Analyzing the Mechanical and Durability Characteristics of Steel Slag-Infused Asphalt Concrete in Roadway Construction

Abstract

:1. Introduction

2. Raw Materials and Test Methods

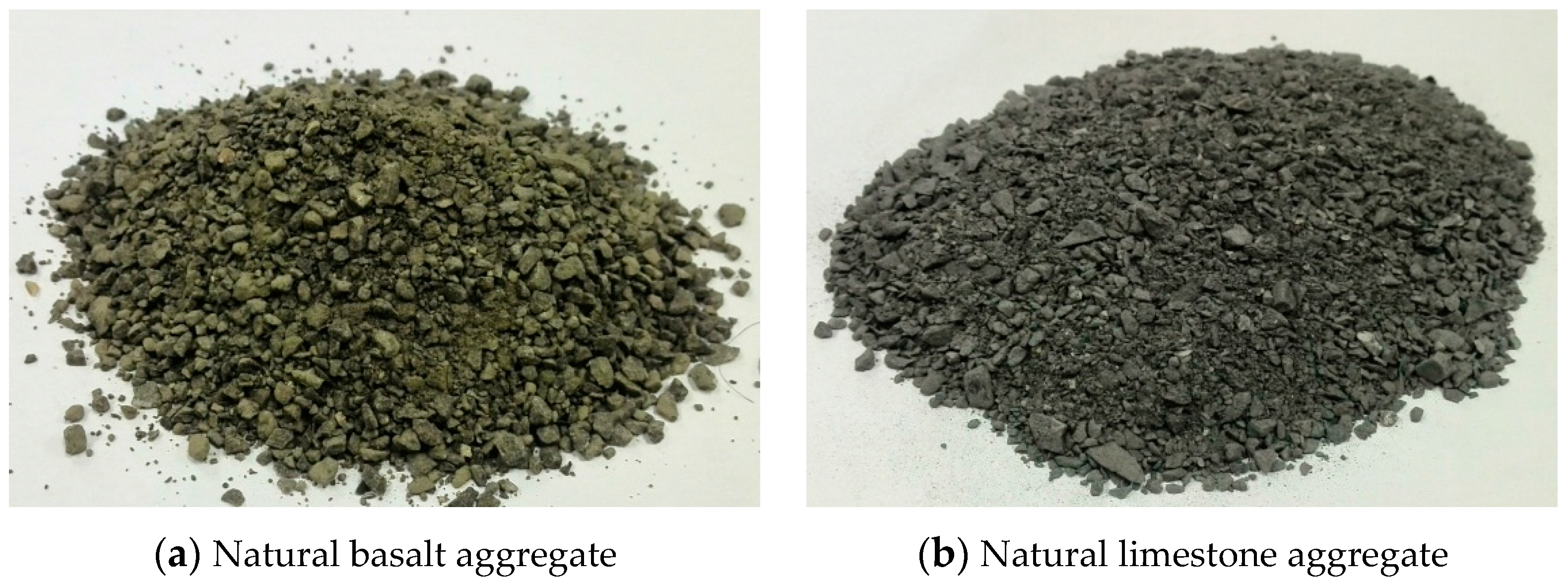

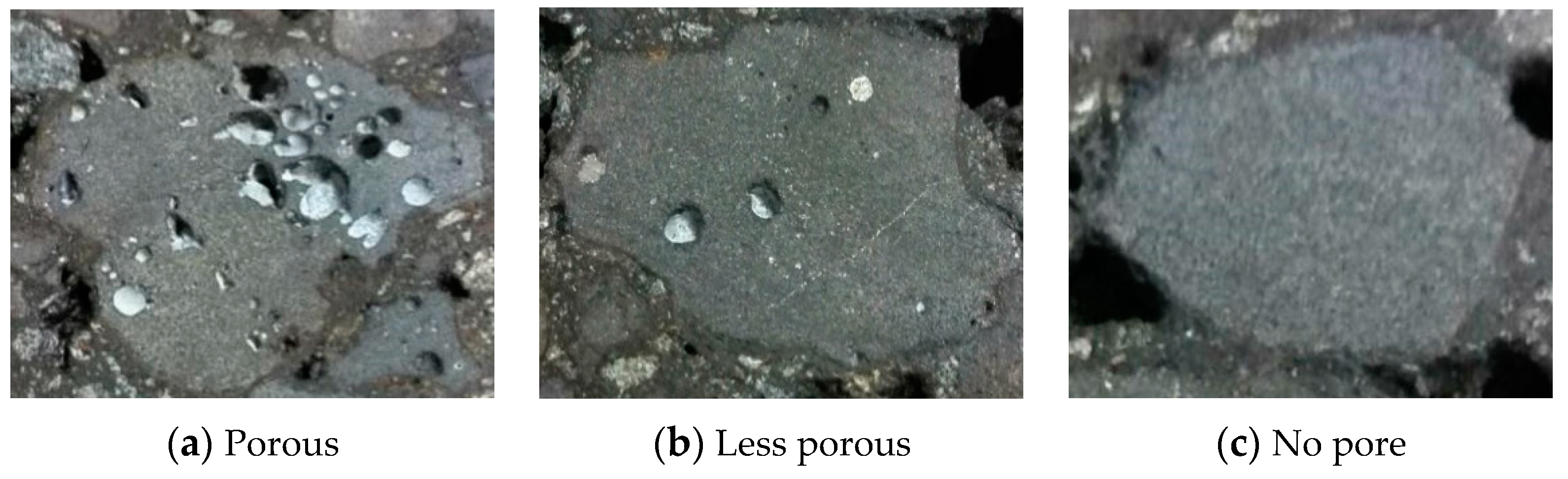

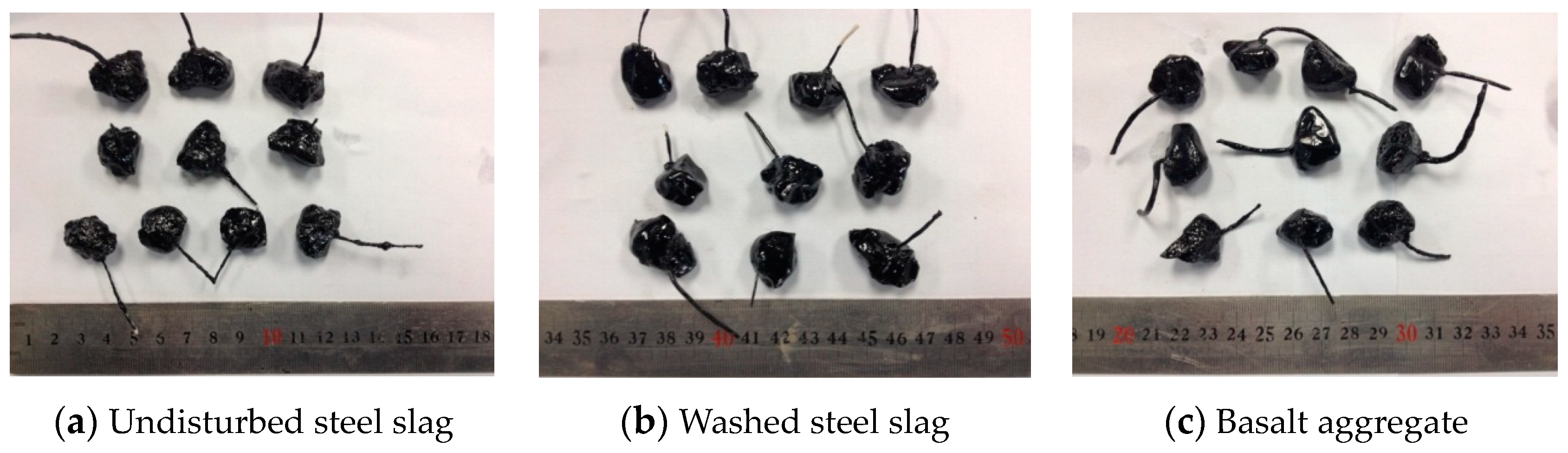

2.1. Steel Slag Coarse Aggregate

2.1.1. Morphological Characteristics

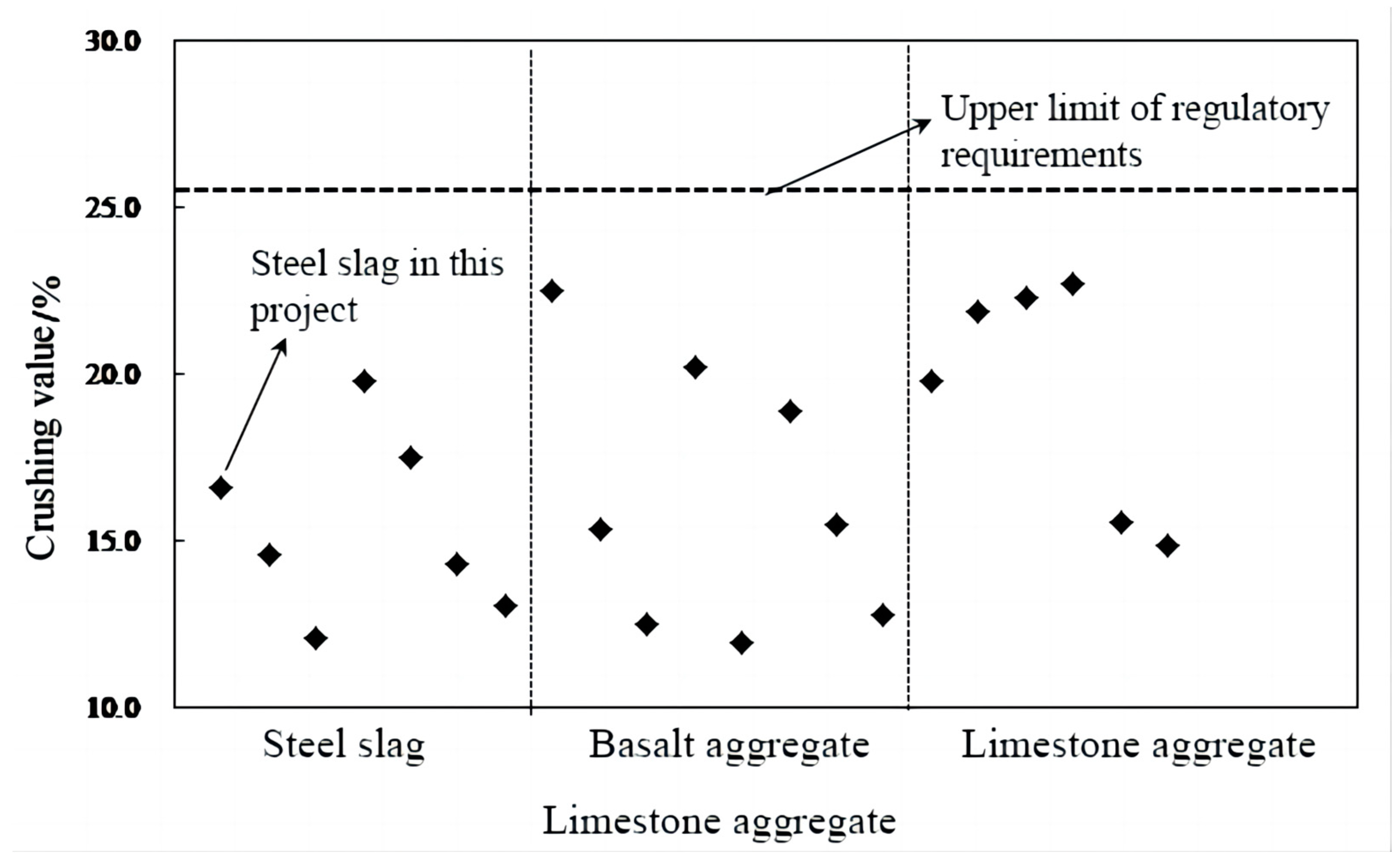

2.1.2. Crushing Value/Crushing Index

2.1.3. Asphalt

2.2. Test Methods

2.2.1. High-Temperature Stability

2.2.2. Low-Temperature Stability

2.2.3. Moisture Sensitivity

2.2.4. Fatigue Characteristics

2.3. Mixed Proportion Design of Steel Slag Asphalt Mixture

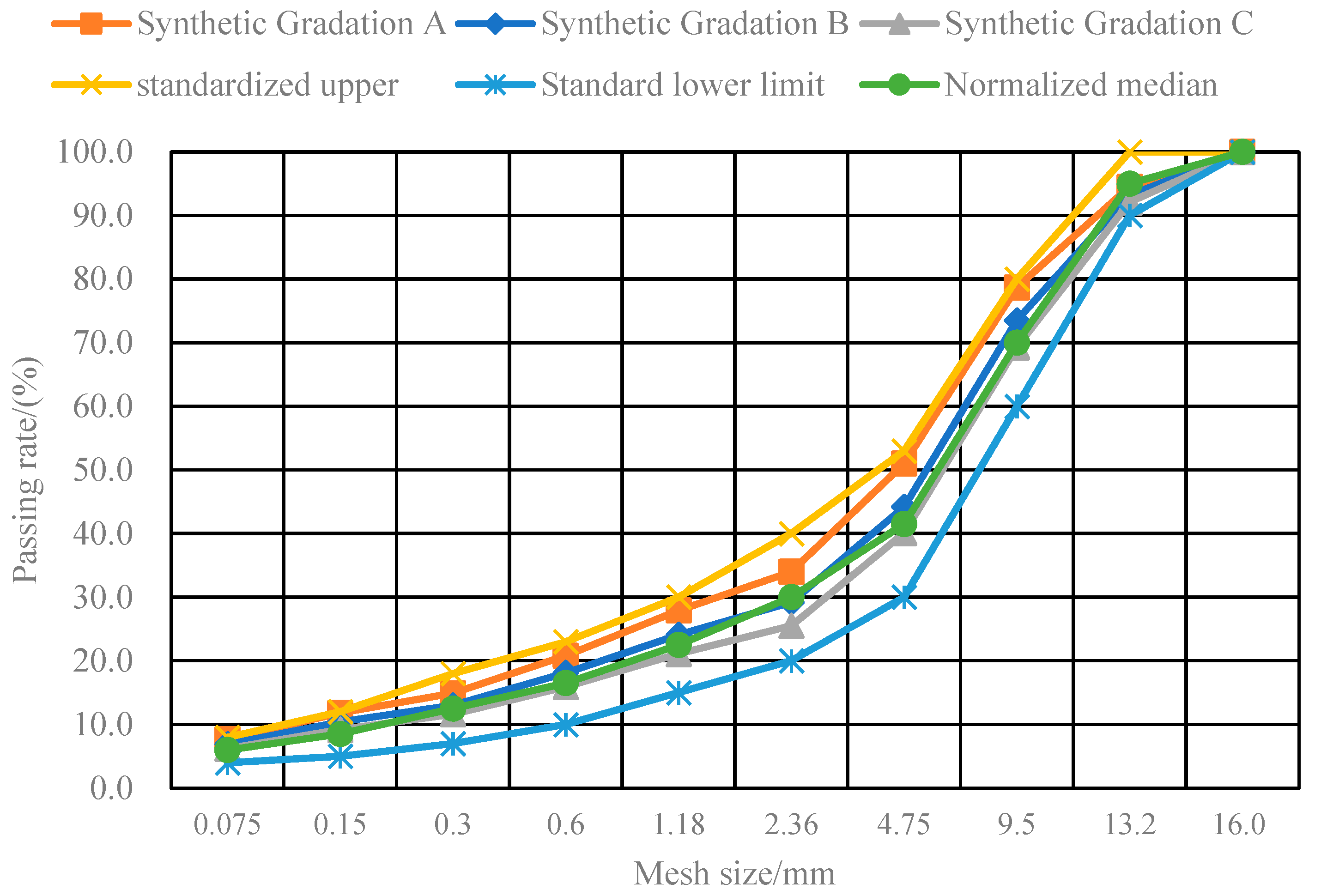

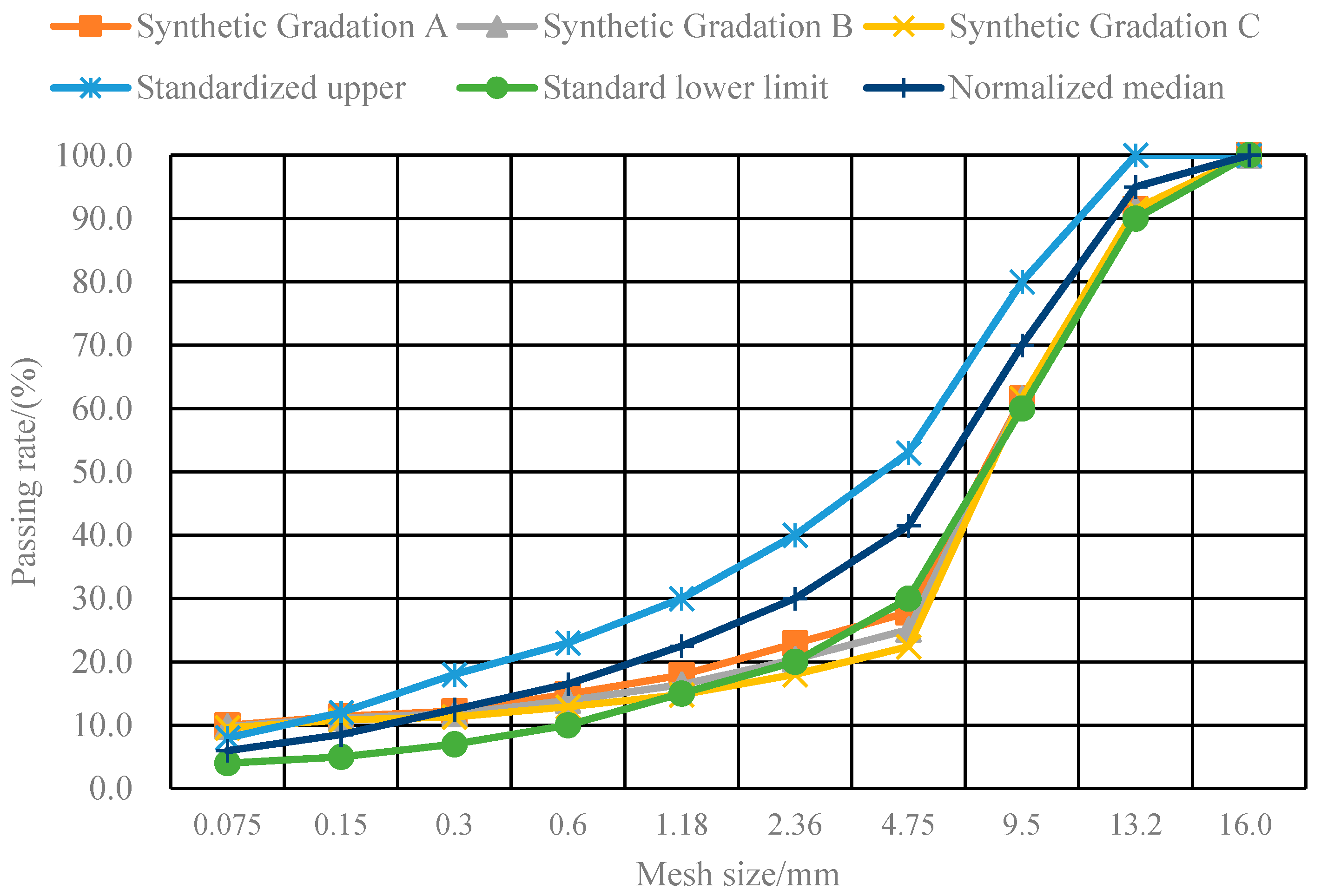

2.3.1. Selection of Gradation Ratio for AC-13C Steel Slag Asphalt Mixture

2.3.2. Selection of Gradation Ratio for SMA-13 Steel Slag Asphalt Mixture

2.3.3. Determination of Optimal Bitumen–Aggregate/Stone Ratio

3. Results and Discussion

3.1. Analysis of Adhesiveness Properties of Steel Slag Aggregates

3.2. Chemical Properties of Steel Slag Aggregates

3.2.1. Chemical Composition

3.2.2. Evaluation of Hazardous Elements

3.3. Road Performance Analysis

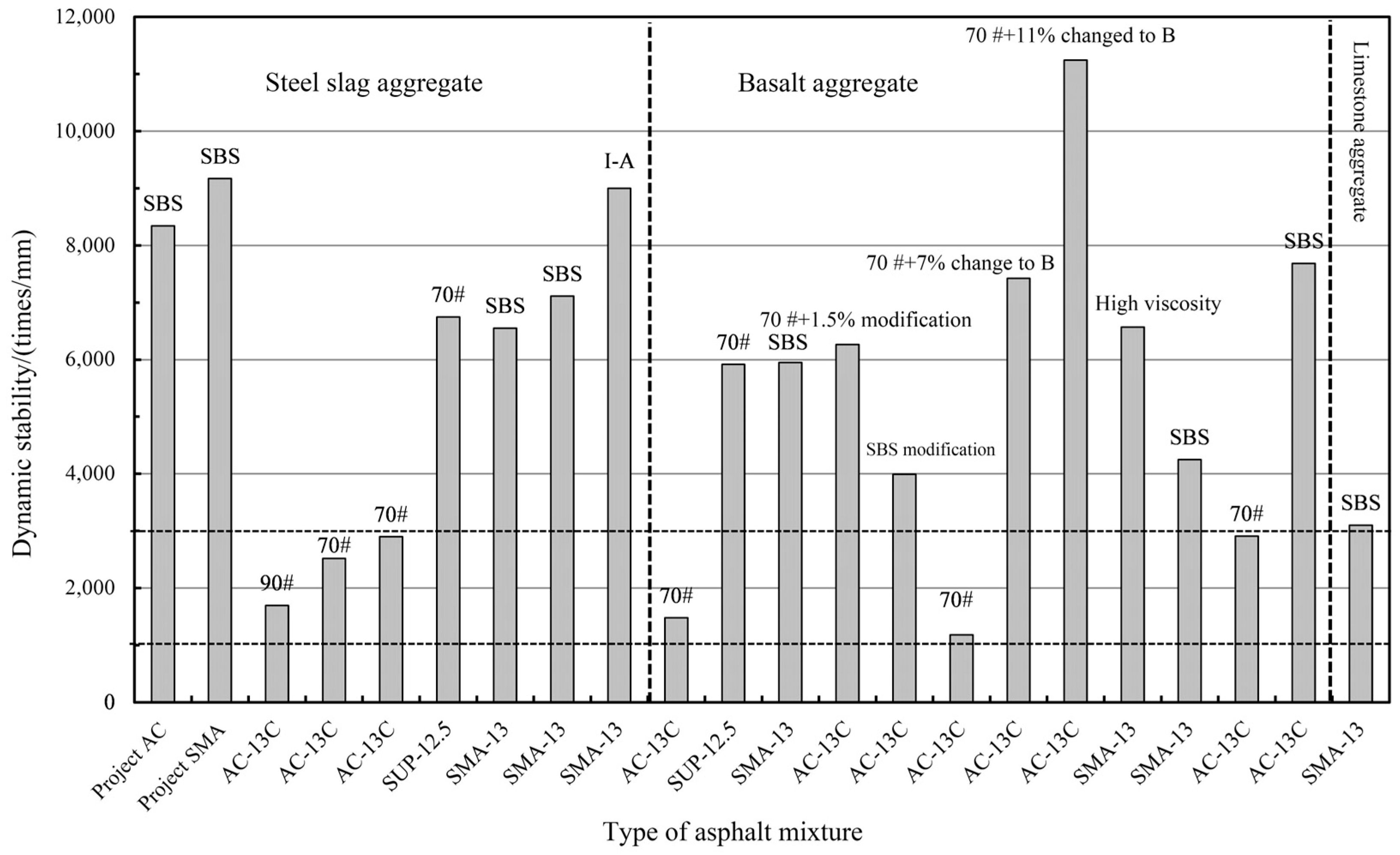

3.3.1. High-Temperature Stability

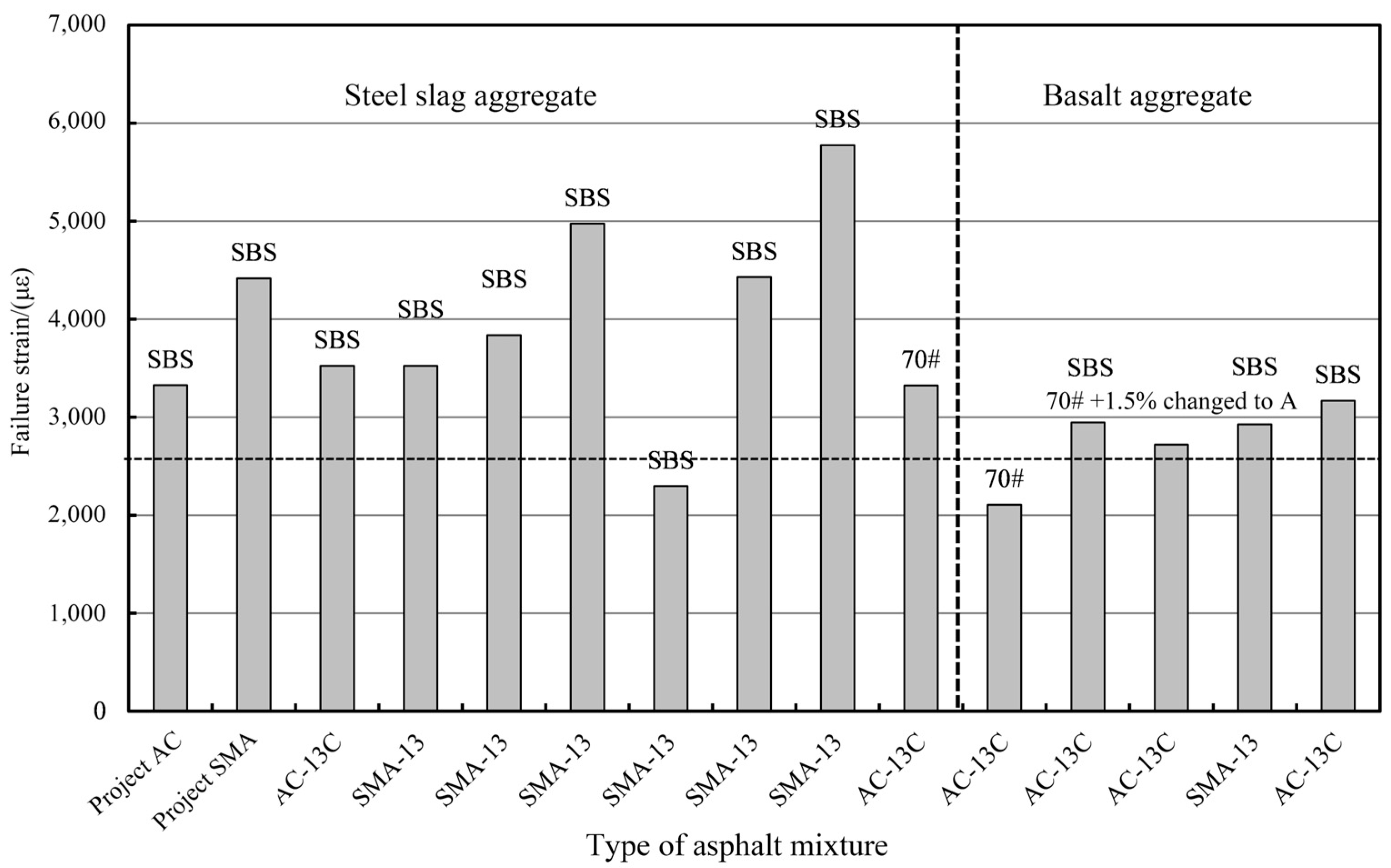

3.3.2. Low-Temperature Stability

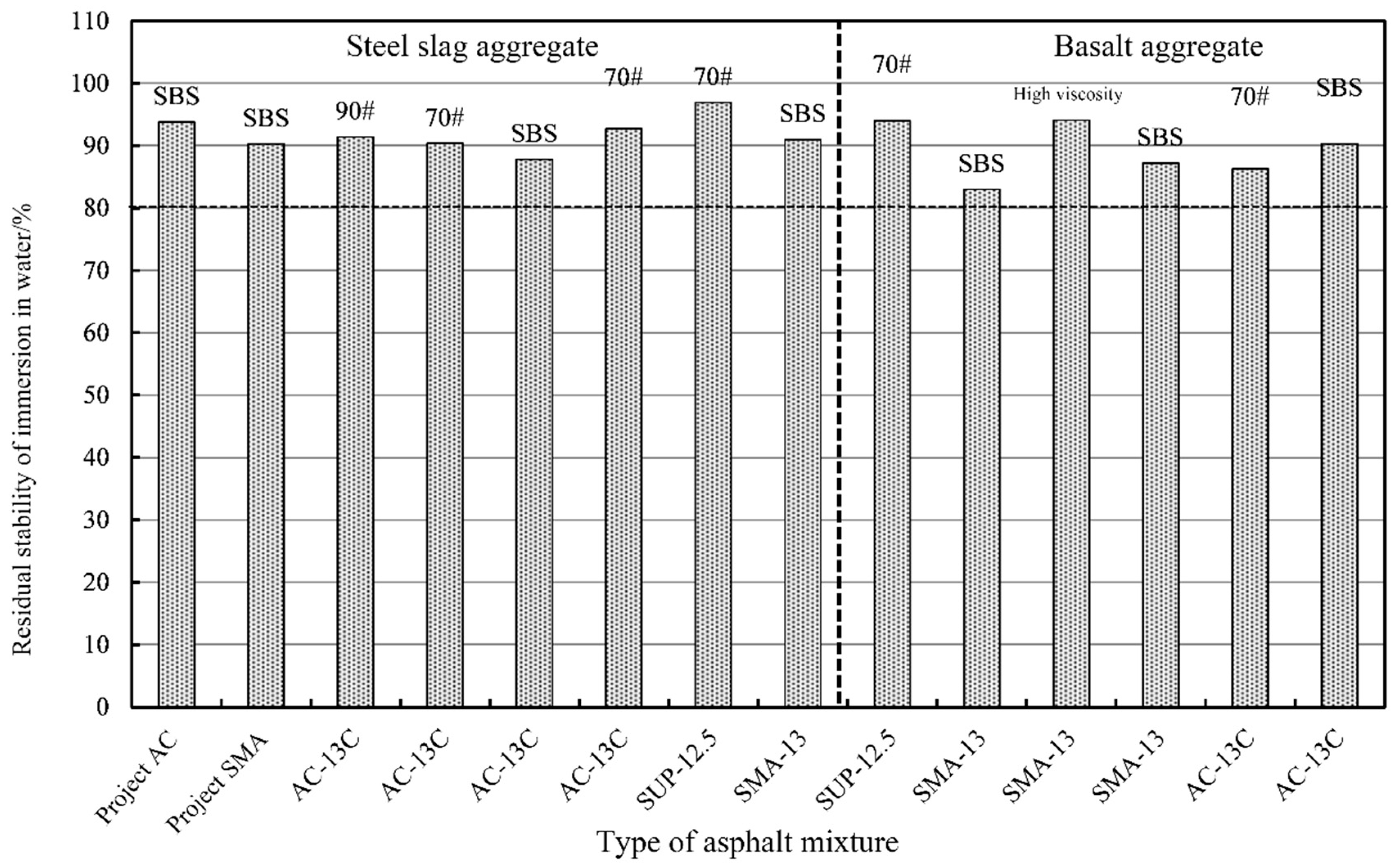

3.3.3. Moisture Sensitivity

3.3.4. Fatigue Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Jiao, W.; Sha, A.; Liu, Z.; Li, W.; Jiang, W.; Qin, W.; Hu, Y. Study on thermal properties of steel slag asphalt concrete for snow-melting pavement. J. Clean. Prod. 2020, 277, 123574. [Google Scholar] [CrossRef]

- Hasita, S.; Suddeepong, A.; Horpibulsuk, S.; Samingthong, W.; Arulrajah, A.; Chinkulkijniwat, A. Properties of asphalt concrete using aggregates composed of limestone and steel slag blends. J. Mater. Civ. Eng. 2020, 32, 06020007. [Google Scholar] [CrossRef]

- Chen, J.-S.; Wei, S.-H. Engineering properties and performance of asphalt mixtures incorporating steel slag. Constr. Build. Mater. 2016, 128, 148–153. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Experimental evaluation of high performance base course and road base asphalt concrete with electric arc furnace steel slags. J. Hazard. Mater. 2010, 181, 938–948. [Google Scholar] [CrossRef]

- Arabani, M.; Azarhoosh, A. The effect of recycled concrete aggregate and steel slag on the dynamic properties of asphalt mixtures. Constr. Build. Mater. 2012, 35, 1–7. [Google Scholar] [CrossRef]

- Wang, T.; Weng, Y.; Cai, X.; Li, J.; Xiao, F.; Sun, G.; Zhang, F. Statistical modeling of low-temperature properties and FTIR spectra of crumb rubber modified asphalts considering SARA fractions. J. Clean. Prod. 2022, 374, 134016. [Google Scholar] [CrossRef]

- Amuchi, M.; Abtahi, S.M.; Koosha, B.; Hejazi, S.M.; Sheikhzeinoddin, H. Reinforcement of steel-slag asphalt concrete using polypropylene fibers. J. Ind. Text. 2015, 44, 526–541. [Google Scholar] [CrossRef]

- Gencel, O.; Karadag, O.; Oren, O.H.; Bilir, T. Steel slag and its applications in cement and concrete technology: A review. Constr. Build. Mater. 2021, 283, 122783. [Google Scholar] [CrossRef]

- Hassan, K.E.; Attia, M.I.; Reid, M.; Al-Kuwari, M.B. Performance of steel slag aggregate in asphalt mixtures in a hot desert climate. Case Stud. Constr. Mater. 2021, 14, e00534. [Google Scholar] [CrossRef]

- Hasita, S.; Rachan, R.; Suddeepong, A.; Horpibulsuk, S.; Arulrajah, A.; Mohammadinia, A.; Nazir, R. Performance improvement of asphalt concretes using steel slag as a replacement material. J. Mater. Civ. Eng. 2020, 32, 04020227. [Google Scholar] [CrossRef]

- Wang, T.; Dra, Y.A.S.S.; Cai, X.; Cheng, Z.; Zhang, D.; Lin, Y.; Yu, H. Advanced cold patching materials (CPMs) for asphalt pavement pothole rehabilitation: State of the art. J. Clean. Prod. 2022, 366, 133001. [Google Scholar] [CrossRef]

- Loureiro, C.D.; Moura, C.F.; Rodrigues, M.; Martinho, F.C.; Silva, H.M.; Oliveira, J.R. Steel slag and recycled concrete aggregates: Replacing quarries to supply sustainable materials for the asphalt paving industry. Sustainability 2022, 14, 5022. [Google Scholar] [CrossRef]

- Behnood, A.; Ameri, M. Experimental investigation of stone matrix asphalt mixtures containing steel slag. Sci. Iran. 2012, 19, 1214–1219. [Google Scholar] [CrossRef]

- Ali, N.A.; Chan, J.S.; Papagiannakis, T.; Theriault, E.G.; Bergan, A.T. The use of steel slag in asphaltic concrete. In Effects of Aggregates and Mineral Fillers on Asphalt Mixture Performance; ASTM International: Atlantic, NK, USA, 1992. [Google Scholar]

- Jiang, X.; Zhu, H.; Yan, Z.; Zhang, F.; Ye, F.; Li, P.; Zhang, X.; Dai, Z.; Bai, Y.; Huang, B. A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Dev. Built Environ. 2023, 16, 100250. [Google Scholar] [CrossRef]

- Martinho, F.; Picado-Santos, L.; Capitão, S. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties. Constr. Build. Mater. 2018, 185, 684–696. [Google Scholar] [CrossRef]

- Hasita, S.; Hoy, M.; Suddeepong, A.; Horpibulsuk, S.; Yeanyong, C.; Arulrajah, A.; Mohammadinia, A. Performance and toxic leaching evaluation of dense-graded asphalt concrete using steel slag as aggregate. J. Mater. Civ. Eng. 2021, 33, 04020432. [Google Scholar] [CrossRef]

- Khodary, F. Comparative study of using steel slag aggregate and crushed limestone in asphalt concrete mixtures. Int. J. Civ. Eng. Technol 2015, 6, 73–82. [Google Scholar]

- Zhou, X.; Adhikari, S. Flow-induced crystallization of biochar in bio-asphalt under various aging conditions. Sci. Total Environ. 2019, 695, 133943. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, W.; Wu, S. Analysis on factors affecting moisture stability of steel slag asphalt concrete using grey correlation method. J. Clean. Prod. 2023, 397, 136490. [Google Scholar] [CrossRef]

- Shatnawi, A.S.; Abdel-Jaber, M.; Abdel-Jaber, M.; Ramadan, K.Z. Effect of Jordanian steel blast furnace slag on asphalt concrete hot mixes. Jordan J. Civ. Eng. 2008, 2, 197–207. [Google Scholar]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Ren, Y.; Chen, M.; Yang, T.; Wu, S.; Wang, K. Effect of steel slag aggregate on pavement and flame-retardant performance of warm-mixed flame-retardant asphalt concrete. Materials 2021, 14, 635. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Gabrielson, J.; Titi, H.; Huang, B.; Bai, Y.; Polaczyk, P.; Hu, W.; Zhang, M.; Xiao, R. Field investigation and numerical analysis of an inverted pavement system in Tennessee, USA. Transp. Geotech. 2022, 35, 100759. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. Properties of a steel slag–permeable asphalt mixture and the reaction of the steel slag–asphalt interface. Materials 2019, 12, 3603. [Google Scholar] [CrossRef]

- Joumblat, R.; Al Basiouni Al Masri, Z.; Elkordi, A. Dynamic modulus and phase angle of asphalt concrete mixtures containing municipal solid waste incinerated fly ash as mineral filler substitution. Int. J. Pavement Res. Technol. 2023, 16, 1196–1216. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Jun, X. Research on the Preparation, Performance and Application of Basic Oxygen Furnace Slag Based Asphalt Concrete; Wuhan University of Technology: Wuhan, China, 2013. [Google Scholar]

- Xu, J.; Huang, S.; Qin, Y. Asphalt pavement recycling in Mainland China. Application of Reclaimed Asphalt Pavement and Recycled Asphalt Shingles in Hot-Mix Asphalt; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Anupama, J.; Balreddy, M.S.; Panditharadhya, B. Sustainable Open-Graded Friction Course asphalt mixes with steel slag aggregates. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Maharaj, C.; White, D.; Maharaj, R.; Morin, C. Re-use of steel slag as an aggregate to asphaltic road pavement surface. Cogent Eng. 2017, 4, 1416889. [Google Scholar] [CrossRef]

- Shiha, M.; El-Badawy, S.; Gabr, A. Modeling and performance evaluation of asphalt mixtures and aggregate bases containing steel slag. Constr. Build. Mater. 2020, 248, 118710. [Google Scholar] [CrossRef]

- Yao, A.-L.; Xu, D.-L.; Sun, Z.-J. Performance test on asphalt mixture of slag powder as filling. China J. Highw. Transp. 2006, 19, 25. [Google Scholar]

- Qibing, G.; Tierui, L.; Donglin, W.; Peng, L.; Ying, Y.; Wei, W.; Yongjie, P. The Indoor Research of Steel Slag Applied in Modified Asphalt Matrix Mixture. Pet. Asph. 2003, 17, 32–35. [Google Scholar]

- Yang, Q.-Z.; Wu, K.-H. Design and test of dense gap graded friction course asphalt mixture using steel slag as coarse aggregate. J. Guangzhou Univ. 2007, 6, 92–94. [Google Scholar]

| Trial Number | Calibrated Quality (g) | Average Value (g) | Total Test Mass (g) | 2.36 mm Sample Mass under Sieve (g) | Crush Value Test Value (%) | Average Value (%) | Specification Requirements |

|---|---|---|---|---|---|---|---|

| 1 | 3343.5 | 3343.5 | 3344.5 | 554.5 | 16.6 | 16.6 | 26.0 |

| 2 | 3343.5 | 3342.4 | 552.5 | 16.5 | |||

| 3 | 3343.5 | 3341.2 | 553.8 | 16.6 |

| Particle Size (mm) | Drying Quality before the Experiment (g) | Residual Mass after Test (g) | Passing Mass after Test (g) | Crush Value Test Value (%) | Measured Crush Value of Single Particle Fraction (%) | Crushing Index Value (%) |

|---|---|---|---|---|---|---|

| 4.75~2.36 | 330 | 307.4 | 22.6 | 93 | 88 | 97 |

| 330 | 296.1 | 33.9 | 90 | |||

| 330 | 305.2 | 24.8 | 92 | |||

| 2.36~1.18 | 330 | 286.6 | 43.4 | 87 | 92 | |

| 330 | 292.9 | 37.1 | 89 | |||

| 330 | 290.3 | 39.7 | 88 | |||

| 1.18~0.6 | 330 | 316.6 | 13.4 | 96 | 96 | |

| 330 | 315.4 | 14.6 | 96 | |||

| 330 | 315.8 | 14.2 | 96 | |||

| 0.6~0.3 | 330 | 319.1 | 10.9 | 97 | 97 | |

| 330 | 319.0 | 11.0 | 97 | |||

| 330 | 319.2 | 10.8 | 97 |

| Pilot Project | Test Results | Specification Requirements |

|---|---|---|

| Penetration (25 °C, 100 g, 5 s) (0.1 mm) | 69 | 60~80 |

| Penetration Index PI (15 °C, 25 °C, 30 °C) | −0.19 | ≥−0.4 |

| ductility (5 cm/min, 5 °C) (cm) | 45 | ≥30 |

| Softening point (TR&B) (°C) | 73 | ≥55 |

| Kinematic viscosity (135 °C) (Pa·s) | 1.69 | ≤3 |

| Flash point (°C) | >300 | ≥230 |

| Relative density (25 °C) | 1.033 | Actual measurement |

| Segregation, softening of spreads (°C) | 0.9 | ≤2.5 |

| Elastic recovery (%) | 97.9 | ≥65 |

| Asphalt film heating test | ||

| Change in quality (%) | −0.162 | ≤±1.0 |

| Residual penetration ratio (25 °C) (%) | 96.6 | ≥65 |

| Residual ductility (5 °C) (cm) | 37 | ≥20 |

| Minerals | Graded A (%) | Graded B (%) | Graded C (%) |

|---|---|---|---|

| 1# | 25 | 31 | 36 |

| 2# | 27 | 28 | 27 |

| 3# | 13 | 11 | 11 |

| 4# | 34 | 29 | 25 |

| Mineral powder | 1 | 1 | 1 |

| Aggregates | Percentage of Passing through the Sieve Hole (Square Hole Sieve, mm) (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 1# | 100.0 | 78.1 | 14.6 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 0.8 | 0.8 |

| 2# | 100.0 | 100.0 | 100.0 | 10.2 | 1.6 | 1.6 | 1.6 | 1.4 | 1.4 | 1.2 |

| 3# | 100.0 | 100.0 | 100.0 | 100.0 | 13.6 | 2.6 | 2.6 | 2.4 | 2.4 | 2.2 |

| 4# | 100.0 | 100.0 | 100.0 | 100.0 | 92.6 | 76.2 | 55.2 | 38 | 29.2 | 17.7 |

| Mineral powder | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | 99.8 | 91.7 |

| Synthetic Gradation A | 100.0 | 94.5 | 78.7 | 51.0 | 34.0 | 27.9 | 20.8 | 14.9 | 11.8 | 7.7 |

| Synthetic Gradation B | 100.0 | 93.2 | 73.5 | 44.2 | 29.2 | 24.1 | 18.1 | 13.0 | 10.4 | 6.9 |

| Synthetic Gradation C | 100.0 | 92.1 | 69.3 | 40.1 | 25.5 | 21.1 | 15.9 | 11.6 | 9.2 | 6.2 |

| Standardized upper | 100.0 | 100.0 | 80.0 | 53.0 | 40.0 | 30.0 | 23.0 | 18.0 | 12.0 | 8.0 |

| Standard lower limit | 100.0 | 90.0 | 60.0 | 30.0 | 20.0 | 15.0 | 10.0 | 7.0 | 5.0 | 4.0 |

| Normalized median | 100.0 | 95.0 | 70.0 | 41.5 | 30.0 | 22.5 | 16.5 | 12.5 | 8.5 | 6.0 |

| Grading Type | Oil–Stone Ratio (%) | Stability (kN) | Flow Value (0.1 mm) | Void Ratio VV (%) | Ore Clearance Rate VMA (%) | Saturation VFA (%) | Gross Volume Relative Density | Theoretical Relative Density |

|---|---|---|---|---|---|---|---|---|

| Graded A | 4.8 | 25.01 | 41.3 | 3.3 | 13.3 | 5.4 | 2.837 | 2.933 |

| Gradation B | 4.8 | 23.85 | 45.8 | 3.5 | 13.5 | 74.3 | 2.853 | 2.955 |

| Gradation C | 4.8 | 23.06 | 47.9 | 4.4 | 14.6 | 70.2 | 2.861 | 2.993 |

| Request | / | ≥8.0 | 20~50 | 4.0~6.0 | ≥14.5 | 65~75 | / | / |

| Minerals | Graded A (%) | Graded B (%) | Graded C (%) |

|---|---|---|---|

| 1# | 46 | 46 | 46 |

| 2# | 29 | 32 | 35 |

| 4# | 16 | 13 | 10 |

| Mineral powder | 9 | 9 | 9 |

| Fiber | 0.3 | 0.3 | 0.3 |

| Aggregates | Percentage of Passing through the Sieve Hole (Square Hole Sieve, mm) (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 1# | 100.0 | 81.5 | 16.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 2# | 100.0 | 100.0 | 100.0 | 9.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 3# | 100.0 | 100.0 | 100.0 | 100.0 | 15.0 | 3.0 | 3.0 | 3.0 | 2.5 | 2.5 |

| 4# | 100.0 | 100.0 | 100.0 | 100.0 | 83.8 | 52.6 | 33.4 | 17 | 11.9 | 7.5 |

| Mineral powder | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100 | 99.8 | 91.7 |

| Synthetic Gradation A | 100.0 | 91.5 | 61.6 | 27.8 | 22.9 | 17.9 | 14.9 | 12.2 | 11.4 | 10.0 |

| Synthetic Gradation B | 100.0 | 91.5 | 61.6 | 25.1 | 20.4 | 16.4 | 13.9 | 11.8 | 11.1 | 9.8 |

| Synthetic Gradation C | 100.0 | 91.5 | 61.6 | 22.4 | 18.0 | 14.8 | 12.9 | 11.3 | 10.8 | 9.6 |

| Standardized upper | 100.0 | 100.0 | 80.0 | 53.0 | 40.0 | 30.0 | 23.0 | 18.0 | 12.0 | 8.0 |

| Standard lower limit | 100.0 | 90.0 | 60.0 | 30.0 | 20.0 | 15.0 | 10.0 | 7.0 | 5.0 | 4.0 |

| Normalized median | 100.0 | 95.0 | 70.0 | 41.5 | 30.0 | 22.5 | 16.5 | 12.5 | 8.5 | 6.0 |

| Grading Type | Bitumen- Aggregate/Stone Ratio (%) | Stability (kN) | Flow Value (0.1 mm) | Porosity VV (%) | Ore Clearance Rate VMA (%) | Saturation VFA (%) | Coarse Aggregate Skeleton Clearance Ratio VCAmix (%) | Gross Volume Relative Density | Theory Relative Density |

|---|---|---|---|---|---|---|---|---|---|

| Graded A | 5.8 | 22.51 | 47.3 | 2.6 | 15.4 | 83.1 | 41.7 | 2.839 | 2.915 |

| Gradation B | 5.8 | 18.73 | 48.8 | 3.7 | 16.6 | 77.5 | 40.7 | 2.814 | 2.928 |

| Gradation C | 5.8 | 17.35 | 47.9 | 4.5 | 17.3 | 73.9 | 38.8 | 2.803 | 2.942 |

| Request | / | ≥6.0 | -- | 3.0~4.0 | ≥16.5 | 75~85 | ≤VCADRC | / | / |

| Grading Type | Bitumen-Aggregate/Stone Ratio (%) | Stability (kN) | Flow Value (0.1 mm) | Porosity VV (%) | Ore Clearance Rate VMA (%) | Saturation VFA (%) | Coarse Aggregate Skeleton Clearance Ratio VCAmix (%) | Gross Volume Relative Density |

|---|---|---|---|---|---|---|---|---|

| AC-13C | 4.2 | 20.01 | 36.5 | 6.7 | 15.1 | 56.0 | 2.831 | 3.032 |

| 4.5 | 23.52 | 43.4 | 5.6 | 14.9 | 62.5 | 2.847 | 3.015 | |

| 4.8 | 20.35 | 44.7 | 4.5 | 14.8 | 69.5 | 2.858 | 2.999 | |

| 5.1 | 19.46 | 47.6 | 3.9 | 14.8 | 73.4 | 2.865 | 2.982 | |

| 5.4 | 18.91 | 51.2 | 3.1 | 14.8 | 78.9 | 2.873 | 2.966 | |

| Request | / | ≥8.0 | 20~50 | 4.0~6.0 | ≥14.5 | 65~75 | / | / |

| Grading Type | Bitumen-Aggregate/Stone Ratio (%) | Stability (kN) | Flow Value (0.1 mm) | Porosity VV (%) | Ore Clearance Rate VMA (%) | Saturation VFA (%) | Coarse Aggregate Skeleton Clearance Ratio VCAmix (%) | Gross Volume Relative Density | Theory Relative Density |

|---|---|---|---|---|---|---|---|---|---|

| SMA-13 | 4.9 | 17.26 | 39.2 | 4.9 | 16.8 | 71.2 | 40.9 | 2.781 | 2.975 |

| 5.2 | 16.39 | 32.7 | 4.8 | 17.0 | 72.0 | 41.0 | 2.784 | 2.959 | |

| 5.5 | 19.48 | 48.6 | 4.3 | 16.8 | 74.4 | 41.1 | 2.797 | 2.943 | |

| 5.8 | 21.15 | 41.2 | 3.9 | 16.7 | 76.8 | 40.8 | 2.810 | 2.927 | |

| 6.1 | 18.12 | 50.1 | 3.2 | 16.3 | 80.5 | 40.5 | 2.830 | 2.913 | |

| Request | / | ≥6.0 | -- | 3.0~4.0 | ≥16.5 | 75~85 | ≤VCADRC | / | / |

| Chemical Composition | Content/% | Chemical Composition | Content/% | ||

|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Coarse Aggregate | Fine Aggregate | ||

| CaO | 36.835 | 37.835 | K2O | 0.047 | 0.345 |

| Fe2O3 | 31.257 | 32.257 | Cl | 0.025 | 0.036 |

| SiO2 | 19.085 | 20.085 | SrO | 0.024 | 0.022 |

| Al2O3 | 4.317 | 5.317 | WO3 | 0.022 | 0.007 |

| MnO | 2.718 | 3.718 | ZrO2 | 0.020 | 0.006 |

| MgO | 1.527 | 2.527 | CuO | 0.015 | 0.024 |

| P2O5 | 1.054 | 2.054 | ZnO | 0.011 | 0.035 |

| TiO2 | 0.779 | 1.779 | Nb2O5 | 0.006 | 0.004 |

| Cr2O3 | 0.683 | 1.683 | PbO | —— | 0.006 |

| SO3 | 0.556 | 1.556 | NiO | —— | —— |

| V2O5 | 0.2287 | 1.2287 | Loss on ignition | 0.699 | 3.209 |

| BaO | 0.101 | 0.123 | —— | —— | —— |

| Al | Ba | Ca | K | Li | Mg | Zn | |

|---|---|---|---|---|---|---|---|

| Standard requirements | 0.05 | 2.000 | - | - | - | - | 5.000 |

| Untreated | 0.315 | 0.815 | 1924 | 0.046 | 7.077 | 0.009 | 0.196 |

| Asphalt wrapping | 0.021 | 0.672 | 824.4 | 0.015 | 0.007 | 0.007 | 0.017 |

| Grading Type | Gross Volume Relative Density | Dynamic Stability (Times/mm) | Coefficient of Variation (%) | Technical Standards |

|---|---|---|---|---|

| Steel slag AC-13C | 2.858 | 8341 | 17.6 | ≥2800 |

| Steel slag SMA-13 | 2.814 | 9168 | 16.1 | ≥3000 |

| Data Source | Type of Asphalt | Type of Asphalt Mixture | Optimal Bitumen- Aggregate/Stone Ratio (%) | Dynamic Stability (Times/mm) | Additive Type | Technology Standard | Aggregates Type |

|---|---|---|---|---|---|---|---|

| The paper | SBS modification | AC-13C | 4.8 | 8341 | not | ≥2800 | Steel slag coarse aggregate |

| SMA-13 | 5.8 | 9168 | not | ≥3000 | |||

| L1 [34] | AH-90 | AC-13C | 5.49 | 1694 | not | ≥1000 | All steel slag |

| L2 [35] | AH-70 | AC-13C | 6.63 | 2516 | not | ≥1000 | 73.9% steel slag |

| L3-1 [36] | AH-70 | AC-13C | 5.6 | 2897 | cement | ≥1000 | All steel slag |

| L3-2 [36] | AH-70 | AC-13C | 4.8 | 1478 | cement | ≥1000 | basalt |

| L4-1 [37] | SBS modification | SMA-13 | 6.1 | 6550 | not | ≥3000 | 75.0% steel slag |

| L4-2 [37] | SBS modification | SMA-13 | 5.8 | 5950 | not | ≥3000 | basalt |

| L4-3 [37] | SBS modification | SMA-13 | — | 3100 | not | ≥3000 | limestone |

| L5 [38] | I-A modification | SMA-13 | 6.4 | 9000 | not | ≥3000 | Steel slag powder |

| Asphalt Mixture Type | Flexural Tensile Strength (MPa) | Destruction Strain (με) | Stiffness Modulus (MPa) | Technical Standards (με) |

|---|---|---|---|---|

| AC-13C | 9.102 | 3105 | 2931 | ≥2500 |

| SMA-13 | 10.47 | 4417 | 2370 | ≥2500 |

| Data Source | Bitumen Type | Type of Asphalt Mixture | Type of Additive | Aggregate Type | Bending and Pulling Strength (MPa) | Destruction Strain (με) | Stiffness Modulus (MPa) | Technology Standard (με) |

|---|---|---|---|---|---|---|---|---|

| The paper | SBS modification | AC-13C | not | Steel slag coarse aggregate | 9.102 | 3325 | 2737 | ≥2500 |

| SMA-13 | not | 10.47 | 4417 | 2370 | ≥2500 | |||

| L1 [36] | AC-13C | cement | all Steel slag | 3.179 | 3423 | 2026.0 | — | |

| L2-1 [38] | SMA-13 | Mineral powder | all Steel slag | 10.58 | 3522.5 | 3002.9 | ≥2500 | |

| L2-2 [38] | Slag powder | 12.25 | 3834.8 | 3212.3 | ≥2500 | |||

| L3-1 [39] | SMA-13 | not | 72.0% Steel slag | 9.3 | 4972.5 | 1873.1 | ≥2500 | |

| L3-2 [39] | 6.7 | 2295.0 | 2929.1 | ≥2500 | ||||

| L3-3 [39] | 9.5 | 4428.0 | 2139.8 | ≥2500 | ||||

| L3-4 [39] | 6.8 | 5775.0 | 1183.4 | ≥2500 | ||||

| L4 [35] | AH-70 | AC-13C | 73.9% Steel slag | 3.7 | 3323 | 1865 | — |

| Asphalt Mixture Type | Freeze–Thaw Splitting Strength Ratio TSR (%) | Technical Standards (%) | Residual Stability of Immersion (%) | Technical Standards (%) |

|---|---|---|---|---|

| AC-13C | 94.07 | ≥80 | 93.8 | ≥85 |

| SMA-13 | 89.10 | ≥80 | 90.27 | ≥80 |

| Data Source | Type of Asphalt | Type of Asphalt Mixture | The Type of Aggregate | Additive Type | Freeze–Thaw Splitting Strength Ratio TSR (%). | Technology Standard (%). | Residual Stability of Immersion (%). | Technology Standard (%). |

|---|---|---|---|---|---|---|---|---|

| The paper | SBS modification | AC-13C | Steel slag coarse aggregate | not | 94.07 | ≥80 | 93.8 | ≥85 |

| SMA-13 | not | 89.10 | ≥80 | 90.27 | ≥85 | |||

| L1 [34] | AH-90 | AC-13C | All steel slag | not | 92 | ≥75 | 91.4 | ≥80 |

| L2 [35] | AH-70 | AC-13C | 73.9% Steel slag | not | 84.98 | ≥75 | 90.36 | ≥80 |

| L3-1 [36] | SBS modification | AC-13C | All steel slag | cement | 81.3 | ≥80 | 87.8 | ≥85 |

| L3-2 [36] | AH-70 | AC-13C | cement | 84.7 | ≥75 | 92.7 | ≥80 | |

| L4-1 [37] | SBS modification | SMA-13 | 75.0% Steel slag | Polyacrylonitrile | 93.7 | ≥75 | 91.0 | ≥80 |

| L4-2 [37] | SBS modification | SMA-13 | basalt | Polyacrylonitrile | 90.1 | ≥75 | 83.0 | ≥80 |

| Type of Mixture | σf/MPa | Technical Requirements |

|---|---|---|

| AC-13C | 1.17 | - |

| SMA-13 | 1.53 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Zhang, Y. Analyzing the Mechanical and Durability Characteristics of Steel Slag-Infused Asphalt Concrete in Roadway Construction. Buildings 2024, 14, 679. https://doi.org/10.3390/buildings14030679

Zhao X, Zhang Y. Analyzing the Mechanical and Durability Characteristics of Steel Slag-Infused Asphalt Concrete in Roadway Construction. Buildings. 2024; 14(3):679. https://doi.org/10.3390/buildings14030679

Chicago/Turabian StyleZhao, Xijuan, and Yemao Zhang. 2024. "Analyzing the Mechanical and Durability Characteristics of Steel Slag-Infused Asphalt Concrete in Roadway Construction" Buildings 14, no. 3: 679. https://doi.org/10.3390/buildings14030679

APA StyleZhao, X., & Zhang, Y. (2024). Analyzing the Mechanical and Durability Characteristics of Steel Slag-Infused Asphalt Concrete in Roadway Construction. Buildings, 14(3), 679. https://doi.org/10.3390/buildings14030679