Interlayer Performance, Viscoelastic Performance, and Road Performance Based on High-Performance Asphalt Composite Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

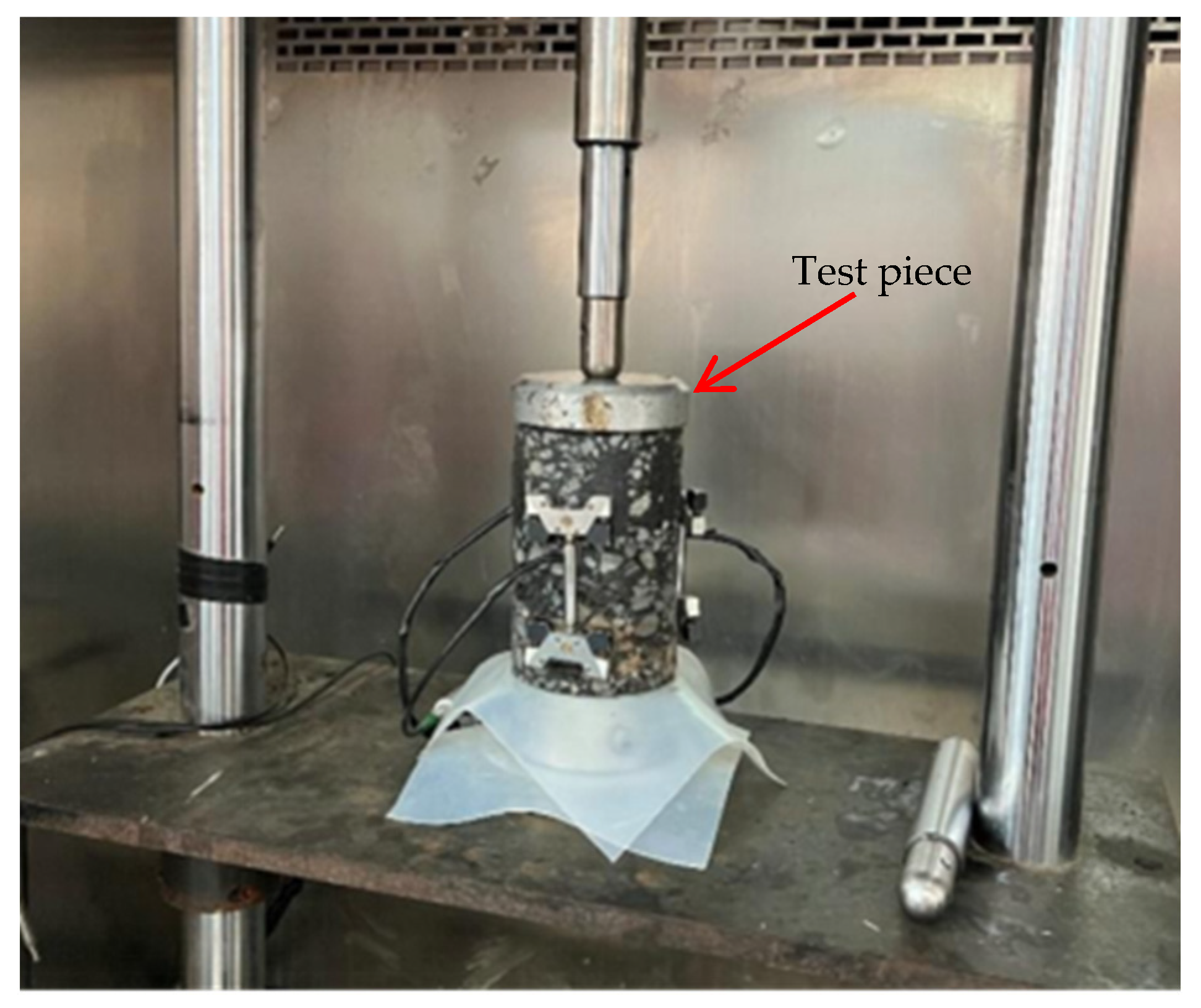

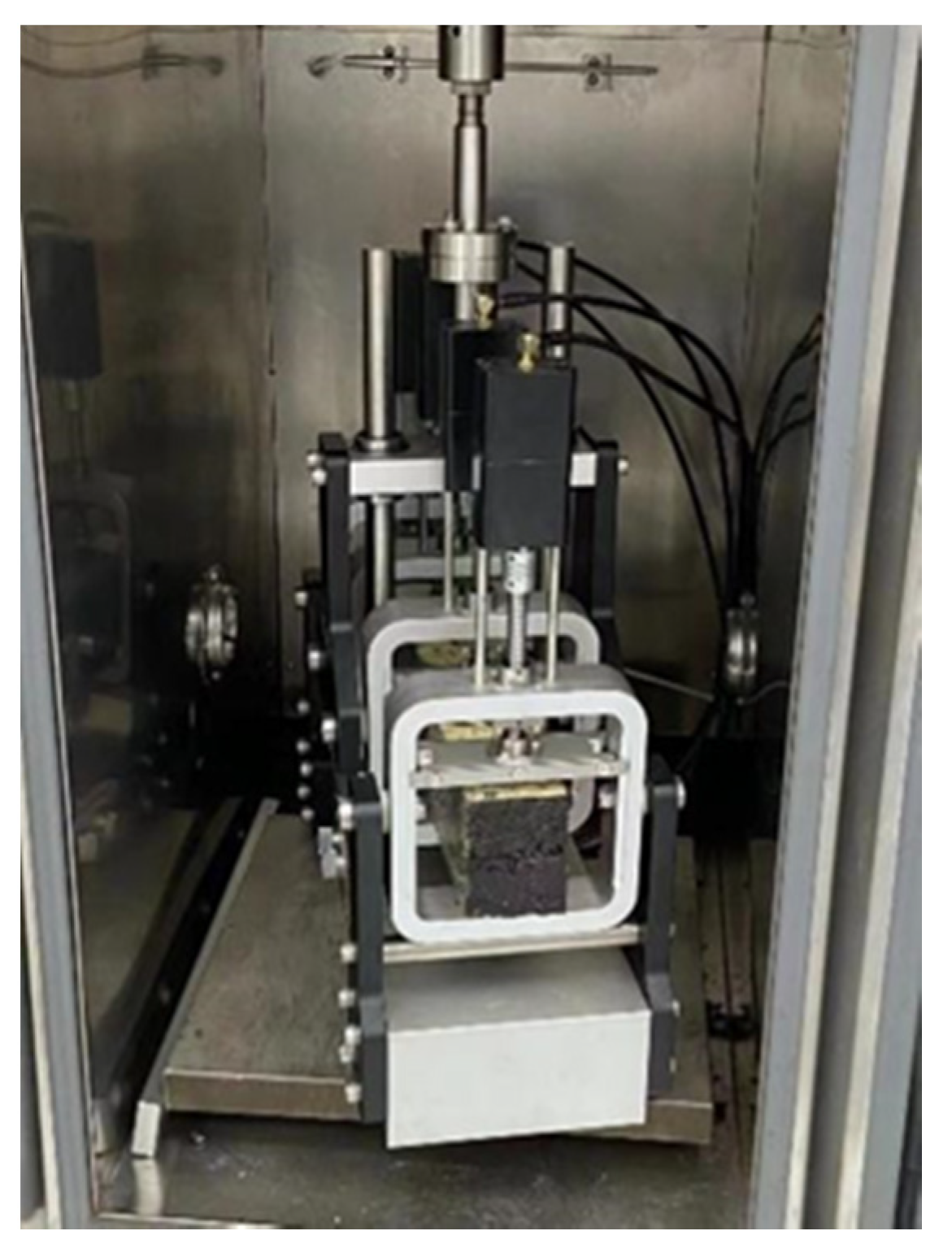

2.2.1. Oblique Shear Test

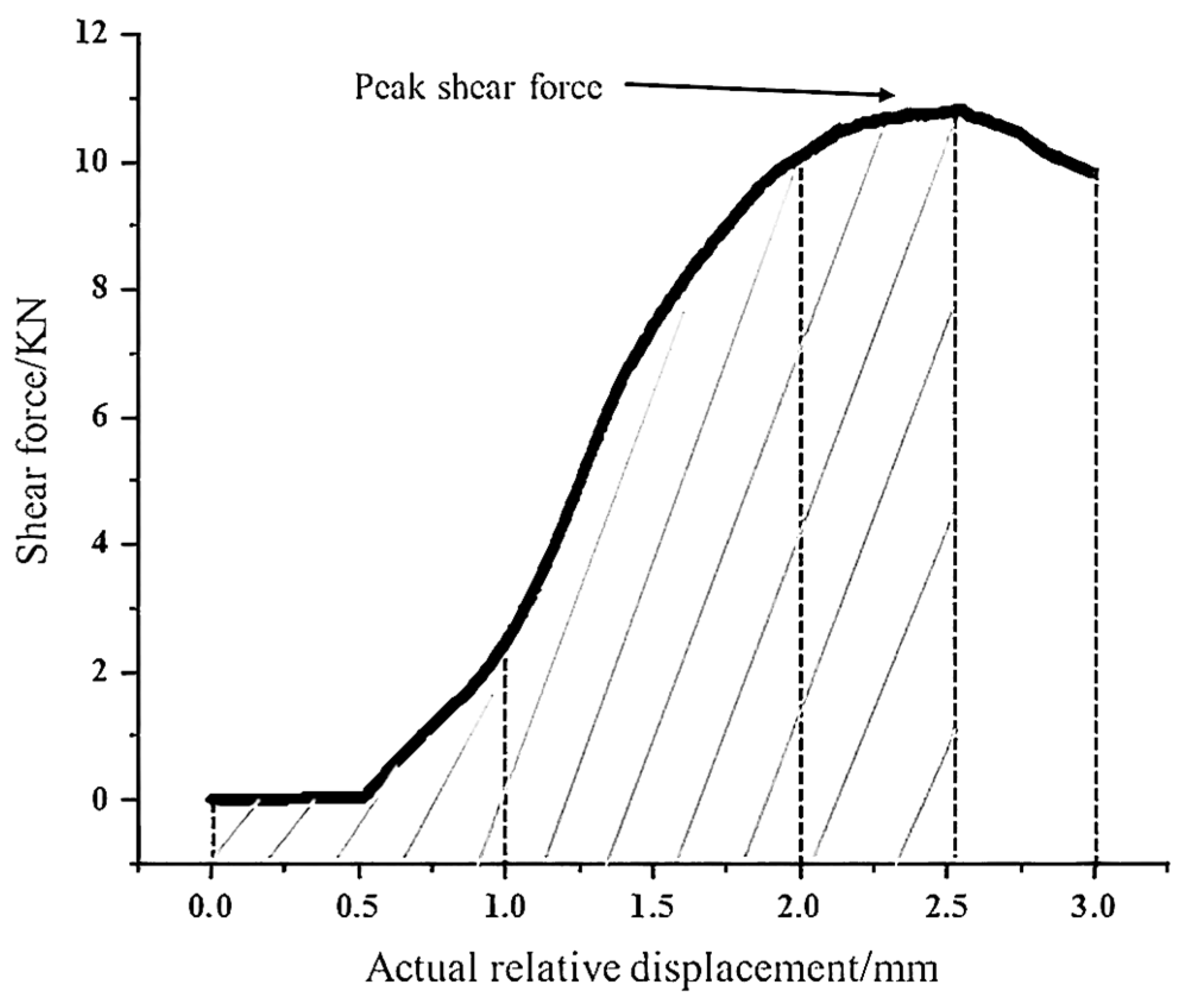

2.2.2. Interlayer Bond Strength Evaluation Based on Energy Method

2.2.3. Dynamic Modulus Test

2.2.4. Analysis of Viscoelastic Properties Based on Haversine Function and CMA Model

2.2.5. Fatigue Test

2.2.6. Rutting Test

- (1)

- According to the method outlined in the “Test Procedures for Asphalt and Asphalt Mixtures in Highway Engineering” (JTG E20-2011) [32], rutting test specimens were fabricated using the T0719-2011 procedure, resulting in specimens with final dimensions of 300 mm × 300 mm × 60 mm (80 mm and 100 mm).

- (2)

- After fabrication, the rutting test specimens were placed within the molds under ambient temperature conditions for no less than 48 h.

- (3)

- Upon reaching the specified curing time, the specimens along with the molds were placed into the rutting test apparatus, insulated for 5 h, and then subjected to the high-temperature rutting test.

- (4)

- The rutting test was terminated when the test duration reached 1 h or the maximum deformation reached 25 mm.

3. Results and Discussions

3.1. High-Performance Asphalt Mixture Interlayer Performance Analysis

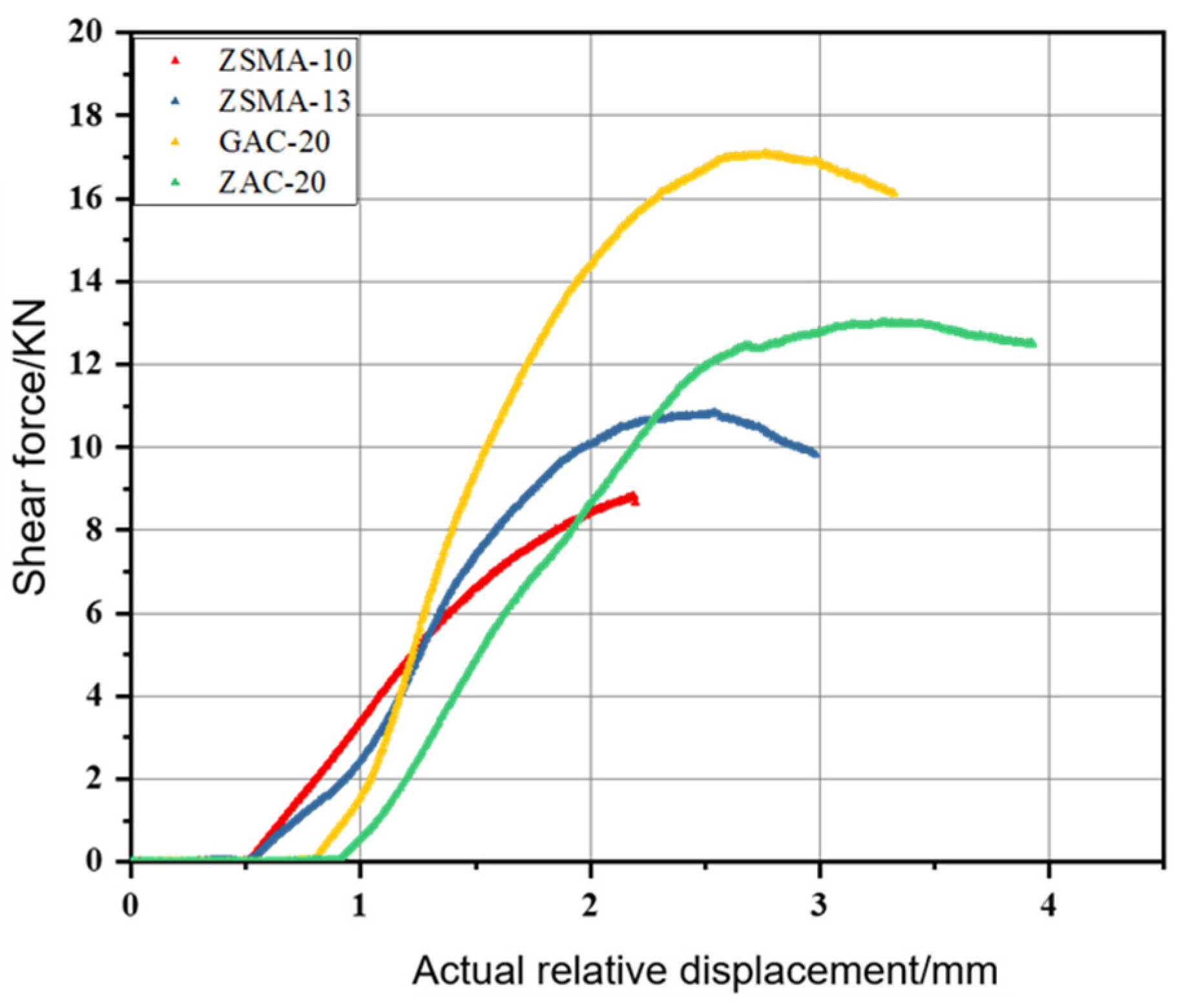

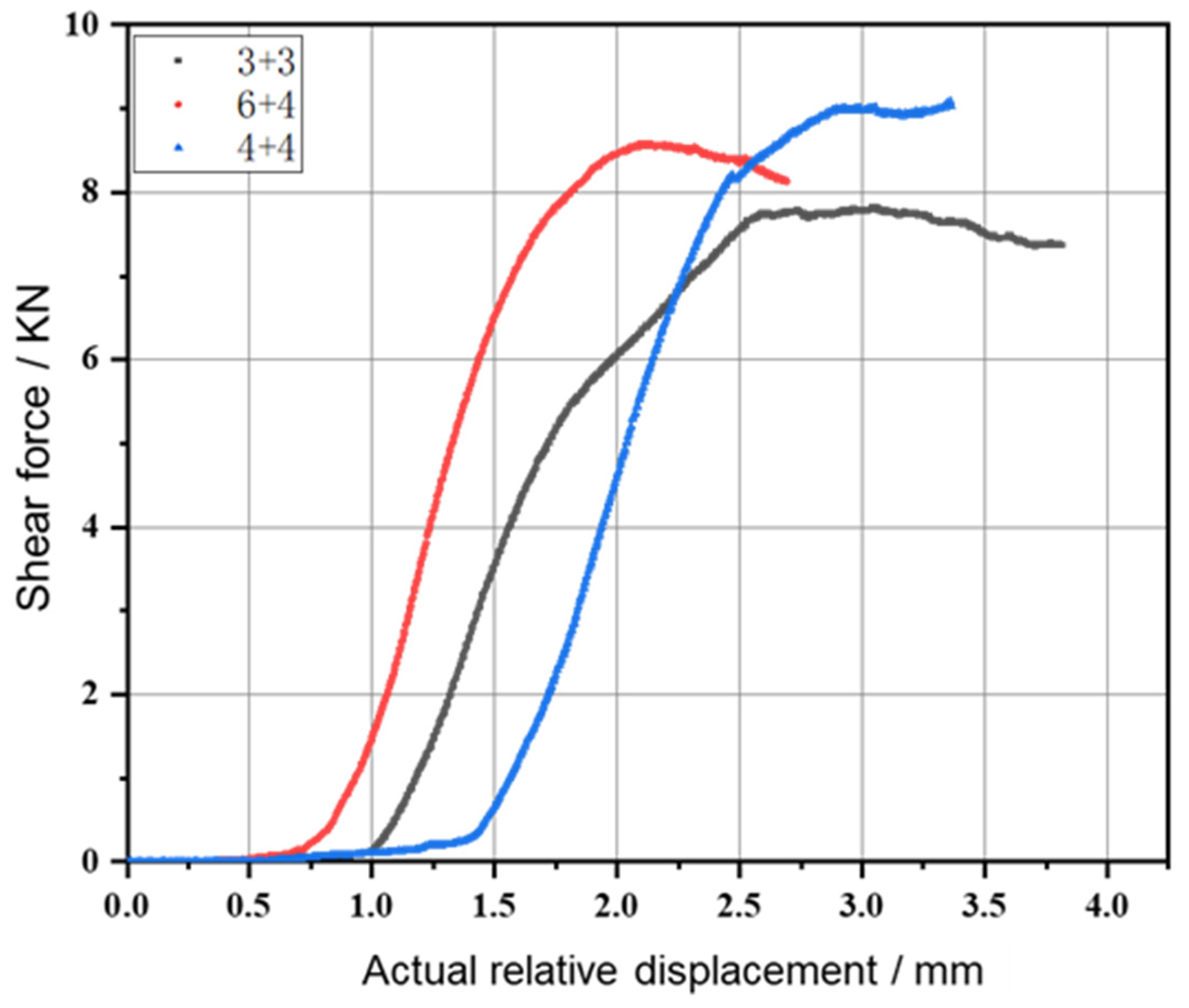

3.1.1. Surface Structure Shear Test Results

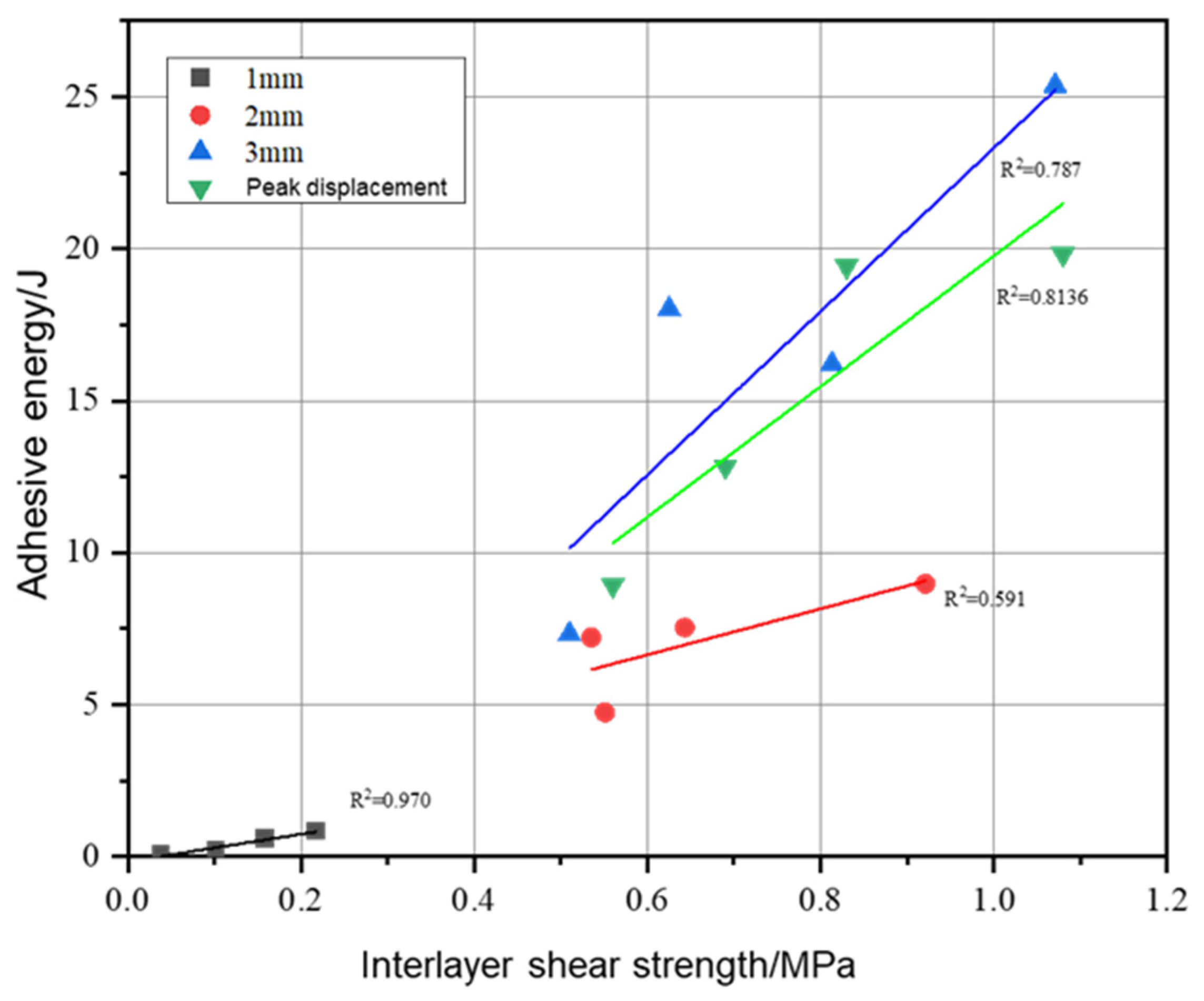

3.1.2. Evaluation and Analysis of Bonding Energy

3.2. High-Performance Composite Structure Viscoelastic Performance Analysis

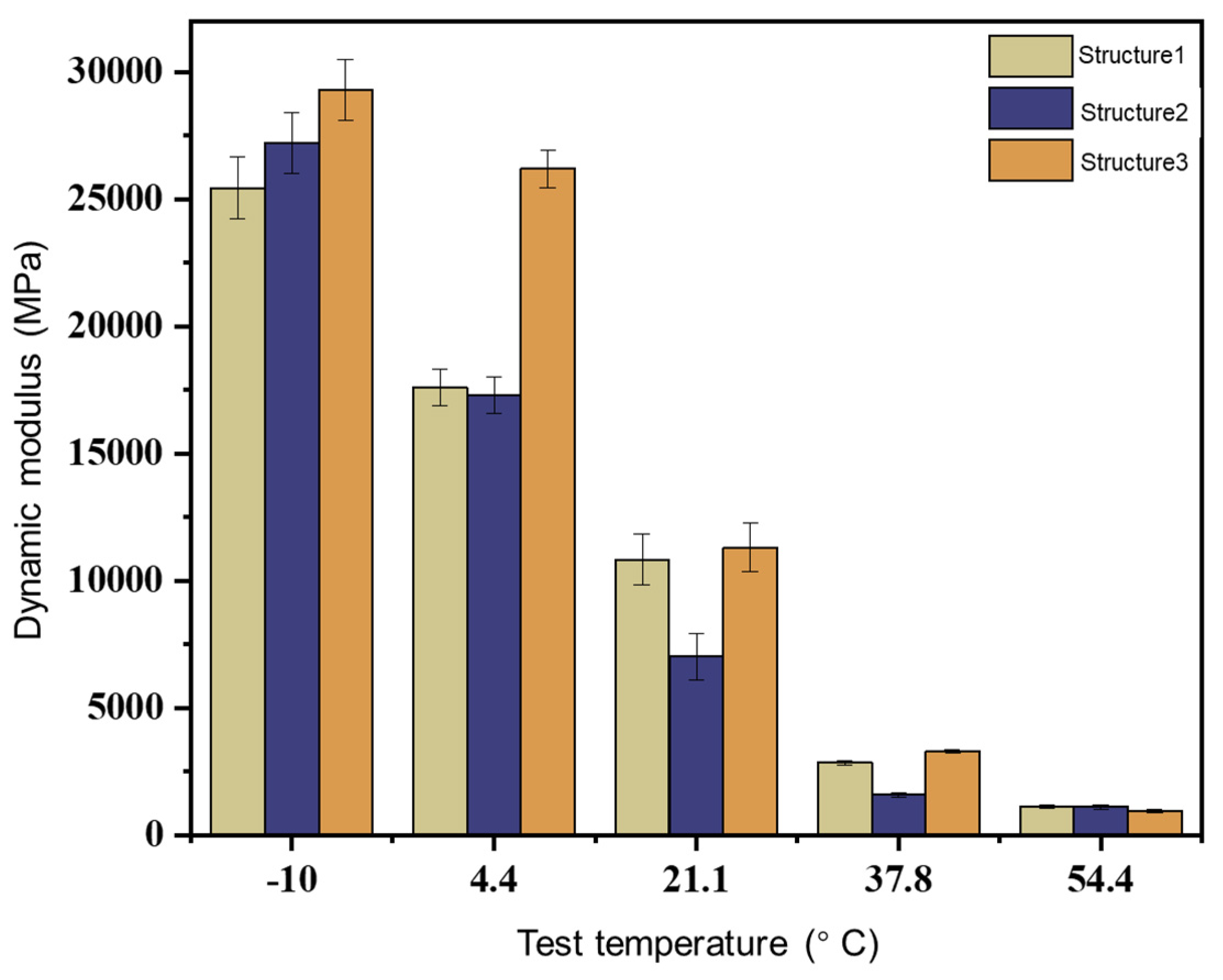

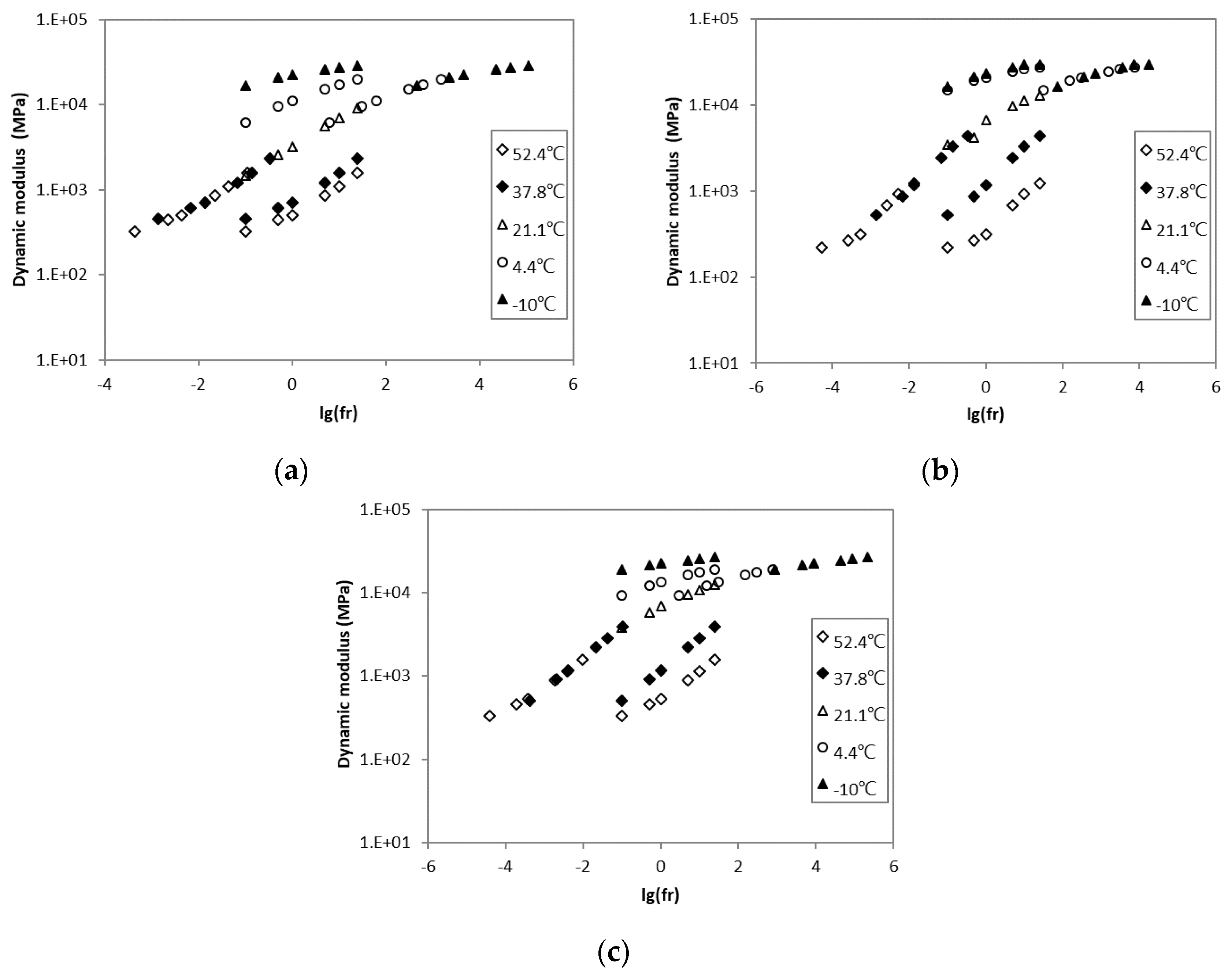

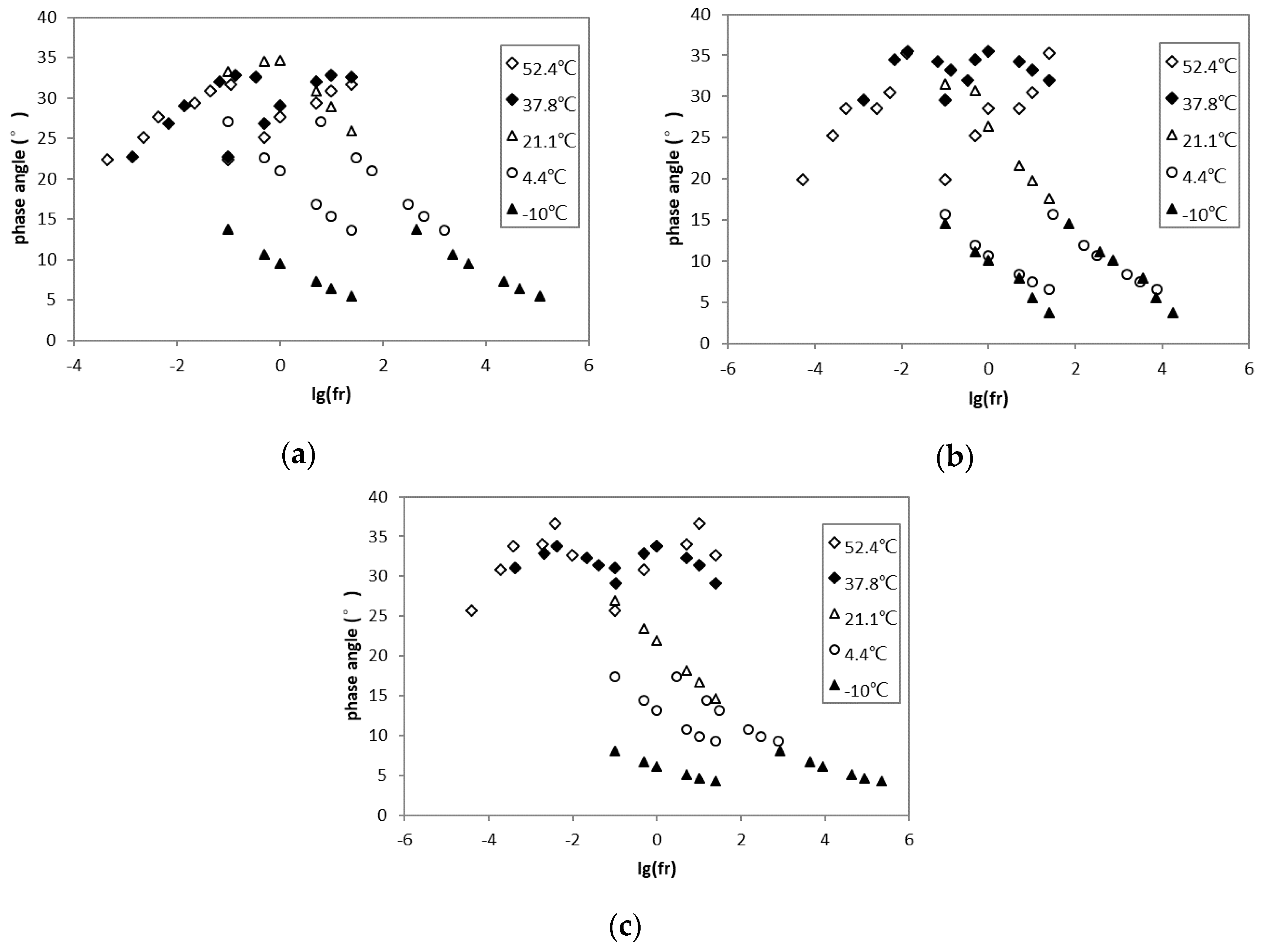

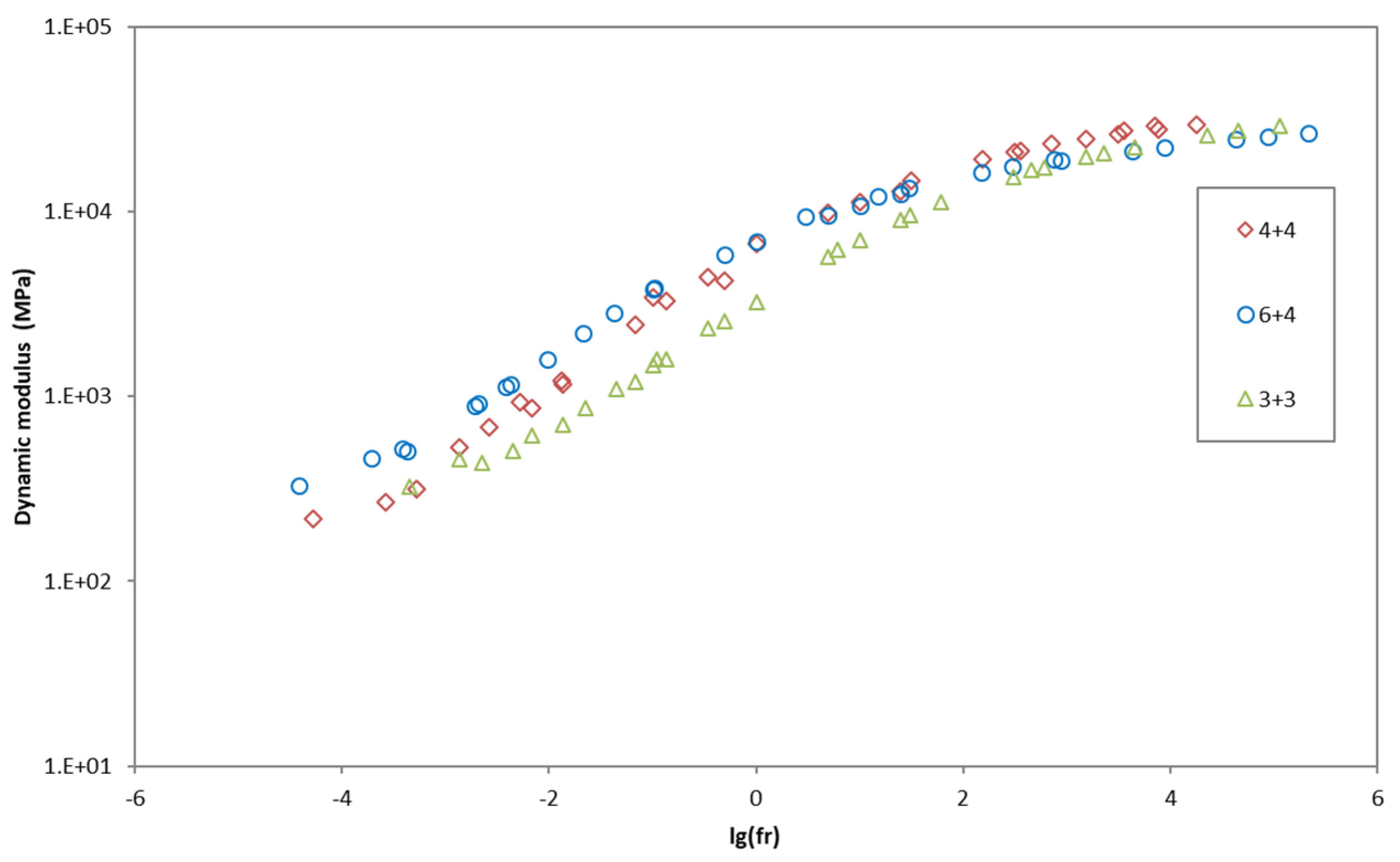

3.2.1. Composite Structure Dynamic Modulus Test Results

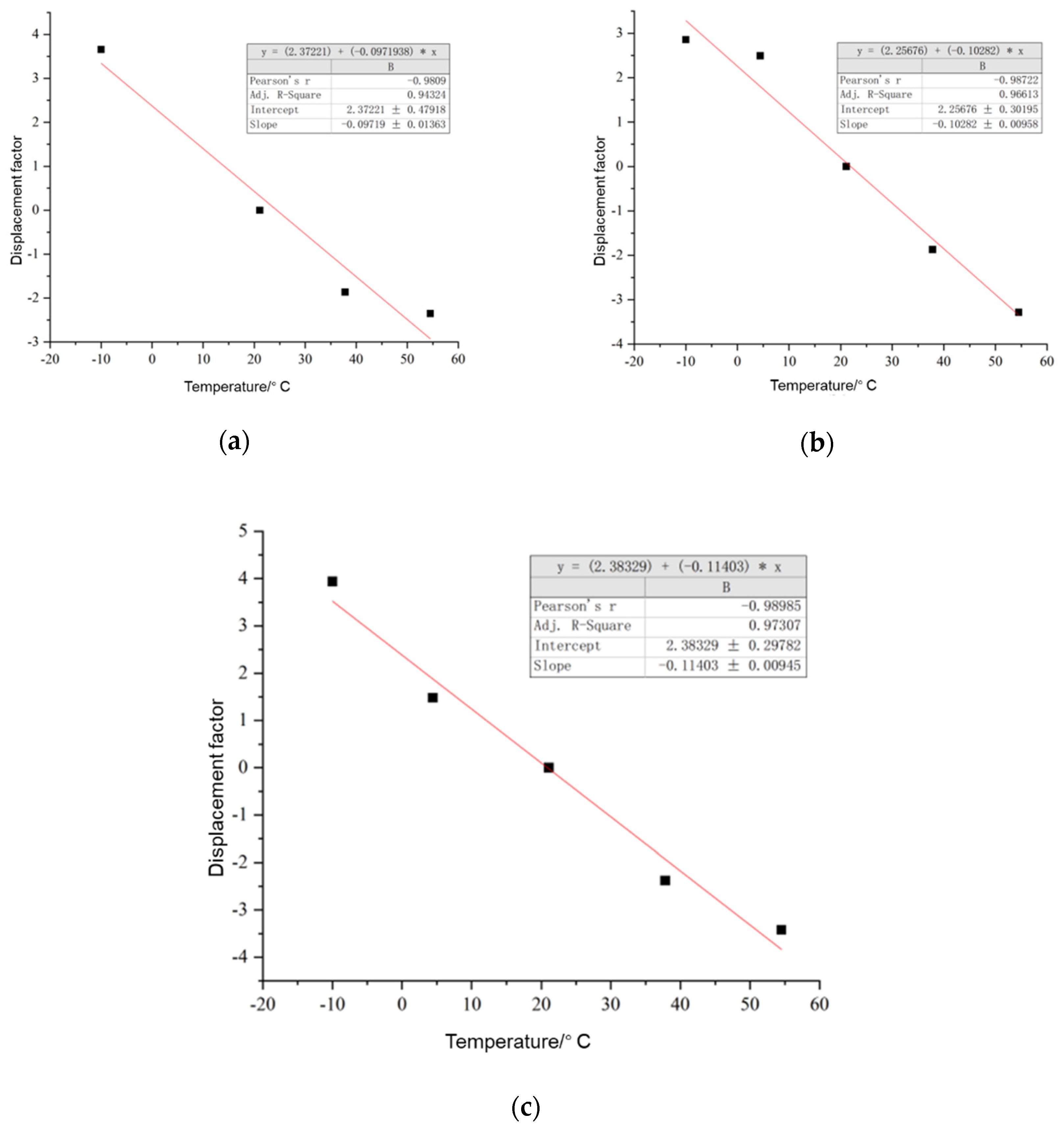

3.2.2. Viscoelastic Behavior Analysis

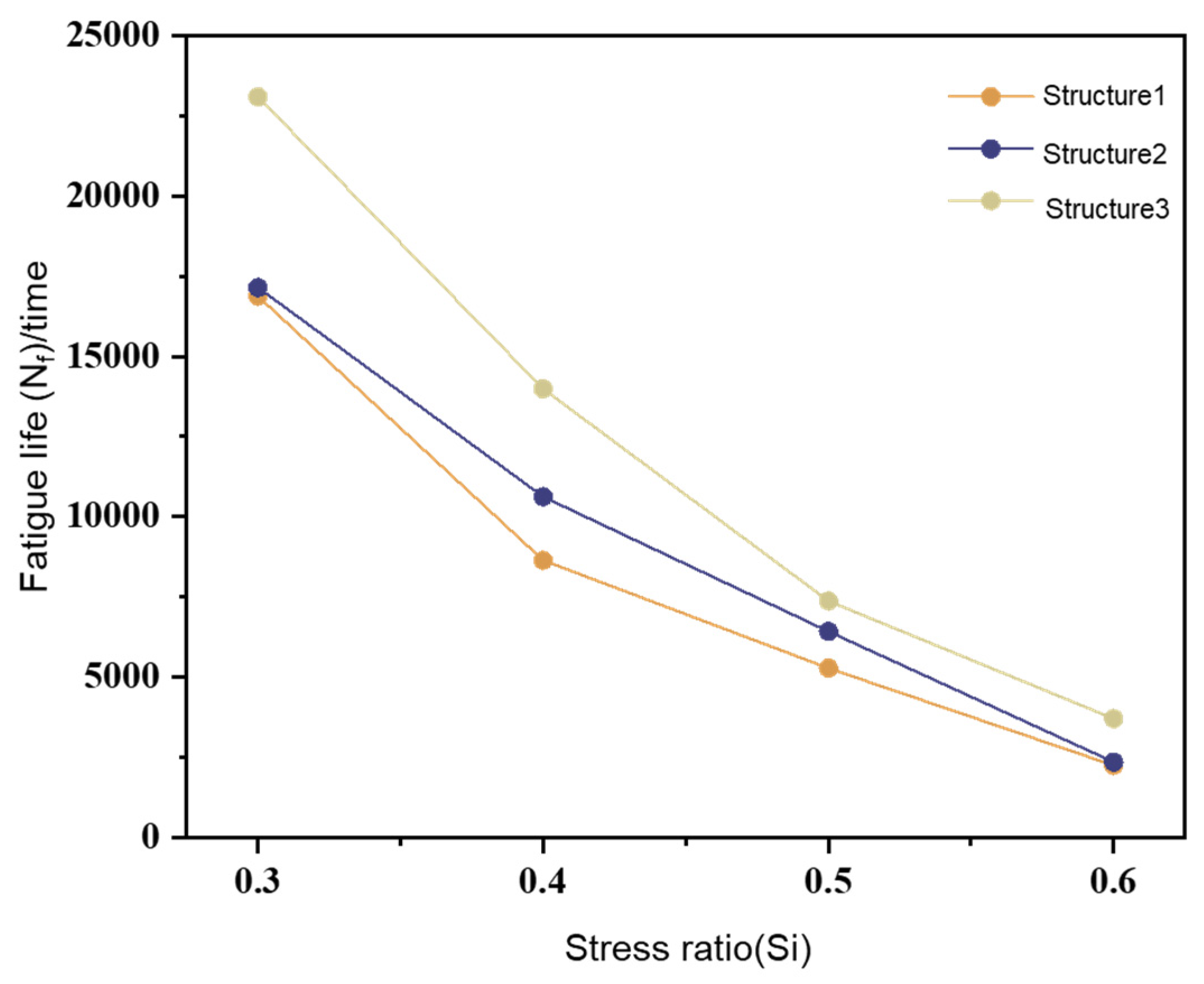

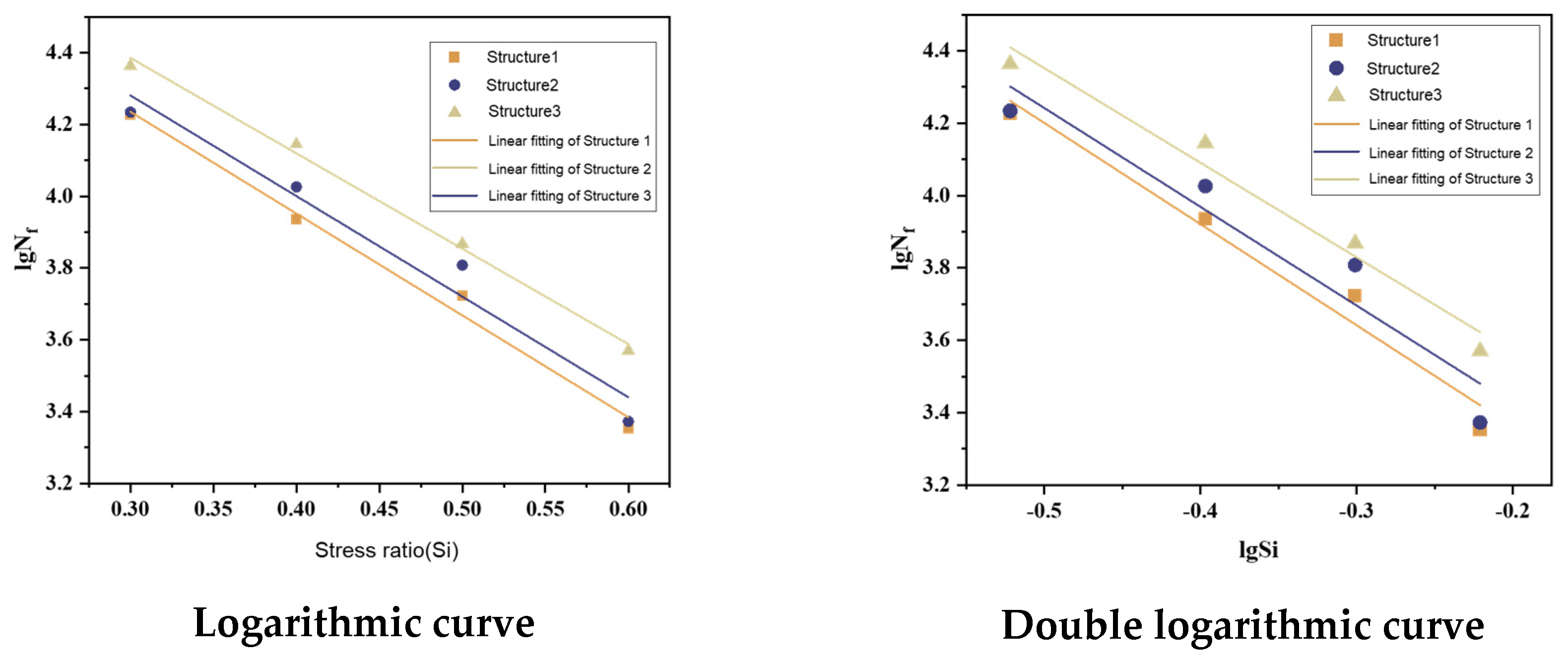

3.3. Fatigue Test Results and Analysis for High-Performance Composite Structures

3.4. Rutting Test Results and Analysis for High-Performance Composite Structures

4. Conclusions

- (1)

- The interlayer shear strength of composite pavement structures is influenced by the asphalt mixture used and the presence of a bonding layer. Among the tested structures, the 4 + 4 combination (4 cm SMA-13 on top + 4 cm SMA-10 below) exhibited the highest shear strength, indicating better interlayer bonding and resistance to shear failure.

- (2)

- The bonding energy evaluation using peak relative displacement as an indicator was found to be an effective method for assessing interlayer shear performance. This approach provided a strong correlation between bonding energy and shear strength, allowing for a more accurate evaluation of interlayer bond strength.

- (3)

- The dynamic modulus tests revealed that the 6 + 4 composite structure (6 cm SMA-13 on top + 4 cm AC-20 below) exhibited superior high-temperature performance compared to the other tested structures. This structure maintained a higher modulus at elevated temperatures, indicating better resistance to deformation and rutting.

- (4)

- The fatigue test results indicated that the 6 + 4 composite structure also performed best in terms of fatigue life. This structure demonstrated the highest fatigue resistance under different stress ratios, making it a favorable choice for applications requiring high durability.

- (5)

- While the 3 + 3 composite structure (3 cm SMA-10 on top + 3 cm SMA-10 below) exhibited the highest dynamic stability in the rutting tests, all tested structures met the minimum requirements for rutting resistance. However, the 6 + 4 structure, with its superior high-temperature performance, is still recommended for applications where high-temperature rutting is a concern.

- (6)

- Limitations and future goals: The tests were conducted under a specific set of conditions (e.g., temperatures, loading frequencies). Expanding the range of conditions tested would provide a more comprehensive understanding of the material’s behavior. Conducting additional tests with a wider range of temperatures, loading frequencies, and asphalt mixture compositions would provide a more robust evaluation of the material’s performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, K.; Liu, Y.; Nassiri, S.; Li, H.; Englund, K. Performance evaluation of porous asphalt mixture enhanced with high dosages of cured carbon fiber composite materials. Constr. Build. Mater. 2021, 274, 122066. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, L.; Li, H.; Zhang, H.; Harvey, J.; Yang, B.; Zhu, Y.; Yu, B.; Fu, K. Laboratory investigation on effects of solid waste filler on mechanical properties of porous asphalt mixture. Constr. Build. Mater. 2021, 279, 122436. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Said, I.M.; Ali, U.M.; Kaddo, J.R. Cracking prediction of asphalt concrete using fracture and strength tests. Int. J. Pavement Eng. 2022, 23, 3333–3345. [Google Scholar] [CrossRef]

- Wang, W.; Duan, S.; Zhu, H. Research on improving the durability of bridge pavement using a high-modulus asphalt mixture. Materials 2021, 14, 1449. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, W.; Yu, G.F.; Zhu, F.F. Research on anti-rutting performance of high modulus asphalt concrete pavement. Adv. Mater. Res. 2011, 163, 4474–4477. [Google Scholar]

- Qian, G.; Yao, D.; Gong, X.; Yu, H.; Li, N. Performance evaluation and field application of hard asphalt concrete under heavy traffic conditions. Constr. Build. Mater. 2019, 228, 116729. [Google Scholar] [CrossRef]

- Si, C.; Zhou, X.; You, Z.; He, Y.; Chen, E.; Zhang, R. Micro-mechanical analysis of high modulus asphalt concrete pavement. Constr. Build. Mater. 2019, 220, 128–141. [Google Scholar] [CrossRef]

- Geng, L.-T.; Xu, Q.; Ren, R.-B.; Wang, L.-Z.; Yang, X.-L.; Wang, X.-Y. Performance research of high-viscosity asphalt mixture as deck-paving materials for steel bridges. Road Mater. Pavement Des. 2017, 18, 208–220. [Google Scholar] [CrossRef]

- Qin, X.; Zhu, S.; He, X.; Jiang, Y. High temperature properties of high viscosity asphalt based on rheological methods. Constr. Build. Mater. 2018, 186, 476–483. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, G. Preparation, Performance, and modification mechanism of high viscosity modified asphalt. Constr. Build. Mater. 2021, 310, 125007. [Google Scholar] [CrossRef]

- Arnold, G.; Darcy, R.; Hall, S.; Mudgway, G. High modulus asphalt to prevent rutting at intersections. In Proceedings of the 17th AAPA International Flexible Pavements Conference, Melbourne, Victoria, Australia, 13–16 August 2017; pp. 13–16. [Google Scholar]

- Espersson, M. Effect in the high modulus asphalt concrete with the temperature. Constr. Build. Mater. 2014, 71, 638–643. [Google Scholar] [CrossRef]

- Jin, D.; Boateng, K.A.; Chen, S.; Xin, K.; You, Z. Comparison of rubber asphalt with polymer asphalt under long-term aging conditions in Michigan. Sustainability 2022, 14, 10987. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Xin, K.; You, Z. Comparison of asphalt emulsion-based chip seal and hot rubber asphalt-based chip seal. Case Stud. Constr. Mater. 2023, 18, e02175. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Malburg, L.; You, Z. Laboratory evaluation and field demonstration of cold in-place recycling asphalt mixture in Michigan low-volume road. Case Stud. Constr. Mater. 2024, 20, e02923. [Google Scholar] [CrossRef]

- Zeng, G.; Wu, W.; Li, J.; Xu, Q.; Li, X.; Yan, X.; Han, Y.; Wei, J. Comparative study on road performance of low-grade hard asphalt and mixture in China and France. Coatings 2022, 12, 270. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Kleizienė, R.; Žiliūtė, L. New solutions for distressed pavement rehabilitation of Vilnius city streets. In Proceedings of the Road and Rail Infrastructure III, Split, Croatia, 28–30 April 2014. [Google Scholar]

- Li, J.; Chai, L. A Case Study of Asphalt Pavement Overlay for Beinjing West Chang’an Avenue Using Modified Bitumen of High Viscosity and Elasticity. In Proceedings of the 2015 4th International Conference on Sensors, Measurement and Intelligent Materials, Shenzhen, China, 27–28 December 2015; Atlantis Press: Amsterdam, The Netherlands, 2016; pp. 27–278. [Google Scholar]

- Wang, T.; Dra, Y.A.S.S.; Cai, X.; Cheng, Z.; Zhang, D.; Lin, Y.; Yu, H. Advanced cold patching materials (CPMs) for asphalt pavement pothole rehabilitation: State of the art. J. Clean. Prod. 2022, 366, 133001. [Google Scholar] [CrossRef]

- Lu, Z.; Feng, Z.-G.; Yao, D.; Li, X.; Jiao, X.; Zheng, K. Bonding performance between ultra-high performance concrete and asphalt pavement layer. Constr. Build. Mater. 2021, 312, 125375. [Google Scholar] [CrossRef]

- Haslett, K.E.; Robinson, Z.; Wielinski, J. Comparison of Bond Strength Evaluation Methods between Pavement Layers; Transportation Research Record: Washington, DC, USA, 2022; p. 03611981221141434. [Google Scholar]

- Bonaquist, R.F. Simple Performance Tester for Superpave Mix Design: First-Article Development and Evaluation; Transportation Research Board: Washington, DC, USA, 2003; Volume 513. [Google Scholar]

- Wang, T.; Li, M.; Cai, X.; Cheng, Z.; Zhang, D.; Sun, G. Multi-objective design optimization of composite polymerized asphalt emulsions for cold patching of pavement potholes. Mater. Today Commun. 2023, 35, 105751. [Google Scholar] [CrossRef]

- Boz, I.; Tavassoti-Kheiry, P.; Solaimanian, M. The advantages of using impact resonance test in dynamic modulus master curve construction through the abbreviated test protocol. Mater. Struct. 2017, 50, 176. [Google Scholar] [CrossRef]

- Corrales-Azofeifa, J.; Archilla, A.R.; Miranda-Argüello, F.; Loria-Salazar, L. Effects of moisture damage and anti-stripping agents on hot mix asphalt dynamic modulus. Road Mater. Pavement Des. 2020, 21, 1135–1154. [Google Scholar] [CrossRef]

- Yuan, D.; Jiang, W.; Hou, Y.; Xiao, J.; Ling, X.; Xing, C. Fractional derivative viscoelastic response of high-viscosity modified asphalt. Constr. Build. Mater. 2022, 350, 128915. [Google Scholar] [CrossRef]

- Zeng, M.; Bahia, H.U.; Zhai, H.; Anderson, M.R.; Turner, P. Rheological modeling of modified asphalt binders and mixtures (with discussion). J. Assoc. Asph. Paving Technol. 2001, 70, 403–441. [Google Scholar]

- Xu, J.; Zheng, C. Random generation of asphalt mixture mesostructure and thermal–mechanical coupling analysis at low temperature. Constr. Build. Mater. 2021, 280, 122537. [Google Scholar] [CrossRef]

- Chehab, G.; Kim, Y.; Schapery, R.; Witczak, M.; Bonaquist, R. Time-temperature superposition principle for asphalt concrete with growing damage in tension state. J. Assoc. Asph. Paving Technol. 2002, 71, 559–593. [Google Scholar]

- Dondi, G.; Pettinari, M.; Sangiorgi, C.; Zoorob, S.E. Traditional and Dissipated Energy approaches to compare the 2PB and 4PB flexural methodologies on a Warm Mix Asphalt. Constr. Build. Mater. 2013, 47, 833–839. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Rajabi, M. The fatigue behavior of SBS/nanosilica composite modified asphalt binder and mixture. Constr. Build. Mater. 2019, 229, 116796. [Google Scholar] [CrossRef]

- JTG E20-2011; Specifications and Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communication Press: Beijing, China, 2011.

| Experimental Indicators | Test Result | Experimental Methods |

|---|---|---|

| Needle penetration (25 °C, 100 g, 5 s)/0.1 mm | 65.0 | T0604-2011 |

| Softening point (global method)/°C | 88.3 | T0606-2011 |

| Elongation (5 °C, 5 cm/min)/cm | 40.0 | T0605-2011 |

| Dynamic viscosity (60 °C)/Pa·s | 61,768 | T0607-2011 |

| Flash point/°C | 290 | T0615-2011 |

| Elastic recovery (25 °C)/% | 91 | T0611-2011 |

| Solubility (trichloroethylene)/% | 99.3 | T0610-2011 |

| Thin film heating (mass change)/% | −0.01 | T0604-2011 |

| Film heating (residual needle penetration ratio)/% | 92.5 | T0606-2011 |

| Thin film heating (residual ductility (5 °C))/cm | 35.2 | T0605-2011 |

| Experimental Indicators | Test Result | Experimental Methods |

|---|---|---|

| Needle penetration (25 °C, 100 g, 5 s)/0.1 mm | 51.0 | T0604-2011 |

| Softening point (global method)/°C | 96.8 | T0606-2011 |

| Elongation (5 °C, 5 cm/min)/cm | 37 | T0605-2011 |

| Flash point/°C | 334 | T0607-2011 |

| Elastic recovery (25 °C)/% | 98 | T0615-2011 |

| Solubility (trichloroethylene)/% | 99.9 | T0611-2011 |

| Thin film heating (mass change)/% | −0.07 | T0610-2011 |

| Film heating (residual needle penetration ratio)/% | 72 | T0604-2011 |

| Thin film heating (residual ductility (5 °C))/cm | 20 | T0606-2011 |

| Experimental Project | Test Result | Experimental Methods | |

|---|---|---|---|

| Asphalt content/% | 65.6 | AASHTO T 59-16 | |

| Remaining amount on 1.18 mm sieve/% | 0.01 | T 0652-199 | |

| 25 °C Saybolt viscosity/s | 82 | SH/T 0779-2005 | |

| Residue properties | 25 °C needle penetration/0.1 mm | 82 | T0604-2011 |

| Breaking speed/s | 63 | ASTM D244 | |

| Softening point (global method)/°C | 73 | T0606-2011 | |

| Solubility (trichloroethylene)/% | 99 | T0611-2011 | |

| 10 °C Elastic recovery/% | 70 | T0611-2011 | |

| Storage stability | 1 d | 0.2 | GB/T37055.4-2020 |

| 5 d | 1.5 | GB/T37055.4-2020 | |

| Composite Pavement Structure Type | Emulsified Asphalt Dosage (kg/m2) | Temperature (°C) |

|---|---|---|

| Structure 1 | 0.7 | 60 |

| Structure 2 | 0.7 | 60 |

| Structure 3 | 0.7 | 60 |

| Structural Hierarchy | Test Piece Type | ||

|---|---|---|---|

| Type 1 | Type 2 | Type 3 | |

| Superstructure | 3 cm SMA-10 | 4 cm SMA-13 | 6 cm SMA-13 |

| Type of adhesive layer oil | emulsified asphalt | ||

| 3 cm SMA-10 | 4 cm SMA-10 | 4 cm AC-20 | |

| Paving Structure | Emulsified Asphalt Dosage (kg/m2) | Normal Stress (MPa) | Shear Strength (MPa) |

|---|---|---|---|

| Structure 1 | 0.7 | 0.86 | 0.47 |

| Structure 2 | 0.99 | 0.57 | |

| Structure 3 | 0.95 | 0.54 | |

| ZAC | 1.43 | 0.83 | |

| GAC | 1.89 | 1.08 | |

| SMA-10 | 0.97 | 0.56 | |

| SMA-13 | 1.20 | 0.69 |

| Asphalt Mixture | ZSMA-10 | ZSMA-13 | GAC-20 | ZAC-20 | |

|---|---|---|---|---|---|

| Calculation Standard (mm) | |||||

| 1 | 0.829 | 0.589 | 0.217 | 0.062 | |

| 2 | 7.213 | 7.546 | 8.979 | 4.750 | |

| 3 | 7.321 | 18.019 | 25.378 | 16.212 | |

| Peak displacement | 8.933 | 12.843 | 19.836 | 19.430 | |

| Asphalt Mixture | ZSMA-10 | ZSMA-13 | GAC-20 | ZAC-20 | |

|---|---|---|---|---|---|

| Calculation Standard (mm) | |||||

| 1 | 0.217 | 0.158 | 0.102 | 0.038 | |

| 2 | 0.535 | 0.643 | 0.921 | 0.551 | |

| 3 | 0.510 | 0.625 | 1.071 | 0.813 | |

| Maximum strength | 0.56 | 0.69 | 1.08 | 0.83 | |

| Structure Type | 3 + 3 | 6 + 4 | 4 + 4 | |

|---|---|---|---|---|

| Calculation Standard (mm) | ||||

| 2 | 3.276 | 6.113 | 1.385 | |

| 3 | 10.609 | 14.387 | 9.092 | |

| Peak displacement | 9.812 | 11.621 | 13.619 | |

| Structure Type | 3 + 3 | 6 + 4 | 4 + 4 | |

|---|---|---|---|---|

| Calculation Standard (mm) | ||||

| 2 | 0.385 | 0.539 | 0.296 | |

| 3 | 0.465 | 0.334 | 0.569 | |

| Peak displacement | 0.47 | 0.54 | 0.57 | |

| Temperature (°C) | Dynamic Modulus at Different Frequencies (Hz)/MPa | |||||

|---|---|---|---|---|---|---|

| 0.1 | 0.5 | 1 | 5 | 10 | 25 | |

| −10 | 16,760 | 20,667 | 22,281 | 25,806 | 27,214 | 28,877 |

| 4.4 | 6234 | 9581 | 11,194 | 15,325 | 17,292 | 19,903 |

| 21.1 | 1474 | 2539 | 3220 | 5666 | 7017 | 9052 |

| 37.8 | 459.2 | 612 | 702 | 1202 | 1580 | 2344 |

| 54.4 | 323.5 | 439.8 | 505 | 862.9 | 1104 | 1593 |

| Temperature (°C) | Dynamic Modulus at Different Frequencies (Hz)/MPa | |||||

|---|---|---|---|---|---|---|

| 0.1 | 0.5 | 1 | 5 | 10 | 25 | |

| −10 | 16,371 | 21,380 | 23,270 | 27,201 | 29,292 | 29,526 |

| 4.4 | 14,794 | 19,131 | 20,925 | 24,644 | 26,186 | 27,625 |

| 21.1 | 3454 | 4218 | 6703 | 9823 | 11,302 | 12,952 |

| 37.8 | 526.9 | 870.1 | 1163 | 2445 | 3289 | 4414 |

| 54.4 | 218.7 | 26.2 | 317.7 | 685.7 | 936.3 | 1218 |

| Temperature (°C) | Dynamic Modulus at Different Frequencies (Hz)/MPa | |||||

|---|---|---|---|---|---|---|

| 0.1 | 0.5 | 1 | 5 | 10 | 25 | |

| −10 | 19,035 | 21,449 | 22,412 | 24,597 | 25,433 | 26,698 |

| 4.4 | 9401 | 12,122 | 13,352 | 16,323 | 17,596 | 19,211 |

| 21.1 | 3836 | 5850 | 6850 | 9549 | 10,836 | 12,566 |

| 37.8 | 503.8 | 312.1 | 1168 | 2217 | 2841 | 3888 |

| 54.4 | 329.8 | 462.2 | 525.4 | 890 | 1128 | 1580 |

| Temperature (°C) | 3 + 3 | 4 + 4 | 6 + 4 |

|---|---|---|---|

| −10 | 3.6562 | 2.8569 | 3.9403 |

| 4.4 | 1.7899 | 2.4934 | 1.4798 |

| 21.1 | 0 | 0 | 0 |

| 37.8 | −1.8641 | −1.8692 | −2.3767 |

| 54.5 | −2.3531 | −3.2813 | −3.4194 |

| Type of Mixture | 3 + 3 | 4 + 4 | 6 + 4 |

|---|---|---|---|

| 2.1615 | 1.7068 | 1.9487 | |

| 2.3658 | 2.8521 | 2.4858 | |

| −0.2921 | −0.9956 | −1.1533 | |

| −0.6112 | −0.5626 | −0.5621 |

| Viscoelastic Parameters | R2 | ||||||

|---|---|---|---|---|---|---|---|

| 3 + 3 | 2.60 | 40695 | 28 | 0.596 | 0.647 | 0.277327 | 0.999 |

| 4 + 4 | 2.73 | 41367 | 34 | 0.695 | 0.569 | 0.367653 | 0.997 |

| 6 + 4 | 3.10 | 42036 | 41 | 0.584 | 0.710 | 0.247583 | 0.998 |

| Structure Type | Stress Ratio | Fatigue Life | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average Value | ||

| Structure 1 | 0.3 | 16,524 | 17,532 | 16,562 | 16,873 |

| 0.4 | 9152 | 8250 | 8528 | 8643 | |

| 0.5 | 5652 | 5012 | 5186 | 5283 | |

| 0.6 | 1896 | 2521 | 2350 | 2256 | |

| Structure 2 | 0.3 | 17,128 | 16,925 | 17,367 | 17,140 |

| 0.4 | 10,547 | 9654 | 11,683 | 10,628 | |

| 0.5 | 6781 | 6149 | 6368 | 6432 | |

| 0.6 | 1987 | 2645 | 2460 | 2364 | |

| Structure 3 | 0.3 | 22,679 | 23,025 | 23,529 | 23,078 |

| 0.4 | 14,456 | 13,856 | 13,552 | 13,988 | |

| 0.5 | 6925 | 7362 | 7856 | 7381 | |

| 0.6 | 4098 | 3625 | 3425 | 3716 | |

| Composite Structure | Single Logarithmic Fatigue Life Equation | Double Logarithmic Fatigue Life |

|---|---|---|

| Structure 1 | ||

| Structure 2 | ||

| Structure 3 |

| Structural Type | Dynamic Stability (times/mm) | Standard Deviation |

|---|---|---|

| 3 + 3 | 5951 | 256 |

| 4 + 4 | 6186 | 245 |

| 6 + 4 | 7881 | 334 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Ma, S.; Zhang, Y. Interlayer Performance, Viscoelastic Performance, and Road Performance Based on High-Performance Asphalt Composite Structures. Buildings 2024, 14, 1885. https://doi.org/10.3390/buildings14071885

Liang Y, Ma S, Zhang Y. Interlayer Performance, Viscoelastic Performance, and Road Performance Based on High-Performance Asphalt Composite Structures. Buildings. 2024; 14(7):1885. https://doi.org/10.3390/buildings14071885

Chicago/Turabian StyleLiang, Yan, Shuaishuai Ma, and Yaqin Zhang. 2024. "Interlayer Performance, Viscoelastic Performance, and Road Performance Based on High-Performance Asphalt Composite Structures" Buildings 14, no. 7: 1885. https://doi.org/10.3390/buildings14071885

APA StyleLiang, Y., Ma, S., & Zhang, Y. (2024). Interlayer Performance, Viscoelastic Performance, and Road Performance Based on High-Performance Asphalt Composite Structures. Buildings, 14(7), 1885. https://doi.org/10.3390/buildings14071885