Review of Soil Creep Characteristics and Advances in Modelling Research

Abstract

:1. Introduction

2. Data Source and Analyzation Method

2.1. Analysis of Annual Publications

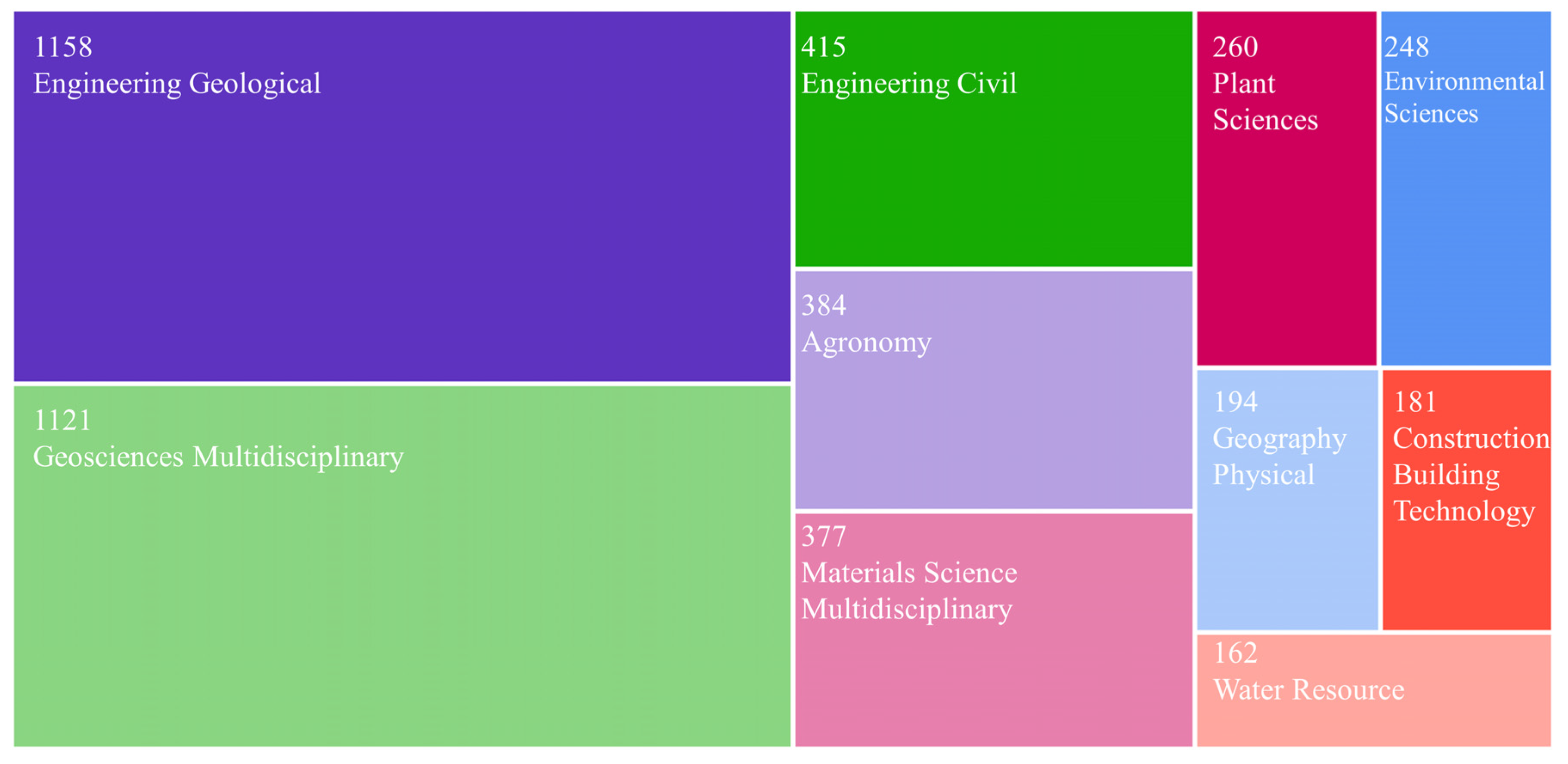

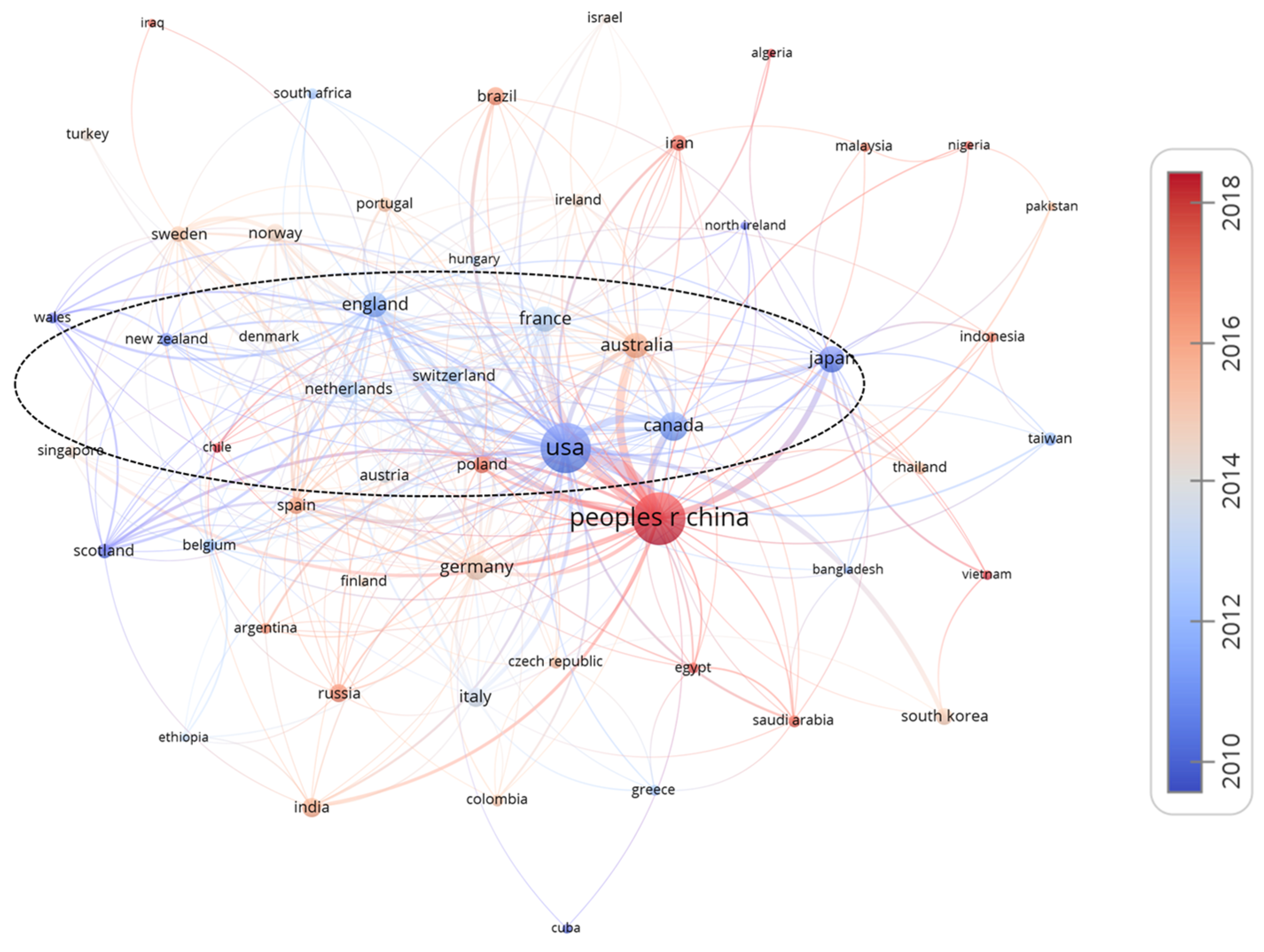

2.2. Bibliometric Analysis on Countries

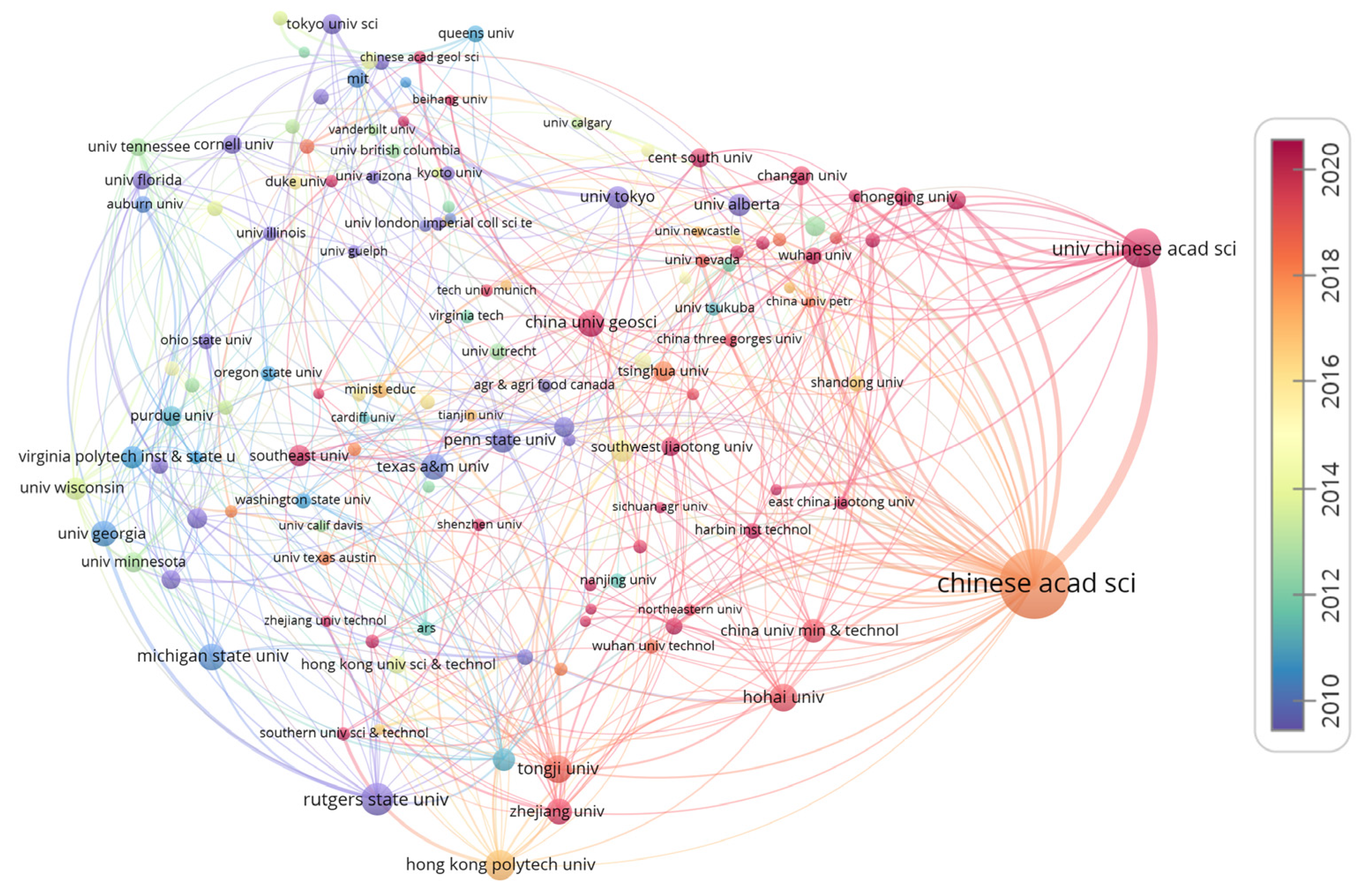

2.3. Analysis of Organizations Co-Occurrence

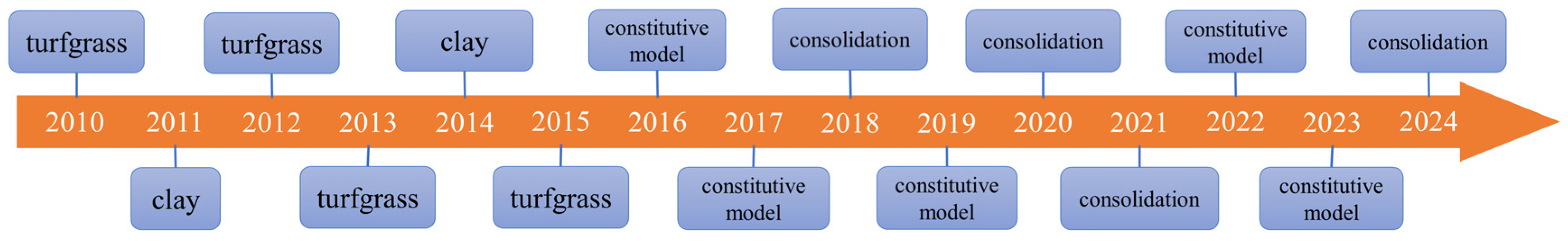

2.4. Analysis of Keywords Co-Occurrence

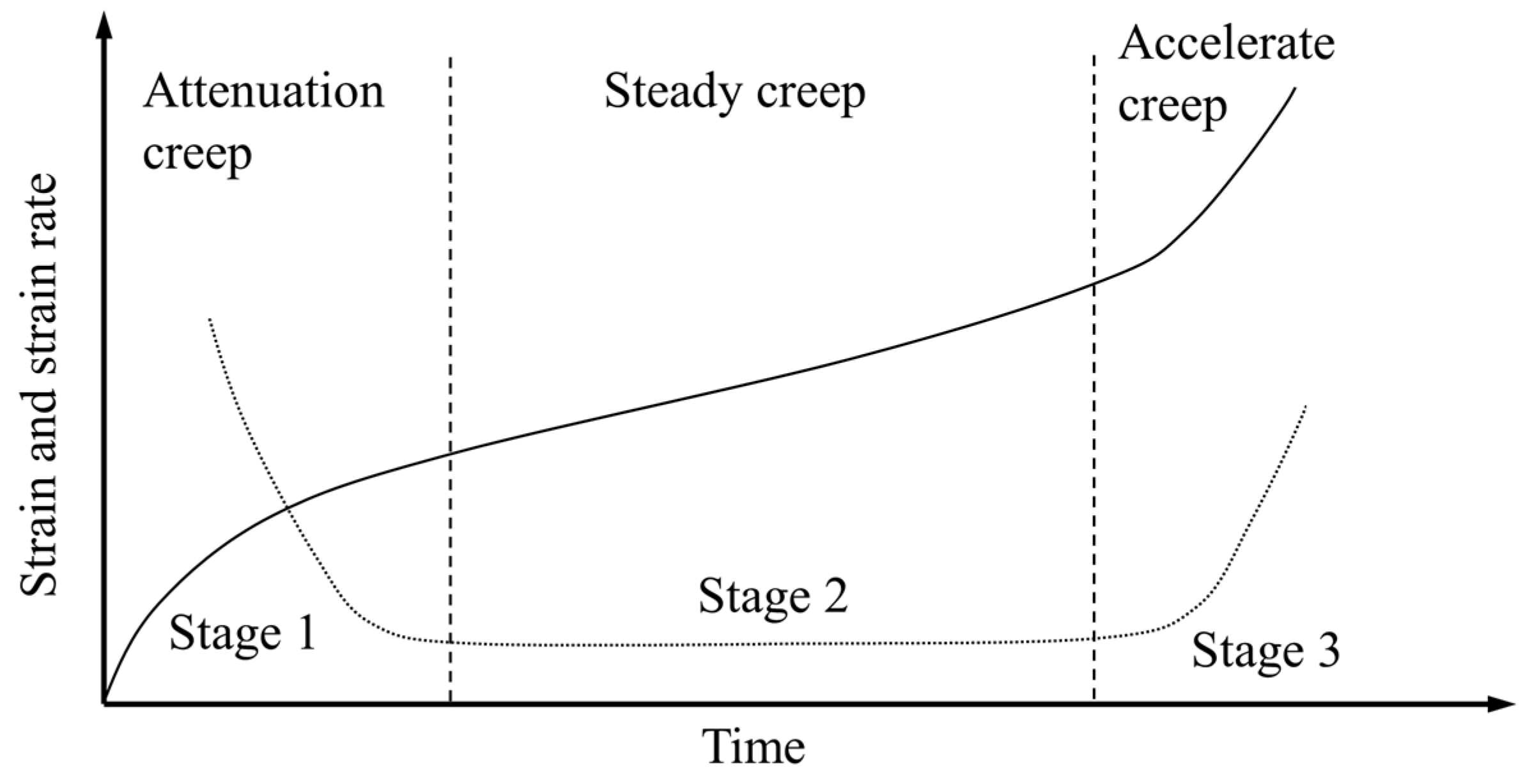

3. Soil Creep Characteristics

4. Creep Influencing Factors

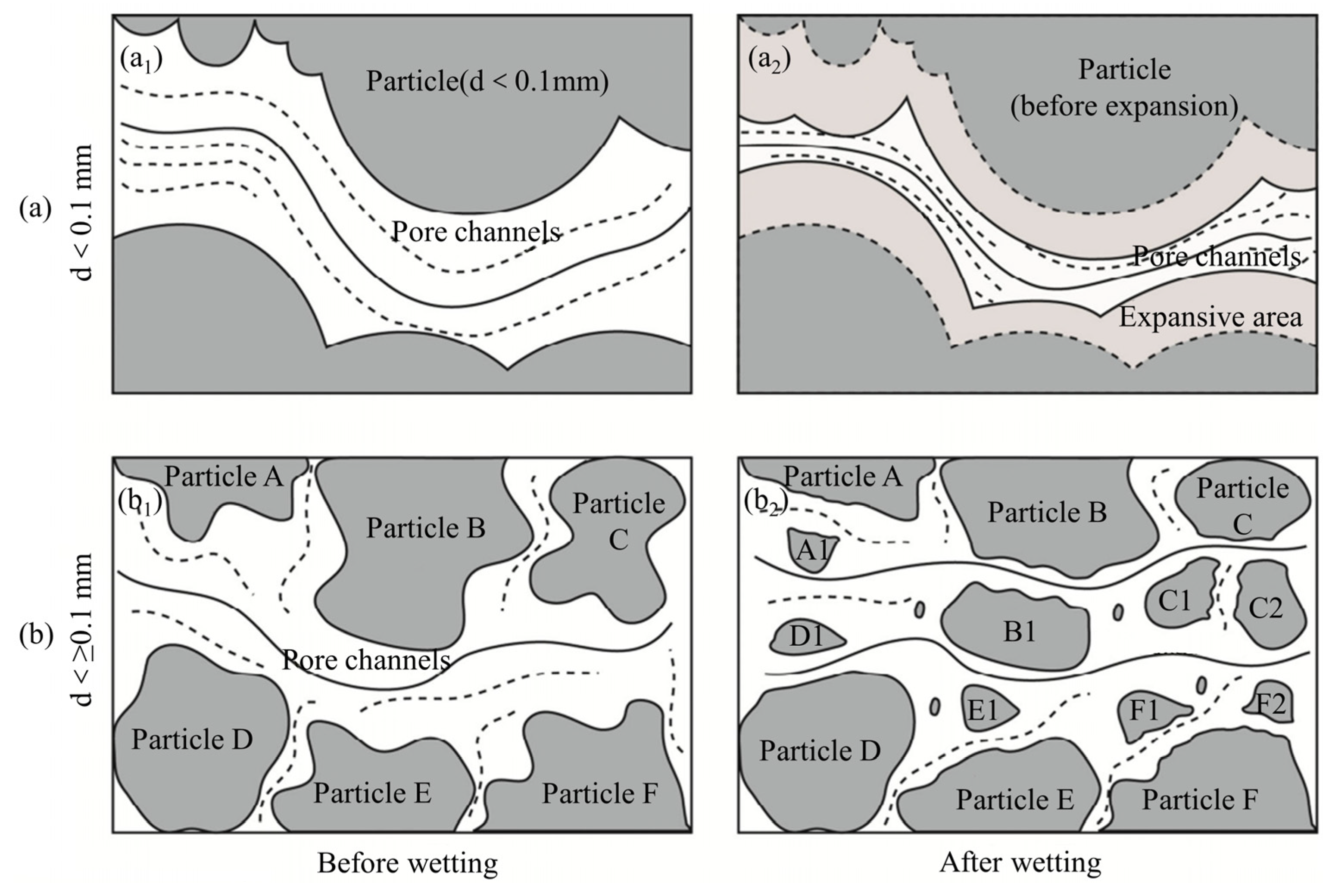

4.1. Microstructural Features

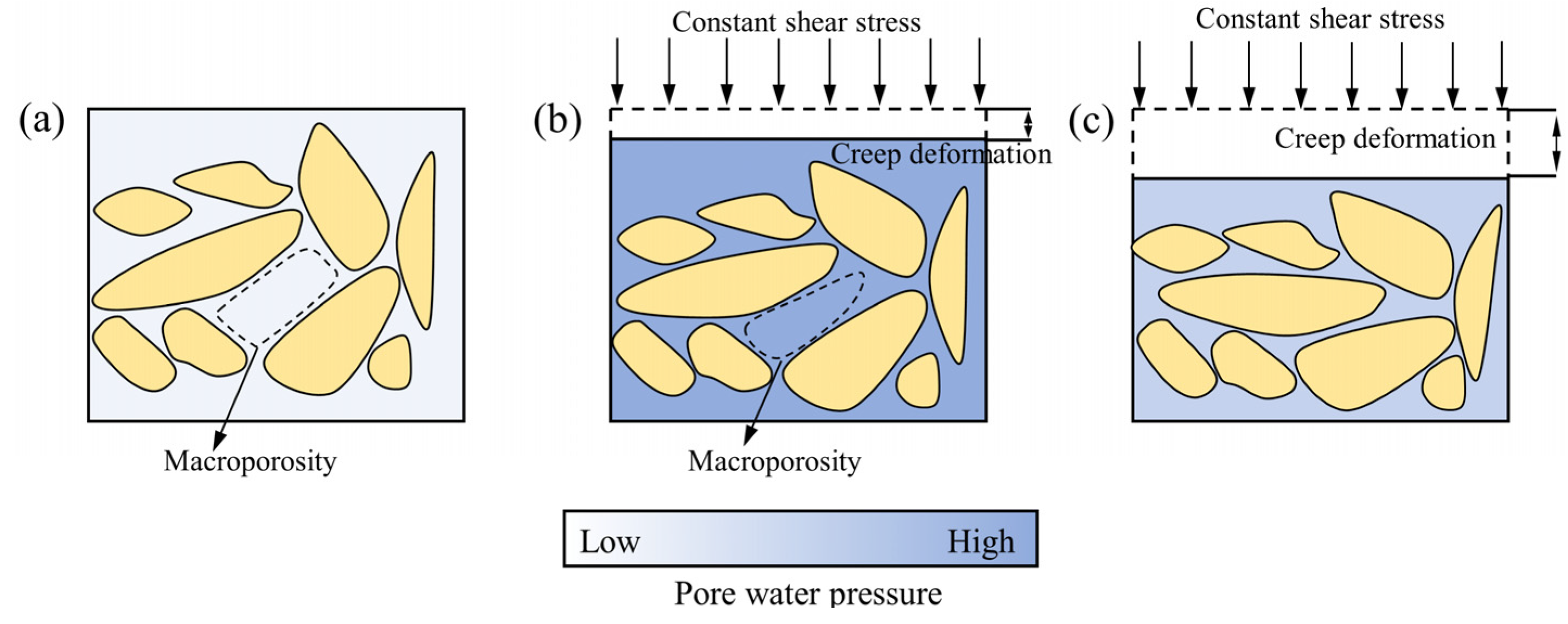

4.2. Moisture Content

4.3. Stress Path

5. Creep Models

5.1. Empirical Models

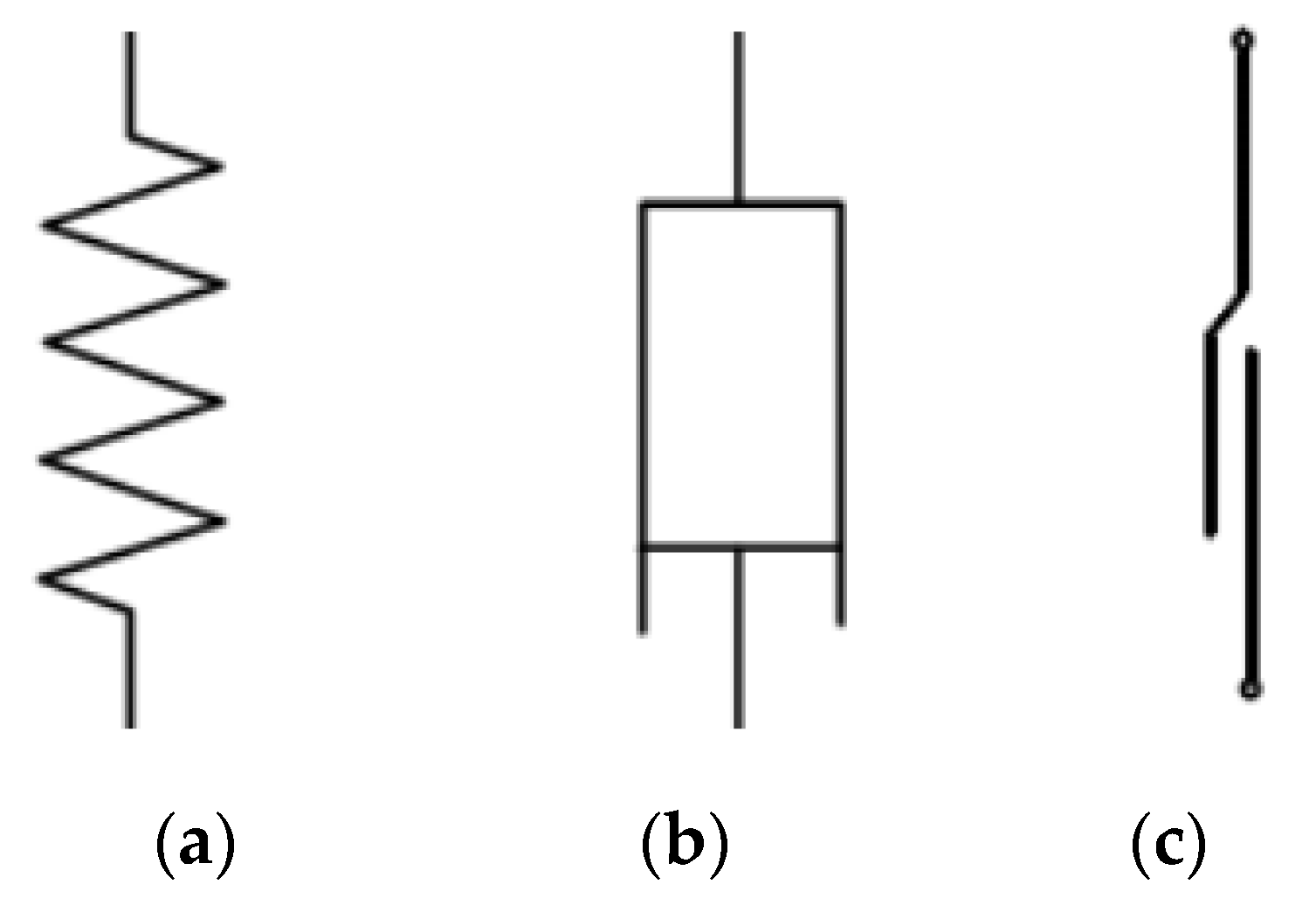

5.2. Component Models

6. The Issue and Prospects of Soil Creep

- (1)

- The changes in soil microstructure are crucial for explaining the mechanism of creep deformation. Given the comprehensive influence of factors such as moisture content, loading, stress path, temperature fluctuations, freeze–thaw cycles, and rainfall, the change in its microstructure is extremely complex. Currently, electron microscopy and optical microscopy are commonly used to observe the microstructure of soil sections, but these methods suffer from limitations in observation range and representativeness [7]. Therefore, in-depth research on changes in soil microstructure will be an important basis for understanding the mechanism of soil creep.

- (2)

- The creep models proposed at present often target specific soils and influencing factors. However, research on soil creep under the combined action of multiple factors is still lacking. This gap makes it difficult to match creep models with actual engineering sites. Therefore, it is necessary to comprehensively consider multiple factors and explore creep models that incorporate these factors to more accurately predict soil creep behaviour.

- (3)

- Finite element software, as an important tool for simulating engineering deformation, can embed creep models to simulate changes in engineering construction effectively. However, many proposed models feature complex relationships between parameters and stress, posing challenges for their implementation in finite element software. In addition, fitted parameters, such as elastic modulus, often differ significantly from the actual elastic modulus of the soil. Therefore, developing creep models that accurately fit data and seamlessly integrate into finite element software is crucial for precise predictions of engineering deformations.

7. Conclusions

- (1)

- Using VOSviewer visualization software, a comprehensive analysis of the literature in the field of soil creep has been conducted, including aspects such as quantity, citation frequency, institutions, countries, and keywords. The results indicate a trend of increasing literature quantity in the field of soil creep followed by a decrease, with developed countries such as Europe and America having an earlier start in creep research compared to countries like China. Currently, the hotspots in soil creep research mainly focus on soil creep mechanisms and predictive models.

- (2)

- Soil creep is influenced by multiple factors. Currently, soil creep mechanisms and creep models are mainly proposed based on individual factor effects, with little consideration for the influence of multiple factors on creep.

- (3)

- Presently, modifications to empirical models primarily focus on adjustments to stress–strain relationships, strain–time relationships, and related parameters. As for component models, modifications primarily concentrate on spring elements and viscous pot elements, usually by introducing other factors through the modification of elastic modulus and viscosity coefficients.

- (4)

- Future research in soil creep deformation is expected to focus on understanding creep microevolution, multi-factor creep models, and creep models embedded in finite element software.

Funding

Conflicts of Interest

References

- Frenelus, W.; Peng, H.; Zhang, J.Y. Creep behavior of rocks and its application to the long-term stability of deep rock tunnels. Appl. Sci. 2022, 12, 8451. [Google Scholar] [CrossRef]

- Liu, Y.C.; Huang, F.; Wang, G.H.; Cao, Y.H.; Li, B. Study on long-span and variable-section foundation pit excavation in muddy silty clay. Int. J. Civ. Eng. 2023, 22, 739–755. [Google Scholar] [CrossRef]

- Guo, S.L.; Yan, C.H.; Yu, L.C.; You, Y. Design of the Supporting structures for large and unusually shaped foundation pit near the Yangtze River. Adv. Civ. Eng. 2020, 2020, 3831805. [Google Scholar] [CrossRef]

- Ye, Y.; Zhang, Q.; Cai, D.; Chen, F.; Yao, J.; Wang, L. Study on new method of accelerated clay creep characteristics test. Challenges and Innovations in Geotechnics. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; Volume 1, pp. 461–464. [Google Scholar]

- Mei, G.X.; Yin, J.H. Coupled model of consolidation and creep for consolidation test. J. Cent. South Univ. Technol. 2008, 15, 357–361. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, Y.Q.; Wu, J.C.; Wang, H.M.; He, J.J. Mechanical modeling of aquifer sands under long-term groundwater withdrawal. Eng. Geol. 2012, 125, 74–80. [Google Scholar] [CrossRef]

- Qi, Z.Y.; Li, Z.Q. Review on creep properties of loess. J. Earth Sci. Environ. 2023, 45, 485–510. (In Chinese) [Google Scholar]

- Wu, Z.L.; Deng, Y.F.; Cui, Y.J.; Zhou, A.N.; Feng, Q.; Xue, H.C. Experimental study on creep behavior in oedometer tests of reconstituted soft clays. Int. J. Geomech. 2019, 19, 4018198. [Google Scholar] [CrossRef]

- Xu, X.B.; Cui, Z.D. Investigation of a fractional derivative creep model of clay and its numerical implementation. Comput. Geotech. 2020, 119, 103387. [Google Scholar] [CrossRef]

- Gu, R.G.; Fang, Y.G. An improved soil direct shear creep apparatus and its application. Chin. J. Rock Mech. Eng. 2006, 25, 3552–3558. (In Chinese) [Google Scholar]

- Wang, S.; Wang, J.E.; Wu, W.; Cui, D.S.; Su, A.J.; Xiang, W. Creep properties of clastic soil in a reactivated slow-moving landslide in the Three Gorges Reservoir Region, China. Eng. Geol. 2020, 267, 105493. [Google Scholar] [CrossRef]

- Yin, Q.; Dai, J.P.; Dai, G.L.; Gong, W.M.; Zhang, F.; Zhu, M.X. Study on creep behavior of silty clay based on fractal derivative. Appl. Sci. 2022, 12, 8327. [Google Scholar] [CrossRef]

- Liingaard, M.; Augustesen, A.; Lade, P.V. Characterization of models for time-dependent behavior of soils. Int. J. Geomech. 2004, 4, 157–177. [Google Scholar] [CrossRef]

- Augustesen, A.; Liingaard, M.; Lade, P.V. Evaluation of time-dependent behavior of soils. Int. J. Geomech. 2004, 4, 137–156. [Google Scholar] [CrossRef]

- Christensen, R.W.; Kim, J.S. Rheological model studies in clay. Clays Clay Miner. 1969, 17, 83–93. [Google Scholar] [CrossRef]

- Chen, Z.J.; Tang, W.F.; Huang, J.F. On the locked in stress, creep and dilatation of rocks, and the constitutive equations. Chin. J. Rock Mech. Eng. 1991, 10, 299–312. (In Chinese) [Google Scholar]

- Taylor, D.W.; Merchant, W. A theory of clay consolidation accounting for secondary compression. Stud. Appl. Math. 1940, 19, 167–185. [Google Scholar] [CrossRef]

- Yu, X.B.; Liu, S.Y.; Miao, L.C. Creep properties of Lianyungang soft clay and its engineering application. Rock Soil Mech. 2003, 24, 1001–1006. (In Chinese) [Google Scholar]

- Degago, S.A.; Grimstad, G.; Jostad, H.P.; Nordal, S.; Olsson, M. Use and misuse of the isotache concept with respect to creep hypotheses A and B. Geotechnique 2011, 61, 897–908. [Google Scholar] [CrossRef]

- Ma, B.N.; Muhunthan, B.; Xie, X.Y. Stress history effects on 1-D consolidation of soft soils: A rheological model. Int. J. Numer. Anal. Met. 2013, 37, 2671–2689. [Google Scholar] [CrossRef]

- Chen, Y.; Marinelli, F.; Buscarnera, G. Mathematical interpretation of delayed instability in viscous unsaturated soil. Geotech. Lett. 2019, 9, 165–172. [Google Scholar] [CrossRef]

- Le, T.M.; Fatahi, B.; Khabbaz, H. Viscous behaviour of soft clay and inducing factors. Geotech. Geol. Eng. 2012, 30, 1069–1083. [Google Scholar] [CrossRef]

- Coop, M.R. The mechanics of uncemented carbonate sands. Geotechnique 1990, 40, 607–626. [Google Scholar] [CrossRef]

- Pusch, R. Creep Mechanisms in Clay; Pergamon Press: Oxford, UK, 1979. [Google Scholar]

- Zhou, C.Y.; Mu, C.M. Relationship between micro-structural characters of fracture surface and strength of soft clay. Chin. J. Geotech. Eng. 2005, 27, 1136–1141. (In Chinese) [Google Scholar]

- Chen, J.P.; Yuan, J.; Ye, L.Y.; Peng, Q.W. Microstructure change of soft soil under consolidation creep. Sci. Technol. Eng. 2020, 20, 4087–4094. (In Chinese) [Google Scholar]

- Xie, X.; Qi, S.W.; Zhao, F.S.; Wang, D.H. Creep behavior and the microstructural evolution of loess-like soil from Xi’an area, China. Eng. Geol. 2018, 236, 43–59. [Google Scholar] [CrossRef]

- Wu, Z.L.; Deng, Y.F.; Cui, Y.J.; Chen, Y.G.; Wang, Q.; Feng, Q. Investigations on secondary compression behaviours of artificial soft sand-clay mixtures. Soils Found. 2019, 59, 326–336. [Google Scholar] [CrossRef]

- Ou, Z.F.; Fang, Y.G. The influence of organic matter content on the rheological model parameters of soft clay. Soil Mech. Found. Eng. 2017, 54, 283–288. [Google Scholar] [CrossRef]

- Xiao, B.; Hu, M.Y.; Zhou, P.J.; Lu, Y.K.; Zhang, Y. Creep behavior of saturated clay in triaxial test and a hyperbolic model. Geofluids 2021, 2021, 7882046. [Google Scholar] [CrossRef]

- Yao, Y.S.; Li, J.; Xiao, Z.Q.; Xiao, H.B. Soil-Water characteristics and creep deformation of unsaturated expansive subgrade soil: Experimental test and simulation. Front. Earth. 2021, 9, 783273. [Google Scholar] [CrossRef]

- Zhao, D.; Gao, Q.F.; Hattab, M.; Hicher, P.Y.; Yin, Z.Y. Microstructural evolution of remolded clay related to creep. Transp. Geotech. 2020, 24, 100367. [Google Scholar] [CrossRef]

- Hicher, P.Y. Experimental study of viscoplastic mechanisms in clay under complex loading. Geotechnique 2016, 66, 661–669. [Google Scholar] [CrossRef]

- Ge, M.M.; Li, N.; Zheng, J.G.; Zhang, J.W.; Zhu, C.H. A creep model for compacted loess based on 1D oedometer test. Rock Soil Mech. 2015, 36, 3164–3170. (In Chinese) [Google Scholar]

- Long, J.H.; Guo, W.B.; Li, P.; Li, T.L. Creep property of soil in sliding zone of loess landslide. Chin. J. Geotech. Eng. 2010, 32, 1023–1028. (In Chinese) [Google Scholar]

- Schapery, R.A. A theory of crack initiation and growth in viscoelastic media: I. Theoretical development. Int. J. Fract. 1975, 11, 141–159. [Google Scholar] [CrossRef]

- Yin, D.S.; Li, Y.Q.; Wu, H.; Duan, X.M. Fractional description of mechanical property evolution of soft soils during creep. Water. Sci. Eng. 2013, 6, 446–455. [Google Scholar] [CrossRef]

- Wang, W.Y.; Luo, Q.Z.; Yuan, B.X.; Chen, X.P. An investigation of time-dependent deformation characteristics of soft dredger fill. Adv. Civ. Eng. 2020, 2020, 8861260. [Google Scholar] [CrossRef]

- Qian, Q.H.; Rong, X.L. State, issues and relevant recommendations for security risk management of China’s underground engineering. Chin. J. Rock Mech. Eng. 2008, 27, 649–655. (In Chinese) [Google Scholar]

- Sun, Y.L.; Tang, L.S. Use of X-ray computed tomography to study structures and particle contacts of granite residual soil. J. Cent. South Univ. 2019, 26, 938–954. [Google Scholar] [CrossRef]

- Wang, L.Z.; Yin, Z.Y. Stress-dilatancy of natural soft clay under undrained creep condition. Int. J. Geomech. 2012, 15, A4014002. [Google Scholar] [CrossRef]

- Chen, X.P.; Bai, S.W. Research on creep-consolidation characteristics and calculating model of soft soil. Chin. J. Rock Mech. Eng. 2003, 22, 728–734. (In Chinese) [Google Scholar]

- Tang, B.; Zeng, Z.; Gong, Y.X. The empirical formula research and the test for the soft clay coupled consolidation and creep character in different drainage conditions. Appl. Mech. Mater. 2011, 90–93, 1819–1823. [Google Scholar] [CrossRef]

- Yin, J.H. Non-linear creep of soils in oedometer tests. Geotechnique 1999, 49, 699–707. [Google Scholar] [CrossRef]

- Sheng, D.C.; Zhang, S.; Yu, Z.W. Unanswered questions in unsaturated soil mechanics. Sci. China Technol. Sci. 2013, 56, 1257–1272. [Google Scholar] [CrossRef]

- Alonso, E.E.; Gens, A.; Josa, A. A constitutive model for partially saturated soils. Geotechnique 1990, 40, 405–430. [Google Scholar] [CrossRef]

- Sheng, D.C.; Zhou, A.N.; Fredlund, D.G. Shear strength criteria for unsaturated soils. Geotech. Geol. Eng. 2011, 29, 145–159. [Google Scholar] [CrossRef]

- Guan, N.; Wang, S.M. Discussion on creep test methods of unsaturated soil. J. China. Three. Gorges. Univ. 2008, 30, 32–34. (In Chinese) [Google Scholar]

- Zhu, Y.B.; Yu, H.M. Unsaturated creep behaviors of weak intercalated soils in soft rock of badong formation. J. Mt. Sci. 2015, 12, 1460–1470. [Google Scholar] [CrossRef]

- Lai, X.L.; Wang, S.M.; Ye, W.M.; Cui, Y.J. Experimental investigation on the creep behavior of an unsaturated clay. Can. Geotech. J. 2014, 51, 621–628. [Google Scholar] [CrossRef]

- Feng, J.; Ma, Y.; Liu, Z.B. A study on the creep characteristics of airport viscous subsoil based on unsaturated stress level. Geofluids 2021, 2021, 6667245. [Google Scholar] [CrossRef]

- Zhao, N.H.; Hu, B.; Yan, E.; Xu, X.; Yi, Q.L. Research on the creep mechanism of Huangniba landslide in the Three Gorges Reservoir Area of China considering the seepage–stress coupling effect. Bull. Eng. Geol. Environ. 2019, 78, 4107–4121. [Google Scholar] [CrossRef]

- Miao, F.S.; Zhao, F.C.; Wu, Y.P.; Li, L.W.; Xue, Y.; Meng, J.J. A novel seepage device and ring-shear test on slip zone soils of landslide in the Three Gorges Reservoir area. Eng. Geol. 2022, 307, 106779. [Google Scholar] [CrossRef]

- Sivasithamparam, N.; Karstunen, M.; Bonnier, P. Modelling creep behaviour of anisotropic soft soils. Comput. Geotech. 2015, 69, 46–57. [Google Scholar] [CrossRef]

- Enomoto, T.; Koseki, J.; Tatsuoka, F.; Sato, T. Creep failure of sands exhibiting various viscosity types and its simulation. Soils Found. 2015, 55, 1346–1363. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Li, F.T.; Yang, F.F.; Zhang, Y.X.; Tian, W.H.; Lan, H.X. Experimental investigation on failure modes and progressive failure process of earthen check dam triggered by upstream flow. Front. Earth. Sci. 2022, 10, 818508. [Google Scholar] [CrossRef]

- Huang, W.; Wen, K.J.; Deng, X.J.; Li, J.J.; Jiang, Z.J.; Li, Y.; Li, L.; Amini, F. Constitutive model of lateral unloading creep of soft soil under excess pore water pressure. Math. Probl. Eng. 2020, 2020, 5017546. [Google Scholar] [CrossRef]

- Zhu, J.G.; Yin, J.H. Deformation and pore-water pressure responses of elastic viscoplastic soil. J. Eng. Mech. 2001, 127, 899–908. [Google Scholar] [CrossRef]

- Wang, X.G.; Yin, Y.P.; Wang, J.D.; Lian, B.Q.; Qiu, H.J.; Gu, T.F. A nonstationary parameter model for the sandstone creep tests. Landslides 2018, 15, 1377–1389. [Google Scholar] [CrossRef]

- Nagaraj, T.S.; Murthy, M.K.; Sridharan, A. Incremental loading device for stress path and strength testing of soils. Geotech. Test. J. 1981, 4, 74. [Google Scholar] [CrossRef]

- Ng, C.W.W. Stress paths in relation to deep excavations. J. Geotech. Geoenviron. 1999, 125, 357–363. [Google Scholar] [CrossRef]

- Lade, P.V.; Duncan, J.M. Stress-Path dependent behavior of cohesionless soil. ASCE J. Geotech. Eng. Div. 1976, 102, 51–68. [Google Scholar] [CrossRef]

- Yu, H.D.; Lu, C.; Chen, W.Z.; Tian, H.M. An insight into the creep mechanisms of a clayey soil through long-term consolidation tests. Bull. Eng. Geol. Environ. 2021, 80, 9127–9139. [Google Scholar] [CrossRef]

- Zhou, Z.W.; Ma, W.; Zhang, S.J.; Mu, Y.H.; Li, G.Y. Experimental investigation of the path-dependent strength and deformation behaviours of frozen loess. Eng. Geol. 2020, 265, 105449. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhou, Z.G.; Cai, Z.Y. Studies about creep characteristic of silty clay on triaxial drained creep test. Appl. Mech. Mater. 2014, 580–583, 355–358. [Google Scholar] [CrossRef]

- Zhu, W.B.; Dai, G.L.; Wang, B.C.; Gong, W.M.; Sun, J.; Hu, H. Study on cyclic characteristics and equivalent cyclic creep model of the soft clay at the bottom of suction caisson foundation. Rock Soil Mech. 2022, 43, 466–478. (In Chinese) [Google Scholar]

- Li, Y.F.; Nie, R.S.; Leng, W.M.; Guo, Y.P.; Dong, J.L.; Sun, B.L. Cumulative permanent strain and critical dynamic stress of silty filler for subgrade subjected to intermittent cyclic loading of trains. Bull. Eng. Geol. Environ. 2021, 80, 3079–3096. [Google Scholar] [CrossRef]

- Han, J.; Yin, Z.Y.; Dano, C.; Hicher, P.Y. Cyclic and creep combination effects on the long-term undrained behavior of overconsolidated clay. Acta. Geotech. 2021, 16, 1027–1041. [Google Scholar] [CrossRef]

- Li, Z.X.; Wang, J.D.; Zhang, D.F. Creep behavior of intact loess followed unloading paths. Front. Earth. Sci. 2021, 9, 744864. [Google Scholar] [CrossRef]

- Huang, W.; Wen, K.J.; Li, D.S.; Deng, X.J.; Li, L.; Jiang, H.F.; Amini, F. Experiment study of lateral unloading stress path and excess pore water pressure on creep behavior of soft soil. Adv. Civ. Eng. 2019, 2019, 9898031. [Google Scholar] [CrossRef]

- Yu, P.Y.; Pan, P.Z.; Feng, G.L.; Wang, Z.F.; Miao, S.T. The effect of unloading path on the time-dependent behavior of beishan granite. Lithosphere 2022, 2022, 3112805. [Google Scholar] [CrossRef]

- Lin, H.D.; Wang, C.C. Stress-strain-time function of clay. J. Geotech. Geoenviron. Eng. 1998, 124, 289–296. [Google Scholar] [CrossRef]

- Liu, Y.K.; Deng, Z.B.; Cao, P.; Huang, Y.H.; Lin, H. Triaxial creep test and modified Singh-Mitchell creep model of soft clay. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 1440–1446. (In Chinese) [Google Scholar]

- Wei, J.B.; Liu, W.B. An experimental study of the creep mechanical properties of unsaturated soil and empirical models. Hydrogeol. Eng. Geol. 2019, 46, 67–73. (In Chinese) [Google Scholar]

- Jia, Y.; Wei, L.S.; Huang, H.F. Study on creep mechanics characteristics and empirical model of soil in the slip zone of red layer landslide. Water Power 2021, 47, 25–30. (In Chinese) [Google Scholar]

- Zhu, Y.B.; Yu, H.M. An improved Mesri creep model for unsaturated weak intercalated soils. J. Cent. South Univ. 2014, 21, 4677–4681. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Zhai, Y.; Dong, Y.H. Modified Mesri creep model of soft clays and its engineering application. J. Hydroelectr. Eng. 2017, 36, 112–120. (In Chinese) [Google Scholar]

- Yang, A.W.; Yan, S.W.; Zhang, Y.; Liu, Q. A study of the empirical creep model of soft dredger fill. Hydrogeol. Eng. Geol. 2012, 39, 54–58. (In Chinese) [Google Scholar]

- Zhang, X.W.; Wang, C.M. Empirical creep model for saturated soft soil. J. Cent. South Univ. (Sci. Technol.) 2011, 42, 791–796. (In Chinese) [Google Scholar]

- Hu, H.H.; He, J.Q.; Nie, S.C. One-dimensional consolidation creep model for sandy grain muddy soil of Dongting lake. Rock Soil Mech. 2022, 43, 1269–1276. (In Chinese) [Google Scholar]

- Gao, H.M.; Chen, G.X. Modified Singh-Mitchell creep model for EPS composite soil. Adv. Mater. Res. 2011, 311–313, 339–343. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Luo, C.L.; Wang, K.; Yue, J.P.; Gao, C.; Tian, X.P.; Zhang, R.C.; Xue, P. Triaxial creep test and model analysis of unsaturated saline soil. J. Southeast Univ. 2022, 52, 704–711. (In Chinese) [Google Scholar]

- Lei, H.Y.; He, C.F.; Ding, X.D.; Qiu, W.W. A modified creep model for clay with unloading disturbance. J. Eng. Geol. 2014, 22, 196–202. (In Chinese) [Google Scholar]

- Wang, C.; Zhang, Y.L.; Liu, H.W. A modified Singh-Mitchell’s creep function of sliding zone soils of Xietan landslide in Three Gorges. Rock Soil Mech. 2005, 26, 415–418. (In Chinese) [Google Scholar]

- Li, X.Z.; Huang, M.S.; Wang, L.M. Bounding surface elastic-viscoplastic constitutive model for rheological behaviors of soft clays. Chin. J. Rock Mech. Eng. 2007, 26, 1393–1401. (In Chinese) [Google Scholar]

- Li, H.F.; Zhang, Y.Q.; Jin, W.; Wen, Y.F.; Chen, N. Experimental study on rockfill creep modeling. J. Hydroelectr. Eng. 2013, 32, 212–217. (In Chinese) [Google Scholar]

- Acharya, M.P.; Hendry, M.T.; Martin, C.D. Creep behaviour of intact and remoulded fibrous peat. Acta. Geotech. 2017, 13, 399–417. [Google Scholar] [CrossRef]

- Madurapperuma, M.A.K.M.; Puswewala, U.G.A. Numerical implementation of a constitutive model for soil creep. J. Mech. Mater. Struct. 2008, 3, 1857–1874. [Google Scholar] [CrossRef]

- Wang, B.D.; Su, L.P.; Liu, Y. Improved Nishihara creep model research and secondary development calculation. J. Saf. Sci. Technol. 2022, 18, 128–134. (In Chinese) [Google Scholar]

- Chang, L.C.; Wang, H.Y.; Wang, Y.; Liu, X.H. Triaxial creep behavior of silted soil in front of dam based on fraction derivatives theory. KSCE J. Civ. Eng. 2022, 26, 3863–3875. [Google Scholar] [CrossRef]

- Tang, H.; Duan, Z.; Wang, D.P.; Dang, Q. Experimental investigation of creep behavior of loess under different moisture contents. Bull. Eng. Geol. Environ. 2020, 79, 411–422. [Google Scholar] [CrossRef]

- Chang, Z.L.; Gao, H.X.; Huang, F.M.; Chen, J.W.; Huang, J.S.; Guo, Z.Z. Study on the creep behaviours and the improved Burgers model of a loess landslide considering matric suction. Nat. Hazards 2020, 103, 1479–1497. [Google Scholar] [CrossRef]

- Ma, Y.; Liang, H.; You, Y.X.; Zhang, W.G.; Guo, L.M.; Fan, J.W.; Cao, Z.H. Elastic-viscoplastic constitutive model of soil under cyclic loading. Adv. Civ. Eng. 2021, 2021, 1602431. [Google Scholar] [CrossRef]

- Li, X.; Liu, E.L.; Song, B.T.; Liu, X.Y. An improved nishihara model for frozen loess considering the influence of temperature. Adv. Mater. Sci. Eng. 2018, 2018, 9073435. [Google Scholar] [CrossRef]

- Shao, Y.W.; Suo, Y.L.; Xiao, J.; Bai, Y.; Yang, T. Creep characteristic test and creep model of frozen soil. Sustainability 2023, 15, 3984. [Google Scholar] [CrossRef]

- Luo, Q.Z.; Chen, X.P.; Wang, S.; Huang, J.W. An experimental study of time-dependent deformation behaviour of soft soil and its empirical model. Rock Soil Mech. 2016, 37, 66–75. (In Chinese) [Google Scholar]

- Wang, K.; Hu, Z.Q.; She, H.C.; Liang, Z.C.; Feng, Z.; Jiao, H.W. Experimental study on creeping of artificial ruin soils. J. Hydroelectr. Eng. 2020, 39, 101–109. (In Chinese) [Google Scholar]

- Cai, W.; Chen, W.; Xu, W.X. Characterizing the creep of viscoelastic materials by fractal derivative models. Int. J. Non-Linear Mech. 2016, 87, 58–63. [Google Scholar] [CrossRef]

- Yao, W.M.; Hu, B.; Zhan, H.B.; Ma, C.; Zhao, N.H. A novel unsteady fractal derivative creep model for soft interlayers with varying water contents. KSCE J. Civ. Eng. 2019, 23, 5064–5075. [Google Scholar] [CrossRef]

- Deng, H.L.; Zhou, H.W.; Wei, Q.; Li, L.F.; Jia, W.H. A creep constitutive model based on Atangana–Baleanu fractional derivative. Mech. Time-Depend. Mater. 2023, 27, 1171–1186. [Google Scholar] [CrossRef]

| Rank | Keyword | Weight <Occurrences> | Weight <Total Link Strength> | Rank | Keyword | Weight <Occurrences> | Weight <Total Link Strength> |

|---|---|---|---|---|---|---|---|

| 1 | creep | 562 | 1554 | 11 | settlement | 45 | 134 |

| 2 | turfgrass | 91 | 170 | 12 | temperature | 43 | 128 |

| 3 | consolidation | 85 | 275 | 13 | viscoplasticity | 42 | 140 |

| 4 | constitutive model | 80 | 191 | 14 | clays | 40 | 159 |

| 5 | geosynthetics | 67 | 204 | 15 | deformation | 40 | 149 |

| 6 | sand | 54 | 180 | 16 | frozen soil | 38 | 71 |

| 7 | creep model | 47 | 82 | 17 | numerical simulation | 38 | 66 |

| 8 | clay | 46 | 164 | 18 | stress relaxation | 38 | 113 |

| 9 | creeping bent grass | 46 | 146 | 19 | permafrost | 37 | 87 |

| 10 | landslide | 45 | 64 | 20 | soft clay | 37 | 105 |

| Models | Equations | Modified Models | Model Additional Parameters | Testing Type and Conditions | Correction Methods |

|---|---|---|---|---|---|

| Mesri | m1, m2, m3, A, n (the parameters of m1, m2 and m3 are the slopes of linear fitting of lnε and lnt at different creep stages; A and n are defined as material constants). | Unsaturated soil triaxial tests | The strain–time is divided into three stages, taking into account the influence of matric suction on creep [49]. | ||

| F, n (F and n are defined as material constants). | Unsaturated soil triaxial tests | The influence of matric suction on creep has been taken into consideration [74]. | |||

| Eu, Rf, ηα (Eu is the initial tangent modulus; Rf is the failure ratio; ηα is the fractional-order viscosity coefficient). | Consolidated Undrained Triaxial Test | By employing fractional calculus theory to depict the strain–time relationship of soil [75]. | |||

| A, a, b (A defined as material constants; a and b are fitting parameters). | Unsaturated soil triaxial tests | The influence of matrix suction on the elastic modulus and the effect of stress on λ have been taken into account [76]. | |||

| ε0, T* (ε0 is the initial strain; T* is the fitting parameter). | Triaxial consolidation drained creep test | In the second stage of deformation, the combination of stress–strain relationship and strain–time relationship is described by a hyperbolic function [77]. | |||

| ς, η, ∂1, ∂2 (ς and η are the coefficients; ∂1 and ∂2 are the corresponding fitting parameters). | Unsaturated soil triaxial tests | A modified creep model considering the unsaturated stress levels has been established [51]. | |||

| ω, Ei1, Ei2 (ω is the damage ratio; Ei1 and Ei2 are the initial tangent moduli for stages 1 and 2, respectively). | Triaxial creep test | The inclusion of structural damage variables into the model has facilitated the development of a rheological model that accounts for structural influences [78]. |

| Models | Equations | Modified Models | Model Additional Parameters | Testing Type and Conditions | Correction Methods |

|---|---|---|---|---|---|

| Singh-Mitchell | C, b, n (C, b, and n are constant coefficients). | Triaxial drained and undrained creep tests | A creep model has been established with the stress–strain relationship described with a hyperbolic function, and the strain–time relationship described with a power function [79]. | ||

| , , c, d, e ( and are normalised hyperbolic fitting parameters; c, d, and e are fitting parameters). | One-dimensional consolidation creep test | A creep model has been developed with the stress–strain relationship modelled using a hyperbolic function, and λ described with a hyperbolic function [80]. | |||

| a, θ, ξ, α (ξ and θ are the slope and the intercept of the fitting straight line; a and α are constant parameters). | Triaxial creep test | Considering the influence of deviatoric stress on the parameter “m” [81]. | |||

| T (T is the pending time parameter). | Triaxial consolidated undrained creep test | Improved the exponential function component and the power function component [73]. | |||

| T (T is the constant coefficient). | Triaxial creep test | The time was corrected using a hyperbolic model [82]. | |||

| A, b, λ, β (A is the constant coefficient; b is the constant coefficient; λ is the slope of lgε-lgt; β is the slope of lnε-D). | Triaxial creep test | A creep model considering unloading disturbance was established [83]. | |||

| t1, t2, λ1, λ2, λ3 (t1, t2 are the times at the end of stages 1 and 2; λ1, λ2, λ3 are the slopes of lgε-lgt for stages 1, 2, and 3, respectively). | Triaxial drained creep test | A segmented creep model was established by fitting the three stages of attenuation, steady flow, and rapid flow creep [84]. |

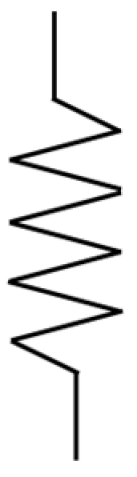

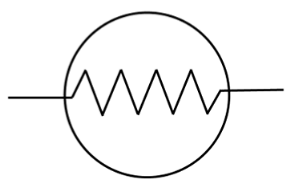

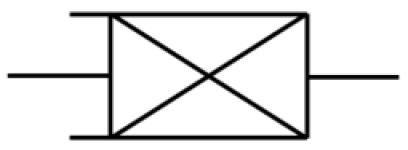

| Elements | Modified Elements | Soil | Testing Type and Conditions | Constitutive Relationships | Element Characteristics |

|---|---|---|---|---|---|

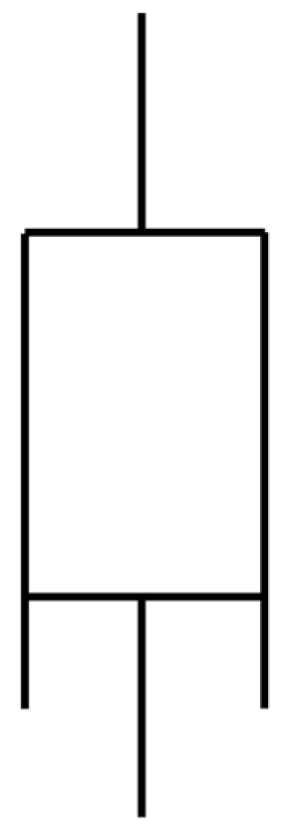

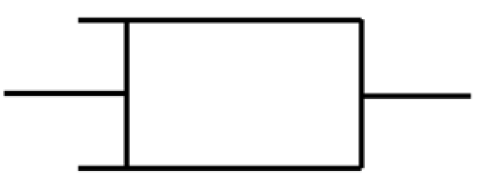

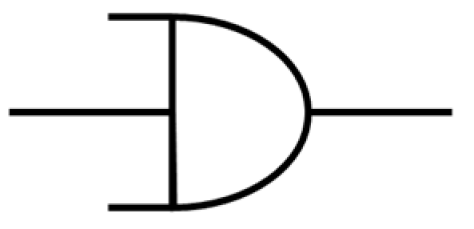

|  | Soft clay | Triaxial creep test | Suitable for triaxial creep of clay at low and high stress levels [89]. | |

| Silty clay | Triaxial drained creep test | The elastic modulus is a function of time and stress decay [90]. | ||

| Loess | Triaxial creep test | Consideration has been given to the influence of soil damage on the elastic modulus [91]. | |||

| Loess | Unsaturated triaxial test | The influence of matrix suction on the elastic modulus has been taken into account [92]. | ||

| Laterite Mixed with Cement | Cyclic loading creep test | The effect of cyclic loading on the elastic modulus has been considered [93]. | |||

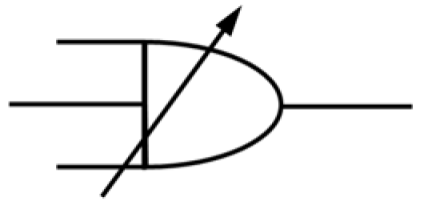

| Soft clay | Shear creep test | Describing nonlinear instantaneous elastoplastic deformation [29]. |

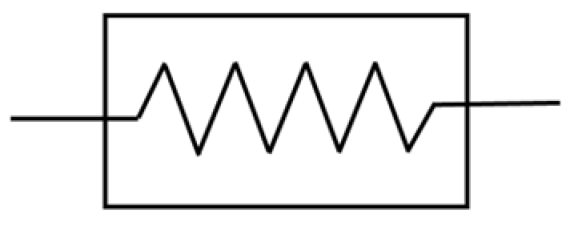

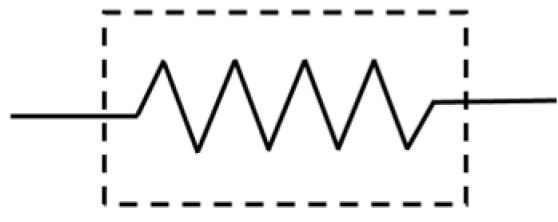

| Elements | Modified Elements | Soil | Testing Type and Conditions | Constitutive Relationships | Element Characteristics |

|---|---|---|---|---|---|

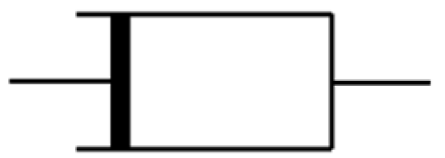

|  | Frozen loess | Triaxial Creep Test | Introducing hardening and damage variables to consider the effects of hardening and damage [94]. | |

| Frozen soil | Uniaxial creep tests | The stress was adjusted through the damage variable; the viscosity coefficient was adjusted through time and stress [95]. | |||

| Laterite Mixed with Cement | Triaxial Creep Test under cyclic loading | A viscosity coefficient related to the number of cycles has been established [93]. | ||

| Soft clay for backfilling | Triaxial Consolidated Undrained Creep Test | Fractional-order dashpots have been introduced to establish elements that lie between ideal solids and ideal fluids [96]. | ||

| Ancient ruins | One-dimensional Consolidation Creep Test | Fractional-order dashpots have been introduced to establish elements that lie between ideal solids and ideal fluids [97]. | ||

| Loess | Triaxial Creep Test | Based on the fact that the viscosity coefficient during soil creep is a decreasing function of stress and an increasing function of time, a viscosity coefficient considering stress and time has been established [69]. | |||

| Silty clay | Triaxial Creep Shear Test with Drainage | During the accelerated creep stage, the viscosity coefficient also increased with time. Based on this, a variable viscosity coefficient element has been established [90]. | |||

| All types | Utilising data from other scholars | For the first time, an attempt was made to apply fractal dashpot to simulate viscoelastic behaviour, reducing computational costs and memory storage requirements [98]. | ||

| Soft interlayer | Ring shear creep test | Based on the theory of fractal dashpot, a non-steady-state fractal derivative creep model was established [99]. | ||

| Utilising data from other scholars | Utilising data from other scholars | A fractional-order buffer with Atangana–Baleanu dashpot was established, possessing viscoelasticity at any given moment [100]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Huang, F.; Cao, Y.; Jin, F.; Wang, G.; Hou, W. Review of Soil Creep Characteristics and Advances in Modelling Research. Buildings 2024, 14, 1668. https://doi.org/10.3390/buildings14061668

Liu Y, Huang F, Cao Y, Jin F, Wang G, Hou W. Review of Soil Creep Characteristics and Advances in Modelling Research. Buildings. 2024; 14(6):1668. https://doi.org/10.3390/buildings14061668

Chicago/Turabian StyleLiu, Yanchao, Feng Huang, Yanhui Cao, Fang Jin, Guihe Wang, and Wei Hou. 2024. "Review of Soil Creep Characteristics and Advances in Modelling Research" Buildings 14, no. 6: 1668. https://doi.org/10.3390/buildings14061668