Contemporary Evaporative Cooling System with Indirect Interaction in Construction Implementations: A Theoretical Exploration

Abstract

:1. Introduction

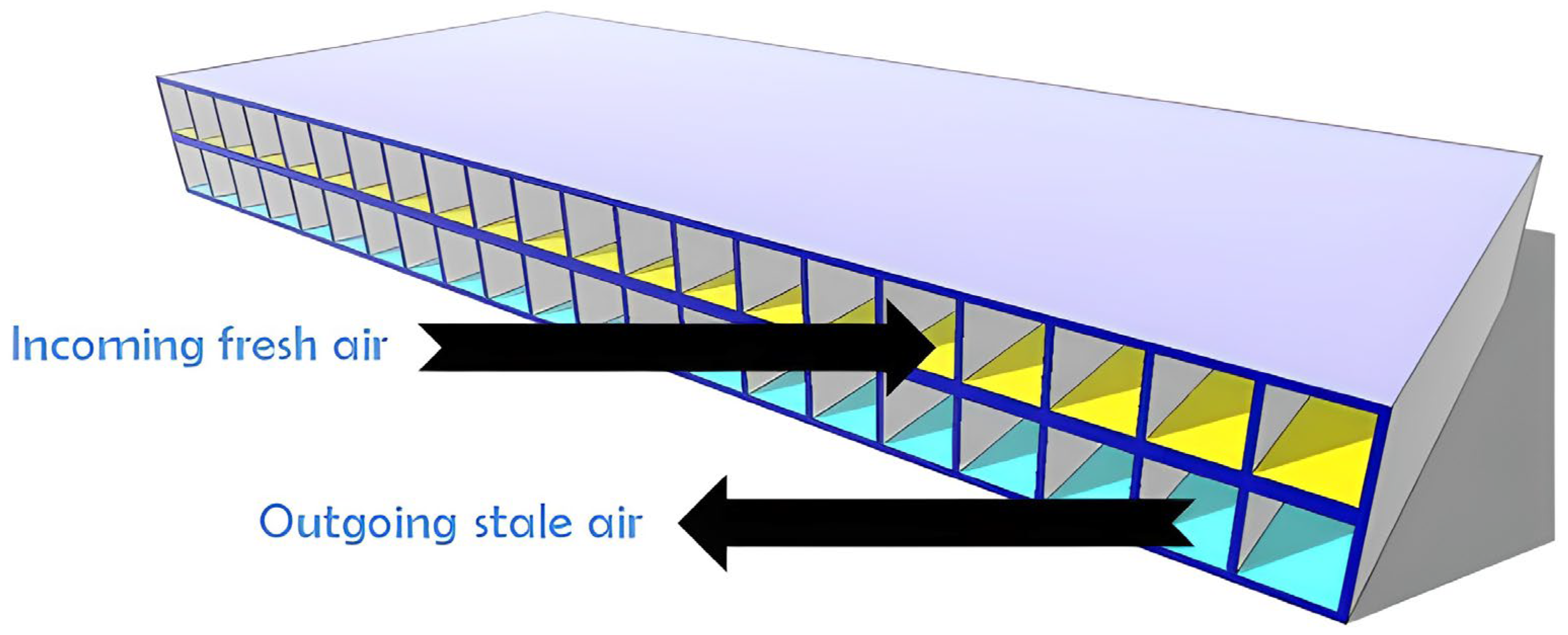

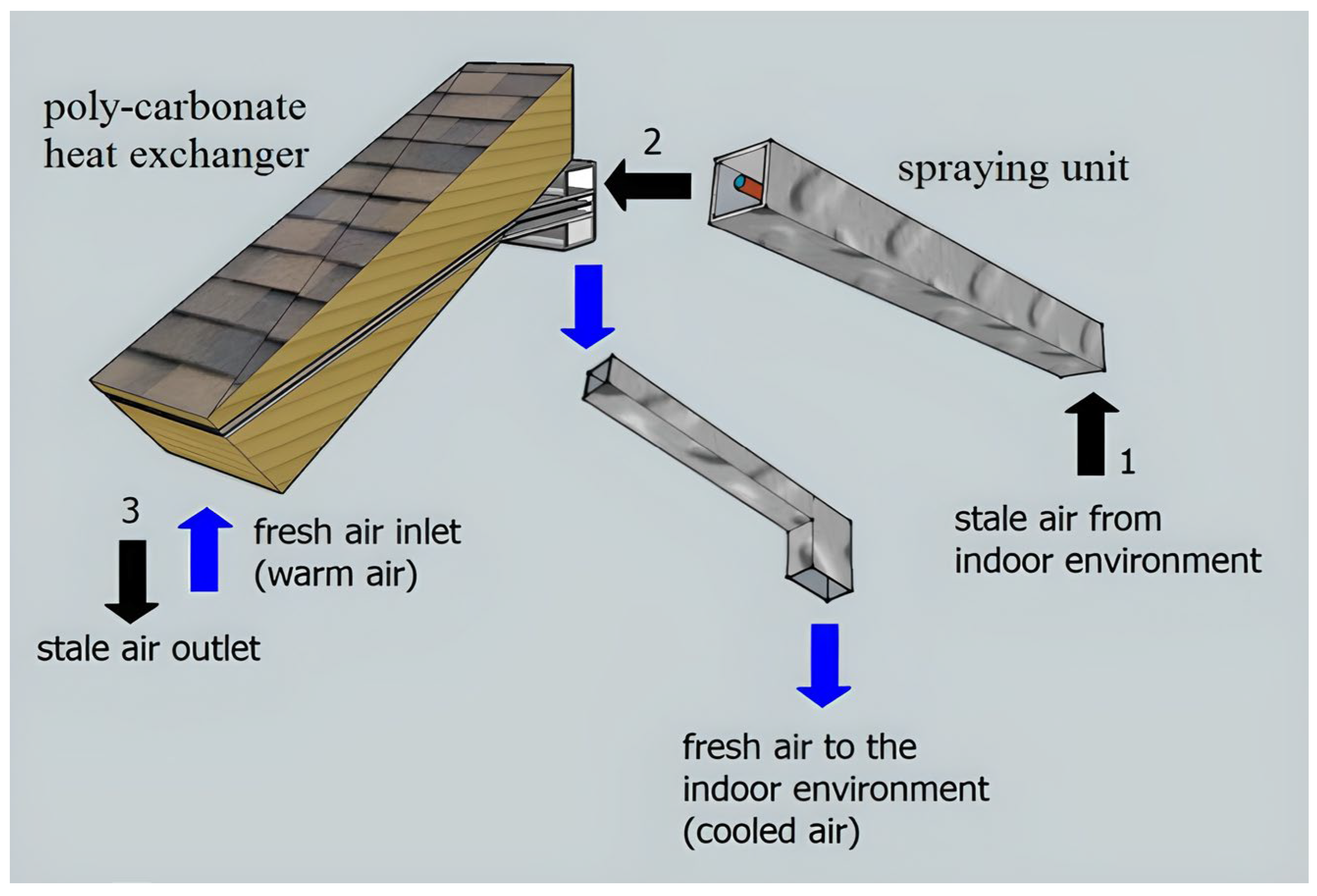

2. An Innovative Evaporative Cooling System

3. Theoretical Framework of the System

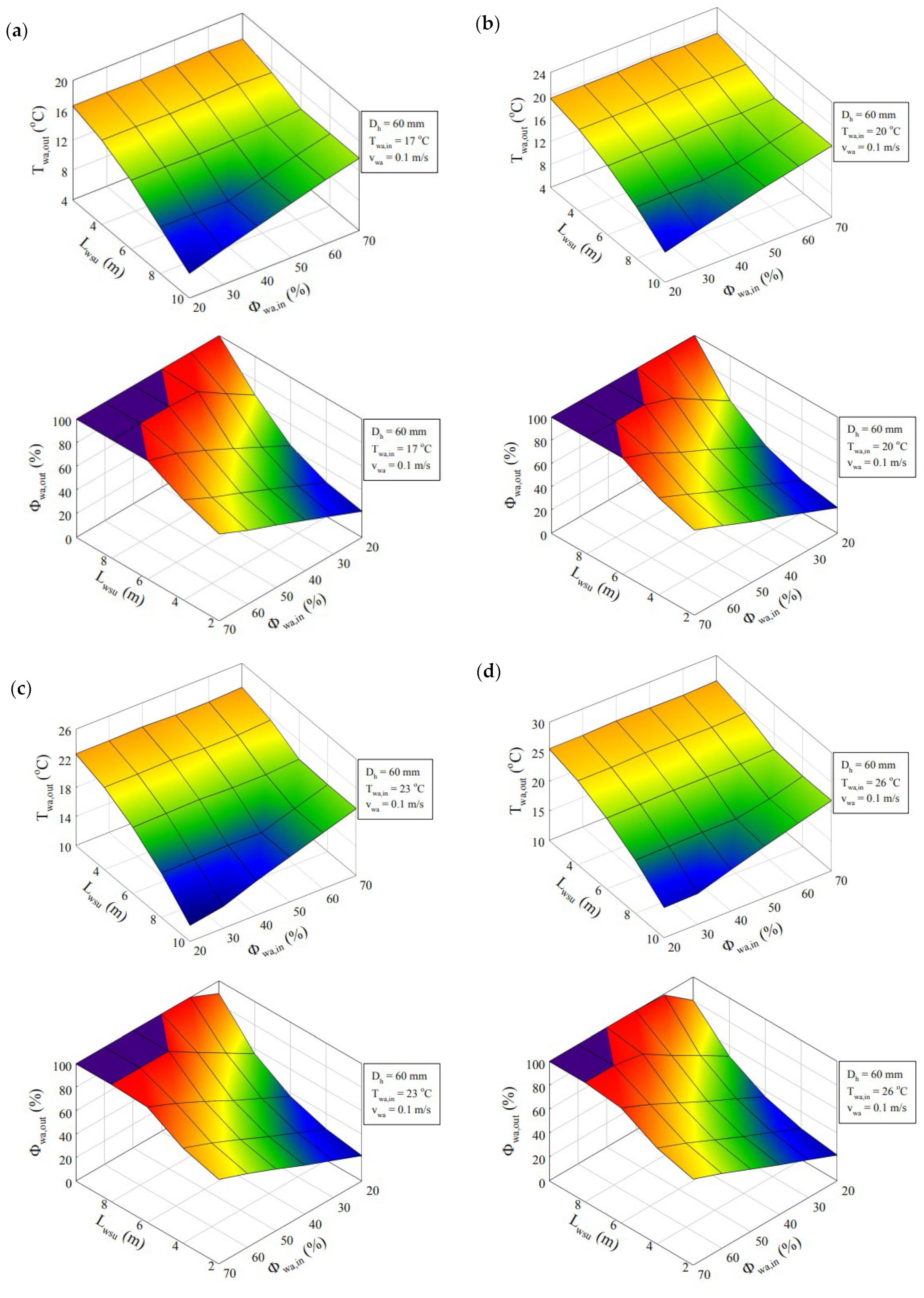

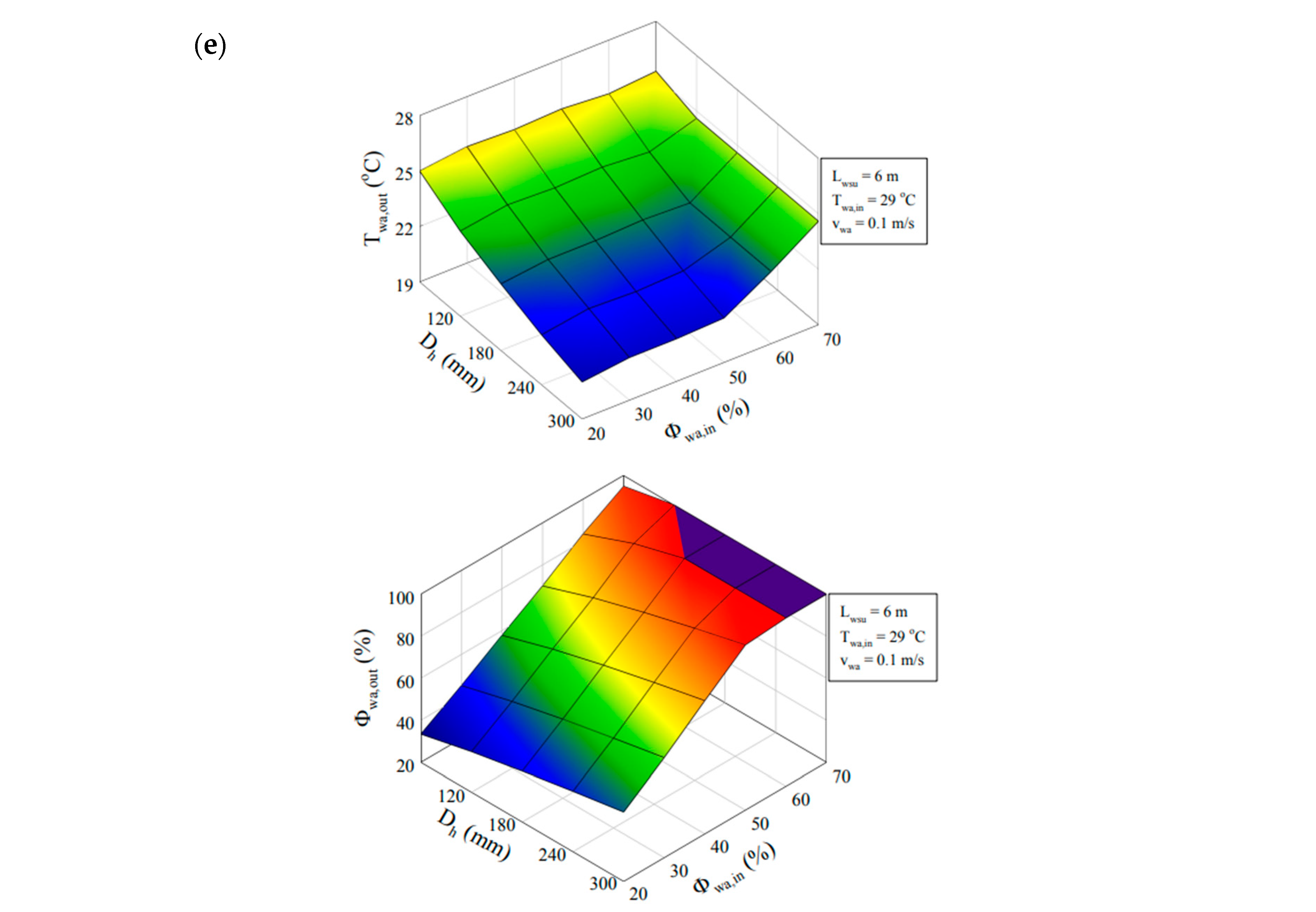

4. Results and Discussion

5. Conclusions

- Enhancing the Dh and extending the size of the WSU could give rise to an increment in the quantity of water vapour.

- Conversely, accelerating the WA speed would contribute to a diminishment in water evaporation.

- When considered in terms of cooling efficiency, it became evident that the temperature of the WA was just as crucial as its ϕ. The findings demonstrated a significant reduction in the Tout of the WA with the rise in WSU size.

- On the flip side, it was proven that the ϕ in the WA attained adiabatic saturation after a certain value of the WSU size, which was the wanted status.

- Based on the findings from the optimisation analyses conducted with various inlet air temperatures, achieving the adiabatic saturation status required a WSU size of at least 8 m.

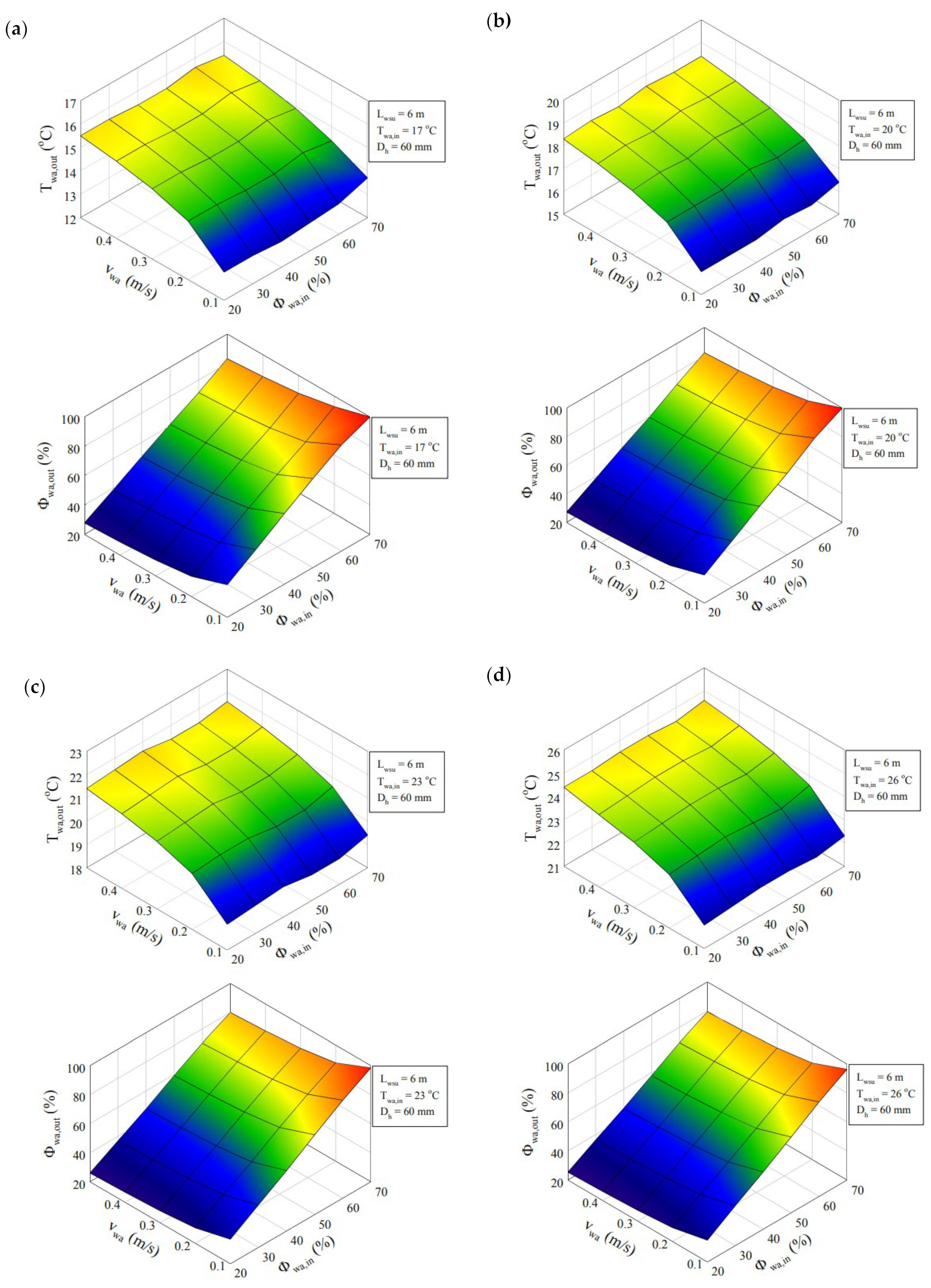

- In another analysis conducted with a similar approach, the focus shifted to diverse relative humidities of the WA. The results showed that an increase in the inlet ϕ of the WA led to higher temperatures and ϕ of the WA. This underscored the significance of selecting an optimal value whilst considering indoor thermal comfort conditions.

- Additionally, the outer temperature and ϕ of the WA were established for , , contemplating severe temperatures of the WA at the interior. The cumulative impacts of Dh and ϕ were also assessed. We derived a conclusion that the Dh had a notable impact on the Tout of the WA. For a Dh of 0.3 m, the Twa,out fell below 10 °C, which appeared to be highly favourable.

- It was stressed that, for the optimal circumstances to be achieved, the ϕ in the inlet WA should be maintained below 50%.

- This study also investigated the impacts of the MFR and ϕ on the Tout. It concluded that achieving the desired low WA temperature at the outlet required maintaining a low air velocity.

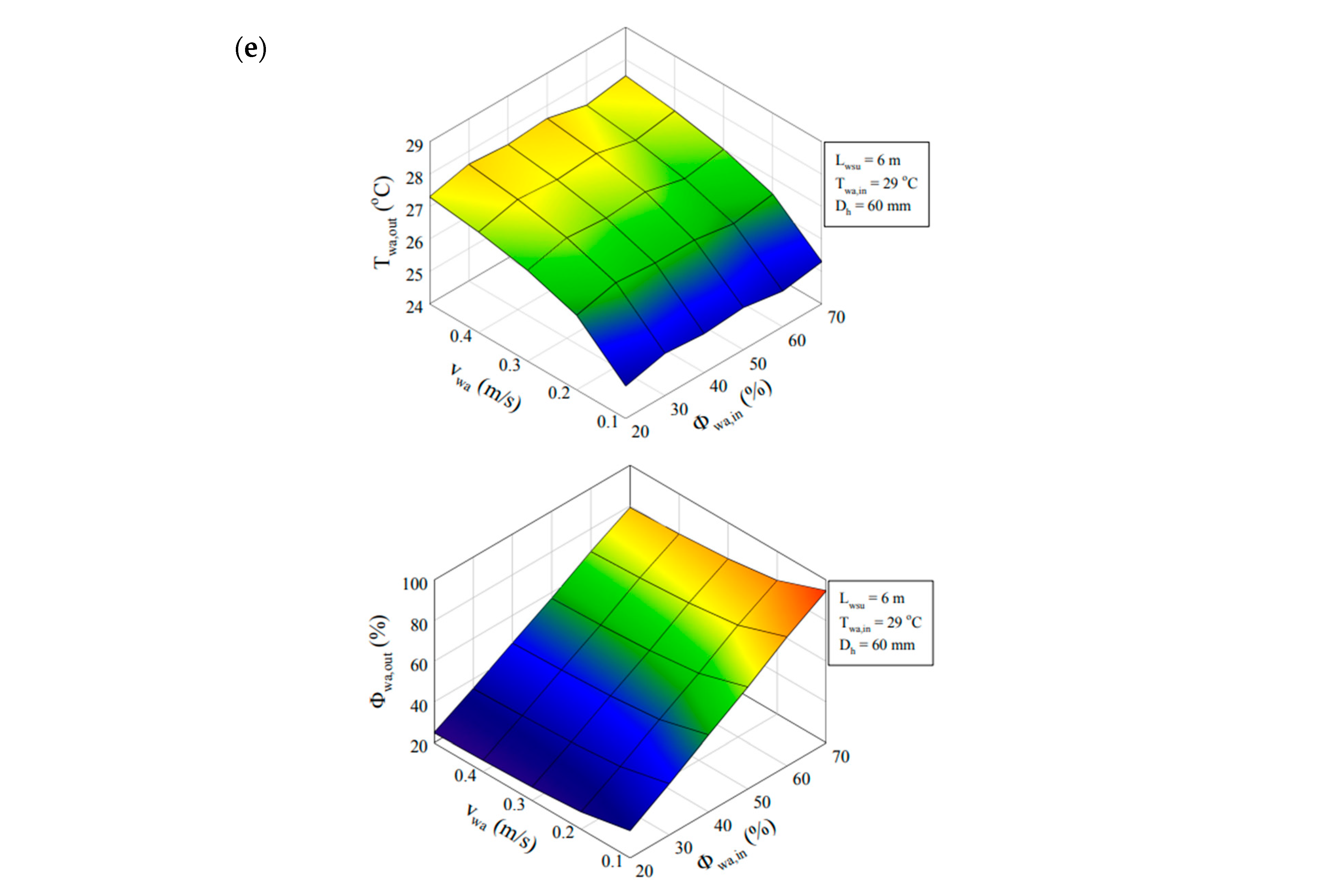

- Tfa,in increased proportionally with both the temperature of the WA and the Tfa,out.

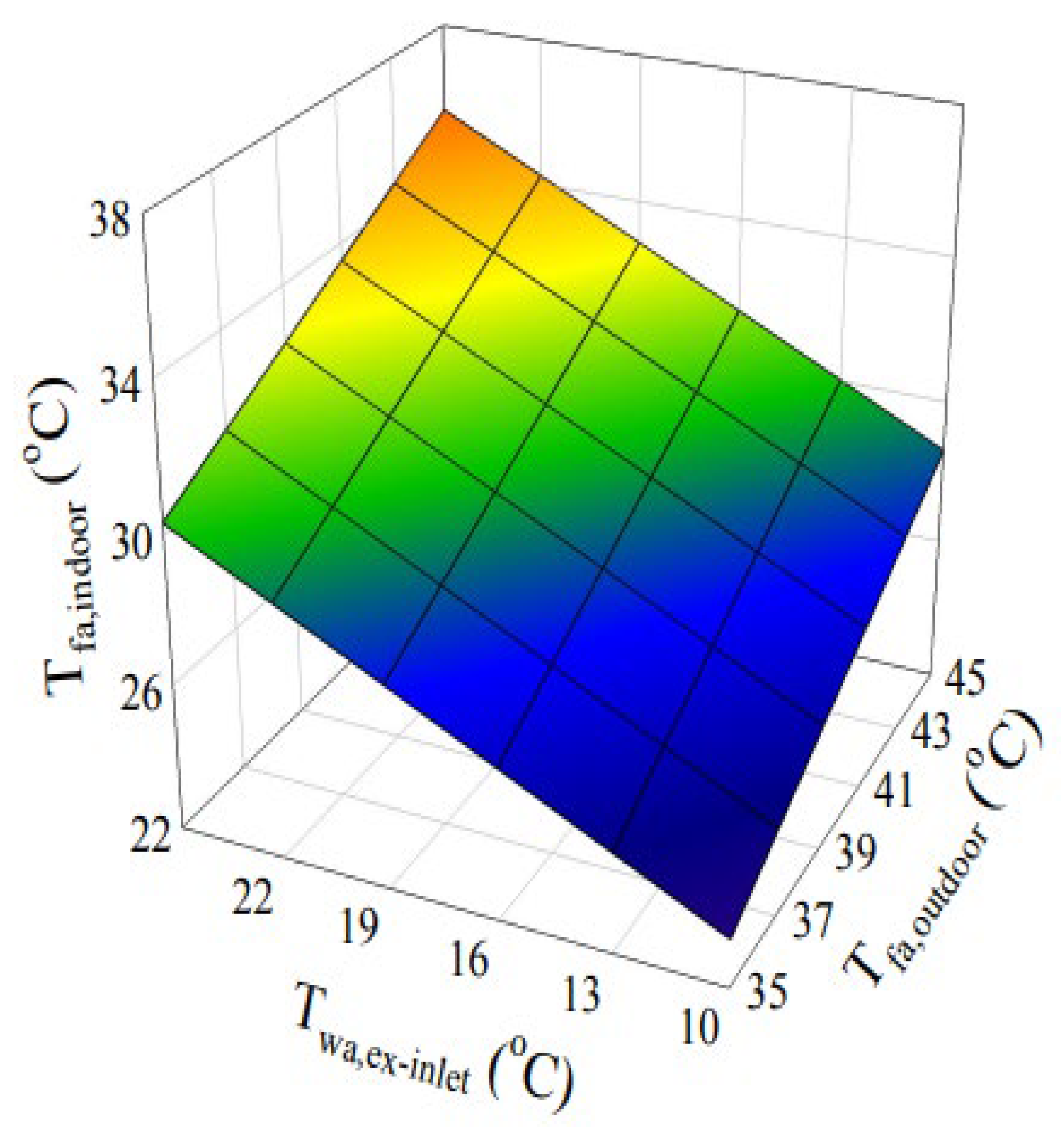

- The Tout significantly influenced the ϕ within the indoor environment. For instance, assuming , if the Tfa,out exceeded 35 °C, it indicated that may not fall within the thermal comfort range, as demonstrated in this study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A: Area [m2] | K: Mass transfer coefficient [m/s] |

| BF: Blowing factor | L: Length |

| c: Specific heat capacity [J/kgK] | mf: Mass fraction |

| D: Diameter [m] | : Mass flow rate [kg/s] |

| Dm: Mass diffusivity [m2/s] | P: Pressure [Pa] |

| HVAC: Heating, ventilating and air conditioning | Re: Reynolds number |

| ICES: Indirect-contact evaporative cooling system | u: Thermal energy |

| PHE: Polycarbonate heat exchanger | x: Distance along the duct |

| Sh: Sherwood number | Sc: Schmidt number |

| T: Temperature [°C] | EWV: Evaporated water vapour |

| MFR: Mass flow rate | DC: Direct contact |

| HT: Heat transfer | |

| SUBSCRIPTS | |

| cor: Corrected | lwf: Liquid water film |

| db: Dry bulb | out: Outside |

| f: Film | sa: Stale air |

| fa: Fresh air | sat: Saturated |

| h: Hydraulic | tot: Total |

| in: Inlet | w: Water vapour |

| j: Stream | wa: Working air |

| L: Length [m] | wsu: Water-spraying unit |

| GREEK LETTERS | |

| Φ: relative humidity | σ: Constant |

| ν: Kinematic viscosity [m2/s] | ξ: Thermal connection constant |

| µ: Dynamic viscosity [kg/ms] | p: Perimeter [m] |

| Ω: Constant | : Density [kg/m3] |

| Ψ: Thermal mass flow rate | : Constant |

| : Overall transfer of heat [W] | |

References

- Zhang, L.; Xu, M.; Chen, H.; Li, Y.; Chen, S. Globalization, green economy and environmental challenges: State of the art review for practical implications. Front. Environ. Sci. 2022, 10, 870271. [Google Scholar] [CrossRef]

- Al-Shetwi, A.Q. Sustainable development of renewable energy integrated power sector: Trends, environmental impacts, and recent challenges. Sci. Total Environ. 2022, 822, 153645. [Google Scholar] [CrossRef] [PubMed]

- Cuce, P.M.; Cuce, E.; Alvur, E. Internal or external thermal superinsulation towards low/zero carbon buildings? A critical report. Gazi Mühendislik Bilim. Derg. 2024, 9, 435–442. [Google Scholar]

- Cuce, E.; Cuce, P.M.; Wood, C.; Gillott, M.; Riffat, S. Experimental Investigation of Internal Aerogel Insulation Towards Low/Zero Carbon Buildings: A Comprehensive Thermal Analysis for a UK Building. Sustain. Clean Build. 2024, 1, 1–22. [Google Scholar]

- Akram, M.W.; Hasannuzaman, M.; Cuce, E.; Cuce, P.M. Global technological advancement and challenges of glazed window, facade system and vertical greenery-based energy savings in buildings: A comprehensive review. Energy Built Environ. 2023, 4, 206–226. [Google Scholar] [CrossRef]

- Ahmed, A.; Ge, T.; Peng, J.; Yan, W.C.; Tee, B.T.; You, S. Assessment of the renewable energy generation towards net-zero energy buildings: A review. Energy Build. 2022, 256, 111755. [Google Scholar] [CrossRef]

- Li, L.; Lin, J.; Wu, N.; Xie, S.; Meng, C.; Zheng, Y.; Wang, X.; Zhao, Y. Review and outlook on the international renewable energy development. Energy Built Environ. 2022, 3, 139–157. [Google Scholar] [CrossRef]

- Bertoldi, P.; Economidou, M.; Palermo, V.; Boza-Kiss, B.; Todeschi, V. How to finance energy renovation of residential buildings: Review of current and emerging financing instruments in the EU. Wiley Interdiscip. Rev. Energy Environ. 2021, 10, e384. [Google Scholar] [CrossRef]

- Tsemekidi Tzeiranaki, S.; Bertoldi, P.; Diluiso, F.; Castellazzi, L.; Economidou, M.; Labanca, N.; Serrenho, T.R.; Zangheri, P. Analysis of the EU residential energy consumption: Trends and determinants. Energies 2019, 12, 1065. [Google Scholar] [CrossRef]

- Drewniok, M.P.; Dunant, C.F.; Allwood, J.M.; Ibell, T.; Hawkins, W. Modelling the embodied carbon cost of UK domestic building construction: Today to 2050. Ecol. Econ. 2023, 205, 107725. [Google Scholar] [CrossRef]

- Rashad, M.; Khordehgah, N.; Żabnieńska-Góra, A.; Ahmad, L.; Jouhara, H. The utilisation of useful ambient energy in residential dwellings to improve thermal comfort and reduce energy consumption. Int. J. Thermofluids 2021, 9, 100059. [Google Scholar] [CrossRef]

- Cuce, P.M. Thermal performance assessment of a novel liquid desiccant-based evaporative cooling system: An experimental investigation. Energy Build. 2017, 138, 88–95. [Google Scholar] [CrossRef]

- Chen, Q.; Ja, M.K.; Burhan, M.; Akhtar, F.H.; Shahzad, M.W.; Ybyraiymkul, D.; Ng, K.C. A hybrid indirect evaporative cooling-mechanical vapor compression process for energy-efficient air conditioning. Energy Convers. Manag. 2021, 248, 114798. [Google Scholar] [CrossRef]

- Chang, C.K.; Yih, T.Y.; Othman, Z.B. Performance Assessment of Green Filtration System with Evaporative Cooling to Improve Indoor Air Quality (IAQ). Int. J. Environ. Sci. Dev. 2022, 13, 1–7. [Google Scholar]

- Zhou, C.; Hu, Y.; Zhang, L.; Fang, J.; Xi, Y.; Hu, J.; Li, Y.; Liu, L.; Zhao, Y.; Yang, L.; et al. Investigation of heat transfer characteristics of deflected elliptical-tube heat exchanger in closed-circuit cooling towers. Appl. Therm. Eng. 2024, 236, 121860. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Evaporative cooling integrated with solid desiccant systems: A review. Energies 2021, 14, 5982. [Google Scholar] [CrossRef]

- Blanco-Marigorta, A.M.; Tejero-Gonzalez, A.; Rey-Hernandez, J.M.; Gomez, E.V.; Gaggioli, R. Exergy analysis of two indirect evaporative cooling experimental prototypes. Alex. Eng. J. 2022, 61, 4359–4369. [Google Scholar] [CrossRef]

- Mohammed, R.H.; El-Morsi, M.; Abdelaziz, O. Indirect evaporative cooling for buildings: A comprehensive patents review. J. Build. Eng. 2022, 50, 104158. [Google Scholar] [CrossRef]

- Shi, W.; Min, Y.; Ma, X.; Chen, Y.; Yang, H. Performance evaluation of a novel plate-type porous indirect evaporative cooling system: An experimental study. J. Build. Eng. 2022, 48, 103898. [Google Scholar] [CrossRef]

- Sun, T.; Tang, T.; Yang, C.; Yan, W.; Cui, X.; Chu, J. Cooling performance and optimization of a tubular indirect evaporative cooler based on response surface methodology. Energy Build. 2023, 285, 112880. [Google Scholar] [CrossRef]

- Putra, N.; Sofia, E.; Gunawan, B.A. Evaluation of indirect evaporative cooling performance integrated with finned heat pipe and luffa cylindrica fiber as cooling/wet media. J. Adv. Res. Exp. Fluid Mech. Heat Transf. 2021, 3, 16–25. [Google Scholar]

- Zhao, X.; Liu, S.; Riffat, S.B. Comparative study of heat and mass exchanging materials for indirect evaporative cooling systems. Build. Environ. 2008, 43, 1902–1911. [Google Scholar] [CrossRef]

- Xu, P.; Ma, X.; Zhao, X.; Fancey, K.S. Experimental investigation on performance of fabrics for indirect evaporative cooling applications. Build. Environ. 2016, 110, 104–114. [Google Scholar] [CrossRef]

- Maclaine-Cross, I.L.; Banks, P.J. A general theory of wet surface heat exchangers and its application to regenerative evaporative cooling. J. Heat Transf. 1981, 103, 579–585. [Google Scholar] [CrossRef]

- Kettleborough, C.F.; Hsieh, C.S. The thermal performance of the wet surface plastic plate heat exchanger used as an indirect evaporative cooler. J. Heat Transf. 1983, 105, 366–373. [Google Scholar] [CrossRef]

- Kettleborough, C.F.; Waugaman, D.G.; Johnson, M. The thermal performance of the cross-flow three-dimensional flat plate indirect evaporative cooler. J. Energy Resour. Technol. 1992, 114, 181–186. [Google Scholar] [CrossRef]

- Wassel, A.T.; Mills, A.F. Design methodology for a counter-current falling film evaporative condenser. J. Heat Transf. 1987, 109, 784–787. [Google Scholar] [CrossRef]

- Hsu, S.T.; Lavan, Z.; Worek, W.M. Optimization of wet surface heat exchanger. Energy 1989, 14, 757–770. [Google Scholar] [CrossRef]

- Erens, P.J.; Dreyer, A.A. Modelling of indirect evaporative air coolers. Int. J. Heat Mass Transf. 1993, 36, 17–26. [Google Scholar] [CrossRef]

- Tsay, Y.L. Analysis of heat and mass transfer in a countercurrent-flow wet surface heat exchanger. Int. J. Heat Fluid Flow 1994, 15, 149–156. [Google Scholar] [CrossRef]

- Guo, X.C.; Zhao, T.S. A parametric study of an indirect evaporative air cooler. Int. Commun. Heat Mass Transf. 1998, 25, 217–226. [Google Scholar] [CrossRef]

- Halasz, B. A general mathematical model of evaporative cooling devices. Rev. Générale De Therm. 1998, 37, 245–255. [Google Scholar] [CrossRef]

- Riffat, S.B.; Zhu, J. Mathematical model of indirect evaporative cooler using porous ceramic and heat pipe. Appl. Therm. Eng. 2004, 24, 457–470. [Google Scholar] [CrossRef]

- Adam, A.; Han, D.; He, W.; Amidpour, M.; Zhong, H. Numerical investigation of the heat and mass transfer process within a cross-flow indirect evaporative cooling system for hot and humid climates. J. Build. Eng. 2022, 45, 103499. [Google Scholar] [CrossRef]

- Belarbi, R.; Ghiaus, C.; Allard, F. Modeling of water spray evaporation: Application to passive cooling of buildings. Sol. Energy 2006, 80, 1540–1552. [Google Scholar] [CrossRef]

- Crafton, E.F.; Black, W.Z. Heat transfer and evaporation rates of small liquid droplets on heat horizontal surfaces. Int. J. Heat Mass Transf. 2004, 47, 1187–1200. [Google Scholar] [CrossRef]

- Kaiser, A.S.; Lucas, M.; Viedma, M.; Zamora, B. Numerical model of evaporative cooling processes in a new type of cooling tower. Int. J. Heat Mass Transf. 2005, 48, 986–999. [Google Scholar] [CrossRef]

- Maheshwari, G.P.; Al-Ragom, F.; Suri, R.K. Energy-saving potential of an indirect evaporative cooler. Appl. Energy 2001, 69, 69–76. [Google Scholar] [CrossRef]

- Falkovich, G. Fluid Mechanics; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Cengel, Y.A.; Ghajar, A.J. Heat and Mass Transfer: Fundamentals & Applications, 4th ed.; The McGraw-Hill Companies: New York, NY, USA, 2011. [Google Scholar]

- Frossling, N. Uber die Verdunstung fallender Tropfen. Gerlands Beitr. Geophysik 1938, 52, 170–216. [Google Scholar]

- Bolz, R.E.; Tuve, G.L. Handbook of Tables for Applied Engineering Sciemce, 2nd ed.; CRC Press: New York, NY, USA, 1976. [Google Scholar]

| Trial Residence | Components | ||||

|---|---|---|---|---|---|

| Exterior | Interior | Windows | Velux Window | Door | |

| Size (m) | 7 | 6.7 | 1.2 | 0.75 | 1.5 |

| Width (m) | 3 | 2.7 | 0.1 | 0.1 | 0.1 |

| Height (m) | 4.3 | 2.45–3.3 | 1 | 0.9 | 2.05 |

| Heat Exchange Plate | Wall Thickness (mm) | ||||

|---|---|---|---|---|---|

| Size (m) | Width (m) | Depth (m) | Upper | Central | Lower |

| 1.7 | 0.425 | 0.01 | 0.8 | 0.2 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuce, P.M.; Cuce, E.; Riffat, S. Contemporary Evaporative Cooling System with Indirect Interaction in Construction Implementations: A Theoretical Exploration. Buildings 2024, 14, 994. https://doi.org/10.3390/buildings14040994

Cuce PM, Cuce E, Riffat S. Contemporary Evaporative Cooling System with Indirect Interaction in Construction Implementations: A Theoretical Exploration. Buildings. 2024; 14(4):994. https://doi.org/10.3390/buildings14040994

Chicago/Turabian StyleCuce, Pinar Mert, Erdem Cuce, and Saffa Riffat. 2024. "Contemporary Evaporative Cooling System with Indirect Interaction in Construction Implementations: A Theoretical Exploration" Buildings 14, no. 4: 994. https://doi.org/10.3390/buildings14040994

APA StyleCuce, P. M., Cuce, E., & Riffat, S. (2024). Contemporary Evaporative Cooling System with Indirect Interaction in Construction Implementations: A Theoretical Exploration. Buildings, 14(4), 994. https://doi.org/10.3390/buildings14040994