Study on Seismic Performance of RC Frame Structures Considering the Effect of Infilled Walls

Abstract

:1. Introduction

2. Materials and Methods

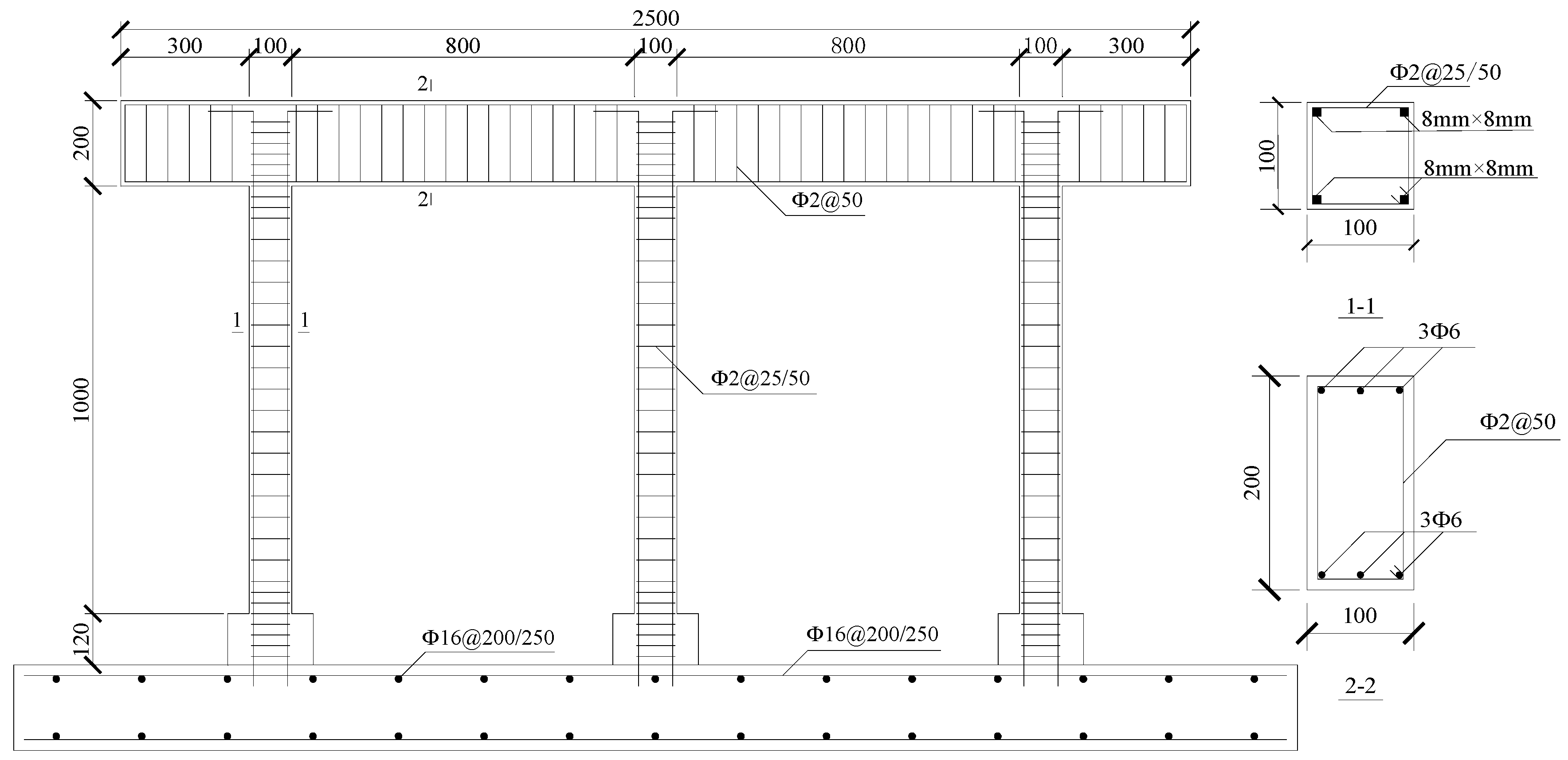

2.1. Design and Manufacturing of Test Model

2.2. Experimental Material

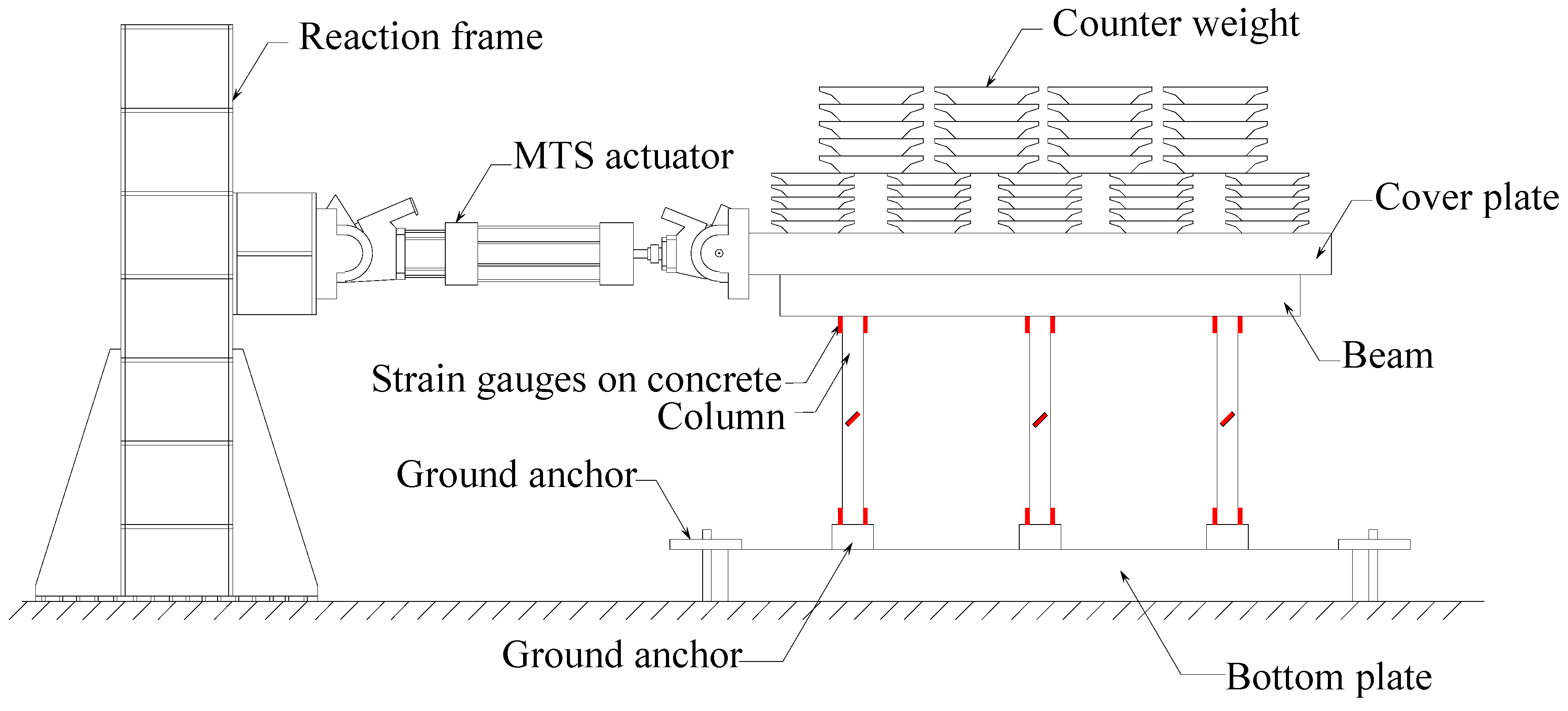

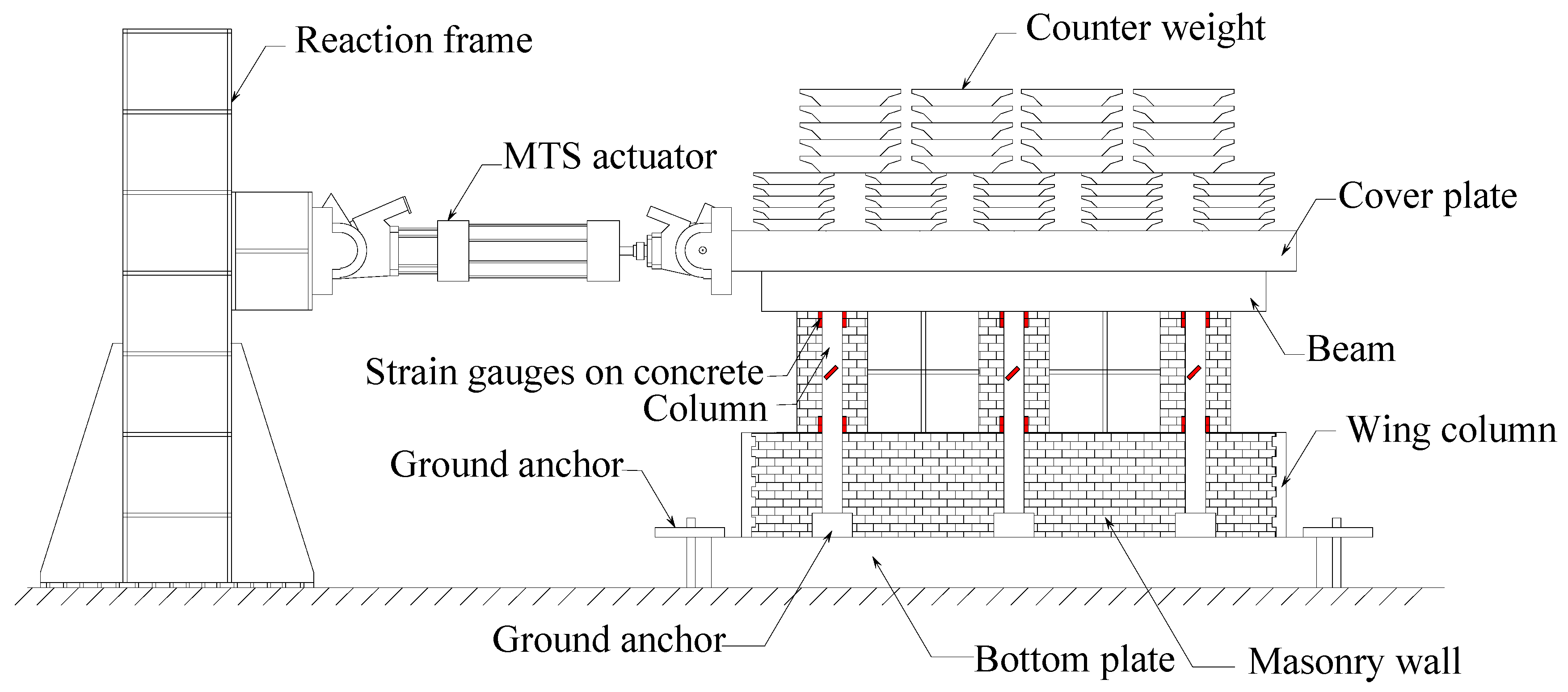

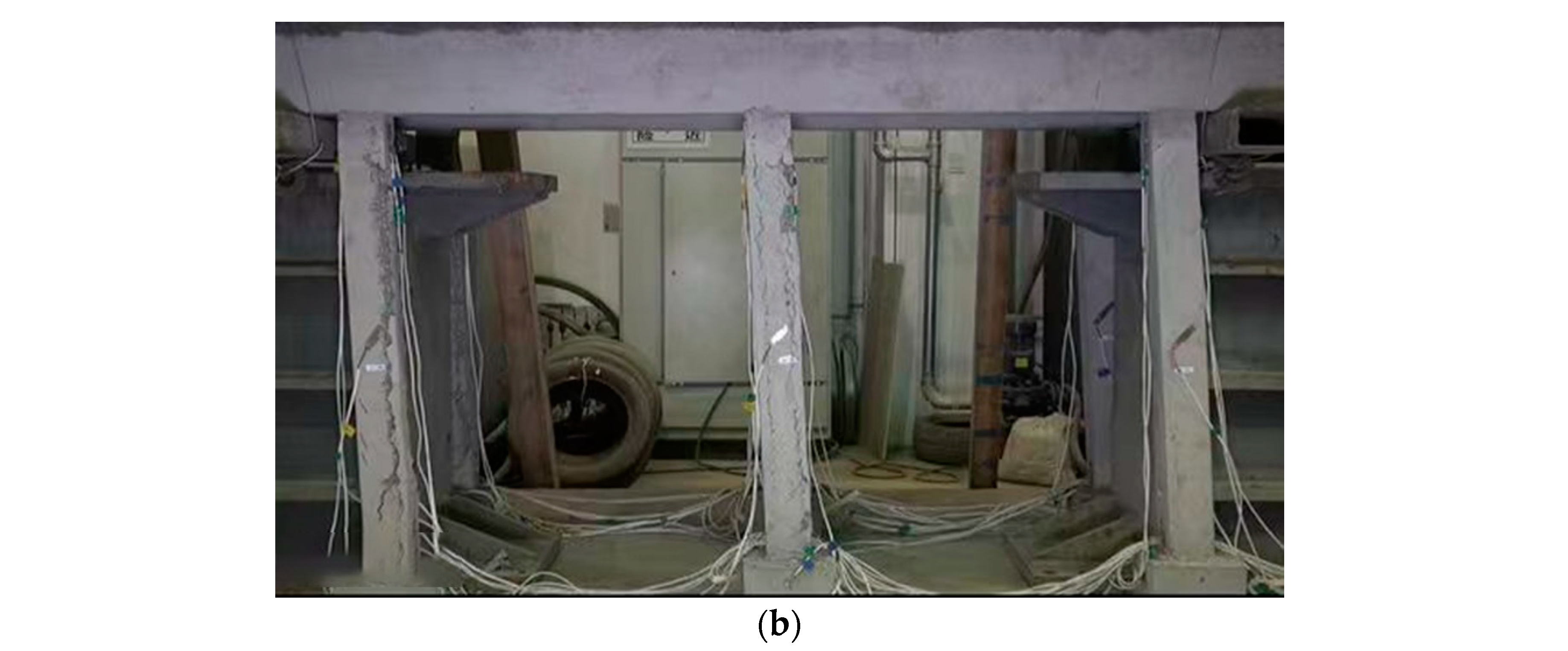

2.3. Experimental Equipment and Loading Scheme

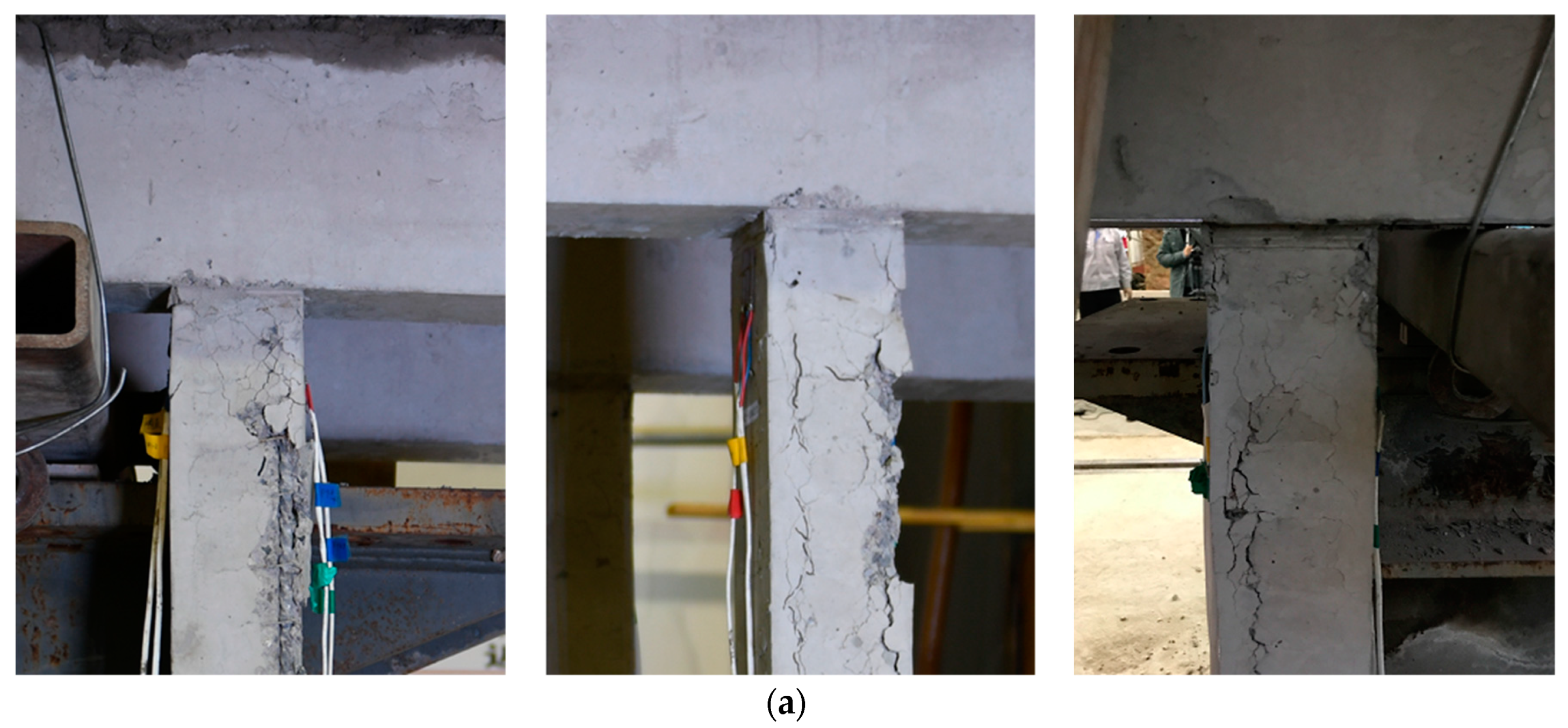

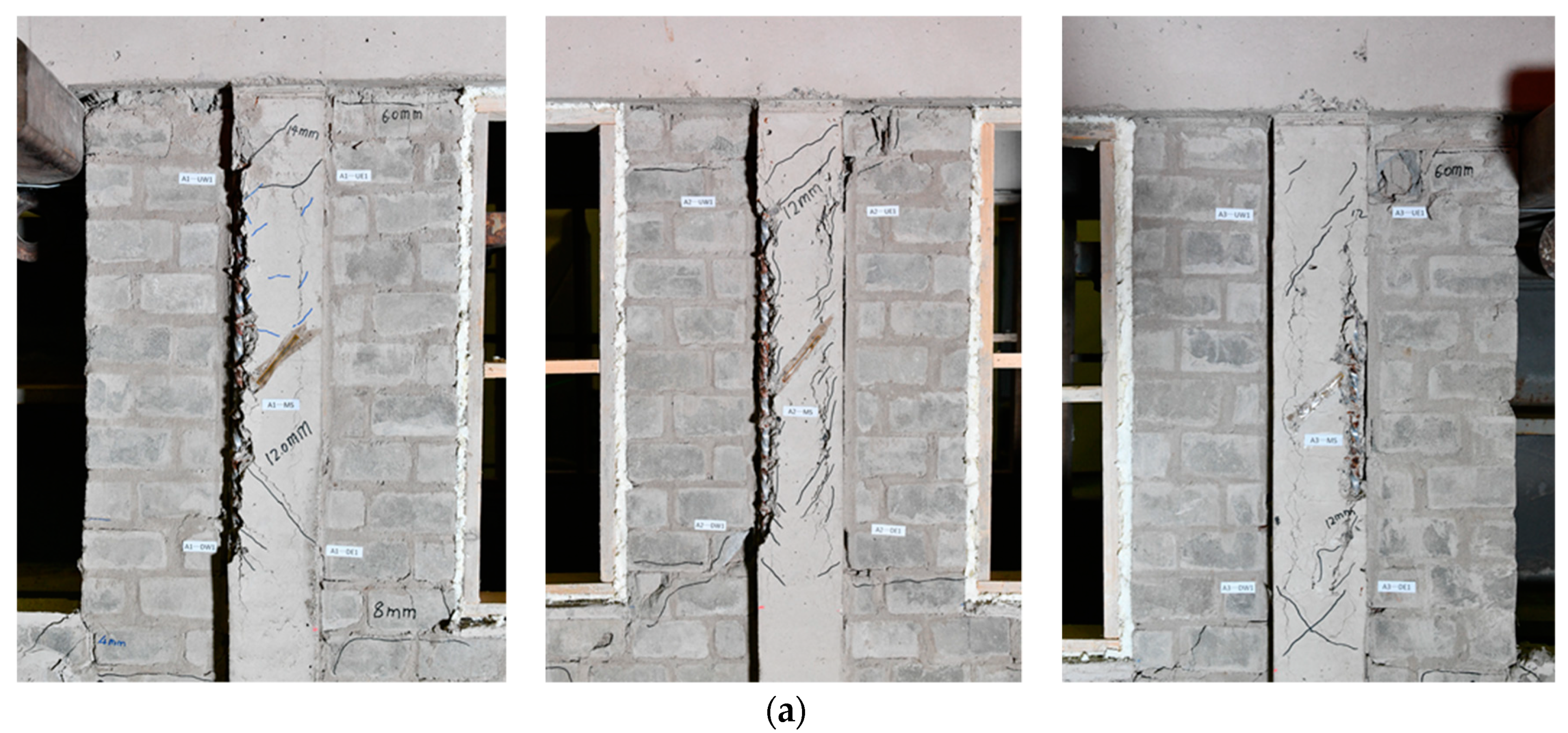

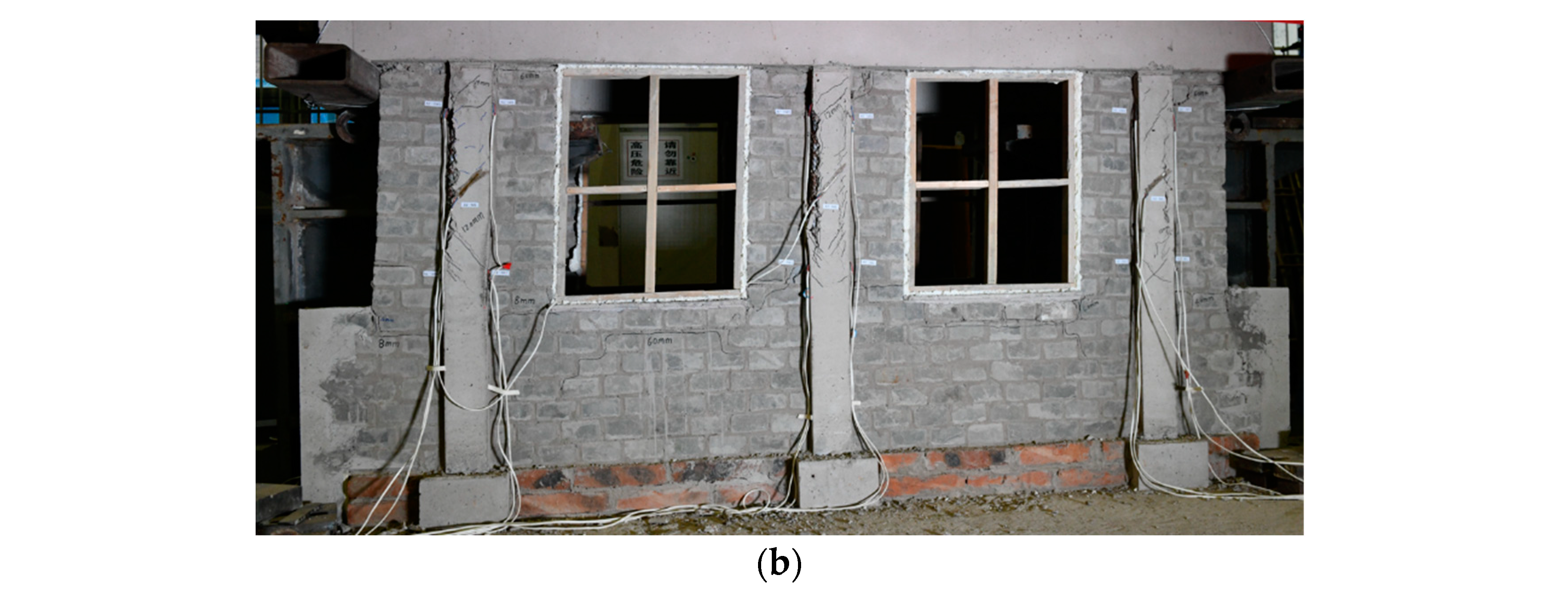

2.4. Experimental Phenomenon Analysis

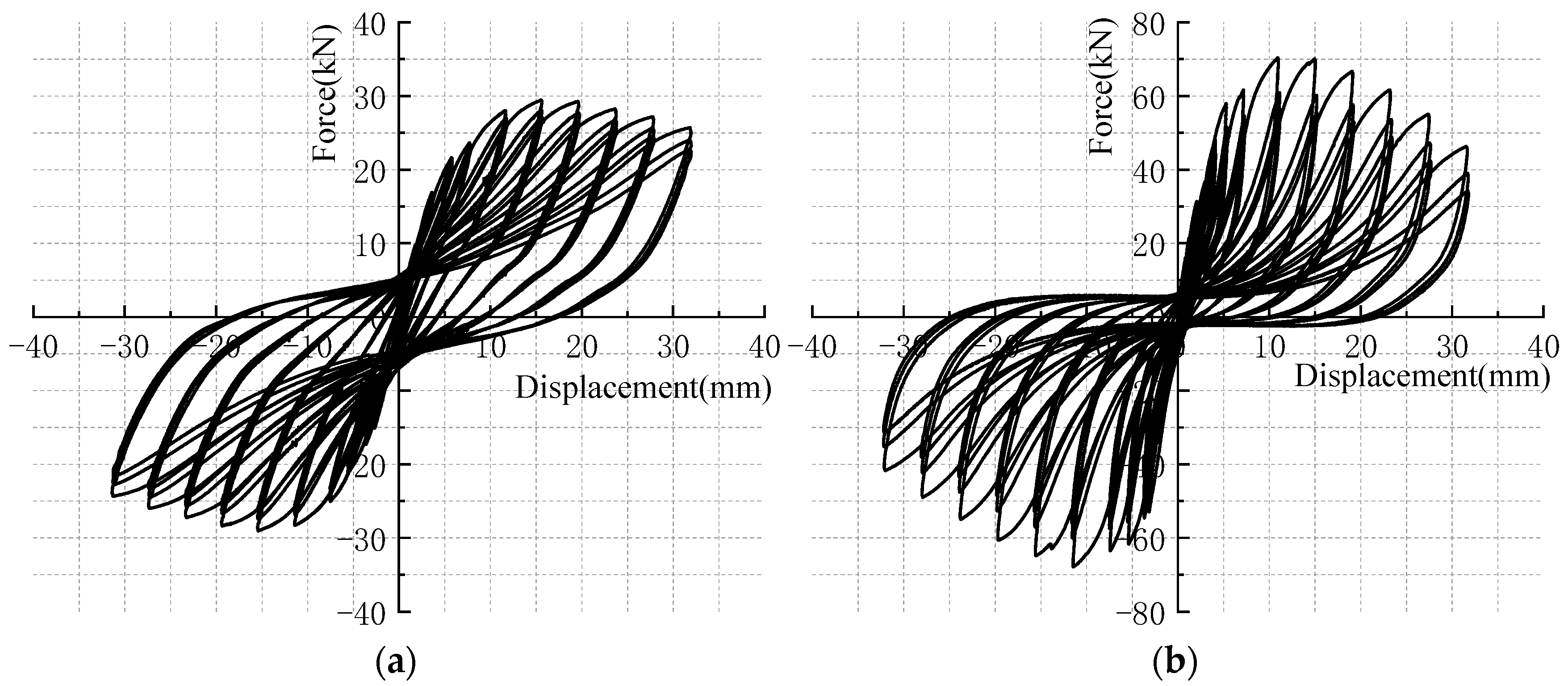

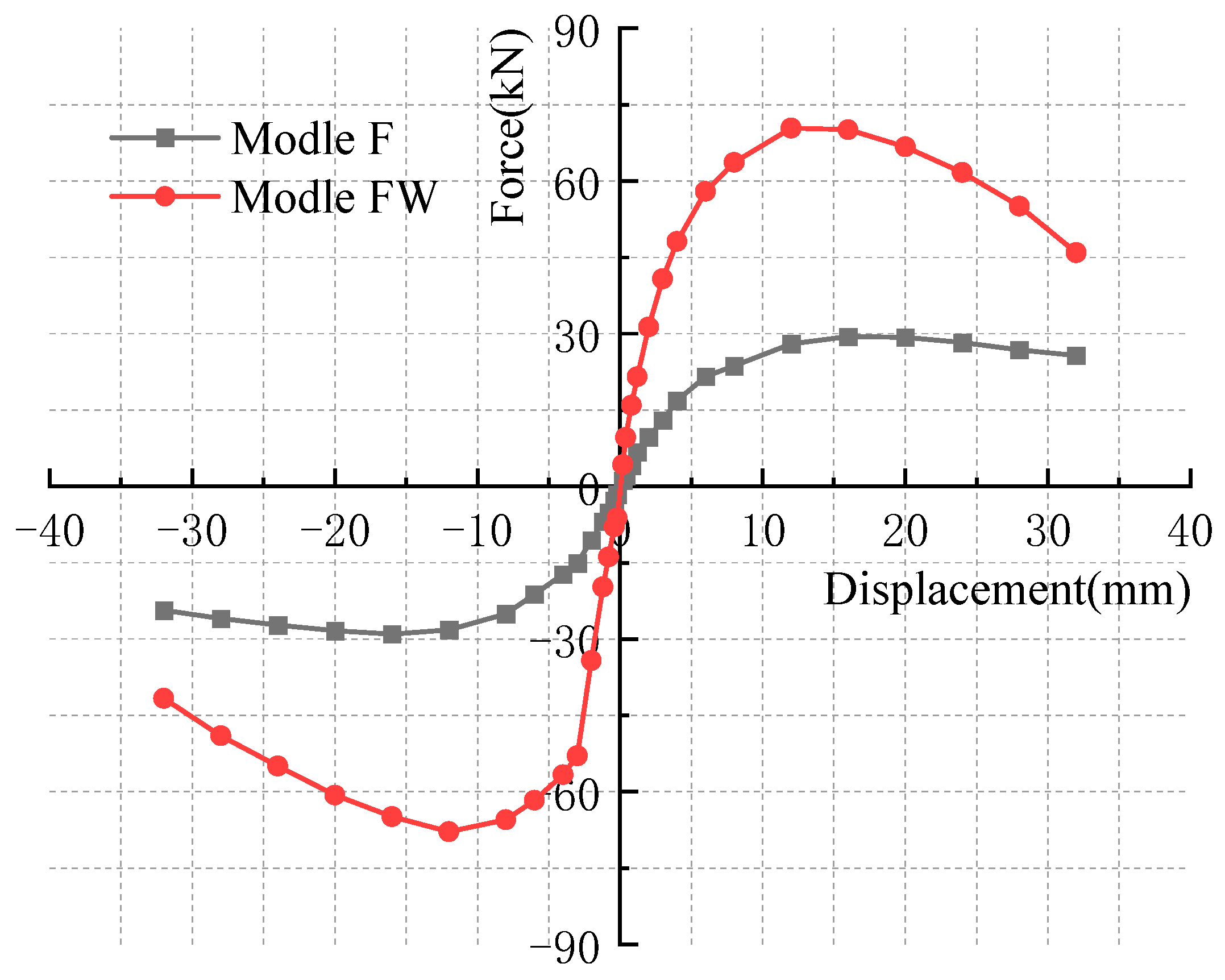

2.5. Experimental Results Analysis

3. Construction of the Numerical Model for RC Frame Structures

3.1. Methodology of Modeling

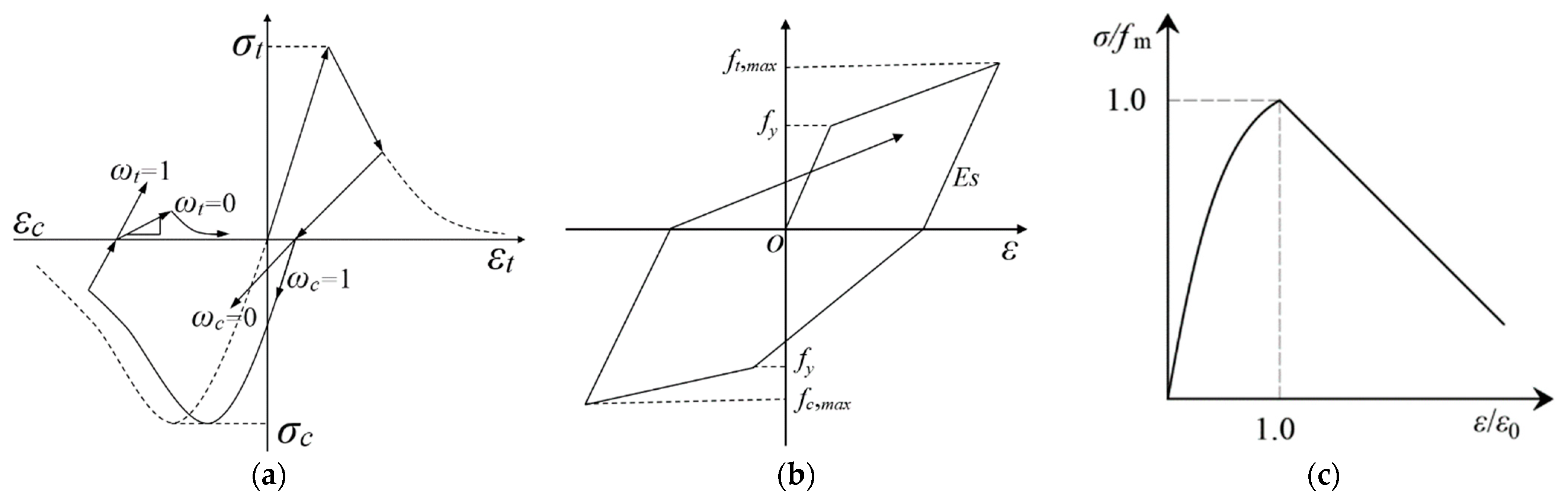

3.2. Constitutive Relationships of Materials

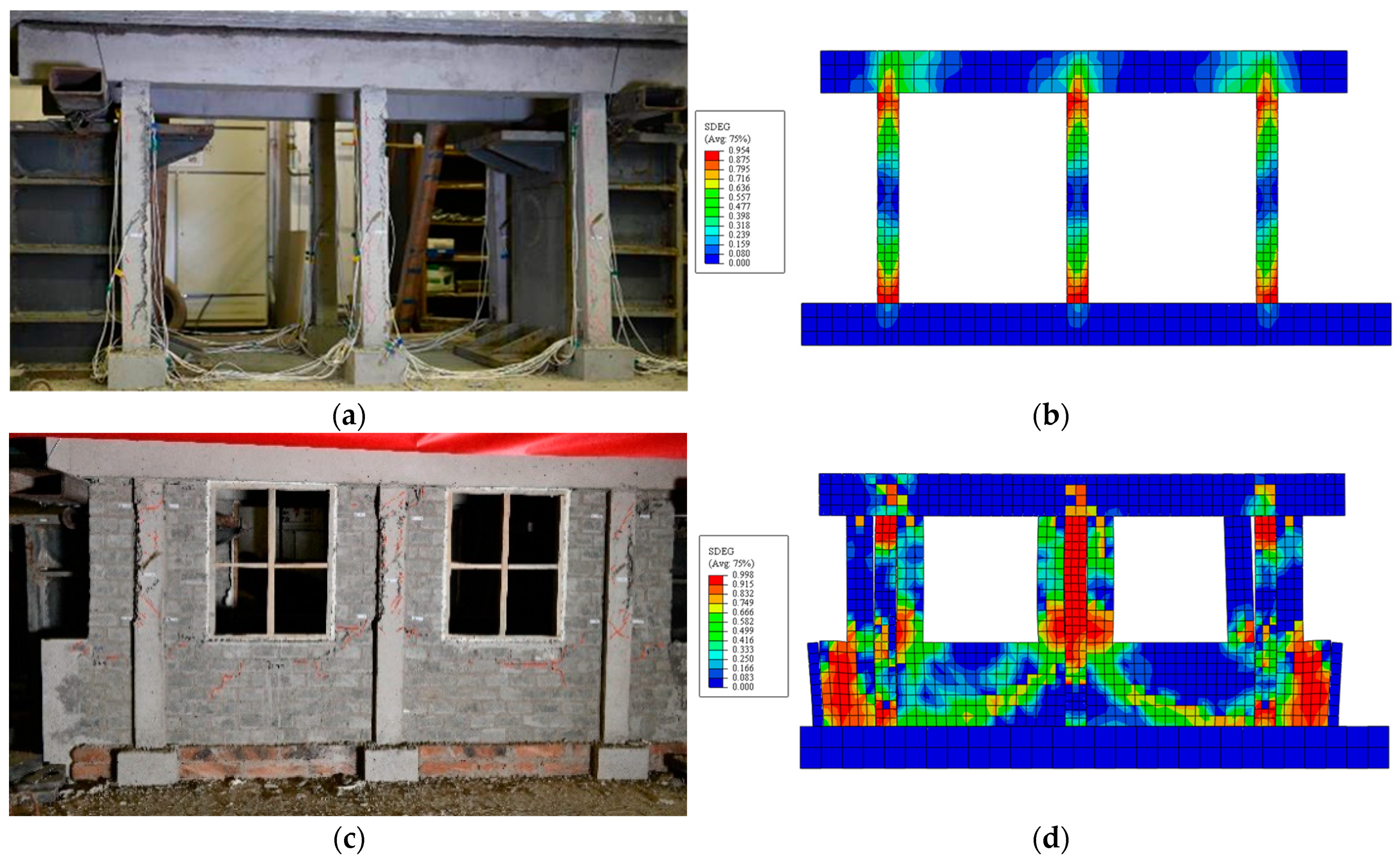

3.3. Model Validation

4. Parametric Modeling Analysis of RC Frame Structures Considering the Influence of Infilled Walls

4.1. Skeleton Curve Analysis under Different Working Cases

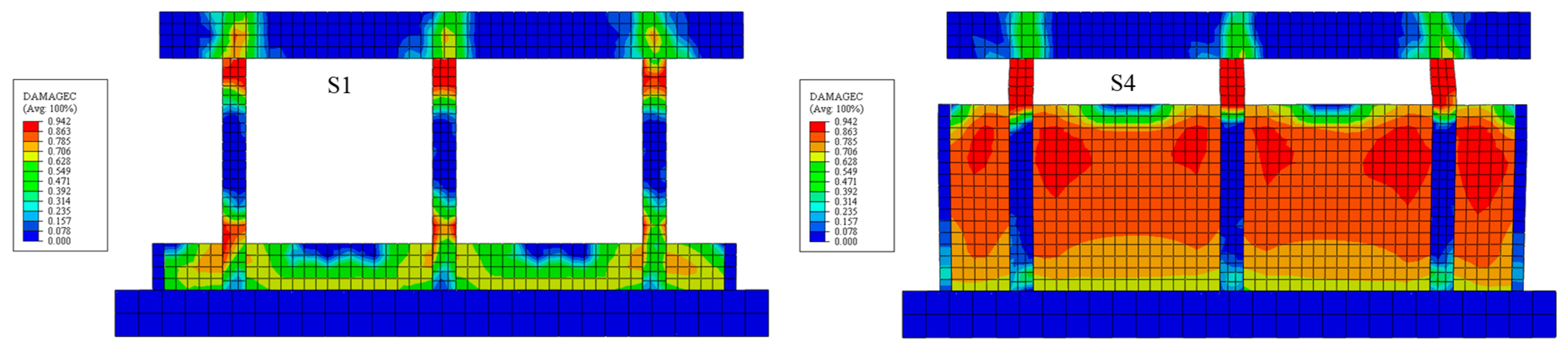

4.2. Failure Phenomena Analysis under Different Working Conditions

4.3. The Description of the Impact of Infilled Walls on the Seismic Performance of Structures

5. Conclusions

- (1)

- The experimental findings reveal that the model with half-height infilled walls exhibits a 138.54% increase in ultimate load-carrying capacity and a 214.81% enhancement in initial stiffness compared to the pure frame model. However, the ductility of the structure notably decreases, along with a reduction in the free height of the frame columns, which makes the structure more prone to shear failure during an earthquake, thereby intensifying the overall extent of structural damage.

- (2)

- At a wall-to-column height ratio of 0.2, the seismic performance of the RC frame structure is marginally influenced by the masonry materials. With the height of the infilled walls increasing, there is an upsurge in both the bearing capacity and the initial stiffness of the structure, with a concomitant reduction in ductility, while the rate of ductility decreases and stiffness degradation increases. When the wall-to-column height ratio reaches 0.6, the failure mode of the frame columns transitions from flexural failure to shear failure. At a wall-to-column height ratio of 0.8, the “short-column effect” is notably distinct, and the damage degree of the aerated concrete block wall is the lightest at this time. When the height of the infilled walls continues to increase, the short-column effect diminishes, and the rates of decline in both structural ductility and stiffness degradation decelerate.

- (3)

- The influence of masonry materials on the seismic performance of structures is not significantly different when the wall-to-column height ratio is 0.4 or below. However, as the wall-to-column height ratio exceeds 0.6, the differences in their impact on seismic performance become increasingly apparent. Under the identical height ratio of wall to column, the seismic performance of the structure is most significantly influenced by solid clay bricks, followed by concrete hollow blocks, and minimally by aerated concrete blocks. Consequently, it is advisable to prioritize aerated concrete blocks as the preferred material for constructing infilled walls in practical engineering implementations.

- (4)

- The properties of commonly used masonry materials substantially affect the seismic performance of structures. Therefore, it is necessary to identify a material that exerts minimal effect on the reduction of concrete stiffness and the alteration of stress in steel reinforcements. This material should fulfill operational demands while reducing the influence of infilled walls on the structure’s seismic performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Qin, Z.X.; Guo, X. Progress and prospect on seismic collapse-resistant capacity of RC frame structures. J. Disaster Prev. Mitig. Eng. 2021, 41, 860–873. [Google Scholar]

- Ditommaso, R.; Lamarucciola, N.; Ponzo, F.C. Prediction of the fundamental period of infilled RC framed structures considering the maximum inter-story drift at different design limit state. Structures 2024, 63, 106422. [Google Scholar] [CrossRef]

- Li, H.N.; Xiao, S.Y.; Huo, L.S. Damage investigation and analysis of engineering structures in the Wenchuan earthquake. J. Build. Struct. 2008, 29, 10–19. [Google Scholar]

- Wang, T.; Lei, Y.; Zhang, Y.; Kong, Z. Seismic damage analysis of school buildings in Lushan earthquake. J. Earthq. Eng. Eng. Vib. 2013, 33, 36–47. [Google Scholar]

- Huang, S.N.; Yuan, Y.F.; Meng, Q.L. Study on seismic resistance of rural houses based on earthquake damage to buildings in Yushu earthquake. World Earthq. Eng. 2011, 27, 77–82. [Google Scholar]

- Yi, P.; Chi, Z.; Xian, G.; Chang, Z.; Zhuo, J. Earthquake damage investigation and analysis of the RC frame structures in Taiwan Meinung Ms 6.7 earthquake. China Civ. Eng. J. 2016, 49, 13–18. [Google Scholar]

- Jingshan, B.O.; Xiaobo, L.I.; Duan, Y. Investigation and analysis of seismic damage to school buildings in Ms 7.0 Jiuzhaigou earthquake. Earthq. Eng. Eng. Dyn. 2018, 38, 120–128. [Google Scholar]

- Dong, X.Y.; Guo, X.; Luo, R.F.; Zhang, Q.Z.; Zhang, J.; Dong, C.; Wang, B. Seismic damage investigation structural force analysis of Luding Ms 68. J. Build Struct. 2023, 44, 11–19. [Google Scholar]

- Al-Chaar, G.; Issa, M.; Sweeney, S. Behavior of masonry-infilled nonductile reinforced concrete frames. J. Struct. 2002, 128, 1055–1063. [Google Scholar] [CrossRef]

- Hashemi, A.; Mosalam, K.M. Shake-table experiment on reinforced concrete structure containing masonry infill wall. Earthq. Eng. Struct. D. 2006, 35, 1827–1852. [Google Scholar] [CrossRef]

- Lin, X.; Pan, P.; Ye, L.; Lu, X.; Zhao, S. Analysis of the damage mechanism of a typical RC frame in Wenchuan Earthquake. China Civ. Eng. J. 2009, 42, 13–20. [Google Scholar]

- Guo, Z.X.; Huang, Q.X.; Wei, R.F.; Liu, Y. Experimental study of the seismic behavior of irregularly brick infilled RC frames. China Civ. Eng. J. 2010, 43, 46–54. [Google Scholar]

- Kakaletsis, D.J.; Karayannis, C.G. Experimental Investigation of Infilled Reinforced Concrete Frames with Openings. ACI Struct. J. 2009, 106, 132–141. [Google Scholar]

- Tasnimi, A.A.; Mohebkhah, A. Investigation on the behavior of brick-infilled steel frames with openings, experimental and analytical approaches. Eng. Struct. 2011, 33, 968–980. [Google Scholar] [CrossRef]

- Mansouri, A.; Marefat, M.S.; Khanmohammadi, M. Experimental evaluation of seismic performance of low-shear strength masonry infills with openings in reinforced concrete frames with deficient seismic details. Struct. Des. Tall Spec. Build. 2014, 23, 1190–1210. [Google Scholar] [CrossRef]

- Jin, H. Research on Seismic Failure Mechanisms and Key Aseismic Measures for Masonry-Infilled RC Frame Structures. Ph.D. Thesis, Institute of Engineering Mechanics, China Earthquake Administration Harbin, Harbin, China, 2014. [Google Scholar]

- Yang, W.S. Experimental Study on Collapse Mechanism of Multi-Story RC Frame School Buildings. Ph.D. Thesis, Institute of Engineering Mechanics, China Earthquake Administration Harbin, Harbin, China, 2015. [Google Scholar]

- Zovkic, J.; Sigmund, V.; Guljas, I. Cyclic testing of a single bay reinforced concrete frames with various types of masonry infill. Earthq. Eng. Struct. Dyn. 2013, 42, 1131–1149. [Google Scholar] [CrossRef]

- Siddiqui, U.A.; Sucuoglu, H.; Yakut, A. Seismic performance of gravity-load designed concrete frames infilled with low-strength masonry. Earthq. Struct. 2015, 8, 19–35. [Google Scholar] [CrossRef]

- Dautaj, A.D.; Kadiri, Q.; Kabashi, N. Experimental study on the contribution of masonry infill in the behavior of RC frame under seismic loading. Eng. Struct. 2018, 165, 27–37. [Google Scholar] [CrossRef]

- Jiang, H.J.; Mao, J.J.; Liu, X.J. Experimental study on seismic performance of masonry infilled RC frame with different types of connections. J. Build Struct. 2014, 35, 60–67. [Google Scholar]

- Zhou, X.J. Study on Seismic Behavior of Flexible Connection Frame Structure Infilled with New Masonry. Ph.D. Thesis, Tianjin University, Tianjin, China, 2014. [Google Scholar]

- Zhou, X.J.; Jiang, X.L.; Xu, D.D.; Song, J.K.; Yang, C.H. Experimental research on seismic behavior of flexible connection frame structure infilled with new masonry. Word Earthq. Eng. 2015, 31, 58–68. [Google Scholar]

- Teguh, M. Experimental evaluation of masonry infill walls of RC fra me buildings subjected to cyclic loads. Procedia Eng. 2017, 171, 191–200. [Google Scholar] [CrossRef]

- Baghi, H.; Oliveira, A.; Valença, J.; Cavaco, E.; Neves, L.; Júlio, E. Behavior of reinforced concrete frame with masonry infill wall subjected to vertical load. Eng. Struct. 2018, 171, 476–487. [Google Scholar] [CrossRef]

- Onat, O.; Correia, A.A.; Lourenço, P.B.; Koçak, A. Assessment of the combined in-plane and out-of-plane behavior of brick infill walls within reinforced concrete frames under seismic loading. Earthq. Eng. Struct. Dyn. 2018, 47, 2821–2839. [Google Scholar] [CrossRef]

- Guljaš, I.; Penava, D.; Laughery, L.; Pujol, S. Dynamic tests of a large-scale three-story RC structure with masonry infill walls. J. Earthq. Eng. 2020, 24, 1675–1703. [Google Scholar] [CrossRef]

- Binici, B.; Canbay, E.; Aldemir, A.; Demirel, I.O.; Uzgan, U.; Eryurtlu, Z.; Bulbul, K.; Yakut, A. Seismic behavior and improvement of autoclaved aerated concrete infill walls. Eng. Struct. 2019, 193, 68–81. [Google Scholar] [CrossRef]

- Zhai, C.H.; Wang, X.M.; Kong, J.C.; Wei, Y.L.; Jin, W.; Zhao, Y. Progress prospect of seismic performance of masonry-infilled RC frames. J. Harbin Inst. Technol. 2018, 50, 1–13. [Google Scholar]

- Zhang, M.H.; Pang, L.; Ding, J.N.; Wang, D. A review of the methods of strengthening RC frames with masonry infilled wall structures. Earthq. Eng. Eng. Dyn. 2021, 41, 53–62. [Google Scholar]

- Almasabha, G.; Chao, S.H. A New Reinforcing Configuration for Achieving High-Ductility High-Strength Rectangular Squat Structural Walls. ACI Struct. J. 2023, 120, 253. [Google Scholar]

- Chao, S.H.; Almasabha, G.; Price, B.; Jiansinlapadamrong, C. A Horizontal Stiffener Detailing for Shear Links at the Link-to-Column Connection in Eccentrically Braced Frames. J. Struct. Eng. 2023, 149, 04023114. [Google Scholar] [CrossRef]

- JGJ/T101-2015; Specification for Seismic Test of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2015.

- Wang, D.; Zhao, H.Q.; Lu, X.L. Loading protocols for quasi-static test of structural components for buildings. Sichuan Build. Sci. 2014, 40, 54–59. [Google Scholar]

- Feng, P.; Cheng, S.; Bai, Y.; Ye, L. Mechanical behavior of concrete filled square steel tube with FRP confined concrete core subjected to axial compression. Compos. Struct. 2015, 123, 312–324. [Google Scholar] [CrossRef]

- GB 50011-2010; Code for Seismic Design of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Liu, G.Q.; Yan, Y.Q.; Shi, C.X. Research on the unified model of the compressive constitutive relations of masonry. J. Hunan Univ. Nat. Sci. 2009, 36, 6–9. [Google Scholar]

- Joyner, W.B.; Chen, A.T.F. Calculation of nonlinear ground response in earthquakes. Bull. Seismol. Soc. Am. 1975, 65, 1315–1336. [Google Scholar]

- Clough, R.W. Effect of Stiffness Degradation on Earthquake Ductility Requirements, 1st ed.; University of California: Berkeley, CA, USA, 1966. [Google Scholar]

- Huang, Q.X. Study on Seismic Behavior and Elastic-Plastic Analysis Method for Seismic Responses of RC Frame Infilled with New Masonry; Huaqiao University: Quanzhou, China, 2011. [Google Scholar]

| Test Group | fcu | Ec | fyc | fu | fyb | fsu | fb |

|---|---|---|---|---|---|---|---|

| F | 13.19 | 20,700.00 | 150.00 | 260.00 | 743.50 | 201.00 | 6.10 |

| FW | 13.03 | 20,537.00 | - | - | - | - | - |

| Test Group | Δu (mm) | Δy (mm) | Fmax (kN) | μ | K (kN/mm) |

|---|---|---|---|---|---|

| F | 32.0 | 5.7 | 28.8 | 5.61 | 8.1 |

| FW | 24.0 | 5.0 | 68.7 | 4.8 | 25.5 |

| Groups | Compressive Strength/MPa | Elastic Modulus/MPa |

|---|---|---|

| Solid clay brick | 5.40 | 4622 |

| Autoclaved aerated concrete block | 2.52 | 3102 |

| Concrete hollow block | 2.30 | 5270 |

| Groups | Pure Frame | Height Ratio of Wall-to-Column | ||||

|---|---|---|---|---|---|---|

| 0.2 | 0.4 | 0.6 | 0.8 | 1.0 | ||

| Solid clay brick | B | S1 | S2 | S3 | S4 | S5 |

| Autoclaved aerated concrete block | C1 | C2 | C3 | C4 | C5 | |

| Concrete hollow block | A1 | A2 | A3 | A4 | A5 | |

| Group | Ultimate Bearing Capacity (kN) | Initial Stiffness (kN/mm) | Ductility Coefficient | |||

|---|---|---|---|---|---|---|

| Value | Raise (%) | Value | Raise (%) | Value | Raise (%) | |

| B | 29.45 | - | 4.28 | - | 4.68 | - |

| S1 | 37.89 | 28.67% | 5.99 | 39.95% | 4.65 | −1.64% |

| S2 | 46.77 | 58.82% | 8.11 | 89.49% | 4.55 | −2.78% |

| S3 | 59.08 | 100.60% | 14.65 | 242.29% | 4.30 | −8.12% |

| S4 | 74.28 | 152.23% | 30.10 | 603.27% | 3.76 | −19.66% |

| S5 | 96.76 | 228.57% | 48.78 | 1039.72% | 3.38 | −27.78% |

| C1 | 37.47 | 27.24% | 5.84 | 36.45% | 4.66 | −0.43% |

| C2 | 45.73 | 55.28% | 7.93 | 85.28% | 4.61 | −1.50% |

| C3 | 55.94 | 89.94% | 12.66 | 195.79% | 4.36 | −6.84% |

| C4 | 68.12 | 131.30% | 27.28 | 537.38% | 3.92 | −16.24% |

| C5 | 84.08 | 185.51% | 40.69 | 850.70% | 3.70 | −20.94% |

| A1 | 36.87 | 25.19% | 5.76 | 34.58% | 4.66 | −0.43% |

| A2 | 44.64 | 51.60% | 7.39 | 72.66% | 4.64 | −0.85% |

| A3 | 54.60 | 85.42% | 12.23 | 185.75% | 4.44 | −5.13% |

| A4 | 64.66 | 119.56% | 22.00 | 414.02% | 4.13 | −11.75% |

| A5 | 80.64 | 173.82% | 30.34 | 608.88% | 4.01 | −14.32% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhou, Y.; Liu, X.; Zheng, Y.; Qi, Z. Study on Seismic Performance of RC Frame Structures Considering the Effect of Infilled Walls. Buildings 2024, 14, 1907. https://doi.org/10.3390/buildings14071907

Zhang X, Zhou Y, Liu X, Zheng Y, Qi Z. Study on Seismic Performance of RC Frame Structures Considering the Effect of Infilled Walls. Buildings. 2024; 14(7):1907. https://doi.org/10.3390/buildings14071907

Chicago/Turabian StyleZhang, Xuetan, Yang Zhou, Xiangyu Liu, Yaoyu Zheng, and Zhengxin Qi. 2024. "Study on Seismic Performance of RC Frame Structures Considering the Effect of Infilled Walls" Buildings 14, no. 7: 1907. https://doi.org/10.3390/buildings14071907

APA StyleZhang, X., Zhou, Y., Liu, X., Zheng, Y., & Qi, Z. (2024). Study on Seismic Performance of RC Frame Structures Considering the Effect of Infilled Walls. Buildings, 14(7), 1907. https://doi.org/10.3390/buildings14071907