M-15; Standard Specifications for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2015.

- Braestrup, M.W.; Nielsen, M.P.; Jensen, B.C.; Bach, F. Axisymmetric Punching and Reinforced Concrete; Report No. R-75; Structural Research Laboratory, Technical University of Denmark: Kongens Lyngby, Denmark, 1976; p. 33. [Google Scholar]

- Salim, W.; Sebastian, W.M. Plasticity Model for Predicting Punching Shear Strengths of Reinforced Concrete Slabs. ACI Struct. J. 2002, 99, 827–835. [Google Scholar]

- Santos, J.B.D.; de Sales Melo, G.; Ruiz, M.F. Punching performance of flat slabs with openings accounting for the influence of moment transfer and shear reinforcement. Eng. Struct. 2024, 303, 117461. [Google Scholar] [CrossRef]

- Kinnunen, S.; Nylander, H. Punching of Concrete Slabs without Shear Reinforcement. Trans. R. Inst. Technol. 1960, 158, 112. [Google Scholar]

- Al-Bayati, A.F.; Lau, T.L.; Clark, L.A. Concentric Punching Shear of Waffle Slab. ACI Struct. J. 2015, 112, 533–542. [Google Scholar] [CrossRef]

| Specimen Designation | Distribution Pattern of Bubbles | Edge Length of Square Opening (mm) | Position of Opening in Relation to the Column | Column’s Distance from the Opening (mm) | |

|---|---|---|---|---|---|

| Group | S0 | - | - | - | - |

| B0 | across all regions | - | - | - | |

| I | B10CI | across all regions | 300 | at corner | 0 |

| B10FI | 300 | in front | 0 | ||

| B12FI | 300 | in front | 200 | ||

| B20FI | 450 | in front | 0 | ||

| II | B10CO | outside the critical section | 300 | at corner | 0 |

| B10FO | 300 | in front | 0 | ||

| B12FO | 300 | in front | 200 | ||

| B20FO | 450 | in front | 0 |

| Specimen | (MPa) | (kN) | (%) | (%) | (kN) | (%) |

|---|---|---|---|---|---|---|

| S0 | 26.6 | 200 | 100 | - | 760 | 100 |

| B0 | 25.5 | 160 | 80 | 100 | 480 | 63 |

| B10CI | 26.3 | 100 | 50 | 62.5 | 340 | 45 |

| B10FI | 26.3 | 80 | 40 | 50.0 | 300 | 39 |

| B12FI | 25.7 | 120 | 60 | 75.0 | 360 | 47 |

| B20FI | 27.4 | 60 | 30 | 37.5 | 260 | 34 |

| B10CO | 28.7 | 140 | 70 | 87.5 | 460 | 61 |

| B10FO | 28.2 | 120 | 60 | 75.0 | 410 | 54 |

| B12FO | 29.5 | 180 | 90 | 112.5 | 480 | 63 |

| B20FO | 27.2 | 100 | 50 | 62.5 | 360 | 47 |

| Specimen | (kN) | (%) | (%) | (%) | ||

|---|---|---|---|---|---|---|

| ACI 318-19 | Eurocode 2 | |||||

| Group | S0 | 760 | 100 | - | 100 | 100 |

| B0 | 480 | 63 | - | 65 | 69 | |

| I | B10CI | 340 | 45 | - | 58 | 61 |

| B10FI | 300 | 39 | - | 53 | 58 | |

| B12FI | 360 | 47 | - | 60 | 64 | |

| B20FI | 260 | 34 | - | 50 | 53 | |

| II | B10CO | 460 | 61 | 135.3 | 100 | 100 |

| B10FO | 410 | 54 | 136.7 | 100 | 100 | |

| B12FO | 480 | 63 | 133.3 | 100 | 100 | |

| B20FO | 360 | 47 | 138.5 | 100 | 100 | |

| Specimens | (kN) | Perimeter Used According to ACI 318-19 | Perimeter Used According to the Reduced-Volume Concept, Equation (16) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voids Are Not Considered | Voids Are Considered | |||||||||

| (mm) | (kN) | (%) | (mm) | (kN) | (%) | (mm) | (kN) | (%) | ||

| S0 | 760 | 2000 | 681 | 10 | 2000 | 681 | +10 | 2000 | 681 | +10 |

| B0 | 480 | 2000 | 667 | −39 | 704 | 235 | +51 | 1327 | 442 | +8 |

| B10CI | 340 | 1660 | 562 | −65 | 528 | 179 | +47 | 1025 | 347 | −2 |

| B10FI | 300 | 1500 | 508 | −69 | 528 | 179 | +40 | 869 | 294 | +2 |

| B12FI | 360 | 1770 | 592 | −64 | 666 | 222 | +38 | 1148 | 384 | −7 |

| B20FI | 260 | 1400 | 484 | −86 | 508 | 176 | +32 | 775 | 268 | −3 |

| B10CO | 460 | 1660 | 587 | −28 | 1660 | 587 | −28 | 1283 | 454 | +1 |

| B10FO | 410 | 1500 | 526 | −28 | 1500 | 526 | −28 | 1123 | 393 | +4 |

| B12FO | 480 | 1770 | 634 | −32 | 1770 | 634 | −32 | 1400 | 502 | −5 |

| B20FO | 360 | 1400 | 482 | −34 | 1400 | 482 | −34 | 985 | 339 | +6 |

| Specimens | (kN) | Perimeter Used According to Eurocode 2 | Perimeter Used According to the Reduced-Volume Concept, Equation (17) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Voids Are Not Considered | Voids Are Considered | |||||||||

| (mm) | (kN) | (%) | (mm) | (kN) | (%) | (mm) | (kN) | (%) | ||

| S0 | 760 | 3712 | 680 | +11 | 3712 | 680 | +11 | 3712 | 680 | +11 |

| B0 | 480 | 3712 | 671 | −40 | 1648 | 297 | +38 | 2367 | 428 | +11 |

| B10CI | 340 | 3012 | 550 | −62 | 1542 | 282 | +17 | 1806 | 330 | +3 |

| B10FI | 300 | 2784 | 508 | −69 | 1236 | 226 | +25 | 1544 | 282 | +6 |

| B12FI | 360 | 3212 | 582 | −62 | 1290 | 234 | +35 | 1985 | 360 | 0 |

| B20FI | 260 | 2462 | 456 | −75 | 1182 | 219 | +16 | 1387 | 257 | +1 |

| B10CO | 460 | 3012 | 566 | −23 | 3012 | 566 | −23 | 2519 | 474 | −3 |

| B10FO | 410 | 2784 | 520 | −27 | 2784 | 520 | −27 | 2291 | 428 | −4 |

| B12FO | 480 | 3212 | 609 | −27 | 3212 | 609 | −27 | 2728 | 518 | −8 |

| B20FO | 360 | 2462 | 455 | −26 | 2462 | 455 | −26 | 1997 | 369 | −3 |

| Standard | Treatment Concept | ) | ) | Coefficient of Variation (CV) |

|---|---|---|---|---|

| ACI 318-19 | Continuous section concept | 1.496 | 0.218 | 0.146 |

| Voided section concept | 0.903 | 0.385 | 0.427 | |

| Proposed reduced-volume concept | 0.995 | 0.05 | 0.05 | |

| Eurocode 2 | Continuous section concept | 1.457 | 0.212 | 0.145 |

| Voided section concept | 0.969 | 0.283 | 0.292 | |

| Proposed reduced-volume concept | 0.997 | 0.057 | 0.057 |

| Slab | (kN) | Perimeter According to Held and Pfefer Methodology | Perimeter According to Reduced-Volume Concept, Equation (16) or Equation (17) | ||||

|---|---|---|---|---|---|---|---|

| ACI 318-19 | Eurocode 2 | ||||||

| (kN) | (%) | (kN) | (%) | (kN) | (%) | ||

| D1-24 | 520 | 840 | −62 | 534 | −3 | 431 | +17 |

| D2-24 | 580 | 945 | −63 | 571 | +2 | 450 | +22 |

| D3-24 | 525 | 893 | −70 | 547 | -4 | 438 | +17 |

| D4-45 | 935 | 1503 | −61 | 888 | +5 | 1009 | −8 |

| D5-45 | 990 | 1701 | −72 | 1005 | −1 | 1095 | −11 |

| D6-45 | 1180 | 1795 | −52 | 1039 | 12 | 1120 | +5 |

| Average of () | 1.632 | 0.983 | 0.929 | ||||

| Standard of deviation () | 0.071 | 0.060 | 0.139 | ||||

| Coefficient of variation (CV) | 0.044 | 0.061 | 0.150 | ||||

| Slab | (kN) | Perimeter According to Valivonis et al. Methodology | Perimeter According to Reduced-Volume Concept, Equation (16) or Equation (17) | ||||

|---|---|---|---|---|---|---|---|

| ACI 318-19 | Eurocode 2 | ||||||

| (kN) | (%) | (kN) | (%) | (kN) | (%) | ||

| BP1-1 | 773 | 838 | −8 | 810 | −5 | 770 | 0 |

| BP1-2 | 801 | 835 | −4 | 801 | 0 | 762 | +5 |

| BP2-1 | 443 | 417 | +6 | 491 | −11 | 351 | +21 |

| BP2-2 | 451 | 436 | +3 | 580 | −29 | 453 | 0 |

| BP3-1 | 630 | 617 | +2 | 697 | −11 | 638 | −1 |

| BP3-2 | 658 | 626 | +5 | 717 | −9 | 657 | 0 |

| Average of () | 0.994 | 1.106 | 0.959 | ||||

| Standard of deviation () | 0.057 | 0.097 | 0.085 | ||||

| Coefficient of variation (CV) | 0.057 | 0.088 | 0.088 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oukaili, N.; Merie, H.; Allawi, A.; Wardeh, G. Reduced Volume Approach to Evaluate Biaxial Bubbled Slabs’ Resistance to Punching Shear. Buildings 2024, 14, 676. https://doi.org/10.3390/buildings14030676

Oukaili N, Merie H, Allawi A, Wardeh G. Reduced Volume Approach to Evaluate Biaxial Bubbled Slabs’ Resistance to Punching Shear. Buildings. 2024; 14(3):676. https://doi.org/10.3390/buildings14030676

Chicago/Turabian StyleOukaili, Nazar, Hammad Merie, Abbas Allawi, and George Wardeh. 2024. "Reduced Volume Approach to Evaluate Biaxial Bubbled Slabs’ Resistance to Punching Shear" Buildings 14, no. 3: 676. https://doi.org/10.3390/buildings14030676

APA StyleOukaili, N., Merie, H., Allawi, A., & Wardeh, G. (2024). Reduced Volume Approach to Evaluate Biaxial Bubbled Slabs’ Resistance to Punching Shear. Buildings, 14(3), 676. https://doi.org/10.3390/buildings14030676