Seismic Performance Analysis of Concrete Columns Reinforced with Prestressed Wire Ropes Embedded in Polyurethane Cement Composites

Abstract

1. Introduction

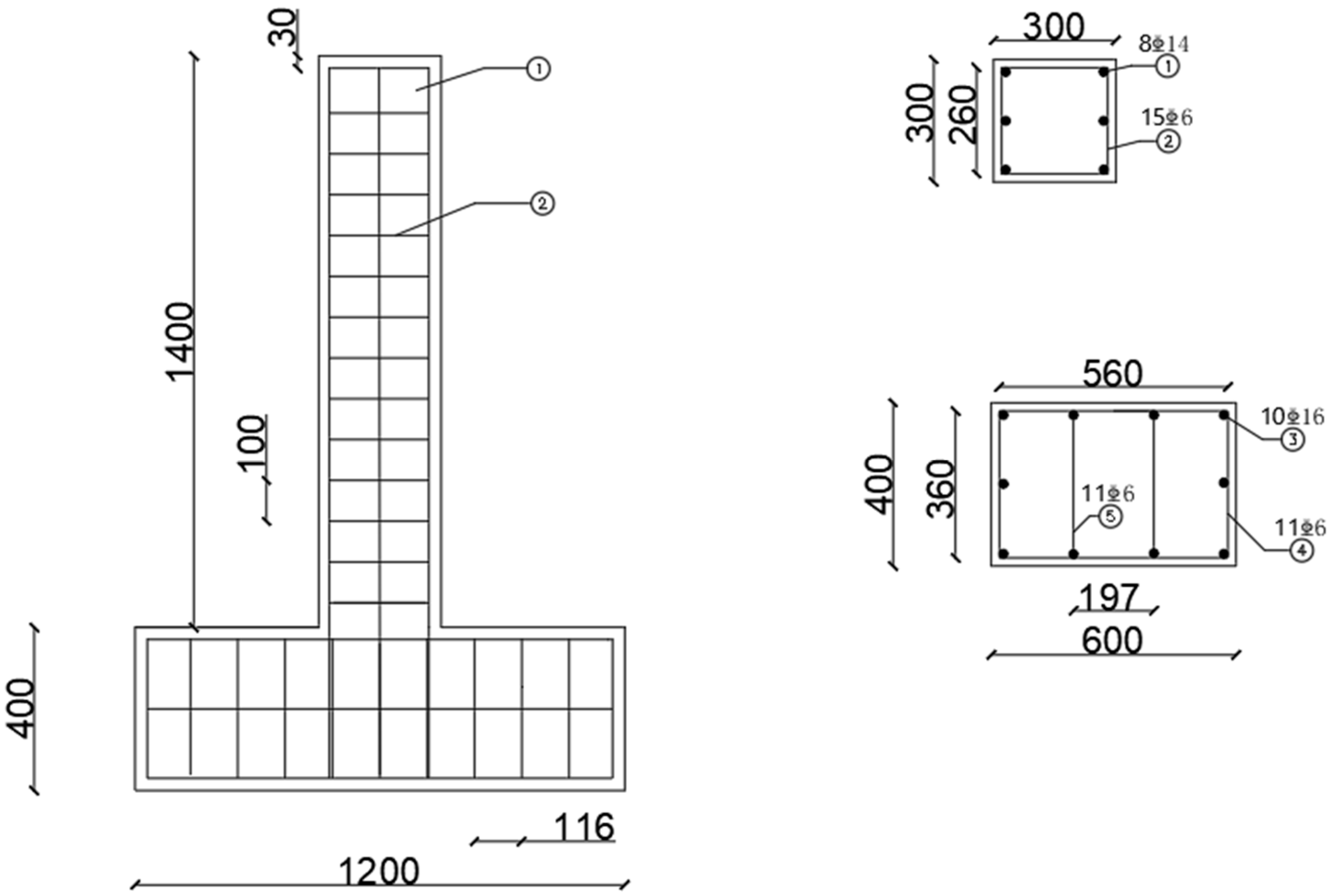

2. Experimental Program

2.1. Materials and Methods

2.2. Loading Method

3. Test Results and Discussion

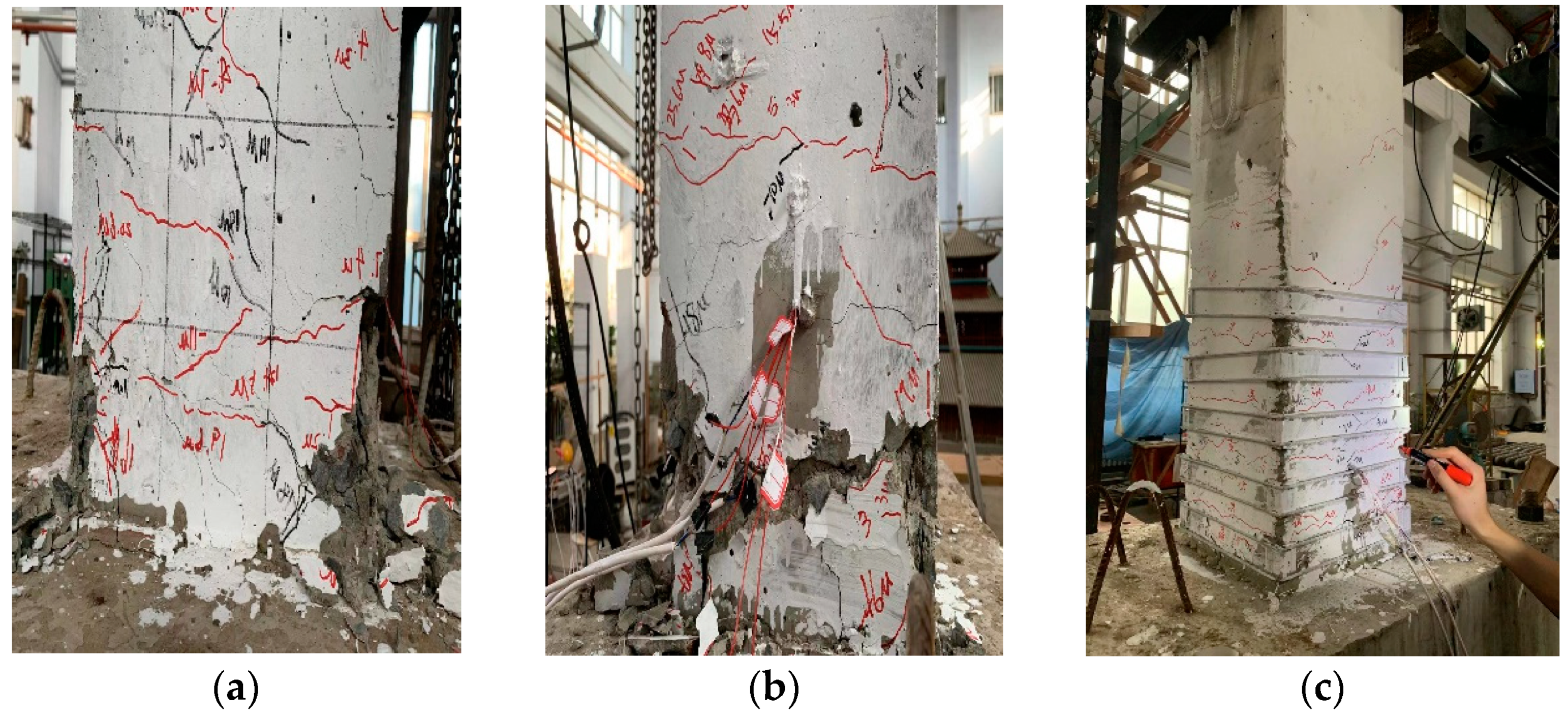

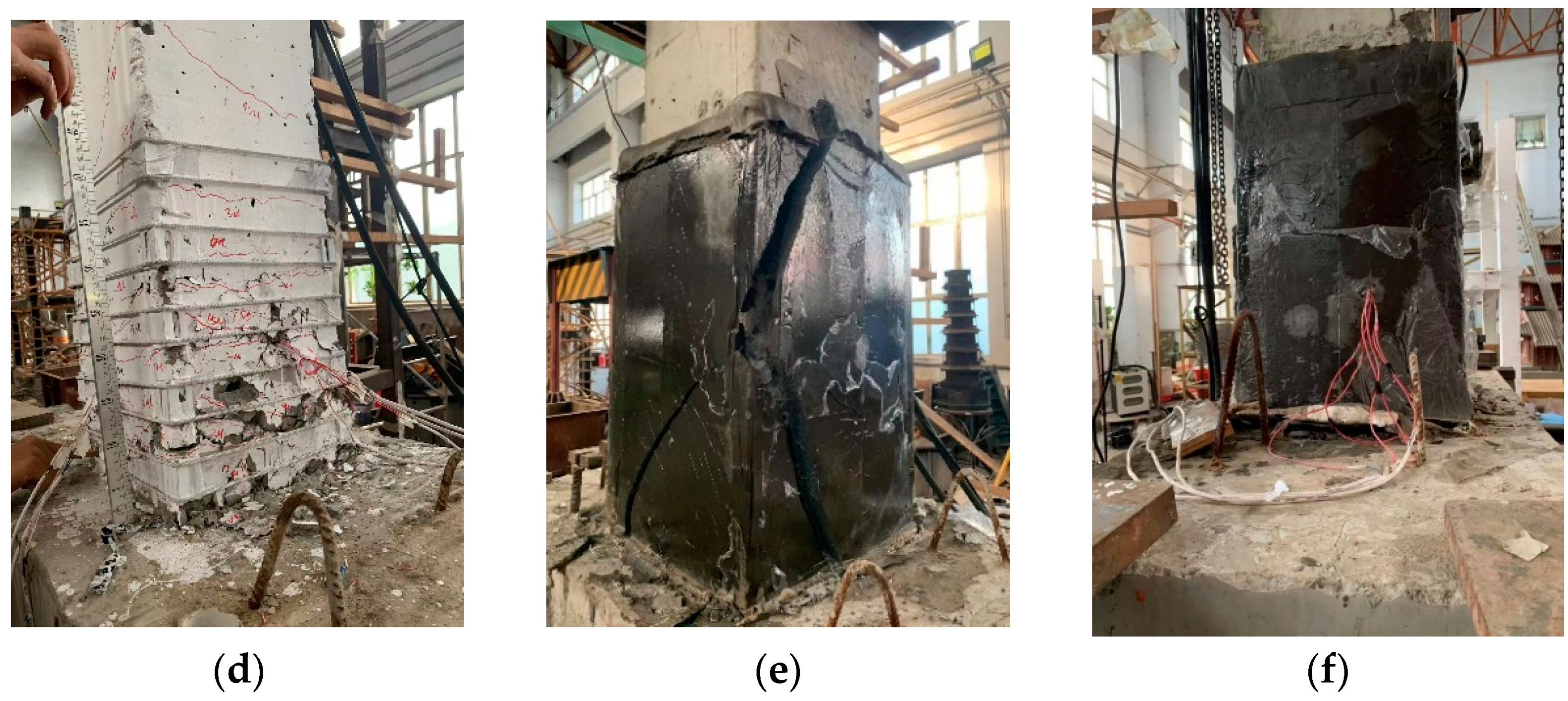

3.1. Destruction Process

3.2. Load–Displacement Hysteresis Curve

3.3. Backbone Curves

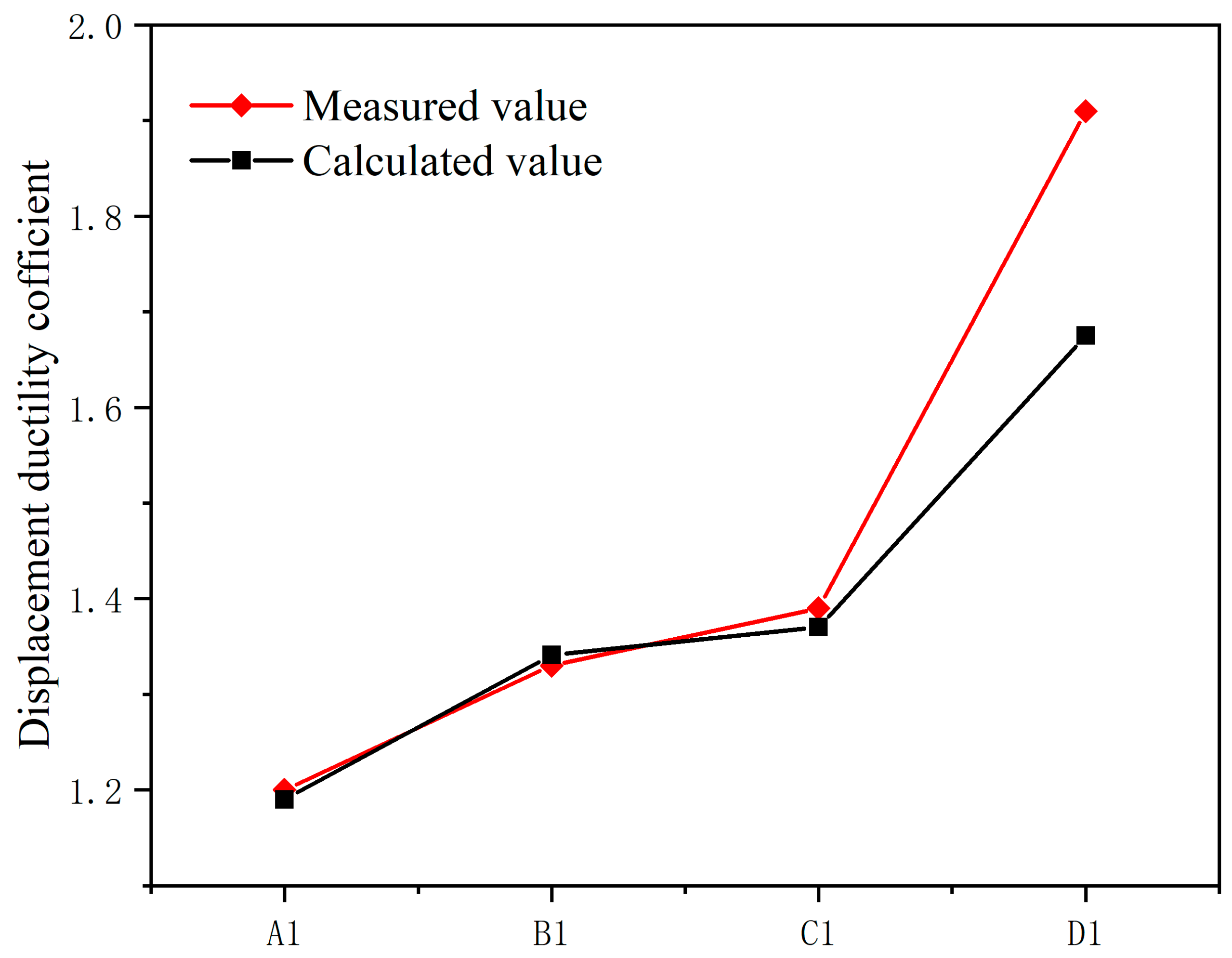

3.4. Displacement Ductility

3.5. Energy Dissipation Capacity

4. Calculated Ductility Coefficient of the Component

5. Conclusions

- (1)

- The analysis of experimental data shows that the seismic performance of RC columns with prestressed steel wire ropes embedded in polyurethane cement composite material has been significantly improved. Compared with unreinforced columns, its load displacement hysteresis curve covers a larger area and is more full, with a 69% increase in ultimate horizontal displacement and a 202% increase in energy dissipation capacity.

- (2)

- Compared with the unreinforced column, the prestressed steel wire rope reinforcement method and the polyurethane cement composite material reinforcement method only improve the ductility and energy dissipation capacity of the column. But the impact on the horizontal bearing capacity of the column is limited. But under the reinforcement method of prestressed steel wire ropes embedded in polyurethane cement composite material, the development of diagonal cracks is effectively suppressed, the initial damage is reduced, and not only are the horizontal bearing capacity and energy dissipation capacity improved, but also the ductility of the column.

- (3)

- Different reinforcement methods have different effects on the seismic performance of columns. The prestressed steel wire rope and polyurethane cement composite material have changed the active restraint force. With the increase in active restraint force, the seismic performance of reinforced columns, such as ductility, energy dissipation capacity, and horizontal bearing capacity, is enhanced to varying degrees. The prestressed steel wire rope has a significant impact on the stiffness and horizontal bearing capacity of the specimen, while the polyurethane cement composite material has a significant impact on the ductility and energy dissipation capacity of the specimen.

- (4)

- This article considers the influence of axial compression ratio, concrete strength grade, and overall reinforcement characteristic values on the displacement ductility coefficient of RC columns. A formula for calculating the displacement ductility coefficient is obtained through nonlinear regression, and the experimental and calculated values are in good agreement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PSWR | prestressed steel wire rope |

| pUC | polyurethane cement |

| represents the spacing of prestressed steel wire ropes | |

| represents the control force for steel wire rope tensioning | |

| represents the ultimate tensile force of the steel wire ropes | |

| horizontal yield displacement | |

| ultimate horizontal displacement | |

| μ | displacement ductility ratio () |

| ultimate displacement ratio (), where L is the height of the column) | |

| E | cumulative energy dissipation |

| represents the overall characteristic value of reinforcement | |

| denotes the characteristic value of stirrup reinforcement | |

| refers to the characteristic value of carbon fiber sheet reinforcement | |

| stands for the effective confinement coefficient of the carbon fiber sheet in the field of civil engineering | |

| represents the average strain | |

| stands for the ultimate strain | |

| denotes the stirrup configuration coefficient | |

| represents the axial compression ratio | |

| a, b, c, and d | are undetermined regression coefficients |

| area of a single shear reinforcement stirrup | |

| perimeter of a single shear reinforcement stirrup | |

| length of shear reinforcement stirrup sides | |

| spacing between shear reinforcement stirrups | |

| tensile strength of shear reinforcement stirrup | |

| tensile strength of concrete | |

| area of a single prestressing steel wire rope | |

| perimeter of a single prestressing steel wire rope | |

| width and height of the section | |

| spacing of the prestressing steel wire ropes | |

| tensile strength of the prestressing steel wire rope | |

| section thickness and total perimeter of polyurethane composite material | |

| tensile strength of the polyurethane composite material |

References

- GB 50011-2010; Chinese Standard, Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- Sharma, K.; Deng, L.; Noguez, C.C. Field investigation on the performance of building structures during the 25 April 2015 Gorkha earthquake in Nepal. Eng. Struct. 2016, 121, 61–74. [Google Scholar] [CrossRef]

- Zhao, B.; Taucer, F.; Rossetto, T. Field investigation on the performance of building structures during the 12 May 2008 Wenchuan earthquake in China. Eng. Struct. 2009, 31, 1707–1723. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, T.; Lin, X.; Qu, Z.; Mao, C. Seismic damages of RC frames in Nepal Ms 8.1 earthquake. Eng. Mech. 2016, 33, 59–68. (In Chinese) [Google Scholar]

- Kawashima, K. Seismic performance of RC bridge piers in Japan: An evaluation after the 1995 Hyogo-ken nanbu earthquake. Prog. Struct. Eng. Mater. 2000, 2, 82–91. [Google Scholar] [CrossRef]

- Wang, W.L.; Wang, T.T.; Su, J.J.; Lin, C.H.; Seng, C.R.; Huang, T.H. Assessment of damage in mountain tunnels due to the Taiwan Chi-Chi Earthquake. Tunn. Undergr. Space Technol. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Shakir, Q.M.; Abdlsaheb, S.D. Rehabilitation of partially damaged high strength RC corbels by EB FRP composites and NSM steel bars. Structures 2022, 38, 652–671. Available online: http://gfbic3d25a792315f4bd8sf9kpnpnuuwf56nkw.fiac.hlju.cwkeji.cn/10.1016/j.istruc.2022.02.023 (accessed on 23 February 2022). [CrossRef]

- Shakir, Q.M.; Abdlsaheb, S.D. Strengthening of the Self-Compacted Reinforced Concrete Corbels Using NSM Steel Bars and CFRP Sheets Techniques. Eng. Sci. Technol. 2022, 7, 764–1780. [Google Scholar]

- Wei, Y.; Li, K.; Fan, J.; Li, Y.; Li, S. Seismic performance of RC columns strengthened with HSSSWR meshes reinforced ECC under high axial compression ratio. J. Build. Eng. 2023, 76, 107350. [Google Scholar] [CrossRef]

- Cao, J.; Hao, J.; Xue, Q.; Fan, C.; Sun, X. Seismic behavior of wall-type spiral stirrups-confined RC column to steel beam joint. J. Constr. Steel Res. 2023, 210, 108051. [Google Scholar] [CrossRef]

- Yadav, R.; Yuan, H.; Chen, B.; Lian, Z. Experimental study on seismic performance of latticed CFST-RC column connected with RC web. Thin-Walled Struct. 2018, 126, 258–265. [Google Scholar] [CrossRef]

- Shan, Z.; Looi, D.; Su, R. A novel seismic strengthening method of RC columns confined by direct fastening steel plates. Eng. Struct. 2020, 218, 110838. [Google Scholar] [CrossRef]

- Huang, H.; Hao, R.; Zhang, W.; Huang, M. Experimental study on seismic performance of square RC columns subjected to combined loadings. Eng. Struct. 2019, 184, 194–204. [Google Scholar] [CrossRef]

- Wang, Q.; Lv, J.; Lu, C.-L.; Zhu, W.-X. Experimental study on seismic performance of square RC columns strengthened with multi-layer prestressed CFRP fabric. J. Build. Eng. 2022, 45, 103589. [Google Scholar] [CrossRef]

- Wang, H.; Xing, G.; Zhao, J.; Wen, F. Seismic behavior of RC columns strengthened with near-surface-mounted aluminum alloy bars and CFRP wraps. Eng. Struct. 2022, 268, 114742. [Google Scholar] [CrossRef]

- Zhang, Y.; Tabandeh, A.; Ma, Y.; Gardoni, P. Seismic performance of precast segmental bridge columns repaired with CFRP wraps. Compos. Struct. 2020, 243, 112218. [Google Scholar] [CrossRef]

- Lu, C.-L.; Xiao, Y.-P.; Wang, Q.; Zhu, W.-X. Study on axial compressive properties of RC square columns strengthened with prestressed CFRP sheets. Structures 2020, 27, 2011–2024. [Google Scholar] [CrossRef]

- Wu, S.; Han, B.; Wu, Z.; Li, H.; Liu, H. Experimental study on axially compressed square RC stub columns strengthened with prestressed CFRP strips. IOP Conf. Ser. Mater. Sci. Eng. 2020, 782, 022104. [Google Scholar] [CrossRef]

- Ma, C.; Gao, H.; Li, K.; Liao, W.; Wang, Z.; Bai, Y. Experimental study on the seismic behavior of RC columns with high axial compression ratios retrofitted by large rupture strain fiber-reinforced polymer. Eng. Struct. 2023, 277, 115448. [Google Scholar] [CrossRef]

- Cao, Y.; Li, L.; Liu, M.; Wu, Y. Mechanical behavior of FRP confined rubber concrete under monotonic and cyclic loading. Compos. Struct. 2021, 272, 114205. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, X.; Wang, X.; Sui, L.; Huang, X.; Guo, M.; Hu, B. Seismic performance of large rupture strain FRP retrofitted RC columns with corroded steel reinforcement. Eng. Struct. 2020, 216, 110744. [Google Scholar] [CrossRef]

- Moran, D.A.; Pantelides, C.P.; Reaveley, L.D. Mohr-coulomb model for rectangular and square FRP-confined concrete. Compos. Struct. 2019, 209, 889–904. [Google Scholar] [CrossRef]

- Dirikgil, T. Experimental investigation of the effects of concrete strength and axial load ratio on the performances of CFRP-wrapped and externally collared RC short columns. Eng. Struct. 2021, 230, 111647. [Google Scholar] [CrossRef]

- Zhao, J.; Ren, W.; Ruan, X.; Gong, X.; Si, C. Experimental Study on the Seismic Performance of Columns Reinforced by the CFRP Bar and Sheet. Appl. Compos. Mater. 2021, 28, 1291–1313. [Google Scholar] [CrossRef]

- Zeng, Z.; Jiang, S.; Deng, K.; Huang, H.; Cui, E. Seismic performance of circular RC columns strengthened in flexure using NSM reinforcement and externally bonded BFRP sheets. Eng. Struct. 2022, 256, 114033. [Google Scholar] [CrossRef]

- Mei, S.-J.; Bai, Y.-L.; Dai, J.-G.; Han, Q. Seismic behaviour of shear critical square RC columns strengthened by large rupture strain FRP. Eng. Struct. 2023, 280, 115679. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Dai, J.-G.; Mohammadi, M.; Lin, G.; Mei, S.-J. Stiffness-based design-oriented compressive stress-strain model for large-rupture-strain (LRS) FRP-confined concrete. Compos. Struct. 2019, 223, 110953. [Google Scholar] [CrossRef]

- Ueda, T. Material Mechanical Properties Necessary for the Structural Intervention of Concrete Structures. Engineering 2019, 5, 1131–1138. [Google Scholar] [CrossRef]

- Ye, Y.-Y.; Liang, S.-D.; Feng, P.; Zeng, J.-J. Recyclable LRS FRP composites for engineering structures: Current status and future opportunities. Compos. Part B Eng. 2021, 212, 108689. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Dai, J.-G.; Teng, J.G. Cyclic Compressive Behavior of Concrete Confined with Large Rupture Strain FRP Composites. J. Compos. Constr. 2014, 18, 04013025. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Zhang, Y.-F.; Jia, J.-F.; Mei, S.-J.; Han, Q.; Dai, J.-G. Simplified plasticity damage model for large rupture strain (LRS) FRP-confined concrete. Compos. Struct. 2022, 280, 114916. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Bai, S.-C.; Mei, S.-J.; Jia, J.-F.; Yang, K. Seismic behavior of RC square columns strengthened with LRS FRP under high axial load ratio. Structures 2023, 56, 104867. [Google Scholar] [CrossRef]

- Tan, J.-Y.; Chin, C.-L.; Ma, C.-K.; Ong, C.-B.; Awang, A.Z.; Omar, W.; Lam, S.-K. Pre-tensioned steel straps for seismic retrofit of reinforced concrete columns under combined loading of flexure, shear and torsion. Structures 2023, 56, 104935. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, M.; Li, T.; Dong, Z. Strengthening of flexure-dominate RC columns with ECC jackets: Experiment and analysis. Eng. Struct. 2021, 231, 111809. [Google Scholar] [CrossRef]

- Jin, L.; Liang, J.; Chen, F.; Du, X. Size effect on the seismic behavior of square CFST short columns. J. Constr. Steel Res. 2022, 199, 107589. [Google Scholar] [CrossRef]

- Qiao, D.-H.; Xu, Y.-Q.; Zhang, X.; Pang, J.-B.; Liu, K.; Wang, S.-J. Seismic behaviour and size effect of column base joints with inverted exposed grouted sleeves. J. Build. Eng. 2022, 51, 104333. [Google Scholar] [CrossRef]

- Jin, L.; Wan, S.; Li, D.; Du, X. Size effect and strain rate effect on seismic behavior of reinforced concrete beam-column joints. Struct. Concr. 2022, 23, 1453–1468. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, Q.; Huang, T.; Zuo, S.; Yao, H. Utilization of novel stranded steel fiber to enhance fiber–matrix interface of cementitious composites. Constr. Build. Mater. 2023, 369, 130525. [Google Scholar] [CrossRef]

- Liu, Z.-Q.; Guo, Z.-X.; Ye, Y. Flexural behaviour of RC beams strengthened with prestressed steel wire ropes polymer mortar composite. J. Asian Arch. Build. Eng. 2021, 21, 48–65. [Google Scholar] [CrossRef]

- Zhang, Y. Experimental and theoretical analysis of flexural reinforcement performance of prestressed high-strength soft steel wire with polymer mortar. Chin. J. Highw. 2017, 30, 10. [Google Scholar]

- Huang, H.; Liu, B.; Xi, K. Interfacial tensile bond behavior of permeable polymer mortar to concrete-sciencedirect. Constr. Build. Mater. 2016, 121, 210–221. [Google Scholar] [CrossRef]

- Hou, N.; Li, J.; Li, X.; Cui, Y.; Xiong, D.; Cui, X. Study on Toughening and Temperature Sensitivity of Polyurethane Cement (PUC). Materials 2022, 15, 4318. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Q. Experimental Research on T-beam Bridge Reinforced with Polyurethane Cement Prestressed Steel Wire Rope. In Proceedings of the 9th Annual Academic Conference of the Maintenance and Management Branch of China Highway Society, Dalian, China, 8–9 June 2019. [Google Scholar]

- Yuan, F.; Shao, Y. Experimental Study on Flexural Strengthening of RC Beam Reinforced with High Strength Steel Wire Net-Engineered Cementitious Composites. Railw. Eng. 2021, 61, 33–38. [Google Scholar]

- Yang, N.; Yang, X. Self-Monitoring of Reinforced Concrete Beam Bending with Carbon Nanofiber Polyurethane Composite. Adv. Civ. Eng. 2022, 2022, 7294899. [Google Scholar] [CrossRef]

- Vijayaraghavan, J.; Jeevakkumar, R.; Venkatesan, G.; Rengasamy, M.; Thivya, J. Influence of kaolin and dolomite as filler on bond strength of polyurethane coated reinforcement concrete. Constr. Build. Mater. 2022, 325, 126675. [Google Scholar] [CrossRef]

- Hussain, H.K.; Liu, G.W.; Yong, Y.W. Experimental study to investigate mechanical properties of new material polyurethane–cement composite (PUC). Constr. Build. Mater. 2014, 50, 200–208. [Google Scholar] [CrossRef]

- Gao, H. Shear Behavior of Reinforced Concrete Beams Strengthen by Prestressed Steel Wire Ropes Embedded in Polyurethane Cement Composite (PSWR-PUC). Ph.D. Thesis, Northeast Forestry University, Harbin, China, 2021. [Google Scholar] [CrossRef]

- Hussain, H.K.; Lian, Z.Z.; Gui, W.L. An experimental study on strengthening reinforced concrete T-beams using new material poly-urethane-cement (PUC). Constr. Build. Mater. 2013, 40, 104–117. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, Q. Experimental Study of Reinforced Concrete T-Beams Strengthened with a Composite of Prestressed Steel Wire Ropes Embedded in Polyurethane Cement (PSWR–PUC). Int. J. Civ. Eng. 2018, 16, 1109–1123. [Google Scholar] [CrossRef]

- Zhang, K.; Qi, T.; Zhu, Z.; Xue, X.; Shen, X. Strengthening of a Reinforced Concrete Bridge with a Composite of Prestressed Steel Wire Ropes Embedded in Polyurethane Cement. J. Perform. Constr. Facil. 2021, 35, 5. [Google Scholar] [CrossRef]

- Zhang, K.; Shen, X.; Liu, J.; Teng, F.; Zhang, G.; Wang, J. Flexural strengthening of reinforced concrete T-beams using a composite of prestressed steel wire ropes embedded in polyurethane cement (PSWR-PUC): Theoretical analysis. Structures 2022, 44, 1278–1287. [Google Scholar] [CrossRef]

- Bert, C.W.; Malik, M. Differential quadrature: A powerful new technique for analysis of composite structures. Compos. Struct. 1997, 39, 179–189. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A generalized 2D Bézier-based solution for stress analysis of notched epoxy resin plates reinforced with graphene nanoplatelets. Thin-Walled Struct. 2021, 169, 108484. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, Y.; Liu, J. A domain-decomposition generalized finite difference method for stress analysis in three-dimensional composite materials. Appl. Math. Lett. 2020, 104, 106226. [Google Scholar] [CrossRef]

- Yu, W.H. Study on Ductility Performance of Reinforced High concrete Columns Confined by CFRP; Dalian University of Technology: Dalian, China, 2010. (In Chinese) [Google Scholar]

- Chen, L. Experimental Study of the Seismic Behavior of RC Column Strengthened with High Strength Steel Wire. Ph.D. Thesis, Nie Jianguo Tsinghua University, Beijing, China, 2004. [Google Scholar]

| Specimen Number | Reinforcement Method | Prestressed Steel Wire Arrangement | |||

|---|---|---|---|---|---|

| (mm) | (KN) | Number of Individuals | |||

| A1 | / | / | / | / | / |

| B1 | PSWR | 30 | 0.5 | 20 | 0.4 |

| C1 | PUC | / | / | / | / |

| D1 | PSWR + PUC | 30 | 0.5 | 20 | 0.4 |

| Specimen Number | (mm) | (mm) | μ | E (KN·mm) | |

|---|---|---|---|---|---|

| 40.4 | 48.5 | 1.20 | 0.035 | 103,873.82 | |

| 45.1 | 60.2 | 1.33 | 0.043 | 127,447.32 | |

| 44.7 | 62.3 | 1.39 | 0.045 | 265,032.78 | |

| 45.9 | 87.8 | 1.91 | 0.063 | 313,414.19 |

| Measured Value | Calculated Value | M/C | |

|---|---|---|---|

| 0.35 | 1.20 | 1.19 | 1.01 |

| 0.76 | 1.33 | 1.34 | 0.99 |

| 0.79 | 1.39 | 1.37 | 1.01 |

| 0.83 | 1.91 | 1.67 | 1.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, R.; Zhang, H.; Chen, K.; Song, Y.; Li, H.; Ding, L.; Liu, Y. Seismic Performance Analysis of Concrete Columns Reinforced with Prestressed Wire Ropes Embedded in Polyurethane Cement Composites. Buildings 2024, 14, 993. https://doi.org/10.3390/buildings14040993

Guo R, Zhang H, Chen K, Song Y, Li H, Ding L, Liu Y. Seismic Performance Analysis of Concrete Columns Reinforced with Prestressed Wire Ropes Embedded in Polyurethane Cement Composites. Buildings. 2024; 14(4):993. https://doi.org/10.3390/buildings14040993

Chicago/Turabian StyleGuo, Runqi, Haiying Zhang, Kezheng Chen, Yang Song, Hongxia Li, Lin Ding, and Yanjie Liu. 2024. "Seismic Performance Analysis of Concrete Columns Reinforced with Prestressed Wire Ropes Embedded in Polyurethane Cement Composites" Buildings 14, no. 4: 993. https://doi.org/10.3390/buildings14040993

APA StyleGuo, R., Zhang, H., Chen, K., Song, Y., Li, H., Ding, L., & Liu, Y. (2024). Seismic Performance Analysis of Concrete Columns Reinforced with Prestressed Wire Ropes Embedded in Polyurethane Cement Composites. Buildings, 14(4), 993. https://doi.org/10.3390/buildings14040993