Research on Temperature Field of Cement-Mixing Pile-Reinforced Soft Soil Foundation

Abstract

:1. Introduction

2. The fundamental Theory of Hydration Heat Analysis

2.1. Hydration Heat of Cement

2.2. Heat Conduction Equation

3. Model Establishment

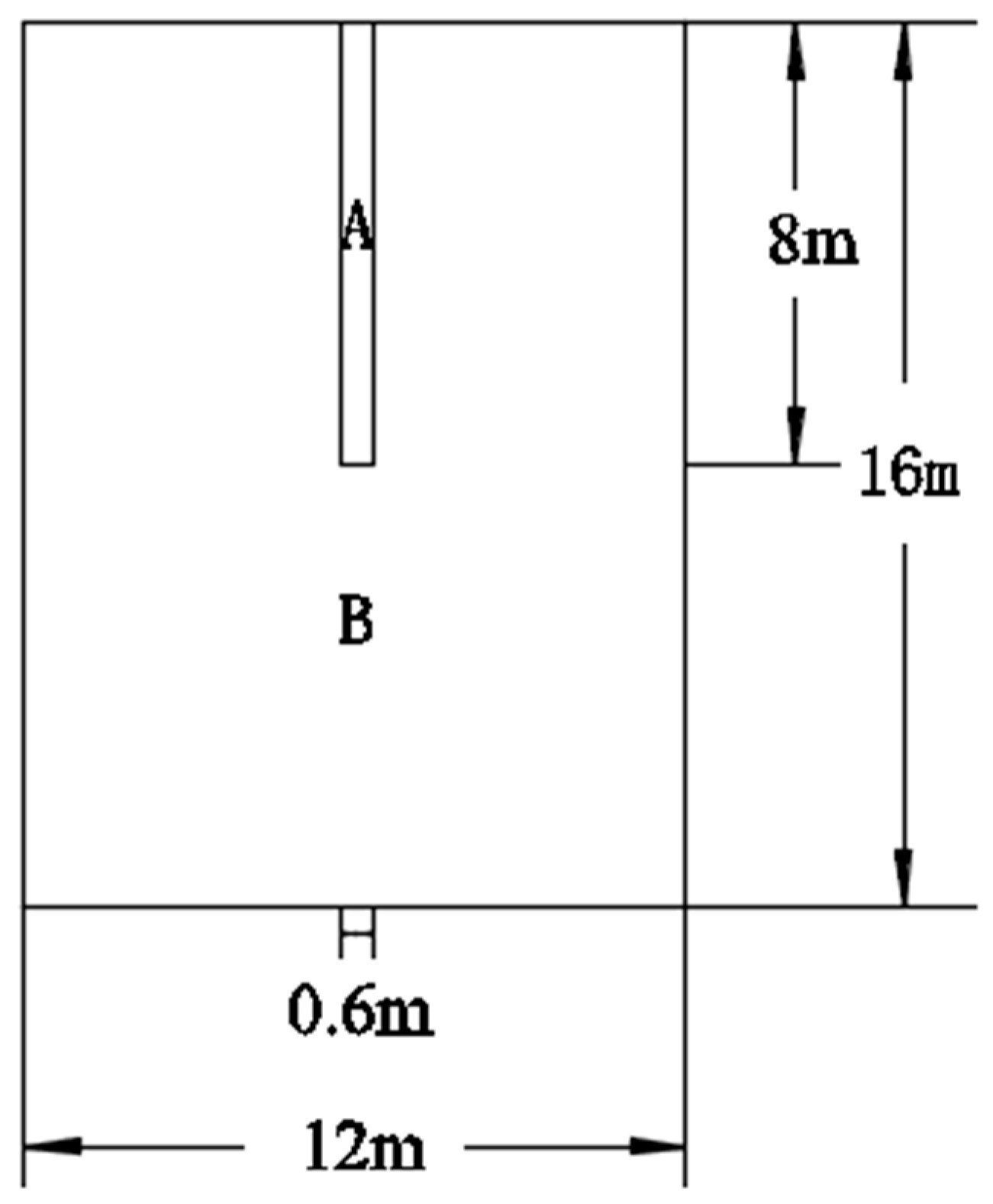

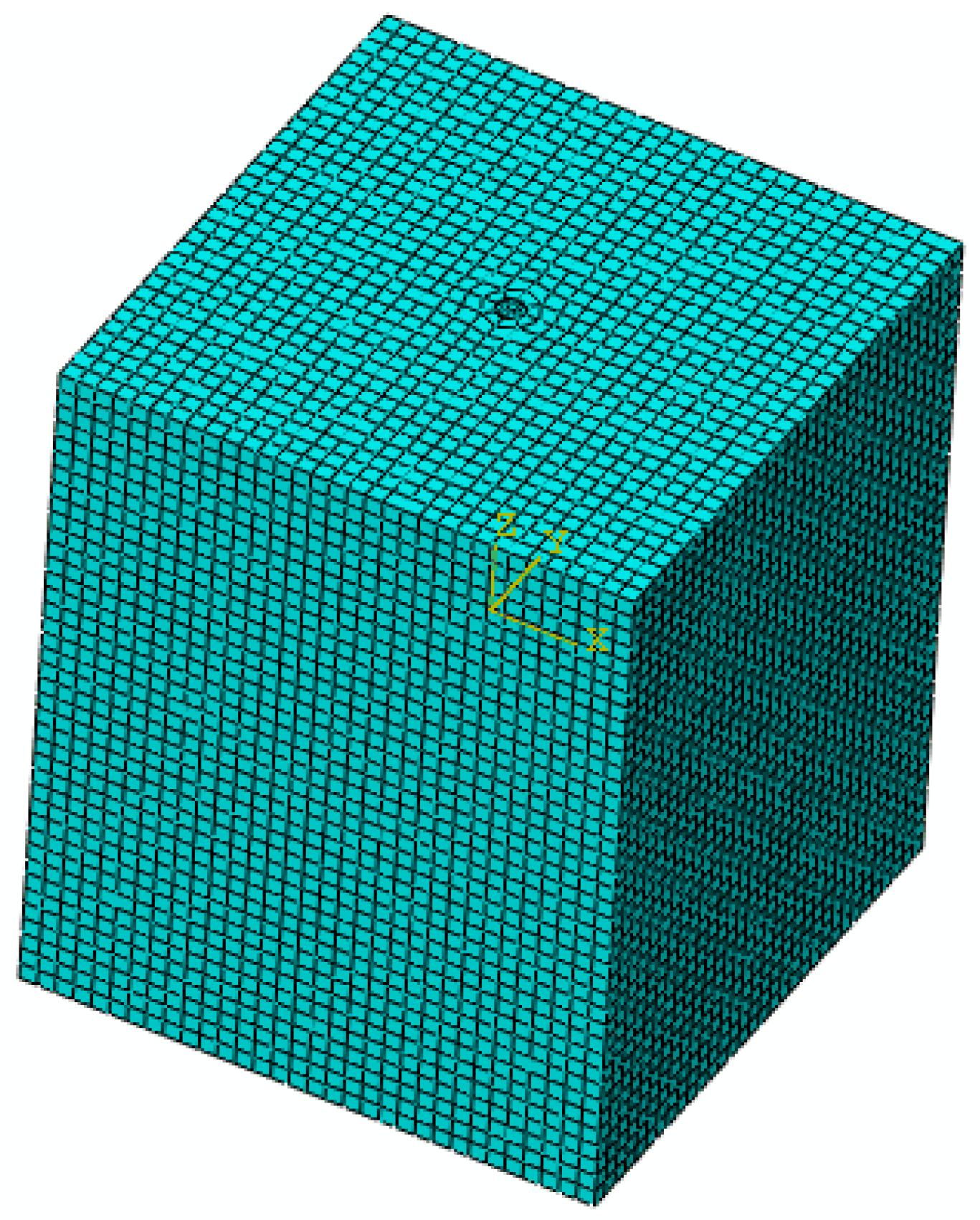

3.1. Geometric Model and Material Parameters

3.2. Initial Conditions

3.3. Boundary Conditions and Interactions

3.4. Include Ground Temperature Variations

3.5. Cement Blending Amount

4. Analysis of the Results

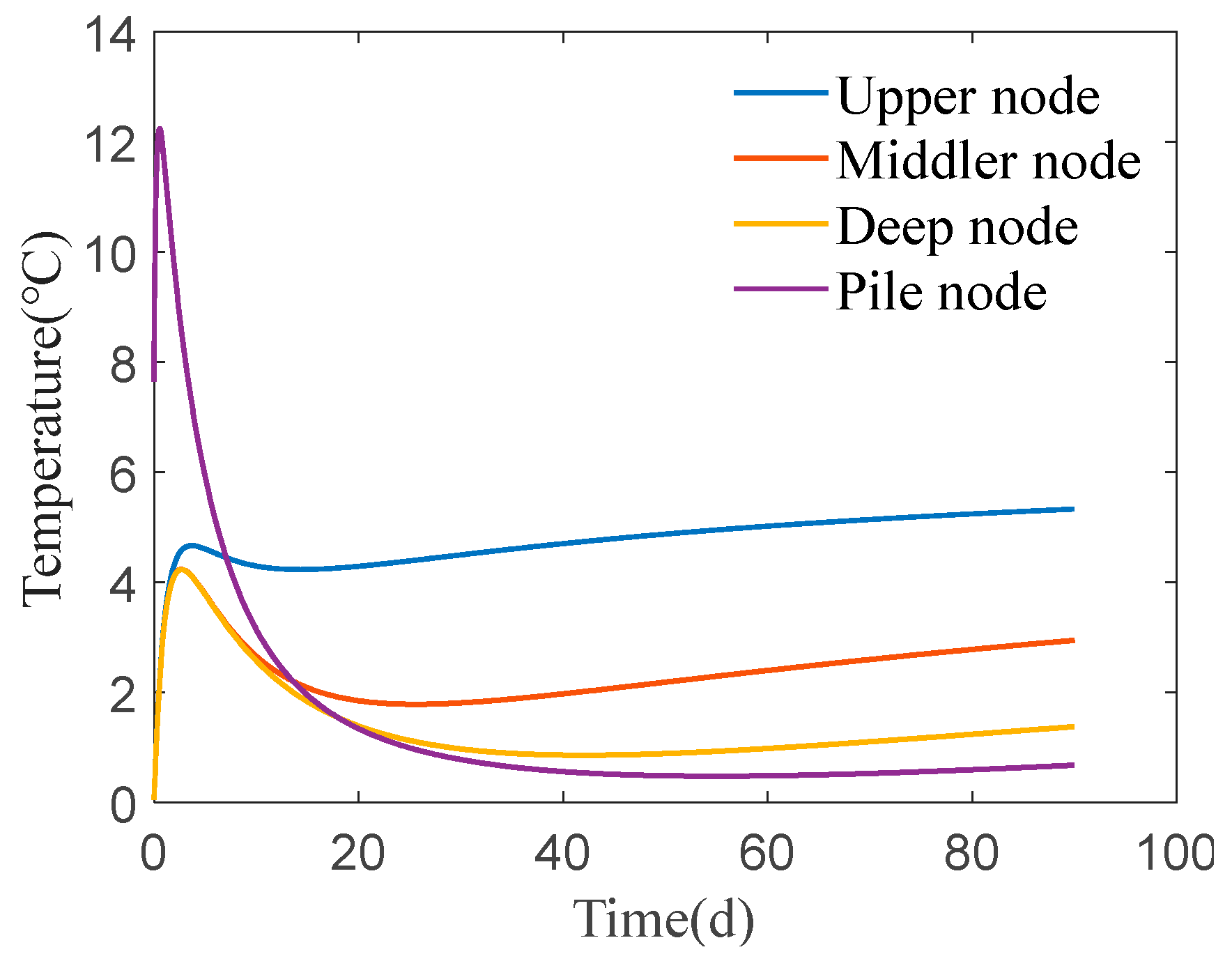

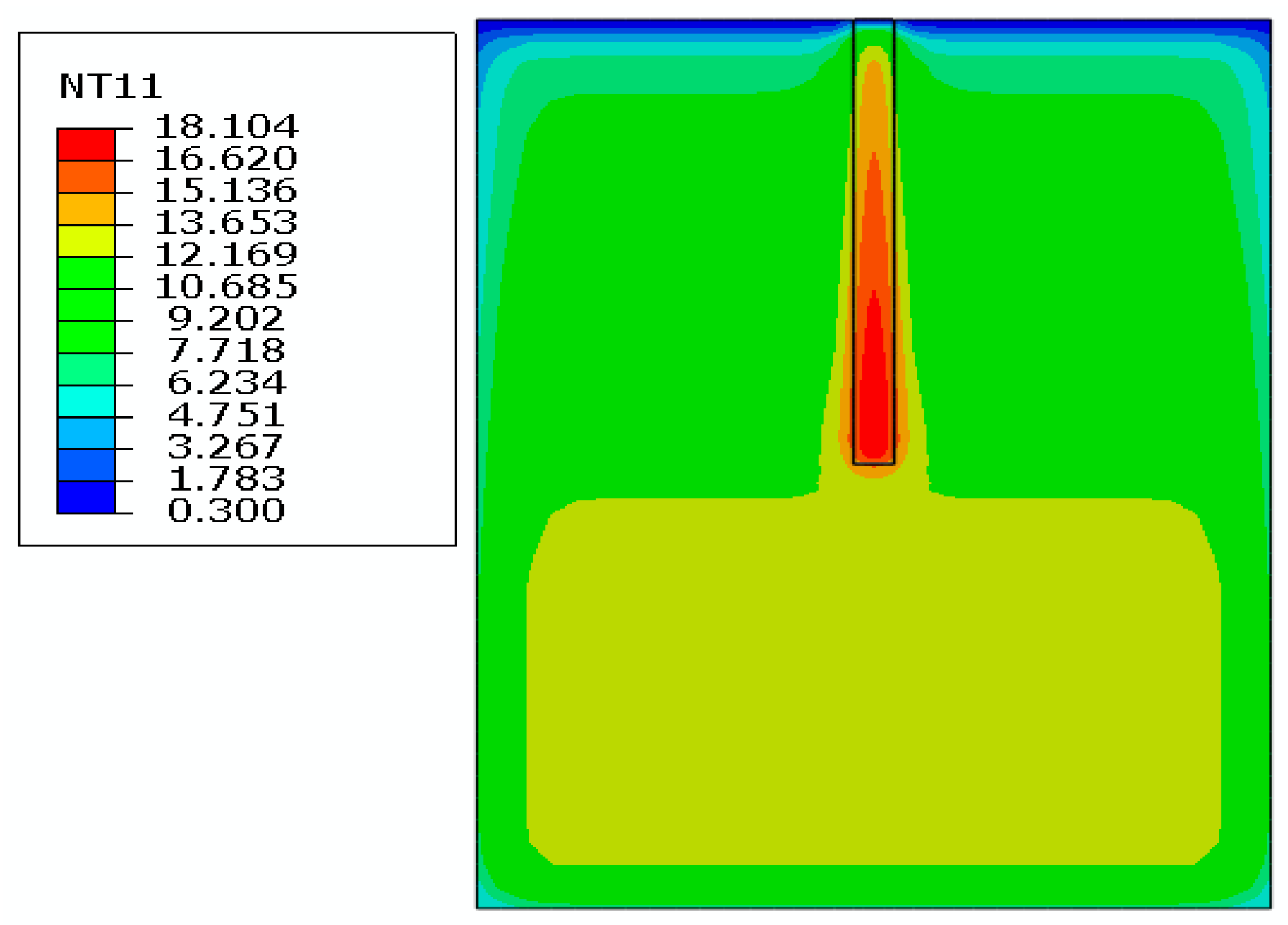

4.1. Calculation Results of the Hydration Heat Temperature Field

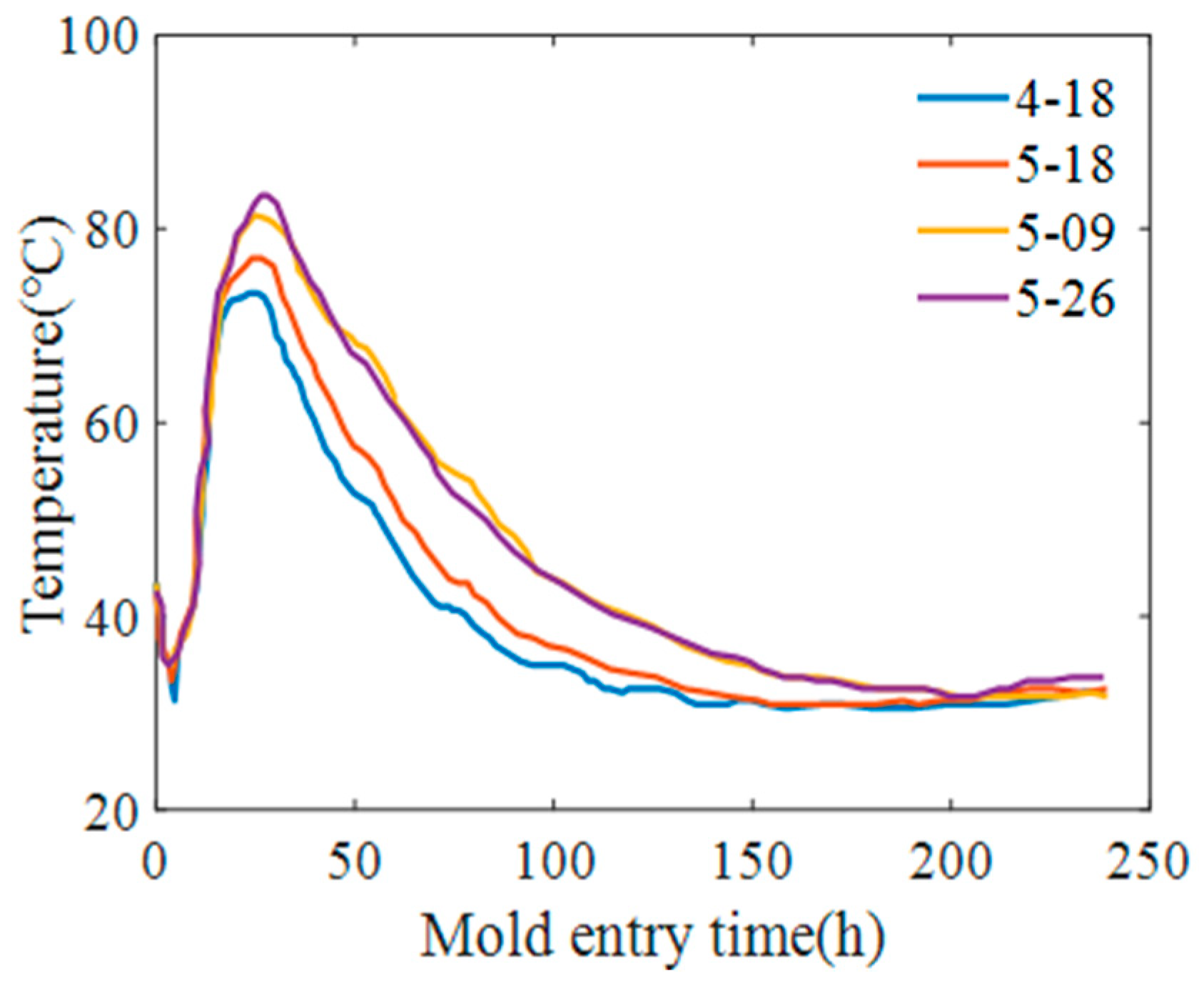

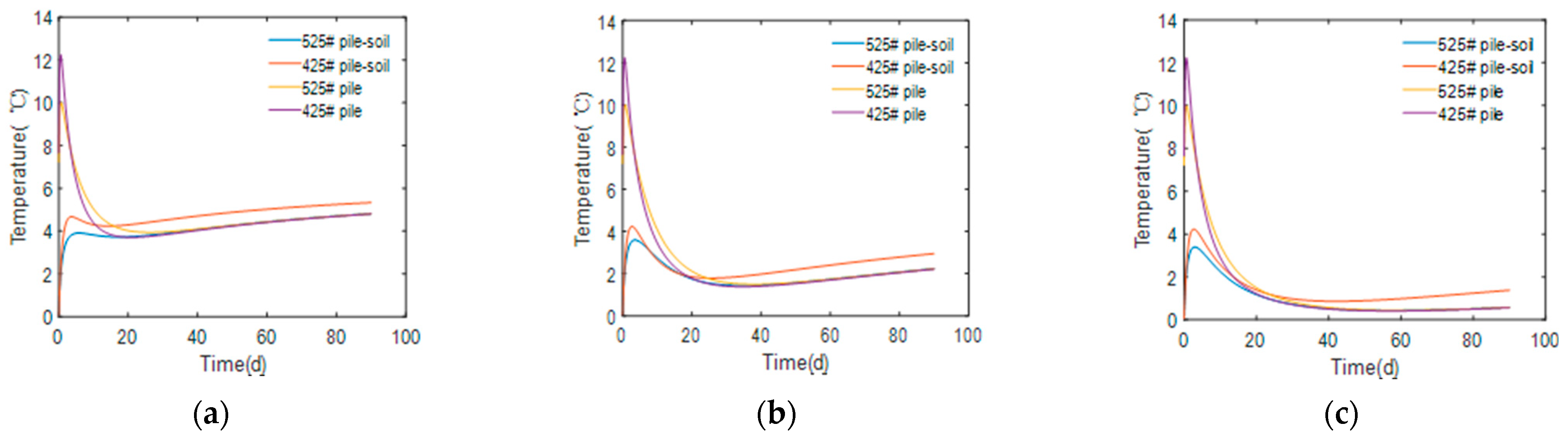

4.2. The Calculated Results of the Temperature Field during the Hydration Heat of Different Types of Cement

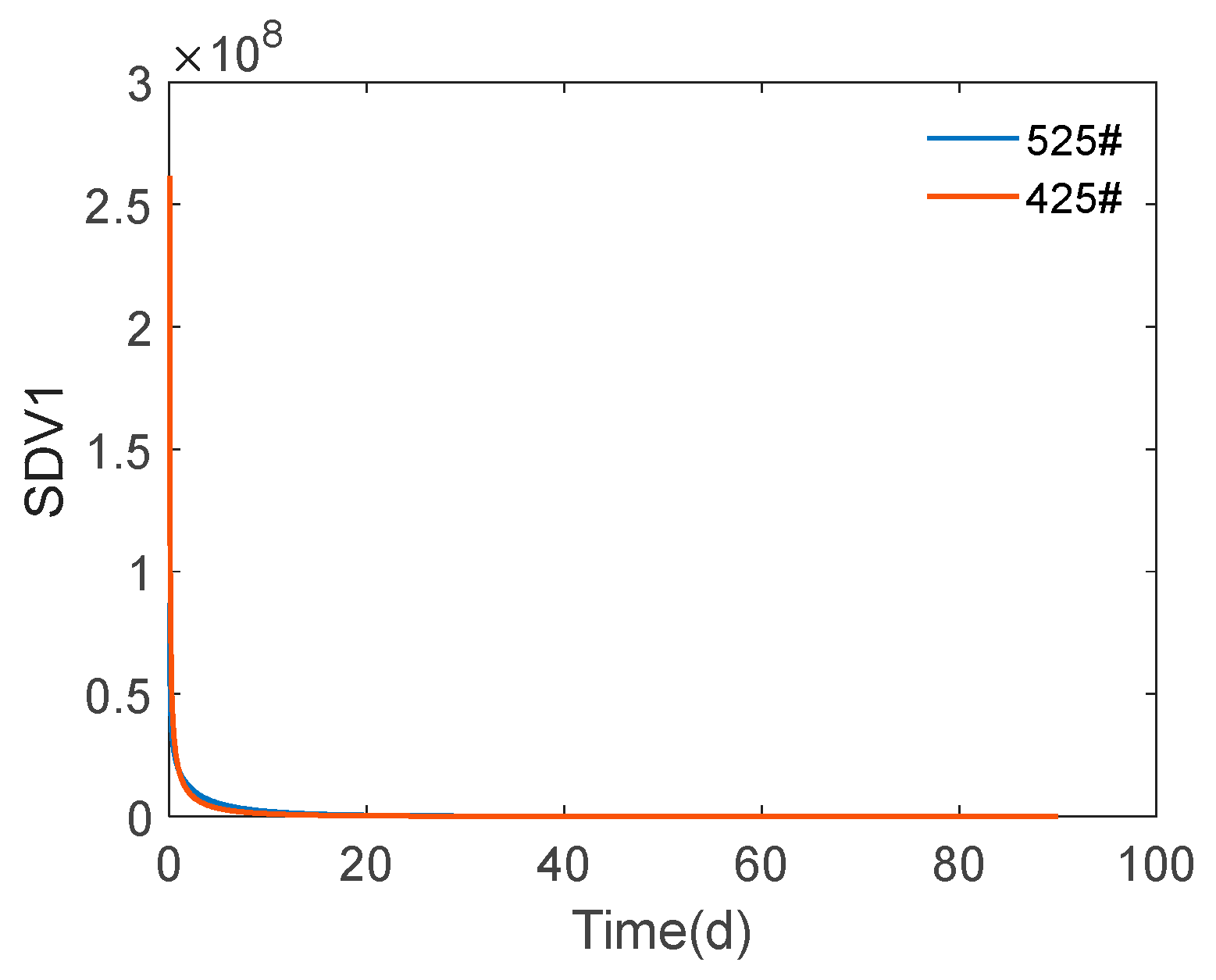

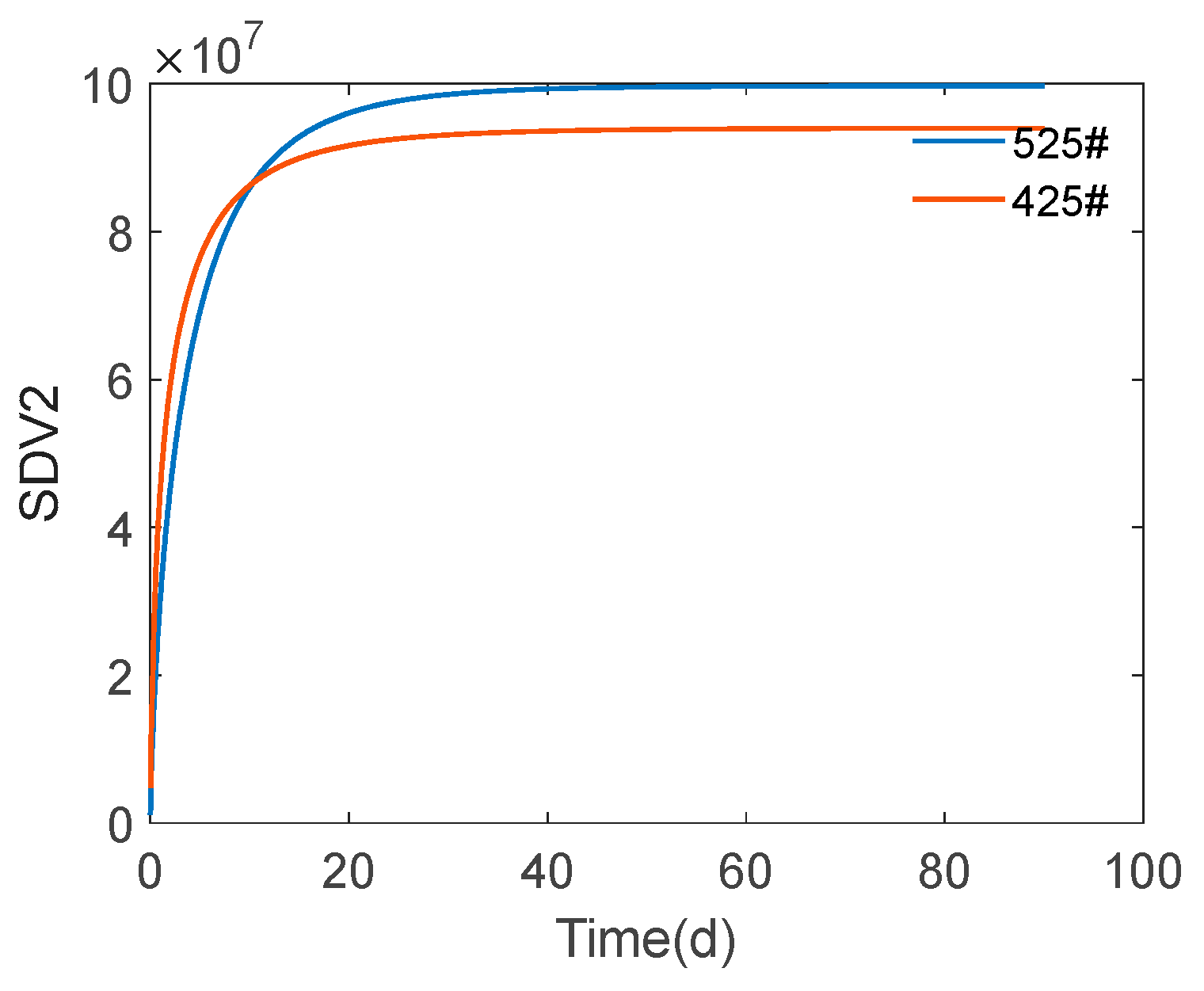

4.3. Results of Hydration Heat Release Rate and Cumulative Heat Release Calculation

4.4. Results of Soil Temperature Variations

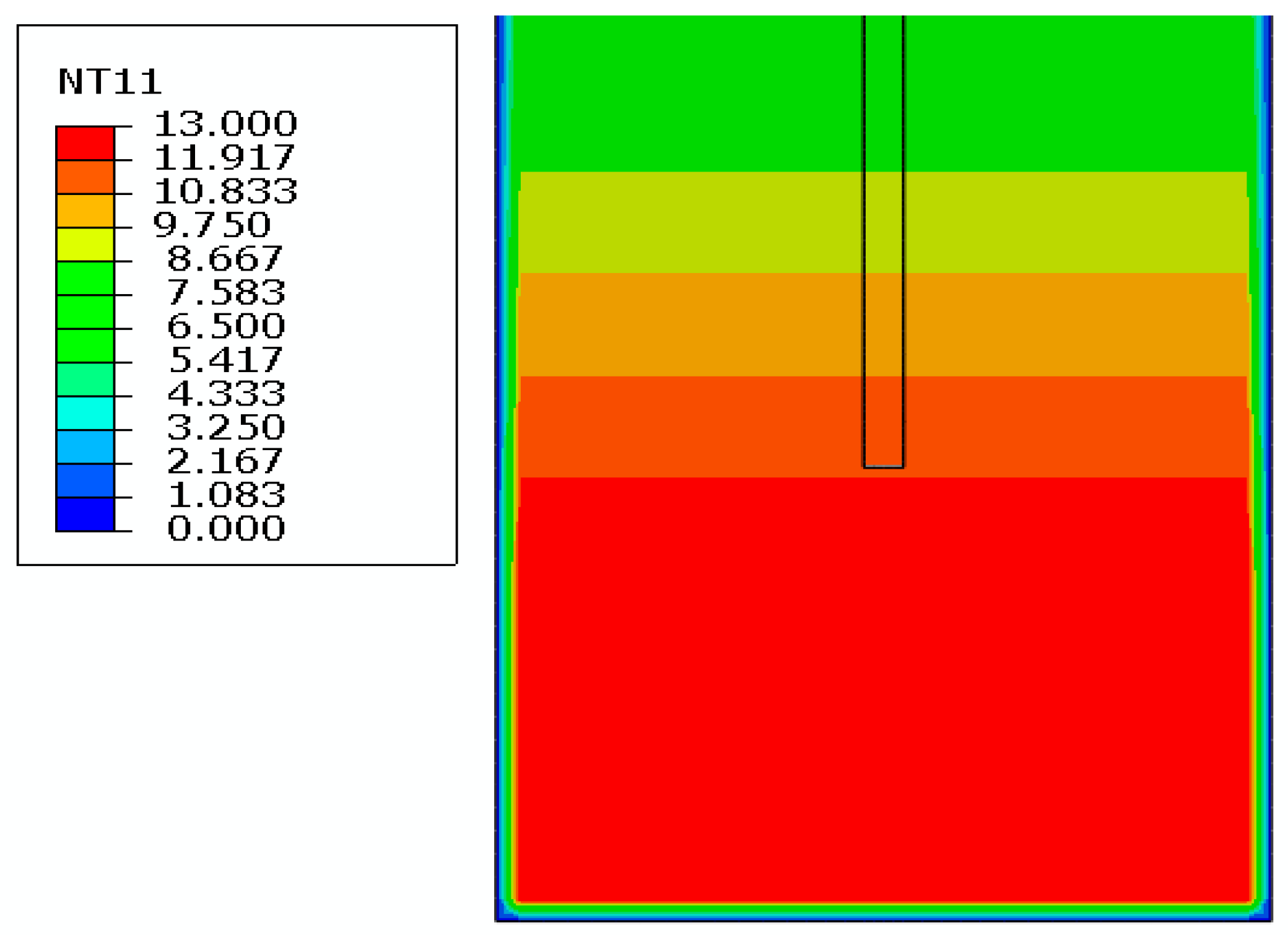

4.5. The Calculation Results at a Certain Moment after Adding the Soil Temperature

4.6. Results of Vertical Temperature Variation

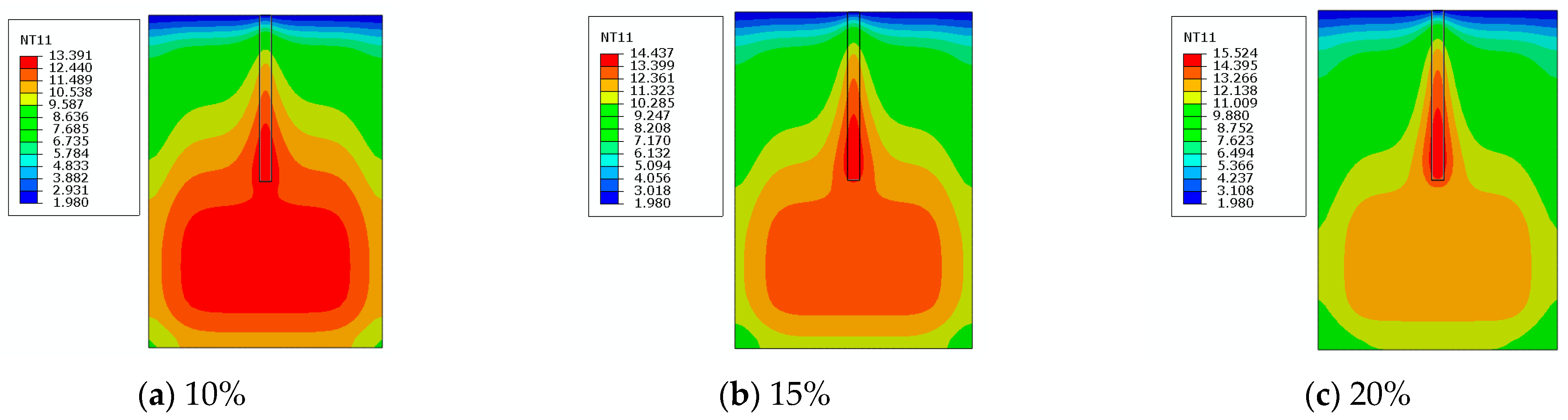

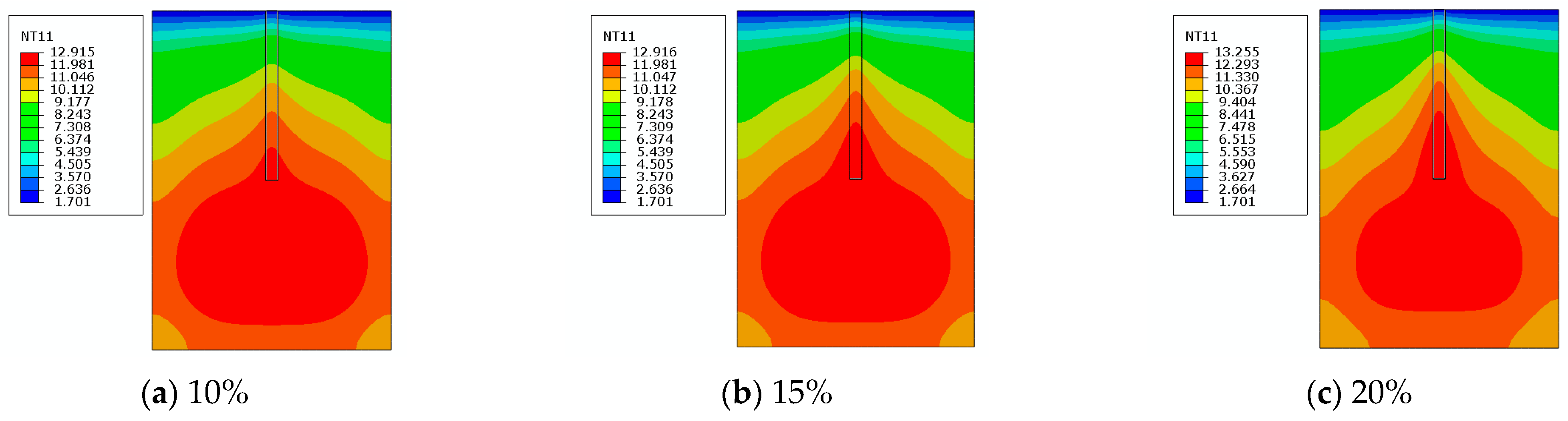

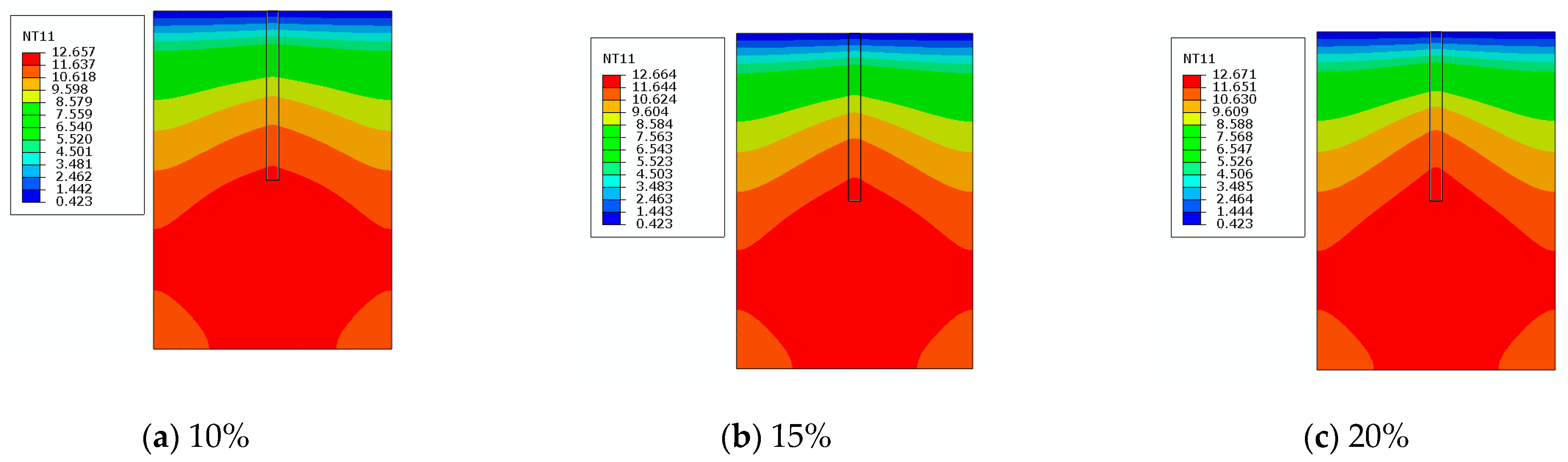

4.7. Temperature Field Changes with Different Cement Blending Amounts

4.8. The Practical Impact

5. Conclusions

- (1)

- Without considering the ground temperature, a 15% cement blending ratio, under the influence of 425# cement hydration, results in an internal temperature rise in the structure, reaching its peak around 5 days and eventually stabilizing with the aging process. The pile itself experiences a temperature increase of 5 °C. The temperature generated by hydration heat causes a 4.2 °C increase in the temperature of the soil around the pile. Due to the temperature at the pile–soil surface, the temperature at upper depths rises by 5 °C. The temperature of the 525# cement pile itself increased by 3 °C, while the heat generated by hydration raised the temperature of the surrounding soil by 3.75 °C.

- (2)

- During the temperature rise phase, the temperature inside the pile generated by the hydration of the 425# cement is higher than that of the 525#. In the temperature decrease phase, the temperature inside the pile produced by the hydration of the 425# cement remains higher than that of the 525#. The temperatures become equal around the 7th day. Additionally, the soil temperature around the pile of the 425# cement is consistently higher than that of the 525#.

- (3)

- The simulation of the hydration heat release rate and cumulative hydration heat of the cement was achieved through an associated subroutine, conforming to the composite index expression of hydration heat. The linear change process of the ground temperature was implemented through programming language.

- (4)

- Upon adding the ground temperature, the temperature curve between the pile shows a pattern of initial rise followed by a decrease, divided into two stages: temperature rise and temperature decrease. Due to the influence of sunlight temperature, the temperature curve of the soil between the upper pile differs from that of the middle and deep layers. The internal temperature of the entire structure reaches its peak around 5 days, resulting in a 4.6 °C increase in the temperature of the soil around the pile.

- (5)

- The temperature generated by the hydration of cement–soil mixing piles increases with the increase in the cement blending amount. The hydration temperature of the pile body increases by 4.4 °C with a 10% cement blending amount, 6.6 °C with a 15% cement blending amount, and 9.1 °C with a 20% cement blending amount. The temperature rise is significant. Therefore, in actual construction, the temperature of the piles should be controlled by adjusting the cement blending amount to avoid adverse effects on the structure caused by excessively high temperatures.

- (6)

- The temperature field of the structure shows minimal changes after 7 days with increasing time and cement blending amount. At 7 days, the temperature changes caused by different cement blending amounts occur within the range of the hydration reaction inside the piles and the surrounding soil. By 14 days, significant temperature gradients appear. At 28 days, the temperature gradient smoothens, with temperature changes beginning to occur in the upper-middle layers. Finally, by 90 days, the temperature field stabilizes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ijaz, N.; Ye, W.M.; Rehman, Z.U.; Ijaz, Z. Novel application of low carbon limestone calcined clay cement (LC3) in expansive soil stabilization: An eco-efficient approach. J. Clean. Prod. 2022, 37, 133492. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.H.; Aziz, M.; Ijaz, N.; Ijaz, Z.; Rehman, Z.U. Strengthening potential of xanthan gum biopolymer in stabilizing weak subgrade soil. Clean. Technol. Environ. Policy 2022, 24, 2719–2738. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wang, S.K.; Liu, H.; Cui, J.; Liu, C.; Meng, X. Assessing the impact of inertial load on the buckling behavior of piles with large slenderness ratios in liquefiable deposits. Soil. Dyn. Earthq. Eng. 2023, 176, 108322. [Google Scholar] [CrossRef]

- Yuan, W.J.; Cai, Z.Q.; Xie, S.; Zhang, J.R.; Pan, J. Study on Construction Technology Coordination Parameters of Cement Soil Mixed Piles Based on Strength Tests. J. Hunan Univ. (Nat. Sci.) 2018, 45, 4651. [Google Scholar] [CrossRef]

- Qian, A.J. Finite Element Simulation Research on Soft Soil Foundation of Embankment Reinforced by Cement-soil Mixing Pile. Shaanxi Water Resour. 2022, 8, 124–126+130. [Google Scholar] [CrossRef]

- Yuan, B.X.; Li, Z.H.; Zhao, Z.Q.; Ni, H.; Su, Z.L.; Li, Z.J. Experimental study of displacement field of layered soils surrounding laterally loaded pile based on Transparent Soil. J. Soils Sediments 2021, 21, 3072–3083. [Google Scholar] [CrossRef]

- Zhao, L.P.; Long, X.P.; Hung, X.Y. Settlement analysis of composite foundation of soil-cement mixing pile. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2020, 17, 30–36+70. [Google Scholar]

- Xu, C.; Ye, G.B.; Jiang, Z.S.; Zhou, Q.Z. Research on mechanism of combined improvement of soft soils based on field monitoring. Chin. J. Geotech. Eng. 2006, 28, 918–921. [Google Scholar]

- Deng, Y.S.; Meng, L.Q.; Cai, M.Z.; Sun, Y.N.; Li, L.; Zhang, Y.F. Research on Stability of Loess Roadbed Reinforced with Cement-soil Mixing Piles. J. Zhengzhou Univ. (Eng. Sci.) 2022, 43, 59–66. [Google Scholar] [CrossRef]

- Guo, Y.; Li, X.; Zhao, R.; Wang, R.C. Analysis of the Reinforcement Mechanism of Cement-Soil Pile Composite Foundation. J. Henan Sci. Technol. 2013, 15, 76. [Google Scholar]

- Li, R.; Hou, T.S. The Cement-Soil Mixing Pile and Its Application in Soft-Soil Subgrades. Build. Sci. 2008, 12, 88–90. [Google Scholar]

- Wang, M. Factors Influencing the Reinforcement Effect of Surrounding Levee Cement Mixing Piles and Engineering Design Optimization. Hydraul. Technol. Superv. 2021, 26, 104–105+109+113+123. [Google Scholar]

- Wang, X.J.; Wang, Y.J.; Wang, H.B. Application of Cement-Soil Mixing Piles in Deep Excavation Support. Chin. Water Transp. (Acad. Ed.) 2007, 9, 110–111. [Google Scholar]

- Yuan, L. Research on the Application of Cement-Soil Mixing Piles in Soft Soil Foundations. Ju She 2023, 19, 163–166. [Google Scholar]

- Phutthananon, C.; Jongpradist, P.; Dias, D.; Guo, X.F.; Jamsawang, P.; Baroth, J. Reliability-based settlement analysis of embankments over soft soils reinforced with T-shaped deep cement mixing piles. Front. Struct. Civ. Eng. 2022, 16, 638–656. [Google Scholar] [CrossRef]

- Ndong Engone, J.G.; El Moumen, A.; Djelal, C.; Imad, A.; Kanit, T.; Page, J. Evaluation of Effective Elastic Properties for Wood–Cement Composites: Experimental and Computational Investigations. Sustainability 2022, 14, 8638. [Google Scholar] [CrossRef]

- Wan, Y.; Song, L.; Zhu, Z.D.; Peng, Y.Y. Research on Construction Quality Monitoring and Evaluating Technology of Soil-Cement Mixing Piles. Soil. Mech. Found. Eng. 2021, 58, 85–91. [Google Scholar] [CrossRef]

- Yuan, B.X.; Liang, J.K.; Lin, H.Z.; Wang, W.Y.; Xiao, Y. Experimental Study on Influencing Factors Associated with a New Tunnel Waterproofing for Improved Impermeability. J. Test. Eval. 2024, 52, JTE20230417. [Google Scholar] [CrossRef]

- Ijaz, N.; Ye, W.M.; Rehman, Z.U.; Ijaz, Z.; Junaid, M.F. Global insights into micro-macro mechanisms and environmental implications of limestone calcined clay cement (LC3) for sustainable construction applications. Sci. Total Environ. 2024, 907, 167794. [Google Scholar] [CrossRef]

- Sheng, X.W.; Xiao, S.M.; Zheng, W.Q.; Sun, H.Z.; Yang, Y.; Ma, K.L. Experimental and finite element investigations on hydration heat and early cracks in massive concrete piers. Case Stud. Constr. Mater. 2023, 18, e01926. [Google Scholar] [CrossRef]

- Liu, R.Y.W.; Fisher, A.; Taborda, D.M.G.; Bourne-Webb, P.J. A practical heat of hydration model for concrete curing for geotechnical applications. Geotech. Res. 2022, 9, 23–31. [Google Scholar] [CrossRef]

- Seyedehelaheh, S.; Masoud, H.B.; Hamid, R.T.; Ali, K. Experimental investigation on the efficiency of the phase change materials for enhancing the thermal performance of energy piles in sandy soils. Energy Build. 2023, 298, 113544. [Google Scholar] [CrossRef]

- Ding, X.M.; Chen, P.; Wang, C.L.; Kong, G.Q. Heat transfer performance of energy piles in seasonally frozen soil areas. Renew. Energy 2022, 190, 903–918. [Google Scholar] [CrossRef]

- Tazi, M.; Sukiman, M.S.; Erchiqui, F.; Imad, A.; Kanit, T. Effect of Wood Fillers on the Viscoelastic and Thermophysical Properties of HDPE-Wood Composite. Int. J. Polym. Sci. 2016, 2016, 9032525. [Google Scholar] [CrossRef]

- Wei, G.H.; Li, J. Study and Simulation Analysis of Hydration Heat in Mass Concrete. Sichuan Archit. 2019, 39, 309–314. [Google Scholar]

- Zhu, B.F. Thermal Stresses and Temperature Control of Mass Concrete; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Xie, Y.D.; Qian, C.X. A novel numerical method for predicting the hydration heat of concrete based on thermodynamic model and finite element analysis. Mater. Des. 2023, 226, 111675. [Google Scholar] [CrossRef]

- Kevin, Z.T.; David, J.P. Creep, shrinkage, and thermal effects on mass concrete structure. J. Eng. Mech. Div. 1991, 16, 31–33. [Google Scholar]

- Wen, W.G.; Lu, Q.; Wang, H.; Liu, X.L. Research on Characteristics of Ground Temperture Variation in Tianjin. Geotech. Eng. Tech. 2021, 35, 318–322. [Google Scholar]

- Wei, F.Y. Modern Climate Statistics Diagnosis and Prediction Technology; Meteorological Press: Beijing, China, 1999; pp. 50–53. [Google Scholar]

- Sukiman, M.S.; Kanit, T.; N’Guyen, F.; Imad, A.; Erchiqui, F. On effective thermal properties of wood particles reinforced HDPE composites. Wood Sci. Technol. 2022, 56, 603–622. [Google Scholar] [CrossRef]

- Li, W.J. Study on Proportioning of Cement-Soil Mixing Piles in the Yellow River Delta Region. Sichuan Cem. 2019, 14, 17. [Google Scholar]

- Wang, P.; Huang, C.; Zhao, G.H.; Zhang, F. Experiment of the model of hydration heat temperature field and strain field pf concrete single box and three chamber girder. J. Shandong Univ. 2024, 54, 109–122+130. [Google Scholar] [CrossRef]

- Yang, S.; Robert, H.M.; Ankit, D. Visualizing Abaqus output database in ParaView: A universal converter in Python and C++. SoftwareX 2023, 22, 101331. [Google Scholar] [CrossRef]

- Chen, J.W.; Zhang, G.Z.; Guo, M.; Chen, L.; Ning, B.W.; Zhang, S.Q.; Ya, Z.; Guo, P.J. Investigation on heat transfer characteristics of PHC energy piles in multi-layer strata. Chin. J. Rock. Mech. Eng. 2020, 39, 3615–3626. [Google Scholar] [CrossRef]

- Fang, D.Z. Numerical Study on the Influence of Temperature on the Interactions between Energy Pile and Soil. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2020. [Google Scholar] [CrossRef]

- Sangwoo, P.; Dongseop, L.; Seokjae, L.; Alexis, C.; Hangseok, C. Experimental and numerical analysis on thermal performance of large-diameter cast-in-place energy pile constructed in soft ground. Energy 2017, 118, 297–311. [Google Scholar] [CrossRef]

| Materials | Density (kg/m3) | Thermal Conductivity Coefficient (J/day·m−1 °C−1) | Specific Heat (J·kg−1·°C−1) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| Soil | 1700 | 116,640 | 840 | 15 | 0.3 |

| Pile | 4000 | 155,520 | 1000 | 800 | 0.16 |

| 10% Blending Temperature/°C | 15% Blending Temperature/°C | 20% Blending Temperature/°C |

|---|---|---|

| 13.391 | 14.437 | 15.524 |

| 12.440 | 13.399 | 14.395 |

| 11.489 | 12.361 | 13.266 |

| 10.538 | 11.323 | 12.138 |

| 9.587 | 10.285 | 11.009 |

| 8.636 | 9.247 | 9.880 |

| 7.685 | 8.208 | 8.752 |

| 6.735 | 7.170 | 7.623 |

| 5.784 | 6.132 | 6.496 |

| 4.833 | 5.094 | 5.336 |

| 3.882 | 4.056 | 4.237 |

| 2.931 | 3.018 | 3.108 |

| 1.980 | 1.980 | 1.980 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Xu, W.; Xu, Q.; Wang, Y.; Zhu, Y. Research on Temperature Field of Cement-Mixing Pile-Reinforced Soft Soil Foundation. Buildings 2024, 14, 845. https://doi.org/10.3390/buildings14030845

Wang Z, Xu W, Xu Q, Wang Y, Zhu Y. Research on Temperature Field of Cement-Mixing Pile-Reinforced Soft Soil Foundation. Buildings. 2024; 14(3):845. https://doi.org/10.3390/buildings14030845

Chicago/Turabian StyleWang, Zhe, Weisheng Xu, Qing Xu, Yangming Wang, and Yingna Zhu. 2024. "Research on Temperature Field of Cement-Mixing Pile-Reinforced Soft Soil Foundation" Buildings 14, no. 3: 845. https://doi.org/10.3390/buildings14030845

APA StyleWang, Z., Xu, W., Xu, Q., Wang, Y., & Zhu, Y. (2024). Research on Temperature Field of Cement-Mixing Pile-Reinforced Soft Soil Foundation. Buildings, 14(3), 845. https://doi.org/10.3390/buildings14030845