Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools

Abstract

1. Introduction

1.1. Importance of Structural Optimization in the Construction Industry

1.2. Available Tools for AI-Based Structural Optimization in BIM Projects

1.3. Scope, and Objective of This Study

2. Methodology

2.1. Preliminaries

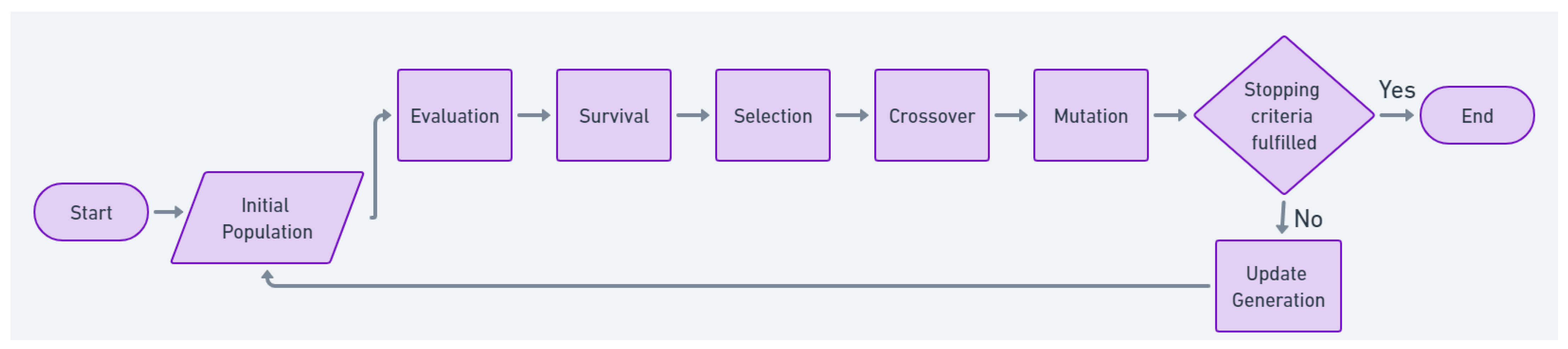

2.1.1. Genetic Algorithm

2.1.2. Formulation of the Truss Optimization Problem

2.2. Proposed Framework

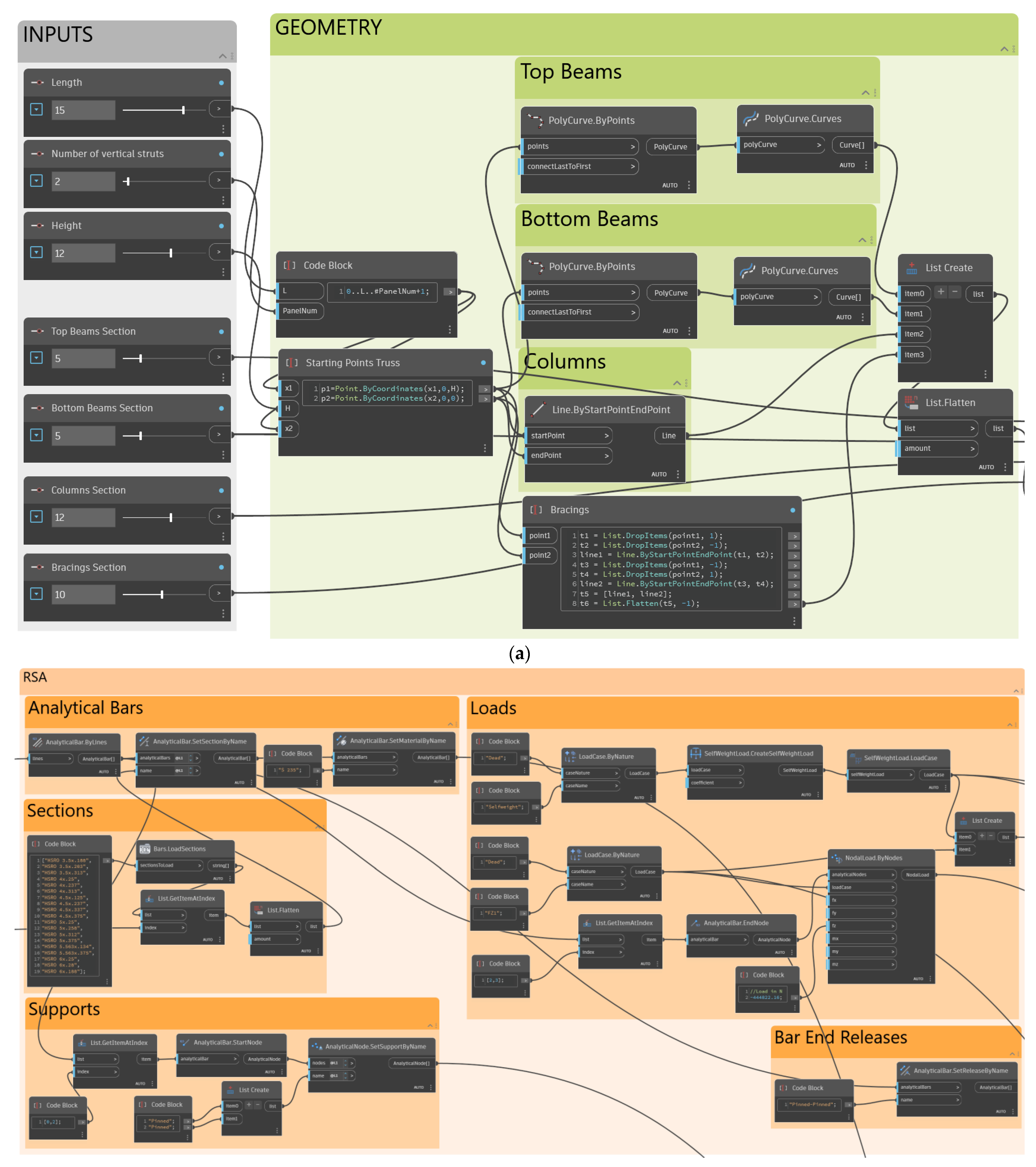

- Create parametric trusses by using visual programming (Figure 2a);

- Perform structural analysis on RSA and retrieve the results through Dynamo (Figure 2b);

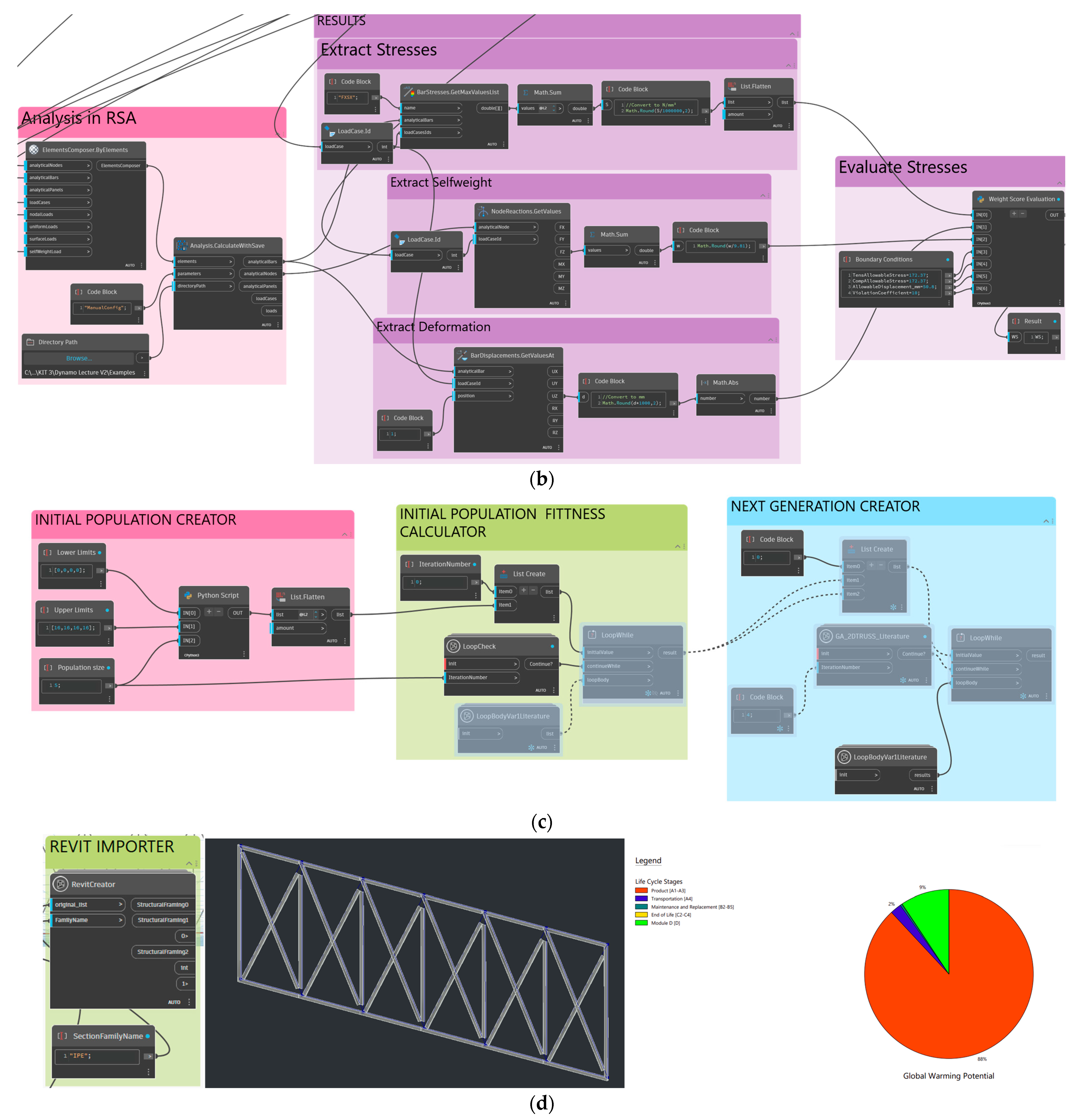

- Perform the first two steps in a loop along with GA operators to reach an optimum design (Figure 2c);

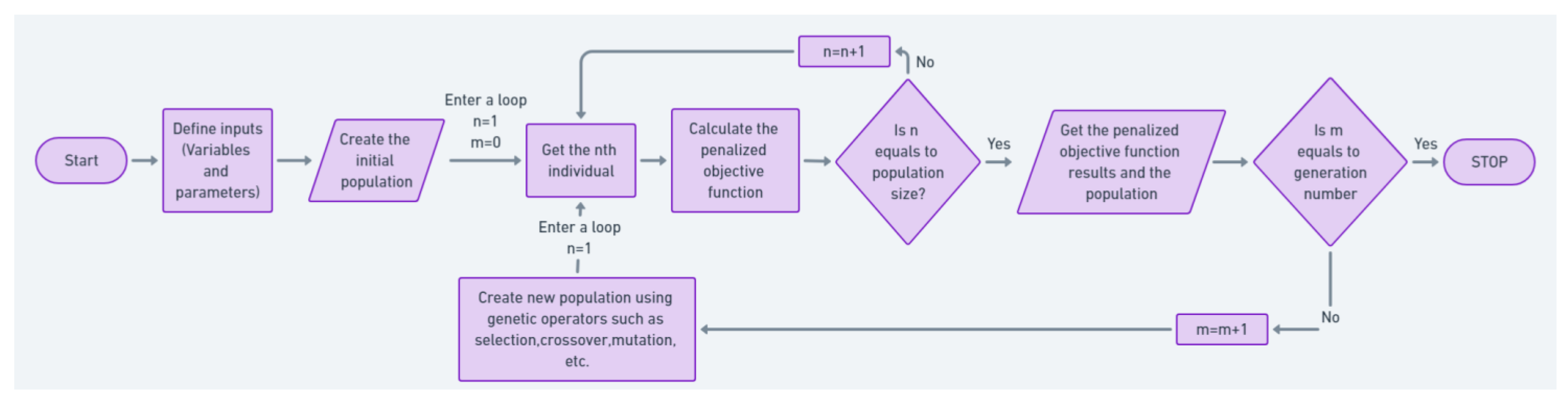

- Import the optimized model on Revit to perform further enhancements such as LCA, cost analysis, etc. (Figure 2d).

2.3. Parametric Model Creation

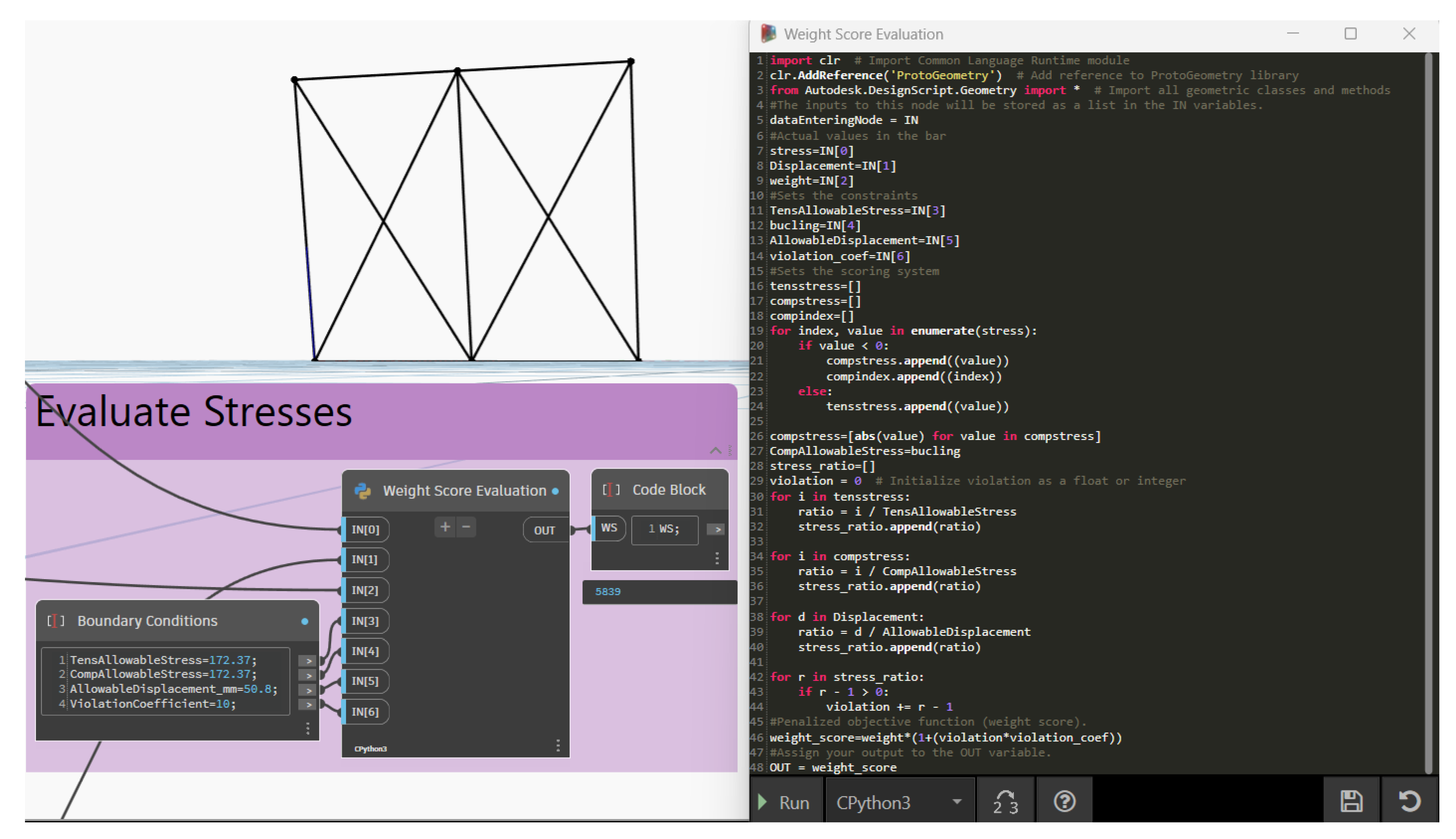

2.4. Calculation and Retrieval of Results

2.5. Structural Optimization

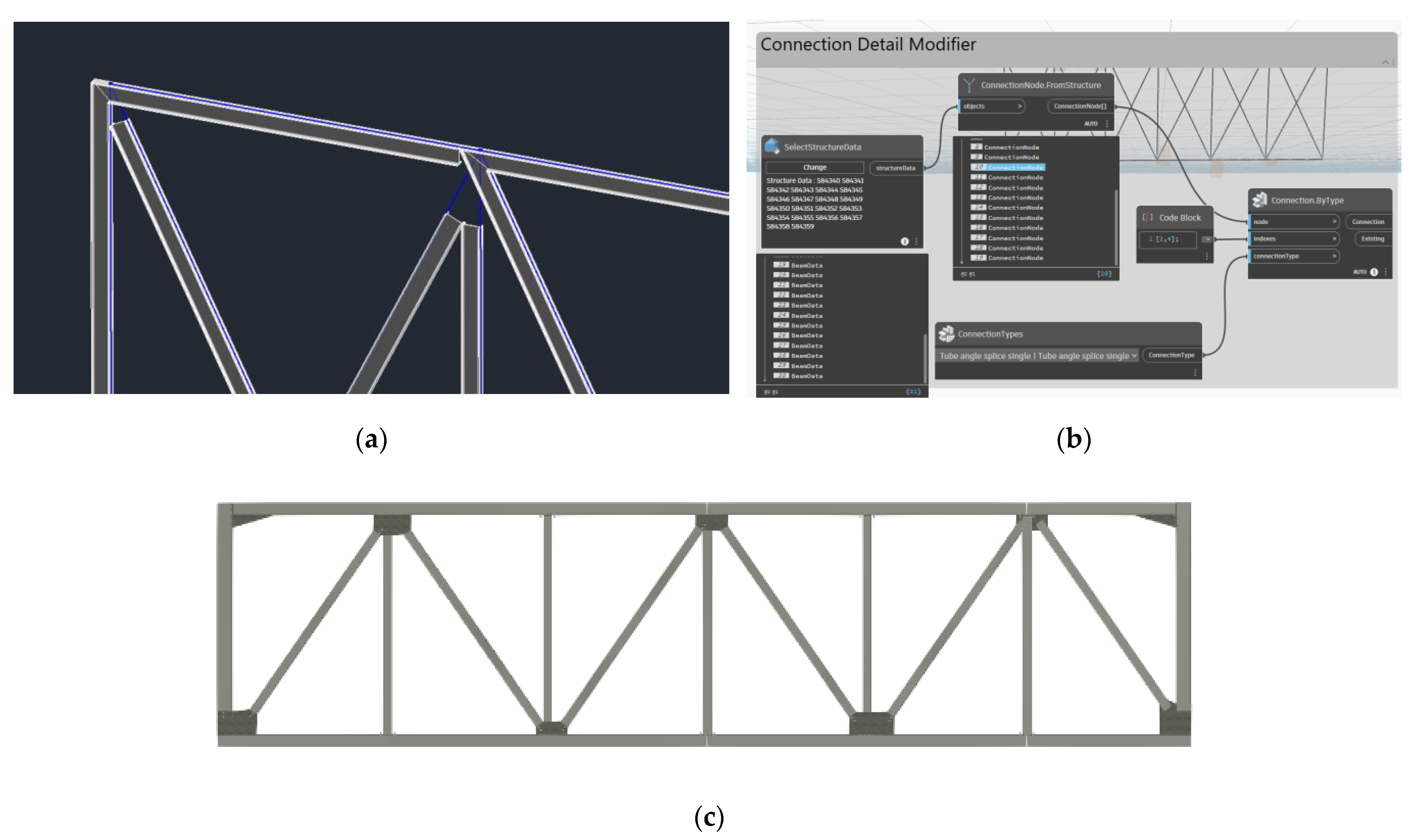

2.6. BIM Integration

3. Results

3.1. Experimental Setup

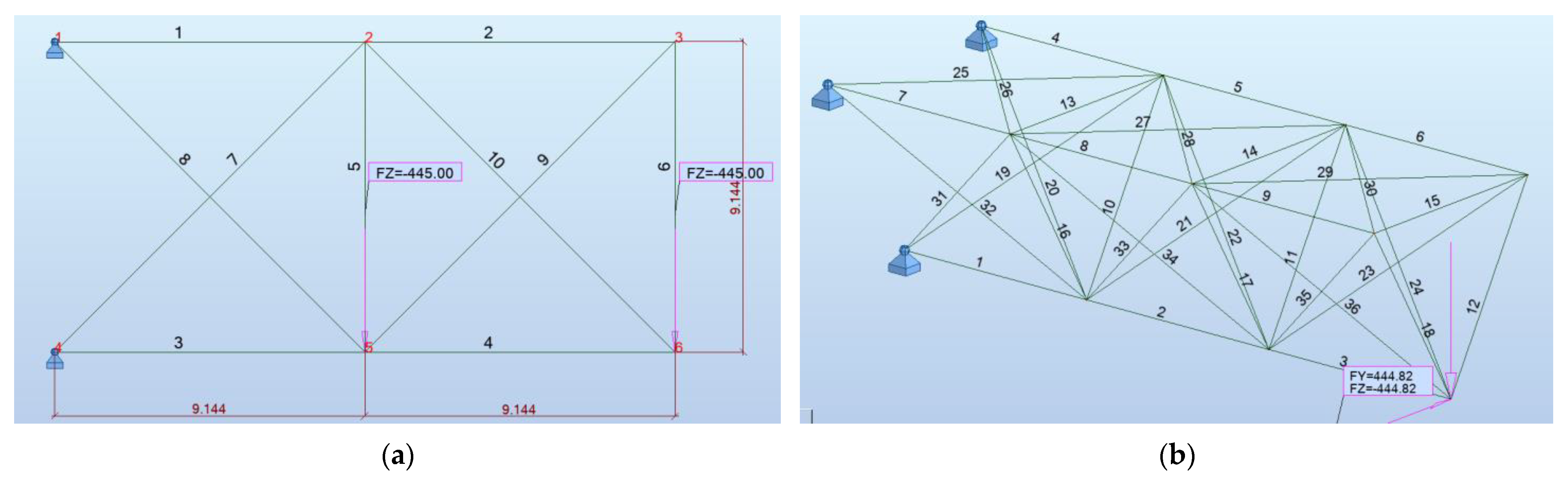

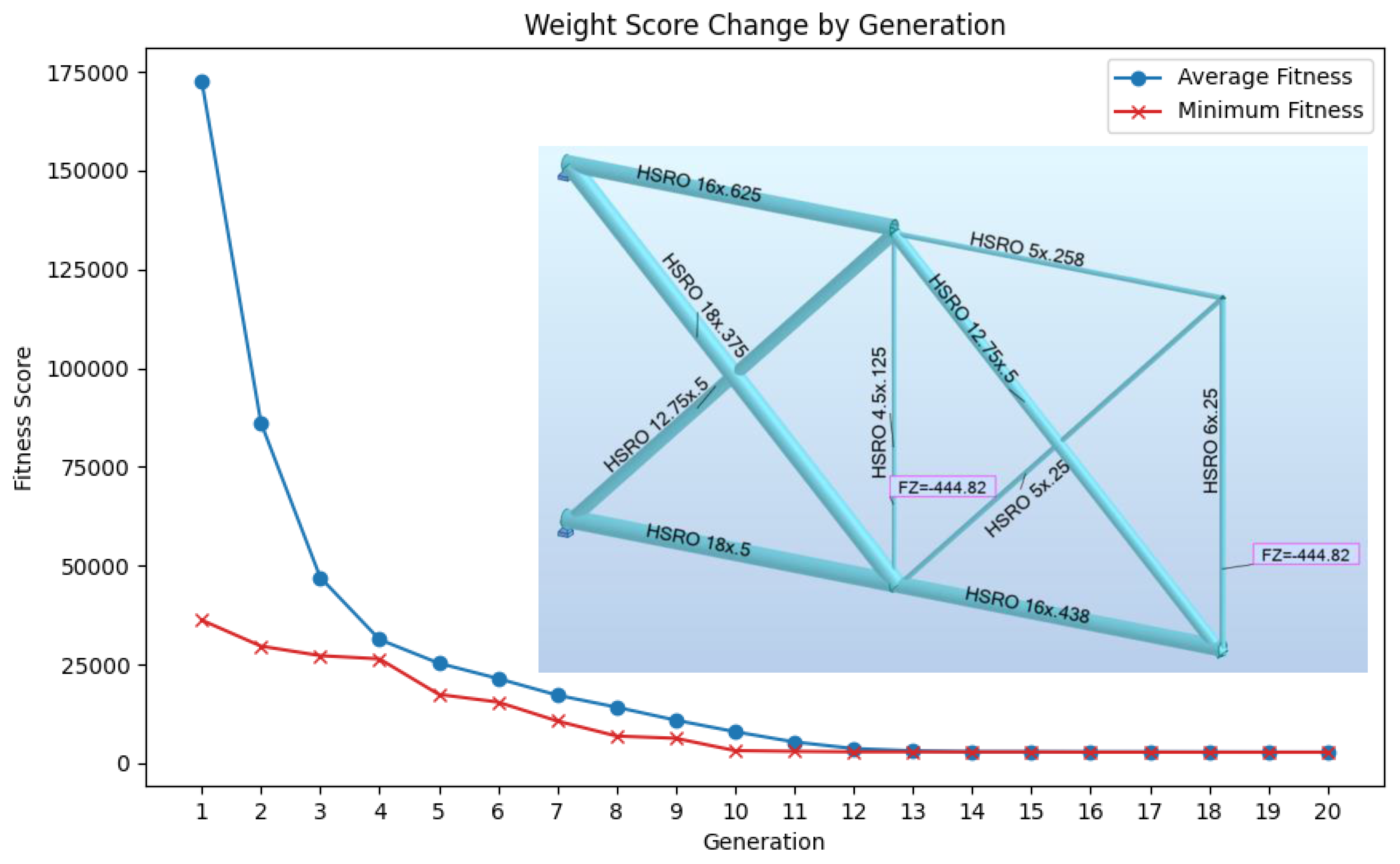

3.2. 10-Bar 2D Truss Problem

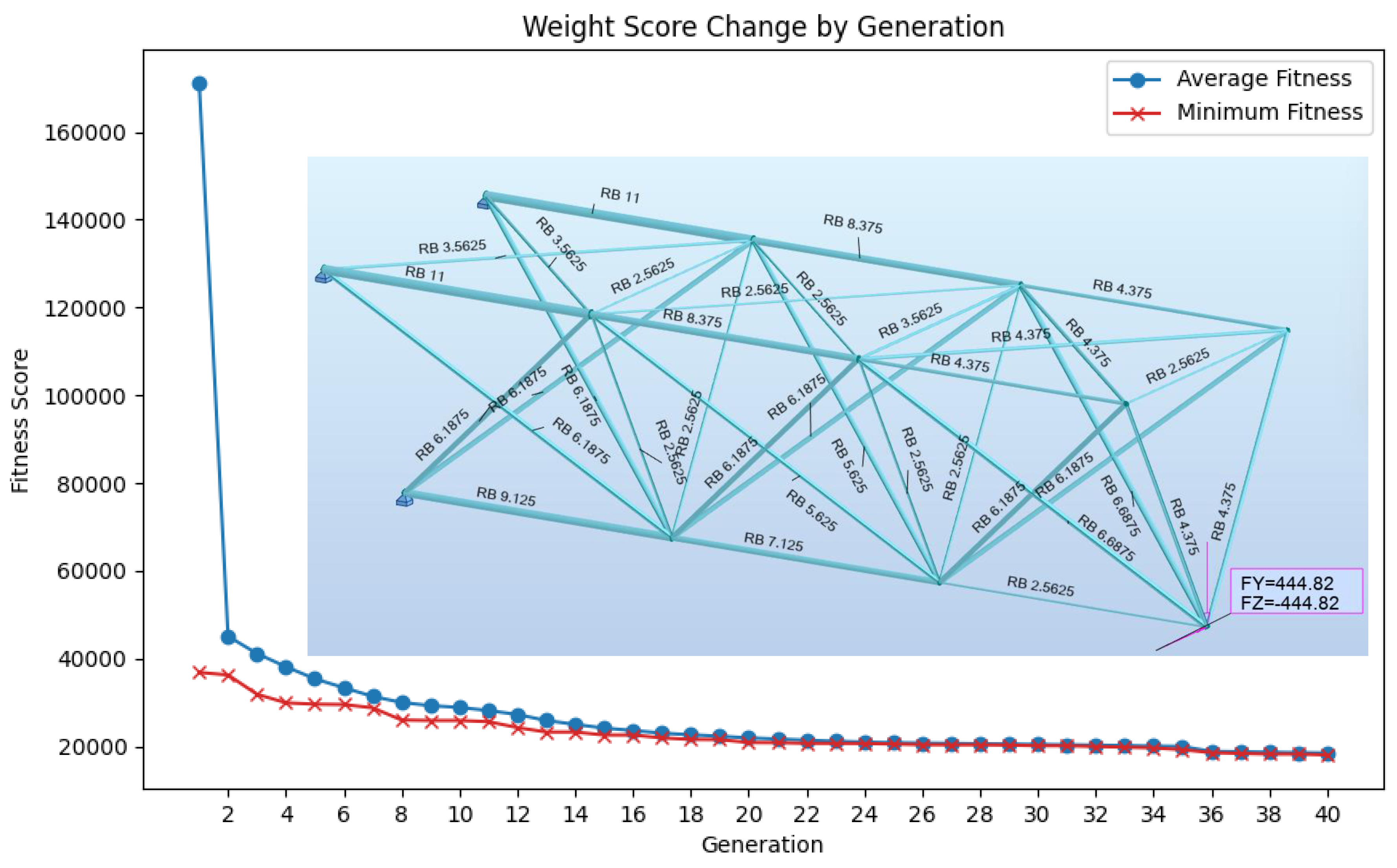

3.3. 36-Bar 3D Truss Problem

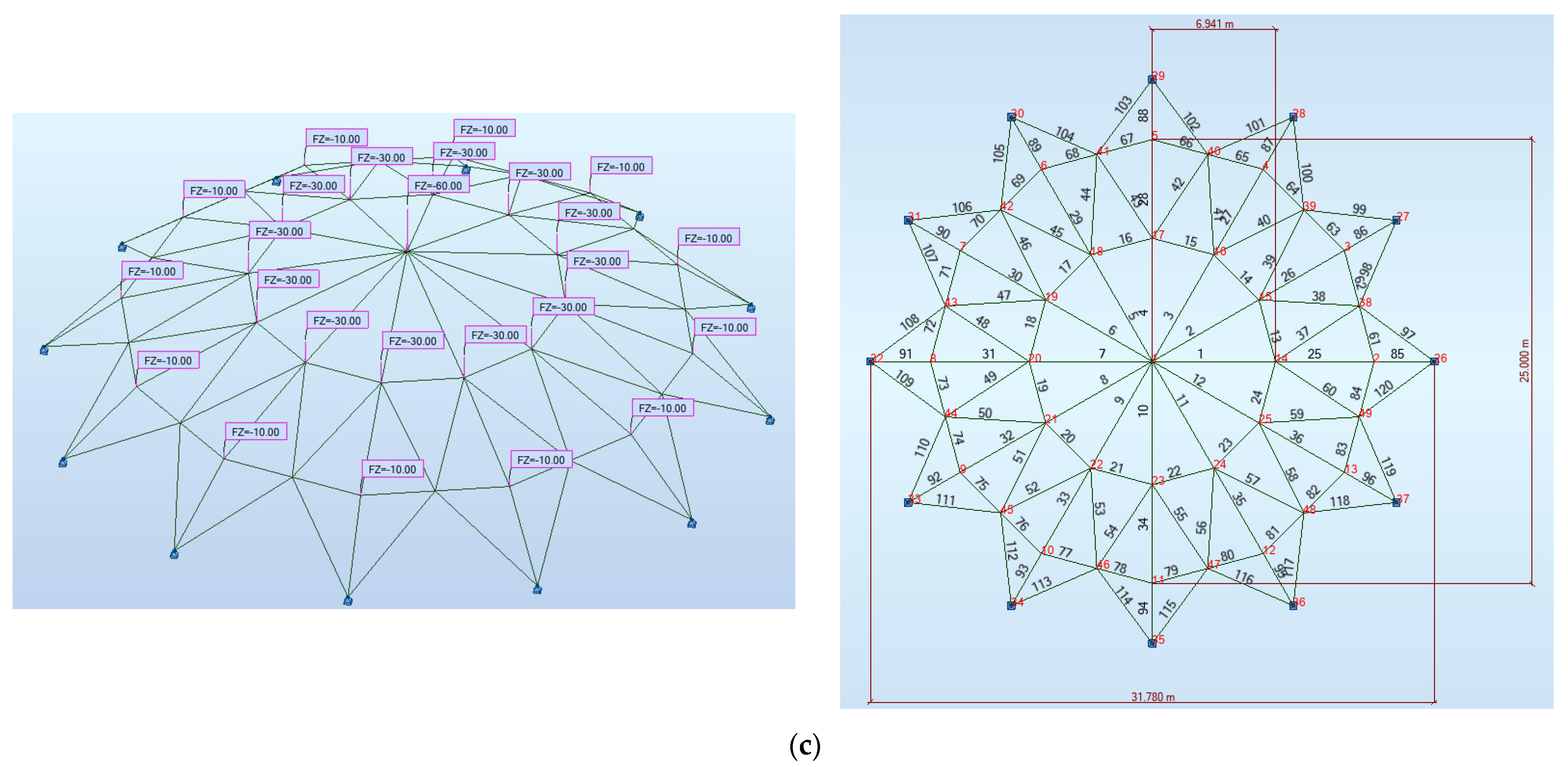

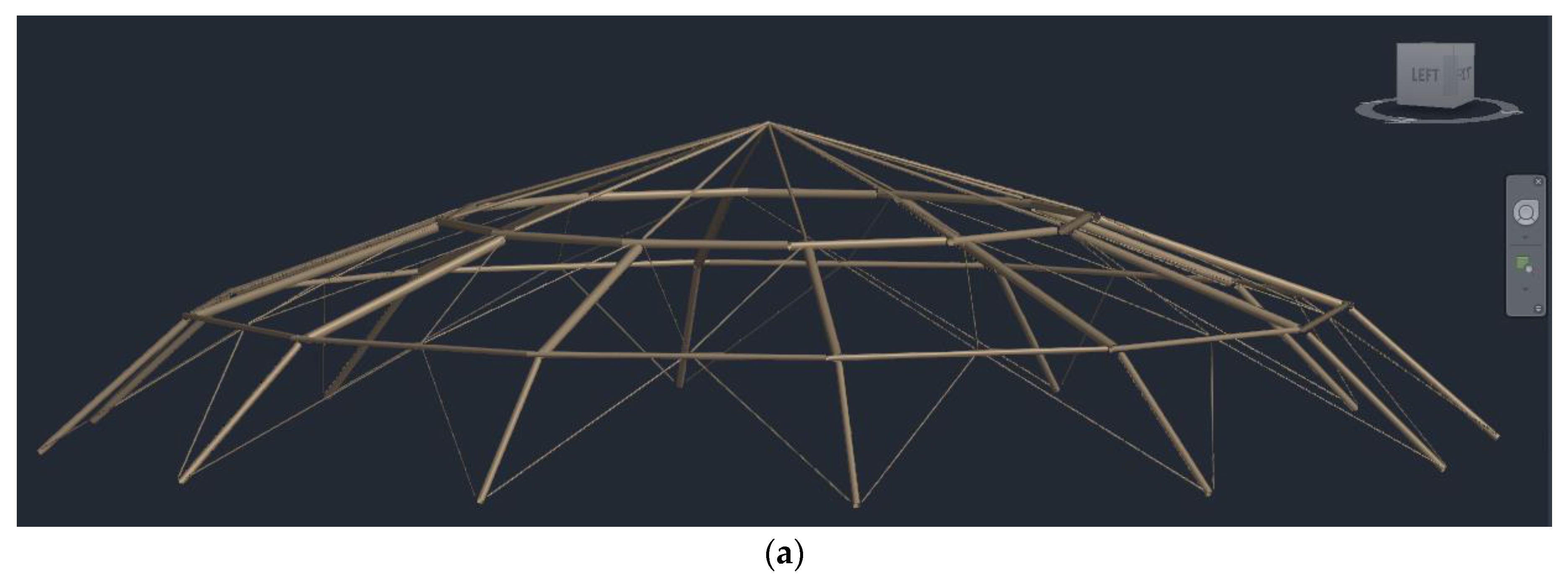

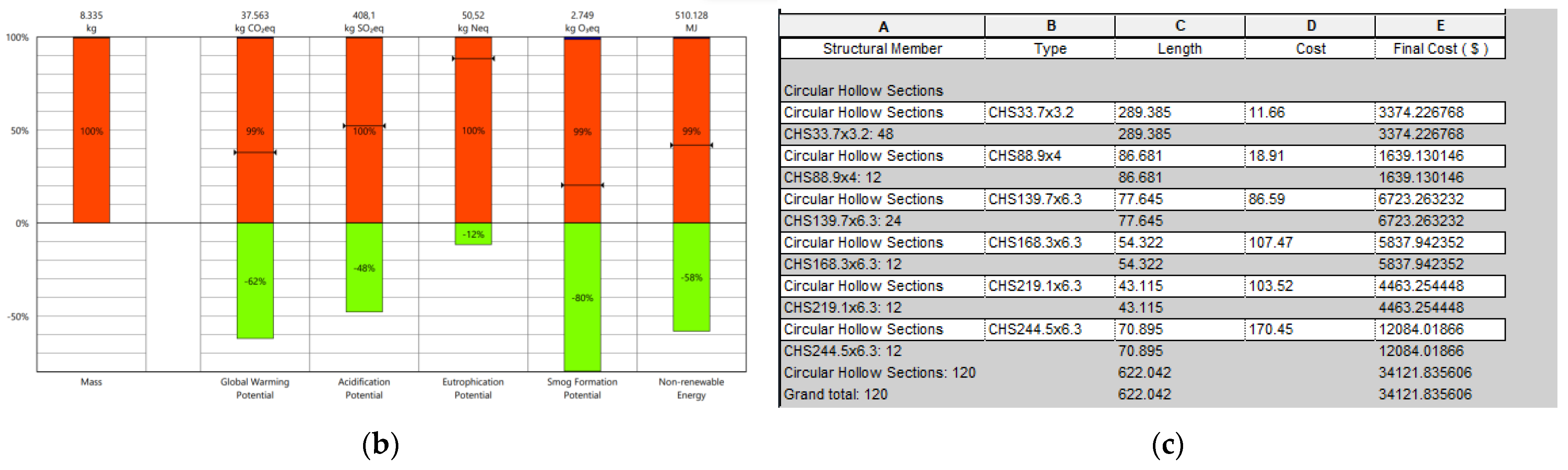

3.4. 120-Bar Dome Truss Problem

LCA and Cost Analysis for the 120-Bar Truss Structure

4. Discussion

5. Final Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gordon, J.E. Designing for safety—Or can you really trust strength calculations? In Structures or Why Things Don’t Fall Down; Springer: Boston, MA, USA, 1978. [Google Scholar] [CrossRef]

- Maalek, R.; Maalek, S. Repurposing Existing Skeletal Spatial Structure (SkS) System Designs Using the Field Information Modeling (FIM) Framework for Generative Decision-Support in Future Construction Projects. Sci. Rep. 2023, 13, 19591. [Google Scholar] [CrossRef] [PubMed]

- Mei, L.; Wang, Q. Structural Optimization in Civil Engineering: A Literature Review. Buildings 2021, 11, 66. [Google Scholar] [CrossRef]

- Bakhtiary, N.; Allinger, P.; Friedrich, M.; Mulfinger, F.; Sauter, J.; Puchinger, M. A New Approach for Sizing, Shape and Topology Optimization. J. Mater. Manuf. 1996, 105, 745–761. [Google Scholar]

- Wang, Z.; Cao, Z.; Fan, F.; Sun, Y. Shape Optimization of Free-Form Grid Structures Based on the Sensitivity Hybrid Multi-Objective Evolutionary Algorithm. J. Build. Eng. 2021, 44, 102538. [Google Scholar] [CrossRef]

- Christensen, P.W.; Klarbring, A. An Introduction to Structural Optimization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; Volume 153, ISBN 1402086660. [Google Scholar]

- Baykasoğlu, A.; Baykasoğlu, C. Weighted Superposition Attraction-Repulsion (WSAR) Algorithm for Truss Optimization with Multiple Frequency Constraints. Structures 2021, 30, 253–264. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Lu, H.; Ye, J.; Zhao, Y.; Min Xie, Y. Layout Optimization of Truss Structures with Modular Constraints. Structures 2023, 55, 1460–1469. [Google Scholar] [CrossRef]

- Stolpe, M. Truss Optimization with Discrete Design Variables: A Critical Review. Struct. Multidiscip. Optim. 2015, 53, 349–374. [Google Scholar] [CrossRef]

- Liu, J.; Xia, Y. A Hybrid Intelligent Genetic Algorithm for Truss Optimization Based on Deep Neutral Network. Swarm Evol. Comput. 2022, 73, 101120. [Google Scholar] [CrossRef]

- Sanchez-Caballero, S.; Selles, M.A.; Pla-Ferrando, R.; Martinez, S.A.V.; Peydro, M.A. Recent Advances in Structural Optimization. Annals of The Oradea University, Fascicle of Management and Technological Engineering, XXI (XI). 2012. Available online: https://riunet.upv.es/handle/10251/35915 (accessed on 17 May 2024).

- Rajeev, S.; Krishnamoorthy, C.S. Discrete Optimization of Structures Using Genetic Algorithms. J. Struct. Eng. 1992, 118, 1233–1250. [Google Scholar] [CrossRef]

- Rasheed, K.M. GADO: A Genetic Algorithm for Continuous Design Optimization; Rutgers The State University of New Jersey, School of Graduate Studies: New Brunswick, NJ, USA, 1998; ISBN 0591759950. [Google Scholar]

- Groenwold, A.A.; Stander, N.; Snyman, J.A. A Regional Genetic Algorithm for the Discrete Optimal Design of Truss Structures. Int. J. Numer. Methods Eng. 1999, 44, 749–766. [Google Scholar] [CrossRef]

- Toǧan, V.; Daloǧlu, A.T. An Improved Genetic Algorithm with Initial Population Strategy and Self-Adaptive Member Grouping. Comput. Struct. 2008, 86, 1204–1218. [Google Scholar] [CrossRef]

- Dorigo, M.; Birattari, M.; Stutzle, T. Ant Colony Optimization. IEEE Comput. Intell. Mag. 2006, 1, 28–39. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the Proceedings of ICNN’95—International Conference on Neural Networks 4, Perth, WA, Australia, 27 November 1995–1 December 1995; pp. 1942–1948. [CrossRef]

- Goodarzimehr, V.; Topal, U.; Das, A.K.; Vo-Duy, T. Bonobo Optimizer Algorithm for Optimum Design of Truss Structures with Static Constraints. Structures 2023, 50, 400–417. [Google Scholar] [CrossRef]

- Dede, T.; Kripka, M.; Togan, V.; Yepes, V.; Rao, R.V. Usage of Optimization Techniques in Civil Engineering During the Last Two Decades. Curr. Trends Civ. Struct. Eng. 2019, 2, 1–7. [Google Scholar] [CrossRef]

- Aydın, Z. Size, Layout and Tendon Profile Optimization of Prestressed Steel Trusses Using Jaya Algorithm. Structures 2022, 40, 284–294. [Google Scholar] [CrossRef]

- Singh, P.; Kottath, R.; Tejani, G.G. Ameliorated Follow The Leader: Algorithm and Application to Truss Design Problem. Structures 2022, 42, 181–204. [Google Scholar] [CrossRef]

- Jawad, F.K.J.; Ozturk, C.; Dansheng, W.; Mahmood, M.; Al-Azzawi, O.; Al-Jemely, A. Sizing and Layout Optimization of Truss Structures with Artificial Bee Colony Algorithm. Structures 2021, 30, 546–559. [Google Scholar] [CrossRef]

- Jafari, M.; Salajegheh, E.; Salajegheh, J. Optimal Design of Truss Structures Using a Hybrid Method Based on Particle Swarm Optimizer and Cultural Algorithm. Structures 2021, 32, 391–405. [Google Scholar] [CrossRef]

- Kaveh, A.; Biabani Hamedani, K.; Milad Hosseini, S.; Bakhshpoori, T. Optimal design of planar steel frame structures utilizing meta-heuristic optimization algorithms. Structures 2020, 25, 335–346. [Google Scholar] [CrossRef]

- Vu-Huu, T.; Pham-Van, S.; Pham, Q.H.; Cuong-Le, T. An Improved Bat Algorithms for Optimization Design of Truss Structures. Structures 2023, 47, 2240–2258. [Google Scholar] [CrossRef]

- Biabani, F.; Shojaee, S.; Hamzehei-Javaran, S. A New Insight into Metaheuristic Optimization Method Using a Hybrid of PSO, GSA, and GWO. Structures 2022, 44, 1168–1189. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, H.; Charkaoui, A.; Hassan, N.M.; Bahroun, Z.; Jiang, J.; Wang, S.; Zhao, L.; Li, W.; Yao, Q.; et al. Truss Optimization Using Genetic Algorithm and FEA. J. Phys. Conf. Ser. 2021, 1965, 012134. [Google Scholar] [CrossRef]

- Maalek, S.; Maalek, R.; Maalek, B. Intrinsic Properties of Composite Double Layer Grid Superstructures. Infrastructures 2023, 8, 129. [Google Scholar] [CrossRef]

- Mai, H.T.; Lieu, Q.X.; Kang, J.; Lee, J. A Novel Deep Unsupervised Learning-Based Framework for Optimization of Truss Structures. Eng. Comput. 2023, 39, 2585–2608. [Google Scholar] [CrossRef]

- Cicconi, P.; Germani, M.; Bondi, S.; Zuliani, A.; Cagnacci, E. A Design Methodology to Support the Optimization of Steel Structures. Procedia CIRP 2016, 50, 58–64. [Google Scholar] [CrossRef]

- SAP2000|STRUCTURAL ANALYSIS AND DESIGN. Available online: https://www.csiamerica.com/products/sap2000 (accessed on 17 May 2024).

- Kaveh, A.; Mirzaei, B.; Jafarvand, A. Shape-Size Optimization of Single-Layer Barrel Vaults Using Improved Magnetic Charged System Search. Int. J. Civil. Eng. 2014, 12, 447–465. [Google Scholar]

- Artar, M.; Carbas, S. Discrete Sizing Design of Steel Truss Bridges through Teaching-Learning-Based and Biogeography-Based Optimization Algorithms Involving Dynamic Constraints. Structures 2021, 34, 3533–3547. [Google Scholar] [CrossRef]

- Vasani, A.; Patel, R.; Savsani, V.; Savsani, P. Parametric Analysis of Genetic Algorithm Toolbox for Truss Problem Optimization. In Reliability and Risk Assessment in Engineering; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 389–398. [Google Scholar] [CrossRef]

- Mirniazmandan, S.; Alaghmandan, M.; Barazande, F.; Rahimianzarif, E. Mutual Effect of Geometric Modifications and Diagrid Structure on Structural Optimization of Tall Buildings. Archit. Sci. Rev. 2018, 61, 371–383. [Google Scholar] [CrossRef]

- Sotiropoulos, S.; Lagaros, N.D. Topology Optimization of Framed Structures Using SAP2000. Procedia Manuf. 2020, 44, 68–75. [Google Scholar] [CrossRef]

- He, L.; Li, Q.; Gilbert, M.; Shepherd, P.; Rankine, C.; Pritchard, T.; Reale, V. Optimization-Driven Conceptual Design of Truss Structures in a Parametric Modelling Environment. Structures 2022, 37, 469–482. [Google Scholar] [CrossRef]

- Lin, J.-R.; Zhang, Y.; Kong SAR, H.; Xiao, J. A Framework to Automate Reliability-Based Structural Optimization Based on Visual Programming and OpenSees. In Proceedings of the 8th International Conference on Construction Engineering and Project Management, Hong Kong, China, 8–10 December 2019. [Google Scholar]

- Kossakowski, P.G. Visual Programming as Modern and Effective Structural Design Technology—Analysis of Opportunities, Challenges, and Future Developments Based on the Use of Dynamo. Appl. Sci. 2023, 13, 9298. [Google Scholar] [CrossRef]

- Choi, S.W.; Oh, B.K.; Park, H.S. Design Technology Based on Resizing Method for Reduction of Costs and Carbon Dioxide Emissions of High-Rise Buildings. Energy Build. 2017, 138, 612–620. [Google Scholar] [CrossRef]

- Rani, H.A.; Al-Mohammad, M.S.; Rajabi, M.S.; Rahman, R.A. Critical Government Strategies for Enhancing Building Information Modeling Implementation in Indonesia. Infrastructures 2023, 8, 57. [Google Scholar] [CrossRef]

- Daloğlu, A.; Armutçu, M. Optimal Design of Plane Steel Frames with Genetic Algorithm. Tek. Dergi 1998, 9, 42. (In Turkish) [Google Scholar]

- Marques, F.d.P.; Arenales, M.N. The Constrained Compartmentalised Knapsack Problem. Comput. Oper. Res. 2007, 34, 2109–2129. [Google Scholar] [CrossRef]

- Darwin, C. On the Origin of Species: A Facsimile of the First Edition; Harvard University Press: Cambridge, MA, USA, 1964; ISBN 0674637526. [Google Scholar]

- Coello Coello, C.A. Theoretical and Numerical Constraint-Handling Techniques Used with Evolutionary Algorithms: A Survey of the State of the Art. Comput. Methods Appl. Mech. Eng. 2002, 191, 1245–1287. [Google Scholar] [CrossRef]

- Blank, J.; Deb, K. Pymoo: Multi-Objective Optimization in Python. IEEE Access 2020, 8, 89497–89509. [Google Scholar] [CrossRef]

- Kamrani, A.K.; Gonzalez, R. A Genetic Algorithm-Based Solution Methodology for Modular Design. J. Intell. Manuf. 2003, 14, 599–616. [Google Scholar] [CrossRef]

- Yang, T.; Kuo, Y.; Cho, C. A Genetic Algorithms Simulation Approach for the Multi-Attribute Combinatorial Dispatching Decision Problem. Eur. J. Oper. Res. 2007, 176, 1859–1873. [Google Scholar] [CrossRef]

- Yeniay, Ö. Penalty Function Methods for Constrained Optimization with Genetic Algorithms. Math. Comput. Appl. 2005, 10, 45–56. [Google Scholar] [CrossRef]

- Ugurfeyzullah/Structural-Optimization-with-VP. Available online: https://github.com/ugurfeyzullah/Structural-optimization-with-VP (accessed on 10 March 2024).

- Ringertz, U.T. On methods for discrete structural optimization. Eng. Optim. 1988, 13, 47–64. [Google Scholar] [CrossRef]

- Saka, M.P.; Ulker, M. Optimum Design of Geometrically Nonlinear Space Trusses. Comput. Struct. 1991, 41, 1387–1396. [Google Scholar] [CrossRef]

- Camp, C.V.; Bichon, B.J. Design of Space Trusses Using Ant Colony Optimization. J. Struct. Eng. 2004, 130, 741–751. [Google Scholar] [CrossRef]

- Cao, H.; Qian, X.; Chen, Z.; Zhu, H. Enhanced Particle Swarm Optimization for Size and Shape Optimization of Truss Structures. Eng. Optim. 2017, 49, 1939–1956. [Google Scholar] [CrossRef]

- Robot Structural Analysis 2018 Help|Section Database|Autodesk. Available online: https://help.autodesk.com/view/RSAPRO/2018/ENU/?guid=GUID-727CAC1A-7ABE-4986-B7A5-4E31ADF1A6AA (accessed on 14 April 2024).

- Schutte, J.F.; Groenwold, A.A. Sizing Design of Truss Structures Using Particle Swarms. Struct. Multidiscip. Optim. 2003, 25, 261–269. [Google Scholar] [CrossRef]

- Capriles, P.V.S.Z.; Fonseca, L.G.; Barbosa, H.J.C.; Lemonge, A.C.C. Rank-Based Ant Colony Algorithms for Truss Weight Minimization with Discrete Variables. Commun. Numer. Methods Eng. 2006, 23, 553–575. [Google Scholar] [CrossRef]

- Ebenau, C.; Rottschäfer, J.; Thierauf, G. An Advanced Evolutionary Strategy with an Adaptive Penalty Function for Mixed-Discrete Structural Optimisation. Adv. Eng. Softw. 2005, 36, 29–38. [Google Scholar] [CrossRef]

- Tejani, G.G.; Savsani, V.J.; Patel, V.K. Modified Sub-Population Teaching-Learning-Based Optimization for Design of Truss Structures with Natural Frequency Constraints. Mech. Based Des. Struct. Mach. 2016, 44, 495–513. [Google Scholar] [CrossRef]

- Azizi, M.; Aickelin, U.; Khorshidi, H.A.; Shishehgarkhaneh, M.B. Shape and Size Optimization of Truss Structures by Chaos Game Optimization Considering Frequency Constraints. J. Adv. Res. 2022, 41, 89–100. [Google Scholar] [CrossRef]

- Kooshkbaghi, M.; Kaveh, A. Sizing Optimization of Truss Structures with Continuous Variables by Artificial Coronary Circulation System Algorithm. Iran. J. Sci. Technol.—Trans. Civil. Eng. 2020, 44, 1–20. [Google Scholar] [CrossRef]

- American Institute of Steel Construction. Specification for the Design, Fabrication, and Erection of Structural Steel for Buildings; American Institute of Steel Construction, New York, NY, USA, 1969. Available online: https://www.aisc.org/globalassets/aisc/manual/15th-ed-ref-list/specification-for-the-design-fabrication-and-erection-of-structural-steel-for-buildings.pdf (accessed on 17 May 2024).

- ParkerSteel—UK Steel Stockholders. Available online: https://www.parkersteel.co.uk/ (accessed on 14 April 2024).

- Almasabha, G.; Alshboul, O.; Shehadeh, A.; Almuflih, A.S.; Yang, B.; Almasabha, G.; Alshboul, O.; Shehadeh, A.; Almuflih, A.S. Machine Learning Algorithm for Shear Strength Prediction of Short Links for Steel Buildings. Buildings 2022, 12, 775. [Google Scholar] [CrossRef]

- Zain, M.; Prasittisopin, L.; Mehmood, T.; Ngamkhanong, C.; Keawsawasvong, S.; Thongchom, C. A Novel Framework for Effective Structural Vulnerability Assessment of Tubular Structures Using Machine Learning Algorithms (GA and ANN) for Hybrid Simulations. Nonlinear Eng. 2024, 13, 20220365. [Google Scholar] [CrossRef]

- Zain, M.; Keawsawasvong, S.; Thongchom, C.; Sereewatthanawut, I.; Usman, M.; Prasittisopin, L. Establishing Efficacy of Machine Learning Techniques for Vulnerability Information of Tubular Buildings. Eng. Sci. 2024, 27, 1008. [Google Scholar] [CrossRef]

| Rajeev et al. [12] | Camp et al. [53] | Jafari et al. [23] | This Study | |

|---|---|---|---|---|

| Weight (kg) | 2549.2 | 2490.6 | 2302.43 | 2763.06 |

| Analysis made | 400 | 10,000 | 15,100 | 400 |

| Separate Runs | - | 24 | 30 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yavan, F.; Maalek, R.; Toğan, V. Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools. Buildings 2024, 14, 1532. https://doi.org/10.3390/buildings14061532

Yavan F, Maalek R, Toğan V. Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools. Buildings. 2024; 14(6):1532. https://doi.org/10.3390/buildings14061532

Chicago/Turabian StyleYavan, Feyzullah, Reza Maalek, and Vedat Toğan. 2024. "Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools" Buildings 14, no. 6: 1532. https://doi.org/10.3390/buildings14061532

APA StyleYavan, F., Maalek, R., & Toğan, V. (2024). Structural Optimization of Trusses in Building Information Modeling (BIM) Projects Using Visual Programming, Evolutionary Algorithms, and Life Cycle Assessment (LCA) Tools. Buildings, 14(6), 1532. https://doi.org/10.3390/buildings14061532