Abstract

Empowering materials with self-healing capabilities is an attractive approach for sustainable development. This strategy involves using different methods to automatically heal microcracks and damages that occur during the service life of materials or structures. Initially, this study begins with an in-depth exploration of self-healing characteristics found in materials such as concrete, asphalt, and polymers. The differences and comparative merits and demerits between autogenous (intrinsic) healing and autonomic (extrinsic) healing are discussed, and it is found that intrinsic healing is more promising. Subsequently, the study explores how models are applied to assess self-healing efficiency. The results indicate that time and temperature have significant impacts on the self-healing process. However, there is a scarcity of research exploring the effects of load factors during service life. Computational simulation methodologies for microcapsules and asphalt within self-healing materials are investigated. Multiscale characterization and machine learning can further elucidate the healing mechanisms and facilitate the establishment of computational models. This study endeavors to realize the maximum capabilities of self-healing materials, paving the way for the design of sustainable and more effective self-repairing materials for various applications.

1. Introduction

For materials subjected to real-world applications, degradation, damage, and eventual failure are unavoidable realities. The field of practical engineering primarily aims to develop materials that are more resilient and robust and thus able to withstand such challenges. However, despite these efforts, materials eventually succumb to wear and tear, leading to a state in which they are compromised. When damage manifests as microcracks that are either not visible to the naked eye or are in hard-to-reach areas, conventional engineering repair solutions are exceedingly challenging and expensive to implement. In stark contrast to traditional materials, self-healing materials have great potential, as they allow the material to heal without human intervention when subjected to specific damage, repairing some or all of its properties [1]. This capability makes them extremely valuable across a range of industries. Their applications span construction [2], road engineering [3], and aerospace [4]. The advantages of self-healing materials are enormous from this point of view, as self-healing behavior not only improves the reliability, durability, and lifetime of materials, but also reduces maintenance costs and natural resource consumption, so the study of self-healing has become a significant focus in research.

White et al. [5] introduced the concept of self-healing in polymer composites in a groundbreaking way that was interesting to apply across a diverse range of materials. The methodologies proposed by researchers for the development of self-healing materials are fundamentally categorized into two distinct healing pathways: intrinsic and extrinsic. The intrinsic approach relies on the potential repair properties of the material. It operates without the need for external human intervention and is activated by damage or external stimuli. The extrinsic approach involves embedding microcapsules filled with healing agents into the material. When the material is injured, these microcapsules rupture, releasing healing agents that fill and cure the fractures. In previous studies, researchers have given creative self-healing capabilities to different material classes, and many research advances have been made in self-healing concrete, asphalt, polymers, ceramics, and other materials [6,7,8,9].

Characterizing the healing capacity of self-healing materials and their suitability for specific applications presents a significant challenge. In this context, the development of a model that can accurately describe the state of healing is particularly crucial. Since different materials exhibit distinct healing mechanisms, each must be studied individually. Visualization and measurement methods are among the most direct techniques used to evaluate self-healing systems. While these methods often yield qualitative rather than quantitative results, they offer a clear view into the healing process and the products formed. In addition to visualization and measurement, the healing efficiency of self-healing materials can be indirectly assessed using mechanical testing methods. Healing efficiency is quantified as the percentage of the repaired material that returns to its original state, with 100% efficiency indicating a complete restoration to the undamaged condition. The formulation of self-healing models aims to characterize how various factors influence healing efficiency. This has been a focal point of research for many scientists.

Self-healing models are used to study the repair behavior of various materials. Sun et al. [10] investigated the healing mechanisms related to asphalt and crafted models to describe the material’s self-healing process. They suggested that a thermodynamic perspective holds promise for studying self-healing models. Moreover, they outlined multi-scale characterization methods for self-healing, ranging from the microscopic to the macroscopic scale and including computational simulations.

These methods show great potential for asphalt materials, although our study acknowledges some limitations, such as an incomplete consideration of the factors affecting self-healing. Currently, the majority of mechanical models used to study self-healing behavior are grounded in continuum damage-healing mechanics models [11,12,13]. These models are instrumental in understanding the complex interplay between material damage and healing. As researchers work to improve their precision and broaden their use, these models continue to evolve and advance.

This study was conducted to explore the healing mechanisms of self-healing materials in civil engineering, as well as the models and computational simulations employed to measure the efficiency of their healing processes. It explores the fundamental distinctions between different self-healing materials and evaluates the effectiveness of various healing models, including continuum damage-healing mechanics (CDHM).

The following section provides an in-depth examination of self-healing materials’ repair mechanisms and models. Section 2 focuses on current analytical techniques and the practical applications of self-healing models in characterizing these materials. It also investigates the factors that affect the repair process, including how they can either accelerate or hinder the healing mechanism. This section also showcases the latest advancements in computational simulation methodologies for microcapsule-based self-healing materials and asphalt materials.

Finally, Section 4 concludes the paper, summarizing the key insights and the future outlook for research into self-healing materials. This study identified time and temperature as the primary factors influencing healing efficiency. Although research by Pittala et al. [14] has found that higher temperatures and appropriate compressive forces can enhance the healing process, there remains a significant gap in current research regarding the consideration of load factors during repair. This gap represents a potential direction for future research in the field of self-healing materials.

2. Materials and Methods

2.1. Self-Healing Concrete Materials

Concrete is the most widely used material in construction and has the advantages of its high compressive strength, low price, and flexibility of use [6,15]. However, the chief limitation of concrete is that it is prone to cracking; this is because its tensile strength is very low, making it very sensitive to the formation of cracks. The development of cracks in concrete seriously damages the stability and performance of the structure, but regular inspection and maintenance require entail a significant cost. To address this issue, extensive research has been conducted on self-healing concrete [2,6,16,17,18,19]. The reparative processes of self-healing materials, especially within concrete, are predominantly divided into autogenous and autonomous healing strategies [17,18,19]. Autogenous healing leverages the complex chemical processes within the cement matrix to facilitate the repair of cracks. This process is initiated by the hydration of any remaining unhydrated cement and the carbonation of cement hydrates present at the crack plane. The healing occurs via the interaction of the concrete’s original components without the addition of external agents. In contrast, autonomous healing is an approach that enhances the self-healing potential of concrete by incorporating specialized components designed to initiate the healing process. These components can include microcapsules and hollow fibers, which are preloaded with healing agents such as polymers or even bacterial spores. When damage occurs, these agents are released and contribute to the repair of the material. Some researchers have further refined the classification of concrete healing into three distinct categories: intrinsic autogenous, stimulated autogenous, and engineered healing. This more nuanced classification [20] provides a clearer understanding of the different pathways through which concrete can achieve self-repair.

2.1.1. Autogenous Healing

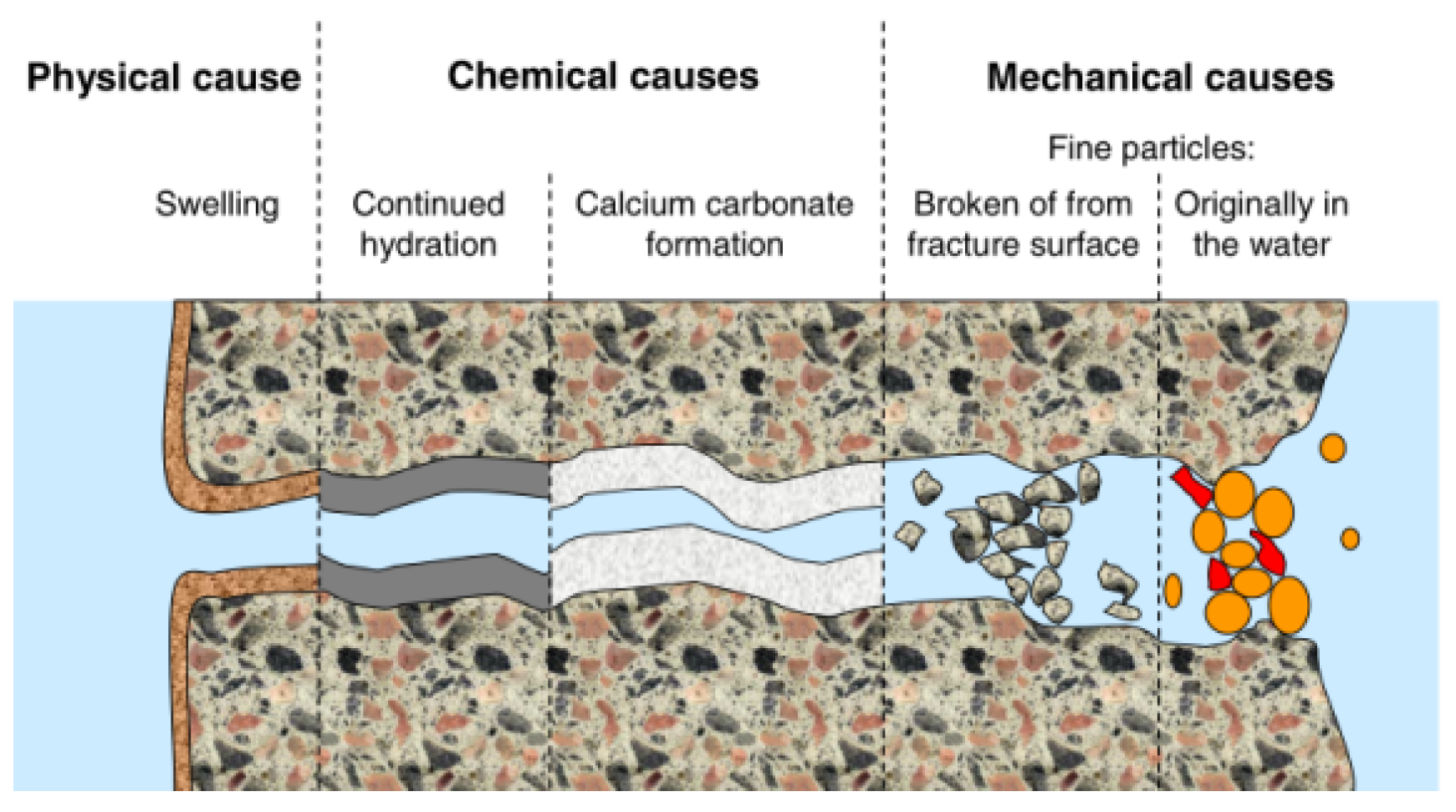

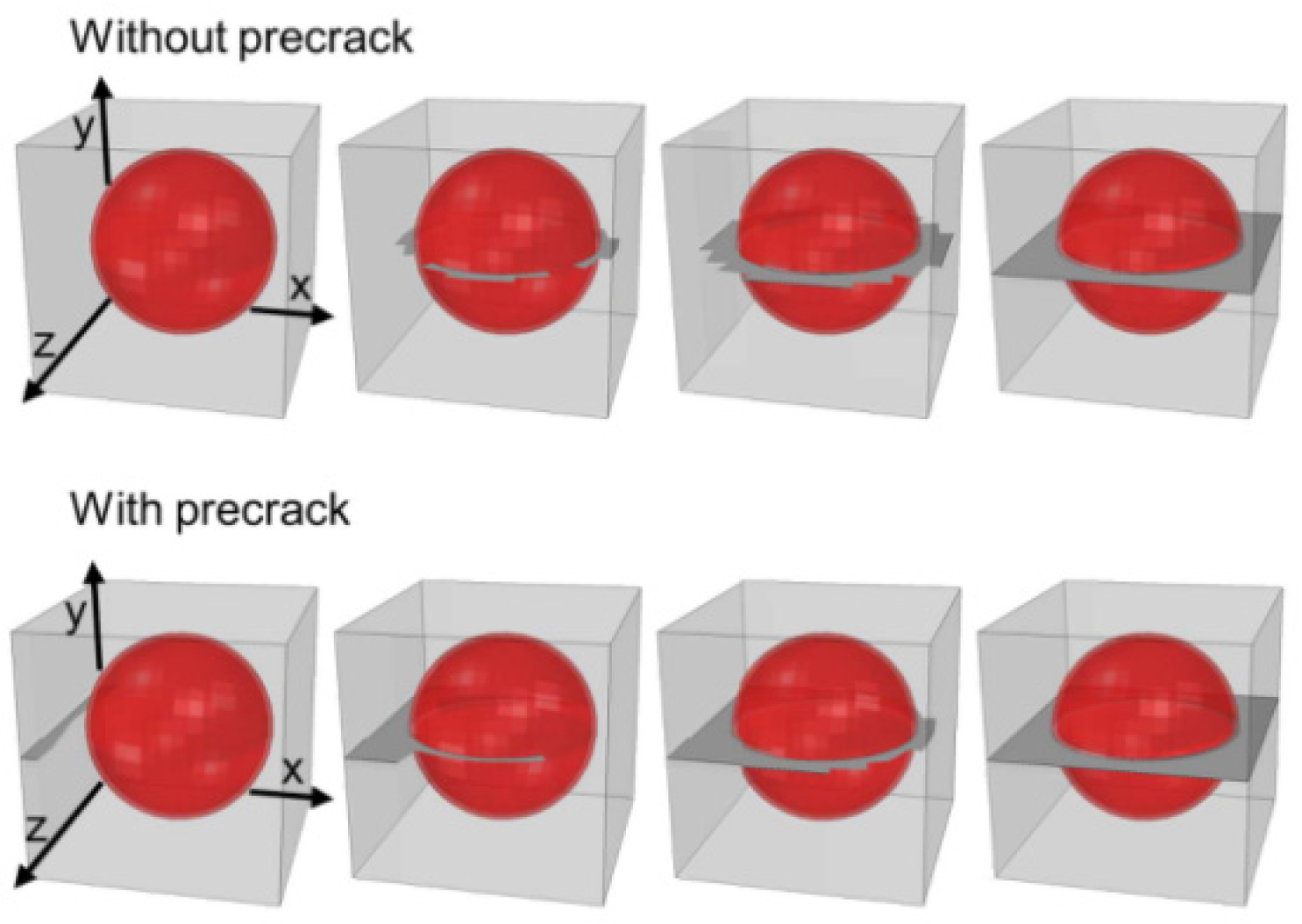

Autogenous healing in concrete refers to the capacity to heal cracks when exposed to moisture, without the influence of tensile stress on the healing process [21,22]. The healing mechanism is divided into three parts [23], which are physical, chemical, and mechanical healing. The physical healing mechanism, shown in Figure 1, refers to the process of crack reduction caused by the expansion of the hydrated cement paste near the surface of the concrete crack. The chemical healing mechanism is manifested in two chemical reactions, namely, the additional hydration of the remaining unhydrated cement particles within the concrete matrix [18,23] and the carbonation of the main cement hydration product in the crack in the presence of carbon dioxide [24]; the formation of calcium carbonate plays a crucial role for self-healing concrete. The last one is a mechanical repair mechanism with relatively low impact, which refers to the presence of fine particles of cement in the concrete cracks, filling the cracks via water transport [25]. In the early stages, the ongoing hydration of cement is a key driver of crack healing, as not all cement particles are fully hydrated, and concrete possesses a high potential for cement hydration. In the later stages, calcium carbonate precipitation is the main healing mechanism [24,25]. In autogenous healing of concrete, chemical mechanisms are mainly considered.

Figure 1.

Autogenous healing due to physical, chemical, and mechanical processes in concrete [23].

The self-healing capability of concrete is further enhanced by the incorporation of supplementary cementitious materials (SCMs) [26]. Expansive minerals, a class of SCMs, expand their own volume when exposed to water, thus filling the cracks in the concrete. This behavior further promotes the formation of cement hydration products, the sealing and healing of cracks [27,28]. Qureshi et al. [29] conducted research into the influence of expansive minerals on the initial self-healing capabilities of Portland cement. Their findings indicated that the hydration processes and the byproducts of expansive minerals play a significant role in initiating the healing response. They determined not only the optimal ratio of expansive minerals but also established a quantitative relationship between the age of the cement paste at the time of cracking and the efficiency of self-healing, supported by their experimental findings [30].

The efficacy of self-healing in cementitious materials is significantly affected by the composition of cement matrix, encompassing factors such as the type and proportion of cement, the moisture level, aggregate characteristics, and the duration of the healing period [31,32,33,34,35]. Huang et al. [32] reported that slag cement pastes exhibit a higher potential for autogenous healing compared to Portland cement pastes. Cement particle size can influence the continuous hydration and carbonation by affecting the content of unhydrated cement and calcium hydroxide. Therefore, a proper cement particle size distribution can also enhance the self-healing capabilities of concrete [33].

Relevant findings indicate that water has a facilitating effect on the further hydration of cement, in other words, the ingress of water into concrete can effectively lead to the formation of calcium carbonate healing products, thereby enhancing the self-healing process [17,19]. Newer concrete has a greater self-healing ability than older concrete due to continuous hydration. Luo et al. [34] conducted a study on the impact of three distinct curing conditions on the cracks healing in cement pastes with different supplementary cementitious materials. Their experimental findings underscore the critical role of water in the autogenous healing of early-stage cracks within cement pastes. The highest crack healing efficiency was achieved for specimens completely submerged in water, but the other two curing conditions could not or need longer time to achieve good healing efficiency due to the lack of moisture. This conclusion has also been corroborated by other studies [23,36]. Some cases of hydrogel systems and epoxy resin systems as SCMs have been studied in recent years, and these have contributed to enhancing the self-healing capabilities of cementitious materials.

Hydrogel particles facilitate the self-healing process in concrete by utilizing their stored water to stimulate the hydration of cement, thereby mitigating the self-shrinkage of the mixture [37]. Huseien et al. [38] added epoxy resins of different mass fractions to concrete and evaluated them comparatively via both microscopic observation and macroscopic tests; they found that specimens prepared with epoxy resins containing 10% by weight of cement had improved mechanical properties after curing. The healing efficiency achieved was 71.8%. The unhardened epoxy resin also affects the hydration of cement and the composition ratio thus requires careful attention. Soltaninejad et al. [39] investigated a composite material, clay plastic concrete, mixing 45% montmorillonite Bentonite soil with cement and epoxy resin. Their findings indicated that after a 24 h water immersion and subsequent 24 h drying cycle, numerous cracks emerged on the sample surfaces. Notably, as the proportion of epoxy resin within the matrix increased, there was a discernible reduction in the prevalence and severity of these cracks. The use of epoxy resin polymer as SCMs has been strongly validated for its high self-healing potential.

2.1.2. Autonomic Self-Healing

In an autonomous healing system, various healing agents are sealed within the concrete in various forms. Upon activation by specific trigger mechanisms, such as heat or the formation of cracks, these agents are released to the site of damage, facilitating the repair and restoring the material’s integrity.

Microcapsules are a commonly accepted self-healing encapsulation technology introduced by White in 2001 [5]. The healing process follows three steps. Initially, a crack initiates within the concrete embedded with microcapsules and starts to widen. Subsequently, the microcapsules rupture due to the crack expansion, releasing the contained healing agent into the fissure. Ultimately, the healing agent undergoes a chemical reaction with the matrix material, fusing the crack surfaces and altering the crack tip’s geometry. As a result, this process can prevent further crack propagation and lead to the recovery of properties like stiffness, strength, and fracture toughness in the concrete.

Huang et al. [40] conducted research on self-healing concrete by incorporating microcapsules at various volume fractions and explored the impact of these microcapsules on the material’s dynamic compression behavior and compared the results with those obtained from quasi-static tests. They found that the dynamic compressive strength of concrete is strain-rate dependent and decreases with increasing volume fraction of microcapsules. In addition, their group further investigated the constitutive relationship, strength, and failure criterion of the system [41]; their experimental findings indicated that the ultimate strength of the specimens tended to decrease as the volume fraction of microcapsules increased across all loading conditions. However, the peritectic pressure exerts a notable influence on boosting the ultimate strength and ductility of the specimens, which is consistent with the phenomenon in normal concrete.

The negative effect of microcapsules on self-healing concrete has been demonstrated in the experiments of others [42,43]. Thus, it is necessary to determine a suitable scheme to maintain the balance between strength and healing efficiency when designing microcapsule self-healing concrete. A method of introducing nanosilica into the capsule shell was used to reduce the porosity of the self-healing cementitious material and improve the thermal stability of the capsule, making it easier to heal due to the tight binding of the nanosilica shell to the cement, which makes the rupture of the capsule more likely to occur [44]. The healing efficiency and compressive strength were increased by 112.7% and 18.9%, respectively, compared to specimens without nanosilica. The careful selection of material composition and adjustment of the volume fraction of the capsules positively impacts the mechanical properties of the existing self-healing cementitious material system.

The width of the cracks and the healing duration are also crucial factors to consider when assessing the extent of repair in self-healing concrete facilitated by microcapsules. When the crack width exceeds 0.15 mm, the healing effect cannot reach the initial strength, whereas, when the crack width is less than 0.05 mm, a kind of super-repair phenomenon can occur, which means that the healing effect exceeds the initial strength. Meanwhile, the growth of the healing effect decreases with the extension of time [45].

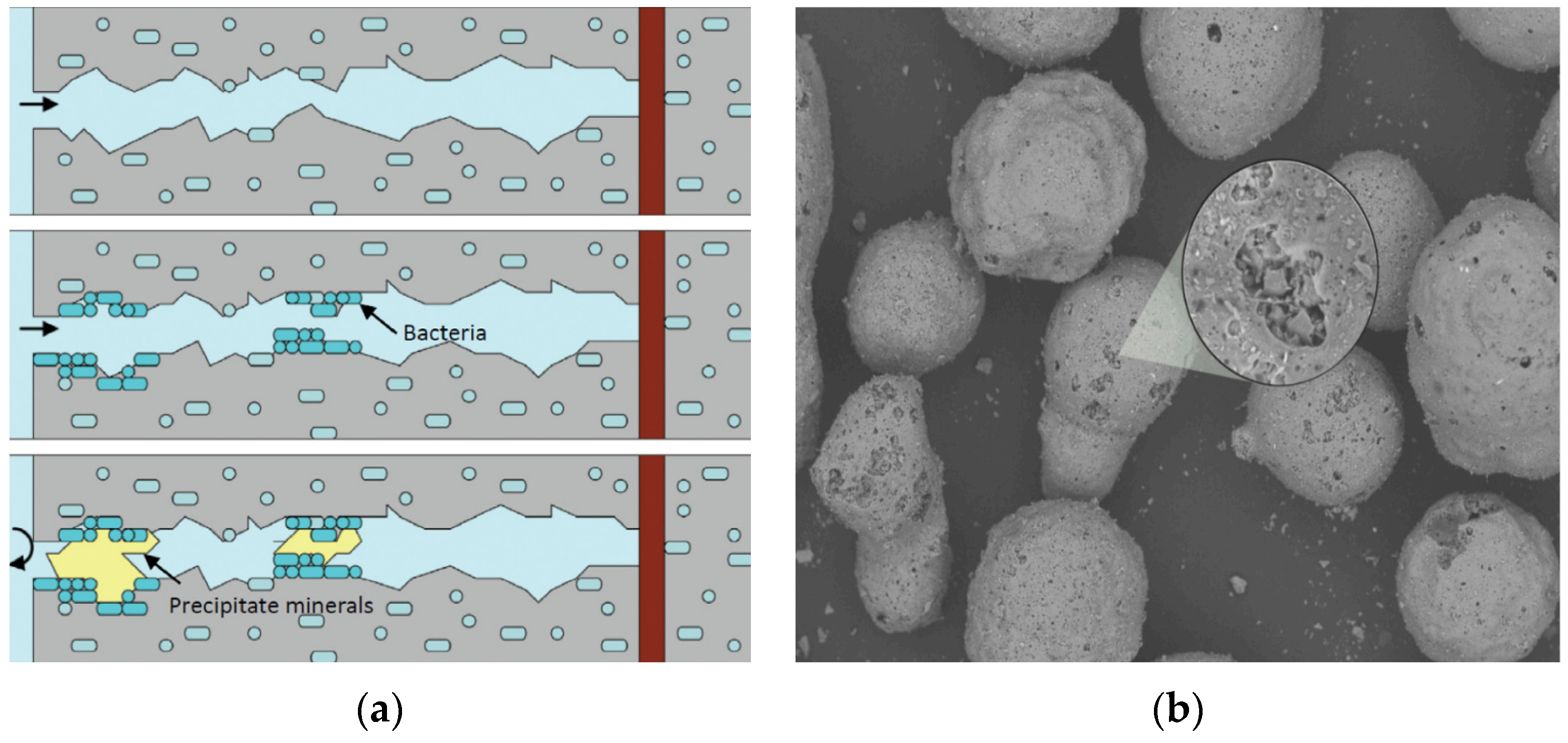

Some researchers have suggested a biological approach, using bioremediation by introducing bacteria into the concrete [46,47,48,49]. The concept of using bacteria to facilitate self-healing in concrete dates to the last century, with a seminal study by Gollapudi et al. [50]. Their approach was rooted in the utilization of ureolytic bacteria, which helped to precipitate calcium carbonate and fill in the microcracked areas, as shown in Figure 2a. The bacterial species produce calcium carbonate via their metabolic cycle. The two primary pathways through which this occurs are hydrolysis of urea and oxidation of organic compounds [46]. The increase in compressive strength results from the aggregation of the cementitious material produced by the microbially induced carbon precipitation (MICP) biomineralization in the concrete voids [51]. The use of bacterially induced carbonate precipitation to fill cracks is the result of biological activity; thus, the method, known as MICP, is an environmentally friendly method and offers a long-lasting alternative to traditional chemical self-healing strategies for addressing concrete cracks. The efficiency of microbially catalyzed calcium carbonate formation, a key component in the self-healing capabilities of concrete, is contingent upon various factors. These include the specific bacteria utilized and their population density, environmental pH, and the existence of suitable nucleation points [52,53,54]. In addition, bacterial growth can be limited by the highly alkaline environment of concrete, unsuitable humidity, and dense substrates. Therefore, incorporating bacteria into self-healing concrete necessitates appropriate strategies to protect the bacteria in the concrete, such as encapsulation techniques and immobilization [21,53,55,56,57]. Expanded glass (EG) is a porous expanded glass particle containing nutrients. Zhang et al. immobilized the bacterial solution, urea, and calcium-derived material into EG via the vacuum impregnation method. Figure 2b represents the form of EG particles in the microscopic state. Using the same method, Bacillus subtilis and its required nutrient solution were immobilized into recycled coarse aggregate (RCA) and, comparing the pre-crack repair at 3, 7, and 28 days, the self-healing concrete with RCA immobilized bacteria had 50% healing efficiency in compression and splitting strength [56]. In calcium alginate–chitosan hydrogel beads immobilization technique, the release of water from the hydrogel shells promotes the hydration of the unhydrated cement and the flexural strength is further improved [58]. In the current study, despite the different immobilization schemes being applied, the healing of bacterial-based self-healing concrete is not applicable to macroscopic cracks and the maximum value of the repaired crack width is about 1 mm [15,58]. Combining bacteria and fibers is one way to improve the self-healing characteristics of concrete. However, it is crucial to recognize that the bacteria used in self-healing concrete produce an unpleasant gas, ammonia, during the decomposition of urea, which is obviously detrimental to the lives of any residents in buildings using this material [59]. Compared to bacterial-based concrete, fungi have higher self-healing efficiency, such as Trichoderma reesei spores [60] and Fusarium oxysporum [61]. Zhang et al. released the full repair potential of fungi-based self-healing concrete by adjusting the pH value; the healing time was as low as 11.3% of that required for bacterial self-healing systems. The water resistance of mycelium improved the permeability of concrete, and there was no emission of toxic gases like ammonia [61].

Figure 2.

(a) Schematic diagram of concrete crack repair using immobilized bacteria [46] and (b) SEM image of expanded glass (EG) immobilized bacteria [55].

2.2. Self-Healing Polymers

The range of emerging materials for self-healing polymers is growing rapidly and researchers have divided them into two categories, i.e., external and intrinsic types, based on the healing mechanism. Extrinsic self-healing polymers rely on chemical reactions between other compounds within the matrix polymer to achieve the healing function. When the polymer matrix is damaged, the outer shell, such as a microcapsule, breaks down and releases chemicals that come into contact with each other and react to fill the microcracks caused by external mechanical forces. Intrinsic self-healing polymers are healed by their own reversible action; when the polymer breaks and cracks, the breaks are brought into contact with each other and the polymer chain segments at the breaks reform new covalent or non-covalent chemical bonds.

2.2.1. Intrinsic Self-Healing

Some reversible chemical bonds can, under certain conditions (such as high temperature, high pressure, light, radiation, etc.), be rearranged to achieve heal damage. According to the different types of molecular bonds, intrinsic self-healing systems are divided into self-healing covalent bonds and self-healing non-covalent bonds. Of these, self-healing covalent bonds can be divided into disulfide bonds [62], acylhydrazone bonds [63], Diels–Alder thermally reversible reaction [64], etc. Self-healing non-covalent bonds can be classified as hydrogen bonds [65], ionic bonds [66], metal–ligand bonds [67], π–π stacking [68], etc. These bonds are reversible and sensitive. Intrinsic self-healing has been widely investigated, due to its design flexibility, low technical difficulty, and its ability to heal the same damaged site multiple times.

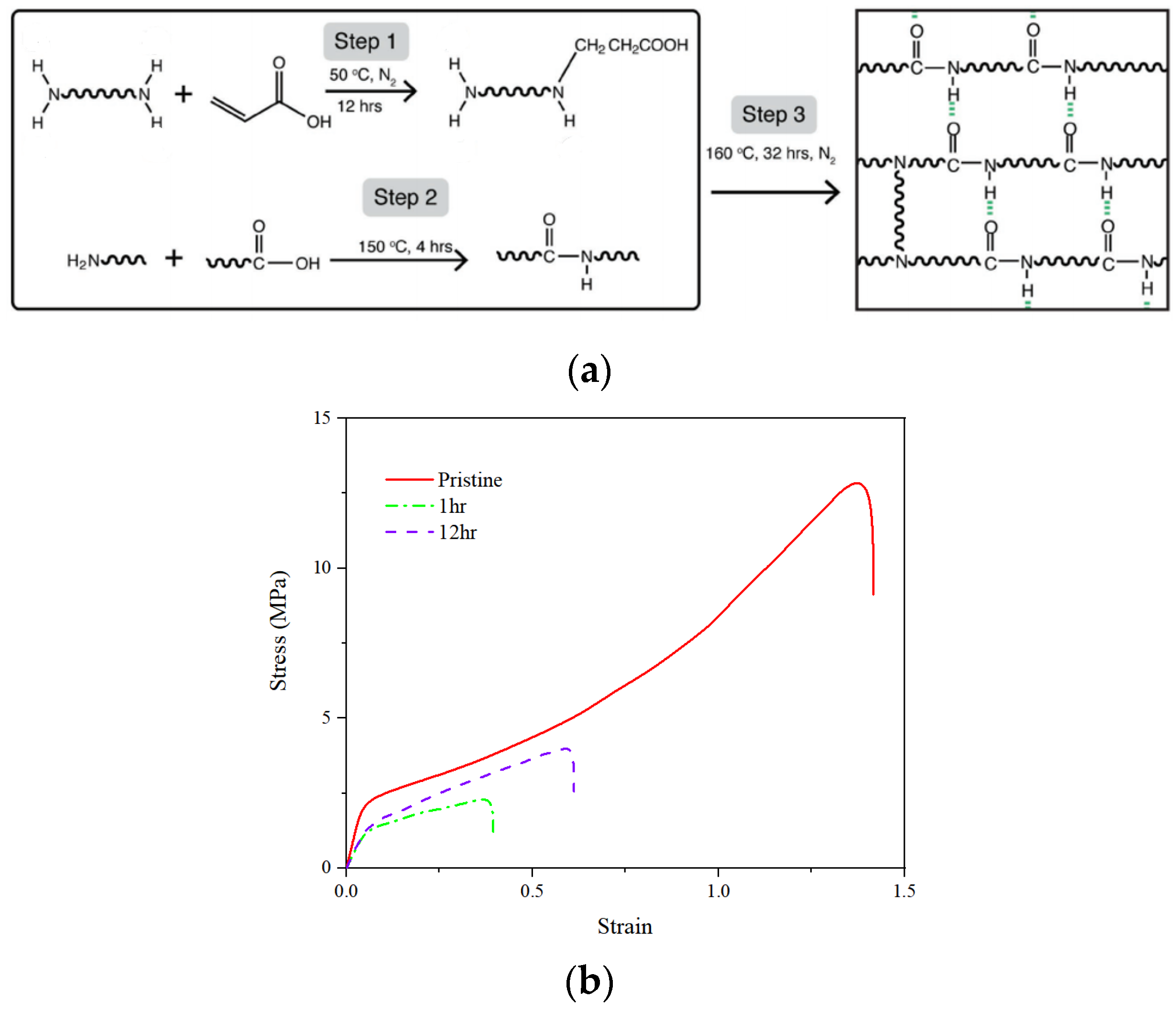

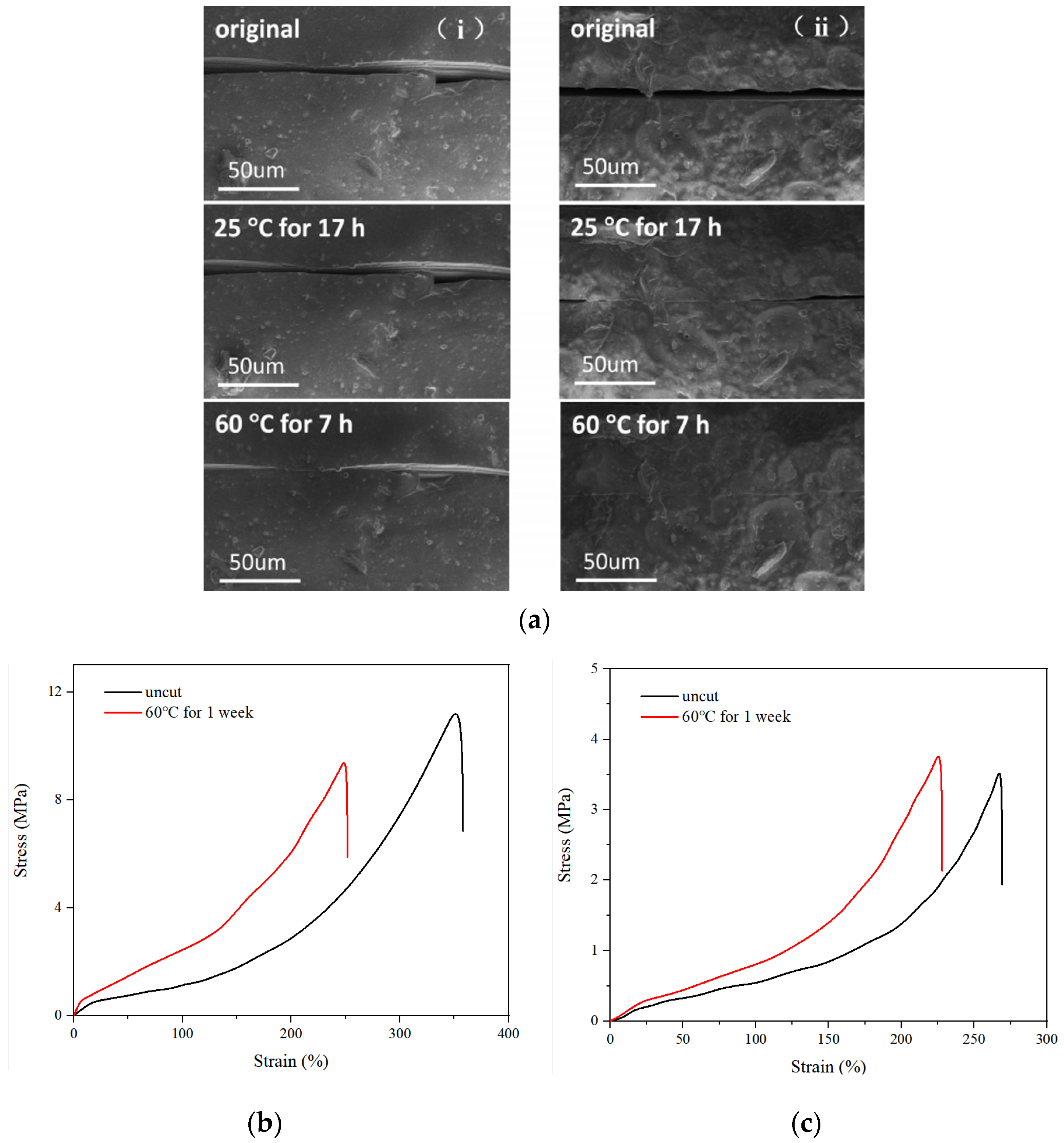

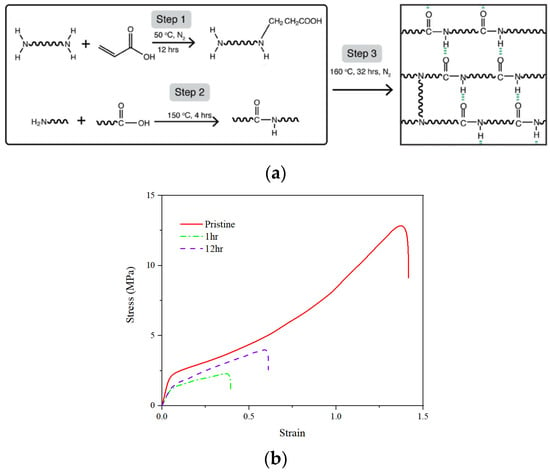

In a recent study, Zhang et al. [69] explored a highly resilient and spontaneously self-healing polymer known as Fe-PPOU. This polymer, which incorporates seven dynamic bonds, demonstrated exceptional healing efficiency at ambient temperatures, a result attributed to its multiple crosslinking sites. A high-performance elastomer with self-healing effect is obtained by crosslinking randomly branched polymers to force reversible hydrogen bonds and covalent bonds to form a double network at the molecular level [70]. The elastomer is self-healing at room temperature and has an appreciable self-healing strength of 4 MPa. The details of the synthesis process are shown in Figure 3a. Also, the author presents the stress–strain curves of the original specimen at different healing times at room temperature after the elastomer was cut; although the strength was higher after 12 h of healing, as shown in Figure 3b, the degree of healing was lacking compared to the initial strength. Considering the need for excellent healing efficiency of elastomers, a robust and pliable self-healing elastomer, which leverages a dual reversible reaction network involving ionic bonds and Diels–Alder (DA) reactions, was successfully synthesized, achieving a healing efficiency of approximately 86% [71]. Figure 4a represents the comparison of electron microscopy images of two types of specimens (DRN-0-6 (i) and DRN-24-6 (ii)), post healing under varying durations and temperatures, and it is clear that the latter has a higher healing efficiency. Figure 4b,c also show the comparison of tensile tests of two types of cut specimens (DRN-24-5 and DRN-16-5) with the original specimens after 1 week of healing at 60 °C. The presence of Young’s modulus and fracture stress exceeding the original specimens after healing is due to the reorganization of ionic aggregates in the healed specimens at room temperature, where the tighter ionic lattices result in greater stiffness, but the fracture strain is not exceeded.

Figure 3.

(a) Synthesis of double-network self-healing elastomers with mixed reversible hydrogen and covalent bonds [70]. (b) Stress–strain curves of a double-network self-healing elastomer with mixed reversible hydrogen and covalent bonds at the initial stage (red represents initial uncut) and after a period of self-healing (green dashed line and Purple dashed line represent 1 h and 12 h of contact after cutting, respectively) [70].

Figure 4.

(a) Electronic microscope image of healed specimens DRN-0-6 (i) and DRN-24-6 (ii). (b,c) Stress–strain curves of cut specimens (DRN-24-5 and DRN-16-5) healed at 60 °C for 1 week versus uncut specimens [71].

2.2.2. External Self-Healing

Similar to encapsulation-based concrete healing, external self-healing of polymers is achieved by virtue of embedding techniques. Self-healing systems in polymers are commonly implemented as single or multiple polymeric containers, including microcapsules [5,72,73,74] or hollow fibers [75,76]. The formation of microcracks triggers the release of healing agents from microvessels, and the healing process is accomplished via the interconnection or chemical interaction of these agents at the site of the cracks. The healing agent material at the core is encased in the shell in a physically isolated manner that reduces the reaction with the matrix, and the capsule shell needs to be cracked by external forces to allow the core material inside to flow out and be repaired. The creation of cracks is both the beginning cause and the target outcome of healing. Following the innovative research of white et al. [5], a large number of different encapsulation forms have been designed and developed [14,75]. The size of the microcapsules, content, location distribution, and type of core healing agent all have different degrees of influence on the polymer healing efficiency [77,78]. As anticipated, enhancing the quantity and dimensions of microcapsules can boost self-healing efficiency. However, this enhancement comes at the expense of the material’s inherent mechanical strength, necessitating a balance to be struck.

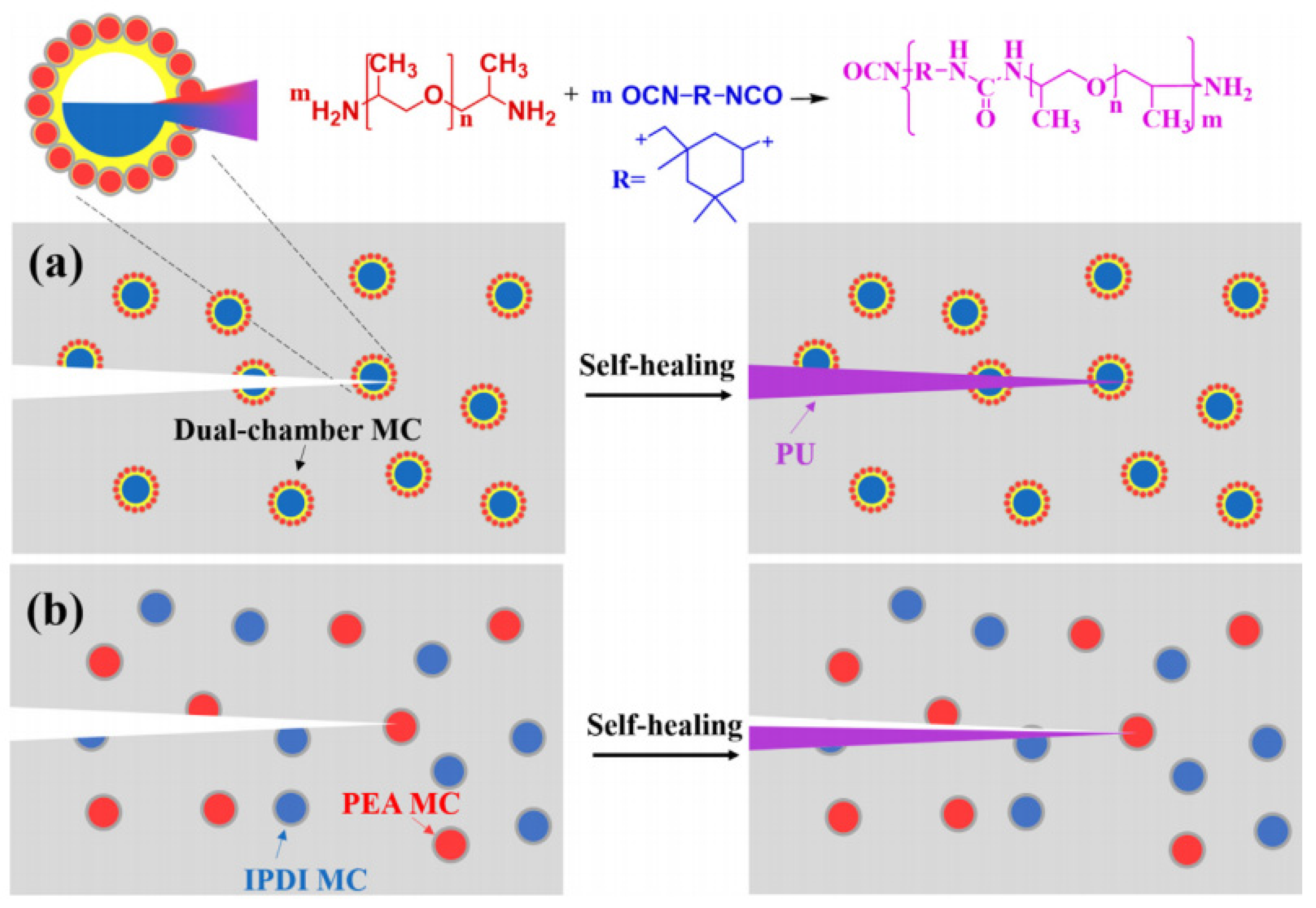

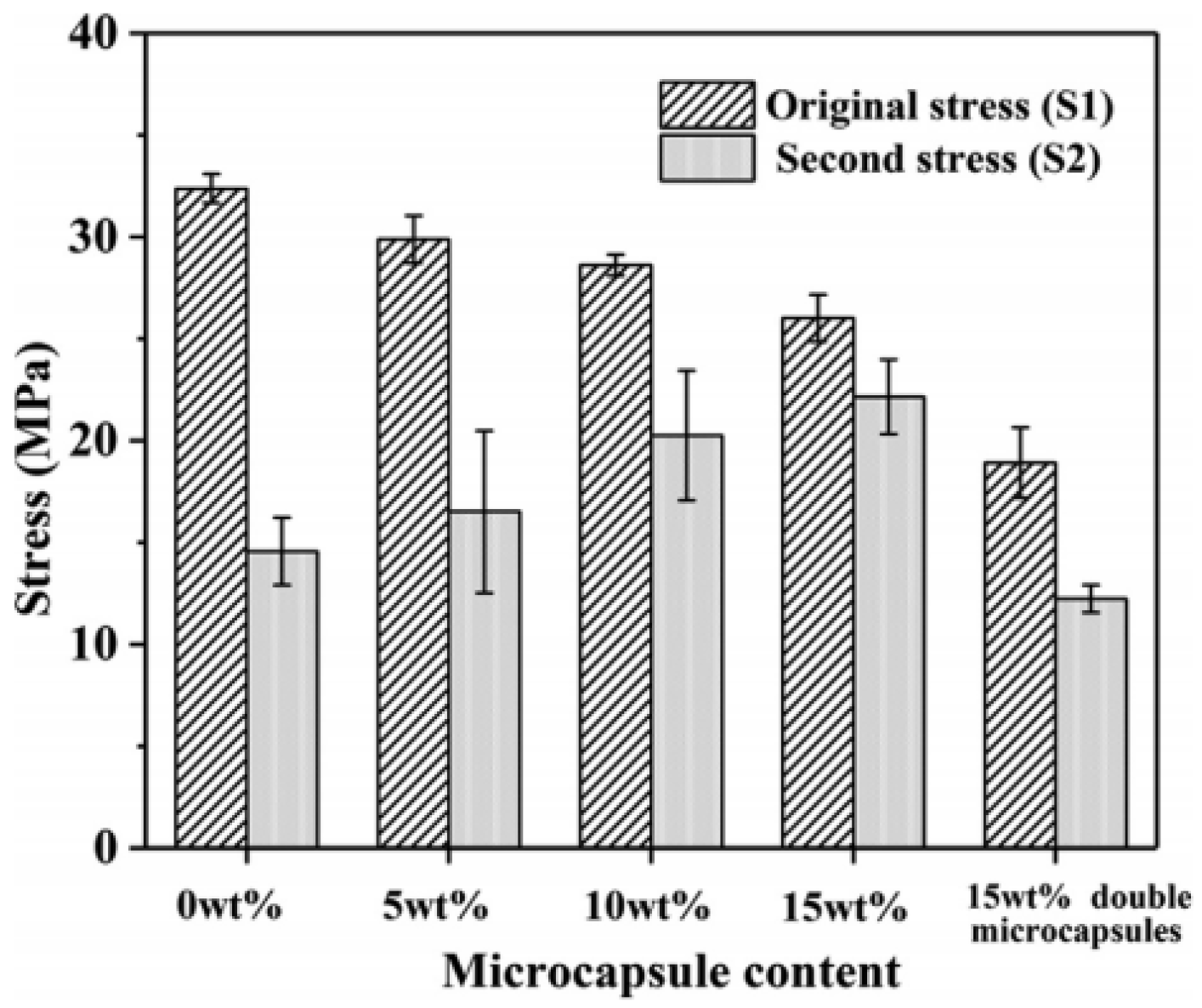

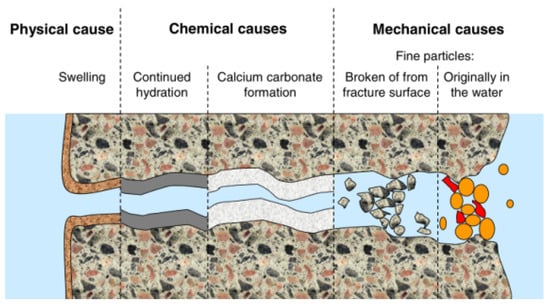

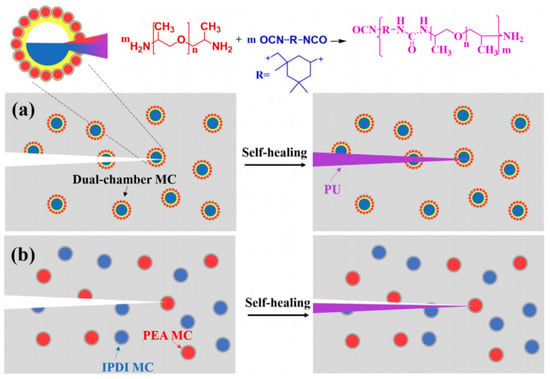

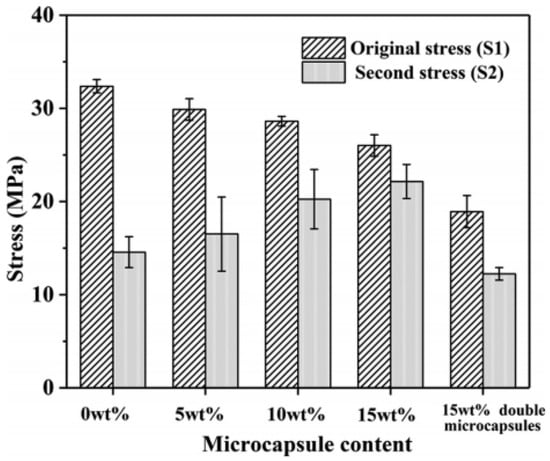

Wu et al. [79] conducted a comparative study to evaluate the impact of double microcapsules, which consist of one microcapsule with the healing agent and another with the catalyst, versus dual-chamber microcapsules, where the healing agent and catalyst are housed in separate compartments within the same microcapsule, on the self-repair capabilities of epoxy resins. The repair principle and repair ability are shown in Figure 5 and Figure 6. It can be seen that, in the epoxy resin containing the same percentage of microcapsules at 15% wt, the second tensile stress can reach 85% of the initial tensile stress for the dual-chamber microcapsules and only 65% for the double microcapsules. This finding further substantiates the superior self-healing efficacy of the dual-chamber microcapsules.

Figure 5.

Healing mechanism of epoxy resin containing different forms of microcapsules: (a) dual-chamber microcapsules and (b) double microcapsules [79].

Figure 6.

Effect of different contents of microcapsules on the second tensile stress of epoxy resin [79].

2.3. Self-Healing Asphalt

2.3.1. Intrinsic Healing of Asphalt Materials

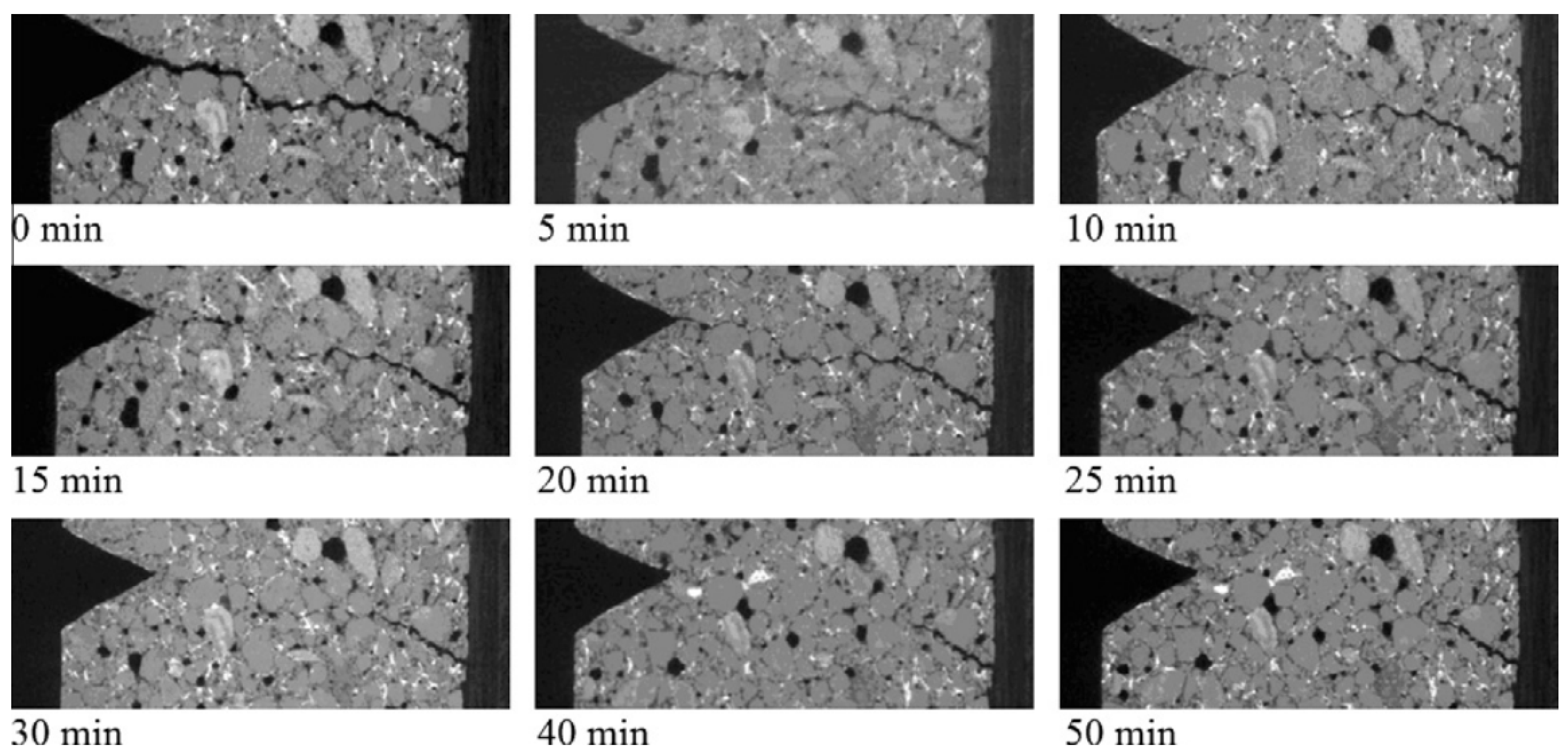

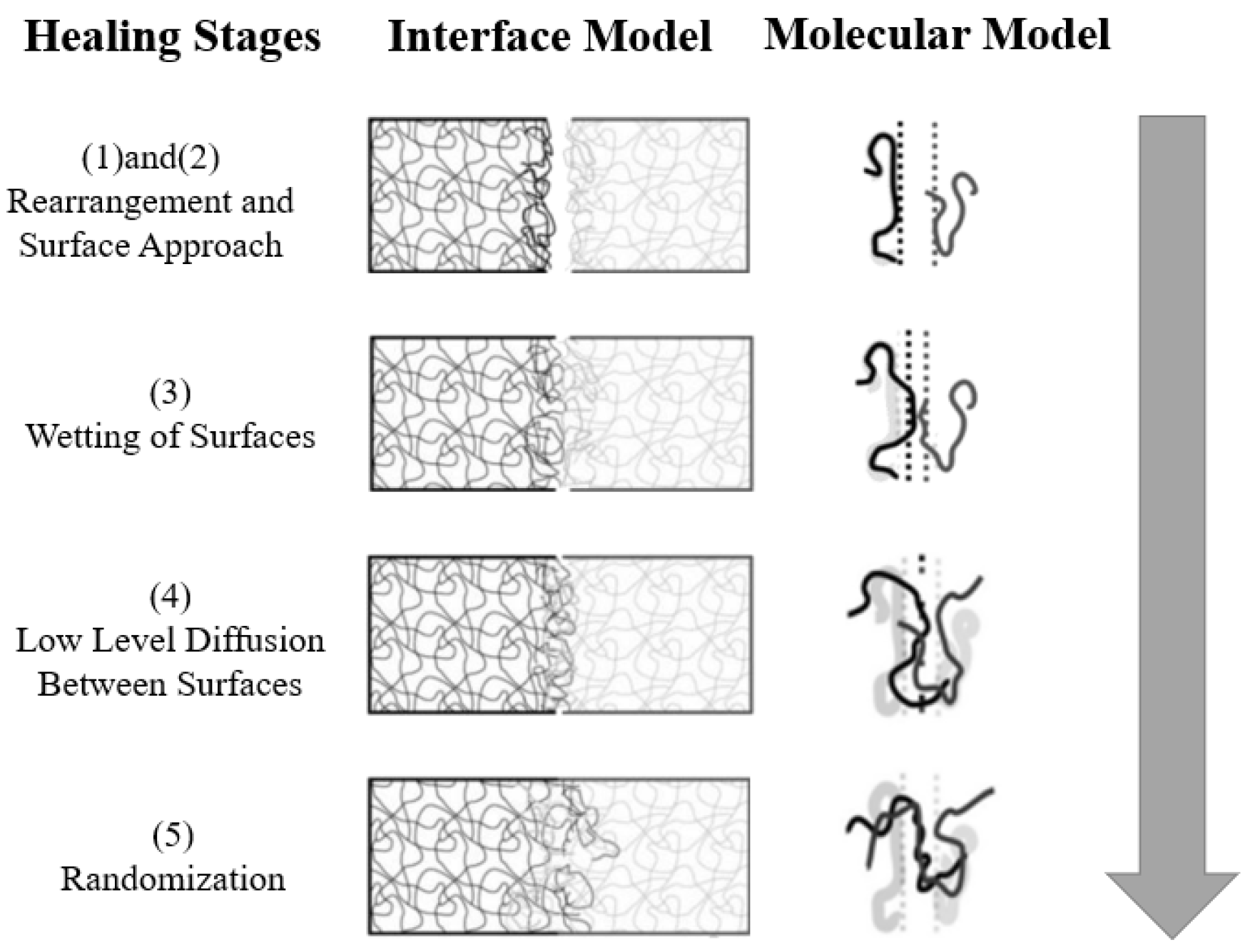

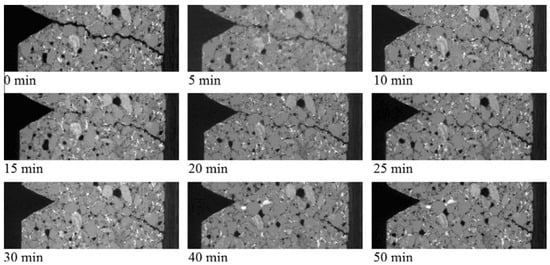

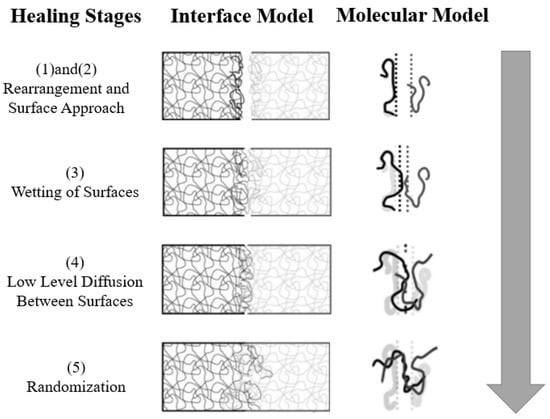

Asphalt is a complex blend of organic polymers with an inherent self-healing ability to heal microcrack damage, which is a material property of asphalt. The healing mechanism of asphalt is not as well defined as that of polymers; it is a complex reaction with a dual overlay of physical and chemical processes. Macroscopically, it can be understood as an intrinsic reaction of crack closure and the material’s mechanical properties are restored. When the temperature exceeds the glass transition temperature, the molecular diffusion within the asphalt becomes more active. This increased mobility facilitates the gradual disappearance of the crack interfaces and the subsequent recovery of mechanical strength. The efficiency and extent of this recovery are influenced by factors such as the material’s surface energy and the inherent molecular diffusion capabilities [80]. Most researchers have employed mechanical testing methods to assess the healing performance of asphalt. These tests typically include evaluations of fatigue life, tensile strength, modulus, stiffness, and crack width [81,82,83,84]. The crack healing of asphalt was examined by García et al. using CT scanning [85]. The healing of asphalt at 70 °C at different healing times is shown in Figure 7, the healing part starts from the contact point and the crack closes gradually. Sun et al. [10] undertook an in-depth study to elucidate the self-healing mechanisms in asphalt across various scales, including the microscale, mesoscale, and macroscale. They proposed a suite of models to elucidate the asphalt healing process: a molecular diffusion healing model for the microscopic level, a surface energy healing model also at the microscopic level, a capillary flow healing theory for the macroscopic perspective, and phase field healing model that encapsulates the complex, multiphase characteristics of asphalt. These models offer a sophisticated framework that enables a deeper comprehension of the intricate healing dynamics inherent in asphalt materials. They divided the healing process into five successive phases based on the interdiffusion theory of polymers, as shown in Figure 8: surface rearrangement, approach, wetting, diffusion, and randomization [80]. A time and temperature dependent healing process was also established in asphalt materials.

Figure 7.

CT scan images of an asphalt beam during healing [85].

Figure 8.

Healing mechanism of molecular interdiffusion in a fractured interface: (1) rearrangement; (2) approach; (3) wetting; (4) diffusion; and (5) randomization [80].

2.3.2. Induction Heating

The capacity of asphalt materials to self-repair is heavily influenced by temperature and the duration of rest. Research indicates that temperature plays a pivotal role in the self-healing efficacy of asphalt. An increase in environmental temperature significantly enhances the healing threshold and accelerates the healing rate, underscoring the importance of temperature in optimizing asphalt’s self-healing capabilities [86]. Nonetheless, the self-healing rate of asphalt at ambient temperatures is typically quite slow and necessitates extended rest periods or the application of external stimuli to enhance the healing process.

Induction heating stands out as an effective technique that can markedly improve the healing capacity of asphalt materials. Two primary methods are employed to induce heating in asphalt for the purpose of enhancing its healing efficiency: electromagnetic induction heating (EIH) and microwave induction heating (MIH). Both techniques utilize different principles to generate heat within the asphalt matrix, thereby accelerating the healing process. The former involves the addition of electrically conductive or magnetically sensitive materials to the asphalt mix. An external electromagnetic field is then used to generate heat within the conductive medium of the asphalt. This heat melts the asphalt, which flows rapidly into any cracks present. The heated asphalt is treated as a Newtonian fluid when its temperature surpasses the softening point. The melted material fills the cracks through capillary action, effectively healing the damage [87].

García et al. sought to augment the self-repairing properties of asphalt mixtures via the integration of steel fibers. They employed external induction heating to elevate the material’s temperature, thereby boosting the mixture’s capacity to mend microcracks [88]. In addition, Liu et al. [89] conducted a study to assess how varying lengths of steel fibers and different volumes of asphalt impact the healing efficiency of asphalt mixtures. Their findings revealed that the rate of induction heating increased gradually with increasing length of steel fibers, but the healing degree threshold decreased gradually. Steel slag with magnetic phase also positively promotes heating-induced healing of asphalt pavements [90]. The MIH technique involves adding materials to the asphalt mixtures that can absorb microwaves and microwave heating can also facilitate the healing process. Various materials, including iron powder, steel fibers, and ferrite, have been thoroughly studied and have demonstrated the ability to enhance the microwave absorption capabilities of asphalt mixtures [89,91,92,93,94].

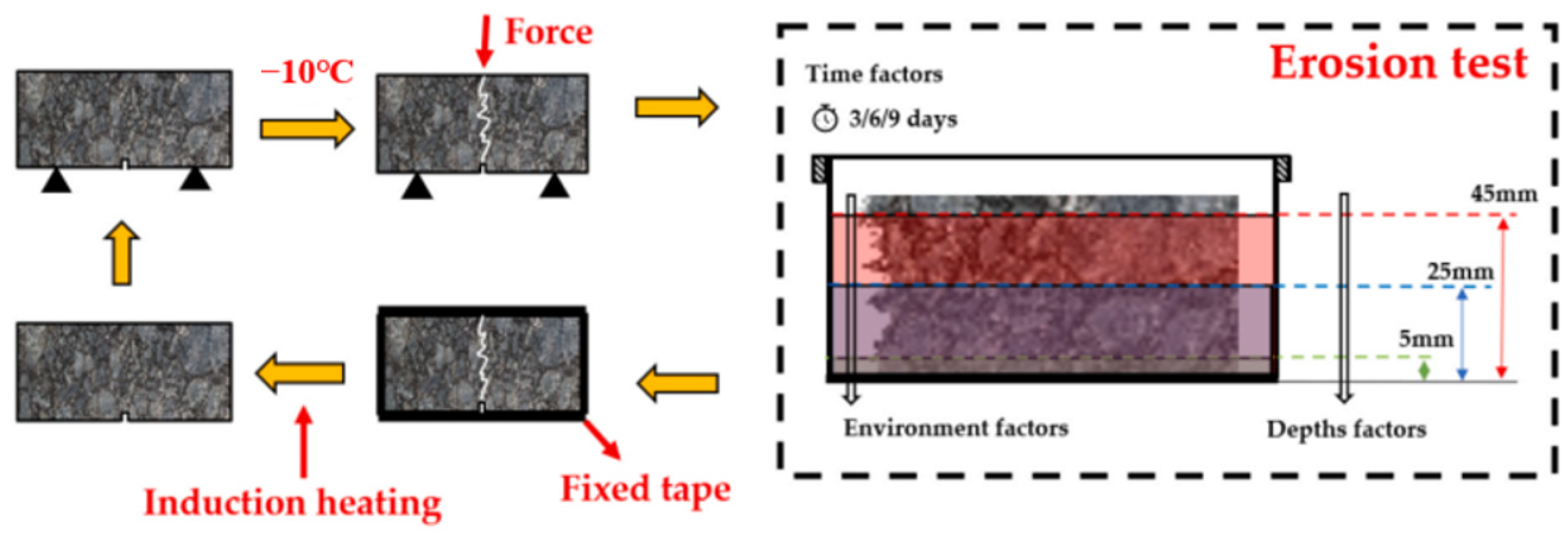

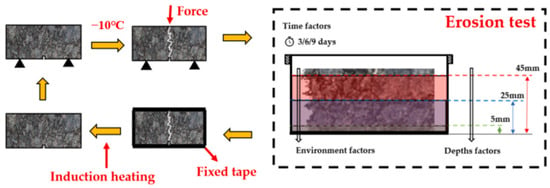

Recently, Lou et al. [95] examined the self-healing characteristics of asphalt mixtures containing hot braised steel slag (HBSS) and showed that the asphalt mixture exhibits better healing performance when the coarse aggregate had a 60% volume share of HBSS. In addition, Liu et al. [96] further demonstrated the good microwave absorption capacity of hot poured steel slag (HPSS) and its effectiveness in increasing the surface temperature of asphalt mixture. Research proves that microwave heating has a better asphalt crack healing effect than electromagnetic induction heating [97]. However, it also has problems, such as nonuniform heating, change in void distribution, and asphalt outflow [98]. Considering the effects of time, erosion environment, and heating depth on the healing efficiency of induction heating, Xu et al. [99] used a machine generating electromagnetism to heat asphalt concrete to different degrees, and 36 sets of specimens (4 environments × 3 times × 3 heating depths) were used for orthogonal tests. The healing process and loading is shown in Figure 9. They concluded that the erosion environment has the greatest degree of influence on accelerated asphalt aging (especially NaOH solution), the depth of heating has the least sensitive degree of influence, and induction heating needs to be executed in time after cracks occur in asphalt pavements.

Figure 9.

Process of asphalt concrete healing and loading fracture [99].

2.4. Self-Healing Models

2.4.1. Continuum Damage-Healing Mechanics

Indeed, the continuum damage-healing mechanics (CDHM) framework is versatile enough to encompass a variety of healing mechanisms. This is because damage and healing are considered as relative physical states within the material. Healing processes effectively reduce the volume of damage, which aligns with the principles of CDHM, so that the applicability of the CDHM appears to be relatively broad. The CDHM is based on continuum damage mechanics (CDM) and the fundamental challenge of CDM lies in quantifying material damage. Numerous researchers have introduced damage variables, commonly defined as the proportion of the damaged area relative to the total area for each idealized homogeneous material. Concurrently, the concept of effective stress has been utilized to characterize damage variables [100], offering a nuanced approach to understanding the degradation of material integrity. For anisotropic materials, the damage variable is expressed in tensor form [101]. In addition, CDM has further applications in the field of composites and non-destructive materials [102,103]. Inspired by the concept of self-healing, Barbero et al. [11] have made significant contributions to the field of self-healing materials by developing the CDHM within a consistent thermodynamic framework for composites. This development involved the integration of healing variables into the constitutive equations, and these healing variables are designed to capture the restoration of material properties following damage. The relationship between these two variables can be considered to be the countdown [104].

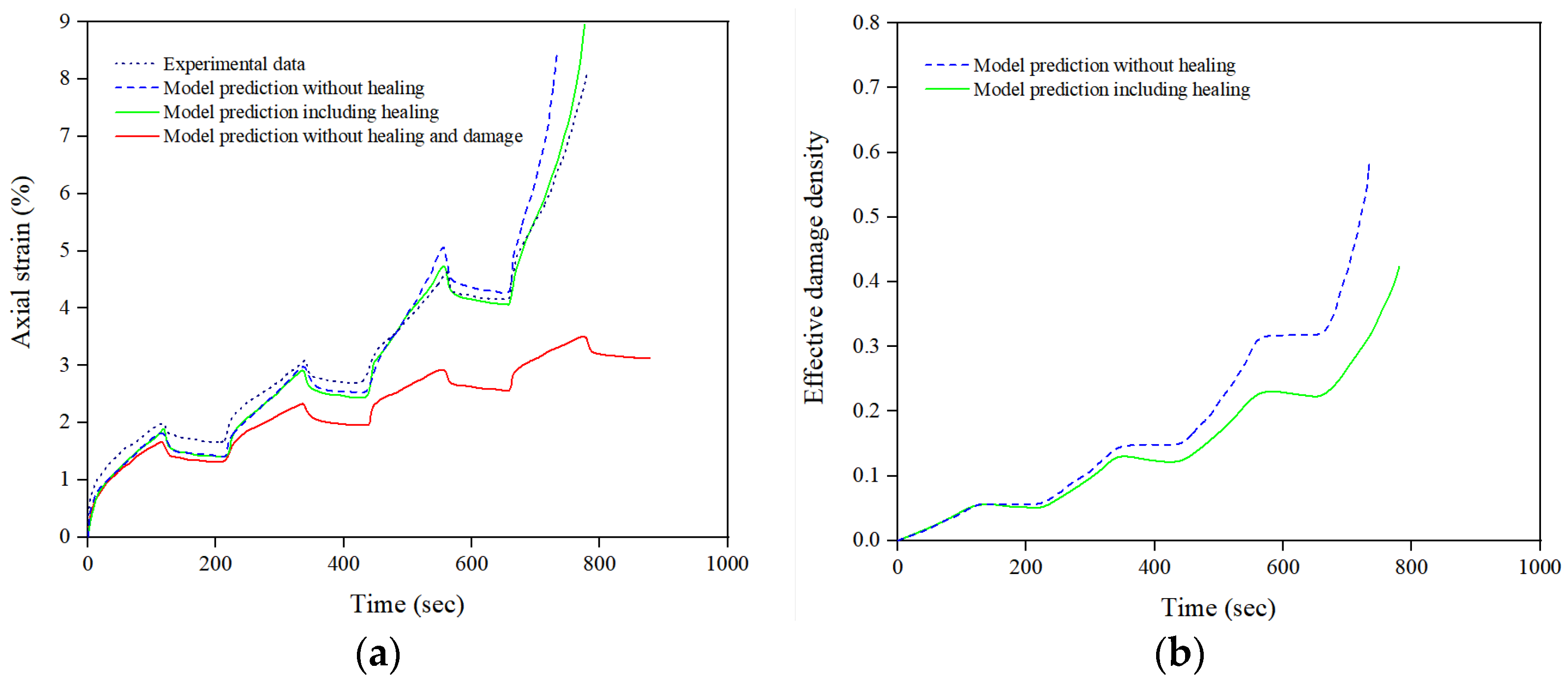

The CDHM model has been adopted by many researchers in their models. Al-Rub et al. [105] have advanced the modeling of asphalt’s self-healing properties, particularly under fatigue loading, by introducing a microdamage healing model. This model is an extension of established viscoelastic, viscoplastic, and viscoplastic damage models, and it incorporates a healing variable that accounts for healing time, damage history, damage severity, and temperature. A healing evolution equation is also defined based on phenomenology:

where h represents the healing variable, is the effective damage density, T is time, Γ is the parameter used to determine the rate of healing, and Y1 and Y2 are material parameters. This model is employed to forecast the responses observed during creep-recovery assessments for materials subjected to compressive and tensile forces. Figure 10 shows the results for creep strain and effective damage density over time. In Figure 10a, incorporating a healing mechanism into the model leads to an enhancement in the material’s performance compared to a model that does not account for healing. Conversely, Figure 10b illustrates that the effective damage accumulates quickly during the loading phase, diminishes during the resting period, and remains steady during unloading. This observation indicates that the effective damage density is not solely irreversible. The model, which includes both healing and damage variables, provides a more accurate prediction of the total creep strain.

Figure 10.

Repeated recovery test in compressive loading rest period: (a) creep strain and (b) the effective damage density under healing [105].

Darabi et al. [106] further investigated the evolutionary laws for microdamage healing proposed in the literature [105] and proposed a CDM framework to simulate the healing of microdamage in materials that are under cyclic loading conditions. Considering the healing evolution law and incorporating the experimental data of Al-Rub et al. [105], Shahsavari et al. [107] found that the healing variable did not significantly influence the predicted mechanical behavior at low levels of damage; the following healing evolution equation was obtained by extending Equation (1):

where u represents the step function and D0 is the damage threshold.

The CHDM model is considered to be stress dependent. Based on the study of materials with healing agents, Pan et al. [108] derived their general self-healing model, where the healing efficiency is quantified by the energy release rate associated with the healing variable h, and the stress state is expressed as an equivalent stress. The chemical energy of the material system with diffuse interfaces is also taken into in the healing evolution equation, as follows:

where L and ζ are proportionality coefficient and thermodynamic perturbation term, respectively; Yh and are the healing strain energy release rate and equivalent stress, respectively; d and h are the damage and repair variables, respectively; and λ and χ are the material parameter and energy gradient coefficient, respectively. This equation further relates the stress state to the internal variables.

Voyiadjis et al. [109] have developed a coupled inelastic damage healing mechanism within a thermodynamic framework. Their approach introduces two yield surfaces for damage and healing that incorporate the effects of isotropic hardening. The theoretical framework detailed in [104] has been enhanced to encapsulate the dual dynamics of damage and healing in self-healing polymers. The model employs an exponential healing function that evolves with time and is directly associated with the damage variable. Esgandi et al. [110] presented a CDHM model tailored for unsaturated materials. This model was crafted by integrating the complementary energy equivalence hypothesis within a damage-healing framework. It uses an elastic–plastic damage-healing intrinsic model with a constant healing rate. The efficacy of the model is illustrated by a range of example problems, which demonstrate that, by incorporating healing behavior, the model can more precisely forecast experimental outcomes.

To account for the time-dependent properties of hydration products, Chen et al. [111] introduced an innovative damage-healing model within the traditional CDM framework. This model is specifically designed to capture the hydration-induced self-healing phenomena. The parametric calibration of the model is based on experimental data. Shahsavari et al. [112] have put forward a thermodynamically coherent intrinsic model for concrete materials. This model is grounded in the CDHM and utilizes the stress spectral decomposition technique to provide a robust framework. The model’s effectiveness for self-healing concrete materials was validated via a parameter study conducted under both tensile and compressive loading conditions. The outcomes of this research were found to be in close correspondence with experimental observations, confirming the model’s practical utility.

The maximum degree of healing can only restore the initial state, but a super-healing phenomenon exists in some materials; this means that the healing variable is greater than 1. The theory of super healing was proposed by Voyiadjis and Kattan [113]. Super healing, as characterized, refers to the enhancement of a material’s strength beyond its original state. This concept has been empirically observed and documented in various experimental studies [114]. This theory was further refined by Oucif et al. [115], by whom the theory of non-linear super healing was extended and planar stress examples were applied. In addition, the authors further studied the differences between different effective variables [12].

2.4.2. The Cohesive Zone Model

The CDHM framework is a good representation of microcrack formation and healing in the continuum body, which is a great advantage for self-healing materials for encapsulated systems with microcapsules. However, it has limitations for some healing mechanisms, such as embedded vascular healing of macroscopic cracks. A correct representation of the crack location formation, geometry, and flow of the healing agent is required at this point to make an accurate prediction of the healing behavior. There appears to be a consensus of using a cohesive-zone intrinsic model to establish a relationship between the traction force acting across a crack and the corresponding crack opening displacement. Unlike CDHM, the cohesive zone model is particularly advantageous for its discrete treatment of material damage as a cohesive crack, facilitating explicit modeling of both crack evolution and the healing process. Maiti et al. [116] have utilized this model to effectively simulate the healing behavior of polymers, capturing the dynamics of how these materials respond to damage and subsequent repair. In their model, self-healing was simulated by introducing wedges in the cracks with an artificial crack closure technique. The experimental observations are consistent with the simulation results.

Building on the thermodynamic framework of Darabi et al. [106], Abu Al-Rub et al. [117] used a thermodynamic-based cohesive zone approach for modelling self-healing behavior by extending prior research on the CDHM to propose a new physics-based internal healing state variable. Further studies were carried out by Alsheghri and Abu Al-Rub et al. [118,119], who assumed that crack closure at bond stress was the cause and that healing occurred at the top of crack. Their cohesive zone model separates the damage and healing variables into components that are perpendicular and tangential to the crack’s orientation. Despite this distinction, a unified evolution equation is applied to both components. The healing degree is determined by an amalgamation of instantaneous effects and time-dependent factors. The time-dependent aspects are formulated as functions that consider the history of damage and healing, the closure of the crack, and the influence of temperature. A model [119] was simulated in the finite element software ABAQUS 6.12, a suite of model parameters was calibrated, and a series of polymethyl methacrylate (PMMA) crack healing simulations were conducted and benchmarked against experimental data [120]. The results demonstrated a high degree of accuracy in replicating the observed experimental behaviors, validating the model’s effectiveness.

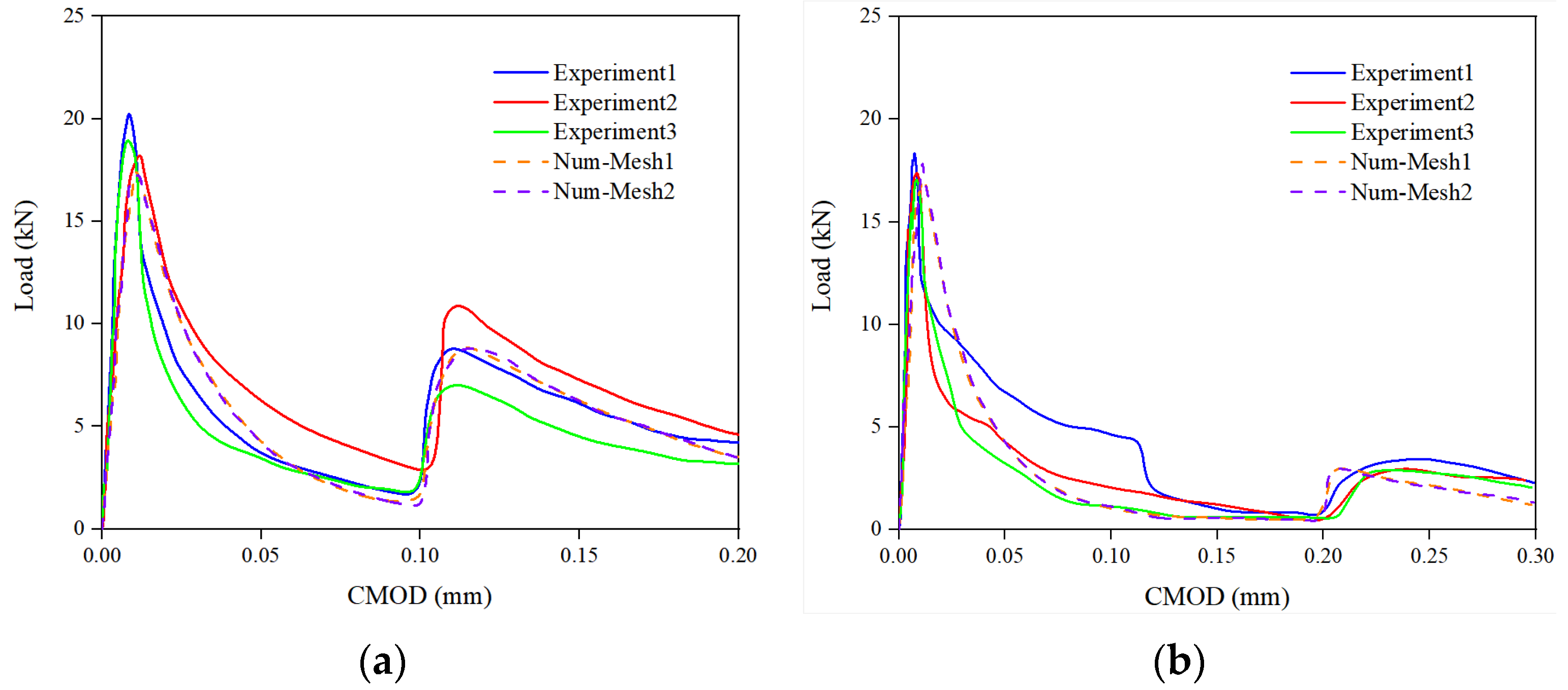

Current models that utilize the CDHM fall short in precisely capturing the concurrent crack healing phenomena in materials that experience considerable crack opening displacement (COD) and variations in COD rate. Jefferson et al. [121] have addressed this by conflating the concepts of damage and cracking. They introduced an innovative damage healing cohesive zone model that elucidates the impact of the healing process on both COD and the rate at which COD changes. This model has been integrated into a finite element analysis framework to emulate the flow dynamics and mechanical properties of the healing agent within the system. Freeman et al. [122] introduced healing variables at element level that used a strong discontinuity method to depict the displacement discontinuities associated with cracks. The cohesive zone model is utilized to simulate the damage healing dynamics, demonstrating its efficacy in accurately capturing the complex interplay of cracking and healing, as exemplified by the vascular self-healing system. The foundation of their model rests on the following set of constitutive equations:

where denotes the traction force, ∈ (0, 1) is the damage variable, is the crack opening displacement, is the healing COD vector, and ∈ [0, ] indicates the proportion of material that has undergone healing at the present moment. The model captures the progression of the healing variable by employing a rate-dependent exponential curing function, which not only simulates the healing process but also accounts for the possibility of the material being redamaged. Consequently, the dynamics of damage, healing, redamage, and subsequent rehealing all contribute to the fluctuation in the healing variable, denoted as h. The model is designed without imposing any constraints on the sequencing of healing and damaging events, thereby enabling a realistic simulation of scenarios where these processes occur concurrently. Experimental data from a set of direct mechanical tests carried out by the authors on notched rectangular cementitious specimens successfully validated the model. The outcomes of two such validation cases are depicted in Figure 11.

Figure 11.

(a,b) Comparison of the predicted crack width–load curve of the model with the experiment [122].

Bacteria-assisted healing mechanisms are dominated by the precipitation of calcium carbonate in self-healing concrete materials and a crystal pillars growth model was developed to explain this mechanism by Xin et al. [123]. They also modelled the cohesive zone at the interfacial bond and investigated the effect on healing performance based on two factors: interface distance and calcium ion concentration. The results of the simulations are consistent with the effect of bacterial-assisted self-healing of ceramics and cements. They used the area bridged by the crystal pillars as the criterion for healing, with modulus calculated as follows:

where Eh(t) and E0 are the healed and initial modulus at time t, respectively; A(t) is the total cross-sectional area of the crystal bridging columns per unit interface area; is the total number of pillars; and r is the kernel radius.

Ponnusami et al. [124] proposed a cohesive zone model capable of simulating multiple healing events. This model employs a bilinear traction–separation law; the normal and shear tractions are calculated as a weighted average of the tractions that would be present if the crack were filled with either the original material or the healing material. This weighting reflects the proportion of the crack surface that is occupied by each material phase, allowing the model to capture the varying mechanical properties at the crack interface as the healing process progresses.

2.4.3. Machine Learning

The healing mechanisms and models underlying the self-healing capabilities of materials have been a focus of extensive research. However, assessing the self-healing efficiency of materials typically relies on laborious and costly laboratory testing [125]. The advent of machine learning (ML) has provided a transformative approach, allowing researchers to harness existing material data (comprising experimental measurements and simulation outcomes) to perform sophisticated feature extraction and classification tasks.

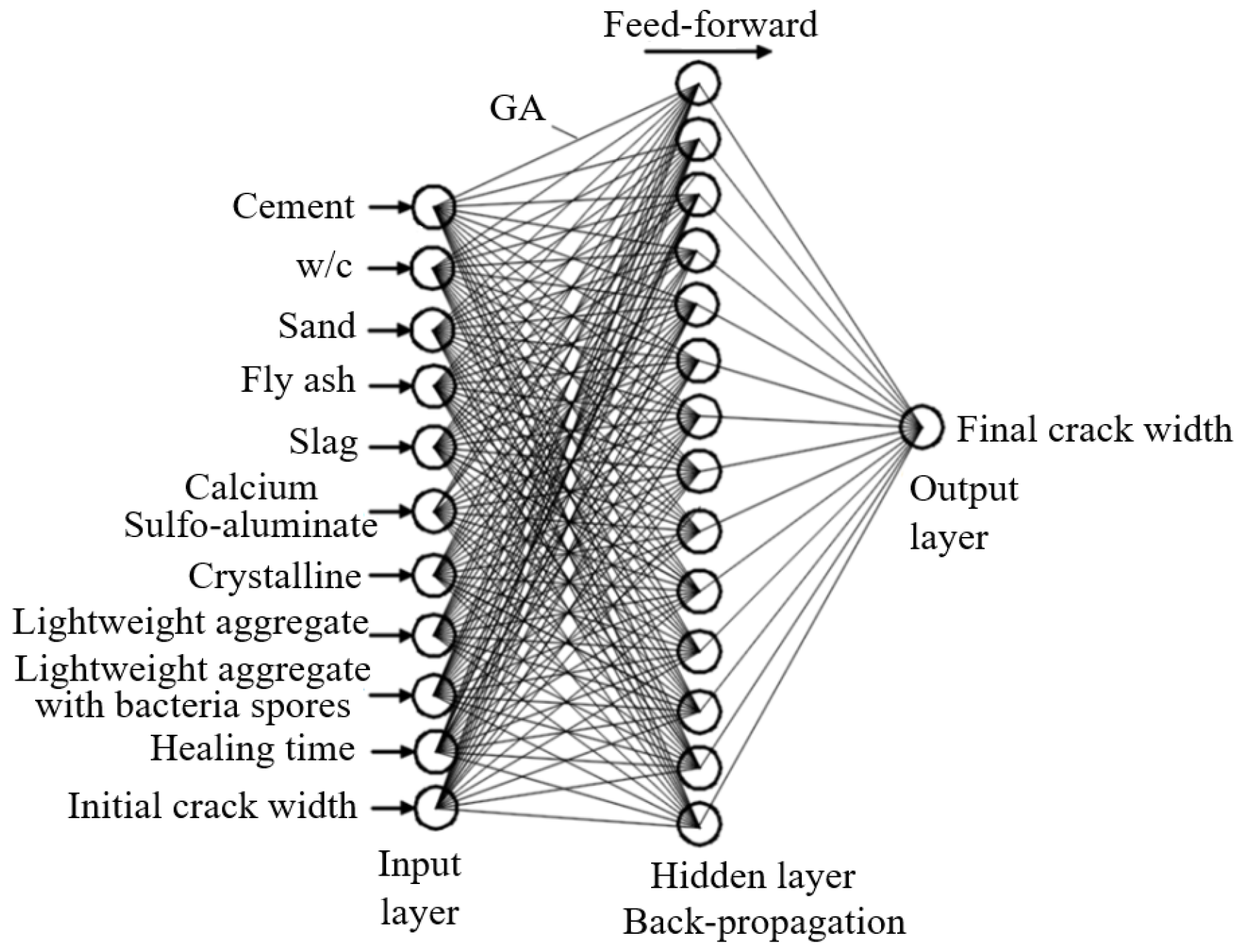

Artificial neural networks (ANN) is a machine learning algorithm based on and modelled on the human brain [126]. The prediction of the compressive strength of self-healing concrete has been studied by Theja et al. [127], who used four key input variables to correspond to the output strength. It was confirmed that the experimental data correlated well with the predicted values of the artificial neural network. Ramadan et al. [128] have employed a sophisticated approach to forecast the crack healing capacity of concrete materials by integrating a hybrid genetic algorithm–artificial neural network (GA–ANN). They amassed an extensive database, drawing upon experimental data from the literature, which encompassed a wide array of concrete compositions and healing agents, initial crack dimensions, and healing durations. This comprehensive dataset served as the foundation for the model’s input parameters. The GA–ANN model, once trained and validated, demonstrated its efficacy in predicting the healing behavior of concrete, as illustrated in Figure 12. The findings indicated that the GA–ANN model, as proposed, successfully encapsulated the intricate impacts of diverse self-healing agents on the inherent healing dynamics of cementitious materials. Based on ML techniques, including regression and classification, Wang et al. [125] developed a neural network model tailored for estimating the self-healing efficiency of materials, with a particular focus on biological self-healing systems, and optimized the prediction model with an online ensemble learning (OEL) framework containing multiple learning methods based on samples and experimental results. The framework can improve the accuracy of the model by using the prediction error of the model and experimental data. The framework and the model are experimentally validated. Determination of whether a new material has self-healing properties can also be achieved using the predictions of the model.

Figure 12.

Architecture of the GA–ANN model [128].

The prediction of material healing properties is also one of the concerns of machine learning modeling studies. Considering that some healing properties such as toughness measurements are destructive and experimentally complex and time consuming. Anwar et al. [129] attempted to predict the material properties of intrinsic self-healing polymers by analyzing images of cuts healed at various times. They combined dynamic and static ML models, proposing an energy functional dynamical model to characterize the evolution of healing performance of self-healing polymers. The model combines a ML model constructed from over 100,000 cut image frames with an energy functional minimization (EFM) model to obtain deeper dynamical systems and establish self-healing dynamics via two-dimensional cut images over time. Given an initial image, a series of healing images are obtained, each representing the healing efficiency at different healing times, i.e., the healing properties under a static model are obtained. In addition, linear regression (LR), back-propagation neural network (BPNN), classification and regression tree (CART), and support vector regression (SVR), which are separate models, were used by Chen et al. [130] to comparatively study the healing capacity of engineered cementitious composites (ECC) and the conclusion pointed out that the LR model and BPNN model have higher predictive performance.

2.5. Computational Simulation

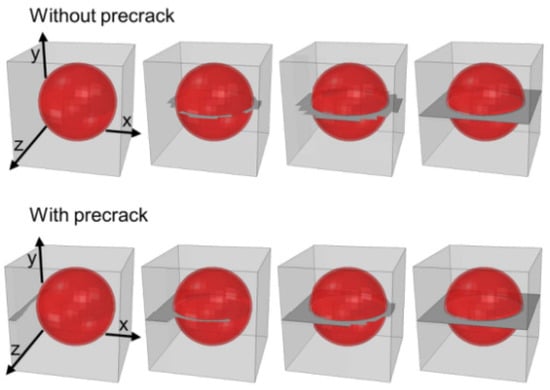

In self-healing concrete, the capsule acts as a carrier of the healing agent and also as an inclusion in the concrete, which will inevitably change the mechanical characteristics of the concrete; it is crucial to understand the effect of the capsule on the mechanical capacity of the self-healing concrete under various mechanical loading conditions. Regarding the aggregation of capsules and their volume fraction, researchers Gilabert et al. [131] employed a dual-model approach that integrates the extended finite element method (XFEM) with the cohesive surfaces (CS) technique to forecast crack propagation. This approach was utilized to analyze the fracture dynamics within a self-healing encapsulation system. They used a representative volume element (RVE) containing a single microcapsule to describe the material, with a uniform distribution of microcapsules and the single microcapsule set at the center of the element, as shown in Figure 13. Comparing concrete beams with elongated capsules in three-point bending tests, the model was found to exhibit similar nonlinear responses in bending and tension, indicating that the model well simulates the elastic and breaking stress with volume fraction, while the anticipated homogeneity of the material aligns well with the observed experimental tendencies.

Figure 13.

RVE modeling of crack evolution [131].

Hanna et al. [132] further developed a simple 2D calculational simulation method based on these two above techniques to investigate the effect of microcapsule size and distribution on microcapsule rupture in self-healing concrete. The findings revealed a direct correlation between the microcapsules’ circumferential contact length and their ability to support load. Additionally, it was observed that microcapsules with thinner shells are more susceptible to rupture. Gao et al. [133] conducted the interaction between microcapsules and extended cracks in a resin matrix in an extended finite element framework. They also utilized the fluid–solid coupling finite element model in COMSOL Multiphysics to simulate the flow and filling process of the healing agent in a self-healing polymer matrix composite. The researchers meticulously analyzed and quantified the impact of microcapsule dimensions and concentration on the healing effectiveness. This effectiveness was gauged by the improvement in the fracture toughness index.

In practical applications, the engineered aggregate (EA) in the actual project is a macroscopic capsule with a cement coating. Pan et al. [134] used the lattice discrete particle model (LDPM) [135] to computationally simulate the effects of various types of EA properties on self-healing concrete. These studies showed that microcapsule size, distribution, volume fraction, shell type, mechanical properties, and binding to surrounding mechanisms all influence the strength of self-healing materials, and these simulations provide specific guidance for the design of microcapsules.

Due to the complex components and structure of asphalt, it is more advantageous to explain its healing mechanism at the molecular scale, but the continuous medium theory and traditional testing methods are used less at the molecular scale. Molecular dynamics (MD) is a powerful tool for studies to simulate the self-healing asphalt. MD simulations offer a sophisticated tool for tracking the dynamic movements of atoms within a system over time, yielding comprehensive insights into molecular motion and interactions. These simulations facilitate a bridge between the microscopic scale of atomic behavior and the macroscopic properties of materials via the application of statistical mechanics.

Pioneering work by Bhasin et al. [136], which integrated MD simulations into the analysis of asphalt’s self-healing capabilities, has paved the way for subsequent research endeavors, significantly influencing the study of asphalt’s reparative properties. In 2018, Sun et al. [137] introduced a three-dimensional microcracking model on the average molecular structure of asphalt to explain the microscopic healing process of asphalt based on MD simulations. Their findings revealed that the healing ability is higher in the range of phase change temperatures, while too high temperatures affect the healing efficiency, with the optimum temperature being 40.3–48.7 °C. Temperature and crack width are more commonly considered for asphalt healing, and in order to further consider the influence of the asphalt crack expansion process on the healing.

He et al. [138] conducted a study in which they utilized MD simulations to develop a detailed molecular model of asphalt binder. This model was meticulously validated against experimental data for key properties such as density and solubility parameters. A 50 Å vacuum pad was added to create an interface system to investigate the evolution of the healing behavior of the asphalt binder. They concluded that the volumetric “compression” and “stretching” was the reason that the microcracks in the vacuum section disappear.

Fu et al. [139] established a molecular model of vegetable oil bio and waste edible oil asphalt to study their adhesion healing behavior. They added cohesive energy density to the validation characteristics of the model. The results from their study suggested that bio-asphalt exhibited greater temperature sensitivity and healing efficiency compared to conventional asphalt. However, they also found that the actual difference in healing capacity between the two types of bio-asphalt was not substantial.

3. Results and Discussion

For autogenous healing to occur, two key prerequisites must be met: the availability of water and the limited crack width. The intrinsic autogenous healing capability of concrete is primarily effective for minor cracks; this self-repair process has been the subject of extensive research. However, there is still no consensus on the maximum healable crack size. It is clear that relying on purely autogenous healing mechanisms alone is unreliable, and in order to obtain better healing performance, materials like minerals into the concrete matrix can enhance the efficiency of crack healing in concrete. These additions are less expensive compared to encapsulated systems. Encapsulation systems tend to be more effective in facilitating concrete healing, yet they can adversely affect the concrete’s mechanical properties. This is particularly true for systems that incorporate larger carriers, such as big capsules. As the size of these capsules increases, it contributes to higher porosity within the material, which in turn can lead to a gradual decline in the concrete’s mechanical strength. Therefore, a balance must be struck between the desired healing performance and the maintenance of structural integrity.

In the realm of encapsulation systems for self-healing, there exists no universal agreement on a particular healing agent. Various researchers employ a range of microcapsule types and quantities, resulting in a lack of standardization for this field. Additionally, self-healing carriers all have a certain healing life, which is much less than the design life of concrete. Studies have shown that self-healing concrete is more sustainable than conventional concrete but requires more inspection and repair during its working life. Self-healing techniques for relevant concrete materials in this research are summarized in Table 1.

Table 1.

Summary of self-healing technology for concrete materials.

From an economic point of view, the practical application of bacterial-based self-healing concrete faces challenges, mainly due to the restrictive nature of the synthetic microbial spores and the culture environment, which will lead to a huge financial and human cost. How to reduce the cost of using self-healing concrete and improve the robustness, durability, and reliability of its healing capabilities should be the focus of future work.

External self-healing polymer materials will create gaps in storage containers and form new defects after releasing the healing agent. There are a series of problems, such as dispersion, reduced activity, and high requirements for storage container production technology and embedding technology conditions, making it difficult for extrinsic self-healing to be widely used in practice.

The deactivation of the healing agent inside the encapsulated material, the conditions and the time required for healing are all things that need further comprehensive consideration in the future before they can be of any real value in engineering applications. Different forms of encapsulation can produce different healing effects. Simple preparation and excellent self-healing properties seem to be more contradictory, as do microcapsule content and raw mechanical strength; the solutions to these problems will be developed even further in the future for practical applications of self-healing polymers. Intrinsic self-healing is highly efficient, reproducible, and stable, but there are some limitations, for example, most materials require the application of external stimuli to heal, such as elevated temperature, and require a long healing time.

In contrast, intrinsic self-healing mechanisms are characterized by their high efficiency, reproducibility, and stability. Compared to external self-healing, intrinsic self-healing has been widely studied and has become a prominent focus in the realm of self-healing polymers. This is attributed to its design flexibility, low technical difficulty, ease of integration into self-healing systems, and the ability to heal the same damaged area repeatedly. Self-healing techniques for relevant polymer materials in this study are summarized in Table 2.

Table 2.

Summary of self-healing technology for polymer materials.

The efficacy of asphalt materials’ self-repair is contingent on factors like time and temperature. Typically, in ambient conditions, the healing performance of standard asphalt materials falls short of expectations. To enhance this healing capability, various strategies can be employed, including the integration of microcapsules [140], nanoparticles, or the application of additional energy sources, such as induction heating. These methods are designed to boost the asphalt’s inherent self-healing capacity, making it more effective at repairing damage and prolonging the material’s lifespan. The use of materials like fibers and steel slag in the induction heating process for asphalt presents certain challenges, particularly in the mixing stage. It also brings negative effects, such as strength loss; the convenience of mixing materials, heating speed, and heating depth need to be investigated in future research. At present, although there are some developed self-healing asphalt research techniques, the mechanism of different technical means and the establishment of a new asphalt self-healing evaluation system need to be explored in depth.

4. Conclusions

The purpose of self-repairing materials is to lessen the detrimental effects of damage, an idea of significant value in the field of applied engineering. The current research into self-healing behaviors lays a solid foundation for the future utilization of these materials. This study provides an extensive examination of the restoration processes in various self-repairing materials, encompassing both theoretical models and computational simulations. Synthesizing the findings from an extensive review of the literature, this study distills the following insights regarding the self-healing characteristics of materials:

- (1)

- The CDHM, grounded in continuum thermodynamics, encapsulates the transition from damage to healing through internal variables. This model is currently the most extensively applied in the field.

- (2)

- Within certain limits, healing capacity is positively correlated with time and temperature. Although there are specialized models for studying external mechanical loads, experimental research in this area is relatively limited.

- (3)

- Using machine learning to build a predictive model of self-healing performance based on simulations of existing experimental data will be helpful for future research efforts.

- (4)

- Multiscale characterization can help deepen our understanding of repair mechanisms and predict and evaluate the performance of self-healing materials, especially via molecular dynamics simulations.

Funding

This research was funded by the National Natural Science Foundation of China (12002247), the National Key Research and Development Program of China (2023YFC3008802) and the Funda-mental Research Fund for the Central Universities of China (WUT: 2021IVB013).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-healing materials: A pathway to immortal products or a risk to circular economy systems? J. Clean. Prod. 2021, 315, 128193. [Google Scholar] [CrossRef]

- Hossain, M.R.; Sultana, R.; Patwary, M.M.; Khunga, N.; Sharma, P.; Shaker, S.J. Self-healing concrete for sustainable buildings. A review. Environ. Chem. Lett. 2022, 20, 1265–1273. [Google Scholar] [CrossRef]

- Ayar, P.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The healing capability of asphalt pavements: A state of the art review. J. Clean. Prod. 2016, 113, 28–40. [Google Scholar] [CrossRef]

- Paolillo, S.; Bose, R.K.; Santana, M.H.; Grande, A.M. Intrinsic self-healing epoxies in polymer matrix composites (PMCs) for aerospace applications. Polymers 2021, 13, 201. [Google Scholar] [CrossRef] [PubMed]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, T.; Al-Tabbaa, A. Self-healing concrete and cementitious materials. Adv. Funct. Mater. 2020, 32, 137–144. [Google Scholar]

- Anupam, B.R.; Sahoo, U.C.; Chandrappa, A.K. A methodological review on self-healing asphalt pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Kadam, S.; Chavan, S.; Kanu, N.J. An insight into advance self-healing composites. Mater. Res. Express 2021, 8, 052001. [Google Scholar] [CrossRef]

- Tavangarian, F.; Hui, D.; Li, G. Crack-healing in ceramics. Compos. Part B Eng. 2018, 144, 56–87. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Zhu, X.; Guarin, A.; Li, B.; Dai, Z.; Ling, J. A comprehensive review on self-healing of asphalt materials: Mechanism, model, characterization and enhancement. Adv. Colloid Interface Sci. 2018, 256, 65–93. [Google Scholar] [CrossRef]

- Barbero, E.J.; Greco, F.; Lonetti, P. Continuum damage-healing mechanics with application to self-healing composites. Int. J. Damage Mech. 2005, 14, 51–81. [Google Scholar] [CrossRef]

- Oucif, C.; Voyiadjis, G.Z.; Kattan, P.I.; Rabczuk, T. Investigation of the super healing theory in continuum damage and healing mechanics. Int. J. Damage Mech. 2019, 28, 896–917. [Google Scholar] [CrossRef]

- Smojver, I.; Ivančević, D.; Brezetić, D. Modelling of micro-damage and intrinsic self-healing in unidirectional CFRP composite structures. Compos. Struct. 2022, 286, 115266. [Google Scholar] [CrossRef]

- Pittala, R.K.; Dhanaraju, G.; Ben, B.S.; Ben, B.A. Self-healing of matrix cracking and delamination damage assessment in microcapsules reinforced carbon fibre epoxy composite under flexural loading. Compos. Struct. 2022, 291, 115691. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Shafaghat, A.; Keyvanfar, A.; Majid, M.Z.A.; Ghoshal, S.K.; Yasouj, S.E.M.; Ganiyu, A.A.; Kouchaksaraei, M.S.; Kamyab, H.; Taheri, M.M. Tests and methods of evaluating the self-healing efficiency of concrete: A review. Constr. Build. Mater. 2016, 112, 1123–1132. [Google Scholar] [CrossRef]

- Demo, P.; Přeučil, F.; Prošek, Z.; Tichá, P.; Domonkos, M. Self-Healing of Cementitious Materials via Bacteria: A Theoretical Study. Crystals 2022, 12, 920. [Google Scholar] [CrossRef]

- Indhumathi, S.; Dinesh, A.; Pichumani, M. Diverse perspectives on self healing ability of Engineered Cement Composite-All-inclusive insight. Constr. Build. Mater. 2022, 323, 126473. [Google Scholar]

- Brasileiro, P.P.F.; Brandão, Y.B.; Sarubbo, L.A.; Benachour, M. Self-healing concrete: Background, development, and market prospects. Biointerface Res. Appl. Chem. 2021, 11, 14709–14725. [Google Scholar]

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Muhammad Rashid, R.S.; Abdelgader, H.; Ozbakkaloglu, T. Self-healing concrete as a prospective construction material: A review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef]

- Kanellopoulos, A. Self-Healing Cement-Based Materials: Mechanisms and Assessment. In Self-Healing Construction Materials: Fundamentals, Monitoring and Large Scale Applications; Springer: Berlin/Heidelberg, Germany, 2022; pp. 13–41. [Google Scholar]

- Rose, J.; Grasley, Z.; Tang, M.; Wang, F. Accelerated autogenous healing of concrete pipe sections with crack and decalcification damage. J. Mater. Civ. Eng. 2018, 30, 04018308. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jonkers, H.; Van Tittelboom, K.; Snoeck, D.; De Belie, K.; De Muynck, W.; Verstraete, W.; Wang, J.; Mechtcherine, V. Recovery against environmental action. In Self-Healing Phenomena in Cement-Based Materials: State-of-the-Art Report of RILEM Technical Committee 221-SHC: Self-Healing Phenomena in Cement-Based Materials; Springer: Berlin/Heidelberg, Germany, 2013; pp. 65–117. [Google Scholar]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T. A review of self-healing concrete for damage management of structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Sealing of cracks in cement using microencapsulated sodium silicate. Smart Mater. Struct. 2016, 25, 084005. [Google Scholar] [CrossRef]

- Yang, S.; Aldakheel, F.; Caggiano, A.; Wriggers, P.; Koenders, E. A review on cementitious self-healing and the potential of phase-field methods for modeling crack-closing and fracture recovery. Materials 2020, 13, 5265. [Google Scholar] [CrossRef] [PubMed]

- Saillio, M.; Baroghel-Bouny, V.; Pradelle, S.; Bertin, M.; Vincent, J.; de Lacaillerie, J.B.D.E. Effect of supplementary cementitious materials on carbonation of cement pastes. Cem. Concr. Res. 2021, 142, 106358. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. The influence of MgO-type expansive agent incorporated in self-healing system of Engineered cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- De Nardi, C.; Cecchi, A.; Ferrara, L.; De Nardi, C.; Benedetti, A. Effect of age and level of damage on the autogenous healing of lime mortars. Compos. Part B Eng. 2017, 124, 144–157. [Google Scholar] [CrossRef]

- Qureshi, T.; Kanellopoulos, A.; Al-Tabbaa, A. Autogenous self-healing of cement with expansive minerals-I: Impact in early age crack healing. Constr. Build. Mater. 2018, 192, 768–784. [Google Scholar] [CrossRef]

- Qureshi, T.; Kanellopoulos, A.; Al-Tabbaa, A. Autogenous self-healing of cement with expansive minerals-II: Impact of age and the role of optimised expansive minerals in healing performance. Constr. Build. Mater. 2019, 194, 266–275. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J. The effects of age, cement content, and healing time on the self-healing ability of high-strength concrete. Constr. Build. Mater. 2018, 187, 149–159. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Damidot, D. Effect of blast furnace slag on self-healing of microcracks in cementitious materials. Cem. Concr. Res. 2014, 60, 68–82. [Google Scholar] [CrossRef]

- Yuan, L.; Chen, S.; Wang, S.; Huang, Y.; Yang, Q.; Liu, S.; Wang, J.; Du, P.; Cheng, X.; Zhou, Z. Research on the improvement of concrete autogenous self-healing based on the regulation of cement particle size distribution (PSD). Materials 2019, 12, 2818. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.; Jing, K.; Bai, J.; Ding, Z.; Yang, D.; Huang, H.; Gong, Y. Effects of curing conditions and supplementary cementitious materials on autogenous self-healing of early age cracks in cement mortar. Crystals 2021, 11, 752. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Nehdi, M.L. Effect of autogenous crack self-healing on mechanical strength recovery of cement mortar under various environmental exposure. Sci. Rep. 2021, 11, 7245. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, L.; Krelani, V.; Carsana, M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr. Build. Mater. 2014, 68, 535–551. [Google Scholar] [CrossRef]

- Wang, H.; Habibi, M.; Marzouki, R.; Majdi, A.; Shariati, M.; Denic, N.; Zakić, A.; Khorami, M.; Khadimallah, M.A.; Ebid, A.A.K. Improving the self-healing of cementitious materials with a hydrogel system. Gels 2022, 8, 278. [Google Scholar] [CrossRef] [PubMed]

- Huseien, G.F.; Sam AR, M.; Faridmehr, I.; Baghban, M.H. Performance of epoxy resin polymer as self-healing cementitious materials agent in mortar. Materials 2021, 14, 1255. [Google Scholar] [CrossRef] [PubMed]

- Soltaninejad, S.; Marandi, S.M.; Bp, N. Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process. Sustainability 2023, 15, 8987. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Sheng, M.; Qin, D.; Ren, J.; Zhou, X.; Zhu, J.; Xing, F. Dynamic behavior of microcapsule-based self-healing concrete subjected to impact loading. Constr. Build. Mater. 2021, 301, 124322. [Google Scholar] [CrossRef]

- Wang, X.; Liang, J.; Ren, J.; Wang, W.; Liu, J.; Xing, F. Constitutive relations, mechanical behavior, and failure criterion of microcapsule-based self-healing concrete under uniaxial and triaxial compression. J. Build. Eng. 2023, 65, 105773. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Al-Tabbaa, A. The effect of varying volume fraction of microcapsules on fresh, mechanical and self-healing properties of mortars. Constr. Build. Mater. 2016, 122, 577–593. [Google Scholar] [CrossRef]

- Sun, J.; Shang, W.; Chen, A. Mechanical and Thermal Properties of Phase Change Aerated Concrete with Paraffin Microcapsule. J. Aerosp. Eng. 2023, 36, 04022132. [Google Scholar] [CrossRef]

- Ying, Y.; Hu, M.; Han, J.; Liu, W.; Qi, B.; Guo, J. Self-healing in cementitious system using interface enhanced capsules prepared at room temperature. J. Clean. Prod. 2023, 395, 136465. [Google Scholar] [CrossRef]

- Lin, Z.; Kanwal, H.; Hao, W. Effects of Crack Width and Healing Time on Healing Performance of Microcapsule-Based Self-Healing Concrete. J. Test. Eval. 2022, 50, 2043–2053. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Choi, S.G.; Wang, K.; Wen, Z.; Chu, J. Mortar crack repair using microbial induced calcite precipitation method. Cem. Concr. Compos. 2017, 83, 209–221. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, J. Application of microbial precipitation in self-healing concrete: A review on the protection strategies for bacteria. Constr. Build. Mater. 2021, 306, 124950. [Google Scholar] [CrossRef]

- Gollapudi, U.K.; Knutson, C.L.; Bang, S.S.; Islam, M.R. A new method for controlling leaching through permeable channels. Chemosphere 1995, 30, 695–705. [Google Scholar] [CrossRef]

- Ramachandran, S.K.; Ramakrishnan, V.; Bang, S.S. Remediation of concrete using micro-organisms. ACI Mater. J.-Am. Concr. Inst. 2001, 98, 3–9. [Google Scholar]

- Algaifi, H.A.; Bakar, S.A.; Sam, A.R.M.; Ismail, M.; Abidin, A.R.Z.; Shahir, S.; Altowayti, W.A.H. Insight into the role of microbial calcium carbonate and the factors involved in self-healing concrete. Constr. Build. Mater. 2020, 254, 119258. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R.; Eddy, N.O. Microbial induced calcite precipitation for self-healing of concrete: A review. J. Sustain. Cem.-Based Mater. 2023, 12, 317–330. [Google Scholar] [CrossRef]

- Skevi, L.; Reeksting, B.J.; Hoffmann, T.D.; Gebhard, S.; Paine, K. Incorporation of bacteria in concrete: The case against MICP as a means for strength improvement. Cem. Concr. Compos. 2021, 120, 104056. [Google Scholar] [CrossRef]

- Zhang, L.V.; Nehdi, M.L.; Suleiman, A.R.; Allaf, M.M.; Gan, M.; Marani, A.; Tuyan, M. Crack self-healing in bio-green concrete. Compos. Part B Eng. 2021, 227, 109397. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef] [PubMed]