Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions

Abstract

1. Introduction

1.1. Background

1.2. Practical Problems and Contributions in the Field

1.3. Significance of the Topic and the Necessity of the Review

2. Assessing the Impact of Reused Building Framework Materials on Sustainability in Construction

2.1. Environmental and Energy Efficiency Advancements through Material Reuse

2.1.1. Mitigation of GHG Emissions via Material Reutilization

2.1.2. Energy Demand Mitigation in Construction

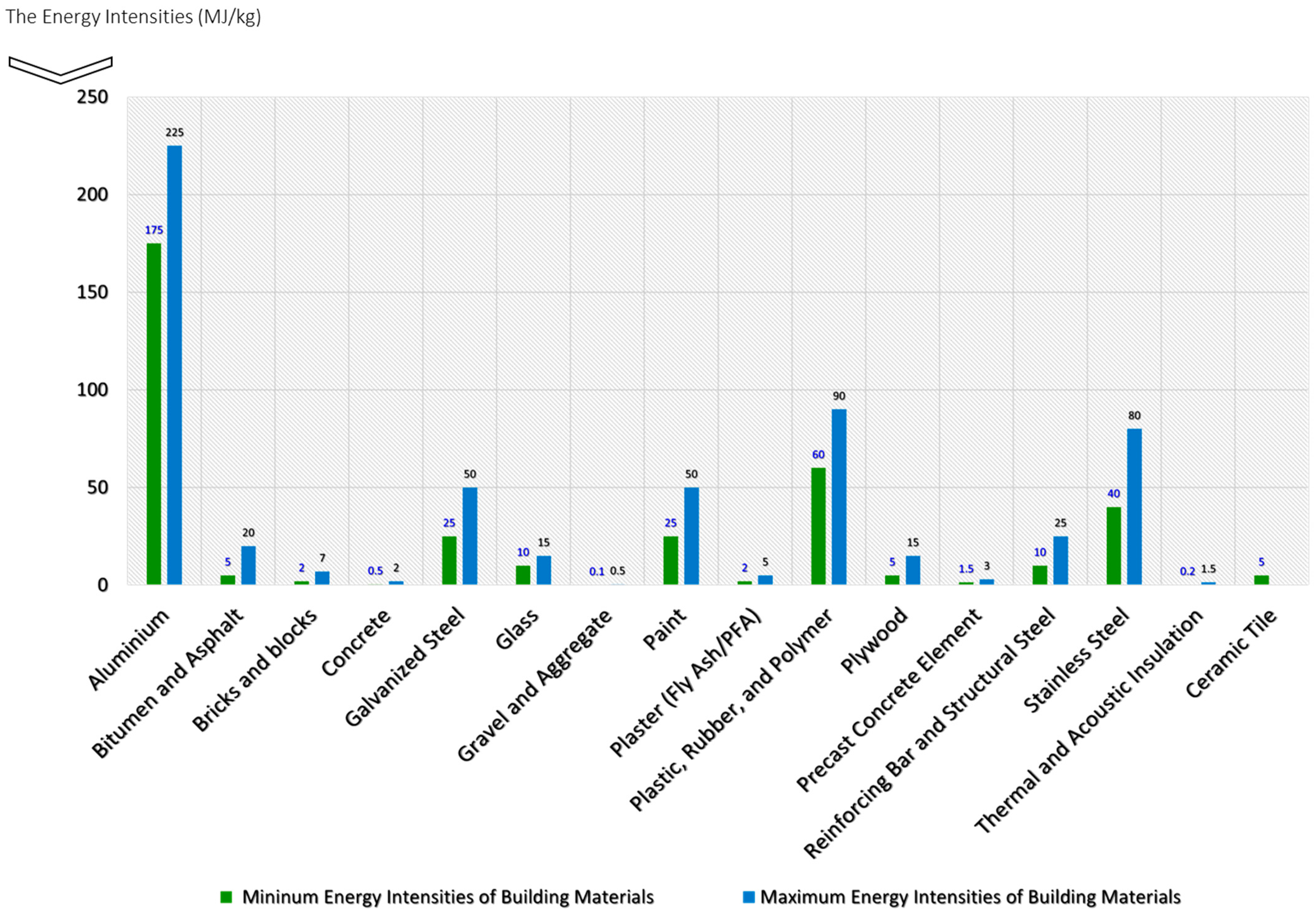

2.1.3. Environmental Impact on Building Materials

2.2. System Architecture and Sustainability Performance Metrics

2.2.1. Sustainable Design Principles in System Architecture

2.2.2. Developing Sustainability KPIs for Construction

3. Materials and Methods

3.1. Specifications of the Materials and Sources Used in the Study

- Techniques of Material Selection

- Specifications of the Source

- Detailed Description of the Sources of the Material

- The acquisition of data across the whole lifecycle

- Instructions for Quality Control and Assurance Procedures

3.2. Assessing the Environmental Impact of Recycling Construction Materials

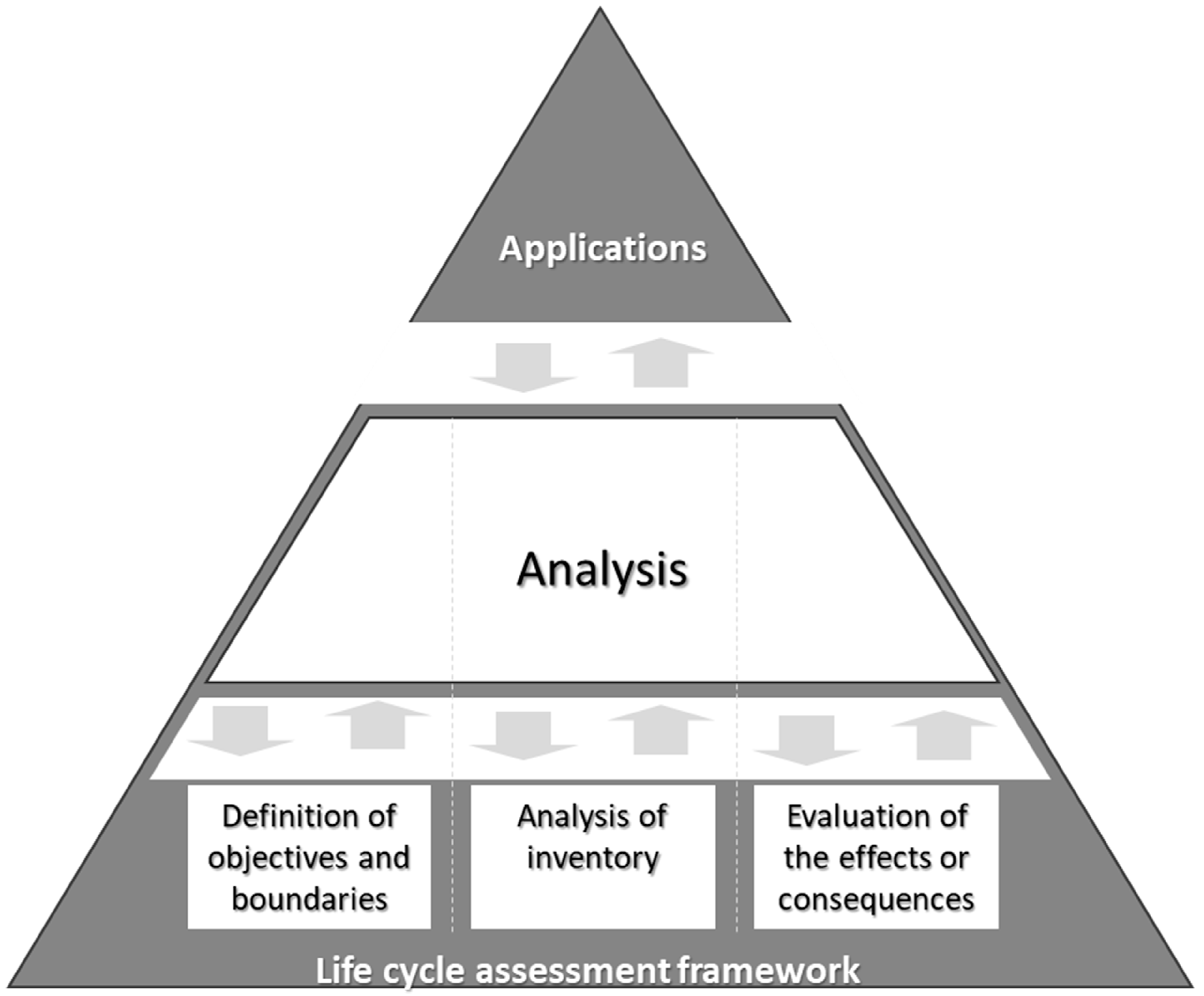

3.3. Recycled Building Material Lifecycle and Material Flow Analysis Framework

4. Lifecycle Impact of Reused Building Materials: Energy and GHG Assessment

4.1. Lifecycle Assessment of Reused Materials: GHG Emissions and Energy Impact

- i.

- Qi and Ui are the quantity and unit factors of the ith input or output, respectively, and n is the total number of inputs or outputs.This equation is crucial in estimating the overall use of resources and the generation of emissions and wastes at every step of the lifecycle, including extraction, production, utilization, end-of-life management, and recycling.

- ii.

- Impact Assessment Formulations

- a.

- Ej is the emission amount of the jth greenhouse gas and GWPj is the corresponding Global Warming Potential factor, with m being the number of different GHGs.This computation combines the overall effect of global warming, including the distinct contributions of different greenhouse gases, using variables determined by the Intergovernmental Panel on Climate Change (IPCC).

- b.

- Cumulative Energy Demand (CED)where [42]:Ek is the energy spent in the kth process and p is the total number of energy-intensive activities.This aggregate represents the overall energy need across all phases of the material’s lifespan.

- iii.

- Comparative Analysis for Reuse Versus New Material Production

- a.

- Impact Differential Due to Material Reusewhere [43]:Inew and Ireuse signify the environmental impacts of new and reused materials, respectively.This equation is essential for quantifying the environmental benefits associated with material reuse.

- iv.

- Environmental Impact Allocation in Reuse Phase

- a.

- Allocation for Reused Material Lifecyclewhere [44]:Ioriginal is the impact from the original lifecycle and L denotes the number of lifecycles over which the material is reused.

- v.

- Normalization and Weighting Mechanisms

- a.

- Normalization Equationwhere [45]:I is the specific impact under consideration and Iref is a reference impact, typically a per capita or industry average.Normalization contextualizes the lifecycle impacts against a standardized benchmark.

- b.

- Weighting Applicationwhere [46]:Ni is the normalized impact and WF is the respective weighting factor.Weighting factors are applied to underscore the relative importance of various environmental impacts.The equations provided are a simplified representation of the intricate calculations involved in a thorough Life Cycle Assessment (LCA) [47].Maintaining uniformity in units and adhering to rigorous methodologies are crucial for guaranteeing the precision and dependability of the LCA results.Advanced life cycle assessment (LCA) software is designed to simplify these calculations by using comprehensive databases of environmental variables and impact coefficients [48].The careful selection of criteria and data sources is crucial as it may significantly affect the results drawn from the LCA.Using these equations, LCA practitioners may systematically evaluate and compare the environmental effects of reused and freshly created building materials. This allows for well-informed choices that match sustainable construction standards.

4.2. Material Flow Analysis (MFA) in Sustainable Construction

- i.

- Input: Total material mass entering the system. This comprises raw, recycled, and repurposed materials.Output: Total material mass exiting the system. This includes building materials, trash, and pollutants.Δ Storage: Change in material mass for the system during analysis.Mass of system-produced materials.Consumption: System material consumption.Accumulation: Change in system material mass.This equation quantifies material flow in sustainable buildings, including sourcing, utilization, waste creation, and recycling. It helps you optimize, reuse, or recycle resources, thereby decreasing waste and enhancing sustainability.

- ii.

- Additional MFA Calculations

- a.

- Material Efficiency

- b.

- Waste Generation Rate

- c.

- Waste Generation RateMaterial recycling methods are used throughout the building process.

- Application in Material Flow Analysis (MFA):

4.3. Energy Efficiency and GHG Accounting

4.3.1. Gathering and Transformation of Data

- a.

- Establish the parameters and limitations.

- b.

- Gather Energy Consumption Data

- c.

- Standardize energy data.

4.3.2. Determination of Energy Consumption and Greenhouse Gas Emissions

- a.

- Overall Energy Consumption

- b.

- GHG Emissions CalculationRelevant GHG types (CO2, CH4, N2O) have been identified.Emission factors for each energy source are applied to calculate GHG emissions in CO2-equivalent [63].

4.3.3. Evaluation and Enhancement

- a.

- Evaluate energy efficiency.

- b.

- Documentation and Comparison

- c.

- Based on the analysis, steps are taken to enhance energy efficiency, such as upgrading equipment or increasing renewable energy use.

4.3.4. Influence of Climate Change and Dynamic Environmental Factors

5. Results and Discussion

5.1. Impact of Construction Material Reuse on GHG Emissions and Energy

5.2. Deeper Insights into Environment Impact

5.3. Theoretical Expansion and Validation

5.4. Significant Impact on Construction Methods

5.5. Practical Implications and Broader Industry Transformation

5.6. Broadening the Scope of Research and Considering Socio-Economic Factors

5.7. Concluding Synthesis

6. Conclusions

- Process and Results of Findings

- Future Scope and perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Edwards, R.E.; Lou, E.C.; Bataw, A.; Kamaruzzaman, S.N.; Johnson, C. Sustainability-led design: Feasibility of incorporating whole-life cycle energy assessment into BIM for refurbishment projects. J. Build. Eng. 2019, 24, 100697. [Google Scholar] [CrossRef]

- Arena, U.; Mastellone, M.; Perugini, F. The environmental performance of alternative solid waste management options: A life cycle assessment study. Chem. Eng. J. 2003, 96, 207–222. [Google Scholar] [CrossRef]

- Laner, D.; Helmut, R. Material Flow Analysis. In Particular Types of Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2016; pp. 293–332. [Google Scholar]

- Liu, Z.; Adams, M.; Cote, R.P.; Chen, Q.; Wu, R.; Wen, Z.; Liu, W.; Dong, L. How does circular economy respond to greenhouse gas emissions reduction: An analysis of Chinese plastic recycling industries. Renew. Sustain. Energy Rev. 2018, 91, 1162–1169. [Google Scholar] [CrossRef]

- Das, S.; Lee, S.-H.; Kumar, P.; Kim, K.-H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Kuo, T.C.; Huang, S.; Zhang, H.-C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Almusaed, A.; Almusaed, A. The urban heat island phenomenon upon urban components. In Biophilic and Bioclimatic Architecture: Analytical Therapy for the Next Generation of Passive Sustainable Architecture; Springer: Berlin/Heidelberg, Germany, 2011; pp. 139–150. [Google Scholar]

- Cao, Y.; Cai, J.; Liu, X. Advancing toward a sustainable future: Assessing the impact of energy transition, circular economy, and international trade on carbon footprint. Econ. Chang. Restruct. 2024, 57, 77. [Google Scholar] [CrossRef]

- Okogwu, C.; Agho, M.O.; Adehinka, M.; Odulaja, B.A. Exploring the integration of sustainable materials in supply chain management for environmental impact. Eng. Sci. Technol. J. 2023, 4, 49–65. [Google Scholar] [CrossRef]

- Almeida, M.; Ascione, F.; Iovane, T.; Mastellone, M.; Mateus, R. Impact of life cycle assessment analysis on energy efficiency projects in Mediterranean residential buildings. Energy 2024, 295, 130994. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, T.; Luo, S.; Abedin, M. Pathways to improve energy efficiency under carbon emission constraints in iron and steel industry: Using EBM, NCA, and QCA approaches. J. Environ. Manag. 2023, 348, 119206. [Google Scholar] [CrossRef]

- Baratta, A.; Cimino, A.; Longo, F.; Solina, V.; Verteramo, S. The impact of ESG practices in industry with a focus on carbon emissions: Insights and future perspectives. Sustainability 2023, 15, 6685. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Circular economy strategies for combating climate change and other environmental issues. Environ. Chem. Lett. 2023, 21, 55–80. [Google Scholar] [CrossRef]

- Somantri, A.; Surendro, K. Greenhouse Gas Emission Reduction Architecture in Computer Science: A Systematic Review. IEEE Access 2024, 12, 36239–36256. [Google Scholar] [CrossRef]

- Sukhinina, E.; Kiseleva, O. Aspects of the Russian Regions Innovative Development: Taking into Account the Environmental Standards Requirements in Construction. In Proceedings of the Limited Liability Company “Institute of Digital Economics and Law” Conference: Ii International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure (ISSDRI 2022), Yekaterinburg, Russia, 14–15 March 2022. [Google Scholar]

- Gehlot, M.R.; Shrivastava, S. An AHP based sustainability assessment of cement mortar with synergistic utilization of granite cutting waste. J. Build. Eng. 2024, 86, 108794. [Google Scholar] [CrossRef]

- Lei, F.; Yan, Y.; Yue, Y.; Bi, W.; Ni, P. The pathway of regional carbon peak in building sector: A case study of Central China. J. Build. Eng. 2023, 80, 108031. [Google Scholar] [CrossRef]

- Ata, B.; Pakrooh, P.; Pénzes, J. Driving factors of energy related CO2 emissions at a regional level in the residential sector of Iran. Sci. Rep. 2023, 13, 17598. [Google Scholar] [CrossRef]

- Neves, S.A.; Marques, A.C. Drivers and barriers in the transition from a linear economy to a circular economy. J. Clean. Prod. 2022, 341, 130865. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. A holistic review on the contribution of civil engineers for driving sustainable con-crete construction in the built environment. Dev. Built Environ. 2023, 16, 100273. [Google Scholar] [CrossRef]

- Samani, P. Synergies and gaps between circularity assessment and Life Cycle Assessment (LCA). Sci. Total Environ. 2023, 903, 166611. [Google Scholar] [CrossRef]

- Özcan, K.A. Determinants of Ecological Footprint: A Quantile Regression Approach. Systems 2024, 12, 59. [Google Scholar] [CrossRef]

- Kullmann, F.; Markewitz, P.; Stolten, D.; Robinius, M. Combining the worlds of energy systems and material flow analysis: A review. Energy Sustain. Soc. 2021, 11, 13. [Google Scholar] [CrossRef]

- Rashid, S.; Malik, S.H. Transition from a Linear to a Circular Economy. In Renewable Energy in Circular Economy; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–20. [Google Scholar]

- Yaro, N.S.A.; Sutanto, M.H.; Baloo, L.; Habib, N.Z.; Usman, A.; Yousafzai, A.K.; Ahmad, A.; Birniwa, A.H.; Jagaba, A.H.; Noor, A. A comprehensive overview of the utilization of recycled waste materials and technologies in asphalt pavements: Towards environmental and sustainable low-carbon roads. Processes 2023, 11, 2095. [Google Scholar] [CrossRef]

- Ciechan-Kujawa, M.; Zarzycka, E.; Krasodomska, J. On the way to a circular economy: Using Key Performance Indicators to measure and report organizations’ progress. In The Human Dimension of the Circular Economy; Edward Elgar Publishing: Cheltenham, UK, 2024; pp. 170–189. [Google Scholar]

- Meglin, R. Economic and Environmental Assessment of a Regional Construction and Building Materials Industry in Switzerland: An Applied Combination of Material-Flow Analysis, Life-Cycle Assessment, and Input-Output Analysis. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2022. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, C.; Qian, Q.; Huang, R.; You, K.; Visscher, H.; Zhang, G. Incentive initiatives on the energy-efficient renovation of existing buildings towards carbon-neutral blueprints in China: Advancements, challenges, and perspectives. Energy Build. 2023, 296, 113343. [Google Scholar] [CrossRef]

- Pishehvarz, G.; Azamat, J. Perspectives of Material Flow Analysis in Plastic Waste Management. Plastic Waste Management: Methods and Applications. In Plastic Waste Management: Methods and Applications; Wiley: Hoboken, NJ, USA, 2024; pp. 279–309. [Google Scholar] [CrossRef]

- Jamatia, P.L. The Role of Youth In Combating Social Inequality: Empowering the Next Generation. Int. J. Soc. Sci. Educ. Econ. Agric. Res. Technol. IJSET 2023, 2, 229–238. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics-a review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2019, 258, 114107. [Google Scholar] [CrossRef]

- Xiong, Y.; Guo, H.; Nor, D.D.M.M.; Song, A.; Dai, L. Mineral resources depletion, environmental degradation, and exploitation of natural resources: COVID-19 aftereffects. Resour. Policy 2023, 85, 103907. [Google Scholar] [CrossRef]

- Kamari, A.; Kotula, B.M.; Schultz, C.P.L. A BIM-based LCA tool for sustainable building design during the early design stage. Smart Sustain. Built Environ. 2022, 11, 217–244. [Google Scholar] [CrossRef]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C.Q. An analytical review on application of life cycle assessment in the circular economy for the built environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life cycle assessment of concrete structures with reuse and recycling strategies: A novel framework and case study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

- Murillo-Zamorano, L.R.; Vega-Cervera, J.A. The use of parametric and non-parametric frontier methods to measure the productive efficiency in the industrial sector: A comparative study. Int. J. Prod. Econ. 2001, 69, 265–275. [Google Scholar] [CrossRef]

- Bunsen, J.; Matthias, F. An Introductory Review of Input-Output Analysis in Sustainability Sciences Including Potential Implications of Aggregation. Sustainability 2022, 15, 46. [Google Scholar] [CrossRef]

- Guan, X. Green Logistics Development and Evaluation of the Carbon Footprint. 2015. Available online: https://core.ac.uk/download/pdf/197965932.pdf (accessed on 22 April 2024).

- Bahrami, M.; Pourfayaz, F.; Kasaeian, A. Low global warming potential (GWP) working fluids (WFs) for Organic Rankine Cycle (ORC) applications. Energy Rep. 2022, 8, 2976–2988. [Google Scholar] [CrossRef]

- Derwent, R.G. Global warming potential (GWP) for hydrogen: Sensitivities, uncertainties, and meta-analysis. Int. J. Hydrogen Energy 2023, 48, 8328–8341. [Google Scholar] [CrossRef]

- Sun, Z.; Wu, B.; Guo, P.; Wang, S.; Guo, S. Enhanced electrokinetic remediation and simulation of cadmium-contaminated soil by superimposed electric field. Chemosphere 2019, 233, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Boldoczki, S.; Thorenz, A.; Tuma, A. The environmental impacts of preparation for reuse: A case study of WEEE reuse in Germany. J. Clean. Prod. 2020, 252, 119736. [Google Scholar] [CrossRef]

- Malabi Eberhardt, L.C.; van Stijn, A.; Nygaard Rasmussen, F.; Birkved, M.; Birgisdottir, H. Development of a life cycle assessment allocation approach for circular economy in the built environment. Sustainability 2020, 12, 9579. [Google Scholar] [CrossRef]

- Mami, F.; Revéret, J.; Fallaha, S.; Margni, M. Evaluating Eco-efficiency of 3D printing in the aeronautic industry. J. Ind. Ecol. 2017, 21, S37–S48. [Google Scholar] [CrossRef]

- Solanki, A.; Sarkar, D.; Shah, D. Evaluation of factors affecting the effective implementation of Internet of Things and cloud computing in the construction industry through WASPAS and TOPSIS methods. Int. J. Constr. Manag. 2023, 24, 226–239. [Google Scholar] [CrossRef]

- Ciroth, A.; Günter, F.; Jörg, S. Uncertainty calculation in life cycle assessments: A combined model of simulation and approximation. Int. J. Life Cycle Assess. 2004, 9, 216–226. [Google Scholar] [CrossRef]

- Wei, W.; Larrey-Lassalle, P.; Faure, T.; Dumoulin, N.; Roux, P.; Mathias, J.-D. How to conduct a proper sensitivity analysis in life cycle assessment: Taking into account correlations within LCI data and interactions within the LCA calculation model. Environ. Sci. Technol. 2014, 49, 377–385. [Google Scholar] [CrossRef]

- Hoekstra, R.; Bergh, J.C.v.D. Constructing physical input–output tables for environmental modeling and accounting: Framework and illustrations. Ecol. Econ. 2006, 59, 375–393. [Google Scholar] [CrossRef]

- Nakamura, S.; Yasushi, K. (Eds.) Waste Input-Output Analysis: Concepts and Application to Industrial Ecology; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Yokoi, R.; Jun, N.; Moriguchi, Y. An extended model for tracking accumulation pathways of mate-rials using input-output tables: Application to copper flows in Japan. Sustainability 2018, 10, 876. [Google Scholar] [CrossRef]

- Dapprich, J.P.; Cockshott, W.P. Input-output planning and information. J. Econ. Behav. Organ. 2023, 205, 412–422. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Ju, H.; Wang, Y.; Yan, C.; Zhang, L.; Liu, Z.; Li, S. Microstructures and mechanical properties of additively manufactured T91 steel and T91/316H bimetallic components by laser powder bed fusion. Mater. Sci. Eng. A 2023, 892, 145277. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, W.Q.; Ruth, M. Measuring material efficiency: A review of the historical evolution of indicators, methodologies, and findings. Resour. Conserv. Recycl. 2018, 132, 79–92. [Google Scholar] [CrossRef]

- Ahmed, J.; Taher, M.A.; Reza, A.A. Solid Waste Generation, Composition and Potentiality of Waste-to-Resource Recovery in Sylhet City Corporation, Bangladesh. Green Build. Constr. Econ. 2023, 4, 306–322. [Google Scholar] [CrossRef]

- Reidy, R. Municipal Solid Waste Recycling in Western Europe to 1996; Elsevier: New York, NY, USA, 2013. [Google Scholar]

- Wankmüller, C.; Pulsfort, J.; Kunovjanek, M.; Polt, R.; Craß, S.; Reiner, G. Blockchain-based tokenization and its impact on plastic bottle supply chains. Int. J. Prod. Econ. 2023, 257, 108776. [Google Scholar] [CrossRef]

- Balador, Z. Increasing the Use of Reclaimed and Recycled Building Materials in New Zealand: Stakeholder Perceptions. Ph.D. Thesis, Open Access Te Herenga Waka-Victoria University of Wellington, Wellington, New Zealand, 2020. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Venkataraman, R.R.; Pinto, J.K. Cost and Value Management in Projects; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Kohli, V.; Chakravarty, S.; Chamola, V.; Sangwan, K.S.; Zeadally, S. An analysis of energy consumption and carbon footprints of cryptocurrencies and possible solutions. Digit. Commun. Netw. 2023, 9, 79–89. [Google Scholar] [CrossRef]

- Ji, Z.; Iryna, M.S. Economic analysis of energy efficiency of China’s and India’s national economies. Mech. Econ. Regul. J. 2023, 10, 11–16. [Google Scholar] [CrossRef]

- Wolf, I.; Holzapfel, P.K.; Meschede, H.; Finkbeiner, M. On the potential of temporally resolved GHG emission factors for load shifting: A case study on electrified steam generation. Appl. Energy 2023, 348, 121433. [Google Scholar] [CrossRef]

- Butler, K. How energy benchmarking in healthcare facilities supports greenhouse gas emission reduction. Health Manag. Forum 2023, 36, 199–206. [Google Scholar] [CrossRef]

- Dokhanian, F.; Mohajerani, M.; Estaji, H.; Nikravan, M. Shading design optimization in a semi-arid region: Considering energy consumption, green-house gas emissions, and cost. J. Clean. Prod. 2023, 428, 139293. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of carbon & energy (ICE) version 2.0. Univ. Bath. 2011, 19, 641. [Google Scholar]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. J. Affect. Disord. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Jeong, Y.S.; Lee, S.E.; Huh, J.H. Estimation of CO2 emission of apartment buildings due to significant construction materials in the Republic of Korea. Energy Build. 2012, 49, 437–442. [Google Scholar] [CrossRef]

- Smith, B.; Abdoli, S. Scenarios of Glass Disposal in Australia from Circular Economy and Life Cycle Assessment Perspective. In Proceedings of the Conference on Production Systems and Logistics: CPSL 2023-2, Querétaro, Mexico, 28 February–2 March 2023; Herberger, D., Hübner, M., Eds.; CPSL: Hannover, Germany, 2023; pp. 893–902. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energy Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S. Life cycle energy assessment of a typical office building in Thailand. Energy Build. 2009, 41, 1076–1083. [Google Scholar] [CrossRef]

- Baird, G.; Alcorn, A.; Haslam, P. The energy embodied in building materials-updated New Zealand coefficients and their significance. Trans. Inst. Prof. Eng. N. Z. Civ. Eng. Sect. 1997, 24, 46–54. [Google Scholar]

- De Wolf, C.; Cordella, M.; Dodd, N.; Byers, B.; Donatello, S. Whole life cycle environmental impact assessment of buildings: Developing software tool and database support for the EU framework Level(s). Resour. Conserv. Recycl. 2023, 188, 106642. [Google Scholar] [CrossRef]

- Fan, Y.; Fang, C. GHG emissions and energy consumption of residential buildings—A systematic review and meta-analysis. Environ. Monit. Assess. 2023, 195, 885. [Google Scholar] [CrossRef] [PubMed]

- Giovanardi, M.; Konstantinou, T.; Pollo, R.; Klein, T. Internet of Things for building facade traceability: A theoretical framework to enable circular economy through life-cycle information flows. J. Clean. Prod. 2023, 382, 135261. [Google Scholar] [CrossRef]

- Chiriță, A.P.; Borș, A.M.; Rădoi, R.I.; Dumitrescu, I.C.; Popescu, A.M. Leveraging Additive Manufacturing and Reverse Engineering for Circular Economy-Driven Remanufacturing of Hydraulic Drive System Components. Appl. Sci. 2023, 13, 12200. [Google Scholar] [CrossRef]

- Lorusso, L.; Lee, J.H.; Worden, E.A.; Allied, A. Design thinking for healthcare: Transliterating the creative problem-solving method into architectural practice. HERD Health Environ. Res. Des. J. 2021, 14, 16–29. [Google Scholar] [CrossRef] [PubMed]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Baldwin, T.T.; Ford, J.K. Transfer of training: A review and directions for future Research. Pers. Psychol. 1988, 41, 63–105. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in building and construction within circular cities and European new green deal. The contribution of concrete recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

| Subject | Ref. No. | Challenges Identified | Practical Problems | Solutions Proposed |

|---|---|---|---|---|

| Advancements in environmental and energy efficiency | [1,2,3,4,5,6,7,10,11,12,16,17,18,19,20,21,23,24,25,26] | The preponderance of greenhouse gas emissions and increased use of energy due to reliance on new materials | Practical obstacles in achieving a harmonious equilibrium between economic expansion and adherence to environmental regulations | The application of Lifecycle Assessment (LCA) and Material Flow Analysis (MFA), incorporation of circular economy principles, focus on material reuse and recycling, and integration of advanced system design and Key Performance Indicators (KPIs) to enhance energy and resource efficiency. |

| Greenhouse Gas Emissions Mitigation | [8,9,13,14] | Dependence on finite resources and inefficiencies in waste disposal methods | A heightened level of regulatory scrutiny and public demand for environmentally responsible processes | The deliberate incorporation of recycled materials, shift towards circular economic models, and use of Computer Science Architecture (CSA) to tackle the consequences of climate change. |

| Construction-Related Energy Demand Reduction | [15,16,17,18,22,23,24,25] | High levels of energy consumption in the manufacture and building processes of materials | As energy prices continue to rise, there is a limited supply of environmentally friendly building materials. | The rapid increase in the use of environmentally friendly technologies, the process of turning building waste into valuable materials, the improvement of how resources are used, and the establishment of laws and technology to support these efforts. |

| Sustainable System Architecture and Performance Evaluation | [19,20,21,22,23,24,25,26] | Inefficiencies in traditional design and a lack of assessment measures focused on sustainability. | Deficiencies in the already accepted design standards that do not adequately embrace sustainable practices | Circular economy principles in designing system architecture and developing sustainability Key Performance Indicators (KPIs) involve circularity evaluations and Life Cycle Assessments (LCAs) facilitated by policy and technical advancements to establish global sustainability benchmarks. |

| Policy and Regulatory Frameworks for Sustainability | [24,25,26] | Lack of comprehensive policy frameworks and regulatory support for environmentally responsible building practices | The gradual incorporation of international standards in the rules of local governing bodies | Formulating and implementing policy and regulatory frameworks that encourage environmentally responsible building practices includes providing financial incentives for the utilization of recycled materials and the implementation of energy-efficient design solutions. |

| Technological Innovation and Digitalization in Construction | [14,22,23] | In the construction business, there is only a limited integration of innovative technology and digital solutions. | Both resistance to change and the substantial expenses associated with digital transformation are included. | Digital transformation and technological advancements are strongly emphasized to optimize building processes, improve material consumption, and promote sustainable construction practices. |

| Collaborative Efforts Among Construction Stakeholders | [9,26] | Collaboration among industry stakeholders is insufficient, and activities are not cohesive. | Fragmented market and competitive tensions hindering joint efforts | Facilitating collaborative engagements and collaborations to use collective knowledge, share best practices, and steer the industry towards unified sustainability goals. |

| Subsection | Key Points | Methodologies Used | Quantitative Findings | Theoretical and Practical Implications |

|---|---|---|---|---|

| 4.1 Impact of Construction Material Reuse | Using recycled materials in buildings, such as wood, metal, and glass, has several positive environmental effects. | LCA stands for life cycle assessment, while MFA stands for material flow analysis. | GHG emissions were lowered by around forty percent, while energy consumption was cut by approximately thirty percent. | There was a reduction of nearly forty percent in greenhouse gas emissions and around thirty percent in energy use. |

| 4.2 Deeper Insights into Environment Impact | Thorough evaluation of the environmental effects during the whole lifecycle of building materials. | Integration of Life Cycle Assessment (LCA) and Material Flow Analysis (MFA) with the European Union’s Level(s) framework. | N/A | Emphasizes the methodological congruence with European Union sustainability strategies. Enhances the comprehensiveness of ecological assessment methodologies. |

| 4.3 Theoretical Expansion and Validation | Strengthens the theoretical concepts underpinning sustainable design in the circular economy context. | Utilizing case studies, doing industrial data research, and seeking expert consultations | N/A | Proficient comprehension of computer engineering concepts in the context of design. Places strongly emphasize the capacity to track and verify the origins and processes involved in sustainable construction methods. |

| 4.4 Significant Impact on Construction Methods | Analyze how Design Thinking has impacted contemporary building techniques. | Design Thinking analysis | N/A | Encourages teamwork and creative ideas in building design and speaks out against environmental injustice. |

| 4.5 Practical Implications and Broader Industry Transformation | Talks about the legislative frameworks and governmental initiatives required to encourage the usage of recycled materials. | Policy analysis | N/A | Emphasizes the significance of government initiatives and regulatory frameworks in promoting sustainable construction practices. |

| 4.6 Broadening the Scope of Research | Supports broadening the area of study to encompass a greater variety of materials and environments. | Socio-economic analysis | N/A | Advocates for the inclusion of socio-economic elements in sustainability studies. Promotes progress in technology and architecture. |

| 4.7 Concluding Synthesis | Provides an overview of the advantages of recycling building materials and coordinating construction methods with environmental objectives. | Quantitative and qualitative analysis | Reaffirmed were the decreases in energy use and greenhouse gas emissions. | Bridges the gap between theoretical frameworks and accurate data. Endorses the ideas of sustainability and the circular economy. |

| Subject | Original Materials | Recycled Materials |

|---|---|---|

| Greenhouse Gas Emissions | Elevated greenhouse gas (GHG) emissions are a result of the manufacturing and processing activities. | There is a 40% reduction in greenhouse gas emissions when compared to the emissions produced by the original materials. |

| Energy Consumption | Elevated energy use throughout the whole lifespan | A 30% decrease in energy use as compared to the initial materials. |

| Production Process | This activity requires a significant amount of resources and involves the extraction and processing of raw materials. | It requires less energy and includes the recycling and processing of recyclable materials. |

| Material Lifecycle Assessment (LCA) | Emphasizes the effects of extraction to disposal. | Highlights the complete life cycle, encompassing the stages of reuse and recycling |

| Material Flow Analysis (MFA) | Monitors the movement of fresh materials from the point of extraction to the point of disposal. | Monitors the movement of recycled materials, encouraging the effective use of resources |

| Cost | Typically elevated as a result of increased raw material expenses | Decreased as a result of decreased processing requirements and the reuse of resources. |

| Socio-economic Impact | Reduced emphasis on socio-economic advantages | Facilitates the growth of employment opportunities in the recycling and material processing sectors |

| Regulatory Frameworks | Mandatory adherence to environmental standards is necessary. | Promotes the creation of strong policies to support the reuse of materials |

| Environmental Standards | Complies with established building codes and requirements | Conforms to sustainability and circular economy concepts |

| Durability and Performance | Implemented quantifiable benchmarks for evaluating performance and dependability. | Similar levels of performance may be achieved if quality standards are upheld. |

| Design and Flexibility | Restricted adaptability resulting from inflexible material characteristics | Enhanced design adaptability through new ways for reusing materials |

| Waste Generation | Construction and demolition activities result in significant garbage production. | Minimized trash production by implementing reuse and recycling methods |

| Resource Efficiency | Inefficient utilization of resources resulting from dependence on novel materials | Maximizing resource efficiency by implementing circular economy methods. |

| Innovation and Technology | Reduced focus on groundbreaking methodologies | Promotes the development of innovative recycling technologies and advancements in materials science. |

| Market Availability | Easily accessible with well-established distribution networks | Developing market with expanding accessibility and distribution networks |

| Public Perception | Universally acknowledged with established efficacy | As awareness of sustainability increases, acceptance is also growing. |

| Health and Safety | Thoroughly detailed health and safety regulations | Thorough testing is necessary to guarantee that safety standards are met. |

| Economic Incentives | Restricted financial motivations | Backed by a range of economic incentives and subsidies |

| Long-term Sustainability | Less environmentally sustainable as a result of the depletion of scarce resources | Highly sustainable, promoting the preservation of resources over the long term |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almusaed, A.; Yitmen, I.; Myhren, J.A.; Almssad, A. Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions. Buildings 2024, 14, 1566. https://doi.org/10.3390/buildings14061566

Almusaed A, Yitmen I, Myhren JA, Almssad A. Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions. Buildings. 2024; 14(6):1566. https://doi.org/10.3390/buildings14061566

Chicago/Turabian StyleAlmusaed, Amjad, Ibrahim Yitmen, Jonn Are Myhren, and Asaad Almssad. 2024. "Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions" Buildings 14, no. 6: 1566. https://doi.org/10.3390/buildings14061566

APA StyleAlmusaed, A., Yitmen, I., Myhren, J. A., & Almssad, A. (2024). Assessing the Impact of Recycled Building Materials on Environmental Sustainability and Energy Efficiency: A Comprehensive Framework for Reducing Greenhouse Gas Emissions. Buildings, 14(6), 1566. https://doi.org/10.3390/buildings14061566