Influence of Pile Spacing on the Compressive Bearing Performance of CEP Groups

Abstract

:1. Introduction

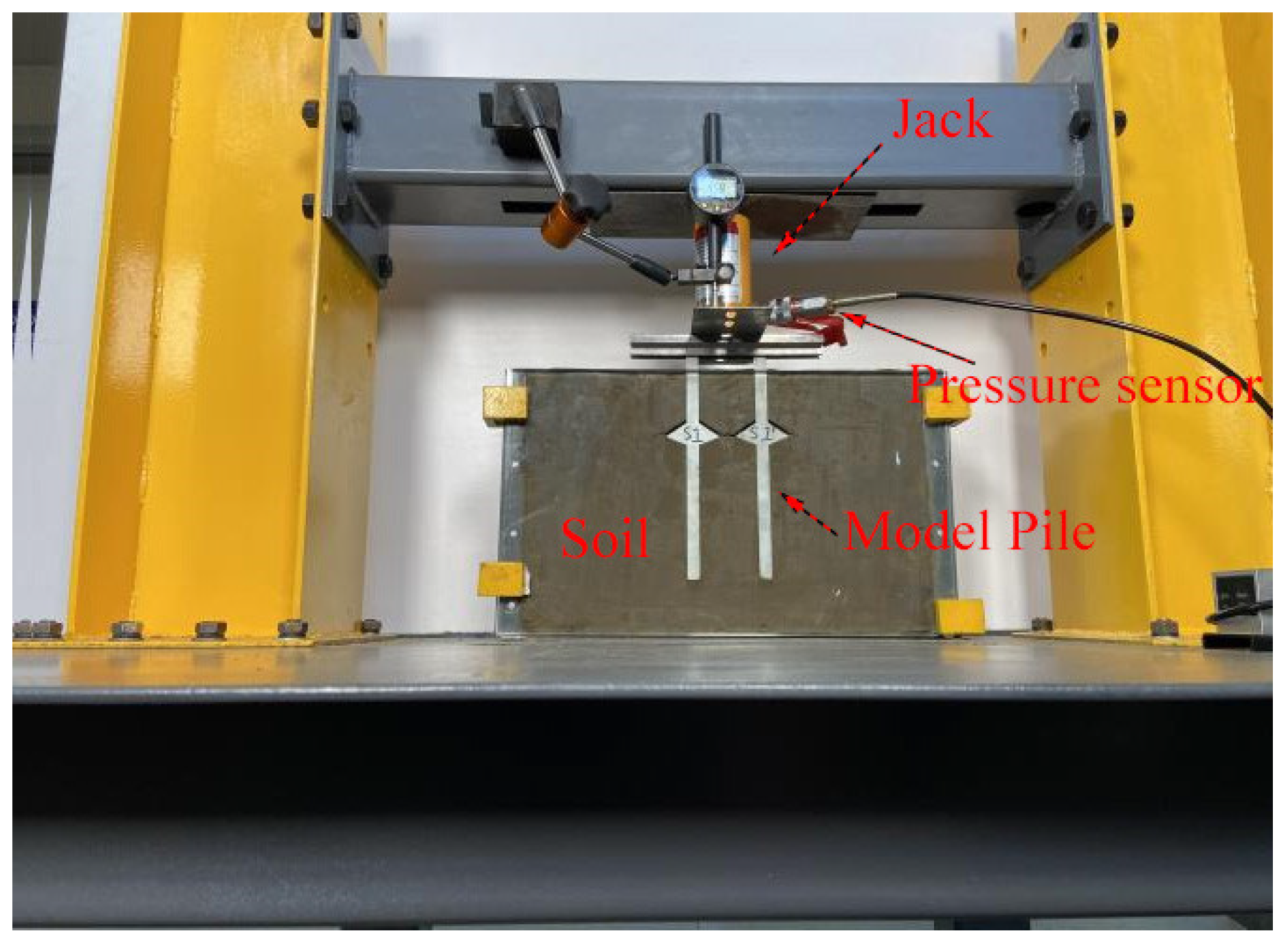

2. ANSYS Finite-Element Modeling

2.1. Material Parameters

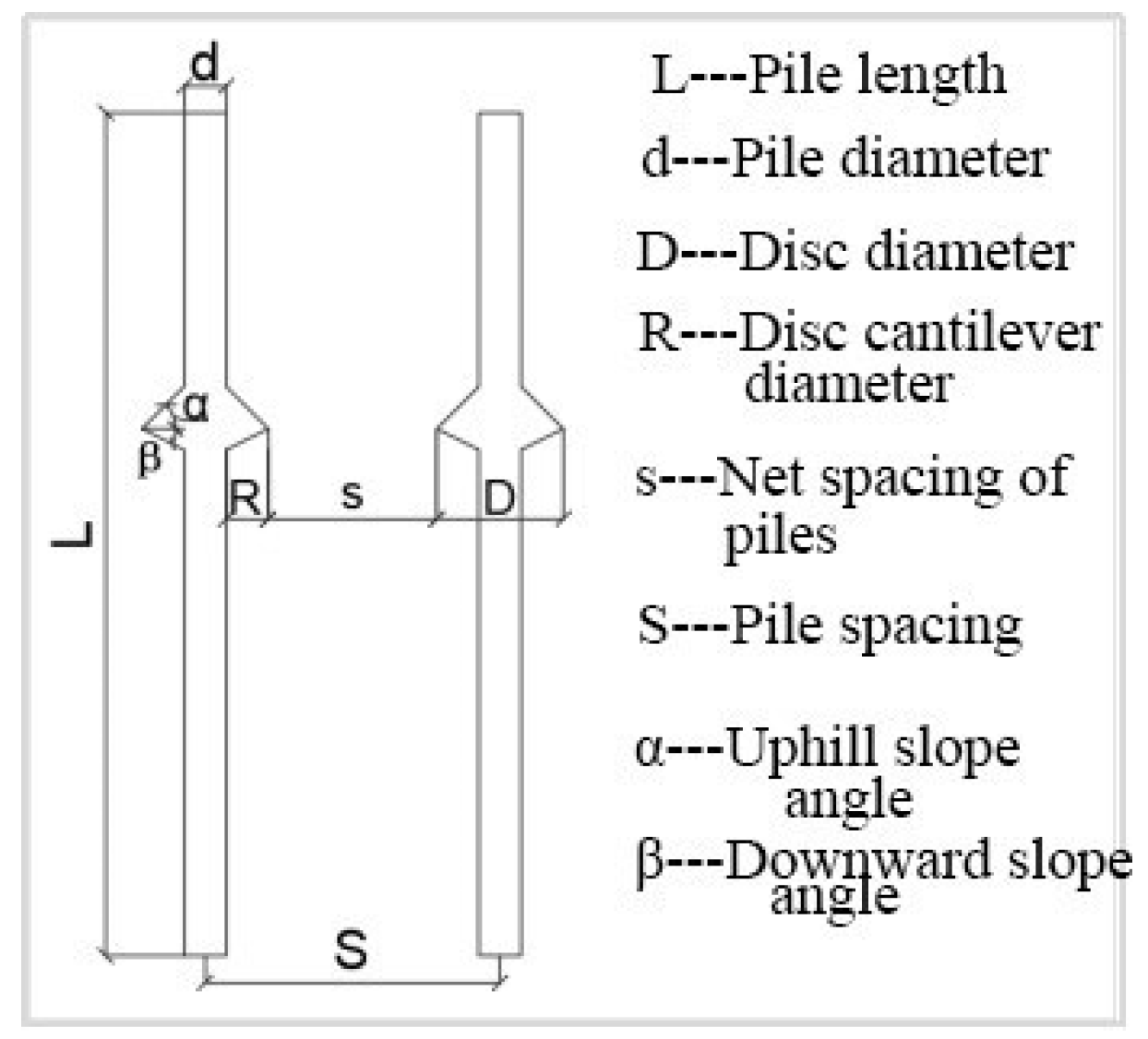

2.2. Model Parameters

2.3. Model Construction Process and Loading Plan

3. Analysis of ANSYS Finite-Element Simulation Results

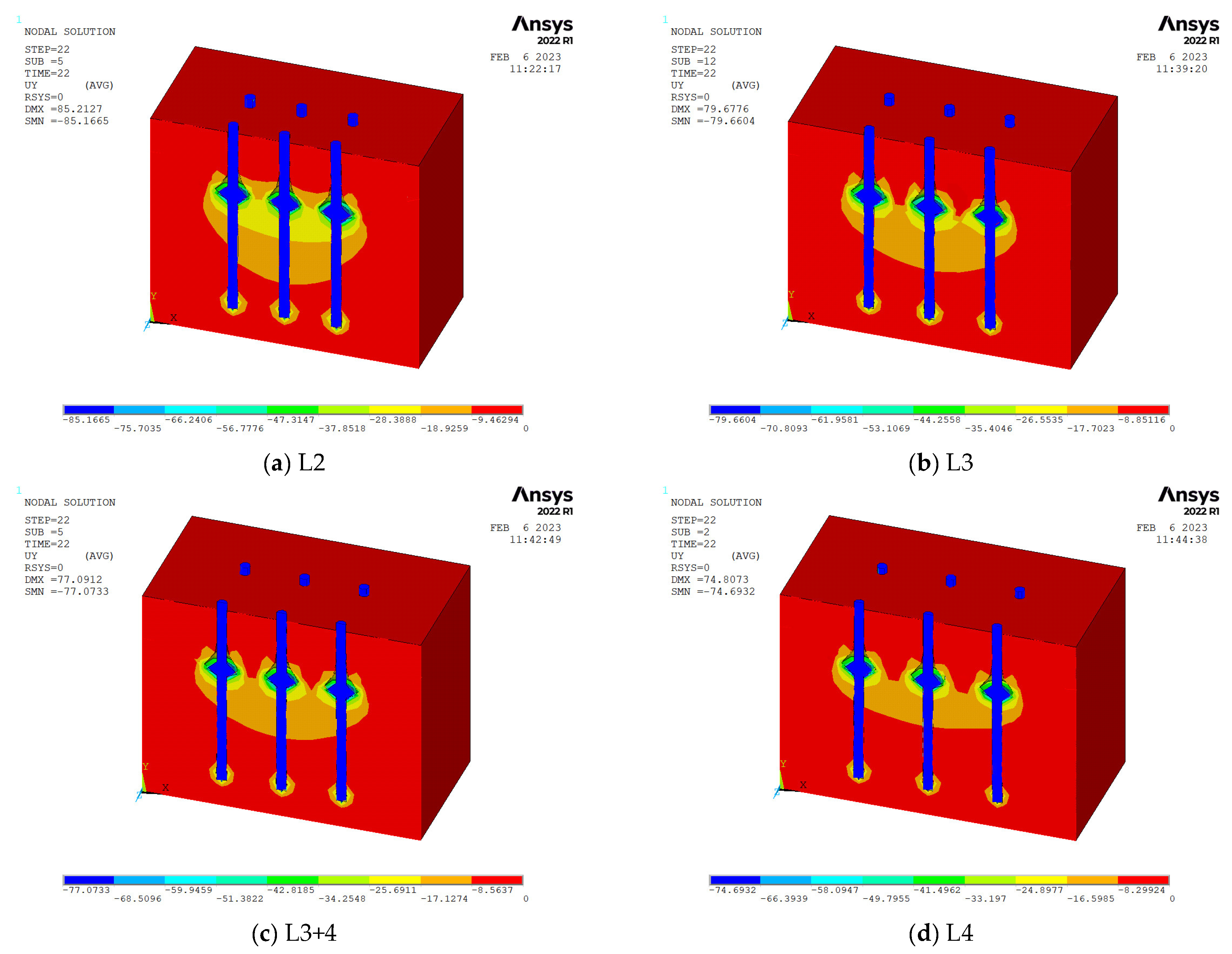

3.1. Displacement Cloud Map

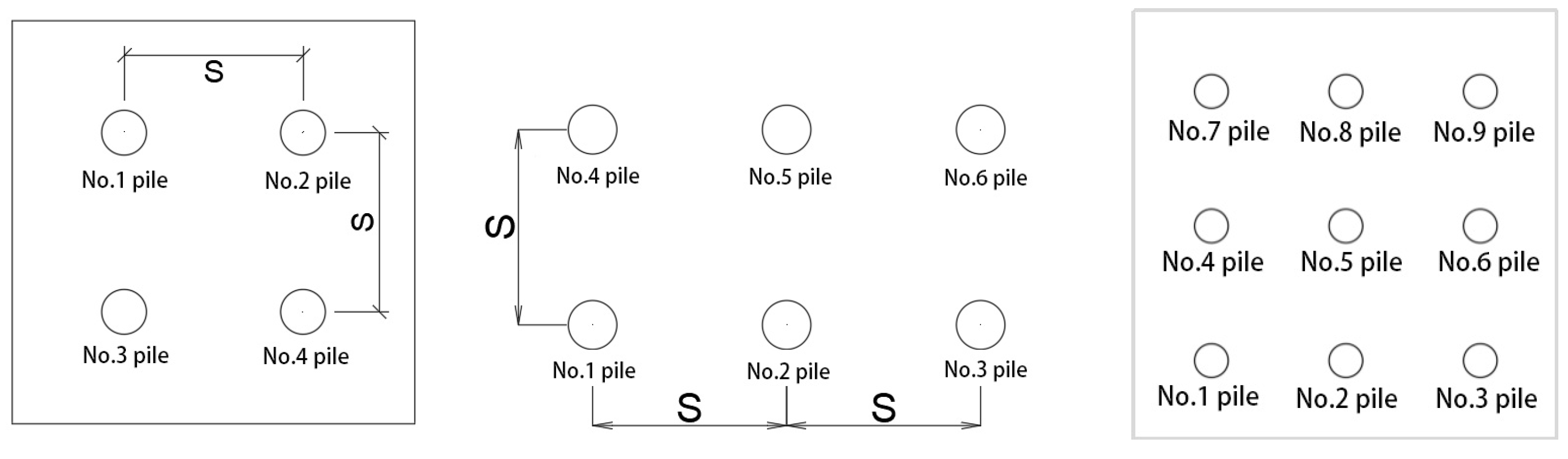

3.1.1. Four-Pile Displacement Cloud Map

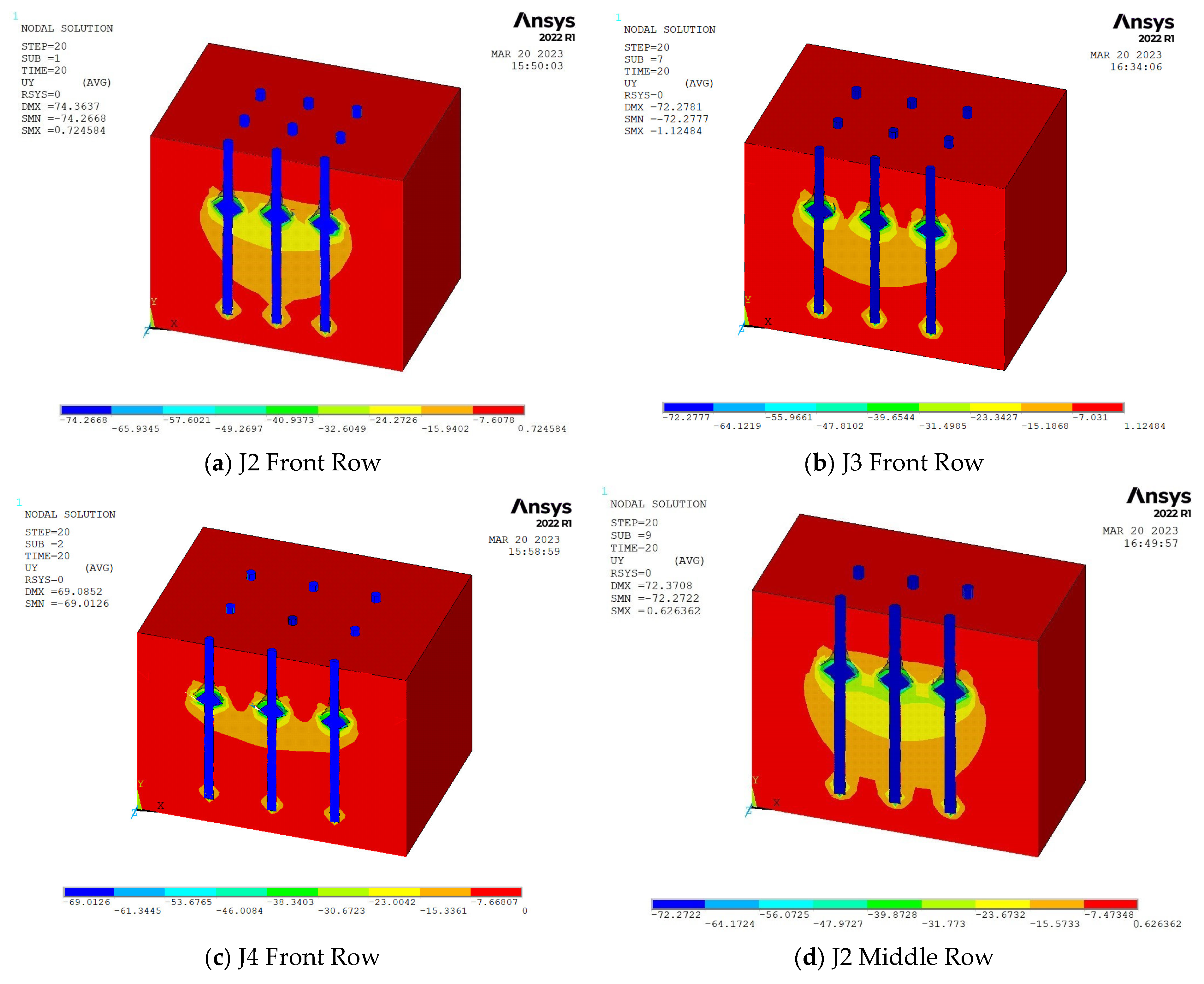

3.1.2. Six-Pile Displacement Cloud Map

3.1.3. Nine-Pile Displacement Cloud Map

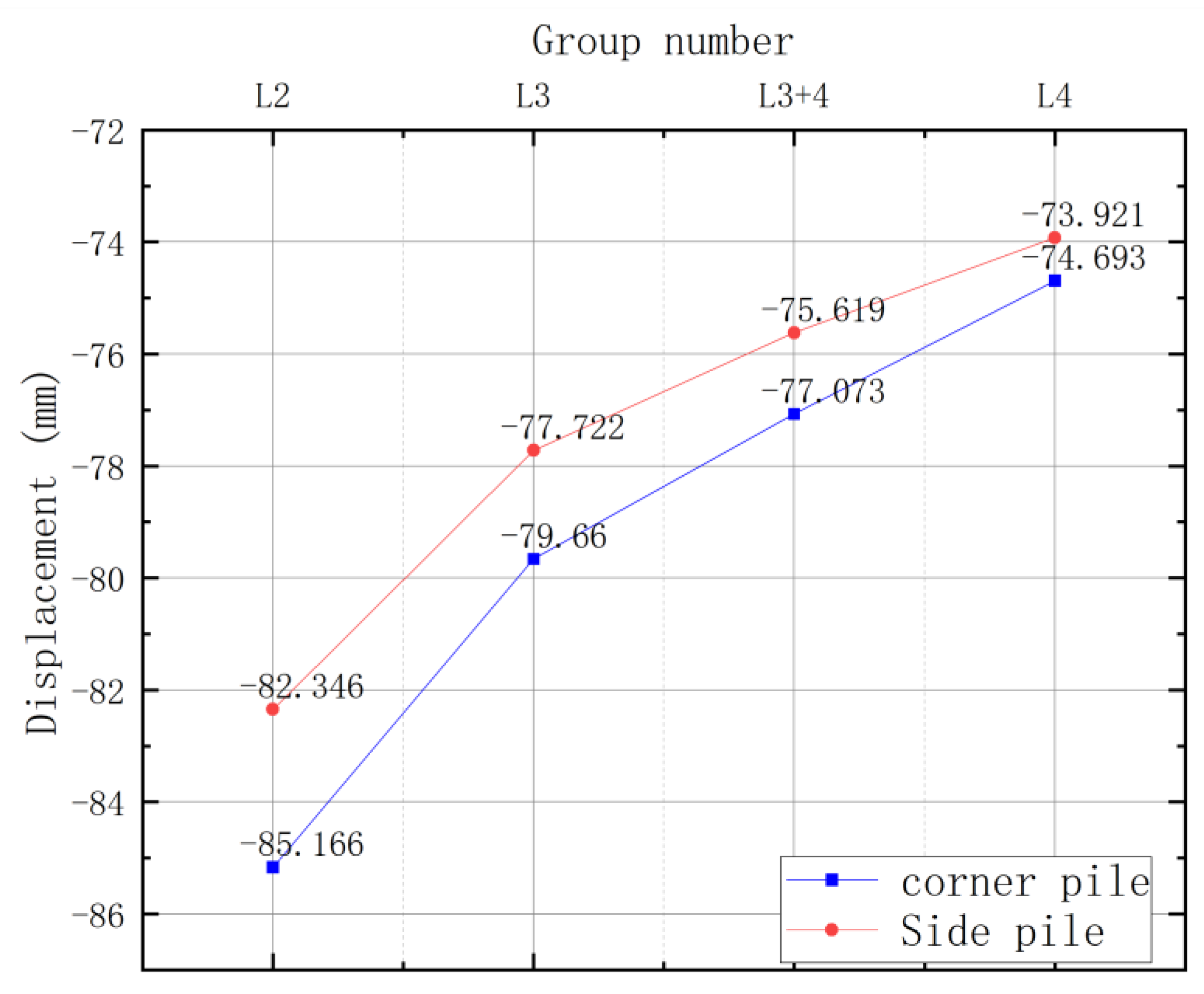

3.2. Comparative Analysis of Pile Displacement

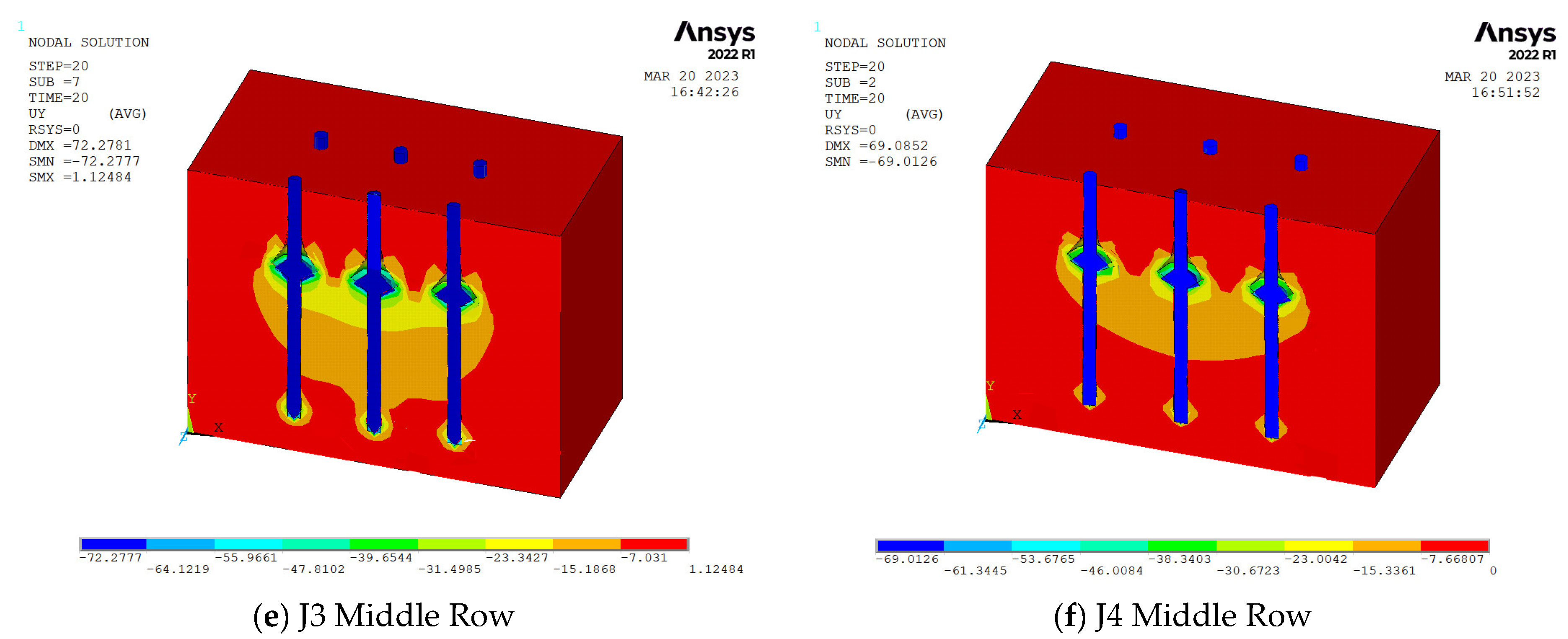

3.2.1. Comparative Analysis of Corner and Edge Piles under Six-Pile Conditions

3.2.2. Comparative Analysis of Displacement at the Tops of Corner, Edge, and Center Piles under the Condition of Nine Piles

3.2.3. Analysis of Displacement at the Top of the Central Pile under the Condition of Nine Piles

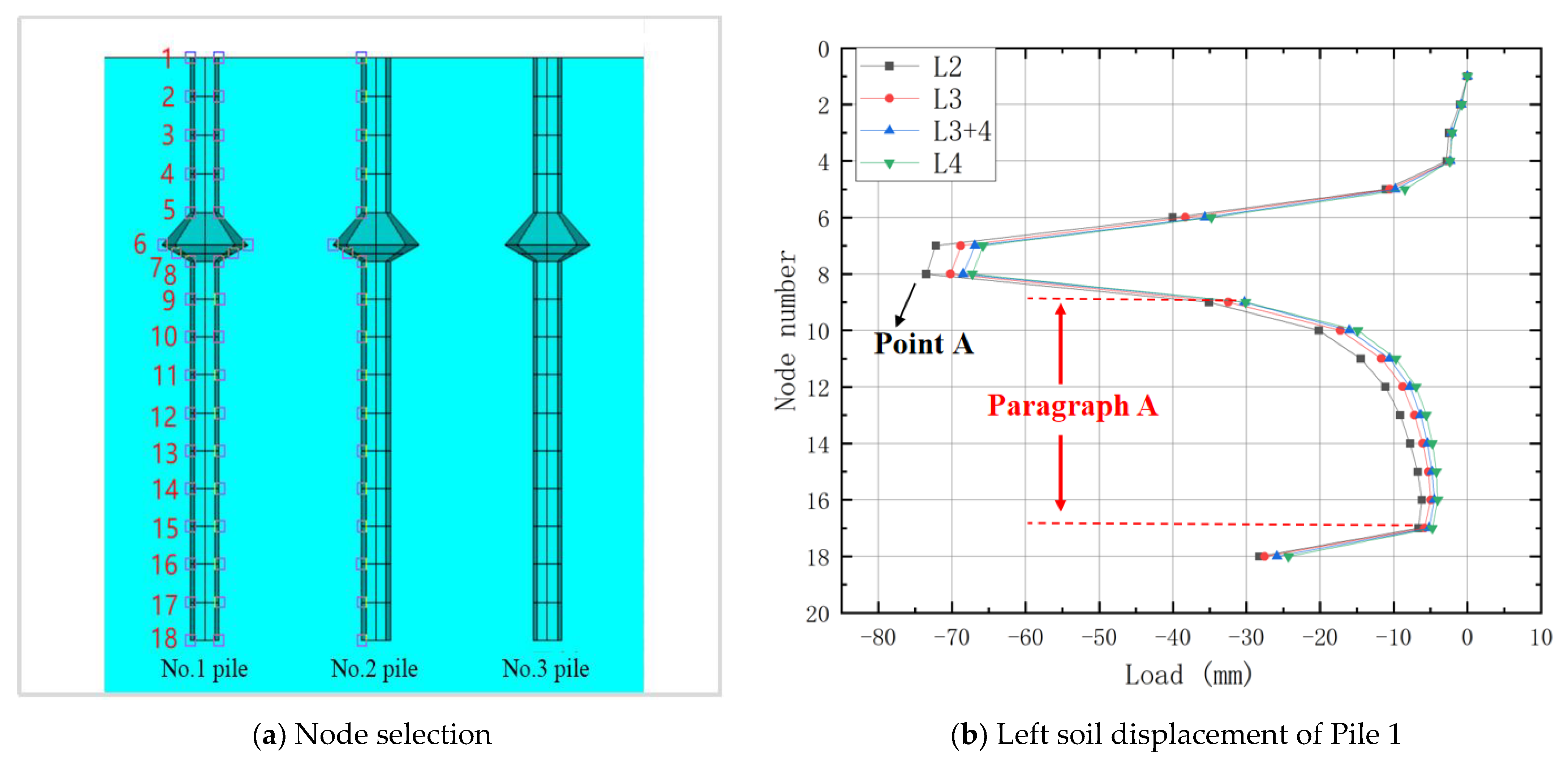

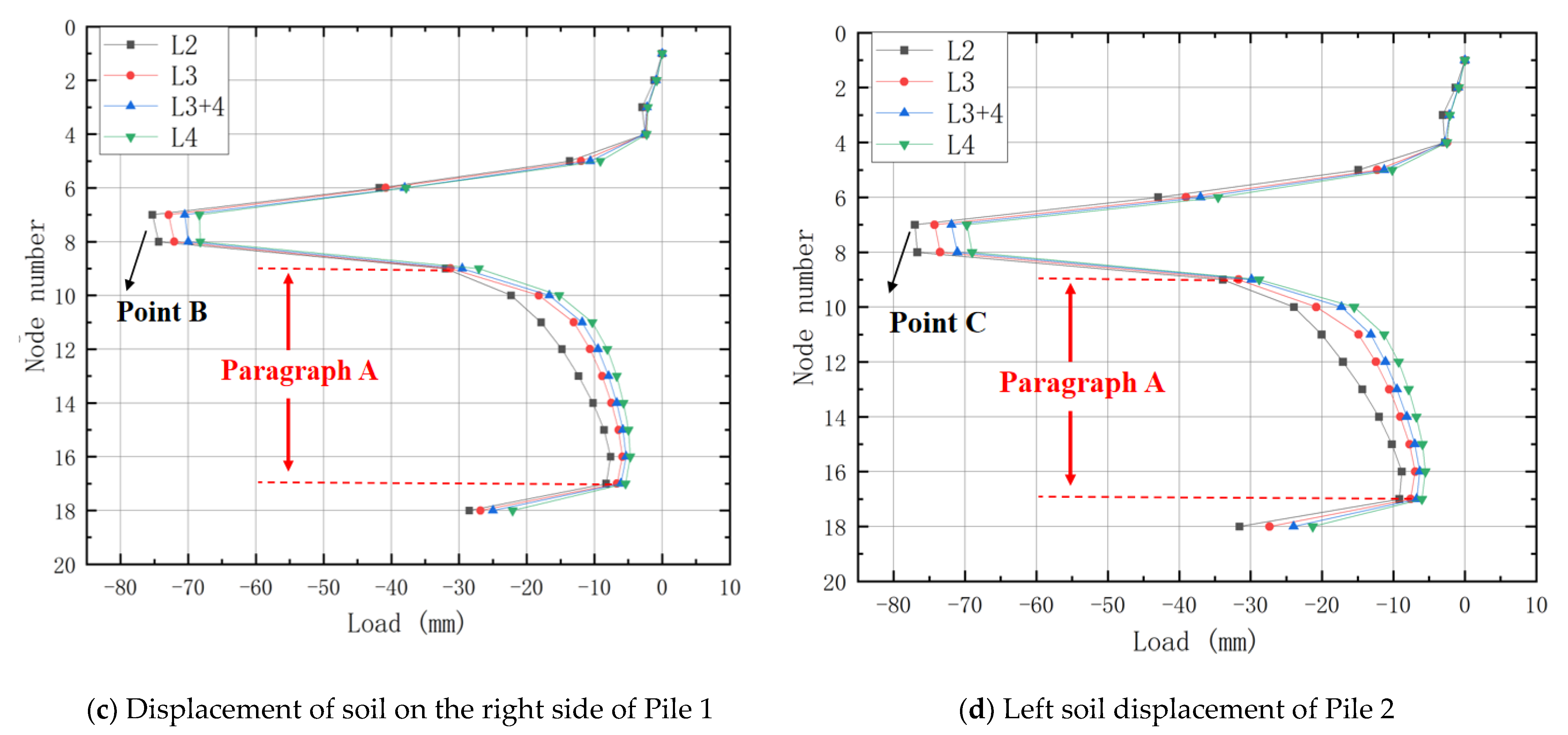

3.3. Comparative Analysis of Soil Displacement on Both Sides of the Edge and Center Piles under Six-Pile Condition

4. Conclusions

- (1)

- The trends in the displacement cloud maps for four, six, and nine piles are consistent. As the spacing between the piles increases, the range of influence of the soil around the piles gradually decreases.

- (2)

- Furthermore, the soil displacement range of the edge pile is slightly larger than that of the corner pile, and this phenomenon gradually decreases with the increase in pile spacing. When the pile spacing increases to four times the overhang length of the plate, the difference in pile displacement at different positions is calculated to be extremely small and can be ignored. Therefore, the spacing between the piles should be controlled to be three to four times the overhang length of the plate, which is more reasonable.

- (3)

- Under the same load, the displacement value of the central pile of the nine piles is −72.278 mm, while the displacement values of the edge pile and corner pile are −69.012 mm and −66.806 mm, respectively. Compared with the central pile, their displacement values have decreased by 4.52% and 7.57%, respectively. The displacement value generated by the central pile is the largest, followed by the edge and corner piles, and the difference increases with increasing load.

- (4)

- When the pile spacing is small, the soil around the pile body shares a larger range. The smaller the pile spacing, the greater the impact on the edge and center piles. As the spacing between piles gradually increases, the mutual influence between adjacent piles gradually decreases, which not only reduces the pile group effect but also improves the bearing capacity.

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, K. On the influence of pile foundation settlement of existing high-rise buildings on the surrounding buildings. Adv. Civ. Eng. 2021, 2021, 5560112. [Google Scholar] [CrossRef]

- Do, D.H.; Pham, T.A. Investigation of performance of soil-cement pile in support of foundation systems for high-rise buildings. Civ. Eng. J. 2018, 4, 266. [Google Scholar] [CrossRef]

- Odeh, N.A.; Al-Rkaby, A.H. Strength, Durability, and Microstructures characterization of sustainable geopolymer improved clayey soil. Case Stud. Constr. Mater. 2022, 16, e00988. [Google Scholar] [CrossRef]

- Al-Rkaby, A.H.; Odeh, N.A.; Sabih, A.; Odah, H. Geotechnical characterization of sustainable geopolymer improved soil. J. Mech. Behav. Mater. 2022, 31, 484–491. [Google Scholar] [CrossRef]

- Abdel-Azim, O.A.; Abdel-Rahman, K.; El-Mossallamy, Y.M. Numerical investigation of optimized piled raft foundation for high-rise building in Germany. Innov. Infrastruct. Solut. 2020, 5, 11. [Google Scholar] [CrossRef]

- Gao, X.; Wang, J.; Zhu, X. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J. Zhejiang Univ.-Sci. A 2007, 8, 1110–1117. [Google Scholar] [CrossRef]

- Ju, Y.; Chen, Y.F. Experimental study for the bearing capacity calculation of concrete expanded plates in squeezed branch piles. Mater. Test. 2018, 60, 1118–1124. [Google Scholar] [CrossRef]

- Tang, S.T.; Chen, L.H. Field test of dx pile group. Adv. Mater. Res. 2011, 243–249, 2451–2455. [Google Scholar] [CrossRef]

- Ma, H.; Wu, Y.; Tong, Y.; Jiang, X. Research on bearing theory of squeezed branch pile. Adv. Civ. Eng. 2020, 2020, 6637261. [Google Scholar] [CrossRef]

- Qian, Y.; Li, X.; Ai, L.; Jiang, Y.; Dong, Y. Simulation Analysis of the Effect of Pile Spacing on the Compressive Load-Bearing Performance of CEP Double Piles. Adv. Civ. Eng. 2023, 2023, 1005985. [Google Scholar] [CrossRef]

- Tian, W.; Qian, Y.; Lang, S.; Wang, R. The Undisturbed-Soil Experimental Analysis of the Destructive-State Influence of the Plate Diameter under the Vertical Tension on the CEP Pile. Chem. Eng. Trans. 2018, 66, 445–450. [Google Scholar]

- Chen, Y.; Lu, F.; Namdar, A.; Cai, J. Working mechanism of pile group with different pile spacing in dense sand. Adv. Civ. Eng. 2019, 2019, 5376594. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Al-Soudani, W.H.; Omar, M. Estimation of bearing capacity of open-ended model piles in sand. Arab. J. Geosci. 2016, 9, 242. [Google Scholar] [CrossRef]

- Qian, Y.; Chen, X.; Sun, L.; Wang, X.; Chen, Y. Effects of Staggered Plates on the Uplift Failure State and Bearing Capacity of NT-CEP Pile Groups. Buildings 2024, 14, 719. [Google Scholar] [CrossRef]

- Xing, J.; Li, J. The modeling method and the mesh division of the ANSYS. China Water Transp. (Acad.) 2006, 10, 116–118. [Google Scholar]

- Tao, L.; Jie, Z.; Long, X. The influence of modeling methods on the meshing when solid element was used in ANSYS–Taking the design by analysis of dry welding experiment module as an example. Appl. Mech. Mater. 2010, 42, 235. [Google Scholar]

- Jalammanavar, K.; Pujar, N.; Vishnu, R.R. Finite element study on mesh discretization error estimation for ANSYS workbench. In Proceedings of the International Conference on Computational Techniques, Electronics and Mechanical Systems, Belgaum, India, 21–22 December 2018. [Google Scholar]

- Tinghai, X.; Guofu, H. Analysis of results and static loading test of squeezed branch pile and boring pile with constant section in soft soil ground. Geotech. Investig. Surv. 2010, 38, 11–15. [Google Scholar]

- Li, Y.H.; Gao, X.J.; Zhong, G.H. Model test and finite element analysis of squeezed and branch pile bared vertical and horizontal loads. Appl. Mech. Mater. 2013, 470, 1101–1104. [Google Scholar] [CrossRef]

- Ouyang, W.; Wan, J.; Liu, S.W.; Li, X. Line-finite-element implementation for driven steel H-piles in layered sands considering post-driving residual stresses. Adv. Struct. Eng. 2021, 24, 1384–1398. [Google Scholar] [CrossRef]

| Materials | Density (kg/m3) | Elastic Modulus (MPa) | Poisson’s Ratio | Cohesion (MPa) | Friction Angle (°) | Expansion Angle (°) | Pile–Soil Friction Coefficient |

|---|---|---|---|---|---|---|---|

| Concrete | 2.25 × 103 | 3.0 × 104 | 0.2 | -- | -- | -- | 0.3 |

| Clay | 1.688 × 103 | 40 | 0.35 | 0.04355 | 10.7 | 10.7 |

| Load (kN) | Displacement (mm) | |||

|---|---|---|---|---|

| L2 | L3 | L3+4 | L4 | |

| 600 | −1.896 | −1.714 | −1.677 | −1.669 |

| 1200 | −3.764 | −3.405 | −3.330 | −3.313 |

| 1800 | −5.610 | −5.076 | −4.964 | −4.935 |

| 2400 | −7.485 | −6.787 | −6.636 | −6.573 |

| 3000 | −9.542 | −8.636 | −8.436 | −8.356 |

| 3600 | −11.758 | −10.625 | −10.370 | −10.244 |

| 4200 | −14.054 | −12.696 | −12.392 | −12.233 |

| 4800 | −16.431 | −14.859 | −14.500 | −14.334 |

| 5400 | −19.095 | −17.332 | −16.954 | −16.680 |

| 6000 | −22.654 | −20.335 | −19.883 | −19.710 |

| 6600 | −26.505 | −23.735 | −23.201 | −23.039 |

| 7200 | −30.675 | −27.473 | −26.842 | −26.625 |

| 7800 | −35.238 | −31.583 | −30.832 | −30.468 |

| 8400 | −39.962 | −36.115 | −35.186 | −34.636 |

| 9000 | −45.070 | −40.942 | −39.807 | −39.084 |

| 9600 | −50.401 | −46.090 | −44.715 | −43.840 |

| 10,200 | −55.965 | −51.546 | −49.957 | −48.874 |

| 10,800 | −61.270 | −57.005 | −55.508 | −54.201 |

| 11,400 | −66.979 | −61.804 | −60.393 | −59.746 |

| 12,000 | −72.141 | −66.995 | −65.449 | −64.474 |

| 12,600 | −78.518 | −72.926 | −70.920 | −69.375 |

| 13,200 | −85.166 | −79.660 | −77.073 | −74.693 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, Y.; Cao, Q.; Yang, Y.; Teng, D.; Zhou, T. Influence of Pile Spacing on the Compressive Bearing Performance of CEP Groups. Buildings 2024, 14, 1447. https://doi.org/10.3390/buildings14051447

Qian Y, Cao Q, Yang Y, Teng D, Zhou T. Influence of Pile Spacing on the Compressive Bearing Performance of CEP Groups. Buildings. 2024; 14(5):1447. https://doi.org/10.3390/buildings14051447

Chicago/Turabian StyleQian, Yongmei, Qingzhi Cao, Yang Yang, Da Teng, and Tingting Zhou. 2024. "Influence of Pile Spacing on the Compressive Bearing Performance of CEP Groups" Buildings 14, no. 5: 1447. https://doi.org/10.3390/buildings14051447

APA StyleQian, Y., Cao, Q., Yang, Y., Teng, D., & Zhou, T. (2024). Influence of Pile Spacing on the Compressive Bearing Performance of CEP Groups. Buildings, 14(5), 1447. https://doi.org/10.3390/buildings14051447