Multi-Objective Optimization of Tasks Scheduling Problem for Overlapping Multiple Tower Cranes

Abstract

1. Introduction

2. Literature Review

3. Mathematical Model

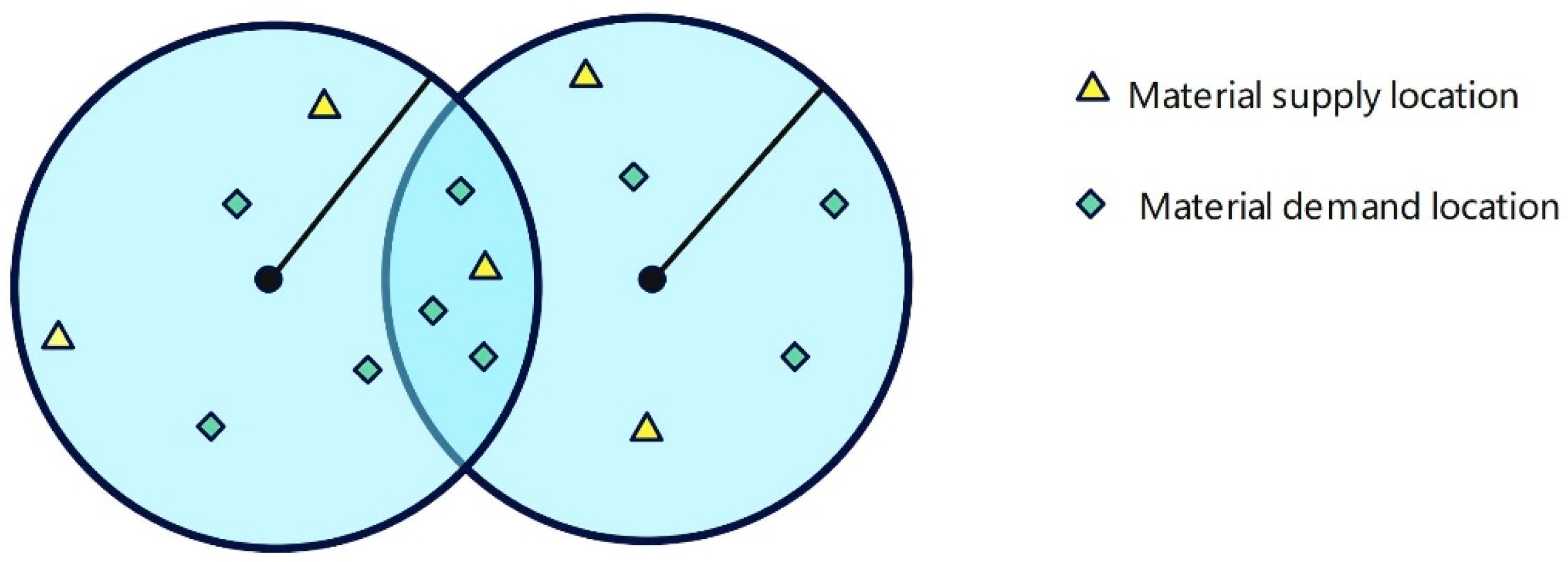

3.1. Problem Description

3.2. Objective Function

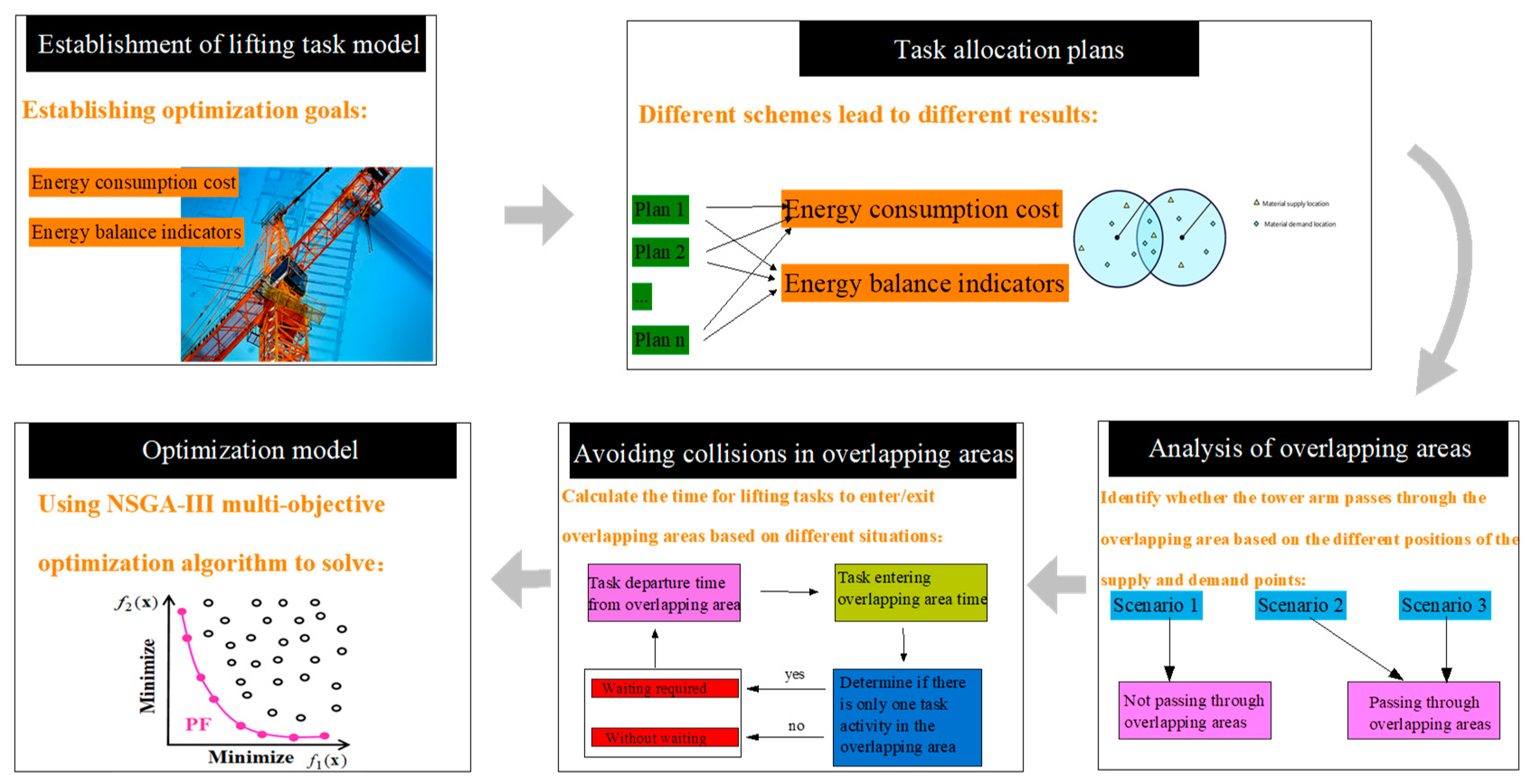

4. Multiple Tower Crane Task Schedule

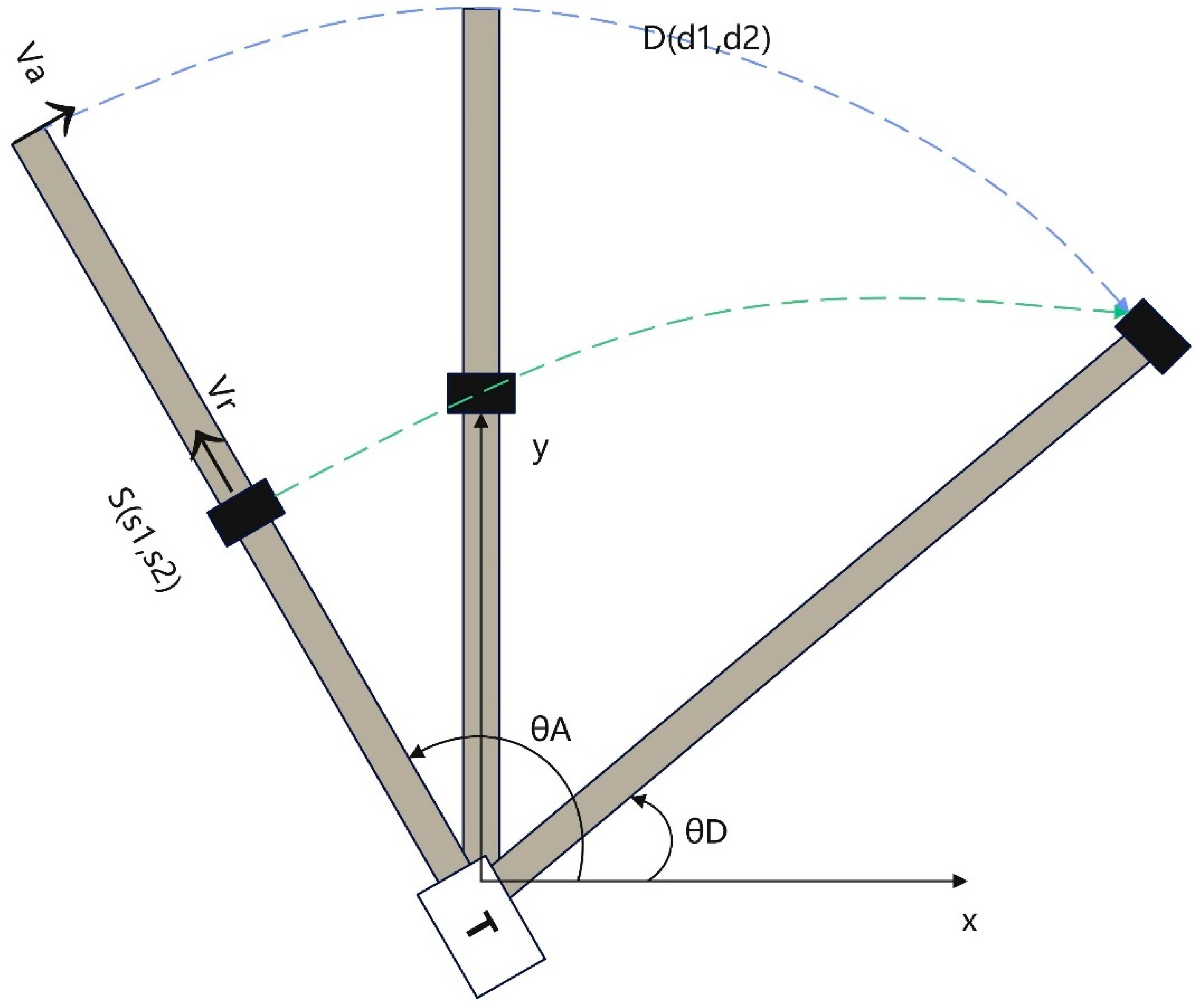

4.1. Estimate Tower Crane Movement Time between Two Locations

4.2. The Constraints of the Proposed Optimization Model

4.2.1. Tower Crane Lifting Task Assignment Feasible Combination

4.2.2. Eliminate the Service Schedules of Simultaneous Movement inside Overlapping Areas

Calculation of Overlapping Area Intersections

Identification of the Movement Routes Passing Overlapping Areas

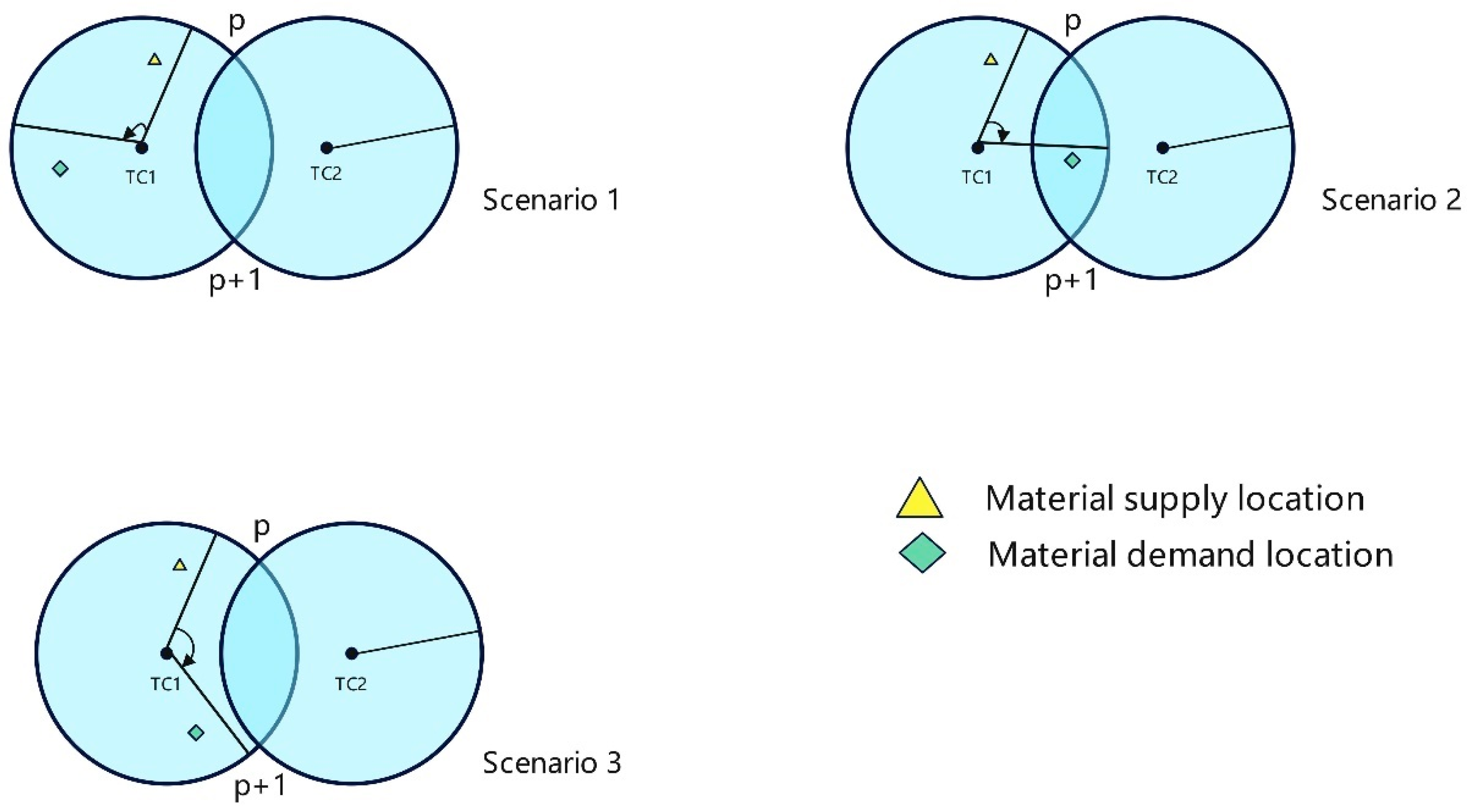

- (1)

- When the demand point is not in the overlapping area, and the tower crane does not pass through the overlapping area, there will be no space conflict between the tower cranes. So, the tower crane does not need to wait. The lifting time of the task is calculated as shown in Formula (25). Situation 1 in Figure 6 is shown;

- (2)

- When the demand point is not in the overlapping area, but the tower crane needs to pass through the overlapping area, space conflict may occur. During the lifting task, when the tower crane is about to enter the overlapping area, it is necessary to determine whether there is a tower crane performing the lifting task in the overlapping area. If there is a tower crane in the overlap area performing the lifting task, then the tower crane needs to wait for the previous tower crane to leave the overlap area. The lifting time of the task is calculated, as shown in Formula (26). If no other tower crane performs the task in the overlapping area, the lifting time of the task is calculated, as shown in Formula (25). Situation 2 in Figure 6 is shown as the following:

- (3)

- When the demand point is in the overlapping area, and the tower crane needs to pass through the overlapping area, space conflict may occur. Similar to scenario 2, it is necessary to determine whether there are other tower cranes performing lifting tasks in the overlapping area when entering the overlapping area. If it is determined that there are other tower cranes performing lifting tasks in the overlapping area, the lifting time of the task is calculated as shown in Formula (26). Otherwise, the Formula (25) is used to calculate. Scenario 3 in Figure 6 is shown.

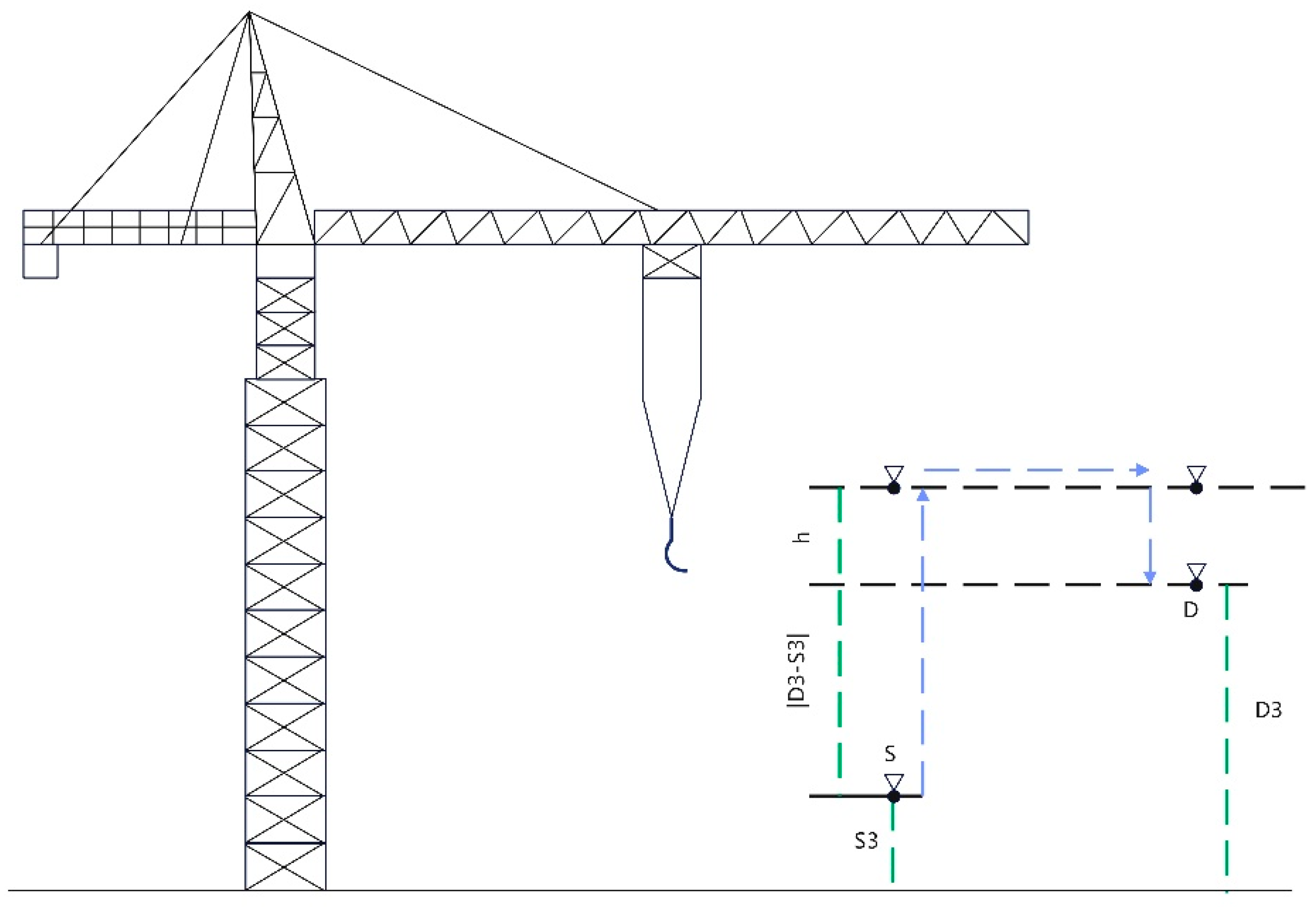

Estimation of the Time for Each Action to Enter and Leave the Overlap Area

4.2.3. Forbid Simultaneous Movements Inside Overlapping Areas

5. Experiment Results and Discussion

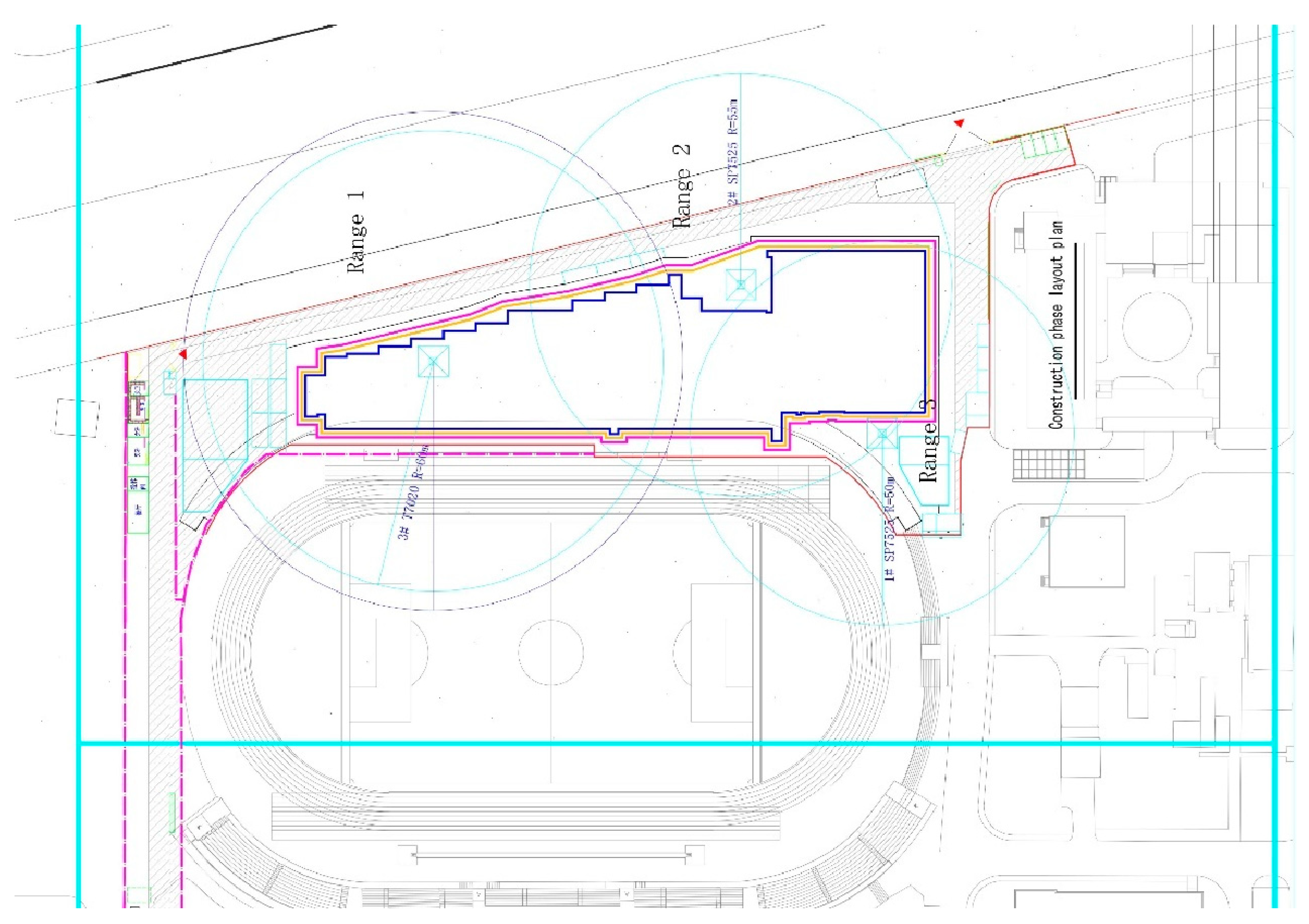

5.1. Case Background

5.2. Input Model Parameter

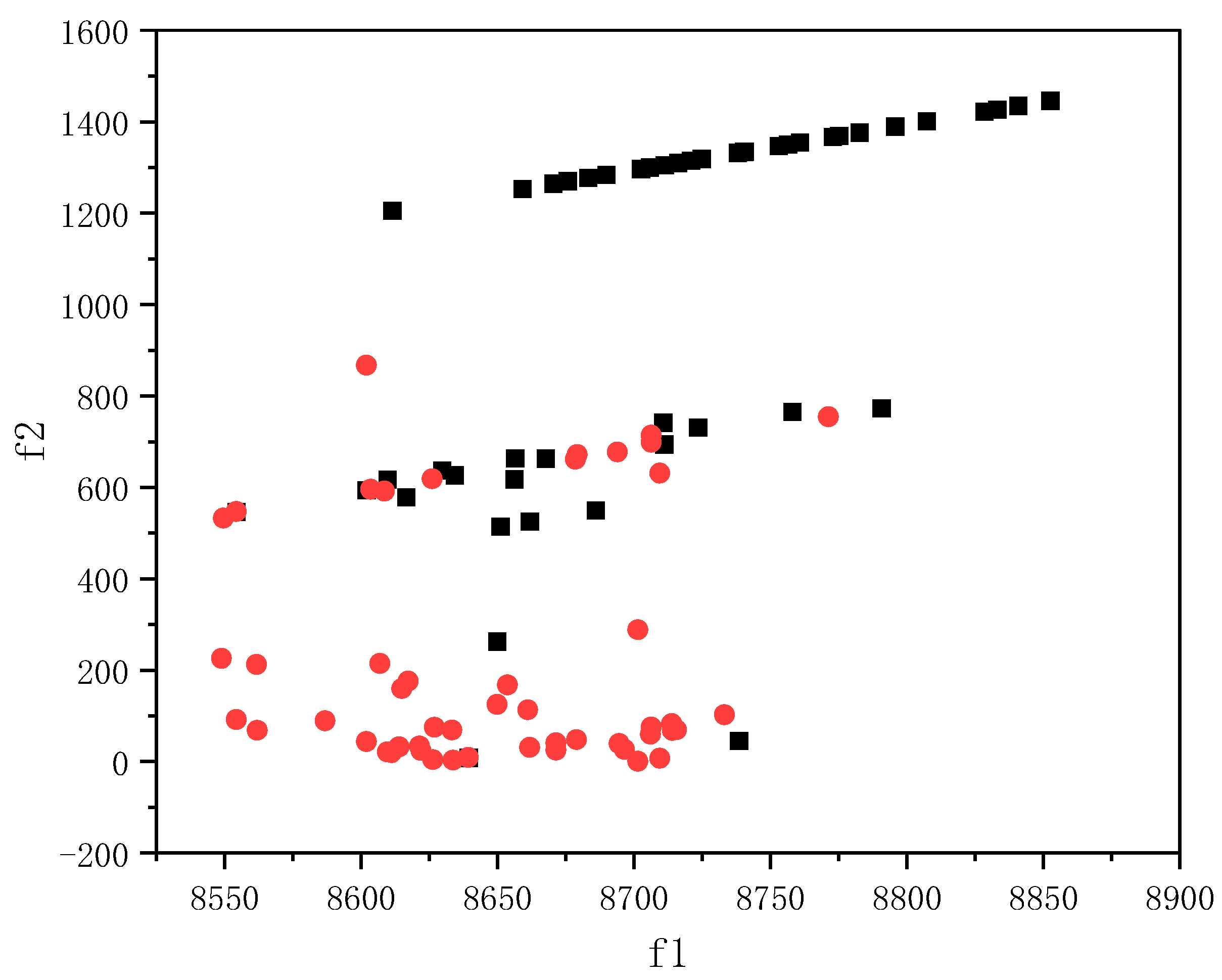

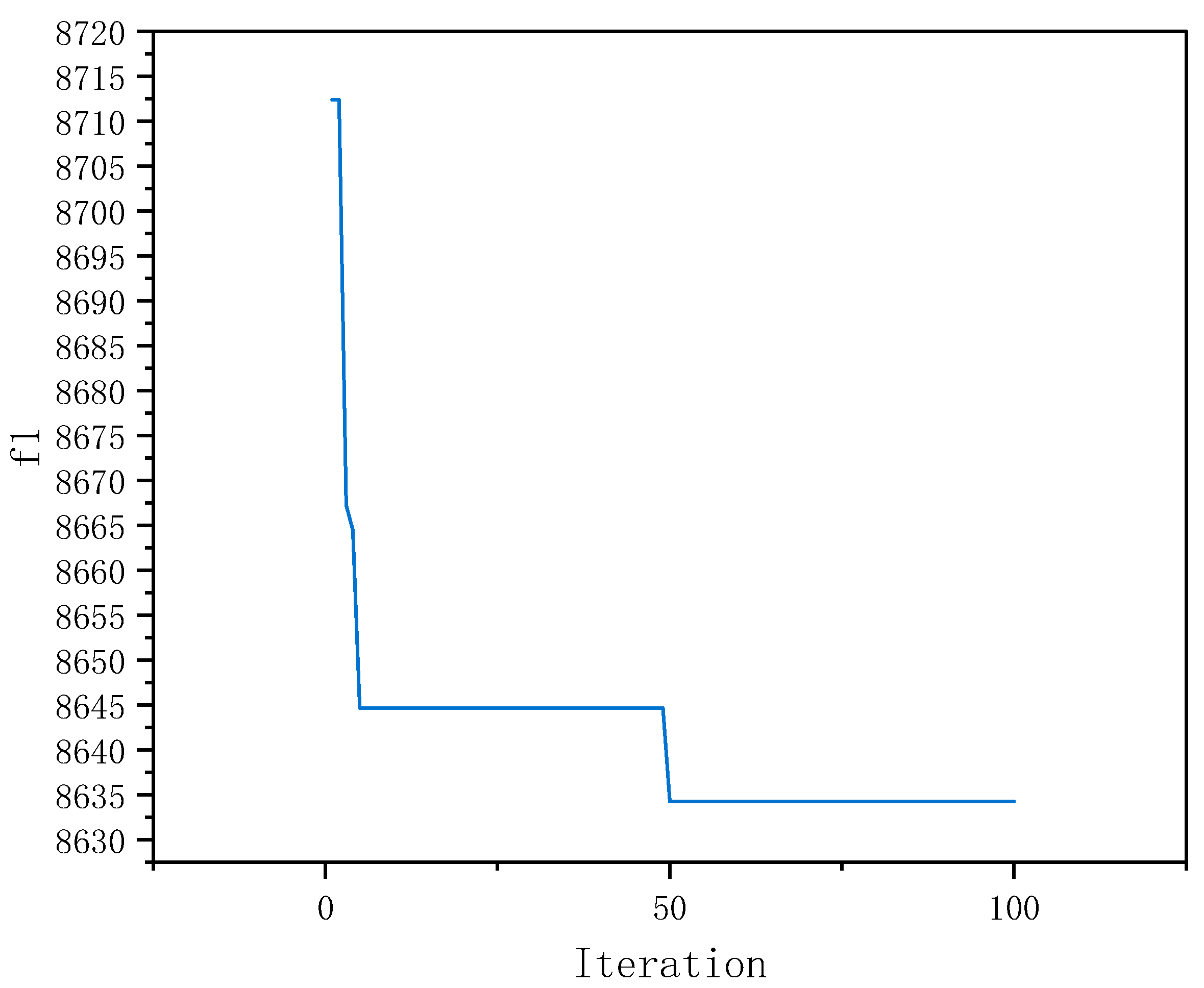

5.3. Multi-Objective Optimized Results

5.4. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| NSGA-III | Non-dominated sorting genetic algorithm-III |

| TOPSIS | Technique for order preference by similarity to an ideal solution |

| MILP | Mixed integer linear problem |

| USCA | Upgraded sine cosine algorithm |

| PSO | Particle swarm optimization |

| TCLP | Tower crane layout planning |

| BIM | Building information modeling |

| GIS | Geographic information system |

| RRT | Rapidly exploring random tree |

| NSGA-II | Non-dominated sorting genetic algorithm-II |

| TOPSIS | Technique for order preference by similarity to an ideal solution |

| MTSP | Multiple traveling salesman problem |

| FIFS | First-in-first-serve |

| SJF | Shortest job first |

| NNF | Nearest neighbor first |

| CCGA | Cooperative coevolutionary genetic algorithm |

| VEGA | Vector-evaluated genetic algorithm |

| MOGA | Multiple objective genetic algorithm |

| SPEA | Strength Pareto evolutionary algorithm |

| 3D-CES | Three-dimensional crane evaluation system |

References

- Yang, Y.H.; Liu, Y.S. Research on the Application of Prefabricated Buildings in Affordable Housing Construction in China. In Proceedings of the 6th International Symposium on Project Management (ISPM), Chongqing University Posts & Telecommunication, Chongqing, China, 21–23 July 2018; Aussino Academic Publishing House: Marrickville, NSW, Australia, 2018. [Google Scholar]

- Yin, J.; Li, J.; Fang, Y.; Yang, A. Service scheduling optimization for multiple tower cranes considering the interval time of the cross-tasks. Math. Biosci. Eng. 2023, 20, 5993–6015. [Google Scholar] [CrossRef]

- Daoud, A.O.; El Hefnawy, M.; Wefki, H. Investigation of critical factors affecting cost overruns and delays in Egyptian mega construction projects. Alex. Eng. J. 2023, 83, 326–334. [Google Scholar] [CrossRef]

- Lin, X.; Han, Y.; Guo, H.; Luo, Z.; Guo, Z. Lift path planning for tower cranes based on environmental point clouds. Autom. Constr. 2023, 155, 105046. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.; Lu, W.; Xue, F.; Liu, M.; Liu, Z. Optimization of multiple-crane service schedules in overlapping areas through consideration of transportation efficiency and operational safety. Autom. Constr. 2021, 127, 18. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Z.K.; Li, B.; Wang, C.; Xu, L.S.; Jiang, K.; Liu, M.; Guo, C.X.; Zhao, X.F.; Yang, H. Discretized Cell Modeling for Optimal Layout of Multiple Tower Cranes. J. Constr. Eng. Manag. 2023, 149, 19. [Google Scholar] [CrossRef]

- Jiang, H.; Miao, Y.B. Construction Site Layout Planning Using Multiple-Level Simulated Annealing. In Proceedings of the Computing Conference, Virtual, 15–16 July 2021; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Kaveh, A.; Vazirinia, Y. An Upgraded Sine Cosine Algorithm for Tower Crane Selection and Layout Problem. Period. Polytech.-Civ. Eng. 2020, 64, 325–343. [Google Scholar] [CrossRef]

- Khodabandelu, A.; Park, J.; Arteaga, C. Improving Multitower Crane Layout Planning by Leveraging Operational Flexibility Related to Motion Paths. J. Manag. Eng. 2023, 39, 17. [Google Scholar] [CrossRef]

- Li, R.; Chi, H.L.; Peng, Z.; Li, X.; Chan, A.P. Automatic tower crane layout planning system for high-rise building construction using generative adversarial network. Adv. Eng. Inform. 2023, 58, 19. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, F.; Han, X.; Ye, H.; Shi, Z.; Zhang, J.; Wang, T.; She, J.; Zhang, T. Intelligent Optimization of Tower Crane Location and Layout Based on Firefly Algorithm. Comput. Intell. Neurosci. 2022, 2022, 13. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, Y.Q. Integrating Hoisting Efficiency into Construction Site Layout Plan Model for Prefabricated Construction. J. Constr. Eng. Manag. 2021, 147, 15. [Google Scholar] [CrossRef]

- Riga, K.; Jahr, K.; Thielen, C.; Borrmann, A. Mixed integer programming for dynamic tower crane and storage area optimization on construction sites. Autom. Constr. 2020, 120, 15. [Google Scholar] [CrossRef]

- Younes, A.; Marzouk, M. Tower cranes layout planning using agent-based simulation considering activity conflicts. Autom. Constr. 2018, 93, 348–360. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Pan, W.; Pan, M. Critical considerations on tower crane layout planning for high-rise modular integrated construction. Eng. Constr. Archit. Manag. 2022, 29, 2615–2634. [Google Scholar] [CrossRef]

- Wu, K.Y.; De Soto, B.G. Lifting Sequence Optimization of Luffing Tower Cranes Considering Motion Paths with Dynamic Programming. J. Constr. Eng. Manag. 2021, 147, 16. [Google Scholar] [CrossRef]

- Burkhardt, M.; Gienger, A.; Sawodny, O. Optimization-Based Multipoint Trajectory Planning Along Straight Lines for Tower Cranes. IEEE Trans. Control Syst. Technol. 2023, 8, 290–297. [Google Scholar] [CrossRef]

- Dutta, S.; Cai, Y.; Huang, L.; Zheng, J. Automatic re-planning of lifting paths for robotized tower cranes in dynamic BIM environments. Autom. Constr. 2020, 110, 19. [Google Scholar] [CrossRef]

- Li, X.; Chi, H.L.; Wu, P.; Shen, G.Q. Smart work packaging-enabled constraint-free path re-planning for tower crane in prefabricated products assembly process. Adv. Eng. Inform. 2020, 43, 16. [Google Scholar] [CrossRef]

- Lin, Z.Y.; Petzold, F.; Hsieh, S.H. Automatic Tower Crane Lifting Path Planning Based on 4D Building Information Modeling. In Proceedings of the Construction Research Congress (CRC) on Construction Research and Innovation to Transform Society, Del E Webb Sch Construct, Arizona State University, Tempe, AZ, USA, 8–10 March 2020; American Society of Civil Engineers: New York, NY, USA, 2020. [Google Scholar]

- Ji, Y.S.; Leite, F. Optimized Planning Approach for Multiple Tower Cranes and Material Supply Points Using Mixed-Integer Programming. J. Constr. Eng. Manag. 2020, 146, 11. [Google Scholar] [CrossRef]

- Zhou, C.; Dai, F.; Xiao, Z.; Liu, W. Location Optimization of Tower Cranes on High-Rise Modular Housing Projects. Buildings 2023, 13, 115. [Google Scholar] [CrossRef]

- Wu, K.Y.; De Soto, B.G.; Zhang, F.L. Spatio-temporal planning for tower cranes in construction projects with simulated annealing. Autom. Constr. 2020, 111, 17. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Yu, L. Collaborative Planning for Stacking and Installation of Prefabricated Building Components Regarding Crane-Collision Avoidance. J. Constr. Eng. Manag. 2023, 149, 04023029. [Google Scholar] [CrossRef]

- Khodabandelu, A.; Park, J.; Arteaga, C. Crane operation planning in overlapping areas through dynamic supply selection. Autom. Constr. 2020, 117, 14. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, E.; Guo, H.; Fang, Y.; Li, H. Lifting path planning of mobile cranes based on an improved RRT algorithm. Adv. Eng. Inform. 2021, 50, 9. [Google Scholar] [CrossRef]

- Zhu, A.M.; Zhang, Z.Q.; Pan, W. Crane-lift path planning for high-rise modular integrated construction through metaheuristic optimization and virtual prototyping. Autom. Constr. 2022, 141, 21. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, Y.; Pan, Z.; Zhang, Z.; Yu, Y.; Li, Y. Automated Selection and Localization of Mobile Cranes in Construction Planning. Buildings 2022, 12, 580. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Yang, B.; Zhang, B. Vision-Based Automated Recognition and 3D Localization Framework for Tower Cranes Using Far-Field Cameras. Sensors 2023, 23, 851. [Google Scholar] [CrossRef]

- Huang, L.; Pradhan, R.; Dutta, S.; Cai, Y. BIM4D-based scheduling for assembling and lifting in precast-enabled construction. Autom. Constr. 2022, 133, 14. [Google Scholar] [CrossRef]

- Tarhini, H.; Maddah, B.; Hamzeh, F. The traveling salesman puts-on a hard hat—Tower crane scheduling in construction projects. Eur. J. Oper. Res. 2021, 292, 327–338. [Google Scholar] [CrossRef]

- Hammad, A.W.; Rey, D.; Akbarnezhad, A.; Haddad, A. Integrated mathematical optimisation approach for the tower crane hook routing problem to satisfy material demand requests on-site. Adv. Eng. Inform. 2023, 55, 13. [Google Scholar] [CrossRef]

- Motyčka, V.; Gašparík, J.; Přibyl, O.; Štěrba, M.; Hořínková, D.; Kantová, R. Effective Use of Tower Cranes over Time in the Selected Construction Process. Buildings 2022, 12, 436. [Google Scholar] [CrossRef]

- Yin, J.; Li, J.; Yang, A.; Cai, S. Optimization of service scheduling problem for overlapping tower cranes with cooperative coevolutionary genetic algorithm. Eng. Constr. Archit. Manag. 2024, 31, 1348–1369. [Google Scholar] [CrossRef]

- Mousaei, A.; Taghaddos, H.; Marzieh Bagheri, S.; Hermann, U. Optimizing Heavy Lift Plans for Industrial Construction Sites Using Dijkstra’s Algorithm. J. Constr. Eng. Manag. 2021, 147, 16. [Google Scholar] [CrossRef]

- Han, S.; Bouferguene, A.; Al-Hussein, M.; Hermann, U. 3D-Based Crane Evaluation System for Mobile Crane Operation Selection on Modular-Based Heavy Construction Sites. J. Constr. Eng. Manag. 2017, 143, 12. [Google Scholar] [CrossRef]

- Wu, K.; García, D.E.; Soto, B. Spatiotemporal Modeling of Lifting Task Scheduling for Tower Cranes with a Tabu Search and 4-D Simulation. Front. Built Environ. 2020, 6, 79. [Google Scholar] [CrossRef]

- Gopu, A.; Thirugnanasambandam, K.; AlGhamdi, A.S.; Alshamrani, S.S.; Maharajan, K.; Rashid, M. Energy-efficient virtual machine placement in distributed cloud using NSGA-III algorithm. J. Cloud Comput.-Adv. Syst. Appl. 2023, 12, 20. [Google Scholar] [CrossRef]

- Saeedvand, S.; Aghdasi, H.S.; Baltes, J. Robust multi-objective multi-humanoid robots task allocation based on novel hybrid metaheuristic algorithm. Appl. Intell. 2019, 49, 4097–4127. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Ma, S.L.; Jiang, X.Y. Research on Multi-Objective Multi-Robot Task Allocation by Lin-Kernighan-Helsgaun Guided Evolutionary Algorithms. Mathematics 2022, 10, 4714. [Google Scholar] [CrossRef]

- Li, K.; Duan, T.; Li, Z.; Xiahou, X.; Zeng, N.; Li, Q. Development Path of Construction Industry Internet Platform: An AHP—TOPSIS Integrated Approach. Buildings 2022, 12, 441. [Google Scholar] [CrossRef]

| Assumptions | Problem Description |

|---|---|

| Assumption 1 | Every time the tower crane moves, it selects the shortest path along a small arc between two positions; |

| Assumption 2 | Each tower crane is only allowed to lift one type of material at a time; |

| Assumption 3 | There is no priority limit between request tasks; |

| Assumption 4 | The default initial position of each tower crane for each task is the supply point position for the current task. |

| Symbol | Type | Expression |

|---|---|---|

| Continuous variable | The total energy cost from material demand locations to material supply locations; | |

| Continuous variable | The total energy cost from material supply locations to material demand locations; | |

| Binary variable | = 1 indicates a tower crane at a location travels from a demand location to a supply location in a work sequence ; | |

| Binary variable | = 1 indicates a tower crane at a location transports material from a supply location to a demand location in a work sequence ; | |

| Continuous parameter | The time to load materials from a material supply location; | |

| Continuous parameter | The time to unload materials to a material demand location; | |

| Continuous parameter | The estimated unit energy cost of empty loaded lifting movement in a minute; | |

| Continuous parameter | The estimated unit energy cost of fully loaded lifting movement in a minute; | |

| Continuous parameter | The hook travel time of a tower crane at location between a supply location and a demand location ; | |

| Continuous parameter | The time required for tower crane to complete the lifting task; | |

| Continuous parameter | The movement time of the hook from the initial position to the supply location; | |

| Continuous parameter | Number of tasks. |

| Symbol | Expression |

|---|---|

| Material supply location ; | |

| Material demand location ; | |

| The tower crane location; | |

| Coordinates of the supply location; | |

| Coordinates of the demand location; | |

| Radial travel time of the hook from to ; | |

| Tangential travel time of the hook from to ; | |

| The horizontal movement time of the hook from to ; | |

| The vertical movement time of the hook from to ; | |

| The speed at which the hook moves in the radial direction; | |

| The speed at which the hook moves in the tangential direction; | |

| The speed at which the hook moves in the vertical direction; | |

| The degree of simultaneous radial and tangential movement of the hook; | |

| The minimum value of the lifting height; | |

| Complexity level of construction environment; | |

| The level of difficulty of tower crane operation; | |

| The horizontal movement of the hook in both the horizontal and vertical directions. |

| Symbol | Type | Expression |

|---|---|---|

| Binary parameter | indicates that the tower crane at requests the lifting task in sequence ; | |

| Binary parameter | indicates that in the work sequence and , when two tower cranes enter or leave the overlapping area at positions and , the time difference between two tower crane movements and cannot be negative; | |

| Continuous parameter | Represents the time difference between the motion and when two tower cranes at positions and in the work sequence and leave and enter the overlapping area. |

| Symbol | Expression |

|---|---|

| The distance between the two tower cranes; | |

| Tower 1 coordinates; | |

| Tower 2 coordinates; | |

| , | The coordinate position of the two intersection points where the working range of the two tower cranes overlaps; |

| Tower 1 forearm length; | |

| Tower 2 forearm length; | |

| The angle of the intersection with respect to the tower crane at the origin; | |

| The range of overlapping areas; | |

| The time that a tower crane needs to wait in order to avoid conflict. |

| Symbol | Type | Expression |

|---|---|---|

| Continuous parameter | The time when the tower crane starts the first lifting task; | |

| Continuous parameter | The start time of each action of the tower crane lifting task; | |

| Continuous parameter | The time when the tower crane enters the overlap area; | |

| Continuous parameter | The movement time of the tower crane into the overlapping area from supply point or demand point to the selected intersection; | |

| Continuous parameter | The time when the tower crane leaves the overlap area; | |

| Continuous parameter | The movement time of the tower crane from entering the overlapping area to leaving the overlapping area; | |

| Continuous parameter | Movement time of tower crane from supply point to intersection point ; | |

| Continuous parameter | Movement time of tower crane from demand point to intersection point ; | |

| Binary parameter | , indicates that the demand points are in the overlap area; | |

| Binary parameter | , indicates that the tower crane moves through overlapping areas; | |

| Binary parameter | represents the transport of materials from supply point to demand point , and the tower crane at position enters or leaves the overlapping area through the intersection point ; | |

| Binary parameter | represents the movement from demand point to supply point , and the tower crane at position enters or leaves the overlapping area through the intersection point . |

| Material Supply | Position Coordinate | ||

|---|---|---|---|

| x | y | z | |

| 1 | 19.901 | 17.124 | 0 |

| 2 | 72.200 | 16.723 | 0 |

| Tower Crane | Position Coordinates of Tower Crane | |||

|---|---|---|---|---|

| x | y | z | r | |

| 1 | 0 | 0 | 70 | 60 |

| 2 | 82.5 | 0 | 70 | 55 |

| Material Demand | Material Demand Coordinates | ||

|---|---|---|---|

| x | y | z | |

| 1 | −30.493 | −10.024 | 9 |

| 2 | 48.933 | 5.348 | 9 |

| 3 | 57.568 | 5.185 | 9 |

| 4 | 72.176 | 17.445 | 9 |

| 5 | −15.209 | −9.002 | 9 |

| 6 | 51.934 | −7.790 | 9 |

| 7 | 80.293 | 7.790 | 9 |

| 8 | −21.442 | 0.761 | 9 |

| 9 | −15.209 | −9.002 | 9 |

| 10 | 65.201 | −33.720 | 9 |

| 11 | 40.748 | −27.651 | 9 |

| 12 | 62.037 | −11.606 | 9 |

| 13 | 26.567 | 6.063 | 9 |

| 14 | 55.834 | −1.722 | 9 |

| 15 | 40.299 | −5.308 | 9 |

| 16 | 88.482 | −9.668 | 9 |

| Scheme | Task Lifting Sequence | Sort Result | |

|---|---|---|---|

| Tower Crane 1 | Tower Crane 2 | ||

| 1 | 1→5→8→9→13→2→11 | 10→16→14→6→4→12→7→3→15 | 2 |

| 2 | 1→5→8→9→13→2→6 | 11→12→4→3→10→16→15→14→7 | 3 |

| 3 | 1→5→8→9→13→2→3 | 16→10→7→12→4→14→6→15→11 | 11 |

| 4 | 1→5→8→9→13→2→15 | 16→10→14→3→12→7→6→4→11 | 7 |

| 5 | 1→5→8→9→13→2→3 | 16→10→4→15→7→11→14→6→12 | 10 |

| 6 | 1→5→8→9→13→2→6 | 12→10→16→14→7→15→4→3→11 | 4 |

| 7 | 1→5→8→9→13→2→14 | 15→10→12→16→4→6→7→3→11 | 5 |

| 8 | 1→5→8→9→13→2→15 | 16→14→6→10→3→4→11→12→7 | 8 |

| 9 | 1→5→8→9→13→2→3 | 12→11→7→15→6→14→10→4→16 | 6 |

| 10 | 1→5→8→9→13→2→3 | 7→6→15→10→4→12→16→14→11 | 9 |

| 1 | 1→5→8→9→13→2→11 | 10→6→16→15→4→12→14→3→7 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, W.; Cui, W.; Zhou, G. Multi-Objective Optimization of Tasks Scheduling Problem for Overlapping Multiple Tower Cranes. Buildings 2024, 14, 867. https://doi.org/10.3390/buildings14040867

Wang Y, Zhao W, Cui W, Zhou G. Multi-Objective Optimization of Tasks Scheduling Problem for Overlapping Multiple Tower Cranes. Buildings. 2024; 14(4):867. https://doi.org/10.3390/buildings14040867

Chicago/Turabian StyleWang, Yanyan, Wenjie Zhao, Wenjing Cui, and Guangqiang Zhou. 2024. "Multi-Objective Optimization of Tasks Scheduling Problem for Overlapping Multiple Tower Cranes" Buildings 14, no. 4: 867. https://doi.org/10.3390/buildings14040867

APA StyleWang, Y., Zhao, W., Cui, W., & Zhou, G. (2024). Multi-Objective Optimization of Tasks Scheduling Problem for Overlapping Multiple Tower Cranes. Buildings, 14(4), 867. https://doi.org/10.3390/buildings14040867