Advances in Modeling Surface Chloride Concentrations in Concrete Serving in the Marine Environment: A Mini Review

Abstract

1. Introduction

2. Deterioration Mechanisms of Chloride Erosion of Concrete

2.1. Chloride Ion Migration Mechanism

2.2. Diffusion Behavior of Chloride Ions

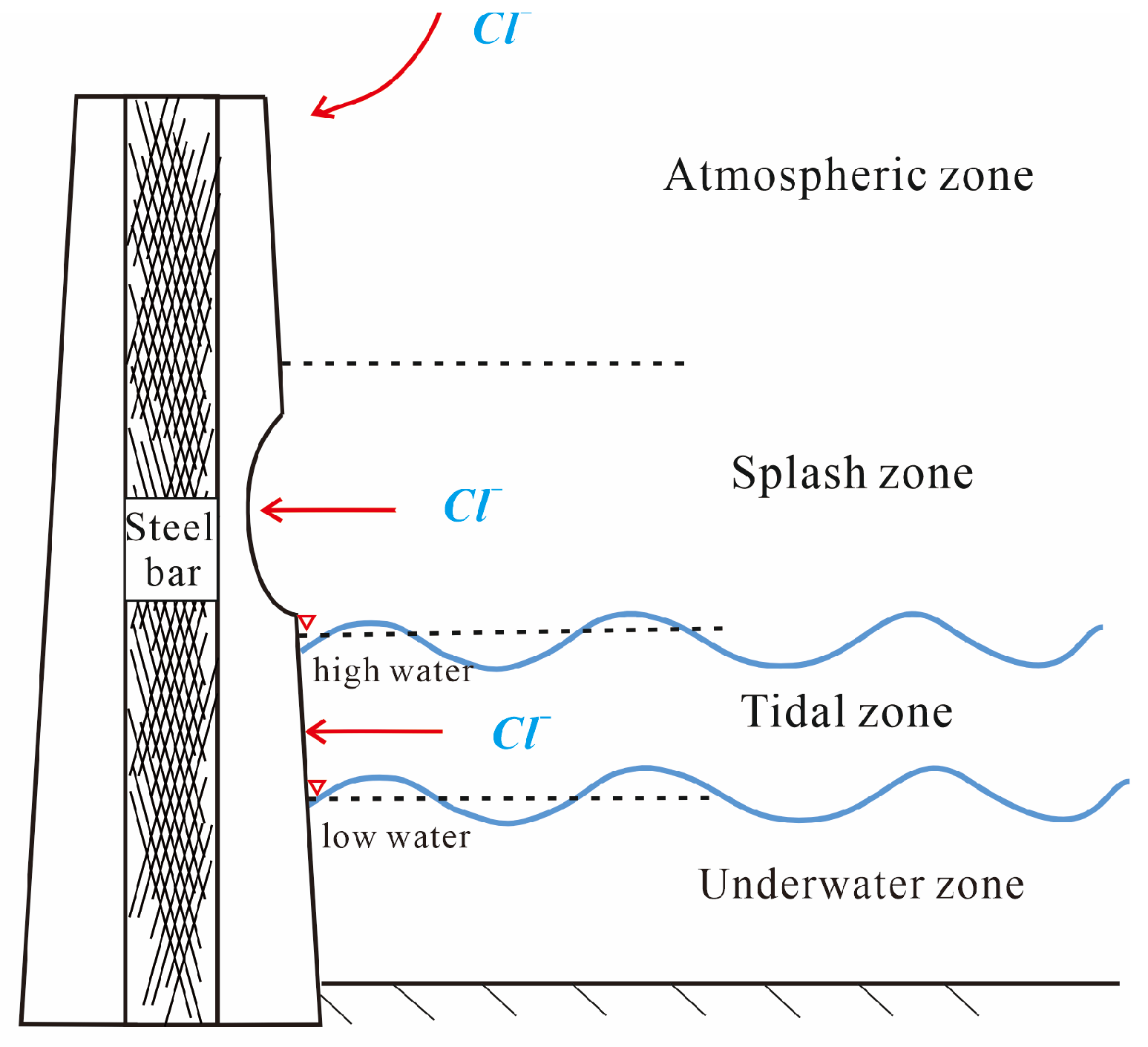

2.3. Corrosion Mechanisms of Concrete under Different Exposure Conditions

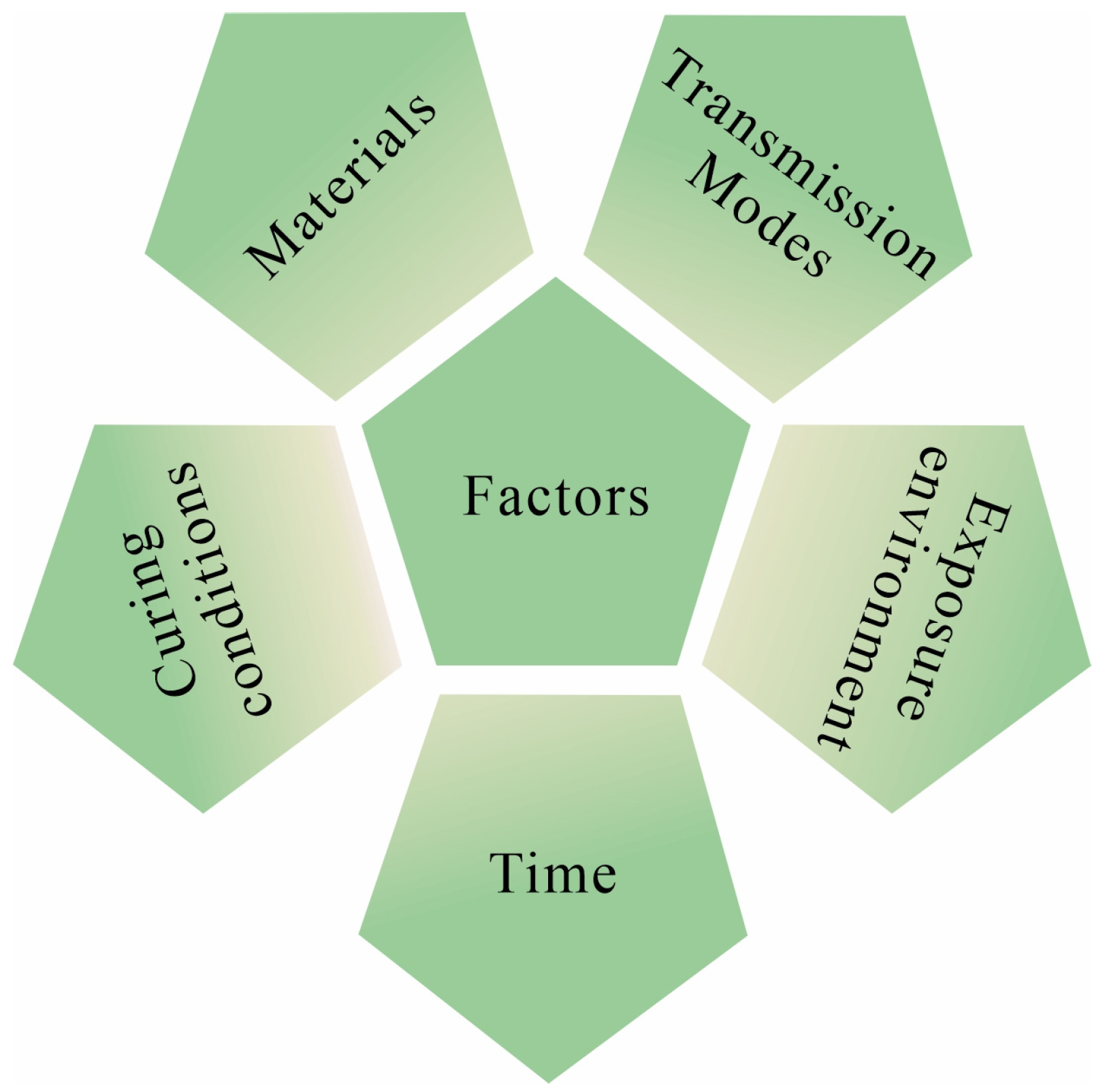

3. Commonly Used Research Tools

3.1. Empirical Formulas

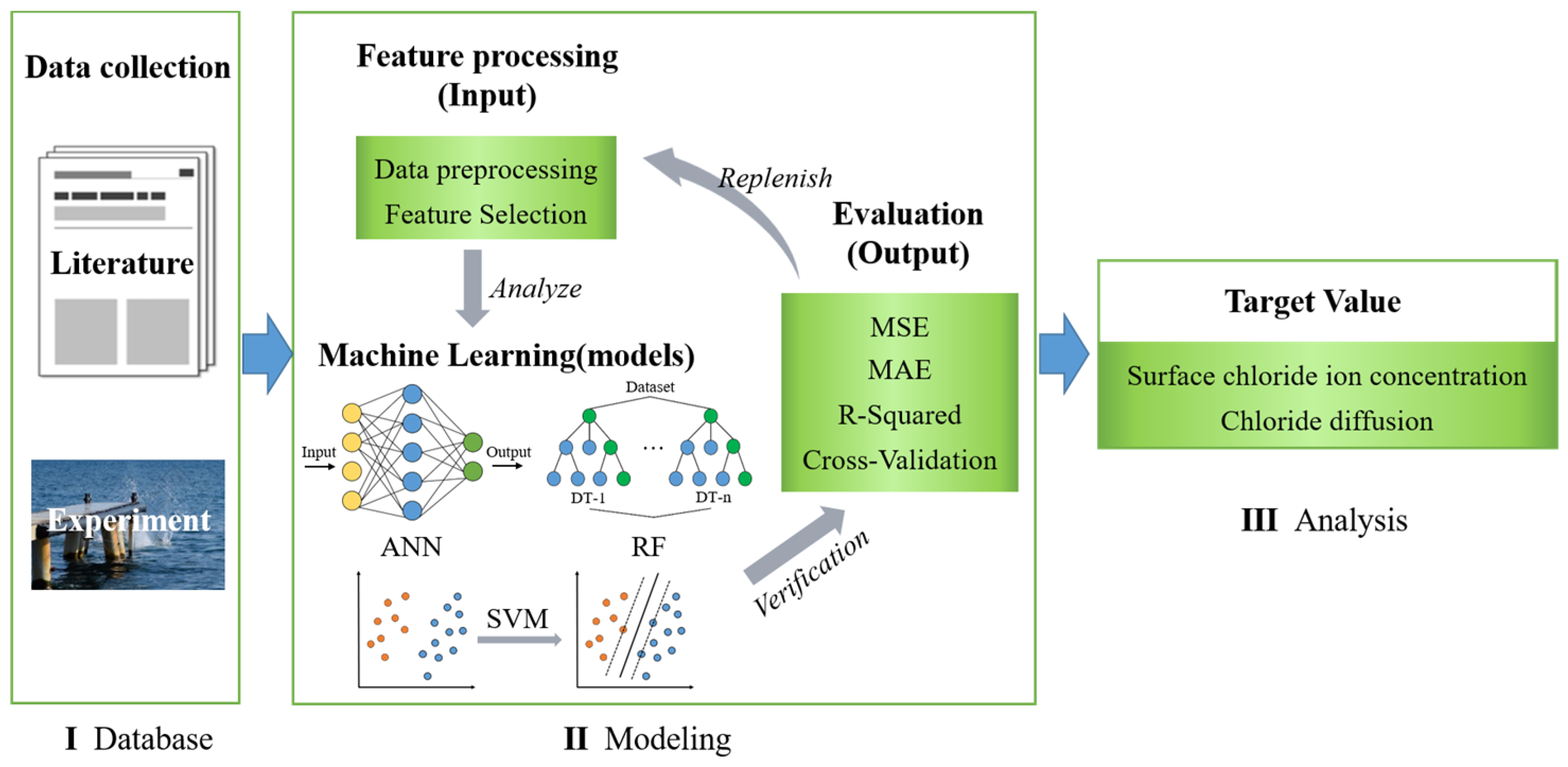

3.2. Machine Learning

- (1)

- Concrete performance prediction and material preparation optimization [116]. Peng [117] conducted an in-depth study on the compressive strength of recycled aggregate using traditional algorithms such as artificial neural network (ANN), support vector machine (SVM), and hybrid algorithms such as particle swarm optimization, grey wolf optimizer, and genetic algorithm (GA), in which uniaxial stress conditions can be used for concrete mechanical properties with accurate prediction.

- (2)

- (1)

- Creation of a database.

- (2)

- Modeling.

- (3)

- Analysis the physical significance of the data.

4. Advances in Research Based on the Empirical Formula Approach

4.1. Time-Varying Modeling Studies

4.2. Multifactor Coupled Studies

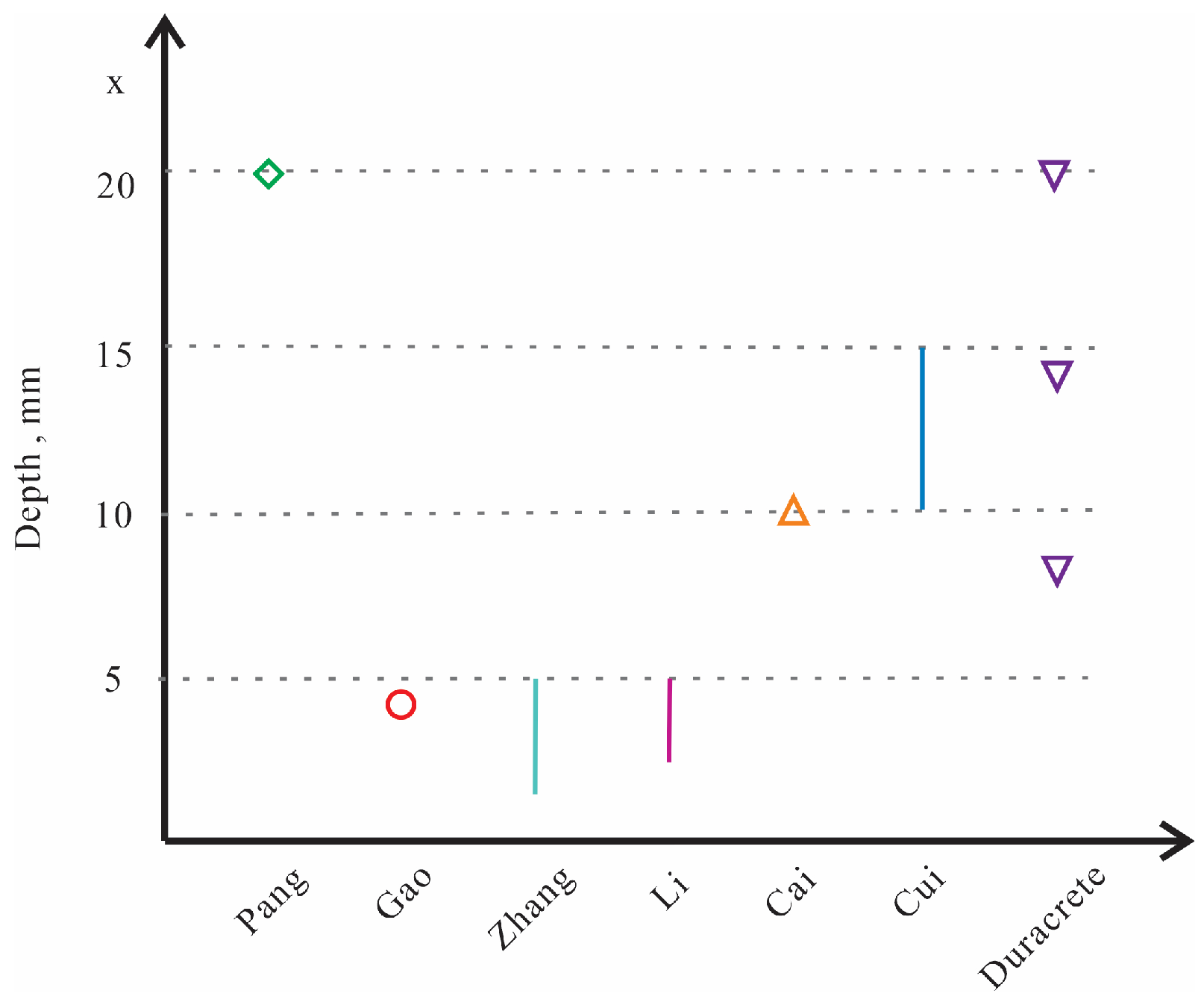

4.3. Analyses and Shortcomings of Existing Models

5. Advances in Research Based on Novel Machine Learning

5.1. Machine Learning Research Updates

- (1)

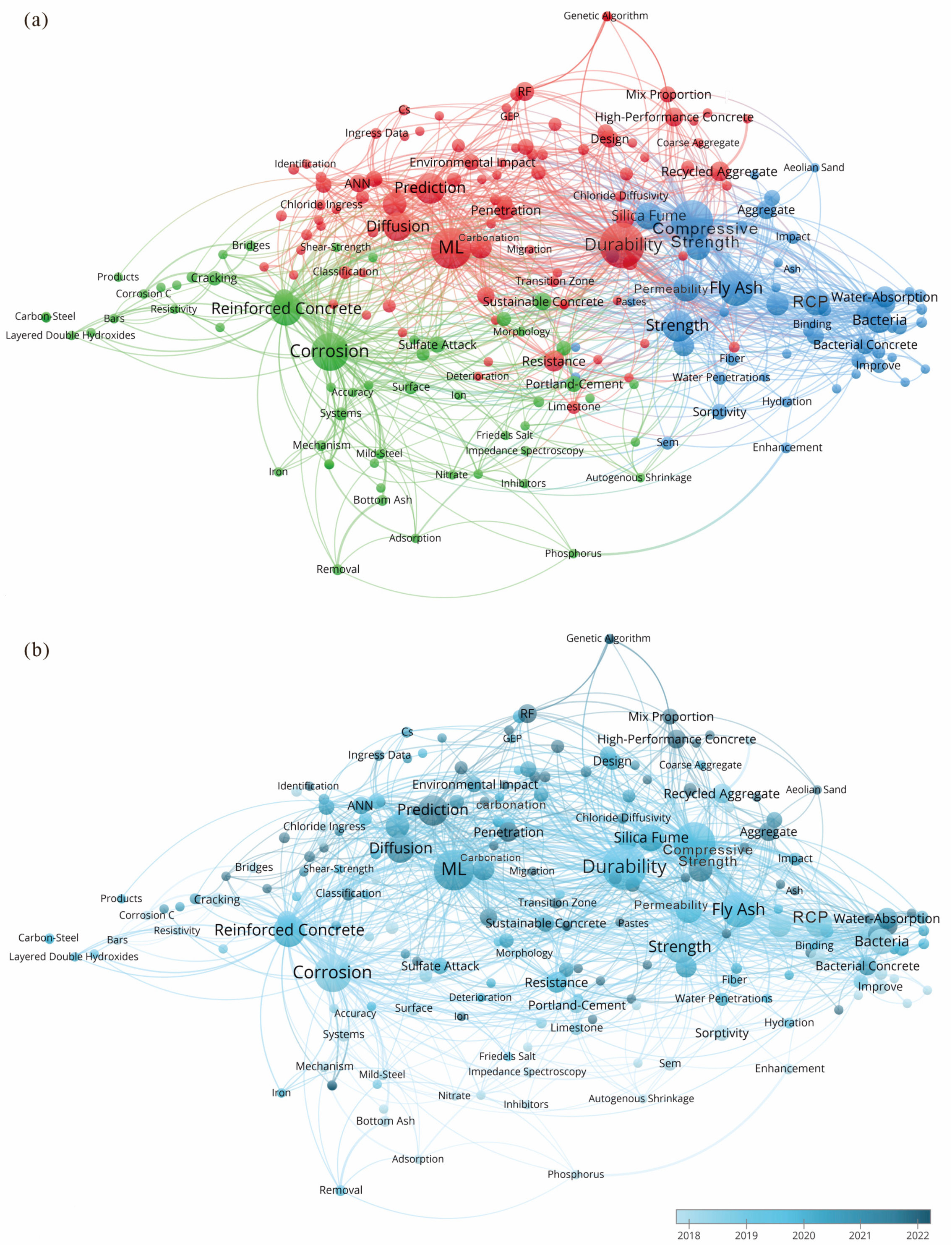

- Research on concrete strength is weakening, while research on ML is becoming more important, e.g., ‘RF’ and ‘genetic algorithm’.

- (2)

- Research on chloride corrosion of concrete is transitioning from durability to model prediction.

- (3)

- Emphasis is placed on the use of other auxiliary materials to obtain better performing concrete, such as the use of bacterial cultures to make concrete.

5.2. Application of Machine Learning to Chloride Penetrations

5.3. Application of Machine Learning in Determining Surface Chloride Ion Concentrations

5.4. Challenges and Future of Machine Learning for Marine Concrete Corrosion

5.4.1. Challenges for Machine Learning for Marine Concrete Corrosion

- (1)

- Difficulty in data collection.

- (2)

- Poor portability of the model.

- (3)

- Inadequate interpretation of data.

- (4)

- Challenges in incorporating concrete curing conditions into machine learning models.

5.4.2. Future Development of Machine Learning for Marine Concrete Corrosion

- (1)

- Data and model sharing and standardization.

- (2)

- Optimization and extension of models.

- (3)

- Optimizing curing conditions.

6. Summary and Outlook

- (1)

- The paper summarized six diffusion models for chloride ions and mainly focused on the convection phenomenon, in which the chloride ion concentration at a certain distance from the concrete surface does not conform to the diffusion law. The introduction of the concretion zone depth can most accurately reflect the diffusion of chloride ions in concrete.

- (2)

- The current status of time-varying and multifactorial models for studying the surface chloride concentration of marine concrete was presented through empirical analysis based on different influencing factors. There is a lack of coupled studies on mineral admixtures. In addition, the existence of “relative theory” may require modification of the model when applied to different conditions or scenarios.

- (3)

- The application of machine learning models in concrete engineering allows for deep learning of nonlinear relationships between multiple factors with good fitting, high accuracy, and high predictive ability, thus compensating for the limitations of empirical models and avoiding repetitive experiments. With new iterations of artificial intelligence and scientific paradigms, machine learning can also make better use of the discovered knowledge to study the corrosion conditions of concrete, extend the study of surface chloride concentration, and optimize the performance of marine concrete. Therefore, future work in machine learning, including the combination and optimization of different algorithms, should receive more attention.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Parameters |

| C | concentration of chloride ions |

| Cs | surface chloride ion concentration |

| D | diffusion coefficient |

| Ds | diffusion coefficient of chloride ions |

| t | diffusion time |

| x | distance from the concrete surface |

| Δx | convection depth |

| C(x,t) | chloride ion concentration at depth x and time t |

| DZ | diffusion zone |

| CZ | convection zone |

| OPC | Ordinary Portland Cement |

| w/c | water–cement ratio |

| /x | concentration gradient |

| ML | machine learning |

| RCP | rapid chloride permeability |

| DT | decision tree |

| RF | random forest |

| GA | genetic algorithm |

| BPNN | back-propagation neural network |

| DCL | chloride diffusion coefficient |

| LR | linear regression |

| EL | ensemble learning |

| ANN | artificial neural network |

| SVM | support vector machine |

| CNN | convolutional neural network |

| HCFA | high-calcium fly ash |

| Xgboost | extreme gradient boosting |

References

- European Commission, Directorate-General for Maritime Affairs and Fisheries. Progress of the EU’s Integrated Maritime Policy—Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Union Publications: Luxembourg, 2012. [Google Scholar] [CrossRef]

- The Central People’s Government of the People’s Republic of China. Report of the 19th National Congress of the Communist Party of China. 2017. Available online: https://www.gov.cn/zhuanti/2017-10/27/content_5234876.htm (accessed on 21 September 2023).

- The Central People’s Government of the People’s Republic of China. Report of the 20th National Congress of the Communist Party of China. 2022. Available online: https://www.gov.cn/xinwen/2022-10/25/content_5721685.htm (accessed on 21 September 2023).

- European Commission; Directorate-General for Maritime Affairs and Fisheries, Joint Research Centre; Addamo, A.; Calvo Santos, A.; Guillén, J.; Neehus, S.; Peralta Baptista, A.; Quatrini, S.; Telsnig, T.; Petrucco, G. The EU Blue Economy Report 2022; European Union Publications: Luxembourg, 2022. [Google Scholar] [CrossRef]

- Ministry of Land and Resources of the People’s Republic of China. Statistical Bulletin on China’s Marine Economy, 2021. 2022. Available online: http://gi.mnr.gov.cn/202204/t20220406_2732610.html (accessed on 21 September 2023).

- Gu, C.P.; Sun, W.; Guo, L.P.; Wang, Q.N. Ultrahigh Performance Concrete: A Potential Material for Sustainable Marine Construction in View of the Service Life. Appl. Mech. Mater. 2013, 438–439, 108–112. [Google Scholar] [CrossRef]

- Fiol, F.; Revilla-Cuesta, V.; Thomas, C.; Manso, J.M. Self-compacting concrete containing coarse recycled precast-concrete aggregate and its durability in marine-environment-related tests. Constr. Build. Mater. 2023, 377, 131084. [Google Scholar] [CrossRef]

- Shafikhani, M.; Chidiac, S.E. A holistic model for cement paste and concrete chloride diffusion coefficient. Cem. Concr. Res. 2020, 133, 106049. [Google Scholar] [CrossRef]

- People’s Daily Online. China’s Marine Corrosion Annual Loss of 700 Billion and If the Protection in Place Can Reduce the Loss of One-Third. 2022. Available online: http://env.people.com.cn/n1/2018/0424/c1010-29947830.html (accessed on 21 September 2023).

- Parkinson, R.W. Speculation on the role of sea-level rise in the tragic collapse of the Surfside condominium (Miami Beach, Florida U.S.A.) was a bellwether moment for coastal zone management practitioners. Ocean Coast Manag. 2021, 215, 105968. [Google Scholar] [CrossRef]

- Zhou, Y.; Gencturk, B.; Willam, K.; Attar, A. Carbonation-Induced and Chloride-Induced Corrosion in Reinforced Concrete Structures. J. Mater. Civ. Eng. 2015, 27, 04014245-1. [Google Scholar] [CrossRef]

- Yu, Z.; Chen, Y.; Liu, P.; Wang, W. Accelerated simulation of chloride ingress into concrete under drying–wetting alternation condition chloride environment. Constr. Build. Mater. 2015, 93, 205–213. [Google Scholar] [CrossRef]

- Liu, Z.; Gan, L.; Rong, H. Durability of concrete exposed to laboratory-simulated marine microbe-induced corrosion. Constr. Build. Mater. 2023, 400, 132563. [Google Scholar] [CrossRef]

- Huang, Y.; Luo, K.; Qin, L. Effects of chloride ions on the durability and protection of concrete structures in marine environments. China Sci. Technol. Inf. 2022, 114–116. [Google Scholar]

- Jung, J.S.; Bang, Y.L.; Lee, K.S. Experimental Study on the Structural Performance Degradation of Corrosion-Damaged Reinforced Concrete Beams. Adv. Civ. Eng. 2019, 2019, 9562574. [Google Scholar] [CrossRef]

- Lu, C.; Yuan, S.; Cheng, P.; Liu, R. Mechanical properties of corroded steel bars in pre-cracked concrete suffering from chloride attack. Constr. Build. Mater. 2016, 123, 649–660. [Google Scholar] [CrossRef]

- Jin, Z.; Zhao, X.; Zhao, T.; Li, J. Chloride ions transportation behavior and binding capacity of concrete exposed to different marine corrosion zones. Constr. Build. Mate. 2018, 177, 170–183. [Google Scholar] [CrossRef]

- Tang, X.; Xu, Q.; Qian, K.; Ruan, S.; Lian, S.; Zhan, S. Effects of cyclic seawater exposure on the mechanical performance and chloride penetration of calcium sulfoaluminate concrete. Constr. Build. Mater. 2021, 303, 124139. [Google Scholar] [CrossRef]

- Al-Sodani, K.A.A.; Al-Zahrani, M.M.; Maslehuddin, M.; Al-Amoudi, O.S.B.; Al-Dulaijan, S.U. Chloride diffusion models for plain and blended cement concretes exposed to laboratory and atmospheric marine conditions. J. Mater. Res. Technol. 2022, 17, 125–138. [Google Scholar] [CrossRef]

- Ashrafian, A.; Panahi, E.; Salehi, S.; Amiri, M. On the implementation of the interpretable data-intelligence model for designing service life of structural concrete in a marine environment. Ocean. Eng. 2022, 256, 111523. [Google Scholar] [CrossRef]

- Yu, F.; Gao, W.; Liu, W. Mechanism analysis and model calculation of chloride ion diffusion in reinforced concrete structure. E3S Web Conf. 2020, 198, 1035. [Google Scholar] [CrossRef]

- Liao, C.; Jin, H.; Liu, W.; Liu, J.; Zhong, S.; Xing, F.; Tang, L. Numerical and experimental analysis of chloride and iodide transports in concrete under natural diffusion. Constr. Build. Mater. 2023, 392, 131902. [Google Scholar] [CrossRef]

- Wang, G.; Wu, Q.; Zhou, H.; Peng, C.; Chen, W. Diffusion of chloride ion in coral aggregate seawater concrete under marine environment. Constr. Build. Mater. 2021, 284, 122821. [Google Scholar] [CrossRef]

- Bao, J.; Wei, J.; Zhang, P.; Zhuang, Z.; Zhao, T. Experimental and theoretical investigation of chloride ingress into concrete exposed to real marine environment. Cem. Concr. Compos. 2022, 130, 104511. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, K.; Tan, Y. Review of research on the influencing factors of chloride Ion diffusional concrete. Mater. Rep. 2021, 35, 13109–13118. [Google Scholar]

- Tipu, R.K.; Batra, V.; Suman; Panchal, V.R.; Pandya, K.S. Predictive modelling of surface chloride concentration in marine concrete structures: A comparative analysis of machine learning approaches. Asian J. Civ. Eng. 2023, 25, 1443–1465. [Google Scholar] [CrossRef]

- Jiang, Q.M.; Nong, Z.L. Summary of field exposure test of marine concrete structures. Sci. Technol. Eng. 2022, 22, 3425–3440. [Google Scholar]

- Lv, Z. Summary of main factors affecting chloride ion concentration on concrete surface. Urban Roads Bridges Flood Control 2021, 182–185. [Google Scholar] [CrossRef]

- Shakir, Q.; Alliwe, R. Upgrading of deficient disturbed regions in precast rc beams with Near Surface Mounted (NSM) Steel Bars. J. Mater. Eng. Struct. 2020, 7, 167–184. [Google Scholar]

- Shakir, Q.; Hannon, H.K. New models for reinforced concrete precast hybrid deep beams under static loads with curved hybridization. Structures 2023, 54, 1007–1025. [Google Scholar] [CrossRef]

- Shakir, Q.M.; Yahya, Y.M. Stitching of T-deep beams with large openings by CFRP sheets and NSM steel bars. Pollack Period 2024. [Google Scholar] [CrossRef]

- Shakir, Q.M.; Hannon, H.K. Innovative model of precast rc curved hybrid deep beams composed partially with high- performance concrete. Asian J. Civ. Eng. 2024, 49, 6045–6060. [Google Scholar] [CrossRef]

- Shakir, Q.M.; Farooq, A. New model of eco-friendly hybrid deep beams with wastes of crushed concrete. J. Teknol. 2023, 85, 145–154. [Google Scholar] [CrossRef]

- Wiesenburg, D.A.; Little, B.J.; A Synopsis of the chemical/physical properties of seawater. Ocean. Phys. Eng. 1988. Available online: https://api.semanticscholar.org/CorpusID:92192370 (accessed on 28 May 2024).

- Sun, D.; Cao, Z.; Huang, C.; Wu, K.; De Schutter, G.; Zhang, L. Degradation of concrete in marine environment under coupled chloride and sulfate attack: A numerical and experimental study. Case Stud. Constr. Mater. 2022, 17, e01218. [Google Scholar] [CrossRef]

- Metalssi, O.O.; Touhami, R.; Barberon, F.; Lacaillerie, J.D.D.; Roussel, N.; Divet, L.; Torrenti, J. Understanding the degradation mechanisms of cement-based systems in combined chloride-sulfate attack. Cem. Concr. Res. 2023, 164, 107065. [Google Scholar] [CrossRef]

- Ran, B.; Omikrine-Metalssi, O.; Fen-Chong, T.; Dangla, P.; Li, K. Impact of leaching and chlorides on sulfate attack for cement paste. Constr. Build. Mater. 2023, 376, 130881. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, L.; Bindiganavile, V.; Yi, C. Coupled models to describe the combined diffusion-reaction behaviour of chloride and sulphate ions in cement-based systems. Constr. Build. Mater. 2020, 243, 118232. [Google Scholar] [CrossRef]

- Jin, Z.Q.; Sun, W.; Zhang, Y.S.; Jiang, J.Y. Damage of concrete in sulfate and chloride solution. J. Chin. Ceram. Soc. 2006, 34, 6. [Google Scholar]

- Cheng, S.; Shui, Z.; Sun, T.; Gao, X.; Guo, C. Effects of sulfate and magnesium ion on the chloride transportation behavior and binding capacity of Portland cement mortar. Constr. Build. Mater. 2019, 204, 265–275. [Google Scholar] [CrossRef]

- Wang, P.G.; Mo, R.; Sui, X.M.; Tian, S.; Xu, J.; Jin, Z.Q. Chemo-Damage-Transport Model of Combined Chloride-sulfate Attack in Concrete. J. Chin. Ceram. Soc. 2022, 50, 512–521. [Google Scholar] [CrossRef]

- Cai, Y.X.; Liu, Q.F. Numerical Estimation on Chloride Erosion Resistance of Alkali-Activated Concrete. J. Build. Mater. 2023, 26, 596–603. [Google Scholar]

- Zhuang, Z.; Mu, S.; Guo, Z.; Liu, G.; Zhang, J.; Miao, C. Diffusion-reaction models for concrete exposed to chloride-sulfate attack based on porosity and water saturation. Cem. Concr. Compos. 2024, 146, 105378. [Google Scholar] [CrossRef]

- Liu, K.; Sun, Y.; Shen, S.; Sun, D.; Wang, A.; Wang, Y. Application of sulfate ion fixation in internal sulfate attack: The gel containing barium salt. Case Stud. Constr. Mater. 2024, 20, e02873. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, C.K.; Jin, W.L.; Xu, C. Experimental analysis on time-dependent law of surface chloride ion concentration of concrete. J. Civ. Environ. Eng. 2010, 32, 8–13. [Google Scholar]

- Jin, W.L.; Zhao, Y.L. Durability of Concrete Structures, 2nd ed.; Science Press: Beijing, China, 2014; p. 372. [Google Scholar]

- Rui, W. Research on Numerical Analysis of Chloride Ion Erosion of Concrete under Continuous Load; Dalian Jiaotong University: Dalian, China, 2018. [Google Scholar]

- Yuan, L.Q.; Sun, C.L.; Cheng, H.Y. Research review of transport mode of chlorine ion in concrete under unsaturated state. Concrete 2015, 32–36. [Google Scholar]

- Zhuo, W.; Yan, Q.; Yang, Z.; Lin, S.; Lin, K.; He, F.; Liu, J. Chloride Penetration in Coastal Concrete Structures: Field Investigation and Model Development. Adv. Mater. Sci. Eng. 2019, 2019, 4537283. [Google Scholar] [CrossRef]

- Jin, W.L.; Zhang, Y.; Lu, Z.Y. Mechanism and mathematic modeling of chloride permeation in concrete under unsaturated state. J. Chin. Ceram. Soc. 2008, 36, 1362–1369. [Google Scholar]

- Andrade, C.; Díez, J.M.; Alonso, C. Mathematical Modeling of a Concrete Surface “Skin Effect” on Diffusion in Chloride Contaminated Media. Adv. Cem. Based Mater. 1997, 6, 39–44. [Google Scholar] [CrossRef]

- Collepardi, M.; Marcialis, A.; Turriziani, R. Penetration of Chloride Ions into Cement Pastes and Concretes. J. Am. Ceram. Soc. 1972, 55, 534–535. [Google Scholar] [CrossRef]

- Yao, S.W.; Wu, P. Analytical solution to chloride diffusion equation. Technol. Manag. Port Harb. Eng. 2006, 9. [Google Scholar]

- Chen, R.X.; Liu, J.P.; Mu, S. Chloride ion penetration resistance and micro structural modification of concrete with the addition of calcium stearate. Constr. Build. Mater. 2022, 321, 126188. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Kong, D. Chloride diffusivity analysis of existing concrete based on Fick’s second law. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 142–146. [Google Scholar] [CrossRef]

- Walraven, J. fib Model Code for Concrete Structures 2010: Mastering challenges and encountering new ones. Struct. Concr. 2013, 14, 3–9. [Google Scholar] [CrossRef]

- Walraven, J.; Balazs, G.L. fib Model Code for Concrete Structures 2010: A landmark in an ongoing development. Struct. Concr. 2013, 14, 1–2. [Google Scholar] [CrossRef]

- Walraven, J.; Bigaj, A. The 2010 fib Model Code for Concrete Structures: A new approach to structural engineering. Struct. Concr. 2011, 12, 139–147. [Google Scholar] [CrossRef]

- Yang, L.F.; Ma, Q.; Yu, B. Analytical solution and experimental validation for dual time-dependent chloride diffusion in concrete. Constr. Build. Mater. 2018, 161, 676–686. [Google Scholar] [CrossRef]

- Yang, X.S.; Wang, Y.J.; Zhai, H.R.; Wang, G.Y.; Su, Y.J.; Dai, L.H.; Ogata, S.; Zhang, T.Y. Time, stress and temperature-dependent deformation in nanostructured copper: Stress relaxation tests and simulations. Acta Mater. 2016, 94, 191–206. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, K. Comparisons of instantaneous chloride diffusion coefficients determined by RCM method and chloride natural diffusion test. Constr. Build. Mater. 2019, 223, 595–604. [Google Scholar] [CrossRef]

- Medeiros, M.H.F.; Helene, P. Surface treatment of reinforced concrete in marine environment: Influence on chloride diffusion coefficient and capillary water absorption. Constr. Build. Mater. 2009, 23, 1476–1484. [Google Scholar] [CrossRef]

- Li, K.F.; Zhang, D.D.; Li, Q.W.; Fan, Z.H. Durability for concrete structures in marine environments of HZM project: Design, assessment and beyond. Cem. Concr. Res. 2019, 115, 545–558. [Google Scholar] [CrossRef]

- Wang, P.; Mo, R.; Li, S.; Xu, J.; Wang, D. A chemo-damage-transport model for chloride ions diffusion in cement-based materials: Combined effects of sulfate attack and temperature. Constr. Build. Mater. 2021, 288, 123121. [Google Scholar] [CrossRef]

- Li, K.F.; Zhao, F.Y.; Zhang, Y.M. Influence of carbonation on the chloride ingress into concrete: Theoretical analysis and application to durability design. Cem. Concr. Res. 2019, 123, 105788. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, Z.; Du, J.; Sui, L.; Xing, F. Bond behavior of FRP-to-concrete interface under sulfate attack: An experimental study and modeling of bond degradation. Constr. Build. Mater. 2015, 85, 9–21. [Google Scholar] [CrossRef]

- Bao, J.; Li, S.; Yu, Z.; Xu, J.; Li, Y.; Zhang, P.; Si, Z.; Gao, S. Water transport in recycled aggregate concrete under sustained compressive loading: Experimental investigation and mesoscale numerical modelling. J. Build. Mater. 2021, 44, 103373. [Google Scholar] [CrossRef]

- Liu, Q.F.; Easterbrook, D.; Jian, Y.; Li, L.Y. A three-phase, multi-component ionic transport model for simulation of chloride penetration in concrete. Eng. Struct. 2015, 86, 122–133. [Google Scholar] [CrossRef]

- Xue, S.; Zhang, P.; Bao, J.; He, L.; Hu, Y.; Yang, S. Comparison of Mercury Intrusion Porosimetry and multi-scale X-ray CT on characterizing the microstructure of heat-treated cement mortar. Mater. Charact. 2020, 160, 110085. [Google Scholar] [CrossRef]

- Pang, L.; Li, Q.W. Service life prediction of RC structures in marine environment using long term chloride ingress data: Comparison between exposure trials and real structure surveys. Constr. Build. Mater. 2016, 113, 979–987. [Google Scholar] [CrossRef]

- Liu, Q.F.; Hu, Z.; Lu, X.Y.; Yang, J.; Sun, W. Prediction of Chloride Distribution for Offshore Concrete Based on Statistical Analysis. Materials 2020, 13, 174. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Lounis, Z. Sensitivity analysis of simplified diffusion-based corrosion initiation model of concrete structures exposed to chlorides. Cem. Concr. Res. 2006, 36, 1312–1323. [Google Scholar] [CrossRef]

- Cai, R. Study on Multi-Factor Computational Models of Surface Chloride Concentration for Concrete Exposed to Marine Environment. Ph.D. Thesis, Guangxi University, Nanning, China, 2017; p. 188. [Google Scholar]

- Moradllo, M.K.; Sadati, S.; Shekarchi, M. Quantifying maximum phenomenon in chloride ion profiles and its influence on service-life prediction of concrete structures exposed to seawater tidal zone—A field oriented study. Constr. Build. Mater. 2018, 180, 109–116. [Google Scholar] [CrossRef]

- Liu, P.; Yu, Z.; Lu, Z.; Chen, Y.; Liu, X. Predictive convection zone depth of chloride in concrete under chloride environment. Cem. Concr. Compos. 2016, 72, 257–267. [Google Scholar] [CrossRef]

- Gao, Y.H.; Zhang, J.Z.; Zhang, S.; Zhang, Y.R. Probability distribution of convection zone depth of chloride in concrete in a marine tidal environment. Constr. Build. Mater. 2017, 140, 485–495. [Google Scholar] [CrossRef]

- Dawang, L.; Long-yuan, L.; Ping, L.; Yao-cheng, W. Modelling of convection, diffusion and binding of chlorides in concrete during wetting-drying cycles. Mar. Struct. 2022, 84, 103240. [Google Scholar]

- .Andrade, C.; Climent, M.A.; de Vera, G. Procedure for calculating the chloride diffusion coefficient and surface concentration from a profile having a maximum beyond the concrete surface. Mater. Struct. 2015, 48, 863–869. [Google Scholar] [CrossRef]

- Yan, S.; Liang, Y. A space fractal derivative temperature model in characterization of chloride ions superdiffusion in concrete in a marine environment. J. Build. Mater. 2023, 78, 107669. [Google Scholar] [CrossRef]

- Chang, H.; Mu, S.; Xie, D.; Wang, P. Influence of pore structure and moisture distribution on chloride “maximum phenomenon” in surface layer of specimens exposed to cyclic drying-wetting condition. Constr. Build. Mater. 2017, 131, 16–30. [Google Scholar] [CrossRef]

- Cai, R.; Hu, Y.; Yu, M.; Liao, W.; Yang, L.; Kumar, A.; Ma, H. Skin effect of chloride ingress in marine concrete: A review on the convection zone. Constr. Build. Mater. 2020, 262, 120566. [Google Scholar] [CrossRef]

- Sadati, S.; Arezoumandi, M.; Shekarchi, M. Long-term performance of concrete surface coatings in soil exposure of marine environments. Constr. Build. Mater. 2015, 94, 656–663. [Google Scholar] [CrossRef]

- Sadati, S.; Moradllo, M.K.; Shekarchi, M. Long-term durability of onshore coated concrete—Chloride ion and carbonation effects. Front Struct. Civ. Eng. 2016, 10, 150–161. [Google Scholar] [CrossRef]

- Balestra, C.E.T.; Reichert, T.A.; Pansera, W.A.; Savaris, G. Chloride profile modeling contemplating the convection zone based on concrete structures present for more than 40 years in different marine aggressive zones. Constr. Build. Mater. 2019, 198, 345–358. [Google Scholar] [CrossRef]

- Du, F.; Jin, Z.; She, W.; Xiong, C.; Feng, G.; Fan, J. Chloride ions migration and induced reinforcement corrosion in concrete with cracks: A comparative study of current acceleration and natural marine exposure. Constr. Build. Mater. 2020, 263, 120099. [Google Scholar] [CrossRef]

- Jin, Z.; Chang, H.; Du, F.; Zhao, T.; Jiang, Y.; Chen, Y. Influence of SAP on the chloride penetration and corrosion behavior of steel bar in concrete. Corros. Sci. 2020, 171, 108714. [Google Scholar] [CrossRef]

- Chang, H.; Mu, S.; Feng, P. Influence of carbonation on “maximum phenomenon” in surface layer of specimens subjected to cyclic drying-wetting condition. Cem. Concr. Res. 2018, 103, 95–109. [Google Scholar] [CrossRef]

- Cao, J.; Jin, Z.; Ding, Q.; Xiong, C.; Zhang, G. Influence of the dry/wet ratio on the chloride convection zone of concrete in a marine environment. Constr. Build. Mater. 2022, 316, 125794. [Google Scholar] [CrossRef]

- Balestra, C.E.T.; Reichert, T.A.; Vizzotto, A.L.P.; Pansera, W.A.; Savaris, G. General model for service life analysis of reinforced concrete structures subject to chloride penetration. Constr. Build. Mater. 2021, 305, 124727. [Google Scholar] [CrossRef]

- Pang, S.; Chen, S.X. Study on chloride ion migration in railway reinforced concrete bridges dry and wet cycling environment. Railw. Eng. Technol. Economy. 2020, 35, 18–21. [Google Scholar]

- Gao, Y.H.; Zhao, J.; Zheng, Y.Y.; Zhang, J.Z.; Zhang, Y.R. Similarity and randomness of convection zone depth of chloride in concrete under simulated tidal environment. J. Nat. Disasters 2018, 27, 63–69. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, S.; Zhang, Y.; Zhou, C.; Fu, C. Similarities and probability distributions of chloride convection zone depth in concrete exposed to cyclic drying-wetting environments. Cem. Concr. Compos. 2023, 139, 105040. [Google Scholar] [CrossRef]

- Li, J.Q.; Jin, Z.Q.; Chen, Y.F. Analysis of chloride ion migration rate and formation mechanism of convection zone in marine concrete. Concrete 2017, 55–58. [Google Scholar]

- Cai, R.; Yang, L.F.; Yu, B. Computing model for surface chloride concentration of concrete in marine tidal and splash zones. Ocean Eng. 2014, 32, 25–33. [Google Scholar] [CrossRef]

- Cui, Z.W.; Liu, R.G.; Lu, C.H.; Wang, H.J. Chloride ion erosion and durability life prediction of marine concrete beams under combined action of dry-wet cycle and flexural cracks. Bull. Chin. Ceram. Soc. 2020, 39, 344–351. [Google Scholar] [CrossRef]

- Edvardsen, C.; Engelund, S.; Mohr, L. General Guidelines for Durability Design and Redesign: DuraCrete, Probabilistic Performance Based Durability Design of Concrete Structures; CUR: Gouda, The Netherlands, 2000. [Google Scholar]

- Jin, H.; Liu, J.; Zhong, D.; Tang, L. Experimental study on chloride ion diffusion behavior and microstructure in concrete under alternating ambient humidity conditions. Constr. Build. Mater. 2023, 401, 132886. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, Y.; Yu, H.; Ma, H.; Xu, M.; Xu, Z.; Feng, T. Time variation law of chlorine diffusion coefficient of marine concrete structures in tidal zone and its influence on service life. J. Build. Mater. 2023, 76, 107379. [Google Scholar] [CrossRef]

- Wu, R.; Xia, J.; Chen, J.; Chen, K.; Zheng, Y.; Mao, J.; Wang, J.; Jin, W. Parametrized division of exposure zone for marine reinforced concrete structures with a multi-class Boosting method. Eng. Struct. 2023, 285, 116079. [Google Scholar] [CrossRef]

- Wu, L.; Li, W.; Yu, X. Time-dependent chloride penetration in concrete in marine environments. Constr. Build. Mater. 2017, 152, 406–413. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Bao, J.W.; Zhuang, Z.J.; Zhang, P.; Wei, J.Q.; Gao, S.; Zhao, T.J. Research progress of chloride corrosion resistance of concrete exposed to marine tidal environment based on similarity theory. Mater. Rep. 2021, 35, 7087–7095. [Google Scholar]

- Chen, P.; Jin, Z.Q.; Li, J.Q.; Chen, Y.F. Compressive strength and chloride penetration of SAP concrete in saline soil environment. Ocean Eng. 2017, 35, 50–55. [Google Scholar] [CrossRef]

- Liu, Q.C.; Sun, L.F.; Zhu, X.J.; Xu, L.J.; Zhao, G.C. Chloride transport in the reinforced concrete column under the marine environment: Distinguish the atmospheric, tidal-splash and submerged zones. Structures 2022, 39, 365–377. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, X.L.; Shen, J.; Chen, J.J.; Yu, B.; Jin, W.L. Influence of non-uniform distribution of surface chloride ion concentration of concrete on reinforcement corrosion. Ind. Constr. 2023, 53, 201–207. [Google Scholar] [CrossRef]

- Chen, D.; Mei, G.; Xiao, L. Chloride diffusion in marine pipe pile considering time-dependent surface chloride concentration: Experimental analysis and analytical model. Appl. Ocean. Res. 2023, 140, 103722. [Google Scholar] [CrossRef]

- Yang, L.F.; Cai, R.; Yu, B. Formation mechanism and multi-factor model for surface chloride concentration of concrete in marine atmosphere zone. Chin. Civ. Eng. J. 2017, 50, 46–55. [Google Scholar] [CrossRef]

- Song, H.W.; Lee, C.H.; Ann, K.Y. Factors influencing chloride transport in concrete structures exposed to marine environments. Cem. Concr. Compos. 2008, 30, 113–121. [Google Scholar] [CrossRef]

- Alcala, F.J.; Custodio, E. Atmospheric chloride deposition in continental Spain. Hydrol. Process. 2008, 22, 3636–3650. [Google Scholar] [CrossRef]

- Chen, X.; He, Y.; Lu, L.; Wang, F.; Hu, S. Effects of curing regimes on the chloride binding capacity of cementitious materials. Constr. Build. Mater. 2022, 342, 127929. [Google Scholar] [CrossRef]

- Xu, H.; Chen, J. Coupling effect of corrosion damage on chloride ions diffusion in cement based materials. Constr. Build. Mater. 2020, 243, 118225. [Google Scholar] [CrossRef]

- Jia, H.; Qiao, G.; Han, P. Machine learning algorithms in the environment alcorrosion evaluation of reinforced concrete structures—A review. Cem. Concr. Comps. 2022, 133, 19. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Amiri, O. Study of electrical double layer effect on chloride transport in unsaturated concrete. Constr. Build. Mater. 2014, 50, 492–498. [Google Scholar] [CrossRef]

- Huang, X.; Wang, S.; Lu, T.; Li, H.; Wu, K.; Deng, W. Chloride Permeability Coefficient Prediction of Rubber Concrete Based on the Improved Machine Learning Technical: Modelling and Performance Evaluation. Polymers 2023, 15, 308. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Wu, K.; Wang, S.; Lu, T.; Lu, Y.; Deng, W.; Li, H. Compressive Strength Prediction of Rubber Concrete Based on Artificial Neural Network Model with Hybrid Particle Swarm Optimization Algorithm. Materials 2022, 15, 3934. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Wang, Y.; Ma, G. Multi-objective optimization of concrete mixture proportions using machine learning and metaheuristic algorithms. Constr. Build. Mater. 2020, 253, 119208. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Modeling the mechanical properties of recycled aggregate concrete using hybrid machine learning algorithms. Resour. Conserv. Recy. 2023, 190, 106812. [Google Scholar] [CrossRef]

- Ai, L.; Bayat, M.; Ziehl, P. Localizing damage on stainless steel structures using acoustic emission signals and weighted ensemble regression-based convolutional neural network. Measurement 2023, 211, 112659. [Google Scholar] [CrossRef]

- Laxman, K.C.; Tabassum, N.; Ai, L.; Cole, C.; Ziehl, P. Automated crack detection and crack depth prediction for reinforced concrete structures using deep learning. Constr. Build. Mater. 2023, 370, 130709. [Google Scholar] [CrossRef]

- Chen, C. Multi-Factor Time-Varying Model of Marine Environment Action on Concrete; Guangxi University: Nanning, China, 2019. [Google Scholar]

- Da, B.; Yu, H.F.; Ma, H.Y.; Zhang, Y.D.; Tan, Y.S.; Mi, R.J. Surface free chloride ion concentration and apparent chloride diffusion coefficient of coral seawater concrete. J. Southeast Univ. (Nat. Sci. Edit.) 2016, 46, 1093–1097. [Google Scholar]

- Tan, Y. Experimental Research on the Effect of Mineral Admixtures on Mechanical Properties and Chloride Permeability of Concrete; Tianjin University: Tianjin, China, 2018. [Google Scholar]

- Yu, H.F. Study on High Performance Concrete in Salt Lake: Durability, Mechanism and Service Life Prediction; Southeast University: Nanjing, China, 2004. [Google Scholar]

- Zhou, L.P.; Liu, G.R.; Chen, Y. Similarity relation in time of marine concrete surface chloride concentration. Bull. Chin. Ceram. Soc. 2017, 36, 803–808. [Google Scholar]

- Yang, L.F.; Chen, C.; Yu, B. Multi-factor Time-varying Model of Marine Environmental Action on Concrete in Splash Zone. J. Chin. Ceram. Soc. 2019, 47, 1566–1573. [Google Scholar] [CrossRef]

- Yang, L.F.; Cai, R.; Yu, B. Investigation of computational model for surface chloride concentration of concrete in marine atmosphere zone. Ocean Eng. 2017, 138, 105–111. [Google Scholar] [CrossRef]

- Kassir, M.K.; Ghosn, M. Chloride-induced corrosion of reinforced concrete bridge decks. Cem. Concr. Res. 2002, 32, 139–143. [Google Scholar] [CrossRef]

- Li, Q.; Li, K.; Zhou, X.; Zhang, Q.; Fan, Z. Model-based durability design of concrete structures in Hong Kong–Zhuhai–Macau sea link project. Struct. Saf. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- Song, H.W.; Shim, H.B.; Petcherdchoo, A.; Park, S.K. Service life prediction of repaired concrete structures under chloride environment using finite difference method. Cem. Concr. Comp 2009, 31, 120–127. [Google Scholar] [CrossRef]

- Pack, S.W.; Jung, M.S.; Song, H.W.; Kim, S.H.; Ann, K.Y. Prediction of time dependent chloride transport in concrete structures exposed to a marine environment. Cem. Concr. Res. 2010, 40, 302–312. [Google Scholar] [CrossRef]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment—Part II: Prediction of long term chloride penetration. Mater. Struct. 1999, 32, 354–359. [Google Scholar] [CrossRef]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment—Part I: Main parameters affecting chloride penetration. Mater. Struct. 1999, 32, 252–259. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.F.; Hu, D.; Ma, H.J.; Yuan, Y.F.; Xiao, W.; Wu, Y.L. Surface chloride concentrate of slag concrete exposed to marine environment. Bull. Chin. Ceram. Soc. 2019, 33, 1058–1063. [Google Scholar] [CrossRef]

- Qian, J.Q.; Qian, X.Q.; Zhang, C.Y. Influence of coupled effects of time and tensile stress on chloride diffusion in concrete. Concrete 2022, 28–32. [Google Scholar]

- Amey, S.L.; Johnson, D.A.; Miltenberger, M.A.; Farzam, H. Predicting the Service Life of Concrete Marine Structures: An Environmental Methodology. Struct. J. 1998, 95, 205–214. [Google Scholar]

- Wang, Z.F.; Yang, D.Y.; Li, P. Model of chloride diffusion analysis ontime-dependent surface chloride ion concentration. Concrete 2016, 29–33. [Google Scholar]

- Elahi, M.M.A.; Shearer, C.R.; Naser Rashid Reza, A.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.; Lee, S.; Karthick, S.; Lee, H. Review of the Effects of Supplementary Cementitious Materials and Chemical Additives on the Physical, Mechanical and Durability Properties of Hydraulic Concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef] [PubMed]

- Huo, Y.; Huang, J.; Lu, D.; Han, X.; Sun, H.; Liu, T.; Wang, J.; Wang, F.; Tan, P.; Wang, M.; et al. Durability of alkali-activated slag concrete incorporating silica fume and rice husk ash. J. Build. Mater. 2023, 78, 107637. [Google Scholar] [CrossRef]

- Xue, H.; Jin, Z.Q.; Wang, X.J. Chloride ion penetration into concrete exposed to marine environment for a long period. Ocean Eng. 2015, 33, 60–65. [Google Scholar] [CrossRef]

- JTS 153-2015; Standard for Durability Design of Port and Waterway Engineering Structure. Ministry of Transport CN-JT: Beijing, China, 2015.

- Cai, R.; Yang, L.F.; Xu, B. lmproved model for surface chloride concentration of concrete in marinetidal and splash zones. J. Civ. Env. Eng. 2019, 41, 122–129. [Google Scholar]

- Giannoni, S.M.; Trachte, K.; Rollenbeck, R.; Lehnert, L.; Fuchs, J.; Bendix, J. Atmospheric salt deposition in a tropical mountain rainforest at the eastern Andean slopes of south Ecuador—Pacific or Atlantic origin? Atmos. Chem. Phys. 2016, 16, 10241–10261. [Google Scholar] [CrossRef]

- Liu, J.; Ou, G.; Qiu, Q.; Xing, F.; Tang, K.; Zeng, J. Atmospheric chloride deposition in field concrete at coastal region. Constr. Build. Mater. 2018, 190, 1015–1022. [Google Scholar] [CrossRef]

- LNEC E465; Methodology for Estimating the Concrete Performance Properties Allowing to Comply with the Reinforced or Pre-Stressed Concrete Structures under Environmental Exposures XC and XS. National Laboratory: Lisbon, Portugal, 2007.

- Chen, C.; Yang, L.F.; Yu, B. Multi-factor model and time-varying law for surface chloride concentration of concrete in marine tidal zone. Mater. Rep. 2019, 33, 321–326. [Google Scholar]

- Akiyama, M.; Dan, M.F.; Yoshida, I. Time-dependent reliability analysis of existing RC structures in a marine environment using hazard associated with airborne chlorides. Eng. Struct. 2010, 32, 3768–3779. [Google Scholar] [CrossRef]

- Chalee, W.; Jaturapitakkul, C.; Chindaprasirt, P. Predicting the chloride penetration of fly ash concrete in seawater. Mar. Struct. 2009, 22, 341–353. [Google Scholar] [CrossRef]

- Petcherdchoo, A. Time dependent models of apparent diffusion coefficient and surface chloride for chloride transport in fly ash concrete. Constr. Build. Mater. 2013, 38, 497–507. [Google Scholar] [CrossRef]

- Muthulingam, S.; Rao, B.N. Consistent models for estimating chloride ingress parameters in fly ash concrete. J. Build. Mater. 2015, 3, 24–38. [Google Scholar] [CrossRef]

- Yang, L.F.; Cai, R.; Yu, B. Modeling of environmental action for submerged marine concrete in terms of surface chloride concentration. Struct Concr. 2018, 19, 1512–1520. [Google Scholar] [CrossRef]

- Yang, L.F.; Wang, L.; Yu, B. Time-varying behavior and its coupling effects with environmental conditions and cementitious material types on surface chloride concentration of marine concrete. Constr. Build. Mater. 2021, 303, 124578. [Google Scholar] [CrossRef]

- Yang, J.Y.; Yi, J.W. Experimental research on time-varying regularity of concrete surface chloride ion concentration in coastal atmospheric environment. J. Chin. Foreign Highw. 2018, 38, 290–293. [Google Scholar] [CrossRef]

- Zhang, R.L.; Yang, J.X.; Yi, W.J. Correlation between chloride ion concentration and diffusion coefficient of chloride ions on concrete surface in coastal atmospheric environment. Highway 2018, 63, 304–308. [Google Scholar]

- Dou, X.M.; Yu, H.F.; Ma, H.Y.; Da, B.; Yuan, Y.F.; Mi, R.J.; Zhu, H.Y. Surface chloride concentration profiles of coral concrete exposed to marine environment. Bull. Chin. Ceram. Soc. 2016, 35, 2695–2700. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Abdulalim Alabdullah, A.; Iqbal, M.; Zahid, M.; Khan, K.; Nasir Amin, M.; Jalal, F.E. Prediction of rapid chloride penetration resistance of metakaolin based high strength concrete using light GBM and XGBoost models by incorporating SHAP analysis. Constr. Build. Mater. 2022, 345, 128296. [Google Scholar] [CrossRef]

- Al, F.A.; Alanazi, H. Prediction of Chloride Diffusion Coefficient in Concrete Modified with Supplementary Cementitious Materials Using Machine Learning Algorithms. Materials 2023, 16, 1277. [Google Scholar] [CrossRef]

- Tran, V.Q. Machine learning approach for investigating chloride diffusion coefficient of concrete containing supplementary cementitious materials. Constr. Build. Mater. 2022, 328, 127103. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Kashani, A.; Kim, T.; Arashpour, M. Concrete chloride diffusion modelling using marine creatures-based metaheuristic artificial intelligence. J. Clean. Prod. 2022, 374, 134021. [Google Scholar] [CrossRef]

- Hoang, N.D.; Chen, C.T.; Liao, K.W. Prediction of chloride diffusion in cement mortar using Multi-Gene Genetic Programming and Multivariate Adaptive Regression Splines. Measurement 2017, 112, 141–149. [Google Scholar] [CrossRef]

- Marks, M.; Glinicki, M.A.; Gibas, K. Prediction of the Chloride Resistance of Concrete Modified with High Calcium Fly Ash Using Machine Learning. Materials 2015, 8, 8714–8727. [Google Scholar] [CrossRef] [PubMed]

- Yu, X. Developing an artificial neural network model to predict the durability of the RC beam by machine learning approaches. Case Stud. Constr. Mater. 2022, 17, e01382. [Google Scholar] [CrossRef]

- Taffese, W.; Sistonen, E. Significance of chloride penetration controlling parameters in concrete: Ensemble methods. Con. Build. Mater. 2017, 139, 9–23. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Espinosa-Leal, L. Prediction of chloride resistance level of concrete using machine learning for durability and service life assessment of building structures. J. Build. Mater. 2022, 60, 105146. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Espinosa-Leal, L. A machine learning method for predicting the chloride migration coefficient of concrete. Constr. Build. Mater. 2022, 348, 128566. [Google Scholar] [CrossRef]

- Kabir, H.; Garg, N. Machine learning enabled orthogonal camera goniometry for accurate and robust contact angle measurements. Sci. Rep. 2023, 13, 1497. [Google Scholar] [CrossRef]

- Bolón-Canedo, V.; Remeseiro, B. Feature selection in image analysis: A survey. Artif. Intell. Rev. 2020, 53, 2905–2931. [Google Scholar] [CrossRef]

- Cai, R.; Han, T.; Liao, W.; Huang, J.; Li, D.; Kumar, A.; Ma, H. Prediction of surface chloride concentration of marine concrete using ensemble machine learning. Cem. Concr. Res. 2020, 136, 106164. [Google Scholar] [CrossRef]

- Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Sliwa-Wieczorek, K.; Czarnecki, S. Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material. Materials 2021, 14, 2297. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Guo, R.; Lin, S. Multi-factor fuzzy prediction model of concrete surface chloride concentration with trained samples expanded by random forest algorithm. Mar. Struct. 2022, 86, 103311. [Google Scholar] [CrossRef]

- Hafez, H.; Teirelbar, A.; Kurda, R.; Tošić, N.; de la Fuente, A. Pre-bcc: A novel integrated machine learning framework for predicting mechanical and durability properties of blended cement concrete. Constr. Build. Mater. 2022, 352, 129019. [Google Scholar] [CrossRef]

- Chuang, Y.; Wang, G.; Yang, F.; Liu, Z.; Cai, X.; Du, M.; Hu, X. Efficient XAI Techniques: A Taxonomic Survey. arXiv 2023, arXiv:2302.03225. [Google Scholar]

- Duan, K.; Cao, S.; Zou, Z.; Huang, L.; He, Z. Revealing the nature of concrete materials using soft computing models. J. Build. Mater. 2022, 59, 105148. [Google Scholar] [CrossRef]

| Way | Author | Values of Cs |

|---|---|---|

| I | Tan [122] | Direct measurement of surface concentration |

| II | Moradllo [74] | Maximal concentration |

| III | Bao [24] | Fitting results after removing the depth of the convective zone |

| Da [121] | by considering the time-varying characteristics of Cs |

| Models | Expressions |

|---|---|

| Exponential type [107,123,126,127] | Cs(t) = Ca (1 − exp (−at)) |

| Inverse type [125,128] | Cs(t) = Ca (1/(t + a)) |

| Logarithmic type [129,130] | Cs(t) = a lnt + b |

| Power function type [70,131,132,133,134] | Cs(t) = a tb |

| Linear type [135] | Cs(t) = at |

| Literature | Models | Parameters | Area of Application |

|---|---|---|---|

| Akiyama [147] | γ, the ratio of sea wind. | Atmospheric zone. | |

| DuraCrete [96] | γ, sub-factor, equals to 1.7, 1.4. and 1.2 for durability costs higher than, equal to, or lower than later maintenance costs. | Tidal and splash zones, atmospheric zone. | |

| JTS153-2015 [141] | γ, effect of randomness on Cs, taken as 1.1. m, the regression coefficient. | Tidal zones, splash zones, atmospheric zone. | |

| LNEC-E465 [145] | Ad, Ah, and AT refer to correction coefficients for the nearshore distance, sea level, and temperature of concrete surface. CST, the surface chloride concentration at a given seawater and temperature. | Tidal zones, splash zones. |

| Literature | Models | Parameters | Area of Application |

|---|---|---|---|

| Chalee [148] | -- | Tidal zone. | |

| Petcherdchoo [149] | -- | Tidal zone. | |

| Muthulingam [150] | -- | Tidal zone. | |

| Li [128] | n, the environmental coefficient. Abt, the correction factor for the type of cementitious material to the time-varying law. | Tidal and splash zone. | |

| Yang [107,151] | Cw, the concentration of chloride ions in seawater. | Atmospheric zone. | |

| Underwater zone. | |||

| Wang [136] | G, the effect on sulphate. | All zones. | |

| Chen [120,125,146] | Abt, the correction factor for the type of cementitious material to the time-varying law. | Atmospheric zone. | |

| Tidal zone. | |||

| Splash zone. | |||

| Cai Model I [94] | Ab using the DuraCrete’s coefficient. | Tidal and splash zone. | |

| Cai Model II [142] | A is corrected. | Tidal and splash zone. | |

| Wang Lu [152] | Cw the concentration of chloride ions in seawater. | Tidal zone. | |

| Splash zone. | |||

| Atmospheric zone. | |||

| Underwater zone. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, R.; Li, C.; Guan, X. Advances in Modeling Surface Chloride Concentrations in Concrete Serving in the Marine Environment: A Mini Review. Buildings 2024, 14, 1879. https://doi.org/10.3390/buildings14061879

Zhao R, Li C, Guan X. Advances in Modeling Surface Chloride Concentrations in Concrete Serving in the Marine Environment: A Mini Review. Buildings. 2024; 14(6):1879. https://doi.org/10.3390/buildings14061879

Chicago/Turabian StyleZhao, Ruiqi, Chunfeng Li, and Xuemao Guan. 2024. "Advances in Modeling Surface Chloride Concentrations in Concrete Serving in the Marine Environment: A Mini Review" Buildings 14, no. 6: 1879. https://doi.org/10.3390/buildings14061879

APA StyleZhao, R., Li, C., & Guan, X. (2024). Advances in Modeling Surface Chloride Concentrations in Concrete Serving in the Marine Environment: A Mini Review. Buildings, 14(6), 1879. https://doi.org/10.3390/buildings14061879