Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials

Abstract

1. Introduction

2. Materials and Methods

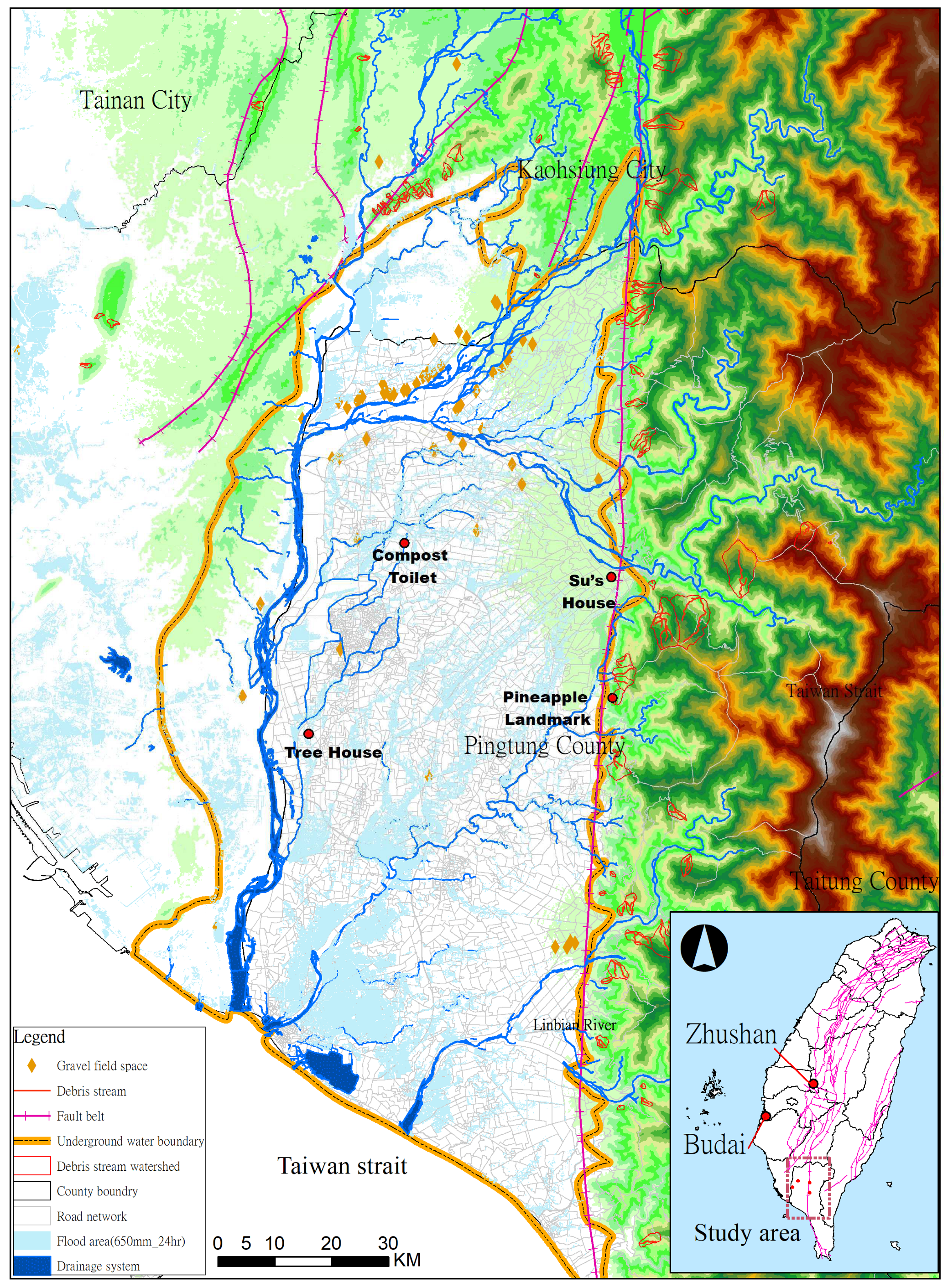

2.1. Study Area

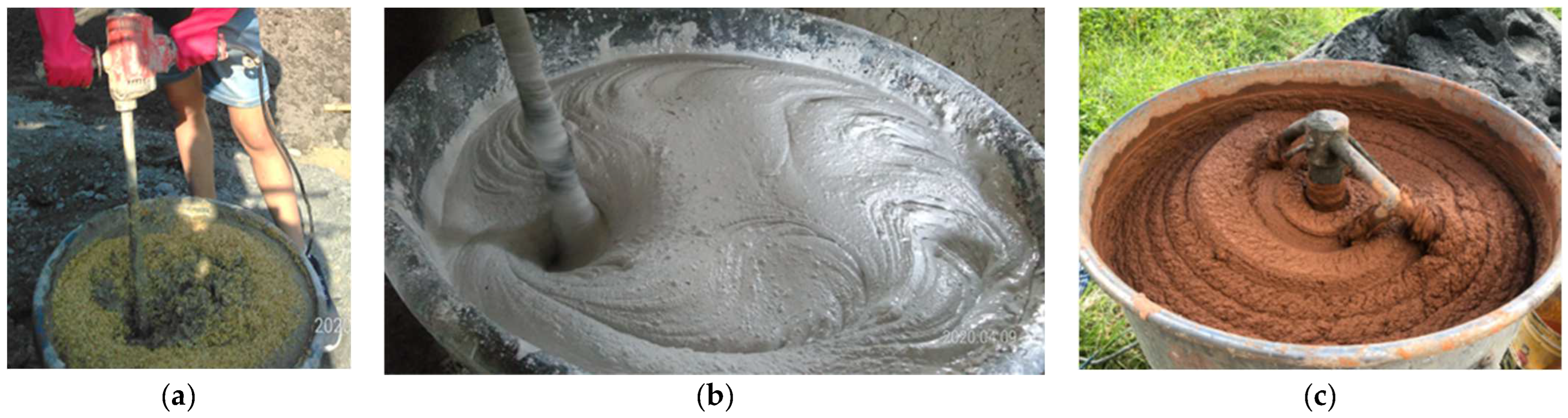

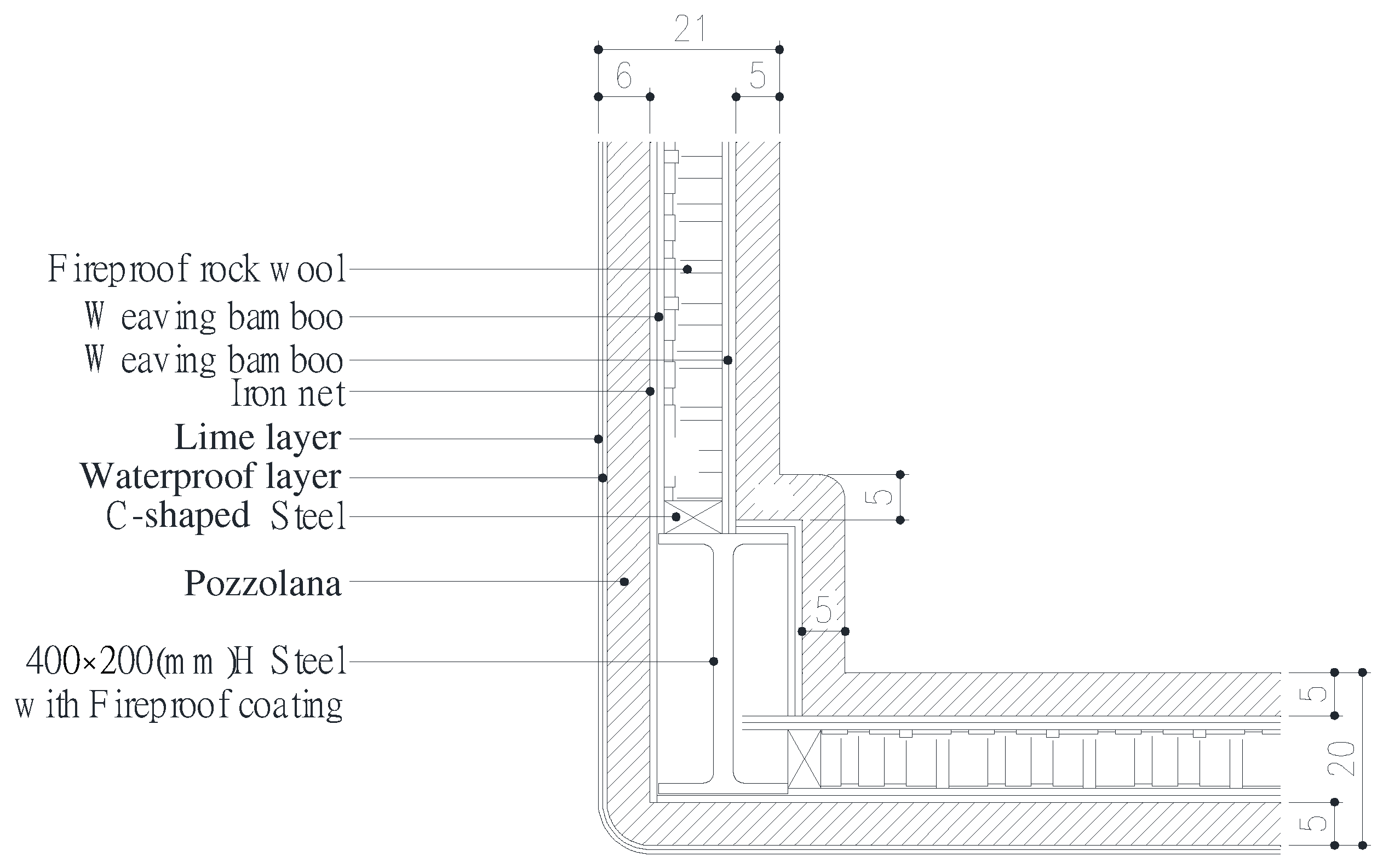

2.2. Material and Practice Detail

3. Results

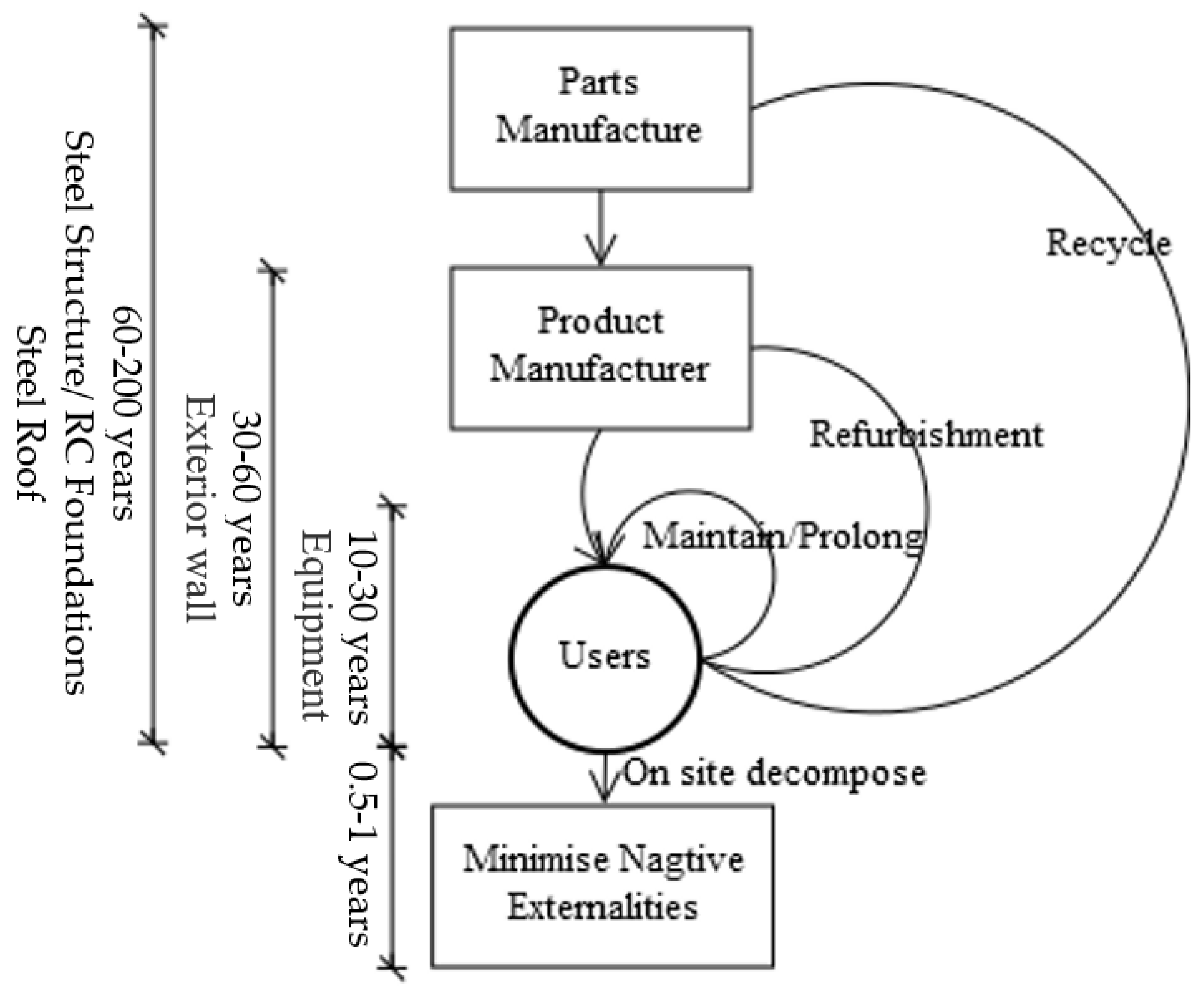

3.1. Nearly Zero Waste

3.2. Technological Changes

3.3. Price Competitiveness

4. Discussion

4.1. Process Safety and Environmental Protection

4.2. Evolutionary Architecture for Sustainable Development

4.3. Structural Resilience and Breathing Walls

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boulding, K.E. The economics of the coming spaceship earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Johns Hopkins University Press: Baltimore, MD, USA, 1966; pp. 3–14. [Google Scholar]

- Ayres, R.U. Peer Reviewed: Toward a Zero-Emissions Economy. Environ. Sci. Technol. 1998, 32, 366A–367A. [Google Scholar] [CrossRef] [PubMed]

- Osmani, M. Construction waste. In Waste; Academic Press: Cambridge, MA, USA, 2011; pp. 207–218. [Google Scholar]

- Hsu, W.-L.; Meen, T.-H.; Yang, H.-C.; Yu, W.-D. Special Issue on Innovative Circular Building Design and Construction. Buildings 2023, 13, 1322. [Google Scholar] [CrossRef]

- Fraser, M.; Haigh, L.; Soria, A.C. The Circularity Gap Report 2023; Circle Economy: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Li, S.-H.; Altan, H. Environmental impacts of building structures in Taiwan. Procedia Eng. 2011, 21, 291–297. [Google Scholar] [CrossRef]

- Leu, L.J.; Wu, Y.W.; Huang, C.H.; Chiu, H.J.; Hsieh, C.C. Circular economy and net zero emissions in construction engineering. J. Chin. Inst. Civ. Hydraul. Eng. 2023, 35, 297–308. [Google Scholar] [CrossRef]

- UN Environment Programme (UNEP); Global Alliance for Buildings and Construction (GlobalABC). Global Status Report for Buildings and Construction; UN Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- Kusi, E.; Boateng, I.; Danso, H. Energy consumption and carbon emission of conventional and green buildings using building information modelling (BIM). Int. J. Build. Pathol. Adapt. 2024. [Google Scholar] [CrossRef]

- Tirth, V.; Algarni, S.; Agarwal, N.; Saxena, A. Greenhouse gas emissions due to the construction of residential buildings in Moradabad, India. Appl. Ecol. Environ. Res. 2019, 17, 12111–12126. [Google Scholar] [CrossRef]

- Architecture 2030. Embodied Carbon Actions. Available online: https://www.architecture2030.org/embodied-carbon-actions/ (accessed on 27 May 2024).

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Akan, M.Ö.A.; Dhavale, D.G.; Sarkis, J. Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. J. Clean. Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Fikri Hasmori, M.; Faizul Md Zin, A.; Nagapan, S.; Deraman, R.; Abas, N.; Yunus, R.; Klufallah, M. The on-site waste minimization practices for construction waste. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012038. [Google Scholar] [CrossRef]

- Llatas, C.; Bizcocho, N.; Soust-Verdaguer, B.; Montes, M.V.; Quiñones, R. An LCA-based model for assessing prevention versus non-prevention of construction waste in buildings. Waste Manag. 2021, 126, 608–622. [Google Scholar] [CrossRef] [PubMed]

- Public Television Service Foundation. Taiwan’s Construction Waste Amounted to Nearly 70 Million Tons the Year before Last. 2021/01/07 Ed.; Taipei. 2021. Available online: https://news.pts.org.tw/article/507909 (accessed on 27 May 2024).

- Waste and Resources Action Programme. Halving Construction Waste to Landfill by 2012; WRAP, Ed.; WRAP: Banbury, UK, 2007. [Google Scholar]

- Erlandsson, M.; Levin, P. Environmental assessment of rebuilding and possible performance improvements effect on a national scale. Build. Environ. 2005, 40, 1459–1471. [Google Scholar] [CrossRef]

- Hsiao, T.Y.; Huang, Y.T.; Yu, Y.H.; Wernick, I.K. Modeling materials flow of waste concrete from construction and demolition wastes in Taiwan. Resour. Policy 2002, 28, 39–47. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University Stanford: Stanford, CA, USA, 1992; Volume 72. [Google Scholar]

- Skoyles, E.R. Waste Prevention on Site; BT Batsford Limited: London, UK, 1987. [Google Scholar]

- Ministry of Environment. Administrative Letter Explanation Content; Ministry of Environment, Ed.; Ministry of Environment: Taipei, Taiwan, 2004; Volume 0930083287.

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Ho, H.-J.; Iizuka, A.; Shibata, E. Chemical recycling and use of various types of concrete waste: A review. J. Clean. Prod. 2021, 284, 124785. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The Butterfly Diagram: Visualising the Circular Economy. Available online: https://www.ellenmacarthurfoundation.org/circular-economy-diagram (accessed on 27 May 2024).

- Brand, S. How Buildings Learn: What Happens after They’re Built; Penguin: New York, NY, USA, 1995. [Google Scholar]

- UN Environment Programme. The Buildings Breakthrough: Global Push for Near-Zero Emission and Resilient Buildings by 2030 Unveiled at COP28. Available online: https://www.unep.org/news-and-stories/press-release/buildings-breakthrough-global-push-near-zero-emission-and-resilient (accessed on 27 May 2024).

- World Meteorological Organization. State of the Climate in Asia 2023; World Meteorological Organization (WMO): New York, NY, USA, 2023. [Google Scholar]

- Dolce, C. The World’s Most Vulnerable Cities For Natural Disasters. Available online: https://weather.com/news/news/worlds-riskiest-cities-for-natural-disasters (accessed on 27 May 2024).

- National Science and Technology Council; Ministry of Environment. National Science Report on Climate Change 2024: Phenomenon, Impacts and Adaptation; National Science and Technology Council: Taipei, Taiwan, 2024.

- Zhang, S.D. The Carbon Dioxide of Building’s Lifecycle in Taiwan; Environmental Protection Administration, Ed.; Environmental Protection Administration: Taiwan, Taiwan, 1989; pp. 23–32.

- Shi, Y. The tug-of-war between life safety and building regulations—Reflections on the 0206 Hualien Earthquake. Civ. Eng. Water Conserv. 2018, 45, 15–18. [Google Scholar] [CrossRef]

- Su, H.-C.; Lin, B.-C. Investigation on the Seismic Assessment of Damaged Buildings by using Modified ATC-40. Struct. Eng. 2004, 19, 69–84. [Google Scholar]

- Chang, C.-Y. The Analysis of the Mechanism of the Rapid-Assessment Regulations for Disaster-Damaging Buildings in Taiwan. J. Disaster Manag. 2012, 1, 63–76. [Google Scholar] [CrossRef]

- Public Construction Commission Executive Yuan. After the 921 Earthquake, the Earthquake Resistance of Public Facilities in Our Country has Been Improved. Available online: https://www.pcc.gov.tw/News_Content.aspx?n=C61062639C0CD29F&sms=21EF9CF82726C1BB&s=18829776AD60139D (accessed on 27 May 2024).

- Vailati, M.; Mercuri, M.; Angiolilli, M.; Gregori, A. Natural-fibrous lime-based mortar for the rapid retrofitting of heritage masonry buildings. Fibers 2021, 9, 68. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Liuzzi, S.; Ayr, U.; Cosma, P.; Rizzi, V.; Petrella, M.; Di Mundo, R. Use of cellulose fibers from wheat straw for sustainable cement mortars. J. Sustain. Cem.-Based Mater. 2019, 8, 161–179. [Google Scholar] [CrossRef]

- Barrios, A.M.; Vega, D.F.; Martínez, P.S.; Atanes-Sánchez, E.; Fernández, C.M. Study of the properties of lime and cement mortars made from recycled ceramic aggregate and reinforced with fibers. J. Build. Eng. 2021, 35, 102097. [Google Scholar] [CrossRef]

- Building Green. Bringing Building Codes into Compliance with Sustainability; Building Green: Brattleboro, VT, USA, 1998. [Google Scholar]

- Eisenberg, D.; Yost, P. “Sustainability and building codes” from environmental building news (2001). In Sustainable Urban Development Reader; Routledge: London, UK, 2014; pp. 323–327. [Google Scholar]

- Wang, C.; Antos, S.E.; Gosling-Goldsmith, J.G.; Triveno, L.M.; Zhu, C.; von Meding, J.; Ye, X. Assessing Climate Disaster Vulnerability in Peru and Colombia Using Street View Imagery: A Pilot Study. Buildings 2024, 14, 14. [Google Scholar] [CrossRef]

- Executive Yuan. Circular Economy Promotion Plan. Available online: https://www.ey.gov.tw/Page/448DE008087A1971/dc1de106-4298-4ad1-a9c7-f5b800f283cb (accessed on 27 May 2024).

- Van Bueren, B.; Leenders, M.; Nordling, T. Case Study: Taiwan’s pathway into a circular future for buildings. Proc. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012060. [Google Scholar] [CrossRef]

- Ou, S. Ayasaka Ichiro and the Development of Geology Research in Modern Taiwan. J. Taiwan Hist. 2020, 71, 53–102. [Google Scholar]

- Tsai, S. Theory on Adaptive Mode and Creative Destruction under the Shift-Reset: A Case Study of Water Distribution in Pingtung Plain. Ph.D. Thesis, National Taiwan Normal University, Taipei, Taiwan, 2020. [Google Scholar]

- Wu, R.-S.; Liu, J.-S.; Chang, S.-Y.; Hussain, F. Modeling of Mixed Crop Field Water Demand and a Smart Irrigation System. Water 2017, 9, 885. [Google Scholar] [CrossRef]

- Wu, C.-C.; Yen, T.-H.; Huang, Y.-H.; Yu, C.-K.; Chen, S.-G. Statistical characteristic of heavy rainfall associated with typhoons near taiwan based on high-density automatic rain gauge data. Bull. Am. Meteorol. Soc. 2016, 97, 1363–1375. [Google Scholar] [CrossRef]

- Chen, G. The path and intensity of typhoon invading Taiwan. Natl. Taiwan Norm. Univ. Geogr. Res. Rep. 1981, 7, 61–74. [Google Scholar]

- Shu, H. Source Materials on The History of Natural Disasters in Ching; National Science Council: Taipei, Taiwan, 1983; pp. 35–105.

- Tsai, S. The measures adopted to Relieve and prevent typhoon disasters in Taiwan during Japan-ruling period. J. Taiwan Hist. 2009, 60, 253–298. [Google Scholar]

- Tan, P.; Tu, H.; Wu, J.; Meng, X.; Huang, W.; Chen, J. Construction of database of meteorological disaster events in 1895–1945 and application on disaster prevention. In Proceedings of the 2020 Symposium on Weather Analysis and Forecasting, Taipei, Taiwan, 13 October 2020. [Google Scholar]

- Dai, Y. A Study of Classical Poetry on Natural Disasters in Taiwan—Ching Dynasty to Japanese Occupation Period; National Chengchi University: Taipei, Taiwan, 2002. [Google Scholar]

- Shyu, J.H.; Sieh, K.; Chen, Y.; Lee, C.; Wang, Y.; Ota, Y.; Lee, J.; Sung, Q.; Rubin, C. A Preliminary Neotectonic Map of Taiwan, and its Implications for Future Destructive Earthquakes. In AGU Fall Meeting Abstracts; American Geophysical Union: San Francisco, CA, USA, 2001. [Google Scholar]

- Shyu, J.B.H.; Chuang, Y.R.; Chen, Y.L.; Lee, Y.R.; Cheng, C.T. A new on-land seismogenic structure source database from the Taiwan earthquake model (TEM) project for seismic hazard analysis of Taiwan. Terr. Atmos. Ocean. Sci. 2016, 27, 311–323. [Google Scholar] [CrossRef]

- He, C. Introduction to Geology of Taiwan—Description of Geological Map of Taiwan; Central Geological Survey, Ministry of Economic Affairs: Taipei, Taiwan, 1986.

- Central Disaster Prevention and Response Council. Pingtung County Regional Disaster Prevention and Rescue Plan; Office, Disaster Prevention and Protection Office, Ed.; Executive Yuan: Taipei, Taiwan, 2024.

- Tsai, S.-C.; Lee, S.-H. Disaster-Resilient Communities on Flood Plains and Their Agricultural Regeneration: A Case Study in Meinong Plain, Taiwan. Water 2022, 14, 1736. [Google Scholar] [CrossRef]

- Juan, Y.-K.; Chen, Y.; Lin, J.-M. Greywater Reuse System Design and Economic Analysis for Residential Buildings in Taiwan. Water 2016, 8, 546. [Google Scholar] [CrossRef]

- Wang, H.-Y. A Preliminary Discussion about the Image and Technological Inheritance of Native Bamboo Architecture in Taiwan- as Traditional Bamboo House and The Bamboo Frame of D.Z. Architects & Associates an Example; National Yunlin University of Science and Technology: Yunlin, Taiwan, 2020. [Google Scholar]

- National Musem of Taiwan History. Bamboo with Pozzolana Wal. Available online: https://tcmb.culture.tw/zh-tw/detail?indexCode=Culture_Object&id=607984 (accessed on 27 May 2024).

- Xie, J.Y. Wall Constructions Research of Traditonal Dwellings in the Linpan Region in the West Sichuan; Southwest Jiaotong University: Sichuan, China, 2016. [Google Scholar]

- Jeng, J.-I. An Investigation and Analysis on the Destructive Factors of In-filled Wattle and Daub Walls within Chuan-dou Timber Frames in Yunlin, Chiayi and Tainan Regions of Taiwan; National University of Kaohsiung: Kaohsiung, Taiwan, 2007. [Google Scholar]

- Li, C.-L. Rustic or Washed Finish and Monolithic Terrazzo—Building Technology of Imitation Stone Craf. Sculpt. Res. Semiyearly 2022, 28, 166–185. [Google Scholar]

- Yi, S.-Y.; Wei, G.-F.; Zhang, B.-J.; Liu, X.-B. Experimental Study on the Recipes of the Traditional Tabia Of China. J. Northwest Minzu Univ. (Nat. Sci.) 2019, 40, 31–41. [Google Scholar]

- Yan-Kai, Y. A Study for Mix Proportion Analysis and Engineering Properties of Mortar; National Cheng Kung University: Tainan, Tiawan, 2007. [Google Scholar]

- Tsai, H.-S. Sustainable Oyster Shell Material: Modern Pozzolana—Take Tainan Anping as an Example; National Cheng Kung University: Tainan, Taiwan, 2022. [Google Scholar]

- Wang, Y.X.; Zhou, B.; Shi, Y. Thermal Comfort Test of Bamboo Plaiting Mudwalls Adapted to Traditional Residential Buildings in Sichuan Basin and Application Prospect; Industrial Construction: Beijing, China, 2020; pp. 982–986,981. [Google Scholar]

- Wang, Y.; Shi, Y.; Zhou, B. Improvement of the Hygrothermal Performance of Mud-coated Material Used in Traditional Bamboo-woven Mud Walls. Int. J. Archit. Herit. 2023, 17, 1630–1647. [Google Scholar] [CrossRef]

- Ching-Chung, W. Study on the Relation between Compressive Strength and Mixing Proportion of San-Ho-Tu; National Chiayi University: Chiayi City, Taiwan, 2007. [Google Scholar]

- Chang, C.-J. Study on Mix Proportioning and Engineering Behavior for San-Ho-Tu Material; National Taiwan University of Science and Technology: Taipei, Taiwan, 2002. [Google Scholar]

- Ting-Hsuan, C. Study on Mix Proportion Analysis of Traditional Mortar and Recent Mortar; National Cheng Kung University: Tainan, Taiwan, 2009. [Google Scholar]

- Hsiu-Chen, L. A Study of Property of Mortar Cementing Material to Maintenance of the Ancient Monuments; National Kaohsiung University of Applied Sciences: Kaohsiung City, Taiwan, 2015. [Google Scholar]

- Cheng, T.S. The Research on the Mechanical Strength of Polymer Modified Cement Mortar; National Cheng Kung University: Tainan, Taiwan, 2001. [Google Scholar]

- Wu, S.-Z. Research and Development of the Production and Utilization of Bamboo in Taiwan, R.O.C. For. Prod. Ind. 1982, 1, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Ma, T. The Physical and Mechanical Properties of Importment Bamboo in Taiwan. Rep. Taiwan For. Exp. Inst. 1964, 106, 1–9. [Google Scholar]

- Ye, M. Bamboo house design. J. Res. Lett. 2011, 18, 33–36. [Google Scholar]

- Yu, C.-C. Bamboo Shed System Planning and Applicationof Historic Buildings; National Chung Kung University: Tainan, Taiwan, 2009. [Google Scholar]

- Amada, S.; Untao, S. Fracture properties of bamboo. Compos. Part B Eng. 2001, 32, 451–459. [Google Scholar] [CrossRef]

- Mu, B.-G. The Study on the Constructions in the Structures of the Bamboo Buildings in Taiwan; National Cheng Hung University: Tainan, Taiwan, 2007. [Google Scholar]

- Wang, C.-F. Establishing an Analysis Protocol for Traditional Earth Building Materials. J. Cult. Herit. Conserv. 2020, 7–26. [Google Scholar] [CrossRef]

- Wang, C.-F. Study of the Earth Composition of Adobe Walls and Bamboo-Daub Walls—A Case Study of Traditional Buildings, Yunlin County and Chiayi County. J. Cult. Herit. Conserv. 2020, 7–26. [Google Scholar] [CrossRef]

- Kuo, K.-C.; Sun, J.-C.; Yao, G.C. Seismic Evaluation of Historic Japanese Wooden Buildings –Examples of School Offices. J. Archit. 2015, 30, 1–21. [Google Scholar] [CrossRef]

- Chen, Y.-Y. Assessment and Calculation of Horizontal Resistance for Japanese Mud-Plastered Wall; National Cheng Kung University: Tainan, Taiwan, 2008. [Google Scholar]

- Su, Y.-L. Rotational Strengthening Method of Wood Frame Joint Used in Japanese Wooden Buildings; National Cheng Kung University: Tainan, Taiwan, 2007. [Google Scholar]

- Chen, C.-C. Structural Behaviors and Strength Evaluation of Japanese Style Bamboo-Mud-Walls Under Horizontal Cyclic Loading; National Cheng Kung University: Tainan, Taiwan, 2007. [Google Scholar]

- Meng-Ting, T. Experimental Study and Equivalent Bracing Simulation for the Bamboo Mud-Wall of Japanese Wooden Buildings; National Cheng Kung University: Tainan, Taiwan, 2006. [Google Scholar]

- Chen, Y. From Bamboo to Bamboo House: A Bamboo Building Guide for Everyone; Lin, M., Lan, Y., Eds.; Taiwan Bamboo Association: Yunlin, Taiwan, 2020; p. 53. [Google Scholar]

- Central Weather Administration. The Earth is Shaking! Why Are There so Many Earthquakes in Taiwan? Available online: https://edu.cwa.gov.tw/PopularScience/index.php/kids/earthquake/433-%E5%A4%A9%E6%90%96%E5%9C%B0%E5%8B%95%EF%BC%81%E7%82%BA%E4%BB%80%E9%BA%BC%E8%87%BA%E7%81%A3%E9%80%99%E9%BA%BC%E5%A4%9A%E5%9C%B0%E9%9C%87%EF%BC%9F (accessed on 27 May 2024).

- Sara, G.; sinwon, K. The Role of Guadua Bamboo in South America-From Vernacular Architecture to Sustainable Building Material. J. Korean Soc. Des. Cult. 2020, 26, 265–278. [Google Scholar] [CrossRef]

- Construction and Planning Agency; Taiwan Architecture & Building Center. Chapter of Construction in Building Technical Regulations. In Diana Williams; Construction and Planning Agency, Taiwan Architecture & Building Center, Ed.; Construction and Planning Agency, Taiwan Architecture & Building Center: Taipei, Taiwan, 2020; Volume 45. [Google Scholar]

- Construction and Planning Agency; Taiwan Architecture & Building Center. Chapter of Construction in Building Technical Regulations. In Diana Williams; Construction and Planning Agency, Taiwan Architecture & Building Center, Ed.; Construction and Planning Agency, Taiwan Architecture & Building Center: Taipei, Taiwan, 2020; Volume 110. [Google Scholar]

- Xu, M.-H. Study on Mix and Strength Properties of the Traditional Limestone Mortar; National Chiao Tung University: Hsinchu, Taiwan, 2007. [Google Scholar]

- Evans, I.; Smith, M.G.; Smiley, L. The Hand-Sculpted House; Freedom hill: Taipei, Taiwan, 2015. [Google Scholar]

- Yeh, H.F.; Lin, H.I.; Lee, C.H. Assessment of Spatial and Temporal Distribution of Reference Evapotranspiration and Pan Evaporation in Taiwan. J. Taiwan Agric. Eng. 2013, 59, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.-H. Application of oyster shell powder in agricultural production. Taichung Dist. Agric. Inf. Mon. 2021, 267, 3-3_2. [Google Scholar]

- Zeng, Y.-H.; Kuo, Y.-W. Application of Oyster Shell Powders Complexed with Bacillus safensis TC3-1S in Production of Cabbage and Muskmelon Bacillus safensis. Taichung Dist. Agric. Improv. Field Res. Rep. 2020, 149, 29–41. [Google Scholar]

- Liao, Y.; Wang, X.; Wang, L.; Yin, Z.; Da, B.; Chen, D. Effect of waste oyster shell powder content on properties of cement-metakaolin mortar. Case Stud. Constr. Mater. 2022, 16, e01088. [Google Scholar] [CrossRef]

- Han, Y.; Lin, R.; Wang, X.-Y. Performance of sustainable concrete made from waste oyster shell powder and blast furnace slag. J. Build. Eng. 2022, 47, 103918. [Google Scholar] [CrossRef]

- Song, Q.; Wang, Q.; Xu, S.; Mao, J.; Li, X.; Zhao, Y. Properties of water-repellent concrete mortar containing superhydrophobic oyster shell powder. Constr. Build. Mater. 2022, 337, 127423. [Google Scholar] [CrossRef]

- Lee, C.-J. A Study on the Application of Oyster Powder as a Cementitious Material; Taiwan Ocean University: Keelung City, Taiwan, 2005. [Google Scholar]

- David Otieno, K. Development of High-Strength Lime-Pozzolana Paste; National Taiwan University of Science and Technology: Taipei, Taiwan, 2015. [Google Scholar]

- Seymour, L.M.; Maragh, J.; Sabatini, P.; Di Tommaso, M.; Weaver, J.C.; Masic, A. Hot mixing: Mechanistic insights into the durability of ancient Roman concrete. Sci. Adv. 2023, 9, eadd1602. [Google Scholar] [CrossRef]

- Lin-shin, T. Research on the Shortage of Professional and Technical Workers in Taiwan’s Construction Industry—Taking Construction Engineering as an Example; National Central University: Taoyuan, Taiwan, 2014. [Google Scholar]

- Ya-Yin, L. Inspiration from natural architecture—Aniu Village Earth House. J. Archit. 2014, 28–33. [Google Scholar] [CrossRef]

- Lu, X.-Y. Study on the Hydrological Characteristics of Guizhou Bamboo Forest and Wormwood Forest in Taiwan. J. Res. Lett. 2011, 18, 30–32. [Google Scholar] [CrossRef]

- Otieno, M.B.; Alexander, M.G.; Beushausen, H.D. Corrosion in cracked and uncracked concrete—Influence of crack width, concrete quality and crack reopening. Mag. Concr. Res. 2010, 62, 393–404. [Google Scholar] [CrossRef]

- Chen, S.-S. Causes and Strategies for Waterproofing and Efflorescence of Buildings of Tainan City Government Fire Bureau; National Cheng Kung University: Tainan, Taiwan, 2022. [Google Scholar]

- Ruan, D.-L. Improvement of Efflorescence Inhibitors for Mortar; National Yunlin University of Science and Technology: Yun-Lin, Taiwan, 2018. [Google Scholar]

- Tsai, C.-L. Renovation of Brick Wall with Efflorescence under Aluminum Window Frame; National Yunlin University of Science and Technology: Yunlin, Taiwan, 2017. [Google Scholar]

- Wen, T.-T. The Causes and Prevention for Water Leakage of Window Frame; National Taipei University of Technology: Taipei, Taiwan, 2019. [Google Scholar]

- Chen, C.-S. A Practical Approach of Wall-mold Removal for Existing RC Buildings in Taiwan; Chaoyang University of Technology: Taichung, Taiwan, 2020. [Google Scholar]

- Chiang, W.-K. A Knowledge Management System For Building Efflorescence Remediation Method; National Chiao Tung University: Sinchu, Taiwan, 2010. [Google Scholar]

- Lin, W. Current situation analysis and future prospects of Taiwan steel structure market. J. Steel Constr. 2017, 28. Available online: https://www.tiscnet.org.tw/28 (accessed on 27 May 2024).

- Lin, W. Taiwan steel structure market analysis. Met. Ind. Res. Dev. Cent. 2006, 1–3. Available online: https://www.mirdc.org.tw/filedownload/epaperfile/2/19/mpnews/text/9607_1_itis02.pdf (accessed on 27 May 2024).

- Chun, H. Thermal Comfort and Energy Efficiency Analysis of Natural Ventilation Conference Hall—A Case Study on the Conference Hall of the Magic School of Green Technology; National Cheng Kung University: Tainan, Taiwan, 2015. [Google Scholar]

| Item | Function | Material |

|---|---|---|

| Pozzolana | Bonding material | Oyster powder (CaO), adhesive, lime (Ca(OH)2); 15 kg/package |

| Cementitious material | Polymer-resin-modified cement (PRMC); 25 kg/package | |

| Fine granular material | Fine sand | |

| Fibrous matter | Hemp plant fiber, coconut fiber, dry straw, rice husk | |

| For dyeing | Color powder (iron oxide powder) | |

| Waterproof material | Waterproof powder |

| Case | Treehouse | Pineapple Landmark | Compost Toilet | Su’s House | |

|---|---|---|---|---|---|

| Process | |||||

| First stage: bamboo work |  |  |  |  | |

| Second stage: mud work |  |  |  |  | |

| Third stage: waterproof coating work |  |  |  |  | |

| Fourth stage: decoration plan |  |  |  |  | |

| Case | Construction Process | Scale and Conditions |

|---|---|---|

| Treehouse of Linyun Elementary School (2016), located in Pingtung City, Pingtung County |

| The sphere of the treehouse is 2 m high from the ground, the indoor diameter is 3 m, and the height is 2.45 m. Conditions: the bark of the tree grew into the treehouse. |

| Pineapple Landmark (2018), located in Neipu Township, Pingtung County |

| Oval pineapple height: 2 m; diameter: 1.45 m; pineapple crown: 0.9 m; total height: 2.9 m. Conditions: completed, in use. |

| Happy Bird’s Compost Toilet (2019–2020), located in Jiouru Township, Pingtung County |

| Building height: 2.8 m; diameter: 1.5 m; total width: 3 m. Conditions: partial roof collapse. |

| AiLiao Su’s house (2020–2021), located in Neipu Township, Pingtung County |

| The building height is 6.5 m, with a total exterior wall area of 307 m2 made out of bamboo and pozzolana. Conditions: completed, legal building with license for use. |

| Case | Material | Weight | Percentage/Mix | Notes |

|---|---|---|---|---|

| Treehouse | Hemp plant fiber | 200 g | 0.84% | Total thickness of wall = 5 cm |

| Rice husk | 3.5 kg | 14.76% | ||

| PRMC | 5 kg | 21.09% | ||

| Lime | 15 kg | 63.29% | ||

| Pineapple Landmark | Hemp plant fiber | 15 g | 0.06% | Total thickness of wall = 5 cm |

| Rice husk | 3.5 kg | 14.88% | ||

| PRMC | 5 kg | 21.26% | ||

| Lime | 15 kg | 63.78% | ||

| Compost Toilet | Coconut fiber | 300 g | 0.94% | Total thickness of wall = 5 cm |

| Dry straw | 3 kg | 9.43% | ||

| Rice husk | 3.5 kg | 11.00% | ||

| Clay | 10 kg | 31.44% | ||

| Oyster powder | 10 kg | 31.44% | ||

| PRMC | 5 kg | 15.72% | ||

| Lime | 10 kg | 30.03% | Protective coating layer, thickness = 2 cm | |

| PRMC | 8 kg | 24.02% | ||

| Oyster powder | 15 kg | 45.04% | ||

| Coconut fiber | 300 g | 0.90% | ||

| Su’s House | Coconut fiber | 300 g | 1.23% | Total thickness of wall = 5 cm × 2 layers |

| Rice husk | 2 kg | 0.82% | ||

| Waterproof powder | 0.5 kg | 2.05% | ||

| PRMC | 8.3 kg | 34.15% | ||

| Lime | 15 kg | 61.72% | ||

| Lime Polymer-resin-modified cement Waterproof powder | 15 kg | 60.97% | Protective coating layer, thickness = 1 cm | |

| 8.3 kg | 33.73% | |||

| 1 kg | 4.06% | |||

| 300 g | 1.21% |

| Item | Pozzolana Exterior Wall (Thickness = 5 cm) | USD/m2 | Reinforced Concrete Exterior Wall (Thickness = 5 cm) | |

|---|---|---|---|---|

| Structural layer | Bamboo strip (Single layer two-way) | 6.00 | 44.65 | Reinforcement #3: 15 cm (including iron wire and wages) |

| Stainless steel self-tapping screws | 0.33 | 0.00 | Iron wire | |

| Lime | 2.40 | 7.80 | Concrete (210 kg/cm2, including wages) | |

| Oyster powder | 3.47 | 1.87 | Cement mortar surface layer (1 cm, inner and outer layers) | |

| Adhesive | 5.00 | 13.33 | Template assembly (including wages) | |

| Waterproof powder | 1.67 | 0.00 | ||

| Coconut fiber | 2.33 | 0.00 | ||

| Sand | 0.17 | 0.00 | ||

| Rice husk | 0.33 | 0.00 | ||

| Fireproof layer | Fireproof rock wool | 5.80 | 0.00 | |

| Waterproof layer | Elastic cement waterproof layer (5 layers) | 6.00 | 6.00 | Elastic cement waterproof layer (5 layers, including wages) |

| Lime layer (including oyster powder and coconut fiber) | 14.83 | 25.00 | Exterior wall paint (including wages) | |

| Waterproof powder | 1.67 | |||

| Wages | Pozzolana and wave bamboo | 45.33 | 0.00 | |

| Total price | 95.33 | 98.65 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, S.-C.; Zhang, X.-F.; Chang, Y.-T. Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials. Buildings 2024, 14, 1584. https://doi.org/10.3390/buildings14061584

Tsai S-C, Zhang X-F, Chang Y-T. Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials. Buildings. 2024; 14(6):1584. https://doi.org/10.3390/buildings14061584

Chicago/Turabian StyleTsai, Shu-Chen, Xue-Fang Zhang, and Yao-Tan Chang. 2024. "Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials" Buildings 14, no. 6: 1584. https://doi.org/10.3390/buildings14061584

APA StyleTsai, S.-C., Zhang, X.-F., & Chang, Y.-T. (2024). Toward Nearly Zero-Waste Architecture: Innovation, Application, and Practice of Construction Methods Using Natural Materials. Buildings, 14(6), 1584. https://doi.org/10.3390/buildings14061584