Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials and Characterisation

2.2. Mix Proportions

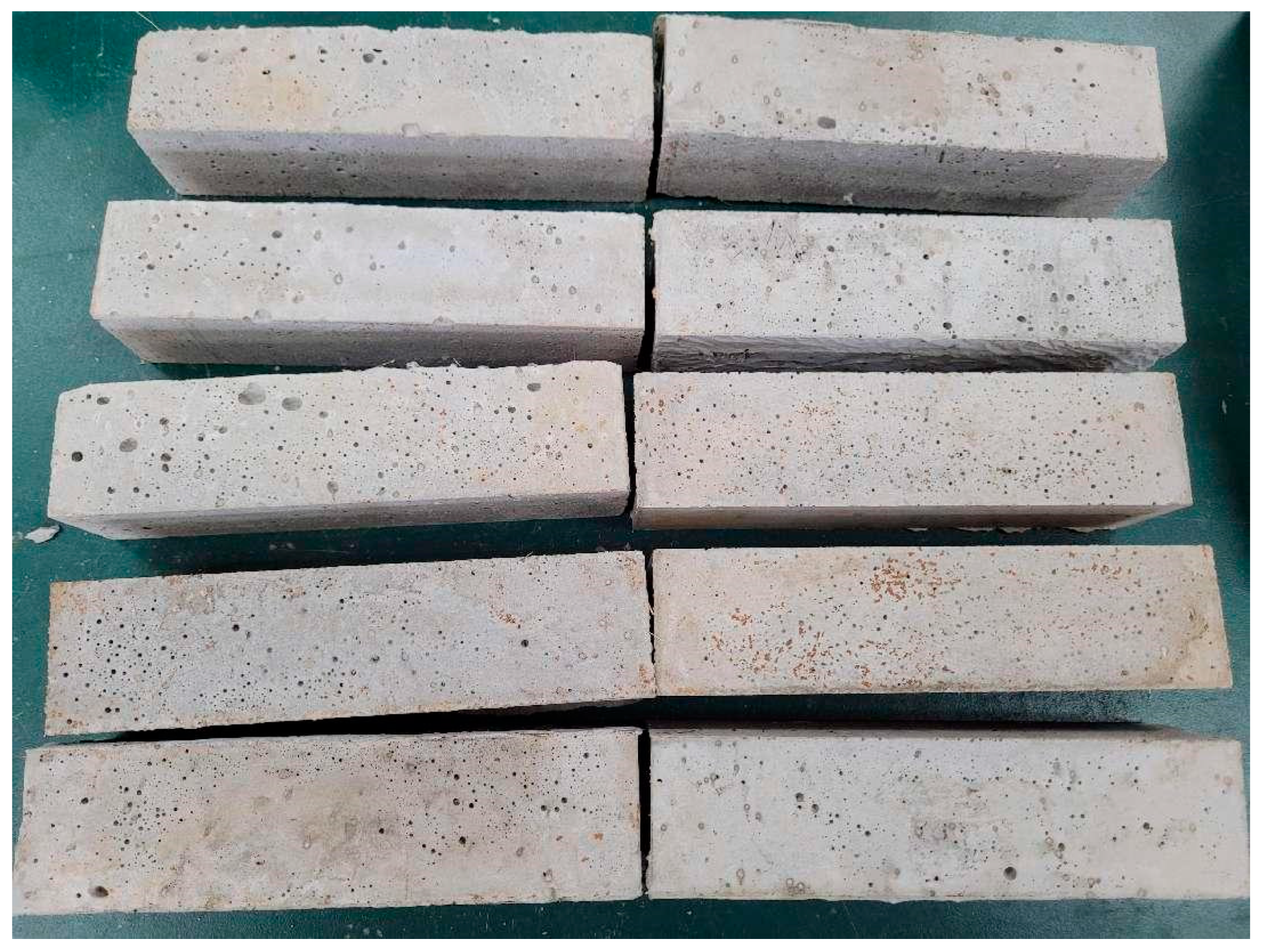

2.3. Specimen Casting and Curing

2.4. Testing Procedures

2.4.1. Slump Flow

2.4.2. Porosity

2.4.3. Water Absorption Testing

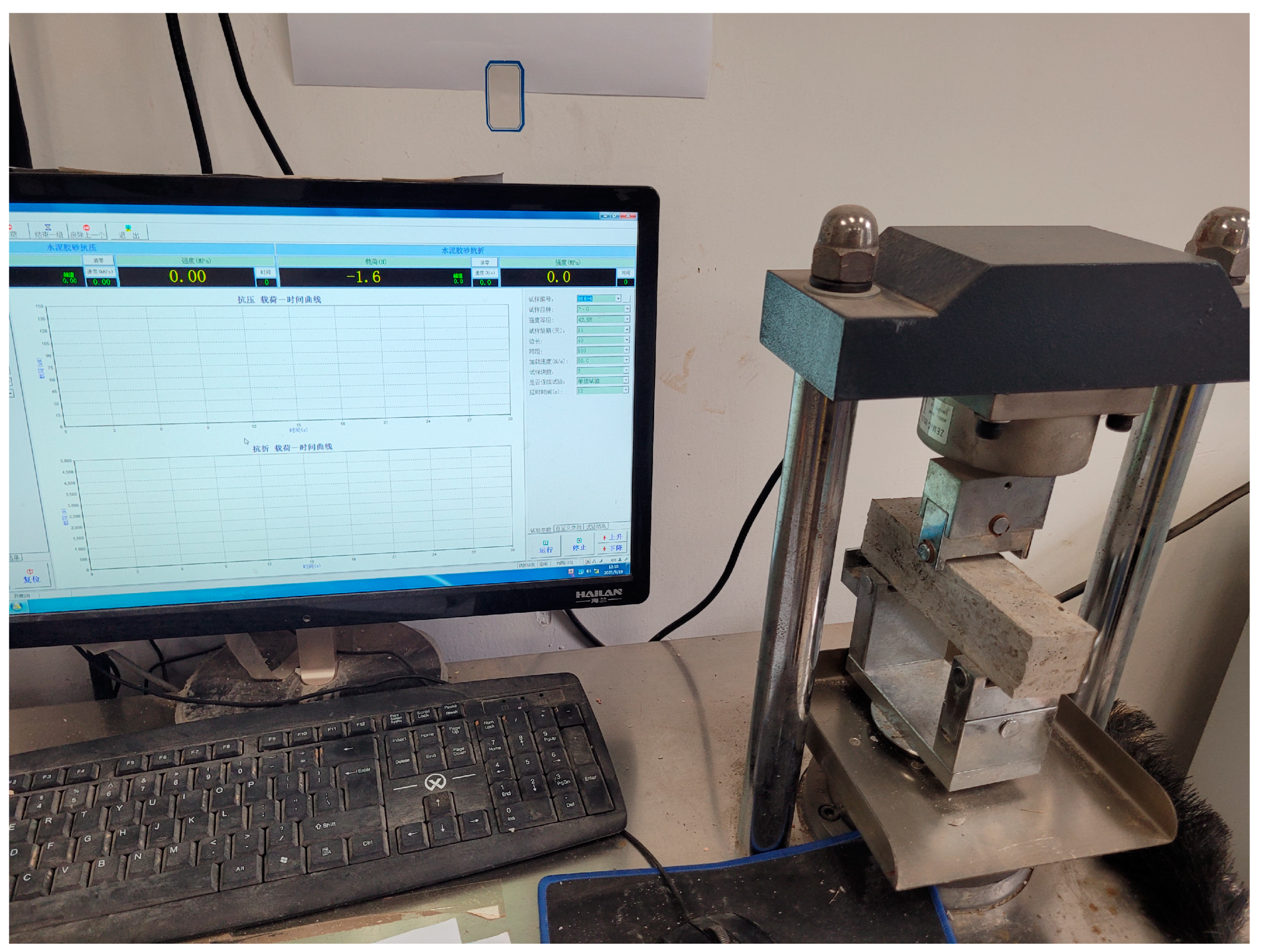

2.4.4. Strength Testing

2.4.5. Drying Shrinkage

3. Results and Discussion

3.1. Properties of ESRFA

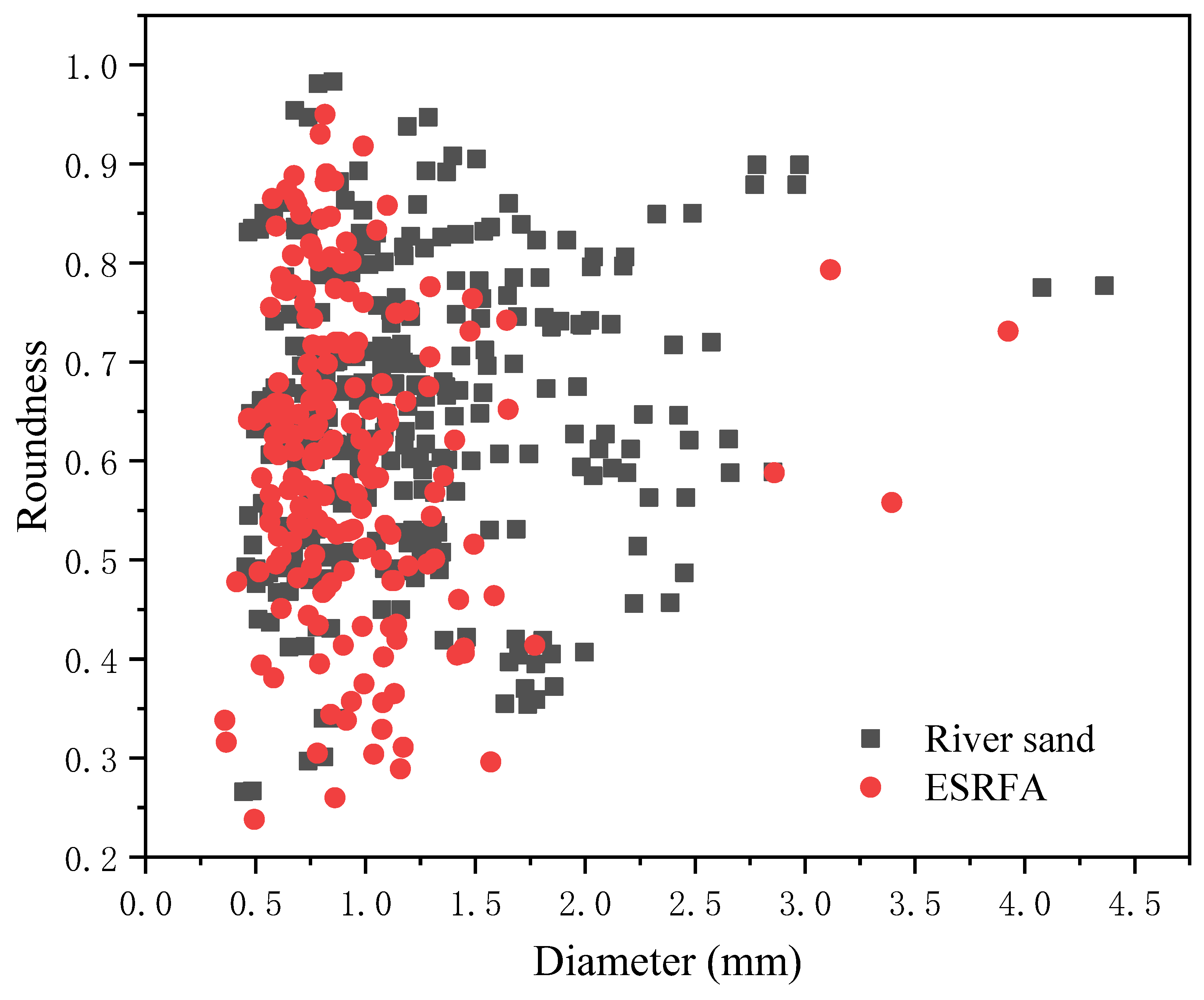

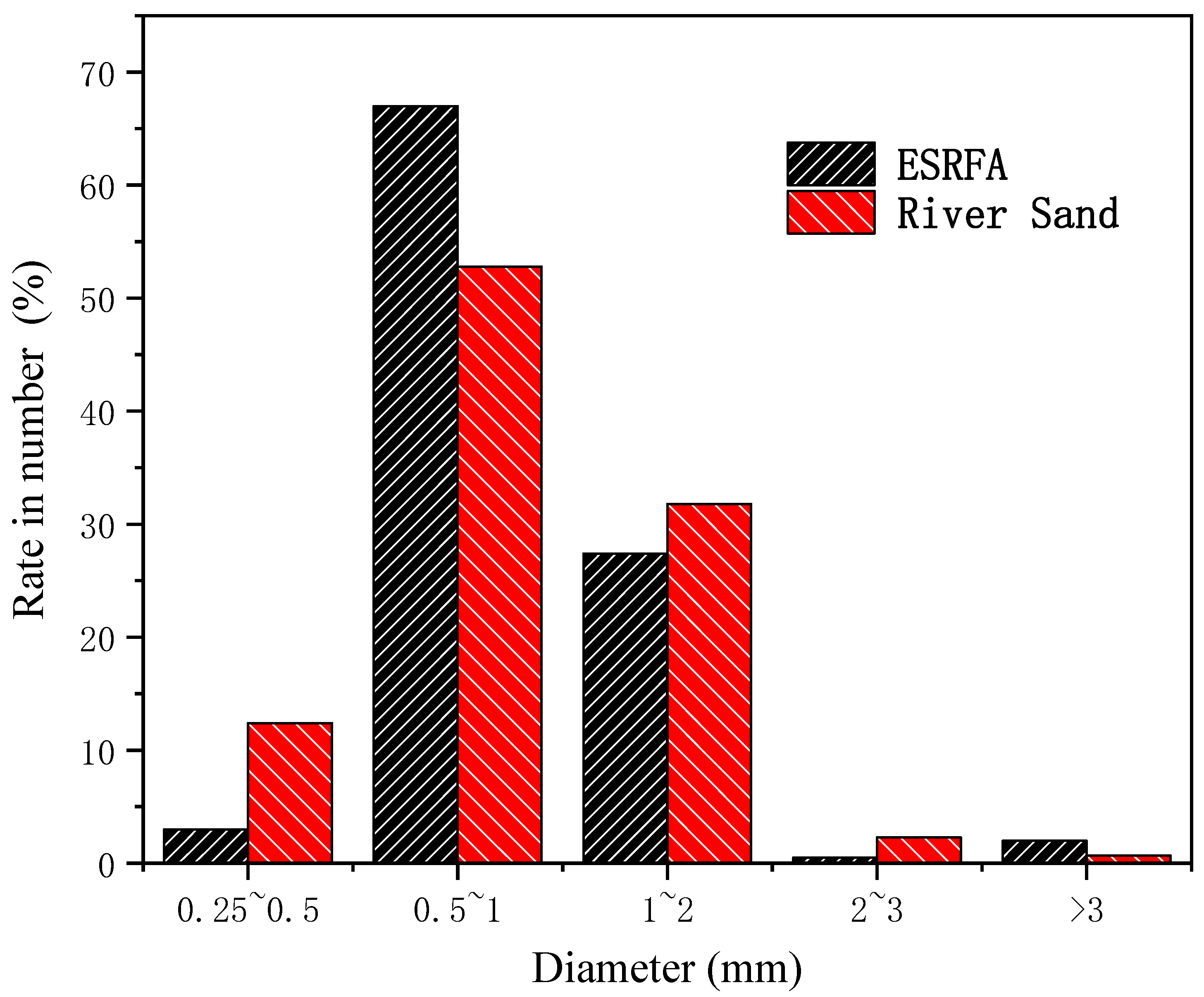

3.2. Micromorphology and Shape Analysis

3.3. Properties of Fresh Mortar

3.4. Physical Properties of Hardened Mortar

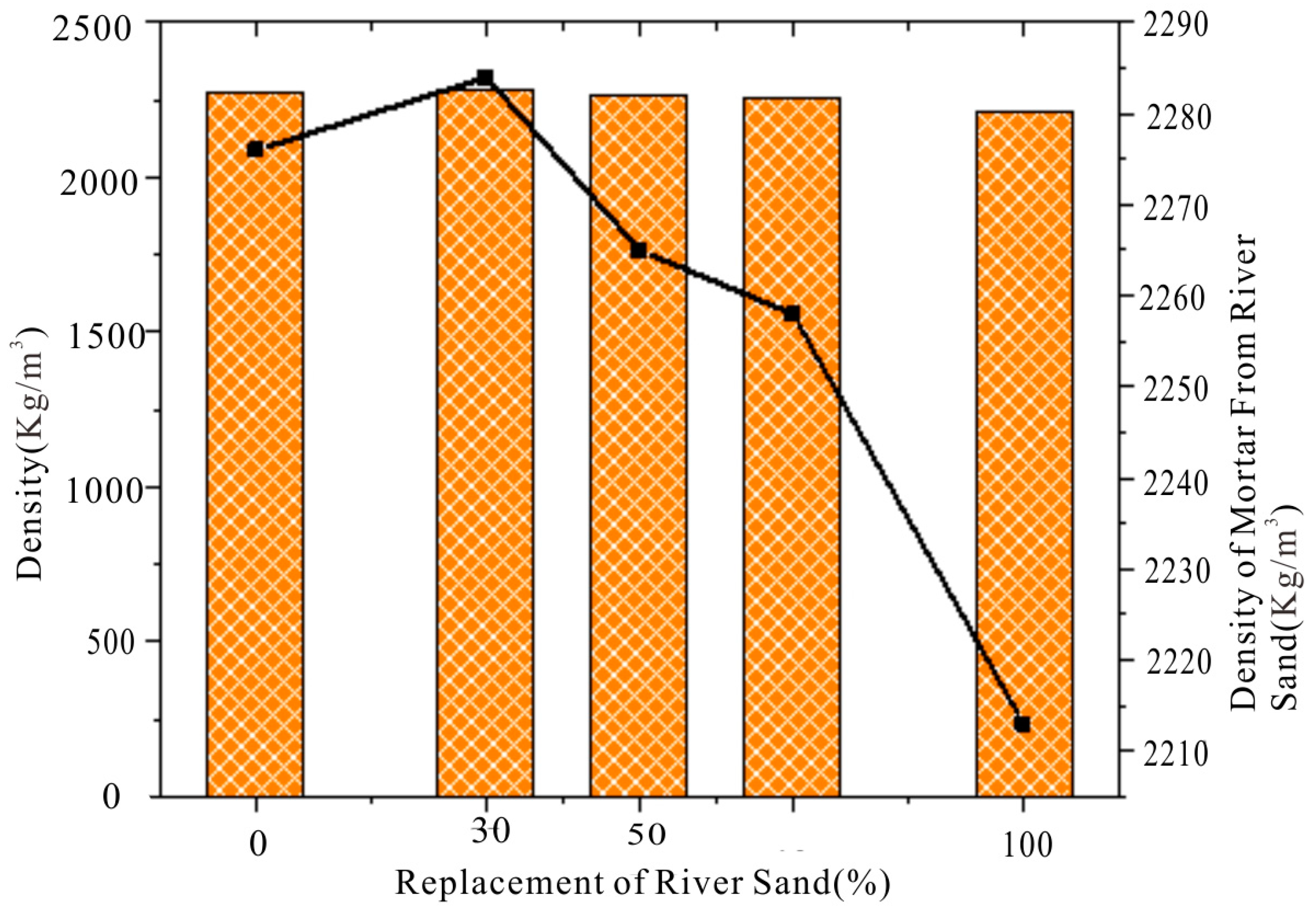

3.4.1. Density

3.4.2. Porosity of the Mortars

3.4.3. Water Absorption

3.5. Mechanical Properties of Hardened Mortar

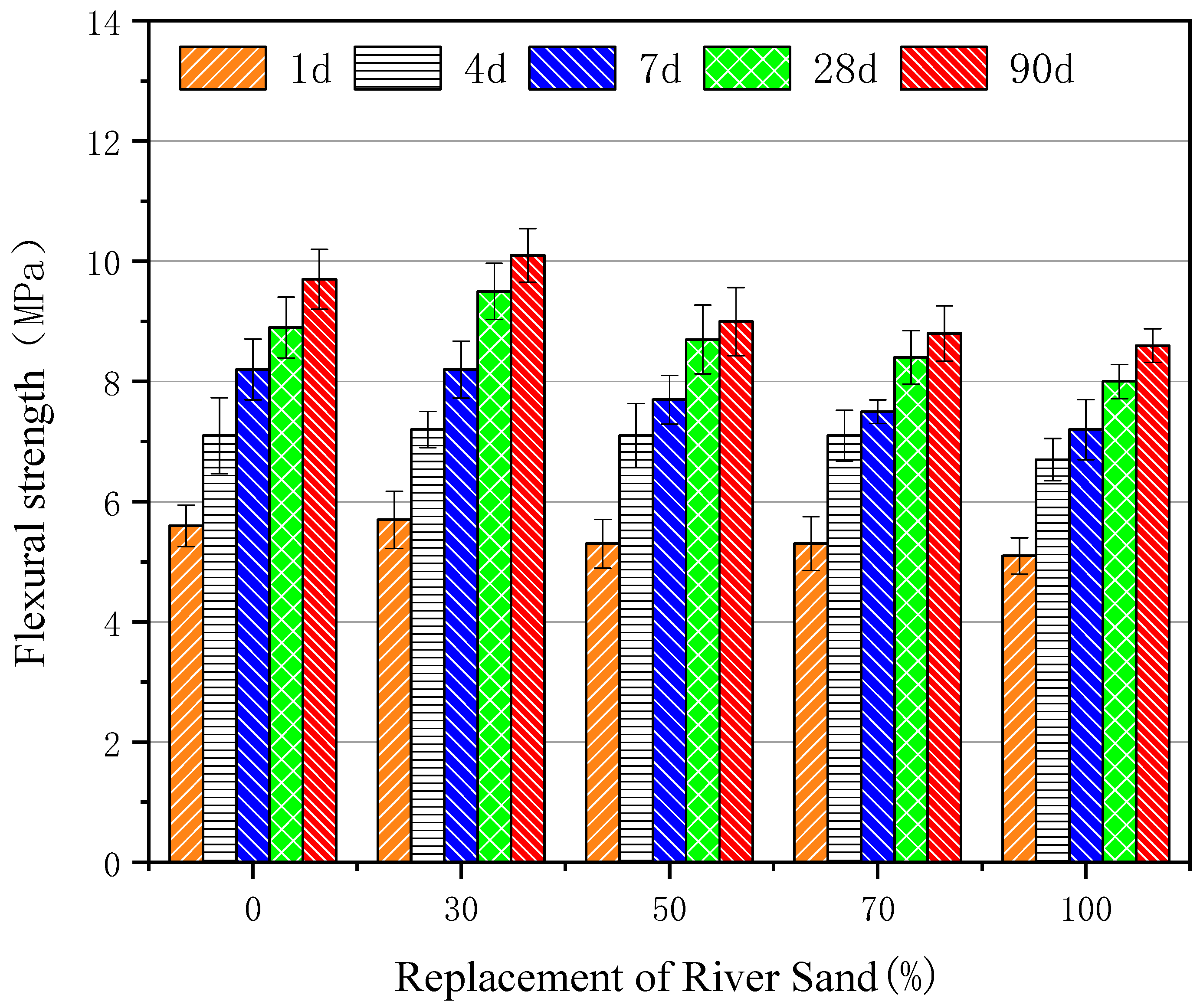

3.5.1. Compressive and Flexural Strengths

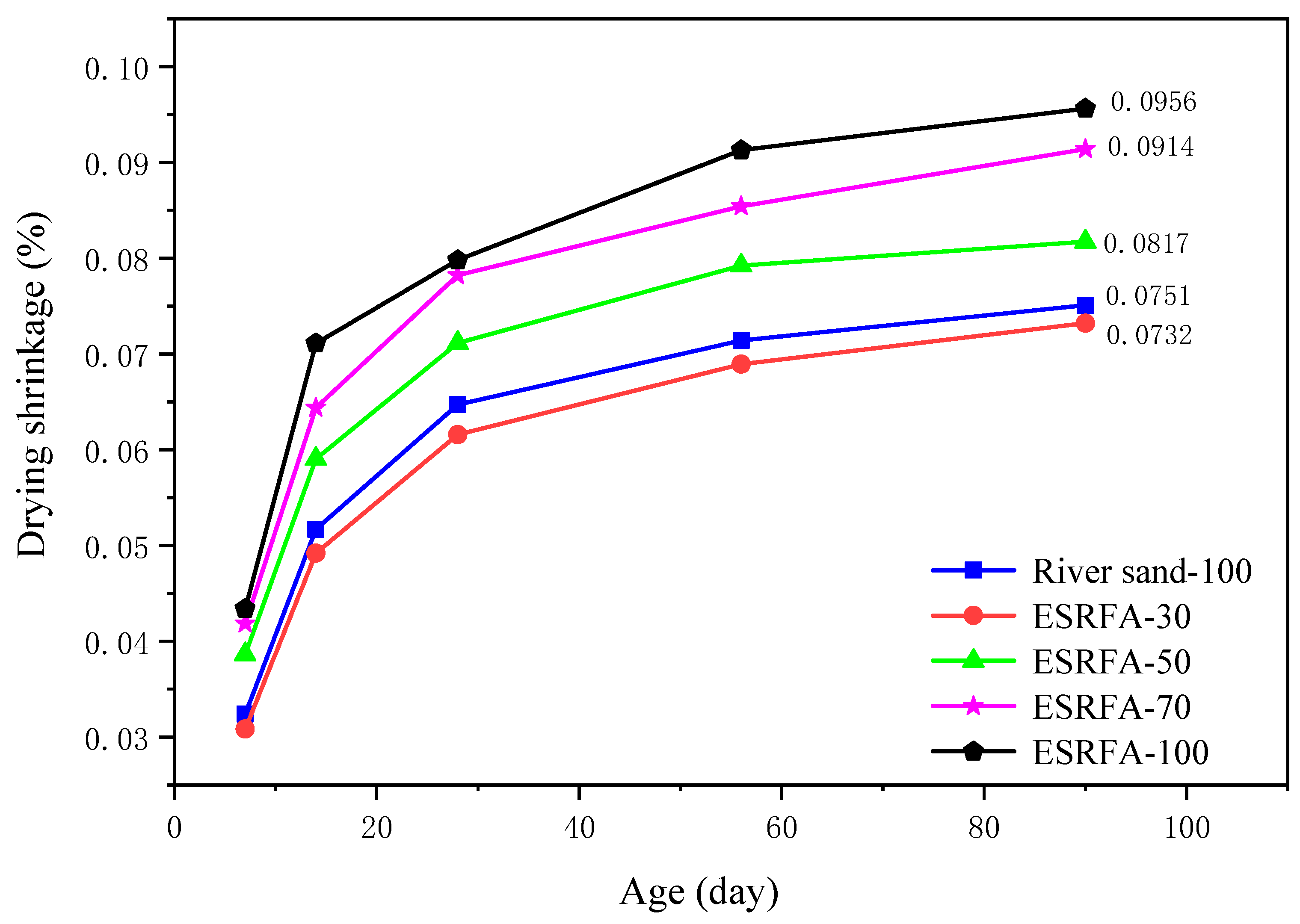

3.5.2. Drying Shrinkage Rate of ESRFA Mortars

4. Conclusions

- Micromorphology and shape analysis revealed that the roundness coefficient of river sand was 6.55% higher than ESRFA. This was reflected in the flowability test of the mortar, where river sand mortar exhibited superior flowability to ESRFA mortar because; when the surface of aggregate particles was more cubic and rougher, they significantly reduced the workability of fresh mortar by increasing the resistance to particle sliding. In addition, river sand exhibited a more uniform particle size distribution than ESRFA, which showed a greater particle size concentration, with 67% of the particles distributed between 0.5 mm and 1 mm. Thus, modifying the uniformity of particle size distribution is a plausible strategy for enhancing the replacement rate of aggregates in mortar.

- The flexural and compressive strength, porosity, water absorption, and dry shrinkage of mortar increased and then decreased upon increasing the ESRFA content.

- When ESRFA replaced about 30% of river sand in mortar, although the flowability decreased, the flexural and compressive strengths, porosity, water absorption, and dry shrinkage all increased. Therefore, the reasonable use of ESRFA during mortar mixing may enhance its performance, but adding ESRFA will decrease the fluidity of mortar, regardless of the mixing ratio. Therefore, the improvement of the workability of ESRFA cement products should be considered during use.

- The experimental results showed that ESRFA could be used to partly replace river sand during the production of cement products and had good physical properties.

- Using ESRFA helps address the environmental issues associated with excavated soil disposal and reduces the reliance on river sand, offering a sustainable alternative for the concrete industry.

- Overall, ESRFA can be a viable partial replacement for river sand in mortar, particularly at substitution rates up to 30%, providing economic and environmental benefits without compromising the mechanical properties of the mortar.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Wang, W.; Jiang, D.; Chen, D.; Chen, Z.; Zhou, W.; Zhu, B. A Material Flow Analysis (MFA)-based potential analysis of eco-efficiency indicators of China’s cement and cement-based materials industry. J. Clean. Prod. 2016, 112, 787–796. [Google Scholar] [CrossRef]

- de Leeuw, J.; Shankman, D.; Wu, G.; de Boer, W.F.; Burnham, J.; He, Q.; Yesou, H.; Xiao, J. Strategic assessment of the magnitude and impacts of sand mining in Poyang Lake, China. Reg. Environ. Chang. 2010, 10, 95–102. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, F.; Zhang, S. Research on Current Supply and Demand Situation and Trend of Sandstone on Guangdong Province. World Build. Mater. 2024, 42, 80–86. [Google Scholar]

- Huang, T.; Kou, S.; Liu, D.; Li, D.; Xing, F. Evaluation of the Techno-Economic Feasibility for Excavated Soil Recycling in Shenzhen, China. Sustainability 2022, 14, 3028. [Google Scholar] [CrossRef]

- Li, S.; Yu, L.; Jiang, W.; Yu, H.; Wang, X. The recent progress China has made in green mine construction, Part I: Mining groundwater pollution and sustainable mining. Int. J. Environ. Res. Public Health 2022, 19, 5673. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Li, J. Construction and demolition waste management: China’s lessons. Waste Manag. Res. 2016, 34, 397–398. [Google Scholar] [CrossRef] [PubMed]

- Poon, C.S.; Ann, T.W.; Ng, L.H. On-site sorting of construction and demolition waste in Hong Kong. Resour. Conserv. Recycl. 2001, 32, 157–172. [Google Scholar] [CrossRef]

- Ziraba, A.K.; Haregu, T.N.; Mberu, B. A review and framework for understanding the potential impact of poor solid waste management on health in developing countries. Arch. Public Health 2016, 74, 54. [Google Scholar] [CrossRef]

- Zhang, Y. Development Situation of Construction Waste Treatment Industry. Recycl. Resour. Circ. Econ. 2023, 16, 22–24. [Google Scholar]

- Wang, Y. Low Utilization Rate of Construction Waste Recycling, Experts Suggest Improving Special Legislation. Resour. Recycl. 2020, 9, 10–12. [Google Scholar]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Song, X.; Qiao, P.; Wen, H. Recycled aggregate concrete enhanced with polymer aluminium sulfate. Mag. Concr. Res. 2015, 67, 496–502. [Google Scholar] [CrossRef]

- 0Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self healing concrete—A review. Constr. Build. Mater. 2017, 152, 1008–1014. [Google Scholar] [CrossRef]

- Purushothaman, R.; Amirthavalli, R.R.; Karan, L. Influence of treatment methods on the strength and performance characteristics of recycled aggregate concrete. J. Mater. Civ. Eng. 2015, 27, 04014168. [Google Scholar] [CrossRef]

- Li, Y. Developing a Sustainable Construction Waste Estimation and Management System; Hong Kong University of Science and Technology (Hong Kong) ProQuest Dissertations Publishing: Hong Kong, China, 2013; p. 3613928. [Google Scholar]

- Singh, A.; Kuhad, R.C.; Ward, O.P. Biological remediation of soil: An overview of global market and available technologies. In Advances in Applied Bioremediation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–19. [Google Scholar] [CrossRef]

- Van Veen, J.A.; Kuikman, P.J. Soil structural aspects of decomposition of organic matter by micro-organisms. Biogeochemistry 1990, 11, 213–233. [Google Scholar] [CrossRef]

- Geisen, S.; Wall, D.H.; van der Putten, W.H. Challenges and opportunities for soil biodiversity in the anthropocene. Curr. Biol. 2019, 29, R1036–R1044. [Google Scholar] [CrossRef] [PubMed]

- Katsumi, T. Towards Sustainable Soil Management-Reuse of Excavated Soils with Contamination; Environmental Science and Engineering; Springer: Singapore, 2018; pp. 99–118. [Google Scholar] [CrossRef]

- Grünner, K.; Durmeková, T.; Wagner, P. Exploitation possibilities of the tunnel’s muck as a construction material. Slovak J. Civ. Eng. 2003, 1, 11–25. Available online: https://www.svf.stuba.sk/buxus/docs/sjce/2003/2003_1/file2.pdf (accessed on 16 August 2004).

- Thalmann-Suter, C.N. Concrete Aggregate Production with TBM Muck Explained on the AlpTransit Tunnel Projects. In Utilizing Ready Mix Concrete and Mortar; Dhir, R.K., Limbachiya, M.C., Eds.; Thomas Telford: London, UK, 1999; pp. 131–144. [Google Scholar]

- Antonaci, P.; Masera, D. Mechanical Behavior of Structural Concrete Made with Recycled Aggregates from Tunnel Excavation. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 452. [Google Scholar] [CrossRef]

- Olbrecht, H.; Studer, W. Use of TBM chip as concrete aggregate. Mater. Struct. 1998, 31, 184–187. Available online: https://www.dora.lib4ri.ch/empa/islandora/object/empa%3A4126/datastream/PDF/Olbrecht-1998-Use_of_TBM_chips_as-%28published_version%29.pdf (accessed on 14 May 2024). [CrossRef]

- Voit, K.; Kuschel, E. Rock material recycling in tunnel engineering. Appl. Sci. 2020, 10, 2722. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Özkiliç, Y.O.; Mansour, W. Improving bond performance of ribbed steel bars embedded in recycled aggregate concrete using steel mesh fabric confinement. Constr. Build. Mater. 2023, 369, 130452. [Google Scholar] [CrossRef]

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J. Mater. Res. Technol. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Başaran, B.; Aksoylu, C.; Karalar, M.; Martins, C.H. Mechanical behavior in terms of shear and bending performance of reinforced concrete beam using waste fire clay as replacement of aggregate. Case Stud. Constr. Mater. 2023, 18, e02104. [Google Scholar] [CrossRef]

- Tu, H.; Wei, Z.; Bahrami, A.; Kahla, N.B.; Ahmad, A.; Özkılıç, Y.O. Recent advancements and future trends in 3D printing concrete using waste materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Zhang, N.; Duan, H.; Sun, P. Characterizing the generation and environmental impacts of subway-related excavated soil and rock in China. J. Clean. Prod. 2020, 248, 119242. [Google Scholar] [CrossRef]

- Bie, J.; de Jong, M.; Derudder, B. Greater Pearl River Delta: Historical evolution towards a global city-region. J. Urban Technol. 2015, 22, 103–123. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing efficient circularity for construction and demolition waste management in fast emerging economies: Lessons learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef] [PubMed]

- Bhatawdekar, R.M.; Singh, T.N.; Tonnizam Mohamad, E.; Armaghani, D.J.; Binti Abang Hasbollah, D.Z. River sand mining vis a vis manufactured sand for sustainability. In Proceedings of the International Conference on Innovations for Sustainable and Responsible Mining: ISRM 2020; Springer International Publishing: Cham, Switzerland, 2021; Volume 1. [Google Scholar] [CrossRef]

- Jiao, S.J.; Wang, S. Utilizing Sea Sand in Construction. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 838. [Google Scholar]

- He, H.; Wang, Y.; Wang, J. Compactness and hardened properties of machine-made sand mortar with aggregate micro fines. Constr. Build. Mater. 2020, 250, 118828. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Shenzhen Housing and Construction Bureau, Letter from the Shenzhen Housing and Construction Bureau in response to Proposal No. 20220605 of the 7th Shenzhen Municipal People’s Congress. 12 July 2022. Available online: http://zjj.sz.gov.cn/csml/bgs/xxgk/tabl_1/jybl/content/post_10310829.html (accessed on 14 May 2024).

- Takashimizu, Y.; Iiyoshi, M. New parameter of roundness R: Circularity corrected by aspect ratio. Prog. Earth Planet. Sci. 2016, 3, 2. [Google Scholar] [CrossRef]

- Mog, K.; Anbazhagan, P. An inexpensive foldscopic approach for quantitative evaluation of the shape of sand particles. Curr. Sci. 2023, 124, 457–466. [Google Scholar]

- Williams, D.A.; Saak, A.W.; Jennings, H.M. The influence of mixing on the rheology of fresh cement paste. Cem. Concr. Res. 1999, 29, 1491–1496. [Google Scholar] [CrossRef]

- Kou, S.-C.; Zhan, B.-J.; Poon, C.-S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Liu, Q.; Singh, A.; Xiao, J.; Li, B.; Tam, V.W. Workability and mechanical properties of mortar containing recycled sand from aerated concrete blocks and sintered clay bricks. Resour. Conserv. Recycl. 2020, 157, 104728. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Press: Beijing, China, 2005.

- SY/T 5336-2006; The Petroleum and Gas Industry Standards of China. National Energy Administration Press: Beijing, China, 2006.

- JGJ 52-2019; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Press: Beijing, China, 2019.

- GB/T 17671-2021; Cement Mortar Strength Testing Method (ISO). China Standards Press: Beijing, China, 2021.

- JGJ/T 70-2009; Standard for test method of basic properties of construction mortar. Ministry of Housing and Urban-Rural Development of the People’s Republic of China Press: Beijing, China, 2009.

- BS EN 1097-6:2022; Tests for mechanical and physical properties of aggregates Determination of particle density and water absorption. British Standards Institution: London, UK, 2022.

- Prakongkep, N.; Suddhiprakarn, A.; Kheoruenromne, I.; Gilkes, R.J. SEM image analysis for characterization of sand grains in Thai paddy soils. Geoderma 2010, 156, 20–31. [Google Scholar] [CrossRef]

- Bahadur, S.; Badruddin, R. Erodent particle characterization and the effect of particle size and shape on erosion. Wear 1990, 138, 189–208. [Google Scholar] [CrossRef]

- Mesbah, H.; Buyle-Bodin, F. Efficiency of polypropylene and metallic fibres on control of shrinkage and cracking of recycled aggregate mortars. Constr. Build. Mater. 1999, 13, 439–447. [Google Scholar] [CrossRef]

- Wu, C.; Kou, S. Effects of high-calcium sepiolite on the rheological behaviour and mechanical strength of cement pastes and mortars. Constr. Build. Mater. 2019, 196, 105–114. [Google Scholar] [CrossRef]

| Cement (g) | Water (g) | River Sand (g) | ESRFA (g) | ||

|---|---|---|---|---|---|

| River sand | River sand-100 | 150 | 82.5 | 450.0 | 0 |

| ESRFA | ESRFA-10 | 150 | 82.5 | 405 | 45 |

| ESRFA-30 | 150 | 82.5 | 315 | 135 | |

| ESRFA-50 | 150 | 82.5 | 225 | 225 | |

| ESRFA-70 | 150 | 82.5 | 135 | 315 | |

| ESRFA-100 | 150 | 82.5 | 0 | 450 |

| Component | Excavated Soil (%) | River Sand (%) | ESRFA (%) | Cement (%) | |

|---|---|---|---|---|---|

| Chemical composition | SiO2 | 58.9 | 97.27 | 88.5 | 21.5 |

| CaO | 0.636 | 0.23 | 0.38 | 58.81 | |

| Al2O3 | 31.5 | 1.08 | 8.17 | 8.33 | |

| Fe2O3 | 3.69 | 0.63 | 0.78 | 3.88 | |

| MgO | 0.596 | 0.13 | 0.184 | 2.67 | |

| K2O | 2.5 | 0 | 1.17 | 0.752 | |

| SO3 | 0.29 | 0 | 0.05 | 3.24 | |

| Cr2O3 | 0.049 | 0.059 | |||

| NiO | 0.021 | 0.019 | |||

| MnO | 0.005 | 0.006 | |||

| LOI | - | - | - | 2.61 | |

| Physical properties | Apparent density | - | 2593 ± 100 kg/m3 | 2605 ± 100 kg/m3 | - |

| Bulk density | - | 1498 ± 50 kg/m3 | 1435 ± 50 kg/m3 | 1540 ± 50 kg/m3 | |

| Water absorption | - |

| River Sand-100 | ESRFA-30 | ESRFA-50 | ESRFA-70 | ESRFA-100 | |

|---|---|---|---|---|---|

| Mean, % | 12.12 | 11.95 | 12.43 | 12.82 | 13.15 |

| Std Dev | 0.38 | 0.25 | 0.33 | 0.29 | 0.21 |

| 1 d | 3 d | 7 d | 28 d | 56 d | ||

|---|---|---|---|---|---|---|

| Flexural strength | River sand-100 | 5.6 | 7.1 | 8.2 | 8.9 | 9.7 |

| ESRFA-30 | 5.7 | 7.2 | 8.2 | 9.5 | 10.1 | |

| ESRFA-50 | 5.3 | 7.1 | 7.7 | 8.7 | 9.0 | |

| ESRFA-70 | 5.3 | 7.1 | 7.5 | 8.4 | 8.8 | |

| ESRFA-100 | 5.1 | 6.7 | 7.2 | 8.0 | 8.6 | |

| Compressive strength | River sand-100 | 19.2 | 26.4 | 33.9 | 39.2 | 43.3 |

| ESRFA-30 | 19.6 | 27.3 | 35.2 | 40.5 | 43.8 | |

| ESRFA-50 | 18.9 | 25.7 | 33.1 | 38.4 | 41.3 | |

| ESRFA-70 | 18.2 | 25.1 | 32.5 | 37.0 | 40.2 | |

| ESRFA-100 | 17.5 | 24.5 | 30.8 | 35.1 | 39.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, R.; Huang, T. Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing. Buildings 2024, 14, 1917. https://doi.org/10.3390/buildings14071917

Xu R, Huang T. Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing. Buildings. 2024; 14(7):1917. https://doi.org/10.3390/buildings14071917

Chicago/Turabian StyleXu, Rong, and Tong Huang. 2024. "Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing" Buildings 14, no. 7: 1917. https://doi.org/10.3390/buildings14071917

APA StyleXu, R., & Huang, T. (2024). Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing. Buildings, 14(7), 1917. https://doi.org/10.3390/buildings14071917