Abstract

The construction industry in New Zealand is significantly impacted by the importance of housing, particularly as urbanisation continues to grow in major cities. Modern construction methods, such as offsite construction and building automation, evolving into digital manufacturing and construction in the industry, have become prominent. Despite the global recognition of 3D printing technology, its adoption in the construction industry in New Zealand is still relatively limited. This study aims to examine the feasibility of 3D printing construction in response to current market challenges, innovation, and the 2050 net-zero carbon goal. Utilising Building Information Modelling (BIM) and Life Cycle Assessment (LCA) approaches, this study investigated the environmental impacts of three housing types: 3D printing (3DP), light steel framed (LSF), and timber. This study used cradle-to-cradle as the system boundary. The results indicate that the 3DP house emits 20% fewer carbon emissions than the traditional timber house and 25% less than the LSF house. Additionally, the 3DP house exhibits a 19% lower annual electric energy consumption than the timber house. Therefore, in response to the growing housing demand in New Zealand, the construction industry must innovate and embrace digital and advanced construction methods, including the adoption of 3D printing.

1. Introduction

The urban landscape of New Zealand’s main cities is experiencing significant changes in the form of increased infrastructure and construction activities. A major share of this activity is linked to the need for an increase in housing supply to support the critical housing shortage. At today’s rate of population growth, Auckland, as one of the main cities in New Zealand, is facing a critical housing shortage, which is projected to require 320,000 new dwellings in the next 30 years. The current construction levels fall short of demand, necessitating urgent changes in housing delivery methods [1]. The building and construction (B&C) industry is not performing as well as it should, according to NZ Productivity Commission evidence. Enhancing industry productivity can reduce construction costs and elevate building standards, with potential contributions from increased scale, innovation, and a diverse skill set [2]. Moreover, notable environmental concerns within the industry were underscored in a recent report focusing on the unexplored capacity of buildings to contribute to New Zealand’s zero-carbon goals by 2050. The B&C sector holds significance in mitigating carbon emissions and meeting energy consumption targets [3]. Construction-related activities and the demolition of buildings account for over 34% of energy demand and 37% of CO2 emissions globally [4]. Approximately fifty percent of emissions originate from construction materials utilised in both buildings and infrastructure, while the remaining fifty percent stem from operating the building stock, specifically the buildings themselves, with a minor portion attributed to end-of-life processes [5].

Embodied energy refers to the cumulative energy required for extracting, processing, manufacturing, and transporting building materials to the construction site. As energy consumption leads to CO2 emissions, thereby contributing to greenhouse gas (GHG) emissions, embodied energy serves as an indicator of a building’s broader environmental footprint [6]. Embodied carbon encompasses carbon emissions associated with different stages of the life cycle, including the extraction and manufacturing of materials and products, operations and replacement, end-of-life processes, and disposal, which also include transportation needs for all these stages [7]. Most embodied carbon emissions arise during the manufacturing of construction materials and products, prior to the building’s utilisation phase, with additional emissions released during the building’s operation due to maintenance activities, and towards the end of its life during demolition, disposal, or recycling phases [8]. Life Cycle Assessment (LCA) is a methodology employed to measure and assess the environmental impact of a product or system throughout its life cycle, spanning from raw material extraction and processing through manufacturing, utilisation, and, ultimately, end-of-life considerations [9]. In conducting LCA, there are four major stages, as stated in ISO 14040:2006 goal and scope definition: life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation [10]. The contemporary construction sector has adopted this approach to measure and enhance the environmental efficiency of designs or products [11,12,13,14]. Over the last two decades, LCA has emerged as a widely employed instrument for assessing the effects of materials, construction components, and buildings [15]. Furthermore, this approach is utilised to enhance sustainability within the construction sector, aiding in the development of eco-friendly solutions [16,17].

Building Information Modelling (BIM) is a widely recognised digital technology increasingly utilised in the B&C industry, aimed at enhancing various lifecycle stages of a building, such as design, construction, project management, and operations, through the creation, utilisation, and transfer of a digital information model. Technically, it uses computer-generated coordinated information to represent the building as an integrated database [18]. Limited information and challenges in obtaining accurate data often result in LCA studies focusing on specific phases rather than the entire process. BIM has proven to be beneficial in this area, especially in quantity surveying, a crucial aspect of LCA. BIM’s digital tools streamline the analysis of vast amounts of data, enhancing accuracy and efficiency compared to manual methods [19]. BIM is extensively used to extract input data accurately for environmental assessments like LCA and energy analysis. Commonly, BIM is understood as digital and intelligent modelling, facilitating rapid access to shared data, timely decision-making, and interoperability among teams [20]. However, in the BIM-based LCA method, the level of development (LOD) and object modelling are considered to be crucial factors that can constrain or influence the input data [21]. The concept of level of development (LOD) delineates the fundamental dimensional, spatial, quantitative, qualitative, and other data integrated within a model element [22]. According to the New Zealand BIM Handbook 2023 [23], LOD is often misunderstood as level of detail, but it fundamentally differs; while level of detail refers to the extent of detail in a model element, LOD signifies the completeness of its geometry and associated information, serving as reliable output for project team members and distinguishing it as an essential component of BIM implementation. There are six levels of LOD in BIM, which are LOD 100, LOD 200, LOD 300, LOD 350, LOD 400, and LOD 500 [24]. The higher LOD represents the cumulative requirement of the building information assigned to the element (except LOD 500, as it is from the existing item or as built) [25]. Hence, varying levels of LOD allocated to building elements in BIM-LCA analyses may influence the precision of the findings and introduce complexity in interpreting LCA results [20].

The utilisation of 3D printing (3DP) as a method for automating processes within the B&C industry has emerged as a prominent trend, garnering heightened international interest [26]. Over the last five years, companies like Apis Cor, CyBe, and Winsun have expanded their adoption of 3D printing technology and begun bidding for projects in Europe, Saudi Arabia, the United Arab Emirates, and China [27,28,29]. 3D printing (3DP) entails fabricating three-dimensional objects by layering various cement mortar materials according to specified designs or geometries. Adding horizontal or vertical reinforcement inside the space between the printed concrete layers on the outside makes 3DP walls stronger and last longer. A polyurethane-based substance is filled into the cavity to act as thermal insulation [30]. Various 3D printing (3DP) technologies utilise distinct methods to process different materials, resulting in the production of diverse final objects [31]. Initially, 3DP was restricted to creating physical models, but it is now being used to construct entire buildings [32]. A significant advancement in 3D printing (3DP) technology occurred through the research project known as Contour Crafting, which was carried out at the University of Southern California. This project demonstrated the feasibility of utilising layered extrusion technologies for large-scale construction projects [33]. Drawing upon previous studies on 3DP, Schuldt et al. [34] reviewed the integration feasibility of 3DP construction into conventional practices, highlighting promising prospects while advising decision-makers to consider trade-offs as the technology progresses. Fiala et al. [35] assessed a cementless blended material’s suitability for 3D-printed concrete spraying, examining viscosity, setting time, spray characteristics, and flow properties. The study affirmed its compatibility with 3D printing, supporting the advancement of high-value industry by-product technology [35]. In addition, Batikha et al. [36] conducted a comparative study of 3DP concrete against other construction methods with regard to cost, construction duration, and environmental impacts. By using LCA, 3DP concrete was found to have the lowest carbon emissions, with other materials such as reinforced concrete and hot-rolled steel showing 25% and 30% higher emissions, respectively [36].

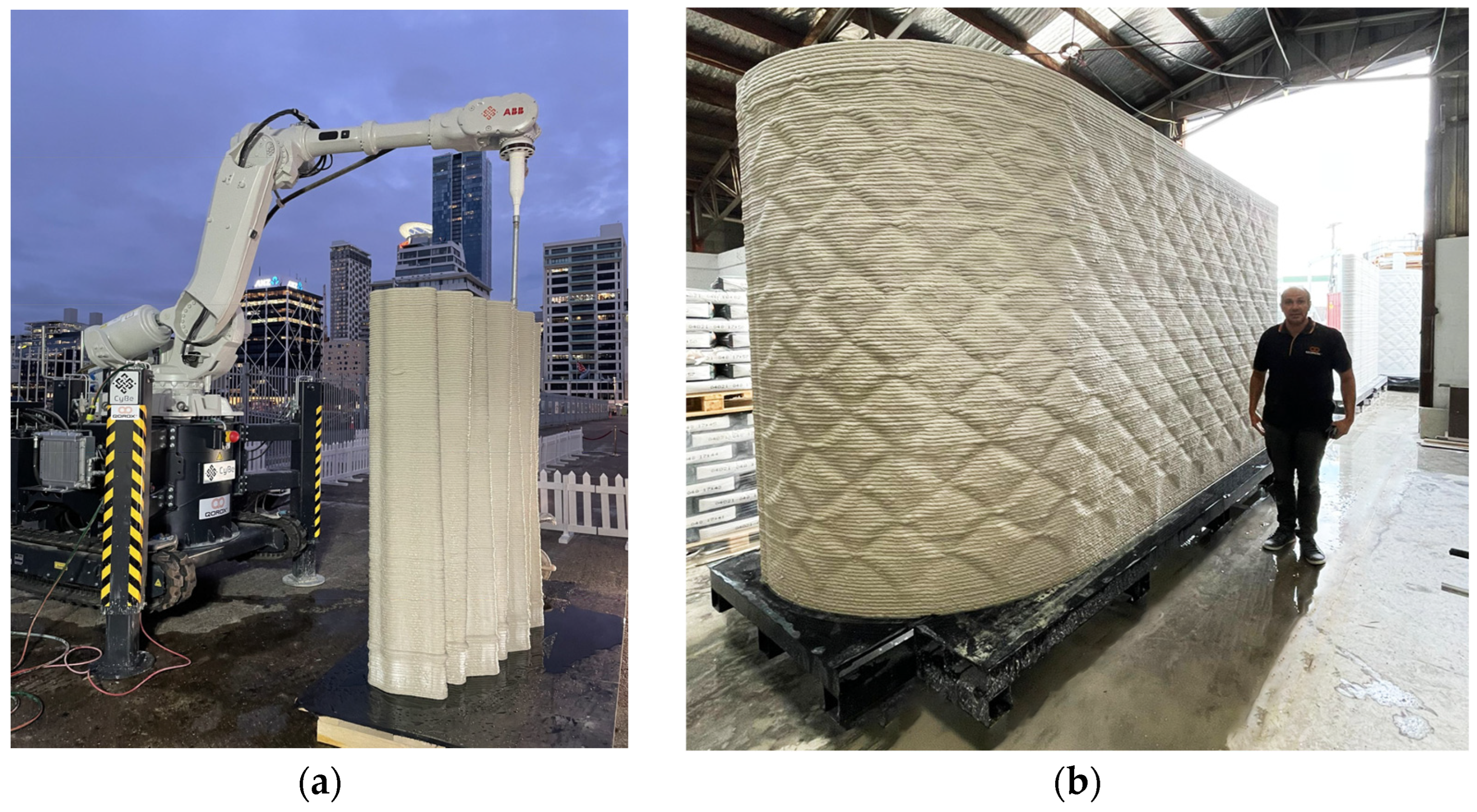

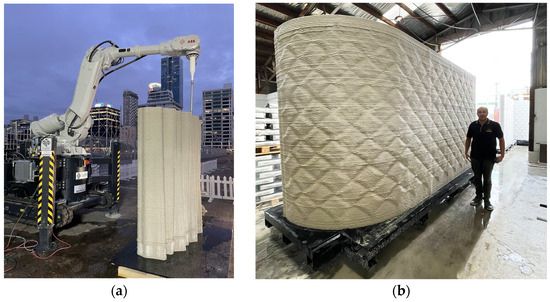

On a global scale, prefabrication in residential construction has advanced as a forward-thinking tactic to promote sustainability and affordability [37]. Companies specialising in this area are emerging as leaders in delivering innovative solutions to achieve these goals [38]. According to QOROX [39], the first New Zealand 3DP concrete company (see Figure 1), 3DP aims to showcase innovation and alternatives for the country’s housing market. The technique is 75 percent faster and reduces waste by 70 percent when compared to traditional construction [39]. Already, a few residential projects have been successfully printed overseas, which exemplifies how the 3DP technique is efficiently transforming construction sites and producing high-quality homes. Although they belong to different regions, 3DP external walls could be used in New Zealand residential practice, which has already been tested by BRANZ [40]. In addition, 3DP has many advantages as a technology, such as reducing time, labour, and costs, minimising environmental impact, and reducing injuries and fatalities on construction sites [31].

Figure 1.

QOROX, the 3DP company in New Zealand: (a) 3D printing process [41]; (b) QOROX’s 3DP wall [42].

Numerous studies globally have investigated building design LCA, yet research in New Zealand on this topic has been relatively scarce. This is because the uptake of LCA in the B&C industry is found to be immature [43] and also because of the complexity of the methodology [44]. Only a few studies have performed LCA to investigate the buildings [45,46] or the building products (e.g., roof cladding) [47,48] environmental performance specific to the New Zealand context. Scoping the use of LCA for 3DP concrete houses, no study has been conducted yet as the technique is found to be relatively new. Masood et al. underscored the necessity for research into the sustainability dimension of offsite construction methods, including 3DP construction, within the country [49]. Moreover, Wu et al. [50] underscored that significant transformation within the housing sector would be necessary to achieve the objectives set forth in the 2050 Paris Agreement. Hence, this study seeks to explore the viability of 3D-printed (3DP) concrete for residential housing in New Zealand, specifically examining its environmental performance in construction. A comparative assessment is undertaken, contrasting it with conventional timber and light steel framed residential buildings, to offer insights into the environmental footprint of 3DP concrete houses compared to prevalent housing types in the nation. This research is important in facilitating the shift towards housing automation in New Zealand, which is facilitated by industry collaboration, the utilisation of BIM-based tools, and advancements in the B&C sector. Furthermore, it aids in establishing the criteria essential for assessing the efficiency and performance levels of buildings.

2. Materials and Methods

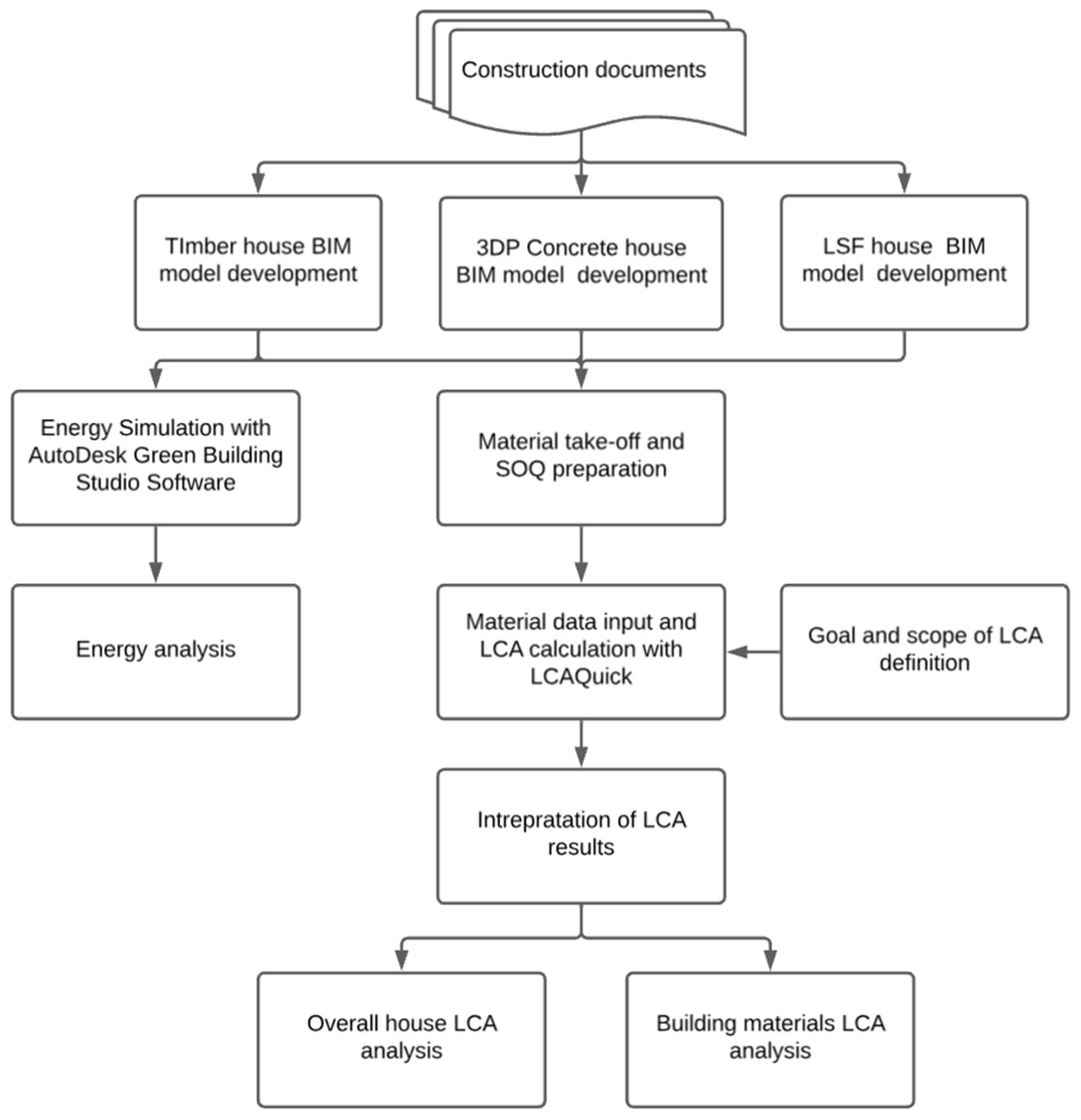

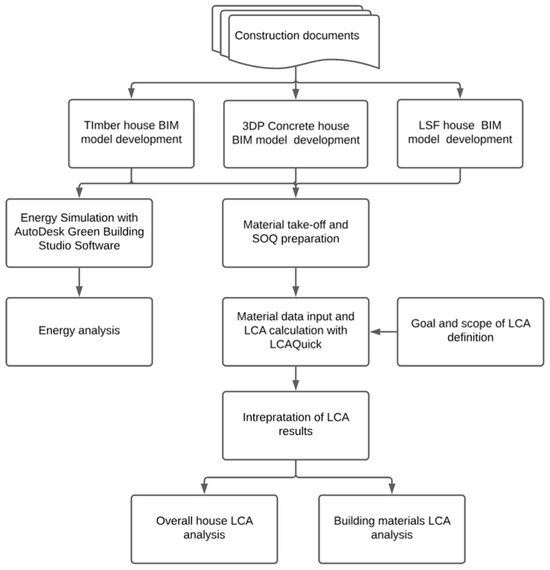

Figure 2 shows the research workflow for this study. It focused on a case study of a two-story house situated in Orewa, Auckland, New Zealand, and involved the development of three distinct house systems: 3D-printed (3DP) concrete, timber, and light steel houses. The work started with BIM design development, where Autodesk Revit 2021 was used. This process enabled a realistic design development of the three investigated houses, in which three different separate BIM models were developed, including their architectural and structural models. The second stage was the BIM quantity take-off. The study utilised Revit Autodesk 2021 and Microsoft Excel in this process, which allowed for the export of inventory of materials and quantities into an Excel spreadsheet. The third stage was the energy simulation using the Autodesk Green Building Studio, which is a BIM model-based energy analysis tool. Finally, an environmental evaluation was conducted using the LCA tool to assess the environmental ramifications of the three examined houses. LCAQuick V3.6, a tool specific to New Zealand, was employed for this purpose. It is a spreadsheet-based LCA tool designed to enable users to evaluate the carbon footprint and other environmental impacts associated with building designs [51].

Figure 2.

Research workflow.

2.1. BIM Development and Project Information

A two-story house constructed with light steel framing, located in Auckland, New Zealand, was chosen as the case building for this LCA. Subsequently, the structure was redesigned using 3D-printed concrete and lightweight timber materials to align with the study’s objectives. The main characteristic difference between a 3DP versus a light steel framed (LSF) and timber model is their construction arrangement and key materials. The primary information was collected from the house owner, such as site, typology, areas, and heights that are essential for the development of the BIM models, as outlined in Table 1.

Table 1.

Case study house key information.

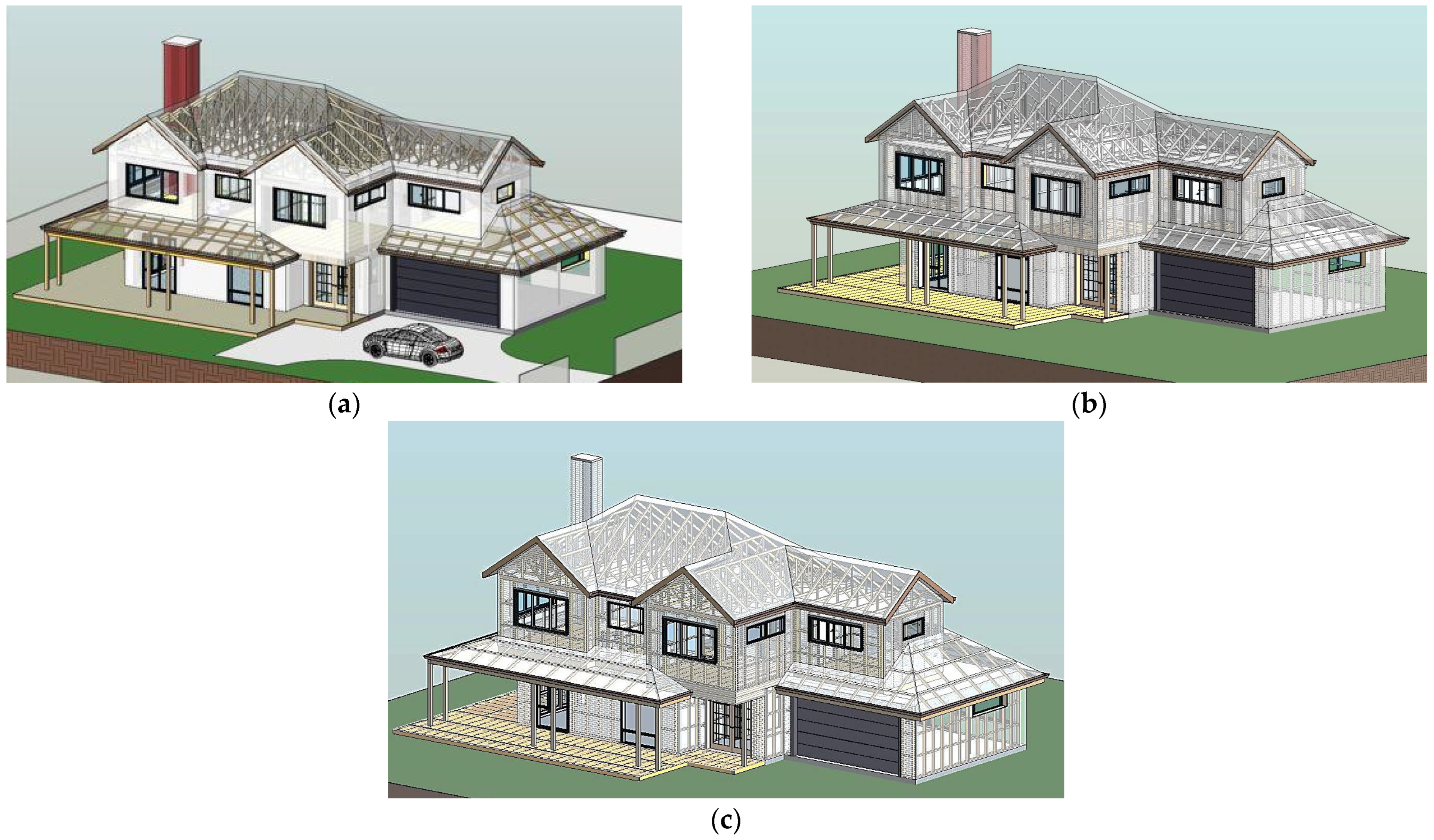

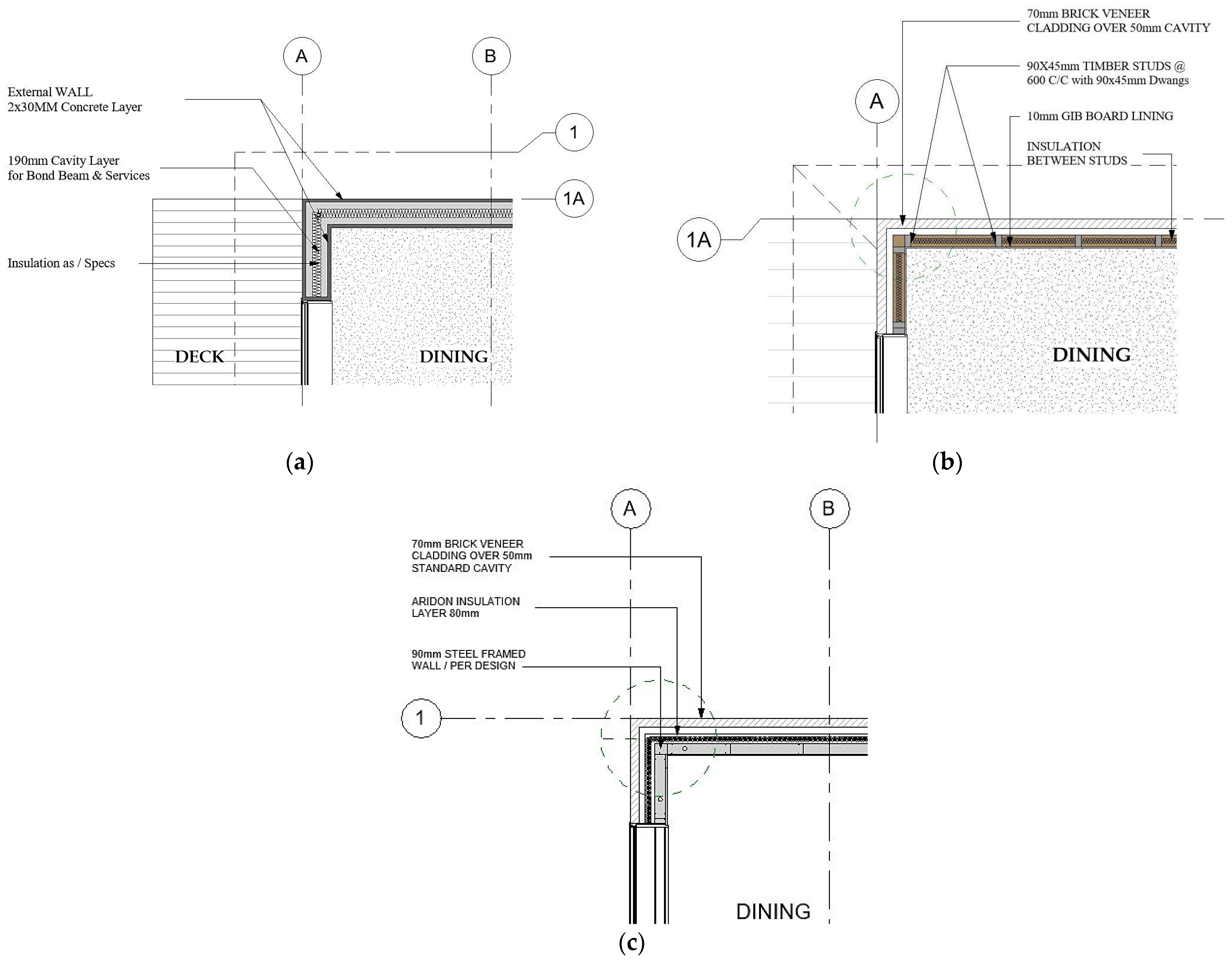

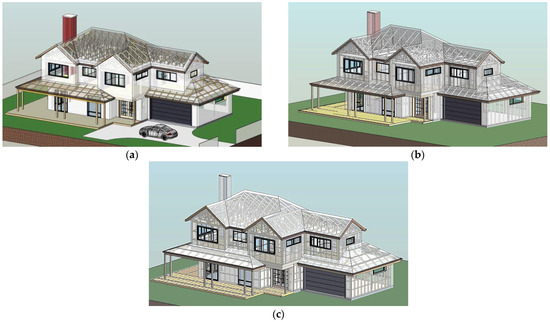

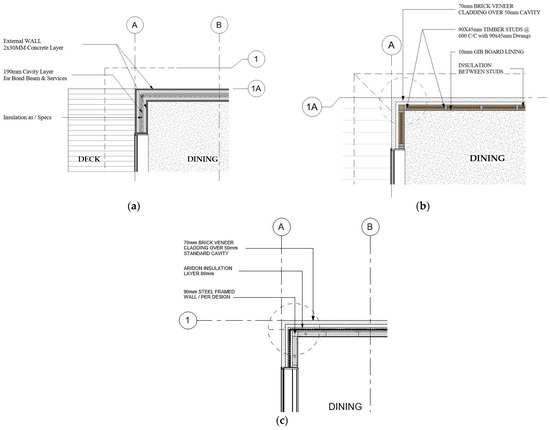

The BIM development scope for this project was limited to federating architecture and structural models to manage and coordinate information. This process simplified complexity resulting from the multitude and variety of essential building elements comprising the model’s envelope. Figure 3 shows all of the three investigated houses’ federated models, while Figure 4 illustrates the detailed wall systems of the three buildings. The LOD level achieved in this assessment is LOD 350 because the models were able to be developed based on the construction documentation of the LSF house.

Figure 3.

Federated models of three investigated houses: (a) a 3DP concrete house; (b) a light steel framed house; and (c) a timber house.

Figure 4.

The detailed wall system of three investigated houses: (a) a 3DP concrete house; (b) a light steel framed house; and (c) a timber house.

Hybrid construction was assumed for the 3DP concrete model as recommended by QOROX and modelled in this study, which was combined with the timber frame as per NZS3604:2011. The thickness of the 3DP walls modelled in this study is 250 mm, which was assumed to be suitable for NZ residential home construction and installed using a 30 mm nozzle-size printer or robot. The timber house models were created to adhere to the building code, which serves as a standard for all timber-framed buildings in New Zealand that do not necessitate specialised structural engineering designs. For LSF, the detailed model was developed based on the information available from the case building. The structural framing members were developed in the FRAMECAD Structure v9.2 software before being exported to the Autodesk Revit 2020 software. It is a structural frame design software that is compatible with cold-formed steel structures and offers an engineering calculation based on the designs [52].

2.2. Material Quantity Take-Off

Material quantity take-off of the three investigated houses was performed with Autodesk Revit, which used the federated models of the houses. Table 2 presents the material quantity of the three houses from each category and element, including their specifications.

Table 2.

Material quantity take-off of the three investigated houses.

2.3. 3DP Construction Time

The difference between the construction of a 3DP house and traditional construction highlights dissimilarities, both in their process of installation and time requirements. A calculation of external wall duration based on the robot specification (e.g., tool path length, and the average speed of printing), collected from the local 3DP concrete printing company (QOROX), and efficiency indicates that only 25.58 h are required to print the 3DP external walls for this case study house (Table 3). Approximately 4.5 days, with assumptions of 6 h per day and 2–3 site workers, will be required to monitor the robot, material, and overall assembly.

Table 3.

Estimated 3DP wall installation completion time of the case study.

In comparison with a standard residential building in New Zealand, an average 100 m2 timber-framed surface area will require a timeline of 270 h or 6–7 weeks to complete as per specification, including framing, building wraps and underlays, weatherboard cladding, exterior trims, cavity battens, insulation, flashings, and interior trims [53]. In a case study of a 100 m2 single-story house in Auckland, a comparable timeframe was analysed, revealing that it takes approximately 6 to 7 weeks (with 3 to 4 weeks dedicated to framing) and involves a team of at least 4 workers to complete wall construction and associated finishes in a timber-framed house [30]. Compared to timber-framed walls, the same wall area can be printed in just 72 h, or 0.6 weeks (based on the Apis Cor estimate and robot specifications), a saving of around 3 weeks [54].

2.4. Energy Simulation

Energy simulation was performed using the Autodesk Green Building Studio (GBS). This software is a cloud-based software for early-stage building design analysis that utilises REVIT model data and site-specific information to provide comprehensive reports on energy usage, including water and electricity, ventilation, space cooling, and carbon emissions [55]. In this study, the energy simulation was only conducted for the comparative energy analysis between the 3DP concrete and timber houses. The selection of these two houses was because the 3DP was the main focus of the study, while the timber house was the most commonly built typology across New Zealand and contributed to 90% of the total house market between 2010 and 2019 [56]. Therefore, only these two houses were analysed with the GBS software (https://gbs.autodesk.com/GBS/, accessed on 11 February 2024), where the LFS house’s annual energy consumption data was collected from the case study building, which was 5520 kWh. Table 4 shows the summary of the energy analysis results from the Autodesk GBS software (https://gbs.autodesk.com/GBS/, accessed on 11 February 2024).

Table 4.

Energy analysis comparison between 3DP concrete and timber houses.

According to the energy analysis results, the annual electricity consumption of 3DP concrete and timber houses was 4186 and 5157 kWh, respectively. The 3DPC house demonstrated a 19% reduction in electricity consumption and a 37% reduction in annual energy costs compared to the timber house.

2.5. Life Cycle Assessment

The LCA adhered to the ISO 14040:2006 standard, encompassing goal and scope definition, LCI, LCIA, and interpretation [10]. The objective of this LCA was to measure the environmental effects of 3D-printed, light steel, and timber houses in New Zealand. The chosen system boundary followed a cradle-to-cradle approach, incorporating potential benefits beyond the immediate boundary while excluding operational building stages (B6 and B7). In this study, the biogenic carbon from the sustainable forestry management practices of timber products was considered in the production stage (Modules A1–A3), and the building service life was 50 years. The functional unit for this study was the kilogramme of environmental impacts per gross floor area of the house.

The BIM approach was performed in the LCI stage, in which Autodesk Revit was utilised to determine the material quantity of the investigated houses. Based on the material data collected from the quantity take-off process, LCAQuick V3.6 was used to assess the environmental impacts of the three houses: 3D printing, light steel, and timber-based buildings. The study referred to Ecoinvent 3.3 and Environmental Product Declarations (EPDs) (e.g., the EPD Australasia database) as the environmental impact databases. Seven impact categories were analysed from the three houses, including climate change (global warming), ozone depletion (stratospheric ozone), acidification for soil and water, eutrophication, photochemical ozone creation (tropospheric ozone), depletion of antibiotic resources (non-fossil fuels), and depletion of antibiotic resources (non-fossil fuels).

3. Results and Discussion

3.1. Overall Environmental Impacts

Table 5 summarises the overall LCA results across the main environmental indicators. According to the LCA results summary, 3DP, followed by timber, has the lowest environmental impact under the investigated environmental impact categories. In comparison, steel (LSF) has a higher environmental impact than the other two houses. A recent article evaluated the environmental trade-offs of using 3DP versus traditional construction systems by conducting a detailed LCA analysis. Compared to conventional construction methods, the 3DP concrete significantly reduced environmental effects in terms of global warming potential (GWP) and other potential environmental categories [57].

Table 5.

Summary of environmental impacts per GFA of three investigated houses.

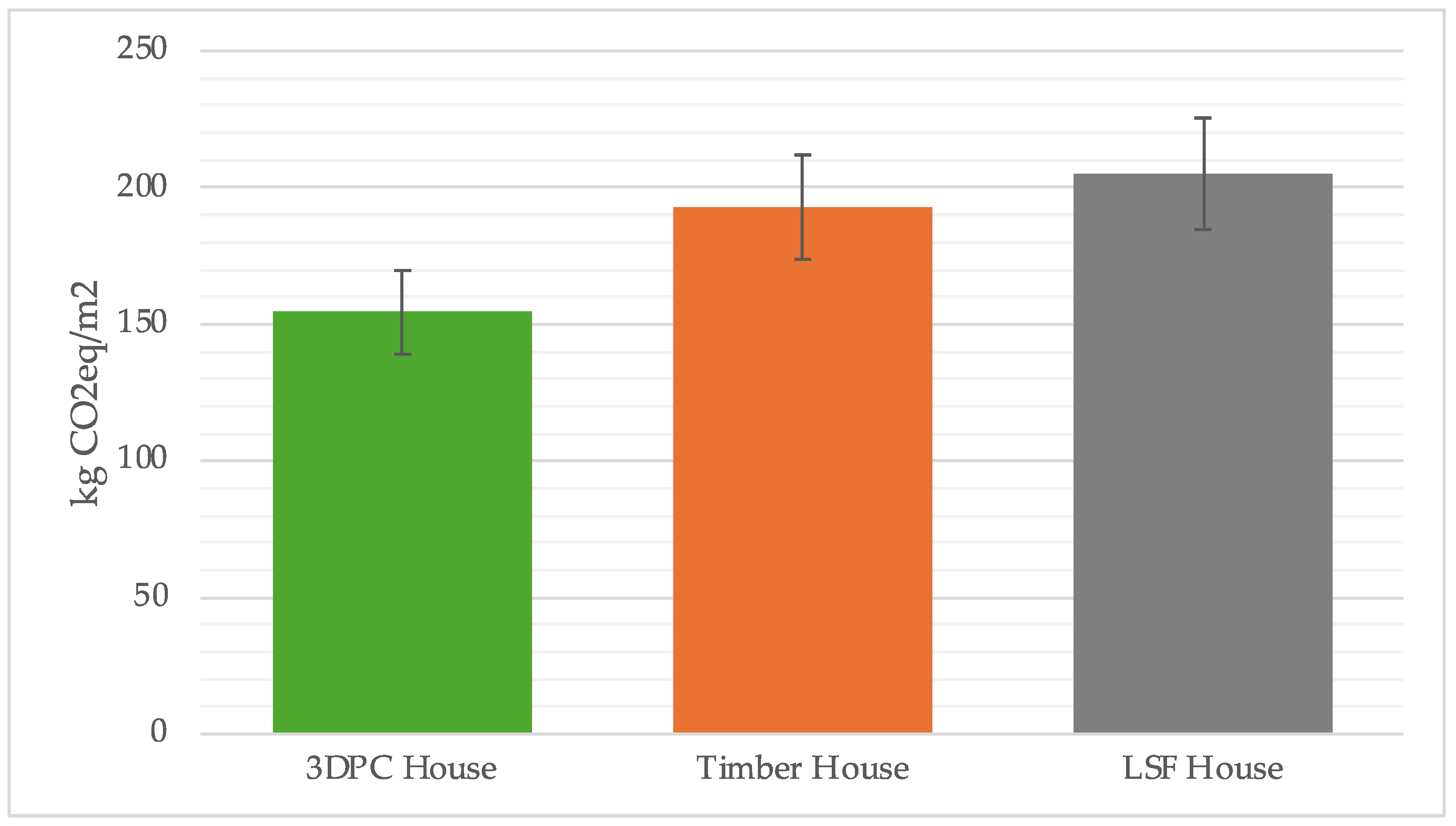

3.2. Global Warming Potential Results Comparison

The following subsection analyses the LCA in each life cycle stage under the GWP category to evaluate the environmental performance of three different houses. Table 6 and Figure 5 show the sum of GWP of the three analytical buildings or houses modelled in this study with a 10% error bar used, followed by the uncertainty analysis study by Abdalla et al. [58]. The total embodied carbon impacts indicate that 3DP concrete house produces the lowest GWP impact (154.35 kgCO2eq/m2) for the whole life cycle stages, in contrast to timber and LSF houses, with reductions of 20% and 25%, respectively. A similar study had been conducted in the USA regarding the performance of a 3DP concrete house [59]. Lolli et al. [59] found that 3D-printed homes result in reduced life cycle carbon emissions, with decreases ranging between 2% and 6% across different climate zones when compared to timber-framed stick houses. A New Zealand study, “Building Comfortable Homes,” discovered that building a concrete house requires less embodied energy than building a lightweight home. Specifically, the energy consumed in producing concrete walls is notably less than the total energy required for constructing timber-framed walls with interior plasterboard lining and exterior cladding [60].

Table 6.

Global warming potential results of the three houses.

Figure 5.

Overall GWP results of the three houses.

During the production stage (A1–A3), the timber house showed the lowest impact of 123.50 kgCO2eq/m2, followed by 3DP concrete (126.58 kgCO2eq/m2), which is nearly 40% less than the LSF house. The GWP impact during the various life cycle stages (A4–A5, B2, B4, and B7) is lowest for 3DP concrete and lower than for timber at the end-of-life (C1–C4) stage. During the maintenance and replacement (B2, B4), the 3DPC house indicates zero impact, which is mainly due to the very low or minimal maintenance required in concrete walls compared to timber or LSF walls over 50 years of building service life. Although the LSF building attributed most environmental damage throughout the production and end-of-life stages, it reported a higher recovery rate in stage D (−39.71 kgCO2eq/m2).

In addition, no EPD has been released for 3DP concrete in Australasia so far. Various categories of OPC-based concrete EPDs are available in the LCAQuick tool. Therefore, standard 20 MPa OPC (ordinary Portland cement) concrete with no reinforcement is substituted with the 3DP concrete. The decision to substitute was discussed with QOROX as a solution, and a reduction factor of 30% of CO2 emissions in 3DP concrete results was applied, as evidenced in various studies. The mortar used in 3DP concrete produces fewer emissions than OPC because the rapid-set mortar kiln operates at a 30% lower temperature (1015 °C) compared to OPC (1450 °C) [61]. The production of cement requires significant energy and results in high carbon emissions due to the intense heat required for processing primary components and the chemical reactions necessary to impart structural properties to cement [62]. Manufacturing 3DP mortar produces up to 32% less CO2 than OPC [63]. 3DP concrete mortar contains cement with low-carbon additives and is different from typical OPC-based mortar.

In reference to low-carbon cement, there are several alternatives to reduce GHG emissions in standard cement. A process was similarly applied to generate additives for the concrete mortar used in the 3DP concrete. The key mitigation options to reduce GHG emissions from ordinary cement are outlined below [62]:

- Embrace innovative approaches like Carbon Capture and Storage (CCS) and alternative binder technologies such as geopolymers and LC3 cement.

- Enhance energy efficiency measures.

- Employ alternative fuels in cement kilns.

- Promote higher clinker substitution and the utilisation of Supplementary Cementitious Materials (SCMs) in conventional Portland cement blends.

Various studies suggest that substituting clinker with SCMs (supplementary cementitious materials) can reduce the carbon footprint of standard Portland cement by up to 50%, representing a straightforward and effective means to minimise carbon emissions from regular cement and produce lower environmental impact eco-blends [62].

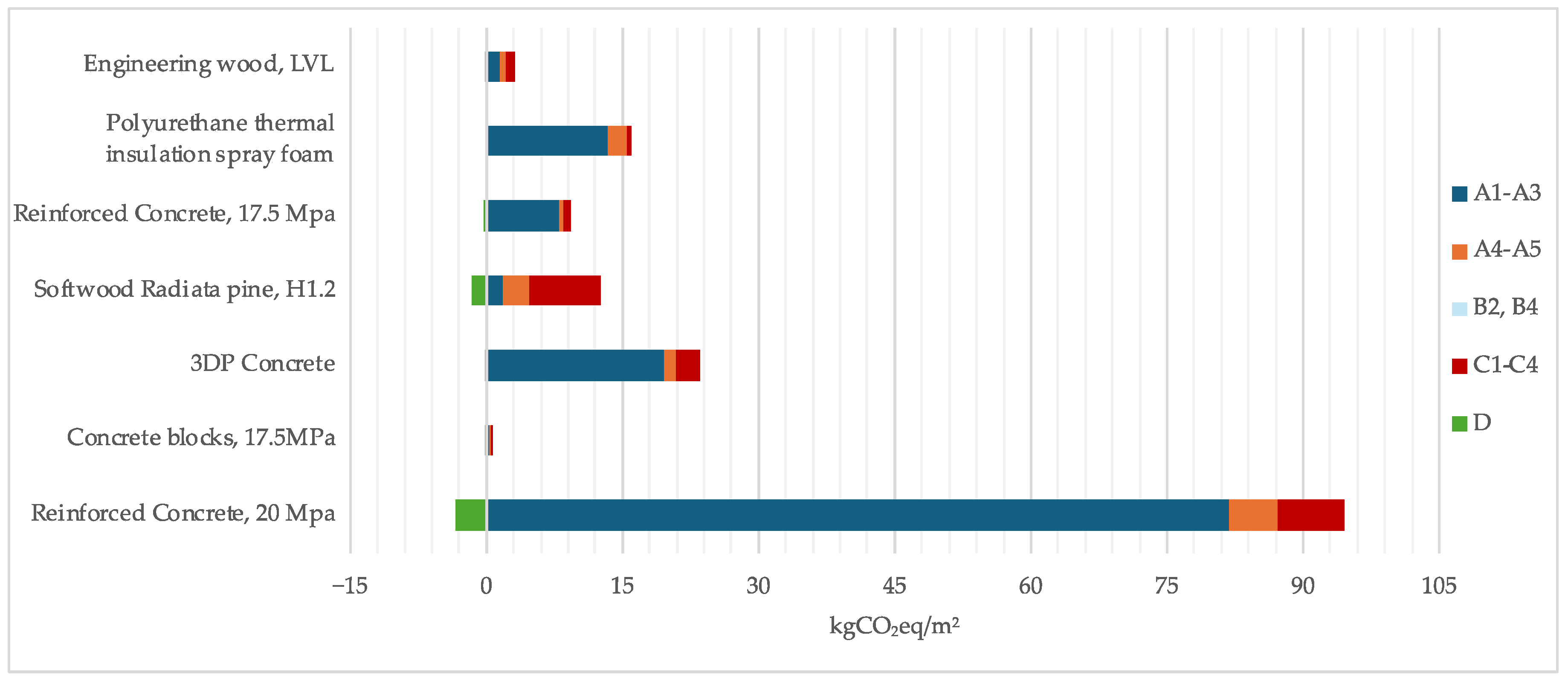

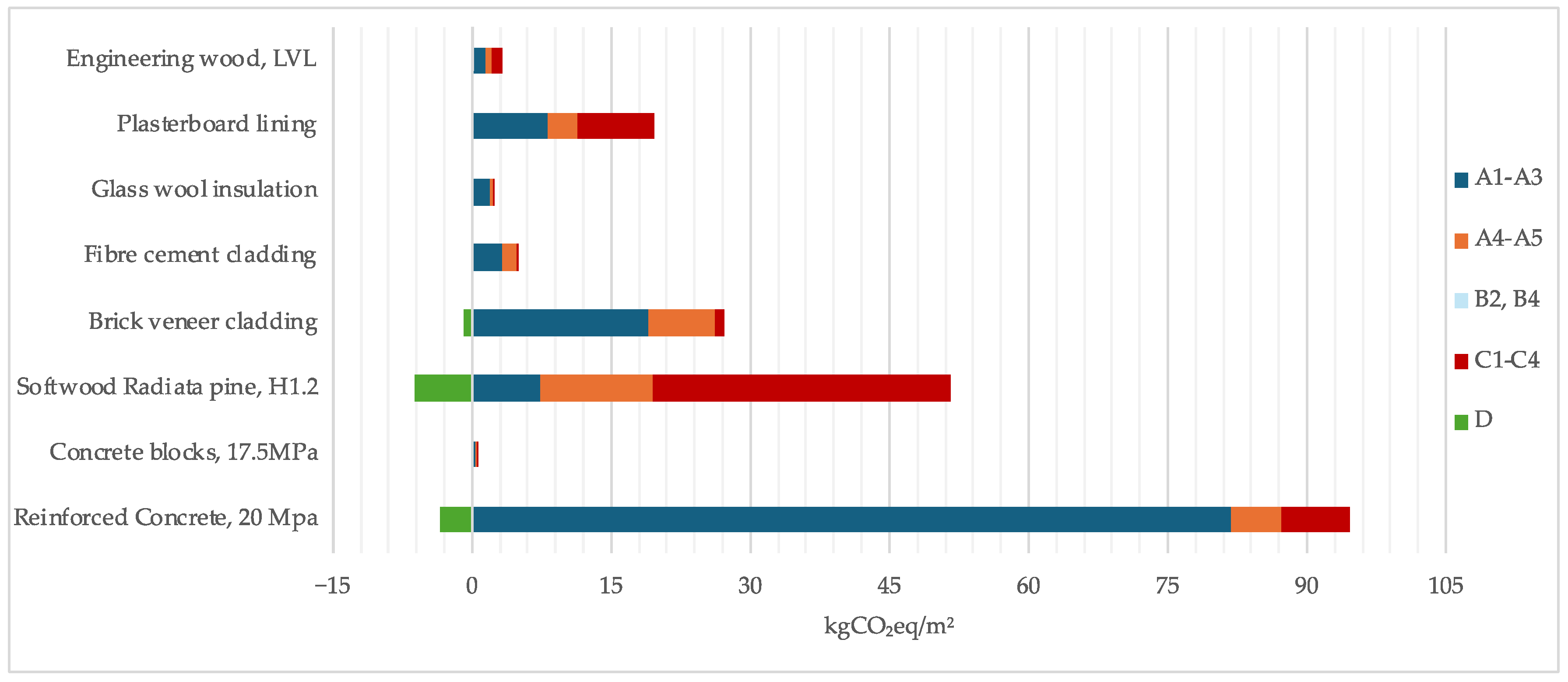

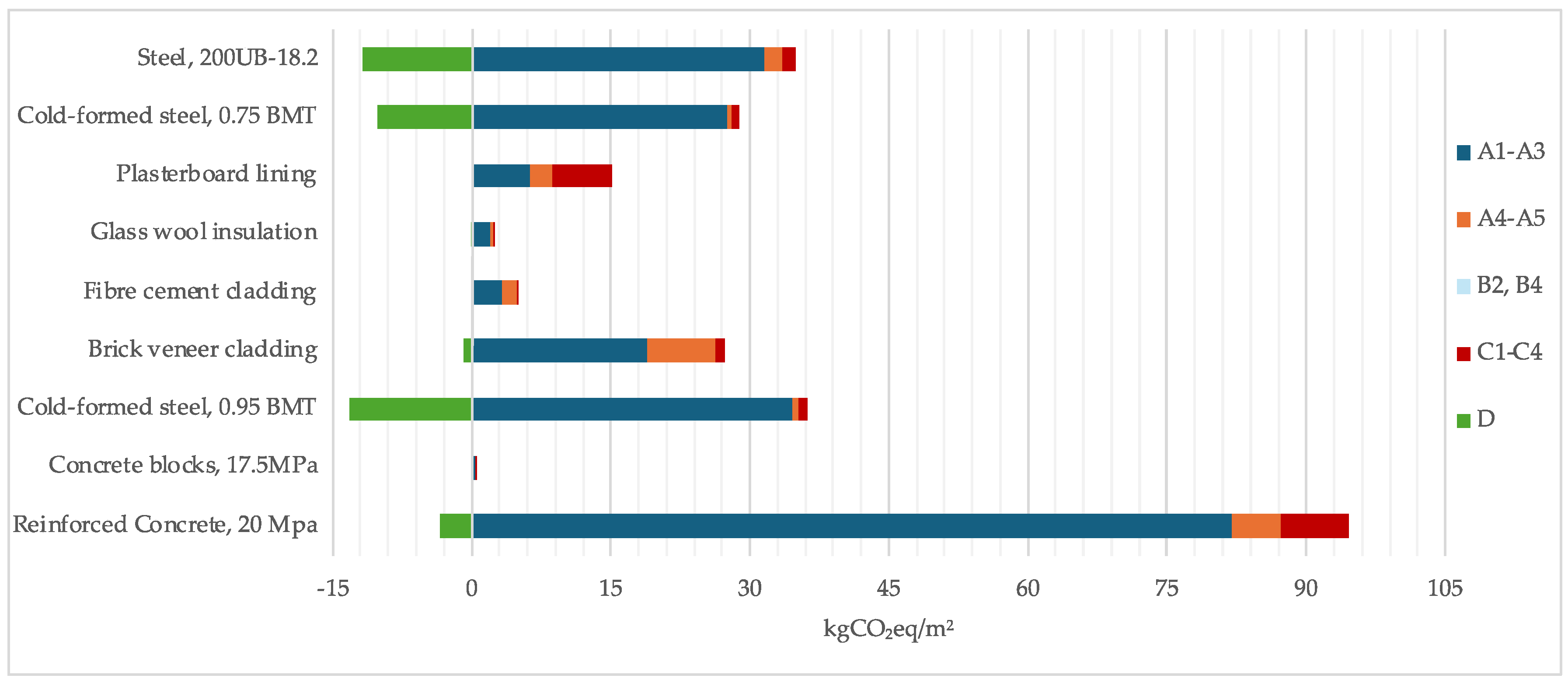

3.3. Material Impacts in Each Stage

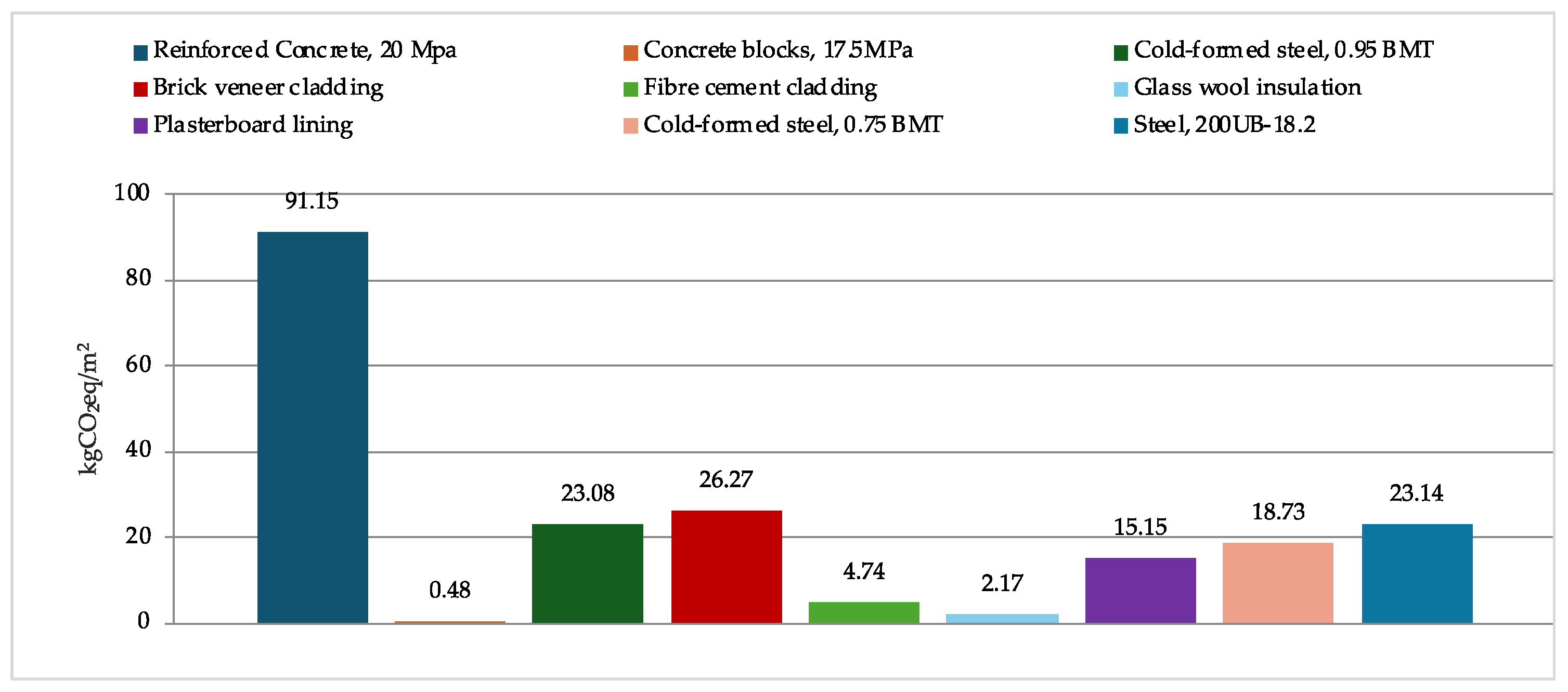

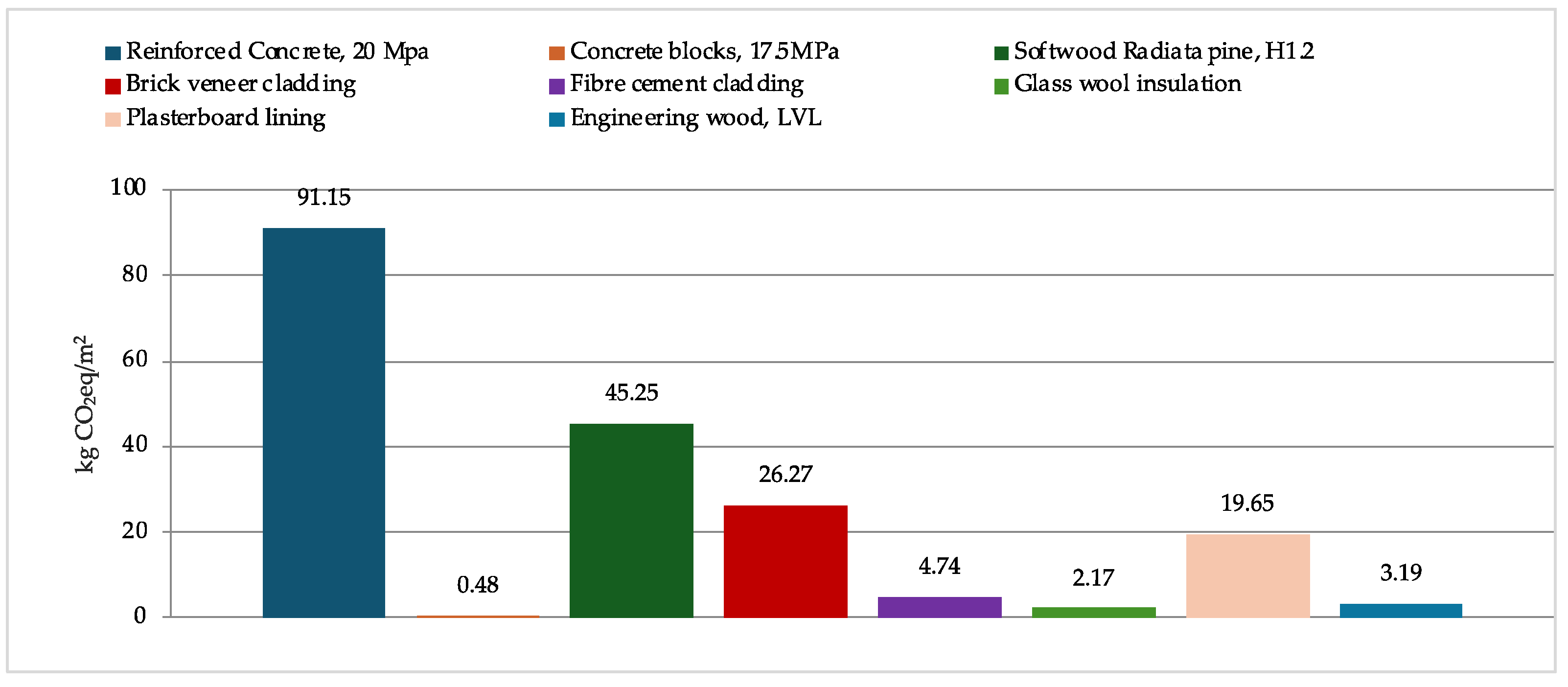

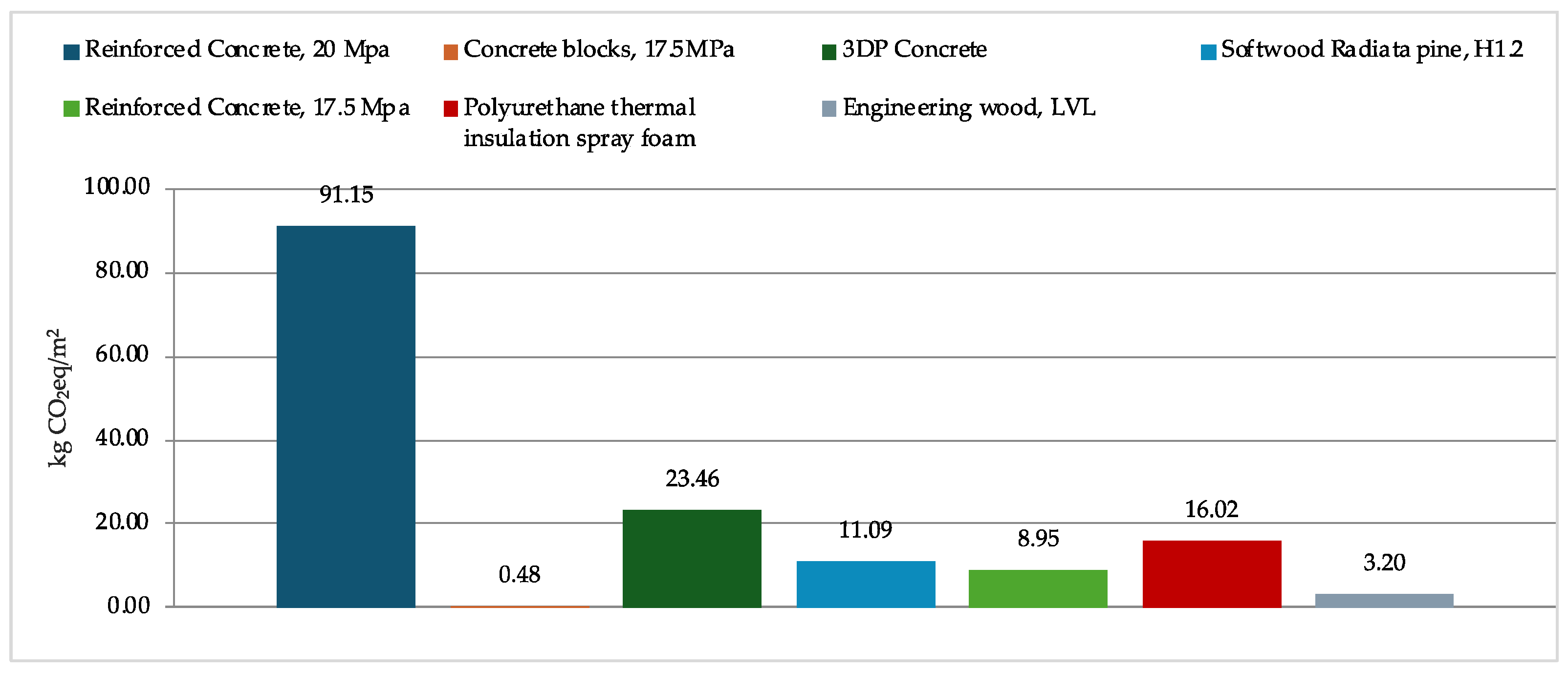

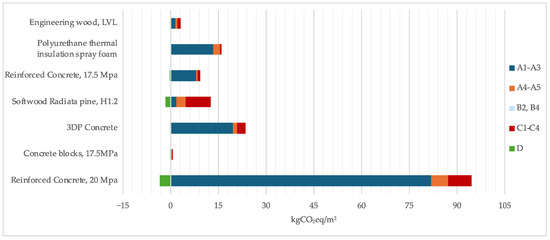

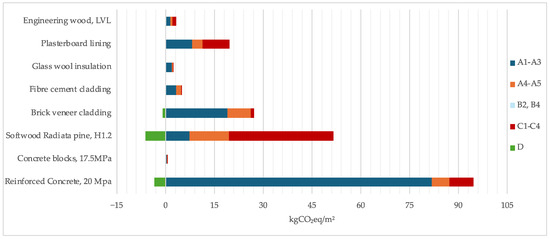

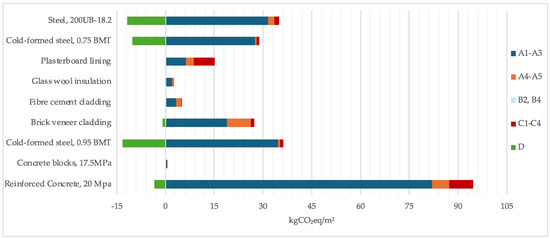

The individual embodied carbon impacts of the main elements directly contributing to GWP in various LCA stages are categorised in this section. The following graphical illustrations (Figure 6, Figure 7 and Figure 8) are a snapshot of the material-based performance of 3DPC, timber, and LSF house results.

Figure 6.

Materials GWP analysis of the 3DPC house.

Figure 7.

Materials GWP analysis of the timber house.

Figure 8.

Materials GWP analysis of the LSF house.

A closer view of results in three different wall structures only indicates the lowest GWP contributor material is softwood timber radiata for the timber frame house (6.02 kgCO2eq/m2) followed by 3DP concrete wall for a 3DP concrete house (23.46 kgCO2eq/m2) and cold-formed steel for an LSF house (27.21 kgCO2eq/m2) in the significant A1–A3 stage. According to Pacific Steel EPD, the rate of NZ steel products is 89%, but they contain over 97% iron sand, which potentially causes air pollution at the A1–A3 stage.

In contrast, the cold-formed steel framed rate of benefits during the recycling and recovery stage D −10.36 kgCO2eq/m2) is higher than that of timber wall framing (−5.11 kgCO2eq/m2), whereas 3DP concrete reflects relatively zero benefits in this stage. At the demolition stage (C1–C4), the 3DP concrete wall (2.63 kgCO2eq/m2) indicates a lower carbon impact compared to timber wall framing, which has 26.15 kgCO2eq/m2. Timber remains go to the landfill, and a tiny percentage can be reused or recycled. Therefore, the timber house has the highest embodied carbon impact in the C1–C4 stage.

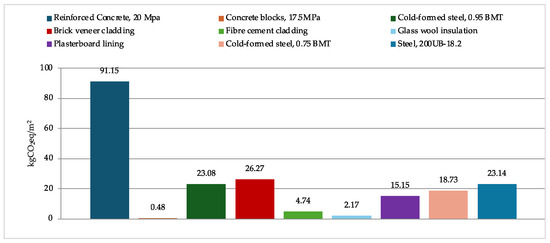

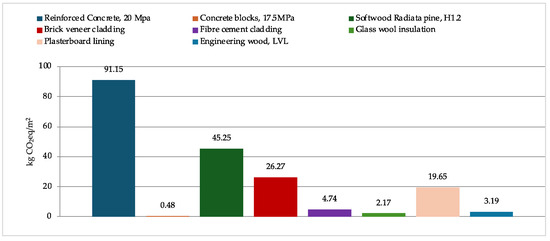

3.4. Summary of Total Material Impacts

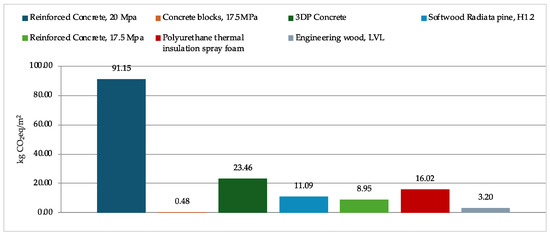

This section differentiates key materials’ embodied carbon impact, representing the total values across the various LCA stages from the previous section. Materials such as reinforced concrete 20 MPa, cold-formed steel framed, 3DP concrete, softwood timber radiata pine, and brick veneer claddings are dominating in the GWP category (refer to Figure 9, Figure 10 and Figure 11).

Figure 9.

Key material GWP analysis of the LSF house.

Figure 10.

Key material GWP analysis of the timber house.

Figure 11.

Material GWP analysis of the 3DPC house.

Figure 7 highlights 20 MPa reinforced concrete for the RibRaft foundation as the most significant contributor (91.15 kgCO2eq/m2) of carbon emissions in LSF houses. It follows the cold-formed steel structure used in the building if both base metal thicknesses (0.95 mm and 0.75 mm) are combined, which is 41.8 kgCO2eq/m2. The previous section discussed that LSF framings have relatively high embodied carbon in the manufacturing stage (A1–A3).

Similarly, the concrete used for the RibRaft foundation contributes the biggest carbon to the timber house, with 91.15 kgCO2eq/m2 (refer to Figure 10). It is followed by the softwood radiata pine timber for the wall frame and roof trusses of the house, which emits 45.25 kgCO2eq/m2 or 23% of the total house carbon emissions. The use of timber products in this assessment is assumed to be sourced from non-sustainable forestry management practices; therefore, the potential biogenic carbon of the timber products is neglected. Therefore, the timber products used in this study have a considerable amount of carbon emitted during the production stage, while in some studies, the consideration of biogenic carbon would reduce the total carbon of the timber house [64].

According to Figure 11, reinforced concrete for the typical foundation used in the assessment for the 3DP concrete house remains to have significant impacts on the environment in terms of carbon emissions. The 3D concrete that is used for the wall system in the assessment contributed as the second largest carbon contributor (15%), with 23.45 kgCO2eq/m2. However, 3DP values could slide further, as emphasised in various studies around the decarbonisation of cement and concrete. According to the Thinkstep consultancy report [5], which specifies low-carbon concrete, the embodied carbon footprint can be reduced by 5% in the short run. In the long run, it might save 29% by altering how important building materials are created. OPC contributes to 70–80% of the carbon emissions associated with virgin concrete, making the substitution of cement with SCMs a widely adopted strategy for reducing carbon emissions in concrete. New Zealand presently exhibits minimal substitution of Portland cement (estimated at 1–2%), indicating significant potential for lowering the carbon emissions associated with concrete production in the country [5].

Furthermore, the insulation material used in the 3DP concrete house was spray foam insulation, as per 3DP concrete company information, which was different from other case houses that had glass wool insulation with an R2.6 value. When integrated with supplementary materials, concrete’s thermal performance may exceed that of timber and steel constructions, thus alleviating the necessity for insulation materials within their respective building envelopes [65]. The term “thermal performance” refers to a building’s capacity to adapt to changes in external conditions while preserving internal thermal comfort [66]. In regard to 3DP concrete walls, it was observed that they exhibit superior thermal performance compared to conventional constructions. However, this performance is significantly influenced by factors such as the infill structure, concrete composition, and void fraction [67]. In a study by Briels et al. [68], the use of internal cellular structure with encapsulated air-filled voids was investigated, revealing that lightweight concrete elements can achieve commendable thermal performance with lower resource consumption. Furthermore, the utilisation of high-strength concrete in 3D printing technology has the potential to produce lighter structures, which could further enhance thermal performance [69].

3.5. Study Assumptions and Limitations

Several assumptions were made during this assessment. Building components and elements that are not listed in Table 2, such as staircases, roof cladding, floor covering, and paint, were excluded as they are outside the scope of this study. The concrete used in the 3DP concrete house was assumed to use the standard OPC cement-based concrete available in the LCA tool, as the 3DP concrete materials are unavailable in the tool as well as the published EPD in New Zealand. Therefore, the carbon emission results of the 3DP concrete house were adjusted (refer to Section 3.2). The construction stage scenario of the 3DP concrete house was assumed to follow the traditional method. All timber used was assumed to be sourced from a non-sustainable forestry management practice, and the biogenic carbons were not considered in modules A1–A3. In addition, this study is only limited to New Zealand, as the environmental indicators used in the study follow the local database available in the LCA tool.

4. Conclusions

This study discussed the potential of adopting 3DP housing technology in New Zealand to address sustainability challenges. Currently, the market is shifting to new housing patterns such as attached, low-rise, terrace, or town homes in strategic urban centres of main cities across New Zealand. This is strongly argued in the vision of a compact city under the Auckland Plan 2050 to balance the housing supply and demand ratio. By offering automation and digitalisation, 3DP concrete emerges as a promising alternative that could revolutionise the labour-intensive housing sector. Notably, this study found that the 3DP concrete walls outperform timber framed wall systems in terms of time efficiency, underscoring the importance of effective delivery in mitigating construction risks and meeting project timelines. Furthermore, through a BIM-based case study, the research demonstrates the feasibility of introducing a 3DP construction system in New Zealand, emphasising the environmental benefits. Following are the outcomes of the study:

- LCA results substantiated positive environmental characteristics in the 3DP concrete house. The average GWP impacts across the different life cycle stages resulted in the 3DP concrete house’s performance being 20% less carbon emissions compared to the timber house and 25% less than the LSF house. Various research justifies this argument: adopting low-CO2-emitting or high-carbon storage materials like concrete can make a significant difference in the process against climate change [70].

- The energy analysis performance tested by Autodesk GBS software also confirmed the eco-friendly aspects of substituting external timber framing with 3DP concrete walls in enhancing the building’s performance in the New Zealand context. The parameters include a realistic reduction in annual energy, lifecycle costs, electric consumption, and CO2 emissions.

- Timber products are found to release significant carbon during the end-of-life stage, which accounts for 17% (only from timber products) of the total timber house’s carbon emissions. This is mainly due to most timber products going to landfills at the end of their service lives. A study conducted in Auckland found that the majority of construction waste consists of timber (20%), plasterboard (13%), packaging (5%), metal (5%), and miscellaneous materials (45%) [71].

Despite the potential environmental benefits of 3DP concrete, the technology of 3D concrete printing is still in its early stages and faces several obstacles before it can penetrate the New Zealand housing market. The initial set-up of resources and costing are overseas-based, including the main robot, mortar, and additives used in 3DP, and the non-availability of EPDs with BRANZ, which is a barrier to decision-making and setting standards. In addition, the use of BIM is gaining traction in many disciplines of the AEC industry, combined with data-driven applications that are applicable to advanced construction improvements. The BIM-generated information used in LCA and energy analysis proved an efficient tool in testing this 3DP house on New Zealand grounds. The research results are a quantitative argument and evidence to position the 3DP concrete hybrid house at the beginning of a new era towards an innovative housing solution for the New Zealand market.

5. Recommendation

Given the rapidly changing housing demand and aspirations in New Zealand, construction companies must innovate to take advantage of market developments and apply potential research studies to reality to boost systems and processes. This study’s findings offer directional guidance for future endeavours and opportunities concerning the advancement of 3DP concrete in New Zealand.

Handling Risks and Challenges: The construction sector and the New Zealand government have prioritised productivity growth, forming the ‘Construction Sector Productivity Partnership’ to explore real solutions to productivity concerns. Additionally, the construction industry is notorious for its high incidence of injuries and even fatal accidents. In 2022, WorkSafe documented 6240 work-related injuries and twelve fatalities within the New Zealand construction sector [72]. Any construction is a labour-oriented activity that necessitates materials, machinery, and equipment. Logistics management is becoming complex in conventional construction practices. As a result, essential supply chains or workforce availability must be uninterrupted to avoid a severe impact on construction outcomes.

Compliance Process: There are common perceptions that the building consent process is lengthy and inconsistent in New Zealand. The existing procedures for obtaining building consent are most compatible with conventional construction techniques and may pose obstacles, redundancies, and slowdowns for adopting innovative products and methodologies [73]. Therefore, the current consenting process requires up-skilling staff or engaging experts capable of advising and inspecting a 3DP construction process from start to finish. New building codes and regulations are also required from overseas housing examples before importing this technology. This approach will mitigate uncertainty and delays, saving time and money while promoting innovation. Furthermore, new consents should incorporate BIM-based LCA and energy reports to enhance public awareness and opportunities.

Remove Barriers to Innovations: Breaking conservatism in housing and promoting modern construction methods tailored to New Zealand’s housing conditions is crucial. Introducing new systems faces challenges due to insufficient research, but collaborative efforts involving building research agencies, councils, developers, and industry stakeholders could shift customer preferences. Incentive schemes should encourage both developers and customers to embrace innovative housing practices. Given the housing sector’s importance in the construction industry and its broader impact on employment and economic growth, achieving sustainable housing options is paramount to overcoming social and cultural housing barriers in the long term. Advanced research and policies focusing on the environmental aspects of new construction are essential to supporting diverse practices and significant efforts in emissions reduction.

Eco-Friendly Homes in New Zealand: The increasing awareness of green building rating schemes, such as Homestar and Greenstar in New Zealand, reflects a shift towards environmentally friendly housing, driven by concerns over maintenance costs, operational efficiency, and carbon emissions. This trend indicates a departure from traditional timber houses. Leveraging the green building rating alongside BIM tools like NAVISWORKS, a comprehensive study is proposed to assess the Homestar value and detailed costs of single-story 3DP concrete houses resembling typical New Zealand designs. This analysis would encompass expenses for robotics, software, skilled labour, and other necessary resources, providing valuable insights for homeowners seeking innovative housing solutions like 3DP technology.

Consideration of Biogenic Carbon from Timber Products: Future studies need to consider the potential benefit of timber products sourced from sustainable forestry management practices in performing a comparative LCA of different types of buildings, mainly timber-framed houses. Future assessments should carefully calculate and include the biogenic carbon in timber products. Therefore, the assessment will not limit the potential carbon removals in one of the case studies.

Author Contributions

Conceptualisation, M.K. and J.B.P.L.; methodology, M.K. and A.A.D.; software, M.K.; validation, M.K., J.B.P.L. and K.R.; formal analysis, M.K. and A.A.D.; investigation, M.K.; resources, M.K. and J.B.P.L.; writing—original draft preparation, M.K. and A.A.D.; writing—review and editing, J.B.P.L. and K.R.; visualisation, M.K. and A.A.D.; supervision, J.B.P.L. and K.R.; project administration, K.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Acknowledgments

The authors want to acknowledge Wafaey Salim (Director—QOROX), who shared important information about 3DP technology, its movement in NZ housing, and its challenges. The authors would also like to acknowledge Bruce Campbell (Director—BC Plans, Orewa) for his interview and relevant information about the case study house.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Auckland Council. Auckland Plan 2050. New Zealand. 2018. Available online: https://www.aucklandcouncil.govt.nz/plans-projects-policies-reports-bylaws/our-plans-strate-gies/auckland-plan/about-the-auckland-plan/docsprintdocuments/auckland-plan-2050-print-document.pdf (accessed on 10 October 2023).

- New Zealand Productivity Commission. Housing Affordability Inquiry. New Zealand. 2012. Available online: https://www.productivity.govt.nz/assets/Documents/9c8ef07dc3/Final-report-Housing-affordability.pdf (accessed on 10 October 2023).

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-based Life Cycle Assessment of Uruguayan timber and concrete-masonry single-family houses in design stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Nairobi. 2022. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 21 November 2023).

- Vickers, J.; Gamage, G.; Fisher, B.; Nebel, B. Hidden Emissions and Untapped Potential of Buildings for New Zealand’s 2050 Zero Carbon Goal. Thinkstep Ltd.: Wellington, New Zealand, 2019. Available online: https://www.thinkstep-anz.com/resrc/reports/hidden-emissions-and-untapped-potential-of-buildings-for-new-zealands-2050-zero-carbon-goal/ (accessed on 19 November 2023).

- Level. Embodied Energy. BRANZ. 2023. Available online: http://www.level.org.nz/material-use/embodied-energy/ (accessed on 21 November 2023).

- Gibbons, O.P.; Orr, J.J. How to Calculate Embodied Carbon; The Institution of Structural Engineers: London, UK, 2020; Available online: https://www.istructe.org/IStructE/media/Public/Resources/istructe-how-to-calculate-embodied-carbon.pdf (accessed on 21 November 2023).

- Ministry of Business, Innovation & Employment. Whole-of-Life Embodied Carbon Emissions Reduction Framework; MBIE: Wellington, New Zealand, 2020; p. 24. Available online: https://www.mbie.govt.nz/dmsdocument/11794-whole-of-life-embodied-carbon-emissions-reduction-framework (accessed on 22 November 2023).

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-based LCA results for building design. Autom. Constr. 2019, 109, 102972. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 11 October 2023).

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Ghattas, R.; Gregory, J.; Olivetti, E.; Greene, S. Life Cycle Assessment for Residential Buildings: A Literature Review and Gap Analysis; Concrete Sustainability Hub, Massachusetts Institute of Technology: Cambridge, MA, USA, 2013; pp. 1–21. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Construction materials for the urban environment: Environmental assessment of life cycle performance. In Handbook of Ecomaterials; Springer International Publishing: Cham, Switzerland, 2019; Volume 3, pp. 2143–2175. [Google Scholar] [CrossRef]

- Hoxha, E.; Habert, G.; Lasvaux, S.; Chevalier, J.; Le Roy, R. Influence of construction material uncertainties on residential building LCA reliability. J. Clean. Prod. 2017, 144, 33–47. [Google Scholar] [CrossRef]

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-Cycle Assessment Modeling of Construction Processes for Buildings. J. Infrastruct. Syst. 2010, 16, 199–205. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Kivits, R.A.; Furneaux, C. BIM: Enabling Sustainability and Asset Management through Knowledge Management. Sci. World J. 2013, 2013, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Wu, X. Case Study of Carbon Emissions from a Building’s Life Cycle Based on BIM and Ecotect. Adv. Mater. Sci. Eng. 2015, 2015, 1–15. [Google Scholar] [CrossRef]

- Safari, K.; AzariJafari, H. Challenges and opportunities for integrating BIM and LCA: Methodological choices and framework development. Sustain. Cities Soc. 2021, 67, 102728. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- American Institute of Architects (AIA). Guide, Instructions and Commentary to the 2013 AIA Digital Practice Documents. 2013. Available online: https://zdassets.aiacontracts.org/ctrzdweb02/zdpdfs/digital-practice_guide.pdf (accessed on 30 March 2024).

- BIMinNZ. Appendix C Levels of Development Definition. Digital Guidance Suite: Aotearoa | New Zealand. 2023. Available online: https://static1.squarespace.com/static/57390d2c8259b53089bcf066/t/6584af7ba253c661b2593b09/1703194493883/BIM+Handbook_%28APPENDIX_C%29.v3.pdf (accessed on 30 March 2024).

- AutoDesk. Levels of Development: Enabling Coordination and Collaboration. Available online: https://www.autodesk.com/solutions/bim-levels-of-development (accessed on 30 March 2024).

- BIMForum. Level of Development (LOD) Specification. 2023. Available online: https://bimforum.org/resource/lod-level-of-development-lod-specification/ (accessed on 30 March 2024).

- Shafighfard, T.; Cender, T.A.; Demir, E. Additive manufacturing of compliance optimized variable stiffness composites through short fiber alignment along curvilinear paths. Addit. Manuf. 2020, 37, 101728. [Google Scholar] [CrossRef]

- Apis Cor. Dubai Municipality 3D Printed Building. 2019. Available online: https://www.apis-cor.com/dubai-project (accessed on 28 March 2024).

- CyBe. 3D Studio 2030. 2018. Available online: https://cybe.eu/cases/3d-studio-2030/ (accessed on 17 November 2023).

- Winsun3D. 3D Printing Architecture’s Future. Available online: http://www.winsun3d.com/En/ (accessed on 17 November 2023).

- Loporcaro, G.; Zhao, A. Exploring opportunities and limitations of 3D concrete printing technology in New Zealand. In Proceedings of the Concrete NZ Conference, Dunedin, New Zealand, 10–12 October 2019. [Google Scholar]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Geneidy, O.; Ismaeel, W.S.E. Investigating the Application of the Three Dimensional Wall Building Technology in Egypt. In Proceedings of the Green Heritage Conference, The British University in Egypt, Cairo, Egypt, 6–8 March 2018; pp. 164–183. [Google Scholar]

- Khoshnevis, B.; Hwang, D.; Yao, K.T.; Yeh, Z. Mega-scale fabrication by Contour Crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, e103642. [Google Scholar] [CrossRef]

- Fiala, L.; Lin, W.-T.; Hotěk, P.; Cheng, A. Feasibility study of developing cementless blended materials as 3D printable materials. Case Stud. Constr. Mater. 2023, 19, e02675. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2021, 134, 104087. [Google Scholar] [CrossRef]

- Masood, R.; Roy, K.; González, V.A.; Lim, J.B.; Nasir, A.R. A supply chain perspective of prefabricated housebuilding diffusion in New Zealand. Eng. Constr. Arch. Manag. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Masood, R.; Roy, K.; Gonzalez, V.A.; Lim, J.B.; Nasir, A.R. Modeling relational performance of the supply chains for prefabricated housebuilding in New Zealand. Smart Sustain. Built Environ. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- QOROX. TV3—The Project & Newshub Article—QOROX® 3d Printed Houses & More. 2023. Available online: https://qorox.co.nz/news-and-media/tv3-the-project-newshub-article/ (accessed on 28 November 2023).

- Construction Sector Accord. Case Study: QOROX 3D Printing Technology. MBIE. 2022. Available online: https://www.constructionaccord.nz/good-practice/beacon-projects/case-study-qorox-3d-printing/ (accessed on 28 November 2023).

- QOROX. QOROX is a 3D Printing Construction Company to Watch by All3DP.COM. 2022. Available online: https://qorox.co.nz/news-and-media/qorox-is-a-3d-printing-construction-company-to-watch-by-all3dp-com/ (accessed on 15 March 2024).

- QOROX. World 1st Solar Passive Home with 3D Printed Concrete Walls Opens Doors to Public. 2023. Available online: https://qorox.co.nz/news-and-media/world-1st-solar-passive-home-with-3d-printed-concrete-walls-opens-doors-to-public/ (accessed on 15 March 2024).

- Abdelaal, F.; Guo, B.H. Stakeholders’ perspectives on BIM and LCA for green buildings. J. Build. Eng. 2021, 48, 103931. [Google Scholar] [CrossRef]

- Chau, C.-K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B.P. A Comparative Study on the Life Cycle Assessment of New Zealand Residential Buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

- Taylor, C.; Roy, K.; Dani, A.A.; Lim, J.B.P.; De Silva, K.; Jones, M. Delivering Sustainable Housing through Material Choice. Sustainability 2023, 15, 3331. [Google Scholar] [CrossRef]

- Roy, K.; Dani, A.A.; Ichhpuni, H.; Fang, Z.; Lim, J.B.P. Improving Sustainability of Steel Roofs: Life Cycle Assessment of a Case Study Roof. Appl. Sci. 2022, 12, 5943. [Google Scholar] [CrossRef]

- Roy, K.; Su, R.; Dani, A.A.; Fang, Z.; Liang, H.; Lim, J.B.P. Spatiotemporal Model to Quantify Stocks of Metal Cladding Products for a Prospective Circular Economy. Appl. Sci. 2022, 12, 4597. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.P.; González, V.A.; Roy, K.; Khan, K.I.A. A Systematic Review on Supply Chain Management in Prefabricated House-Building Research. Buildings 2022, 12, 40. [Google Scholar] [CrossRef]

- Wu, H.; Liang, H.; Roy, K.; Harrison, E.; Fang, Z.; De Silva, K.; Collins, N.; Lim, J.B.P. Analyzing the Climate Change Potential of Residential Steel Buildings in New Zealand and Their Alignment in Meeting the 2050 Paris Agreement Targets. Buildings 2022, 12, 290. [Google Scholar] [CrossRef]

- BRANZ. LCAQuick: Life Cycle Assessment Tool. Available online: https://www.branz.co.nz/environment-zero-carbon-research/framework/lcaquick/ (accessed on 15 October 2023).

- FRAMECAD. FRAMECAD Structure—Cold Formed Steel Software. Available online: https://www.framecad.com/en/framecad-system/software/structure/ (accessed on 2 October 2023).

- NZIQS. Detailed Cost Breakdown for Project Examples YourQS, 2020. New Zealand Institute of Quantity Surveyors. 2020. Available online: https://www.nziqs.co.nz (accessed on 18 October 2023).

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Autodesk, Inc. Green Building Studio®. Available online: https://gbs.autodesk.com/GBS/ (accessed on 28 December 2020).

- BRANZ. Research Now Physical Characteristics of New Buildings #1; BRANZ: Porirua, New Zealand, 2020; p. 6. [Google Scholar]

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D Concrete Printing Sustainability: A Comparative Life Cycle Assessment of Four Construction Method Scenarios. Buildings 2020, 10, 245. [Google Scholar] [CrossRef]

- Abdalla, H.; Fattah, K.P.; Abdallah, M.; Tamimi, A.K. Environmental Footprint and Economics of a Full-Scale 3D-Printed House. Sustainability 2021, 13, 11978. [Google Scholar] [CrossRef]

- Lolli, F.; Jafari, H.A.; Monkman, S.; Mehlomakulu, B.; Kirchain, R.; Reducing Carbon Emissions in the Built Environment: A Case Study in 3D Printed Homes. MIT Concrete Sustainability Hub. 2024. Available online: https://cshub.mit.edu/2024/03/12/whitepaper-reducing-carbon-emissions-in-the-built-environment-a-case-study-in-3d-printed-homes/ (accessed on 25 March 2024).

- Alcorn, A.; Bellamy, L.; Gjerde, M.; Munn, C.A. Comparison of Cost and Thermal Performance of Concrete and Lightweight Housing Systems in New Zealand. 2002. Available online: https://cdn.ymaws.com/concretenz.org.nz/resource/resmgr/docs/conf/2002/s3_paper_3_-_munn.pdf (accessed on 25 March 2024).

- QOROX. First Fully 3D Printed Home Completed in Paremoremo. 2023. Available online: https://qorox.co.nz/news-and-media/first-fully-3d-printed-home-completed-in-paremoremo/ (accessed on 30 October 2023).

- World Wildlife Fund. Eco-Blend Cements for Low-Carbon Construction. 2018. Available online: https://www.international-climate-initiative.com/fileadmin/Dokumente/2018/180723_WWF_Publikation4_Eco-blend_Cement.pdf (accessed on 25 October 2023).

- CyBe. CyBe Mortar. Available online: https://cybe.eu/3d-concrete-printing/mortar/ (accessed on 25 October 2023).

- Roy, K.; Lim, J.; Dani, A.A.; Masood, R. LCA Case Study of Stand-Alone Houses. 2023. Available online: https://www.buildmagazine.org.nz/articles/show/lca-case-study-of-stand-alone-houses (accessed on 25 March 2024).

- Al-Radhi, Y.; Roy, K.; Liang, H.; Ghosh, K.; Clifton, G.C.; Lim, J.B. Thermal performance of different construction materials used in New Zealand dwellings comparatively to international practice—A systematic literature review. J. Build. Eng. 2023, 72, 106346. [Google Scholar] [CrossRef]

- Liang, H.; Roy, K.; Fang, Z.; Lim, J.B.P. A Critical Review on Optimization of Cold-Formed Steel Members for Better Structural and Thermal Performances. Buildings 2022, 12, 34. [Google Scholar] [CrossRef]

- AlZahrani, A.A.; Alghamdi, A.A.; Basalah, A.A. Computational Optimization of 3D-Printed Concrete Walls for Improved Building Thermal Performance. Buildings 2022, 12, 2267. [Google Scholar] [CrossRef]

- Briels, D.; Kollmannsberger, S.; Leithner, F.; Matthäus, C.; Nouman, A.S.; Oztoprak, O.; Rank, E. Thermal Optimization of Additively Manufactured Lightweight Concrete Wall Elements with Internal Cellular Structure through Simulations and Measurements. Buildings 2022, 12, 1023. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Sakdanaraseth, T.; Horayangkura, V. Design and Construction Method of a 3D Concrete Printing Self-Supporting Curvilinear Pavilion. J. Arch. Eng. 2021, 27, 05021006. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, H.; Bergman, R.D.; Liang, S. Comparative Life-Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- BRANZ. Reducing Construction and Demolition Waste. Building Research Association of New Zealand. 2022. Available online: https://d39d3mj7qio96p.cloudfront.net/media/documents/Bulletin_671_reducing_construction_waste-web_1.pdf (accessed on 3 November 2023).

- WORKSAFE. Construction. Available online: https://data.worksafe.govt.nz/focus/construction (accessed on 3 November 2023).

- Building Performance. Discussion Document. Building System Reform. MBIE. New Zealand. 2021. Available online: https://www.mbie.govt.nz/dmsdocument/14150-building-amendment-bill-proposals-for-regulations-discussion-document (accessed on 3 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).