A Real-Time Study on the Cracking Characteristics of Polyvinyl Alcohol Fiber-Reinforced Geopolymer Composites under Splitting Tensile Load Based on High-Speed Digital Image Correlations

Abstract

1. Introduction

2. Experimental and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Geopolymer Specimens

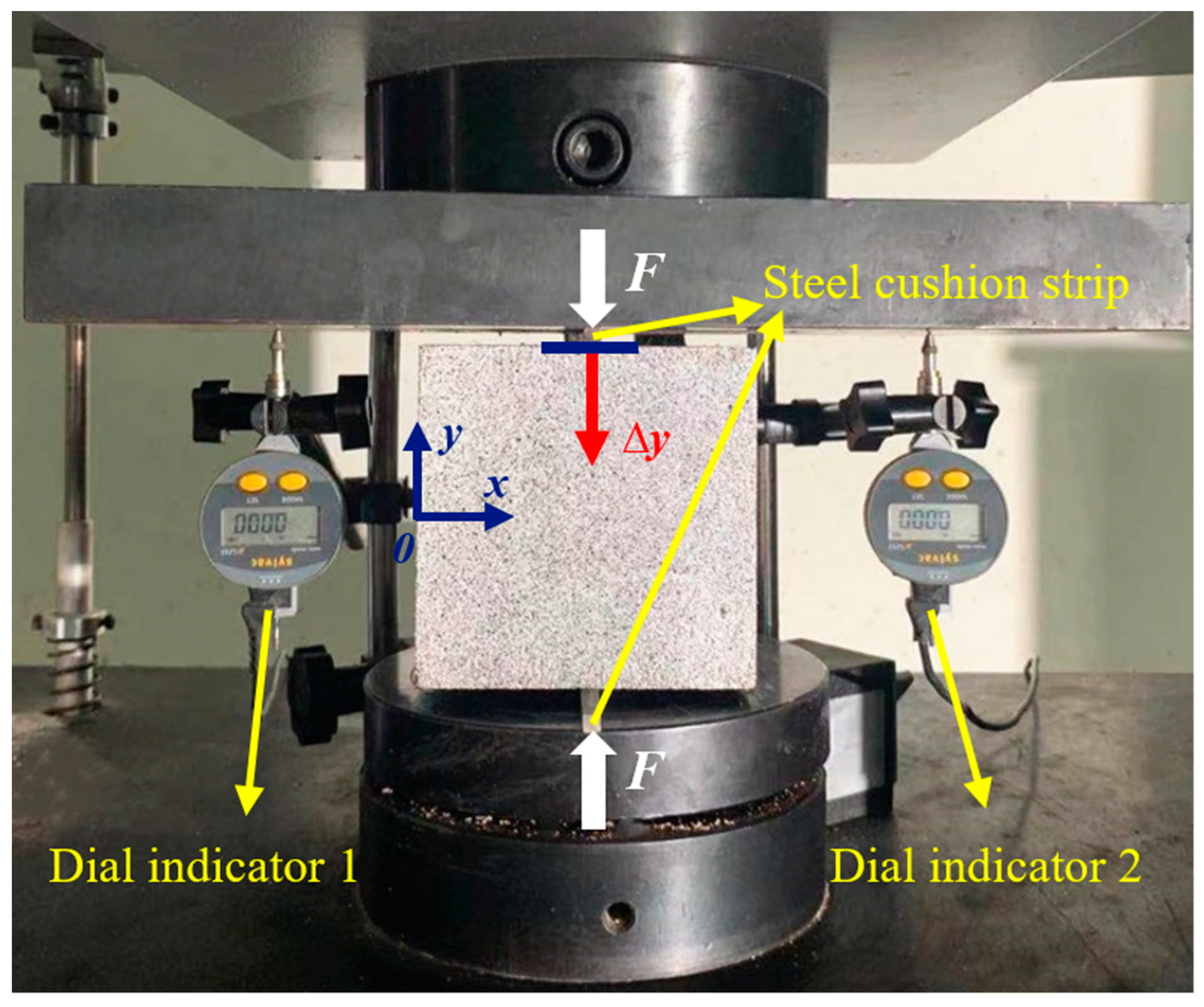

2.2.2. Splitting Tensile Test

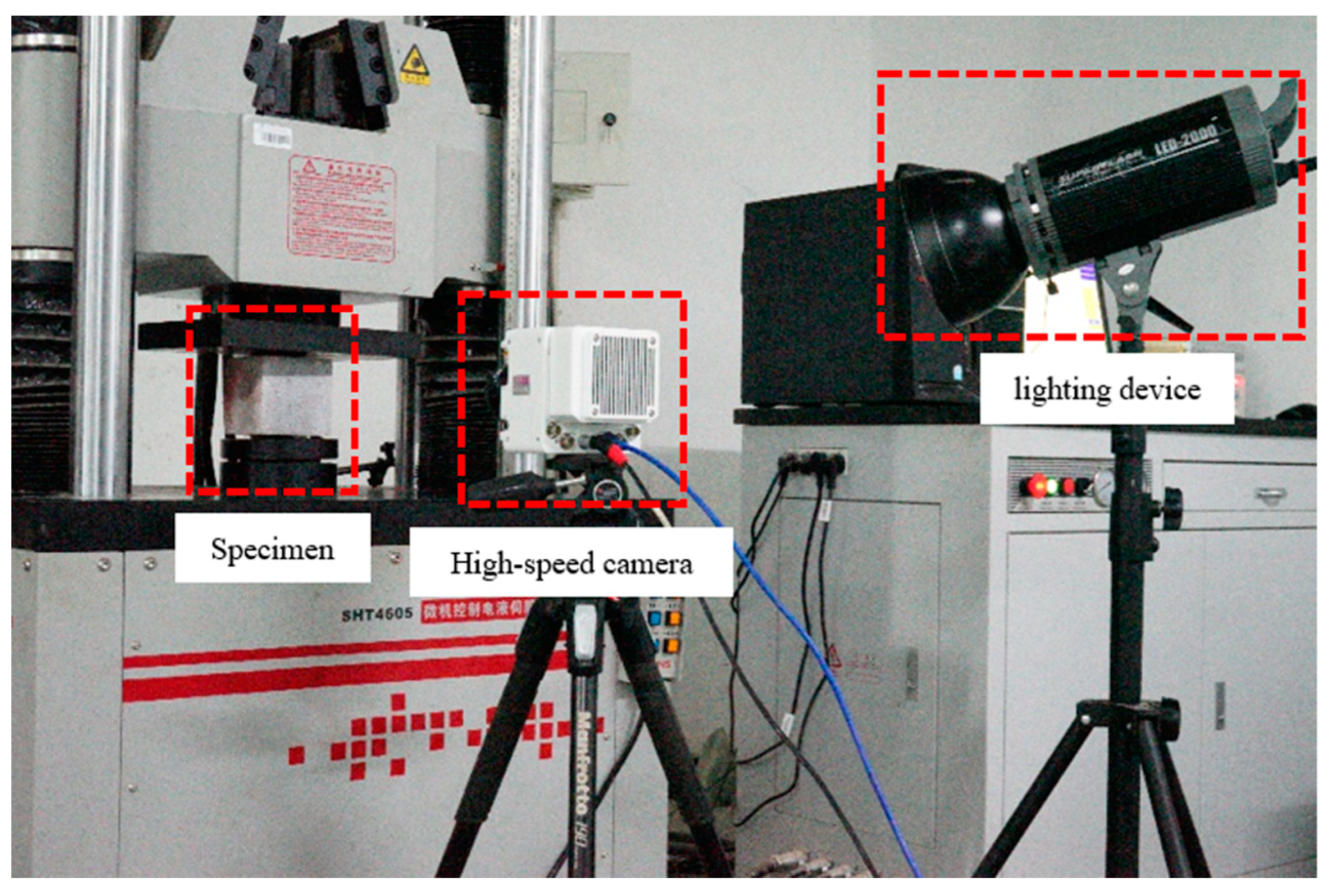

2.2.3. High-Speed Digital Image Correlation (HDIC)

3. Results and Discussion

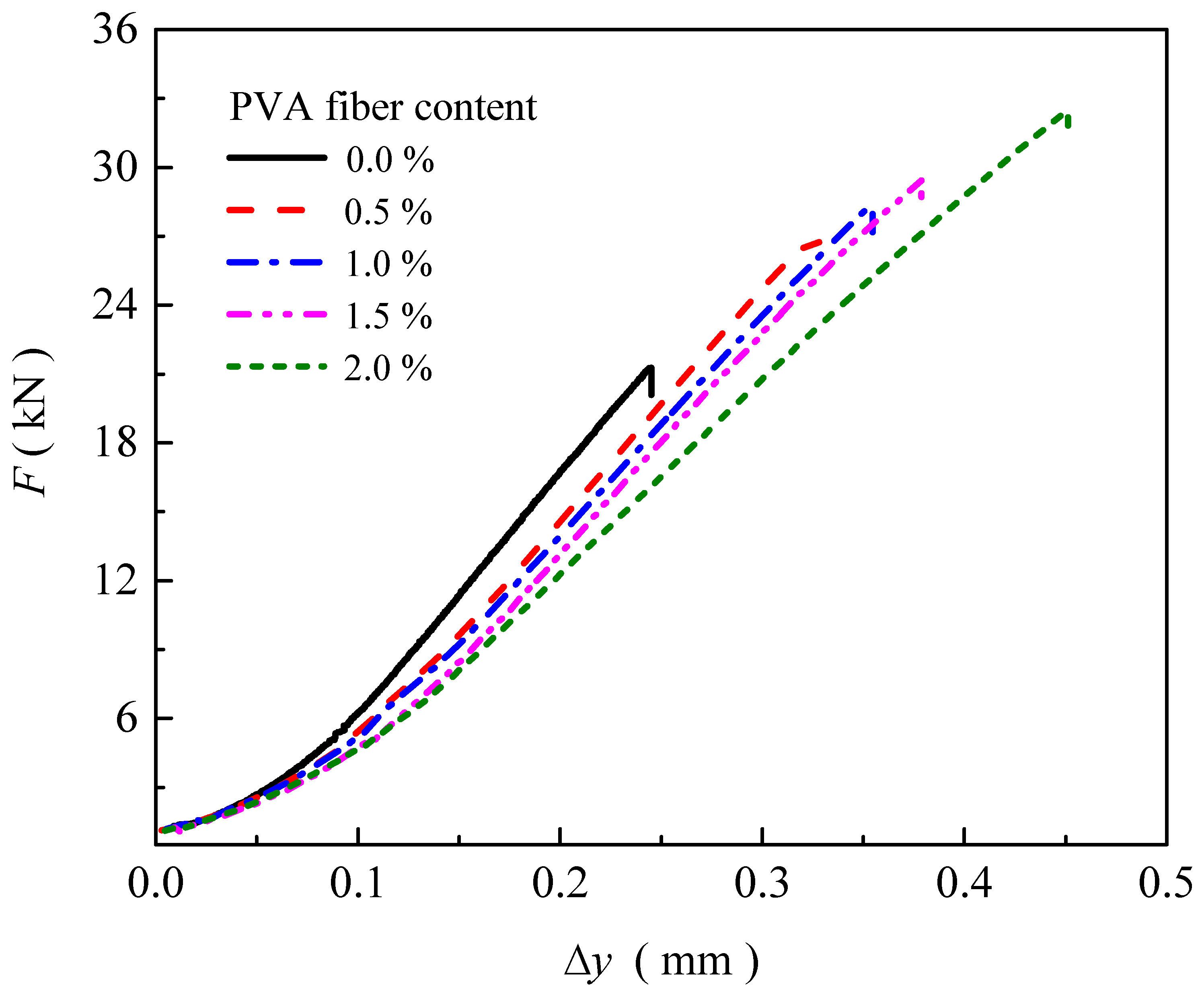

3.1. Splitting Tensile Strength

3.2. Geopolymer Specimen Failure Modes

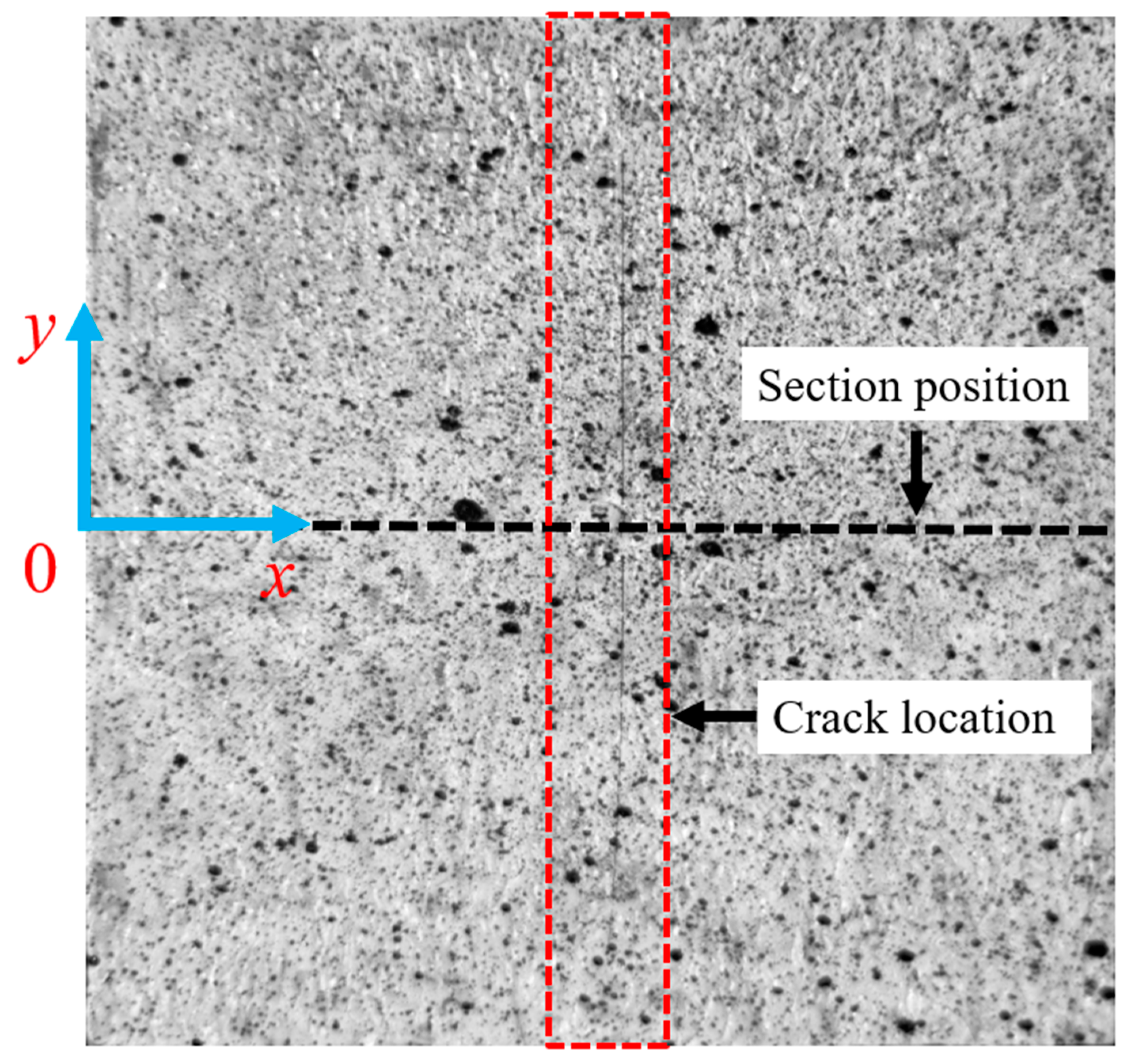

3.3. The Variation of Full-Field Displacement and Strain

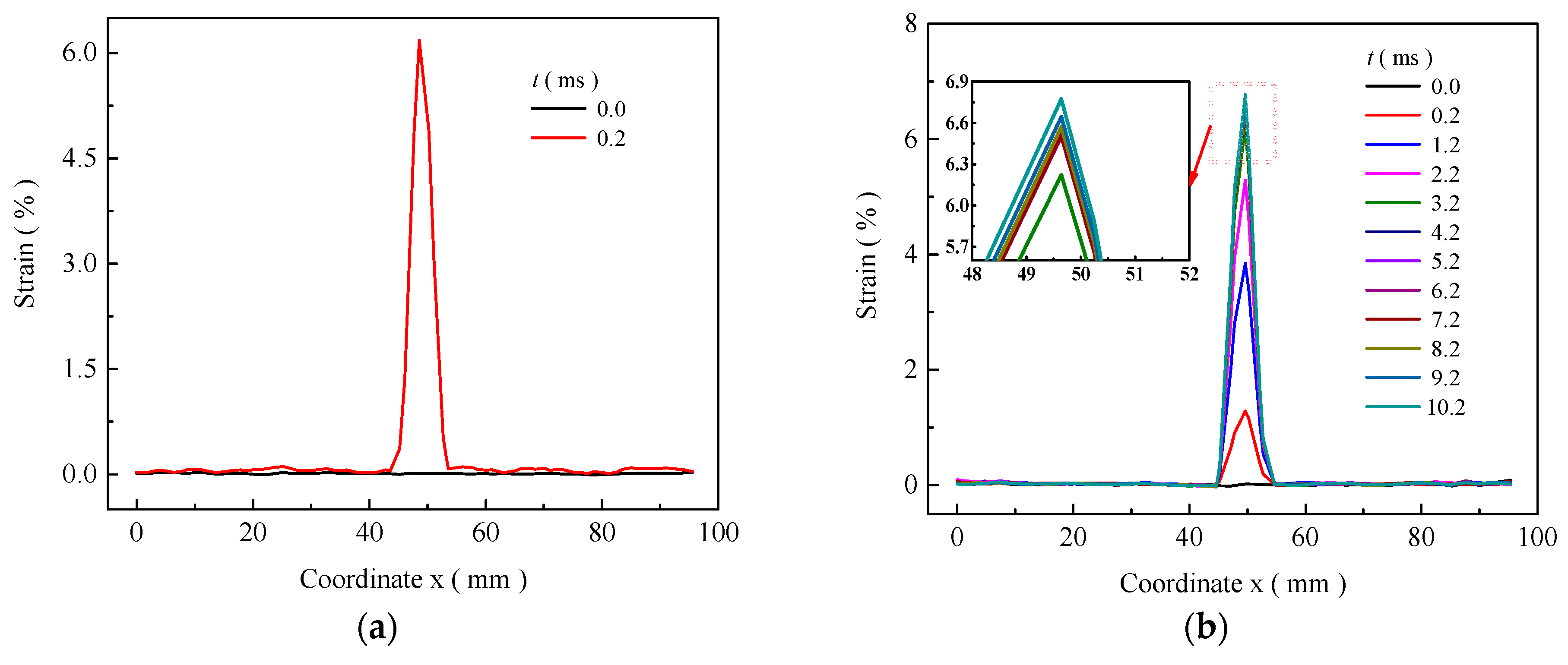

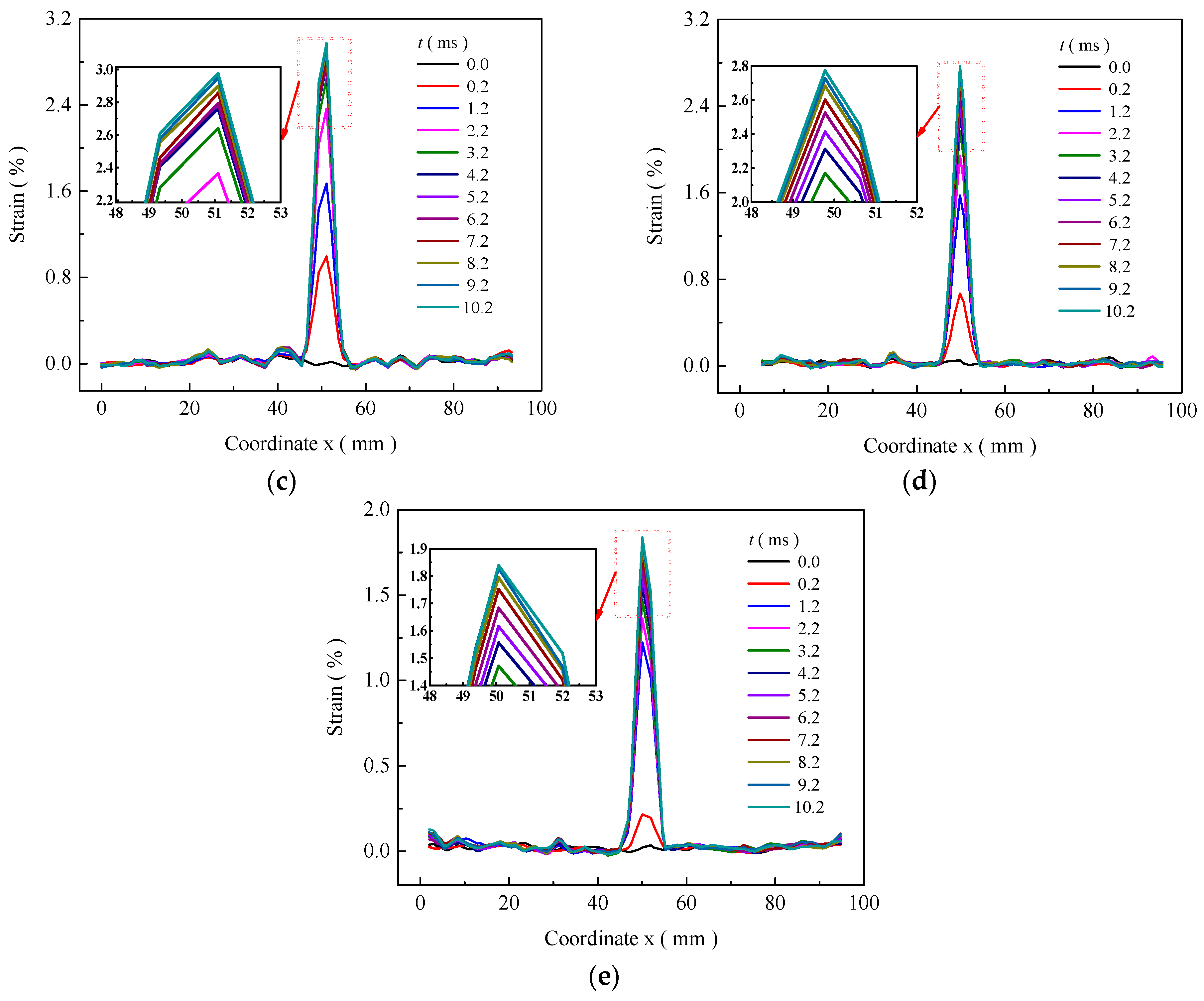

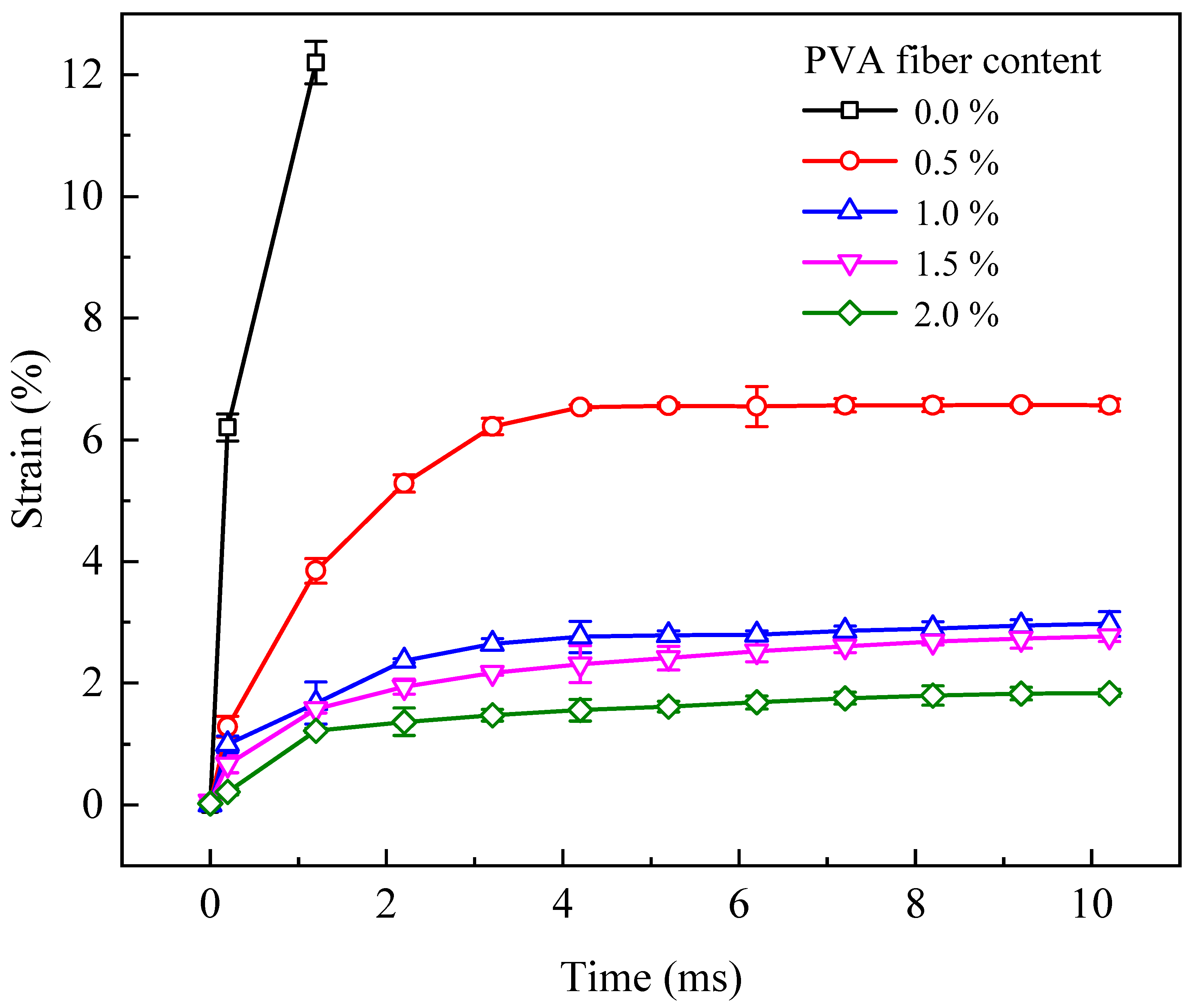

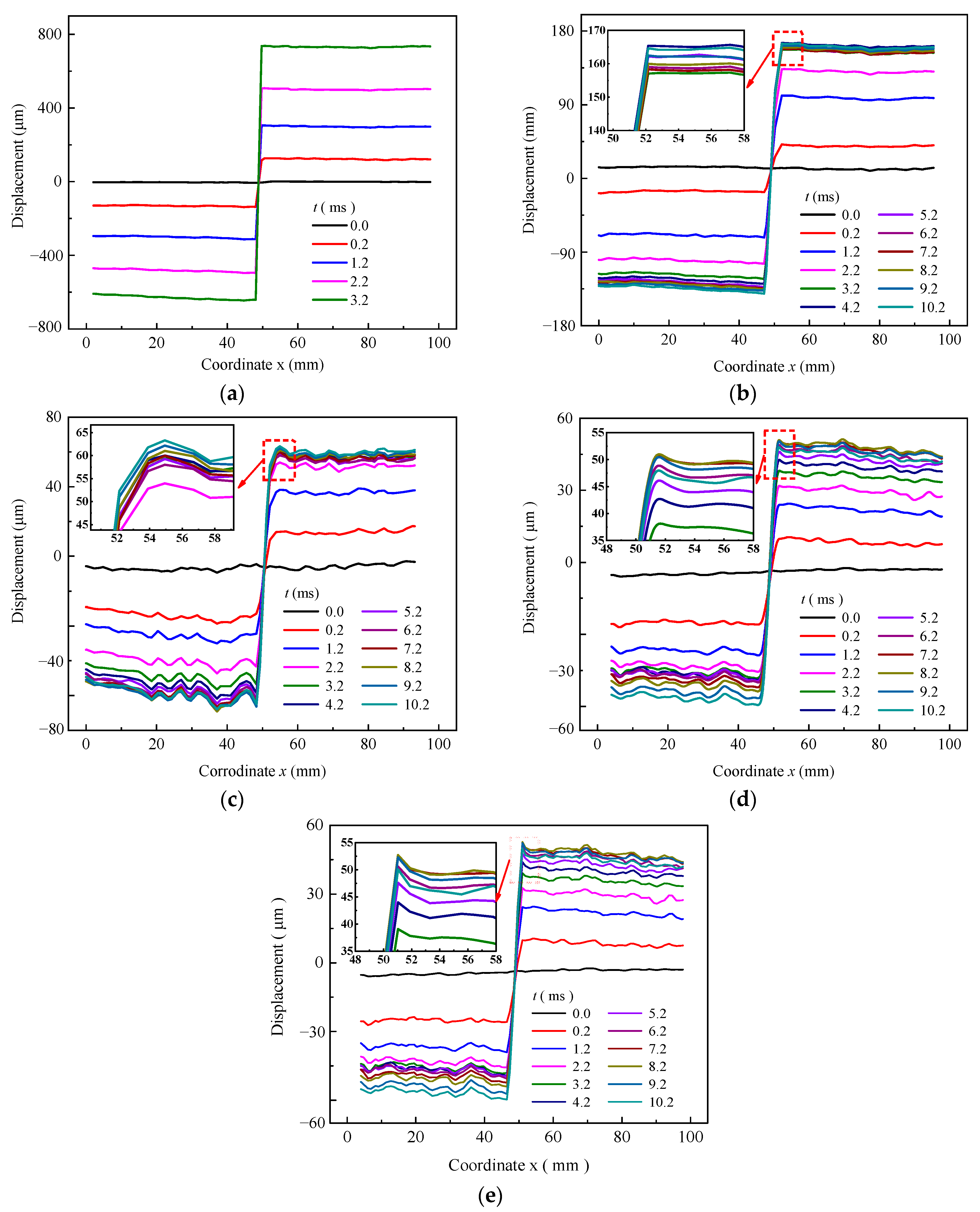

3.4. Analysis of Cracking Propagation Behavior

4. Conclusions

- (1)

- The PVA fiber can enhance the splitting mechanical properties of geopolymer. The splitting tensile strength and ultimate deformation increase as PVA fiber content increases, while the strain and displacement decrease as PVA fiber content increases. The splitting tensile strength of the geopolymer without PVA fiber is 1.22 MPa, and the ultimate compression deformation is 0.245 mm. When the fiber content was increased to 2.0%, the split tensile strength increased by 52.9%, and the ultimate compression deflection increased by 84.2%.

- (2)

- The incorporation of fiber can delay the cracking time and reduce strain change during the splitting process. When the fiber content is larger than 0.5%, the peak strain gradually increases with time and then tends to be stable. The maximum peak strain of the geopolymer decreases by 72.0% as the fiber content increases from 0.0% to 2.0%.

- (3)

- With the increase in PVA fiber content, the crack width gradually decreases, and the crack propagation speed gradually slows down. The maximum crack width was 0.3 mm at 0.5% PVA fiber content, while it decreased by 53.0%, 66.4%, and 70.9% as the PVA fiber content increased to 1.0%, 1.5%, and 2.0%, respectively.

- (4)

- Geopolymers with 1.0%, 1.5%, and 2.0% PVA fiber all meet the standard of GB50010-2010 for concrete structures, which requires crack widths to be less than 0.3 mm. The geopolymer with 2.0% fiber content shows the best anti-cracking performance, and the crack width is only 0.087 mm, less than 0.1 mm, which meets the crack resistance requirements of the actual project for economic consideration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Davidovits, J. Geopolymers: Inorganic Polymeric New Materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Roy, D.M. New strong cement materials: Chemically bonded ceramics. Science 1987, 235, 651–658. [Google Scholar] [CrossRef] [PubMed]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S.J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloid Surf. A-Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Ferone, C.; Roviello, G.; Colangelo, F.; Cioffi, R.; Tarallo, O. Novel hybrid organic-geopolymer materials. Appl. Clay Sci. 2013, 73, 42–50. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Conc. Res. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Sun, W.; Li, Z.J.; Zhou, X.M.; Eddie; Chau, C.K. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2006, 22, 370–383. [Google Scholar]

- Zhang, Y.S.; Sun, W.; Li, Z.J. Impact behavior and microstructural characteristics of PVA fiber reinforced fly ash-geopolymer boards prepared by extrusion technique. J. Mater. Sci. 2006, 41, 2787–2794. [Google Scholar]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Tensile strain hardening behavior of PVA Fiber-reinforced engineered geopolymer composite. J. Mater. Civil Eng. 2015, 27, 04015001. [Google Scholar] [CrossRef]

- Guo, X.L.; Yang, J.Y. Intrinsic properties and micro-crack characteristics of ultra-high toughness fly ash/steel slag based geopolymer. Constr. Build. Mater. 2020, 230, 116965. [Google Scholar] [CrossRef]

- Kan, L.L.; Zhang, L.; Zhao, Y.J.; Wu, M. Properties of polyvinyl alcohol fiber reinforced fly ash based Engineered Geopolymer Composites with zeolite replacement. Constr. Build. Mater. 2019, 231, 117161. [Google Scholar] [CrossRef]

- Kan, L.L.; Lv, J.W.; Duan, B.B.; Wu, M. Self-healing of Engineered Geopolymer Composites prepared by fly ash and metakaolin. Cem. Concr. Res. 2019, 125, 105895. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Matrix design of strain hardening fiber reinforced engineered geopolymer composite. Compos. Part B Eng. 2016, 89, 253–265. [Google Scholar] [CrossRef]

- Odimegwu, T.C.; Kaish, A.B.M.A.; Jamil, M.; Zain, M.F.M.; Turlanbekov, A.; Al Zand, A.W. Mechanical characterization of geopolymer paste and mortar fabricated from alum sludge and fly ash. Buildings 2023, 13, 2118. [Google Scholar] [CrossRef]

- Zuaiter, M.; El-Hassan, H.; El-Maaddawy, T.; El-Ariss, B. Properties of slag-fly ash blended geopolymer concrete reinforced with hybrid glass fibers. Buildings 2022, 12, 1114. [Google Scholar] [CrossRef]

- Ramesh, V.A.; Jarghouyeh, E.N.; Alraeeini, A.S.; Al-Fakih, A.; Li, C.G. Optimisation investigation and bond-slip behaviour of high strength PVA-engineered geopolymer composites (EGC) cured in ambient temperatures. Buildings 2023, 13, 3020. [Google Scholar] [CrossRef]

- Michaud, K.; Hoult, N.; Lotfy, A.; Lum, P. Performance in shear of reinforced concrete slabs containing recycled concrete aggregate. Mater. Struct. 2016, 49, 4425–4438. [Google Scholar] [CrossRef]

- El Ghadioui, R.; Proske, T.; Tran, N.L.; Graubner, C.A. Structural behaviour of CFRP reinforced concrete members under bending and shear loads. Mater. Struct. 2020, 53, 63. [Google Scholar] [CrossRef]

- Wu, B.; Jin, H.M. Compressive fatigue behavior of compound concrete containing demolished concrete lumps. Constr. Build. Mater. 2019, 210, 140–156. [Google Scholar] [CrossRef]

- Lai, D.D.; Demartino, C.; Db, Y.X. High-strain rate tension behavior of fiber-reinforced rubberized concrete. Cem. Concr. Compos. 2022, 131, 104554. [Google Scholar] [CrossRef]

- Roziere, E.; Cortas, R.; Loukili, A. Tensile behaviour of early age concrete: New methods of investigation. Cem. Concr. Compos. 2015, 55, 153–161. [Google Scholar] [CrossRef]

- Lee, I.W.; Park, J.; Kim, D.J.; Pyo, S. Effects of abraded fine particle content on strength of quick-hardening concrete. Cem. Concr. Compos. 2019, 96, 225–237. [Google Scholar] [CrossRef]

- Zhang, D.B.; Zhao, J. Determination of mechanical properties and full-field strain measurements of rock material under dynamic loads. Int. J. Rock Mech. Min. Sci. 2013, 60, 423–439. [Google Scholar] [CrossRef]

- Fan, L.F.; Yang, Q.H.; Du, X.L. Spalling characteristics of high-temperature treated granitic rock at different strain rates. J. Rock Mech. Geotech. Eng. 2024, 16, 1280–1288. [Google Scholar] [CrossRef]

- Yang, Q.H.; Fan, L.F.; Du, X.L. Determination of wave propagation coefficients of the granite by high-speed digital image correlation (HDIC). Rock Mech. Rock Eng. 2022, 55, 4497–4505. [Google Scholar] [CrossRef]

- Flores, M.; Mollenhauer, D.; Runatunga, V.; Beberniss, T.; Rapking, D.; Pankow, M. High-speed 3D digital image correlation of low-velocity impacts on composite plates. Compos. Part B-Eng. 2017, 131, 153–164. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M.Z. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Abbas, A.G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Palomoa, A.; Grutzeck, M.W.; Blancoa, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Jiang, W.; Xie, Y.; Li, W.; Wu, J.; Long, G. Prediction of the Splitting Tensile Strength of the Bonding Interface by Combining the Support Vector Machine with the Particle Swarm Optimization Algorithm. Eng. Struct. 2021, 230, 111696. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, J.; Li, Q.; Wan, J.; Ling, Y. Mechanical and Fracture Properties of Steel Fiber-Reinforced Geopolymer Concrete. Sci. Eng. Compos. Mater. 2021, 28, 299–313. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- Zhong, W.L.; Zhang, Y.H.; Fan, L.F. High-ductile engineered geopolymer composites (EGC) prepared by calcined natural clay. J. Build. Eng. 2023, 63, 105456. [Google Scholar] [CrossRef]

- Zhong, W.L.; Sun, Y.H.; Zhao, X.; Fan, L.F. Study on synthesis and water stability of geopolymer pavement base material using waste sludge. J. Clean. Prod. 2024, 445, 141331. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2010.

| Composition | Al2O3 | SiO2 | Na2O/K2O | Others |

|---|---|---|---|---|

| Content | 43.20% | 49.10% | 0.57% | 7.13% |

| Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Diameter (mm) | Length (mm) |

|---|---|---|---|---|

| 1.3 | 1620 | 42.8 | 0.039 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Sun, Y.; Zhong, W.; Fan, L. A Real-Time Study on the Cracking Characteristics of Polyvinyl Alcohol Fiber-Reinforced Geopolymer Composites under Splitting Tensile Load Based on High-Speed Digital Image Correlations. Buildings 2024, 14, 1986. https://doi.org/10.3390/buildings14071986

Zhang Y, Sun Y, Zhong W, Fan L. A Real-Time Study on the Cracking Characteristics of Polyvinyl Alcohol Fiber-Reinforced Geopolymer Composites under Splitting Tensile Load Based on High-Speed Digital Image Correlations. Buildings. 2024; 14(7):1986. https://doi.org/10.3390/buildings14071986

Chicago/Turabian StyleZhang, Yunhan, Yuhang Sun, Weiliang Zhong, and Lifeng Fan. 2024. "A Real-Time Study on the Cracking Characteristics of Polyvinyl Alcohol Fiber-Reinforced Geopolymer Composites under Splitting Tensile Load Based on High-Speed Digital Image Correlations" Buildings 14, no. 7: 1986. https://doi.org/10.3390/buildings14071986

APA StyleZhang, Y., Sun, Y., Zhong, W., & Fan, L. (2024). A Real-Time Study on the Cracking Characteristics of Polyvinyl Alcohol Fiber-Reinforced Geopolymer Composites under Splitting Tensile Load Based on High-Speed Digital Image Correlations. Buildings, 14(7), 1986. https://doi.org/10.3390/buildings14071986