Enhancing Human Reliability Prediction in Smart Tower Crane Interfaces: A Refined Approach Using Simplified Plant Analysis Risk–Human Reliability Assessment and the Decision Making Trial and Evaluation Laboratory–Analytic Network Process

Abstract

1. Introduction

2. Research Process

- Text Mining (TF-IDF-TruncatedSVD-ComplementNB): Analyzing 229 Chinese tower crane reports using text mining techniques to extract information about accident causation. The aim is to precisely categorize characteristic terms associated with the causes of accidents.

- Identification of Tower Crane Human Error Types: Classifying the terms obtained from text mining and aligning them with the Performance Shaping Factors (PSFs) in the SPAR-H model. This step involves finding corresponding failure modes and potential causes in the existing literature to refine the understanding of PSFs.

- Determination of PSF Levels in Tower Crane Cabs: The SPAR-H method simplifies human cognitive processes into diagnostic and executive elements. Each PSF’s level is established through comparisons with prior research to define standardized levels.

- Quantification of Human Error Probability (HEP): Due to the intricate relationships between PSFs in SPAR-H involving both causal and correlational aspects, the DEMATEL-ANP method is employed here for quantitative assessment.

- Demonstration of Method Feasibility through Practical Cases: The viability of the methodology is showcased through practical case studies.

3. Research Methodology

3.1. SPAR-H Methodology

- (1)

- Reducing Overlap: Excessive overlap between PSFs can hinder experts in reducing the uncertainty of specific human error events. Therefore, it is crucial to clearly define the scope of each PSF to avoid redundancy with others.

- (2)

- Hierarchical Structure: Describing each PSF should adhere to a hierarchical framework, such as components, factors, and indicators. Given the multitude of factors influencing the HRA process, a hierarchical framework for PSFs provides clear guidance in minimizing their impact.

- (3)

- Flexibility: The work environments of personnel in different industries vary, necessitating adaptability in Human Reliability Analysis methods. The states of PSFs should be flexible to address different events based on the characteristics of each PSF.

- (4)

- Digitization: Considering the trend toward digitization, especially in industries like crane operations, with visualized hook technology, it is essential to factor in the impact of digital environments on operators. Digitalization is becoming increasingly prevalent, making it necessary to account for its influence.

3.2. Text Mining for Tower Crane Accidents

3.3. Types of Human Error in Tower Crane Operations

3.4. Standard for Determining the Level of PSFs in the Cab of Tower Cranes

- (1)

- Diagnostic Component: This involves personnel understanding the current conditions and operational status of the system based on their knowledge and experience. They then formulate appropriate plans accordingly.

- (2)

- Executive Component: Personnel operate the equipment based on specified procedures, plans, and operational instructions.

3.5. Verification of Human Error Classification in Tower Crane Operation

4. Quantification of Human Error Probability (HEP)

4.1. Determining Interrelationships of Factors Based on DEMATEL

4.2. ANP Analysis Procedure

- Step 1: Pairwise Comparisons.

- Step 2: Forming the Supermatrix.

- Step 3: Obtaining the Weighted Supermatrix.

- Step 4: Limiting the Supermatrix.

4.3. DEMATEL-ANP Analysis Process

4.3.1. Intelligent Tower Crane Operator Misbehavior Traceability Analysis and Evaluation System

4.3.2. Data Collection

4.3.3. DEMATEL Analysis

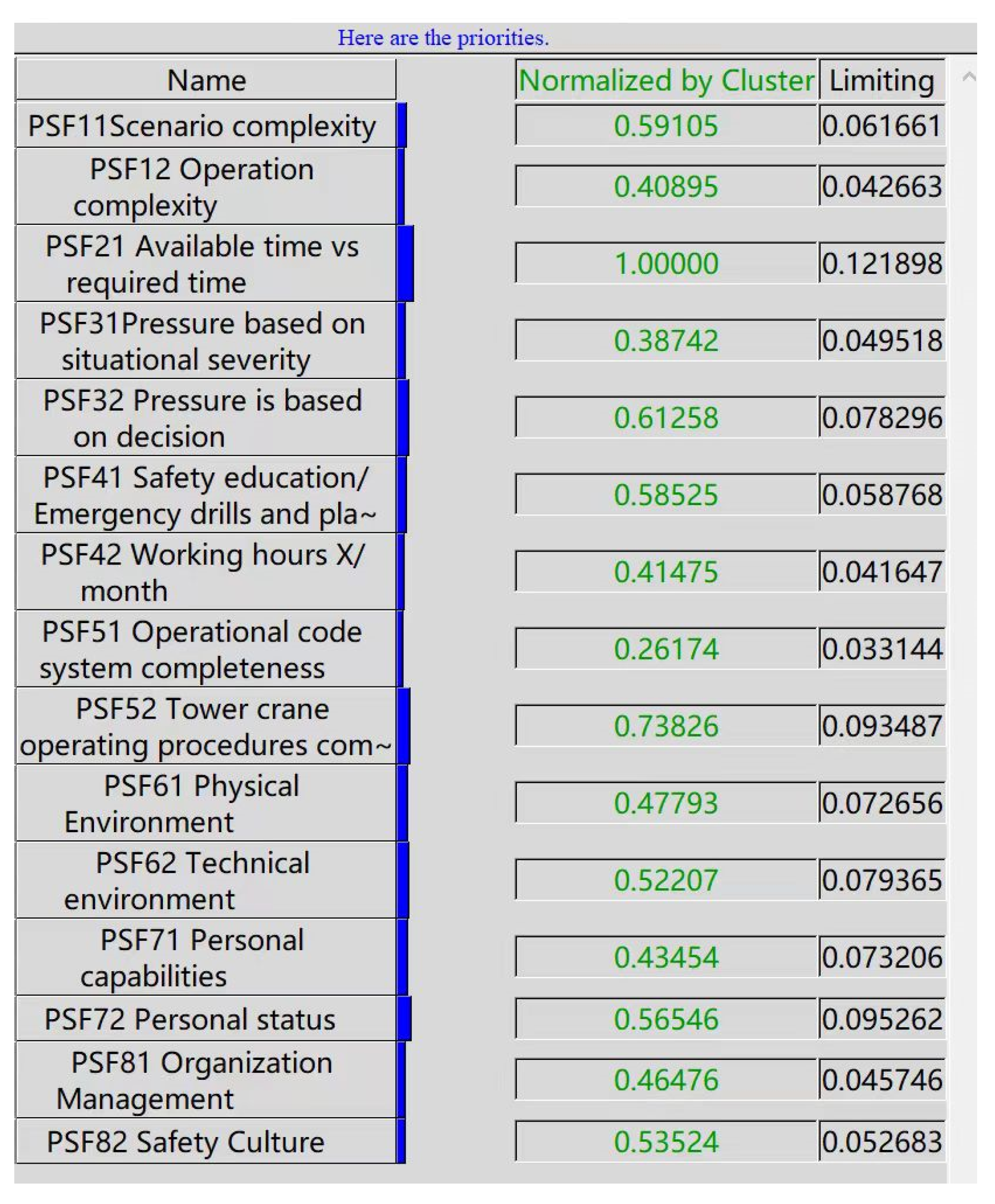

4.3.4. ANP Analysis

5. Case Calculation

5.1. Accident Background

5.2. Analysis and Calculation

- (1)

- Diagnosis: Personnel rely on their knowledge and experience to understand the current system conditions and operating status, and based on that, develop an appropriate plan.

- (2)

- Action: Personnel operate the equipment according to the corresponding procedures, instructions, and operational guidelines.

- Task Complexity: At the time of the accident, the driver had to handle the tower crane, requiring relevant experience/knowledge to make reasonable judgments. Multiple targets needed to be lifted, and they might not have the same weight or shape. There are two target paths, from point A to point B and from point A to point C. Additionally, the internal environment needed to be observed for issues. Therefore, the complexity of the diagnostic scenario during the accident is high (PSF11 Diagnosis = 5, PSF11 Action = 5). The operational part follows corresponding procedures, with discrete control actions such as pulling control levers. The diagnostic operational behavior is relatively clear, but in emergency situations, comprehensive scenario consideration is required. Thus, the diagnostic operational complexity is moderate (PSF12 Diagnosis = 5, PSF12Action = 2).

- Task Processing Time: Given the accident background, it is evident that the tower crane operator does not have sufficient time to react in the event of an emergency. Therefore, the diagnosis of PSF21 task processing time is inadequate, with PSF21 Diagnosis = 10. The accident occurs as a sudden event, and during crisis management, the operator’s task processing time for executing PSF21 is insufficient, with PSF21 Action = 10.

- Pressure: The direct cause of the accident was the loosening of the U-shaped buckle of the wire rope binding the steel pipes, constituting a sudden event. In tower crane lifting operations, operators face significant pressure during sudden events, and this incident posed a threat to life safety. There is stress based on the severity of the situation and decision-making pressure. Therefore, PSFs31 Action = 5, PSFs31 Diagnosis = 5, PSFs32 Action = 5, and PSFs32 Diagnosis = 5.

- Experience/Safety Training: The company provides minimal safety training, graded safety training, and specialized safety training for tower crane operators. Hence, safety education/emergency drills and plans (PSF41 Diagnosis/Action = 10) are lacking. Tower crane operators have over 6 months of experience or training, are familiar with basic operational knowledge, and have experience in handling emergencies. Therefore, diagnostic/action PSF42 Diagnosis/Action = 1.

- Operating Procedures System: The tower crane involved in the accident has a comprehensive sign-oriented procedure, equipped with appropriate monitoring and detection systems for visualizing the hook. It monitors parameters such as the crane’s operational status, load conditions, tilt, and vibration, to promptly detect anomalies. This supports the operator in correctly diagnosing events and effectively reduces negative outcomes due to human error. Therefore, in the diagnostic/execution completeness of the operating procedure system, PSF51 Diagnosis/Action = 0.5. Regarding this accident, the construction company has well-established operating procedures for reference and compliance. In the diagnostic availability of tower crane operation sub-procedures, PSFs52 Diagnosis = 0.5, and the execution availability and quality level are moderate (PSFs52 Action = 1).

- Human–Machine Environment: The environment where the tower crane accident occurred was relatively cold, the construction site had obstacles, and the management of construction site noise was not strict. Therefore, the physical environment for diagnosis/action (PSF61 Diagnosis/Action) = 10. The digital interface was not properly designed and somewhat chaotic, resulting in a technical environment for diagnosis/execution (PSF62 diagnosis/Action) = 1.

- Occupational Suitability: The tower crane driver had a moderate level of teamwork, knowledge, skills, and job capabilities (PSF71 Diagnosis/Action = 5). It was understood that work at the construction site often continued until late at night, and the driver had a moderate individual state during the accident (PSF72 Diagnosis/Action = 5).

- Process: The company’s organizational management had one or two areas that were not satisfactory, such as poor communication between the substitute drivers and the usual drivers as well as low reliability and level of automation. Therefore, the diagnostic/execution PSF81 Diagnosis/Action = 1. The company’s safety culture was somewhat lacking. Periodic safety production months were not regularly held to encourage employee safety commitments. There were fewer organizational safety culture promotion and education activities (PSF82 Diagnosis/Action = 5).

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Wang, J.; Guo, F.; Song, Y.; Liu, Y.; Hu, X.; Yuan, C. Safety Risk Assessment of Prefabricated Buildings Hoisting Construction: Based on IHFACS-ISAM-BN. Buildings 2022, 12, 811. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Durso, F.; Seo, J. Assessment of operator’s situation awareness for smart operation of mobile cranes. Autom. Constr. 2018, 85, 65–75. [Google Scholar] [CrossRef]

- Chen, L.; Shimei, S.; Yinjie, Z.; Mingrui, D. Statistical Analysis of Accidents Involving Tower Cranes in Construction from 2016 to 2020. Ind. Saf. Environ. Prot. 2022, 48, 53–55+63. [Google Scholar]

- Raviv, G.; Fishbain, B.; Shapira, A. Analyzing risk factors in crane-related near-miss and accident reports. Saf. Sci. 2017, 91, 192–205. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Chen, J. A framework for real-time pro-active safety assistance for mobile crane lifting operations. Autom. Constr. 2016, 72, 367–379. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Cyber physical system for safety management in smart construction site. Eng. Constr. Archit. Manag. 2020, 28, 788–808. [Google Scholar] [CrossRef]

- Stone, R.W. Industrial Accident Prevention, H. W. Heinrich; Service Review; The University of Chicago Press Books: Chicago, IL, USA, 1931; Volume 5, pp. 323–324. [Google Scholar] [CrossRef]

- Porthin, M.; Liinasuo, M.; Kling, T. Effects of digitalization of nuclear power plant control rooms on human reliability analysis—A review. Reliab. Eng. Syst. Saf. 2020, 194, 106415. [Google Scholar] [CrossRef]

- Jeon, M. Chapter 1—Emotions and Affect in Human Factors and Human–Computer Interaction: Taxonomy, Theories, Approaches, and Methods. In Emotions and Affect in Human Factors and Human-Computer Interaction; Jeon, M., Ed.; Academic Press: San Diego, CA, USA, 2017; pp. 3–26. ISBN 978-0-12-801851-4. [Google Scholar]

- Chandrasegaran, D.; Ghazilla, R.A.R.; Rich, K. Human factors engineering integration in the offshore O&G industry: A review of current state of practice. Saf. Sci. 2020, 125, 104627. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, T.; Liu, W.; Tang, J. Tower crane safety on construction sites: A complex sociotechnical system perspective. Saf. Sci. 2018, 109, 95–108. [Google Scholar] [CrossRef]

- Lingard, H.; Cooke, T.; Zelic, G.; Harley, J. A qualitative analysis of crane safety incident causation in the Australian construction industry. Saf. Sci. 2021, 133, 105028. [Google Scholar] [CrossRef]

- Sadeghi, H.; Zhang, X.; Mohandes, S.R. Developing an ensemble risk analysis framework for improving the safety of tower crane operations under coupled Fuzzy-based environment. Saf. Sci. 2023, 158, 105957. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, W.; Jiang, L.; Zhao, T. Identification of Critical Causes of Tower-Crane Accidents through System Thinking and Case Analysis. J. Constr. Eng. Manag. 2020, 146, 04020071. [Google Scholar] [CrossRef]

- Shin, I.J. Factors that affect safety of tower crane installation/dismantling in construction industry. Saf. Sci. 2015, 72, 379–390. [Google Scholar] [CrossRef]

- Kaber, D.B.; Endsley, M.R. The effects of level of automation and adaptive automation on human performance, situation awareness and workload in a dynamic control task. Theor. Issues Ergon. Sci. 2004, 5, 113–153. [Google Scholar] [CrossRef]

- Cheng, T.; Teizer, J. Modeling Tower Crane Operator Visibility to Minimize the Risk of Limited Situational Awareness. J. Comput. Civ. Eng. 2014, 28, 04014004. [Google Scholar] [CrossRef]

- Jiang, T. Safety risk analysis and control of tower crane. IOP Conf. Ser. Earth Environ. Sci. 2020, 546, 042070. [Google Scholar] [CrossRef]

- Zhang, W.; Xue, N.; Zhang, J.; Zhang, X. Identification of Critical Causal Factors and Paths of Tower-Crane Accidents in China through System Thinking and Complex Networks. J. Constr. Eng. Manag. 2021, 147, 04021174. [Google Scholar] [CrossRef]

- Ramalan, M.A.H.; Fikri, M. A Study on Human Factor That Lead to Tower Crane Accident at Construction Site in Malaysia. Recent Trends Civ. Eng. Built Environ. 2021, 2, 852–861. [Google Scholar]

- Rasmussen, M.; Standal, M.I.; Laumann, K. Task complexity as a performance shaping factor: A review and recommendations in Standardized Plant Analysis Risk-Human Reliability Analysis (SPAR-H) adaption. Saf. Sci. 2015, 76, 228–238. [Google Scholar] [CrossRef]

- Liu, J.; Zou, Y.; Wang, W.; Zhang, L.; Qing, T.; Zheng, T.; Ding, Q. A study on assigning performance shaping factors of the SPAR-H method for adequacy human reliability analysis of nuclear power plants. Int. J. Ind. Ergon. 2021, 81, 103051. [Google Scholar] [CrossRef]

- Park, J.; Jung, W. A Study on the Validity of a Task Complexity Measure for Emergency Operating Procedures of Nuclear Power Plants—Comparing with a Subjective Workload. IEEE Trans. Nucl. Sci. 2006, 53, 2962–2970. [Google Scholar] [CrossRef]

- Hoogeboom, P.; Joosse, M.; Hodgetts, H.; Straussberger, S.; Schaefer, D. Does the “silent cockpit” reduce pilot workload? In Proceedings of the 23rd Digital Avionics Systems Conference (IEEE Cat. No.04CH37576), Salt Lake City, UT, USA, 28 October 2004; Volume 1, pp. 5.D.5/1–5.D.5/9. [Google Scholar]

- Gertman, D.; Blackman, H.; Marble, J.; Smith, C.; Boring, R. The SPAR-H human reliability analysis method. In Proceedings of the Fourth American Nuclear Society International Topical Meeting on Nuclear Plant Instrumentation, Controls and Human-Machine Interface Technologies (NPIC&HMIT 2004), Columbus, OH, USA, 19–22 September 2004. [Google Scholar]

- Moriyama, T.; Ohtani, H. Risk assessment tools incorporating human error probabilities in the Japanese small-sized establishment. Saf. Sci. 2009, 47, 1379–1397. [Google Scholar] [CrossRef]

- Barati, R.; Setayeshi, S. Human reliability analysis of the Tehran research reactor using the SPAR-H method. Nucl. Technol. Radiat. Prot. 2012, 27, 319–332. [Google Scholar] [CrossRef]

- Sujan, M.A.; Embrey, D.; Huang, H. On the application of Human Reliability Analysis in healthcare: Opportunities and challenges. Reliab. Eng. Syst. Saf. 2020, 194, 106189. [Google Scholar] [CrossRef]

- Ade, N.; Peres, S.C. A review of human reliability assessment methods for proposed application in quantitative risk analysis of offshore industries. Int. J. Ind. Ergon. 2022, 87, 103238. [Google Scholar] [CrossRef]

- Maniram Kumar, A.; Rajakarunakaran, S.; Arumuga Prabhu, V. Application of Fuzzy HEART and expert elicitation for quantifying human error probabilities in LPG refuelling station. J. Loss Prev. Process Ind. 2017, 48, 186–198. [Google Scholar] [CrossRef]

- Hollnagel, E. Cognitive Reliability and Error Analysis Method: CREAM, 1st ed.; Elsevier: Oxford, UK; New York, NY, USA, 1998; ISBN 978-0-08-042848-2. [Google Scholar]

- Kančev, D. A plant-specific HRA sensitivity analysis considering dynamic operator actions and accident management actions. Nucl. Eng. Technol. 2020, 52, 1983–1989. [Google Scholar] [CrossRef]

- Abílio Ramos, M.; López Droguett, E.; Mosleh, A.; Das Chagas Moura, M. A human reliability analysis methodology for oil refineries and petrochemical plants operation: Phoenix-PRO qualitative framework. Reliab. Eng. Syst. Saf. 2020, 193, 106672. [Google Scholar] [CrossRef]

- Pandya, D.; Podofillini, L.; Emert, F.; Lomax, A.J.; Dang, V.N.; Sansavini, G. Quantification of a human reliability analysis method for radiotherapy applications based on expert judgment aggregation. Reliab. Eng. Syst. Saf. 2020, 194, 106489. [Google Scholar] [CrossRef]

- Ung, S.-T. Evaluation of human error contribution to oil tanker collision using fault tree analysis and modified fuzzy Bayesian Network based CREAM. Ocean. Eng. 2019, 179, 159–172. [Google Scholar] [CrossRef]

- Park, J.; Arigi, A.M.; Kim, J. Treatment of human and organizational factors for multi-unit HRA: Application of SPAR-H method. Ann. Nucl. Energy 2019, 132, 656–678. [Google Scholar] [CrossRef]

- Xiao, T.; Yongping, Q.; Yucheng, Z.; Wenjing, L.; Juntao, H. Study of Application Optimization of SPAR-H Human Reliability Analysis Method. In Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 2, Beijing & Chengdu, China, 1–4 November 2022; Springer Proceedings in Physics. Liu, C., Ed.; Springer Nature Singapore: Singapore, 2023; Volume 284, pp. 91–102, ISBN 978-981-19877-9-3. [Google Scholar]

- Laumann, K.; Rasmussen, M. Suggested improvements to the definitions of Standardized Plant Analysis of Risk-Human Reliability Analysis (SPAR-H) performance shaping factors, their levels and multipliers and the nominal tasks. Reliab. Eng. Syst. Saf. 2016, 145, 287–300. [Google Scholar] [CrossRef]

- Elidolu, G.; Il Ahn, S.; Ilke Sezer, S.; Emek Kurt, R.; Akyuz, E.; Gardoni, P. Applying evidential reasoning extended SPAR-H modelling to analyse human reliability on crude oil tanker cargo operation. Saf. Sci. 2023, 164, 106169. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, L.; Qing, T.; Liu, X. Use of Bayesian networks and improved SPAR-H for quantitative analysis of human reliability during severe accidents mitigation process in nuclear power plant. J. Nucl. Sci. Technol. 2021, 58, 1099–1112. [Google Scholar] [CrossRef]

- Yan, S.; Yao, K.; Li, F.; Wei, Y.; Tran, C.C. Application of a Bayesian network to quantify human reliability in nuclear power plants based on the SPAR-H method. Int. J. Occup. Saf. Ergon. 2022, 28, 2588–2598. [Google Scholar] [CrossRef]

- Yang, Y.; Karakaya, B.; Dominioni, G.C.; Kawabe, K.; Bengler, K. An HMI Concept to Improve Driver’s Visual Behavior and Situation Awareness in Automated Vehicle. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 650–655. [Google Scholar]

- Jia, Y.; Shen, X.; Lin, X. Exploration of the Development Strategy of Building Industrialization Based on the Application of Smart Construction Technology. In Proceedings of the 2023 4th International Conference on Management Science and Engineering Management (ICMSEM 2023), Nanchang, China, 2–4 June 2023; Advances in Economics, Business and Management Research. Zailani, S.H.B.D.M., Yagapparaj, K., Zakuan, N., Eds.; Atlantis Press International BV: Dordrecht, Germany, 2024; Volume 259, pp. 1175–1185, ISBN 978-94-6463-255-2. [Google Scholar]

- Wu, H.-H.; Chen, H.-K.; Shieh, J.-I. Evaluating performance criteria of Employment Service Outreach Program personnel by DEMATEL method. Expert Syst. Appl. 2010, 37, 5219–5223. [Google Scholar] [CrossRef]

- Liu, P.; Qiu, Y.; Hu, J.; Tong, J.; Zhao, J.; Li, Z. Expert judgments for performance shaping Factors’ multiplier design in human reliability analysis. Reliab. Eng. Syst. Saf. 2020, 194, 106343. [Google Scholar] [CrossRef]

- Dehdasht, G.; Mohamad Zin, R.; Ferwati, M.; Mohammed Abdullahi, M.; Keyvanfar, A.; McCaffer, R. DEMATEL-ANP Risk Assessment in Oil and Gas Construction Projects. Sustainability 2017, 9, 1420. [Google Scholar] [CrossRef]

- Pourahmad, A.; Hosseini, A.; Banaitis, A.; Nasiri, H.; Banaitienė, N.; Tzeng, G.-H. Combination of fuzzy-ahp and dematel-anp with gis in a new hybrid mcdm model used for the selection of the best space for leisure in a blighted urban site. Technol. Econ. Dev. Econ. 2015, 21, 773–796. [Google Scholar] [CrossRef]

- Sebastiani, F. Machine learning in automated text categorization. ACM Comput. Surv. 2002, 34, 1–47. [Google Scholar] [CrossRef]

- Qaiser, S.; Ali, R. Text Mining: Use of TF-IDF to Examine the Relevance of Words to Documents. IJCA 2018, 181, 25–29. [Google Scholar] [CrossRef]

- Soumya, G.K.; Shibily, J.; Department of Computer Science and Engineering, Government Engineering College, Thrissur, India; George, K.S.; Joseph, S. Text Classification by Augmenting Bag of Words (BOW) Representation with Co-occurrence Feature. IOSR J. Comput. Eng. 2014, 16, 34–38. [Google Scholar] [CrossRef]

- Dzieciątko, M. Application of Text Analytics to Analyze Emotions in the Speeches. In Information Technology in Biomedicine; Advances in Intelligent Systems and Computing; Pietka, E., Badura, P., Kawa, J., Wieclawek, W., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 762, pp. 525–536. ISBN 978-3-319-91210-3. [Google Scholar]

- Falini, A. A review on the selection criteria for the truncated SVD in Data Science applications. J. Comput. Math. Data Sci. 2022, 5, 100064. [Google Scholar] [CrossRef]

- Niu, Y.; Fan, Y.; Ju, X. Critical review on data-driven approaches for learning from accidents: Comparative analysis and future research. Saf. Sci. 2024, 171, 106381. [Google Scholar] [CrossRef]

- Shishkin, S.L.; Shalaginov, A.; Bopardikar, S.D. Fast approximate truncated SVD. Numer. Linear Algebra Appl. 2019, 26, e2246. [Google Scholar] [CrossRef]

- Kim, S.-W.; Gil, J.-M. Research paper classification systems based on TF-IDF and LDA schemes. Hum. Cent. Comput. Inf. Sci. 2019, 9, 30. [Google Scholar] [CrossRef]

- Dewi, C.; Chen, R.-C. Complement Naive Bayes Classifier for Sentiment Analysis of Internet Movie Database. In Intelligent Information and Database Systems; Nguyen, N.T., Tran, T.K., Tukayev, U., Hong, T.-P., Trawiński, B., Szczerbicki, E., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2022; Volume 13757, pp. 81–93. ISBN 978-3-031-21742-5. [Google Scholar]

- Lukan, J.; Bolliger, L.; Pauwels, N.S.; Luštrek, M.; Bacquer, D.D.; Clays, E. Work environment risk factors causing day-to-day stress in occupational settings: A systematic review. BMC Public Health 2022, 22, 240. [Google Scholar] [CrossRef] [PubMed]

- Groth, K.M.; Mosleh, A. A data-informed PIF hierarchy for model-based Human Reliability Analysis. Reliab. Eng. Syst. Saf. 2012, 108, 154–174. [Google Scholar] [CrossRef]

- Parhizkar, T.; Utne, I.B.; Vinnem, J.-E. Human Factor Analysis and Quantification. In Online Probabilistic Risk Assessment of Complex Marine Systems; Springer Series in Reliability Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 75–102. ISBN 978-3-030-88097-2. [Google Scholar]

- Ham, D.-H.; Park, J.; Jung, W. Model-based identification and use of task complexity factors of human integrated systems. Reliab. Eng. Syst. Saf. 2012, 100, 33–47. [Google Scholar] [CrossRef]

- Sandi, C. Stress and cognition. WIRES Cogn. Sci. 2013, 4, 245–261. [Google Scholar] [CrossRef]

- Pooladvand, S.; Hasanzadeh, S. Neurophysiological evaluation of workers’ decision dynamics under time pressure and increased mental demand. Autom. Constr. 2022, 141, 104437. [Google Scholar] [CrossRef]

- Gottschalk, M.G.; Domschke, K.; Schiele, M.A. Epigenetics Underlying Susceptibility and Resilience Relating to Daily Life Stress, Work Stress, and Socioeconomic Status. Front. Psychiatry 2020, 11, 163. [Google Scholar] [CrossRef] [PubMed]

- Kerautret, L.; Dabic, S.; Navarro, J. Exploration of driver stress when resuming control from highly automated driving in an emergency situation. Transp. Res. Part F Traffic Psychol. Behav. 2023, 93, 222–234. [Google Scholar] [CrossRef]

- Rivaldo, Y.; Nabella, S.D. Employee Performance: Education, Training, Experience and Work Discipline. QAS 2023, 24, 182–188. [Google Scholar] [CrossRef]

- Choudhry, R.M. Behavior-based safety on construction sites: A case study. Accid. Anal. Prev. 2014, 70, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Li, Z. A study on the effect of training interval on the use of computerized emergency operating procedures. Reliab. Eng. Syst. Saf. 2011, 96, 250–256. [Google Scholar] [CrossRef]

- O’Keefe, R.M.; O’Leary, D.E. Expert system verification and validation: A survey and tutorial. Artif. Intell. Rev. 1993, 7, 3–42. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, L.; Dai, L.; Li, P.; Qing, T. Human Reliability Analysis for Digitized Nuclear Power Plants: Case Study on the LingAo II Nuclear Power Plant. Nucl. Eng. Technol. 2017, 49, 335–341. [Google Scholar] [CrossRef]

- Chemweno, P.; Pintelon, L.; Van Horenbeek, A.; Muchiri, P. Development of a risk assessment selection methodology for asset maintenance decision making: An analytic network process (ANP) approach. Int. J. Prod. Econ. 2015, 170, 663–676. [Google Scholar] [CrossRef]

- Maynard, S.; Filtness, A.; Miller, K.; Pilkington-Cheney, F. Bus driver fatigue: A qualitative study of drivers in London. Appl. Ergon. 2021, 92, 103309. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.-W.; Chiang, T.-L. Reducing occupational injuries attributed to inattentional blindness in the construction industry. Saf. Sci. 2016, 89, 129–137. [Google Scholar] [CrossRef]

- Chen, L.; Li, H.; Tian, S. Application of AHP and DEMATEL for Identifying Factors Influencing Coal Mine Practitioners’ Unsafe State. Sustainability 2022, 14, 14511. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, N.; Jiang, H.; Wang, S.; Wang, W.; Wang, J. Psychological Driving Mechanism of Safety Citizenship Behaviors of Construction Workers: Application of the Theory of Planned Behavior and Norm Activation Model. J. Constr. Eng. Manag. 2020, 146, 04020027. [Google Scholar] [CrossRef]

- Stern, H.S.; Blower, D.; Cohen, M.L.; Czeisler, C.A.; Dinges, D.F.; Greenhouse, J.B.; Guo, F.; Hanowski, R.J.; Hartenbaum, N.P.; Krueger, G.P.; et al. Data and methods for studying commercial motor vehicle driver fatigue, highway safety and long-term driver health. Accid. Anal. Prev. 2019, 126, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Osintsev, N.; Rakhmangulov, A.; Baginova, V. Evaluation of logistic flows in green supply chains based on the combined dematel-anp method. FU Mech. Eng. 2021, 19, 473. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Güleryüz, S. An integrated DEMATEL-ANP approach for renewable energy resources selection in Turkey. Int. J. Prod. Econ. 2016, 182, 435–448. [Google Scholar] [CrossRef]

- Ghosh, S.; Das Chatterjee, N.; Dinda, S. Urban ecological security assessment and forecasting using integrated DEMATEL-ANP and CA-Markov models: A case study on Kolkata Metropolitan Area, India. Sustain. Cities Soc. 2021, 68, 102773. [Google Scholar] [CrossRef]

- Zaman, U.K.U.; Rivette, M.; Siadat, A.; Mousavi, S.M. Integrated product-process design: Material and manufacturing process selection for additive manufacturing using multi-criteria decision making. Robot. Comput. Integr. Manuf. 2018, 51, 169–180. [Google Scholar] [CrossRef]

- Der, O.; Başar, G.; Ordu, M. Statistical Investigation of the Effect of CO2 Laser Cutting Parameters on Kerf Width and Heat Affected Zone in Thermoplastic Materials. J. Mater. Mechatron. A 2023, 4, 459–474. [Google Scholar] [CrossRef]

- Saaty, T.L. Theory and Applications of the Analytic Network Process: Decision Making with Benefits, Opportunities, Costs, and Risks; RWS Publications: Pittsburgh, PA, USA, 2009; ISBN 978-1-888603-06-4. [Google Scholar]

- Lee, G.; Cho, J.; Ham, S.; Lee, T.; Lee, G.; Yun, S.-H.; Yang, H.-J. A BIM- and sensor-based tower crane navigation system for blind lifts. Autom. Constr. 2012, 26, 1–10. [Google Scholar] [CrossRef]

- Jannati, M.; Aghaei, H.; Askaripoor, T.; Khazaei, M.; Khalaji, E.B.; Kazemi, E. Ergonomic Assessment and Design of the Tower Crane Cabin Based on Anthropometric Dimensions of Iranian Operators. Iran J. Ergon. 2020, 8, 26–38. [Google Scholar] [CrossRef]

| Impact Factors | Frequency | Impact Factors | Frequency | Impact Factors | Frequency |

|---|---|---|---|---|---|

| Feel unwell | 0.1273 | Teamwork | 0.0202 | Cockpit temperature | 0.0015 |

| Physical state | 0.0079 | Teamwork | 0.0015 | Cockpit humidity | 0.0014 |

| Illness | 0.0318 | Operating specification | 0.0099 | Illumination | 0.0028 |

| Health | 0.0015 | Operating system | 0.0128 | Hue | 0.0014 |

| Fatigued | 0.0012 | Rules and regulations | 0.0124 | Noise | 0.0014 |

| Dispersion of attention | 0.0012 | Reward and punishment system | 0.0028 | Vibration | 0.0012 |

| Distracted | 0.0020 | Management system | 0.0076 | Crossing condition | 0.0014 |

| Inattention | 0.0021 | Job training | 0.0318 | Construction site | 0.0049 |

| Emotional stability | 0.0014 | Safety education | 0.0341 | Site obstacle | 0.0330 |

| Testiness | 0.0021 | Job management | 0.0012 | Weather | 0.0034 |

| Safety awareness | 0.0069 | Operating procedure | 0.0180 | Digital interface display | 0.0049 |

| Professional skill | 0.0861 | Technical specification | 0.0036 | Digital interface information delivery | 0.0055 |

| Operational skill | 0.0359 | Regulation | 0.0031 | Information transmission | 0.0082 |

| Defense | 0.0038 | Long working hours | 0.1220 | Safety sign | 0.0440 |

| Safety belt | 0.0029 | Work schedule is not reasonable | 0.0012 | Display and control page layout | 0.0070 |

| Safety Helmet | 0.0015 | Cable worker communication | 0.0021 | Display and control operation mode | 0.0015 |

| Safety measure | 0.0018 | Signalman | 0.0096 | Display and control device density | 0.0073 |

| Protective device | 0.0015 | Untimely signal | 0.0055 | Drive-by-wire reliability | 0.0144 |

| Working hours | 0.0021 | Improper command | 0.0250 | Space comfort | 0.0063 |

| Staffing | 0.0023 | Emergency drill | 0.0507 | Cockpit seat comfort | 0.0011 |

| Distribution of responsibilities | 0.0423 | Emergency plan | 0.0032 | Communication equipment | 0.0064 |

| Time pressure | 0.0091 | Preventive measures | 0.0061 | System intelligence | 0.0076 |

| Time shortage | 0.0334 | Working atmosphere | 0.0954 | System reliability | 0.0070 |

| PSFs | Human Error Factor | Index | Description | Literature Reference |

|---|---|---|---|---|

| Task availability time | Time pressure | Time pressure, time shortage | The time crunch and pressure that tower crane drivers feel at work | [62] |

| Experience and training | Adequacy of job training | Job training, safety education | Whether the work training is similar to the actual working conditions of the tower crane, and whether it covers all working scenarios | [18] |

| Emergency drills and plans | Emergency drills, emergency plans, preventive measures | The frequency and quality of emergency drills and the adequacy of safety plans for emergencies | [18] | |

| Human–machine environment | Digital interface information delivery | Device interface information is poorly designed, device is over-used/fatigued, and device panel alarm is not clear | The prominence of important information display in the digital interface, the speed of obtaining information, text, icon symbols | [76] |

| Mandatory sign | Safety sign | Clarity, legibility, and reliability | [17] | |

| Crossing conditions, site obstacles | Crossing condition | The accuracy and differentiation of relevant indicator symbols and marks in the display control panel | [76] | |

| Construction site, site road conditions | Multiple working conditions or conditions that exist at the construction site simultaneously and affect each other | |||

| Display and control device layout | Display and control page layout, display and control operation mode, display and control device density, display and control device reliability | Road and traffic conditions around the construction site | [77] | |

| Overall spatial layout | Space comfort, vision, operating lever | The visibility of the display device, the position reachability of the control device, and the corresponding relation of the display and control combination layout | [77] | |

| Cockpit seat | Cockpit seat | Department, function division in line with personnel experience and expectations | [2] | |

| Communication equipment | Communication equipment | Structural dimensions of work areas, channels, and activity Spaces | [18] | |

| Abnormal climate change | Weather anomaly | The degree to which the structure of the seat matches the operation of the sitting position and the comfort of the human spine | [77] | |

| Lighting, color | Lighting, color | The good working condition of communication equipment, the stability and clarity of communication signals | [77] | |

| Noise and vibration | Noise and vibration | Unusual or abrupt weather conditions at the construction site will affect the work of the tower crane driver | [77] | |

| Completeness of operating system standards | Operation standard, operation system | Whether the lighting and color are conducive to the visual recognition function of personnel, visual information exchange, etc. | [18] | |

| Operating procedure | Completeness of operating procedures for tower cranes | Complete operating procedures, technical procedures | Whether noise and vibration are beneficial to people’s auditory sensitivity, manipulation accuracy, and emotional state | [16] |

| Rationality of reward and punishment system | Rules and regulations, reward and punishment system, management system | Organization and management, operating standards and systems are scientific and accurate | [18] | |

| Process | Clear division of labor and responsibilities | Division of labor, staffing, responsibility distribution | The adequacy of procedures and specifications for the flight deck crew to perform operational tasks | [18] |

| Degree of teamwork | Teamwork | Whether the reward and punishment system can effectively mobilize the enthusiasm of tower crane drivers | [76] | |

| Communicate properly with the operator | Cable worker and signal worker communication, signal is not timely, improper command | The positioning of the tower crane staff for their role and the clarity of their job responsibilities | [16] | |

| System automation level | System intelligence, system reliability | The quality of information exchange between staff and the quality of operation coordination | [14] | |

| Working atmosphere | Working atmosphere | Able to communicate properly with the operator and ensure smooth work | [20] | |

| Safety atmosphere | Safety culture, safety training | Automation system reliability, equipment complexity | ||

| Fatigue degree | Fatigued | Harmonious working atmosphere | [77] | |

| Occupational suitability | Physical fitness | Physical discomfort, physical condition, disease | Relevant departments supervise building safety and publicize and educate around safety culture | [77] |

| Knowledge skills and business ability | Safety awareness, professional skills, operational skills | An individual’s subjective perception of physical fatigue | [17] | |

| Degree of teamwork | Teamwork | Whether the personal physical quality is good, such as eyesight, physical coordination, and other elements | [12] | |

| Concentration level | Distraction, inattention | The reserve of personal knowledge of tower cranes, the mastery level of tower crane skills, and the cognition and decision-making levels of situational awareness | [72] | |

| Emotional state | Emotionally stable, irritable | The quality of information exchange and operation cooperation between team members | [12] | |

| Working time rationality | Long working hours and unreasonable working schedule | Personal focus on work | [12] |

| PSFs | Level | Adjustment Factor | ||

|---|---|---|---|---|

| PSF11 Scenario Complexity | More than three changing targets need to be monitored | Meeting three is very high | 5 | |

| PSF12 Operation Complexity | The observed parameters need to be calculated/ estimated/transformed | Meeting two is high | 2 | |

| Need to recall relevant experience/knowledge to make judgment | Satisfying less than two is normal | 1 | ||

| Different alarm signals need to be distinguished | ||||

| PSF1 task complexity | Common sense can accomplish this | Easy to diagnose | 0.1 | |

| The operation is simple/l to 2 objects need to be observed | Normal | 1 | ||

| The complexity of the operation requires that multiple objects be observed simultaneously | Medium complexity | 2 | ||

| Tasks are beyond the operator’s cognitive and skill level | Highly complex | 5 | ||

| Insufficient information | 1 | |||

| PSF2 task processing time | PSF11 Available time vs. required time | ≥50 times the required time | Time affluence | 0.01 |

| ≥5 times the required time | Plenty of time | 0.1 | ||

| ≈Required time | Just in time | 1 | ||

| ≈2/3 times the required time | Hardly enough time | 10 | ||

| Insufficient information | 1 | |||

| PSF3 Pressure | PSF31Pressure based on the severity of the situation | The operator has no life-threatening pressure | Normal | 1 |

| Operator experiencing low life-threatening pressure | High | 2 | ||

| Operator experiencing high life-threatening pressure | Very high | 5 | ||

| Insufficient information | 1 | |||

| PSF32 Pressure based on the severity of the | The operator has no life-threatening pressure | Normal | 1 | |

| Decision | Operator experiencing low life-threatening pressure | High | 2 | |

| Operator experiencing high life-threatening pressure | Very high | 5 | ||

| Insufficient information | 1 | |||

| PSF4 Experience/safety training | PSF41 Safety Education/Emergency Drills and plans | 1. Receive safety training before operation | All satisfied | 0.5 |

| 2. Regular safety training | Normal: 1 or 2 items are not satisfied | 1 | ||

| 3. Classified safety training | Low: More than 2 items are not satisfied | 10 | ||

| 4. Graded safety training | Insufficient information | 1 | ||

| 5. Special safety training | ||||

| PSF42 Working hours X/month | X ≥ 12 | High | 0.5 | |

| 6 ≤ X ≤ 12 | Normal | 1 | ||

| X ≤ 12 | Low | 10 | ||

| Insufficient information | 1 | |||

| PSF51 operating code system completeness | 1. Symptom-oriented procedure | Good | 0.5 | |

| 2. It matches with the current task and has a direct guiding role | Normal | 1 | ||

| PSF5 Operating procedures | 3. The number of operating procedures is less than the actual number of steps | Range | 5 | |

| 4. No operating procedures | Worse | 20 | ||

| Insufficient information | 1 | |||

| 1. Symptom oriented procedure | Good | 0.5 | ||

| PSF52 Tower crane operating procedure completeness | 2. It matches with the current task and has a direct guiding role | Normal | 1 | |

| 3. The number of operating procedures is less than the actual number of steps | Range | 5 | ||

| 4. No operating procedures | Worse | 20 | ||

| Insufficient information | 1 | |||

| PSF6 Human–machine environment | PSF61 Physical environment | 1. Lighting, color suitable | All satisfied | 0.5 |

| 2. The noise is not more than 88 db | Normal: 1 or 2 items are not satisfied | 1 | ||

| 3. Clear indication mark | Low: More than 2 items are not satisfied | 10 | ||

| 4. Cross conditions are clear, no obstacles on the site | Insufficient information | 1 | ||

| 5. The overall layout of the cab space is suitable | ||||

| 6. The height of the cab seat and the operating table is suitable, and the seat is suitable | ||||

| 7. Suitable temperature and humidity | ||||

| 8. The climate is suitable | ||||

| PSF62 Technical environment | 1. The digital interface is clear | All satisfied | 0.5 | |

| 2. Excessive/fatigued use of equipment | Normal: 1 or 2 items are not satisfied | 1 | ||

| 3. Communication equipment functions normally | Low: More than 2 items are not satisfied | 10 | ||

| 4. The device panel alarm is not clear | Insufficient information | 1 | ||

| 5. The density of display and control equipment is suitable | ||||

| 6. Display and control operation mode is suitable | ||||

| 7. Reliability of display and control device | ||||

| PSF7 Occupational suitability | PSF71 Personal capabilities | 1. Have sufficient team cooperation, knowledge, skills and business ability | Good | 1 |

| 2. General level of team cooperation, knowledge, skills, and business ability | Normal | 5 | ||

| 3. Less team cooperation, knowledge, skills, and business ability | Indisposition | P (Failure) = 1.0 | ||

| PSF72 Individual status | 1. Individual state (physical fitness, fatigue, concentration) can complete the task with high quality | Good | 1 | |

| 2. Individual state (physical fitness, fatigue, concentration) can complete the task | Normal | 5 | ||

| 3. Individual state (physical fitness, fatigue, concentration) cannot complete the task | Indisposition | P(Failure) = 1.0 | ||

| PSF8 Process | PSF81 Organization Management | 1. Reasonable staffing and responsibility allocation | All satisfied | 0.8 (diagnosis)/0.5 (action) |

| 2. Perfect reward and punishment system | Normal: 1 or 2 items are not satisfied | 1 | ||

| 3. High degree of teamwork | Low: More than 2 items are not satisfied | 5 | ||

| 4. Unimpeded communication with the cable operator, cable operator commands properly | Insufficient information | 1 | ||

| 5. Regular safety training | ||||

| 6. High reliability and intelligence of the system | ||||

| PSF82 Safety Culture | 1. Incorporate safety culture construction into cultural construction planning | All satisfied | 0.8 (diagnosis)/0.5 (action) | |

| 2. Organize safety culture publicity and educational activities in various forms | Normal: 1 or 2 items are not satisfied | 1 | ||

| 3. Disclose the contact information of safety complaints | Low: More than 2 items are not satisfied | 5 | ||

| 4. Hold safety production month | Insufficient information | 1 | ||

| 5. Carry out safety commitment activities | ||||

| Factor | AVE | CR |

|---|---|---|

| PSF1 | 0.691 | 0.94 |

| PSF2 | 0.753 | 0.859 |

| PSF3 | 0.682 | 0.951 |

| PSF4 | 0.71 | 0.907 |

| PSF5 | 0.622 | 0.831 |

| PSF6 | 0.716 | 0.968 |

| PSF7 | 0.659 | 0.939 |

| PSF8 | 0.672 | 0.953 |

| PSF1 | PSF2 | PSF3 | PSF4 | PSF5 | PSF6 | PSF7 | PSF8 | |

|---|---|---|---|---|---|---|---|---|

| PSF1 | 0.831 | |||||||

| PSF2 | 0.934 | 0.868 | ||||||

| PSF3 | 0.944 | 0.93 | 0.826 | |||||

| PSF4 | 0.926 | 0.907 | 0.931 | 0.843 | ||||

| PSF5 | 0.891 | 0.881 | 0.914 | 0.877 | 0.788 | |||

| PSF6 | 0.945 | 0.929 | 0.971 | 0.943 | 0.909 | 0.846 | ||

| PSF7 | 0.935 | 0.903 | 0.942 | 0.923 | 0.907 | 0.949 | 0.812 | |

| PSF8 | 0.947 | 0.925 | 0.956 | 0.934 | 0.902 | 0.963 | 0.949 | 0.82 |

| Target Layer | Criterion Layer | Index Level |

|---|---|---|

| PSF1 task complexity | PSF11 Scenario complexity | |

| PSF12 Operation complexity | ||

| PSF2 task processing time | PSF21 Available time vs. required time | |

| F3 Pressure | PSF31 Pressure based on situational severity | |

| Human error | PSF32 Pressure based on situational severity in terms of decisions | |

| PSF4 Experience/safety training | PSF41 Safety education/Emergency drills and plans | |

| PSF42 Working hours X/month | ||

| PSF5 Operating procedures | PSF51 Operational code system completeness | |

| PSF52 Tower crane operating procedure completeness | ||

| PSF6 Human–Machine Environment | PSF61 Physical Environment | |

| PSF62 Technical environment | ||

| PSF7 Occupational suitability | PSF71 Personal capabilities | |

| PSF72 Personal status | ||

| PSF8 Process | PSF81 Organization Management | |

| PSF82 Safety Culture |

| Years of Experience in Construction | Job Position | ||||||

|---|---|---|---|---|---|---|---|

| Description | Less than 10 years | 10–20 years | More than 20 years | Safety supervisor | Equipment maintenance technician | Tower crane operator | Quality control personnel |

| Number of people | 2 | 7 | 1 | 4 | 2 | 3 | 1 |

| Percent | 20% | 70% | 10% | 40% | 20% | 30% | 10% |

| F11 | F12 | F21 | F31 | F32 | F41 | F42 | F51 | F52 | F61 | F62 | F71 | F72 | F81 | F82 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F11 | 0.00 | 0.79 | 1.10 | 1.21 | 1.31 | 0.95 | 1.05 | 1.26 | 1.00 | 1.21 | 0.84 | 0.68 | 0.74 | 0.95 | 0.79 |

| F12 | 0.73 | 0.00 | 0.29 | 0.26 | 0.18 | 0.44 | 0.29 | 0.48 | 0.51 | 0.26 | 0.33 | 0.15 | 0.11 | 0.40 | 0.18 |

| F21 | 0.36 | 1.07 | 0.00 | 1.07 | 0.87 | 1.17 | 0.77 | 1.23 | 1.12 | 1.17 | 1.33 | 0.61 | 0.77 | 1.17 | 0.97 |

| F31 | 0.87 | 0.82 | 0.68 | 0.00 | 0.68 | 1.11 | 0.82 | 1.01 | 0.97 | 0.87 | 0.68 | 1.11 | 0.92 | 1.16 | 0.87 |

| F32 | 0.98 | 0.33 | 0.84 | 0.75 | 0.00 | 0.75 | 0.65 | 1.07 | 0.98 | 0.84 | 0.89 | 0.61 | 0.51 | 1.03 | 0.89 |

| F41 | 0.72 | 1.18 | 1.08 | 1.02 | 0.92 | 0.00 | 0.77 | 1.08 | 0.97 | 1.18 | 1.08 | 1.28 | 1.18 | 0.92 | 0.87 |

| F42 | 0.63 | 0.83 | 0.53 | 0.88 | 1.02 | 0.49 | 0.00 | 0.97 | 1.07 | 0.78 | 0.83 | 0.97 | 0.92 | 0.83 | 0.97 |

| F51 | 0.90 | 1.00 | 1.30 | 1.15 | 1.25 | 0.80 | 0.90 | 0.00 | 1.00 | 1.05 | 1.20 | 1.10 | 1.15 | 0.70 | 0.85 |

| F52 | 1.00 | 0.95 | 0.90 | 1.05 | 1.09 | 0.81 | 0.95 | 0.71 | 0.00 | 0.67 | 0.86 | 0.71 | 0.62 | 0.52 | 0.33 |

| F61 | 0.72 | 0.29 | 0.95 | 0.91 | 1.05 | 0.95 | 1.00 | 1.05 | 0.86 | 0.00 | 0.81 | 0.67 | 0.52 | 0.91 | 1.00 |

| F62 | 0.92 | 0.56 | 1.17 | 0.92 | 1.12 | 1.12 | 1.02 | 1.27 | 0.97 | 1.02 | 0.00 | 0.92 | 1.02 | 0.87 | 0.82 |

| F71 | 0.99 | 1.10 | 0.82 | 1.32 | 0.99 | 1.43 | 1.26 | 1.32 | 0.99 | 0.88 | 1.10 | 0.00 | 1.26 | 1.04 | 1.15 |

| F72 | 1.08 | 0.70 | 0.91 | 1.08 | 0.75 | 1.35 | 1.18 | 1.29 | 1.24 | 1.40 | 0.91 | 0.81 | 0.00 | 1.02 | 1.18 |

| F81 | 1.01 | 0.48 | 1.28 | 1.39 | 1.34 | 1.01 | 1.12 | 0.96 | 0.75 | 1.12 | 1.23 | 1.34 | 1.28 | 0.00 | 1.23 |

| F82 | 0.89 | 1.00 | 1.05 | 1.15 | 1.26 | 0.95 | 1.10 | 0.79 | 0.53 | 1.21 | 0.95 | 0.84 | 1.05 | 1.15 | 0.00 |

| r | s | r + s | r − s | |

|---|---|---|---|---|

| F11 | 26.4 | 23.9 | 50.3 | 2.5 |

| F12 | 12.6 | 21.8 | 34.4 | −9.2 |

| F21 | 26.8 | 25.7 | 52.5 | 1.1 |

| F31 | 26 | 27.9 | 53.9 | −1.9 |

| F32 | 23.8 | 27.3 | 51.1 | −3.5 |

| F41 | 27.8 | 26.5 | 54.3 | 1.3 |

| F42 | 24.1 | 25.5 | 49.6 | −1.4 |

| F51 | 28.7 | 28.9 | 57.6 | −0.2 |

| F52 | 23.5 | 25.9 | 49.4 | −2.4 |

| F61 | 24.5 | 26.9 | 51.4 | −2.4 |

| F62 | 26.9 | 25.9 | 52.8 | 1 |

| F71 | 28.5 | 23.5 | 52 | 5 |

| F72 | 27.7 | 23.8 | 51.5 | 3.9 |

| F81 | 29.1 | 25.4 | 54.5 | 3.7 |

| F82 | 26.5 | 24 | 50.5 | 2.5 |

| Target Layer | Criterion Layer | Index Level | Mixed Weights | Normalized Weights |

|---|---|---|---|---|

| PSF1 Task complexity | PSF11 Scenario complexity | 0.986 | 0.071 | |

| PSF12 Operation complexity | 0.347 | 0.025 | ||

| PSF2 Task processing time | PSF21 Available time vs. required time | 0.971 | 0.070 | |

| F3 Pressure | PSF31 Pressure based on situational severity | 0.881 | 0.064 | |

| Human error | PSF32 Pressure based on situational severity in terms of decisions | 0.808 | 0.058 | |

| PSF4 Experience/safety training | PSF41 Safety education/Emergency drills and plans | 1.031 | 0.075 | |

| PSF42 Working hours X/month | 0.836 | 0.060 | ||

| PSF5 Operating procedures | PSF51 Operational code system completeness | 1.058 | 0.077 | |

| PSF52 Tower crane operating procedure completeness | 0.824 | 0.060 | ||

| PSF6 Human–Machine Environment | PSF61 Physical Environment | 0.843 | 0.061 | |

| PSF62 Technical environment | 0.998 | 0.072 | ||

| PSF7 Occupational suitability | PSF71 Personal capabilities | 1.076 | 0.078 | |

| PSF72 Personal status | 1.045 | 0.076 | ||

| PSF8 Process | PSF81 Organization Management | 1.131 | 0.082 | |

| PSF82 Safety Culture | 0.989 | 0.072 |

| PSF | Diagnosis | Weight | Adjustment Factor | Result | Action | Weight | Adjustment Factor | Result |

|---|---|---|---|---|---|---|---|---|

| PSF1 Task complexity | PSF11 Scenario complexity | 0.071 | 5 | 0.355 | PSF11 Scenario complexity | 0.071 | 5 | 0.355 |

| PSF12 Operation complexity | 0.025 | 5 | 0.125 | PSF12 Operation complexity | 0.025 | 2 | 0.05 | |

| PSF2 Task processing time | PSF21 Available time vs. required time | 0.07 | 10 | 0.7 | PSF21 Available time vs. required time | 0.07 | 10 | 0.7 |

| F3 Pressure | PSF31 Pressure based on situational severity | 0.064 | 5 | 0.32 | PSF31 Pressure based on situational severity | 0.064 | 5 | 0.32 |

| PSF32 Pressure based on situational severity in terms of decisions | 0.058 | 5 | 0.29 | PSF32 Pressure based on situational severity in terms of decisions | 0.058 | 5 | 0.29 | |

| PSF4 Experience/safety training | PSF41 Safety education/Emergency drills and plans | 0.075 | 10 | 0.75 | PSF41 Safety education/Emergency drills and plans | 0.075 | 10 | 0.75 |

| PSF42 Working hours X/month | 0.06 | 1 | 0.06 | PSF42 Working hours X/month | 0.06 | 1 | 0.06 | |

| PSF5 Operating procedures | PSF51 Operational code system completeness | 0.077 | 0.5 | 0.0385 | PSF51 Operational code system completeness | 0.077 | 0.5 | 0.0385 |

| PSF52 Tower crane operating procedure completeness | 0.06 | 0.5 | 0.03 | PSF52 Tower crane operating procedures completeness | 0.06 | 1 | 0.06 | |

| PSF6 Human–Machine Environment | PSF61 Physical Environment | 0.061 | 10 | 0.61 | PSF61 Physical Environment | 0.061 | 10 | 0.61 |

| PSF62 Technical environment | 0.072 | 1 | 0.072 | PSF62 Technical environment | 0.072 | 1 | 0.072 | |

| PSF7 Occupational suitability | PSF71 Personal capabilities | 0.078 | 5 | 0.39 | PSF71 Personal capabilities | 0.078 | 5 | 0.39 |

| PSF72 Personal status | 0.076 | 5 | 0.38 | PSF72 Personal status | 0.076 | 5 | 0.38 | |

| PSF8 Process | PSF81 Organization Management | 0.082 | 1 | 0.082 | PSF81 Organization Management | 0.082 | 1 | 0.082 |

| PSF82 Safety Culture | 0.072 | 5 | 0.36 | PSF82 Safety Culture | 0.072 | 5 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, W.; Niu, L. Enhancing Human Reliability Prediction in Smart Tower Crane Interfaces: A Refined Approach Using Simplified Plant Analysis Risk–Human Reliability Assessment and the Decision Making Trial and Evaluation Laboratory–Analytic Network Process. Buildings 2024, 14, 1083. https://doi.org/10.3390/buildings14041083

Si W, Niu L. Enhancing Human Reliability Prediction in Smart Tower Crane Interfaces: A Refined Approach Using Simplified Plant Analysis Risk–Human Reliability Assessment and the Decision Making Trial and Evaluation Laboratory–Analytic Network Process. Buildings. 2024; 14(4):1083. https://doi.org/10.3390/buildings14041083

Chicago/Turabian StyleSi, Wen, and Lixia Niu. 2024. "Enhancing Human Reliability Prediction in Smart Tower Crane Interfaces: A Refined Approach Using Simplified Plant Analysis Risk–Human Reliability Assessment and the Decision Making Trial and Evaluation Laboratory–Analytic Network Process" Buildings 14, no. 4: 1083. https://doi.org/10.3390/buildings14041083

APA StyleSi, W., & Niu, L. (2024). Enhancing Human Reliability Prediction in Smart Tower Crane Interfaces: A Refined Approach Using Simplified Plant Analysis Risk–Human Reliability Assessment and the Decision Making Trial and Evaluation Laboratory–Analytic Network Process. Buildings, 14(4), 1083. https://doi.org/10.3390/buildings14041083