Abstract

The concept of self-healing materials and the development of encapsulated curing agents represent a cutting-edge approach to enhancing the longevity and reducing the maintenance costs of cementitious structures. This systematic literature review aims to shed light on the parameters involved in the autonomous self-healing of cementitious materials, utilizing various encapsulated healing agents such as pellets, granules, and capsules. This review also identifies and selects studies that offer additional insights into the efficacy of the self-healing process in cementitious materials and the influence of these specific encapsulated healing agents on the physical mechanical properties of mortars. This comprehensive approach provides a deep understanding of the interplay between self-healing and the physical–mechanical properties of mortars containing these encapsulated healing agents. The main findings indicate that the cement-to-sand ratio, characteristics of fine aggregates, and encapsulation methods significantly impact crack control, self-healing efficiency, and properties of mortar in both fresh and hardened states. The content of encapsulated healing agents within the cementitious matrix affects both the initial workability or flow and subsequent mechanical properties. While pellets coated with PVA film typically reduce workability in the fresh state and compressive strength, capsules coated with Portland cement and sodium silicate mitigate these effects and improve crack sealing in fresh and hardened states without compromising the self-healing capacity of cracks. The three-point flexural test has emerged as the preferred method for a pre-crack assessment over 28 days, with variations depending on the type of healing agent used. As noted in the literature, water has been identified as the optimal environment for autonomous healing. These findings underscore the potential of encapsulation techniques to enhance self-healing capabilities through the controlled release of agents within the cementitious matrix, thereby advancing the research on and development of intelligent construction materials and increasing the durability of cement-based structures.

1. Introduction

Cracking is inevitable in cementitious materials and can compromise durability by creating pathways for aggressive agents, such as chlorides. Microcracks affect water permeability and the esthetics of buildings. Additionally, cracks can lead to concrete deterioration due to reinforcement corrosion, potentially resulting in structural collapse depending on the severity and size of the cracks. This necessitates continuous maintenance and generates significant repair costs. To address these issues and reduce infrastructure maintenance costs, researchers are exploring self-healing cementitious materials, which can repair themselves under specific conditions without external intervention [1,2,3,4].

Self-healing cementitious materials and developing encapsulated healing agents represent promising scientific approaches to solving common problems in the construction industry. There are two self-healing mechanisms: autogenous and autonomous. Autogenous healing occurs naturally from the materials’ constituents. Still, it can be enhanced by adding mineral additives, crystalline admixtures, expansive agents based on calcium sulfoaluminate (CSA) cement, and superabsorbent polymers [5,6,7,8]. The self-healing ability of polypropylene fiber-reinforced cementitious composites has recently been highlighted [9]. The fibers enhance the concrete’s self-healing capability by restricting crack propagation. This prevents brittle behavior in concrete during cracking as fibers can control crack initiation, propagation, or coalescence, resulting in fewer extensive cracks in the concrete [10].

However, autogenous self-healing is limited to filling cracks up to 0.1 mm in size [11,12]. In contrast, autonomous self-healing can fill cracks up to 0.3 mm in size and, sometimes, seal cracks up to 1 mm [13]. In this system, self-healing occurs by encapsulating healing agents in microcapsules, granules, pellets, and capsules incorporated into the cementitious matrix.

Autogenous self-healing can result from physical, chemical, or mechanical causes. Physical causes occur due to the swelling of the hydrated cement paste from water absorption, which can reduce fluid flow in the cracks by up to 10% [14]. Chemical causes include the hydration of unhydrated cement particles and the precipitation of calcium carbonate in the cracks resulting from the reaction between calcium ions (Ca2+) and carbonate ions from water or carbon dioxide (CO2) [13]. Mechanical causes involve the presence of fine particles in water passing through the cracks and small fragments of the fractured cementitious matrix. The self-healing capacity is related to the hydration time of the cementitious matrix at the moment of cracking: in the early stages, the continuous hydration of anhydrous cement particles is the primary mechanism, while in later stages, calcium carbonate precipitation becomes the primary mechanism. The presence of water is essential for both self-healing mechanisms [15,16].

In contrast, autonomous self-healing occurs through encapsulating healing agents in microcapsules, granules, pellets, and capsules incorporated into the cementitious matrix. Commonly used healing agents include silica fume (SF), magnesium oxide (MgO), sodium carbonate (Na2CO3), sodium nitrate, bentonite, Portland cement, polyurethane, sodium monofluorophosphate, and calcium sulfoaluminate (CSA) cement [17,18,19,20]. Encapsulation-based self-healing occurs when cracking in the cementitious matrix breaks the capsules, releasing the healing agent, which then reacts and fills the cracks [15]. Some healing agents react with air moisture due to heating, or with the cementitious matrix itself or other agents in the matrix or agents provided by additional capsules [21]. Only the capsules in direct contact with the crack release the healing agent; the others remain intact. Catalysts can be added to accelerate the healing agent’s reaction [22].

Encapsulated healing agents can also be composed of biological materials [23,24]. For biological agents, bacterial spores, along with their respective nutrients and sources of calcium, are used so that when a crack occurs, the bacteria react with oxygen and water to form calcium carbonates that close the cracks [25,26]. Various encapsulation techniques can be employed when discussing mineral and chemical encapsulated healing agents, such as pellets, microcapsules, concentric capsules, and granules. Additionally, there is no consensus on the use of these agents; some studies employ substitution in inert materials, i.e., sand [27,28,29,30], while others perform substitution [31,32] or even addition [33,34,35] in cement.

Encapsulation techniques are employed to prevent the immediate reaction of crystalline agents or admixtures, which can reduce the efficiency of concrete self-healing. Microcapsules have diameters smaller than 1 mm, while those with diameters larger than 1 mm are designated as macrocapsules [13]. Capsules can be composed of glass, ceramic, or silica [36,37,38,39], although alkali–aggregate reactions and difficulty in dispersion may occur in glass capsules [38]. Several encapsulation techniques can be employed, including in situ polymerization, interfacial polymerization, Pickering emulsions, mini emulsion polymerization, solvent evaporation/solvent extraction, and sol–gel reaction [40].

In granules and pellets manufactured through granulators, the healing agent is typically incorporated as a substitution for the fine aggregate, contributing to superior mechanical performance [41]. The release of the healing agent is governed by the hardness of the granule and the thickness of the water-soluble film coating. The diameter of these materials can vary between 0.5 mm and 2 mm [31].

This study aims to identify the parameters adopted among different encapsulation methods for healing agents (pellets, microcapsules, concentric capsules, and granules) and how they affect cementitious materials’ workability, mechanical strength, and self-healing capacity. To achieve this, a systematic review was conducted to identify the predominant forms of surface coating, the types of coating, and the most efficient agents for self-healing materials.

Most research on self-healing in cementitious materials focuses on capsule production, characterization, bacterial introduction, and the self-healing process and parameters [42,43,44]. This article discusses critical parameters, particularly the influence of encapsulating healing agents through pellets and granules, on mortars’ physical, mechanical, and self-healing properties. Recent studies on self-healing mortars have considered the mixed composition, types of healing agents, methods for inducing cracks, the crack healing time, and curing environments to assess self-healing efficiency. The content of incorporated pellets, granules, and capsules, as well as the type of coating, significantly influences the physical–mechanical properties of mortar. This study systematically presents insights into self-healing mortars, contributing to a comprehensive understanding of the mentioned methods and parameters and enabling a more precise direction for achieving effective crack sealing without compromising mortar properties.

2. Systematic Literature Review

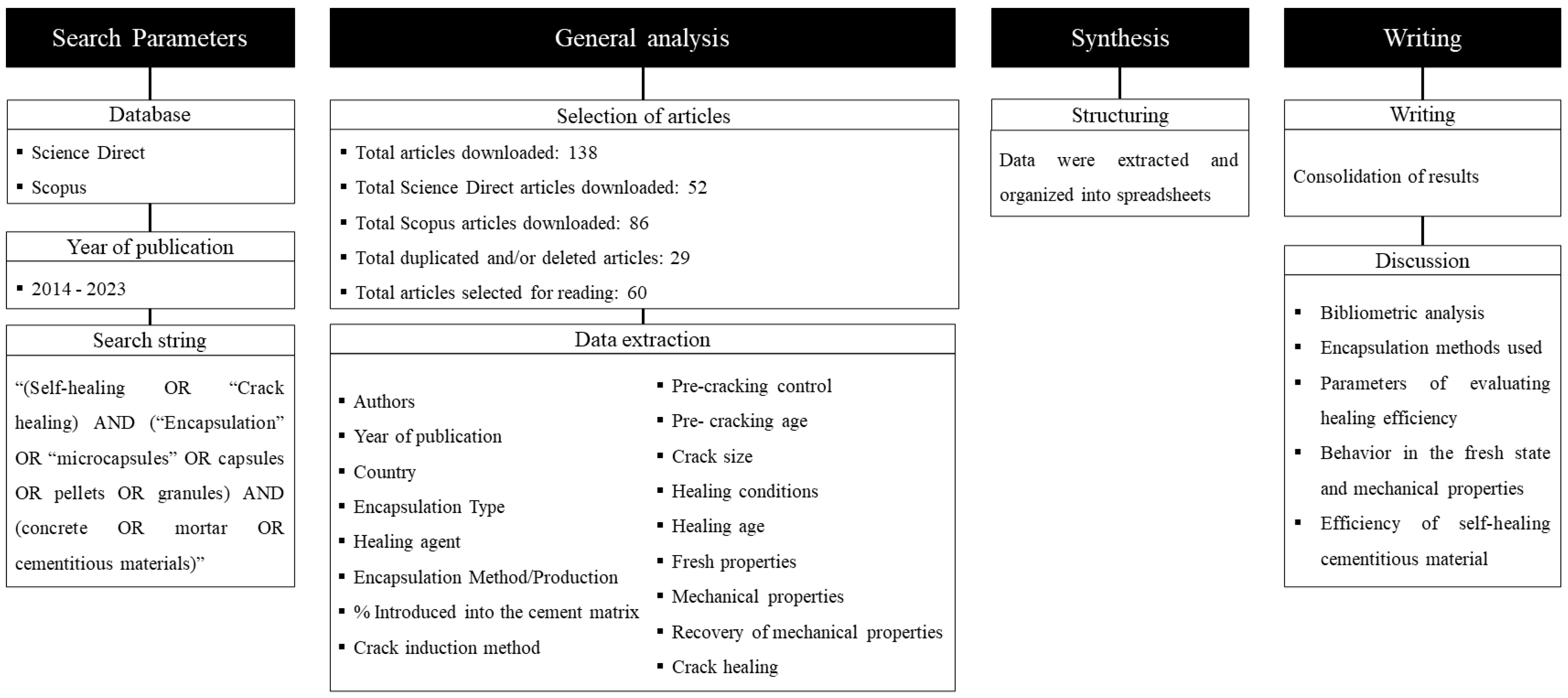

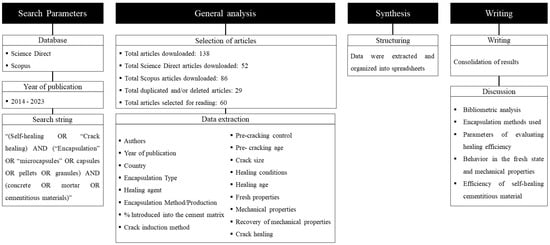

This study employed the systematic review method to conduct information retrieval. We chose to adopt the procedure known as the Systematic Search Flow (SSF) method, which unfolds in four crucial phases: the definition of the search protocol (encompassing the specification of search parameters, database exploration, and the management of identified documents), analysis, synthesis, and the writing phase [45].

The Scopus and ScienceDirect platforms were utilized as primary search sources for the research conducted between 2014 and the first semester of 2023. The search employed the following terms: (“Self-healing” OR “Crack healing”) AND (“Encapsulation” OR “microcapsules” OR “capsules” OR “pellets” OR “granules”) AND (“concrete” OR “mortar” OR “cementitious material”).

Figure 1 details the implementation of the four stages of the method for specific research related to identifying crucial parameters for the self-healing of cementitious materials. Thus, the following information was gathered from the articles: authors, publication year, country, type of encapsulation, type of curing agent, method/production of encapsulation, incorporation content of capsules/pellets/granules in the cementitious matrix, crack induction method, pre-crack age, crack size, curing conditions, self-healing curing time, properties in the fresh state, mechanical properties, and material self-healing.

Figure 1.

The stages of the procedures implemented to conduct the systematic literature review.

Bibliometric Analysis

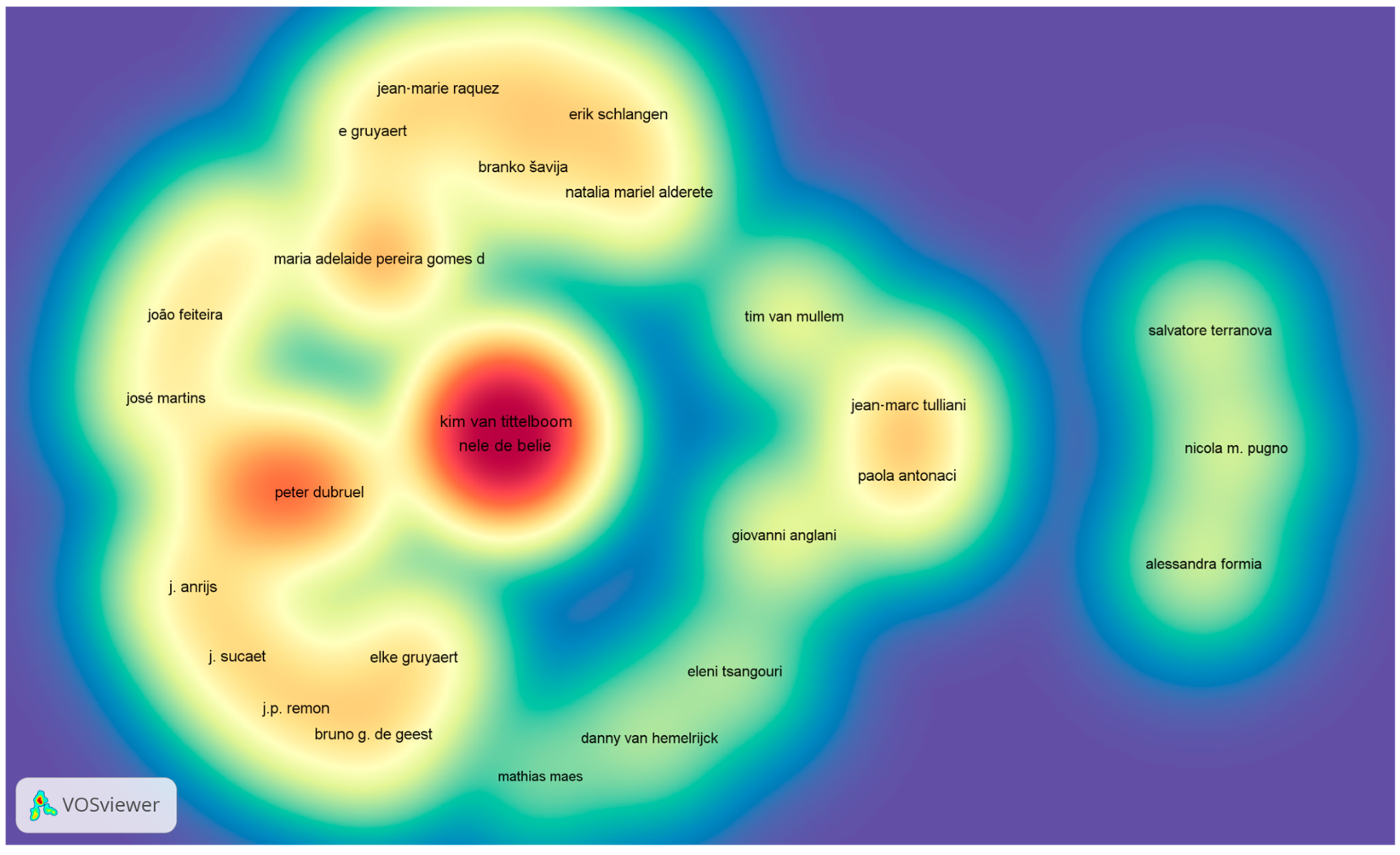

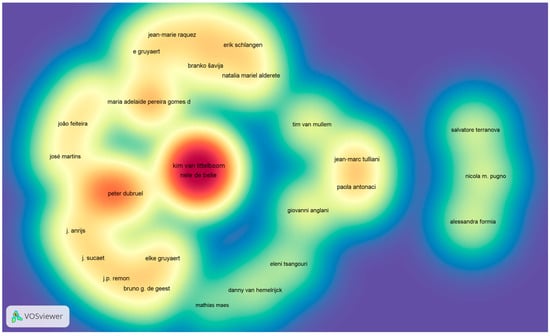

Figure 2 presents a density map highlighting the prominence of 16 authors in the context of citation coupling, co-authorship, and article quantity out of 77 authors analyzed using the VOSviewer software, version 1.6.17 in self-healing materials. This analysis addresses relevant procedures for encapsulating curing agents through capsules, microcapsules, pellets, and granules. Researchers Van Tittelboom, K. and De Belie, N. are particularly notable, with total linked indices of 26 and 24, respectively, underscoring their significant contributions to this research area. Furthermore, although not included in the density map, author Al-Tabbaa, A. is also prominently featured, focusing on advancing research on using expansive minerals through pellet encapsulation, marked by an index of 12.

Figure 2.

Density map with author identification, covering the analysis of co-authorship interconnection, citation, and article quantity through the VOSviewer software.

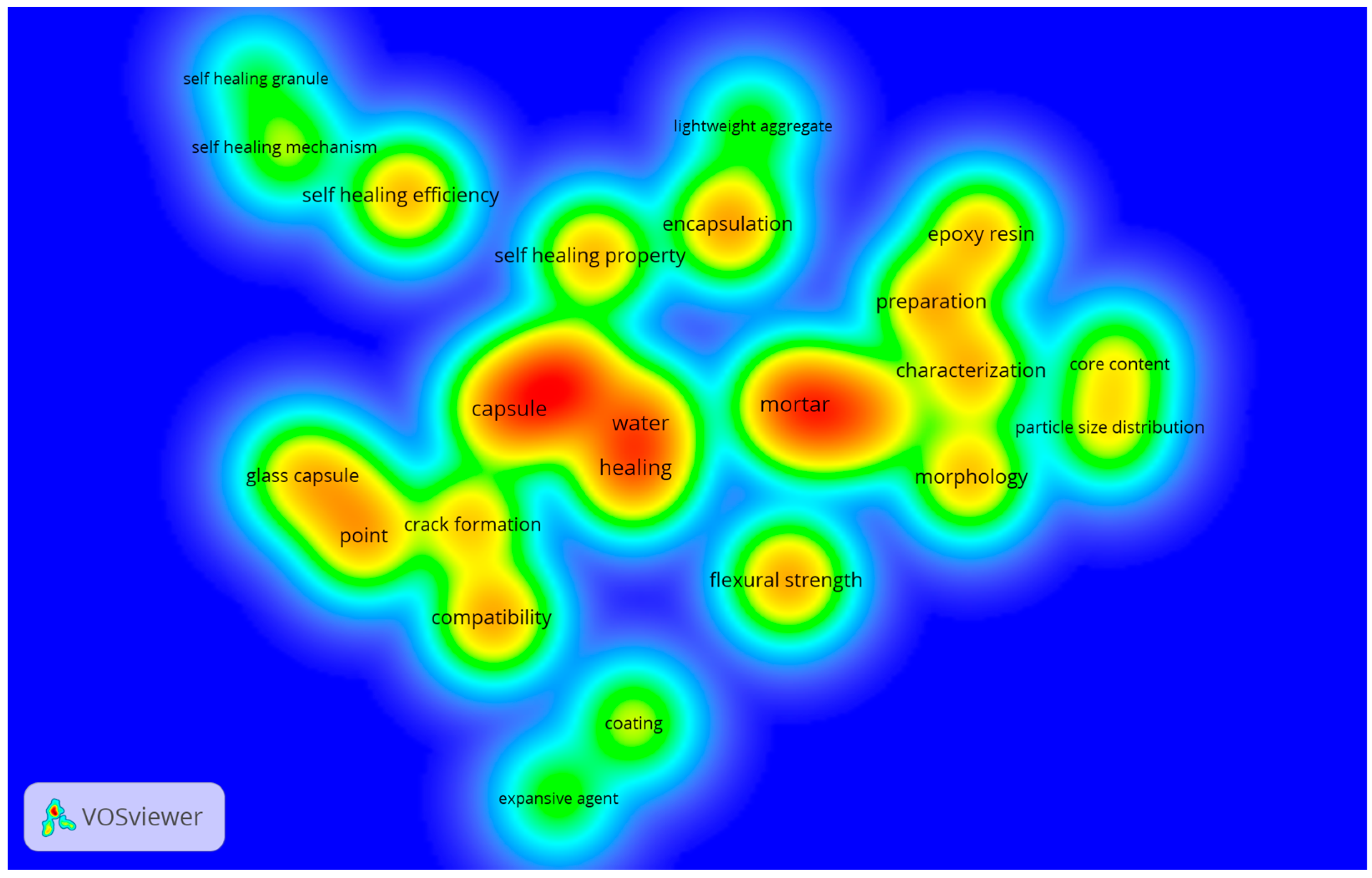

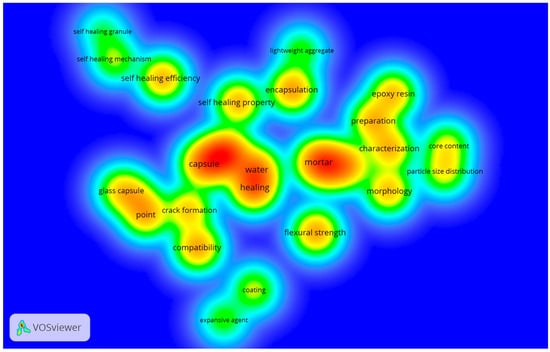

The most relevant keywords identified in the articles’ titles and abstracts included “Capsule”, “Microcapsule”, and “Self-healing efficiency”. They also included “Mechanical properties”, such as the compressive and flexural strength of the cementitious materials under study, and “Expanding agent” and its corresponding “Coating”, as illustrated in Figure 3.

Figure 3.

The relevant keywords identified in the evaluated articles using the VOSviewer software.

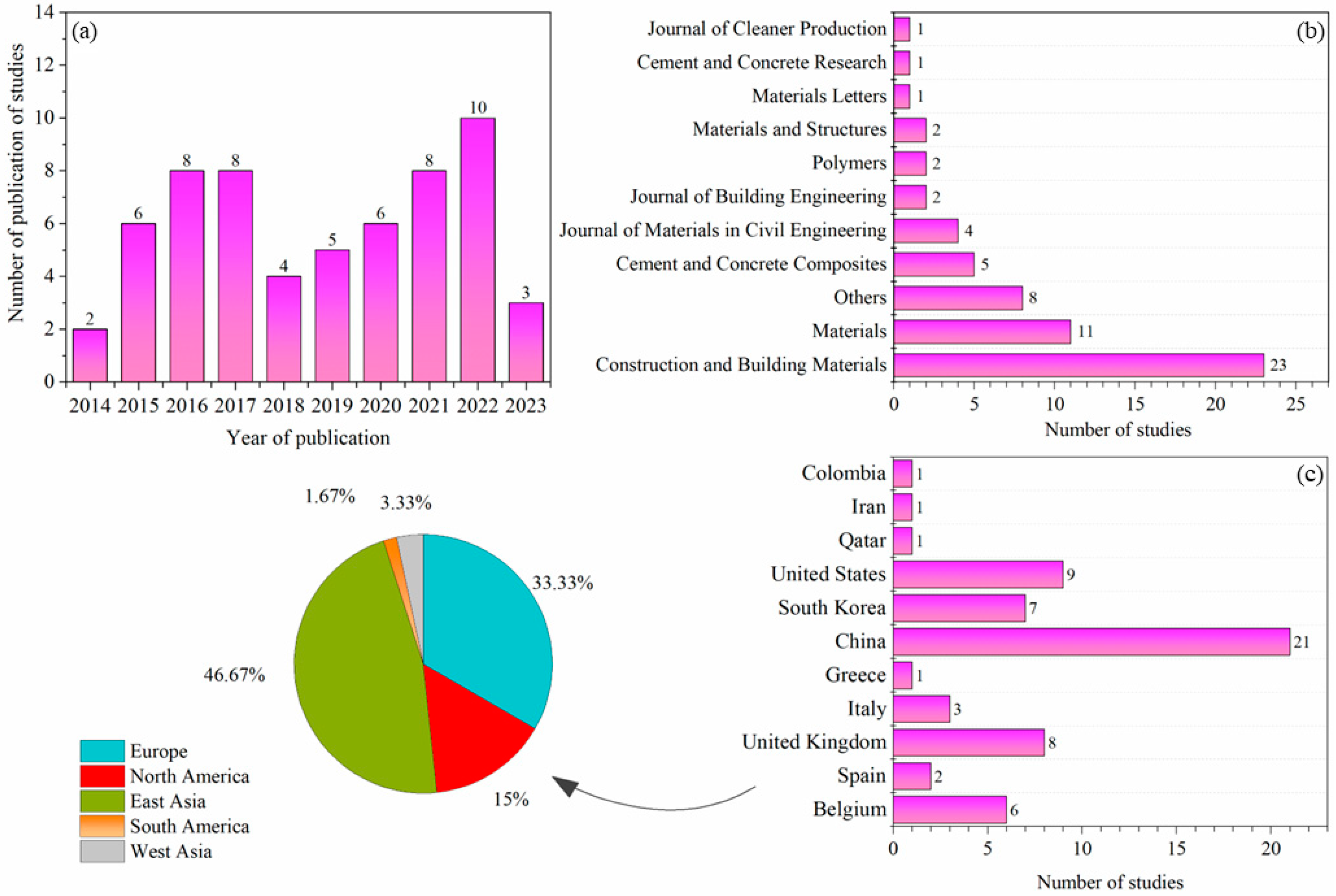

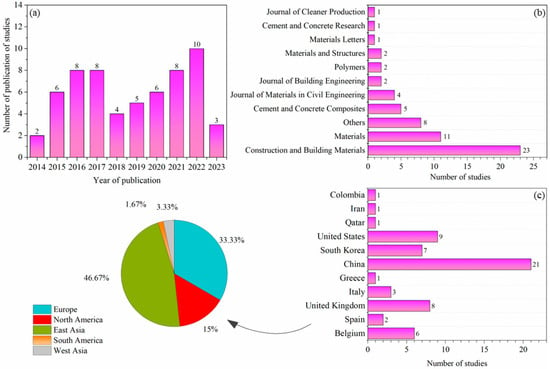

Figure 4 provides an overview of the bibliometric data associated with the 60 articles selected in the systematic review analysis, organized by year of publication, journal title, and geographical distribution by continent. There is a significant concentration of articles between 2015 and 2017, culminating in a peak of publications in 2022 (Figure 4a). This phenomenon highlights the relevance of the topic and the urgent need for further improvement and ongoing investigations in self-healing cementitious materials. The collected data came from a total of 18 journals, with highlights including the following: Construction and Building Materials (23), Materials (11), Cement and Concrete Composites (5), the Journal of Materials in Civil Engineering (4), the Journal of Building Engineering (2), Polymers (2), and Materials and Structures (2) (Figure 4b). Figure S1 presents the citation connection among all the journals evaluated.

Figure 4.

Bibliometric analysis of studies on self-healing: (a) year of publication, (b) journal type, and (c) number of studies published in countries.

The analysis revealed that the majority of the 60 selected articles originate from research institutions located in East Asia (46.7%), followed by Europe (33.33%) and North America (15%) (Figure 4c). This geographical concentration likely reflects the interest of these regions in seeking solutions to reduce costs related to the maintenance and repair of civil structures. Furthermore, it is observed that in South America, a notable research gap still exists, particularly concerning the development of studies related to autonomous self-healing in cementitious materials [4,18,22,27,28,29,31,32,33,34,35,36,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91].

Eleven studies were identified and selected to evaluate the effectiveness of the self-healing process in cementitious materials and to understand the impacts of pellets, granules, and capsules on the physical–mechanical properties of mortars, providing complementary results on both issues (as detailed in the Supplementary Materials of this document). This allowed for a comprehensive and in-depth understanding of the relationships between self-healing and the physical–mechanical properties of mortars with pellets, granules, and capsules.

3. Results and Discussion

3.1. Parameters for the Preparation and Composition of Self-Healing Material Mixtures

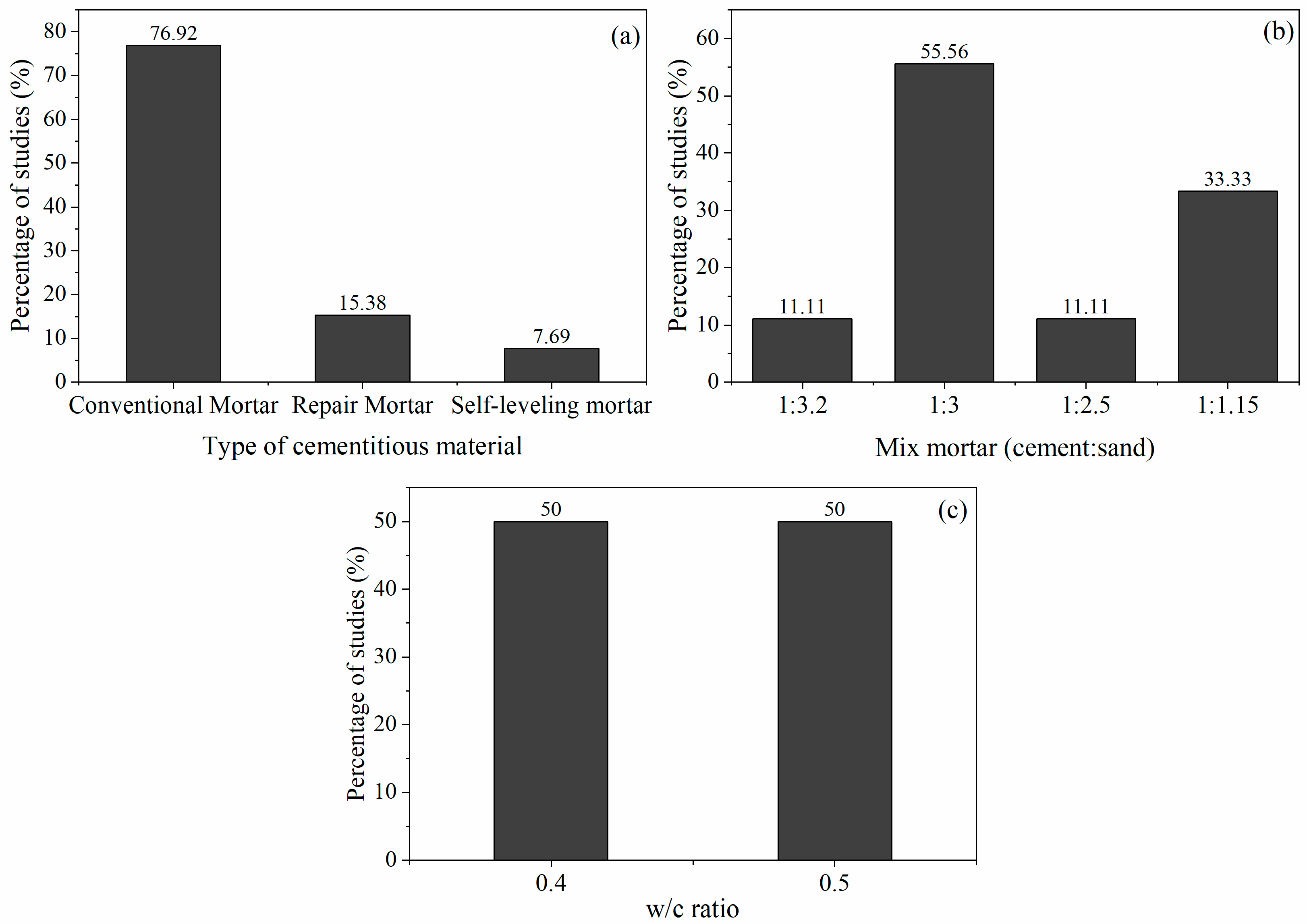

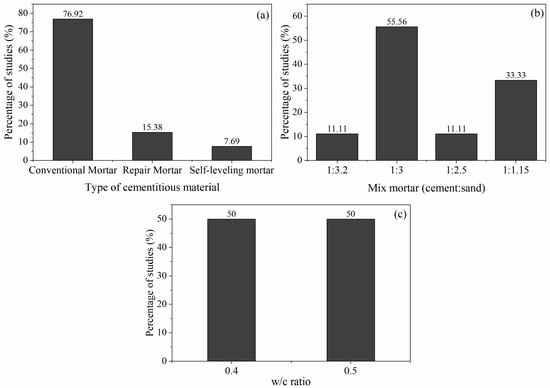

The analysis identified a series of standard parameters commonly adopted in producing and preparing self-healing cementitious materials (Figure 5). In a large portion of the examined studies, the elemental composition of the mortar used was conventional mortar (~77%) with a cement/sand ratio of 1:3 (~56%), and a water-to-cement ratio (w/c) ranging between 0.4 and 0.5 was maintained. A relevant aspect observed was the predominance of fine aggregates of small dimensions, with the everyday use of fine sands, whose grains generally have a size of less than 2 mm. This is because materials with these characteristics can assist in crack control, achieving highly uniform cracks and developing more stable behavior at the cracking moment [92,93,94].

Figure 5.

Survey of standard parameters used in development of self-healing material mixture compositions: (a) type of cementitious material, (b) mix mortar, and (c) w/c ratio.

3.2. Parameters Adopted in the Encapsulation of Healing Agents

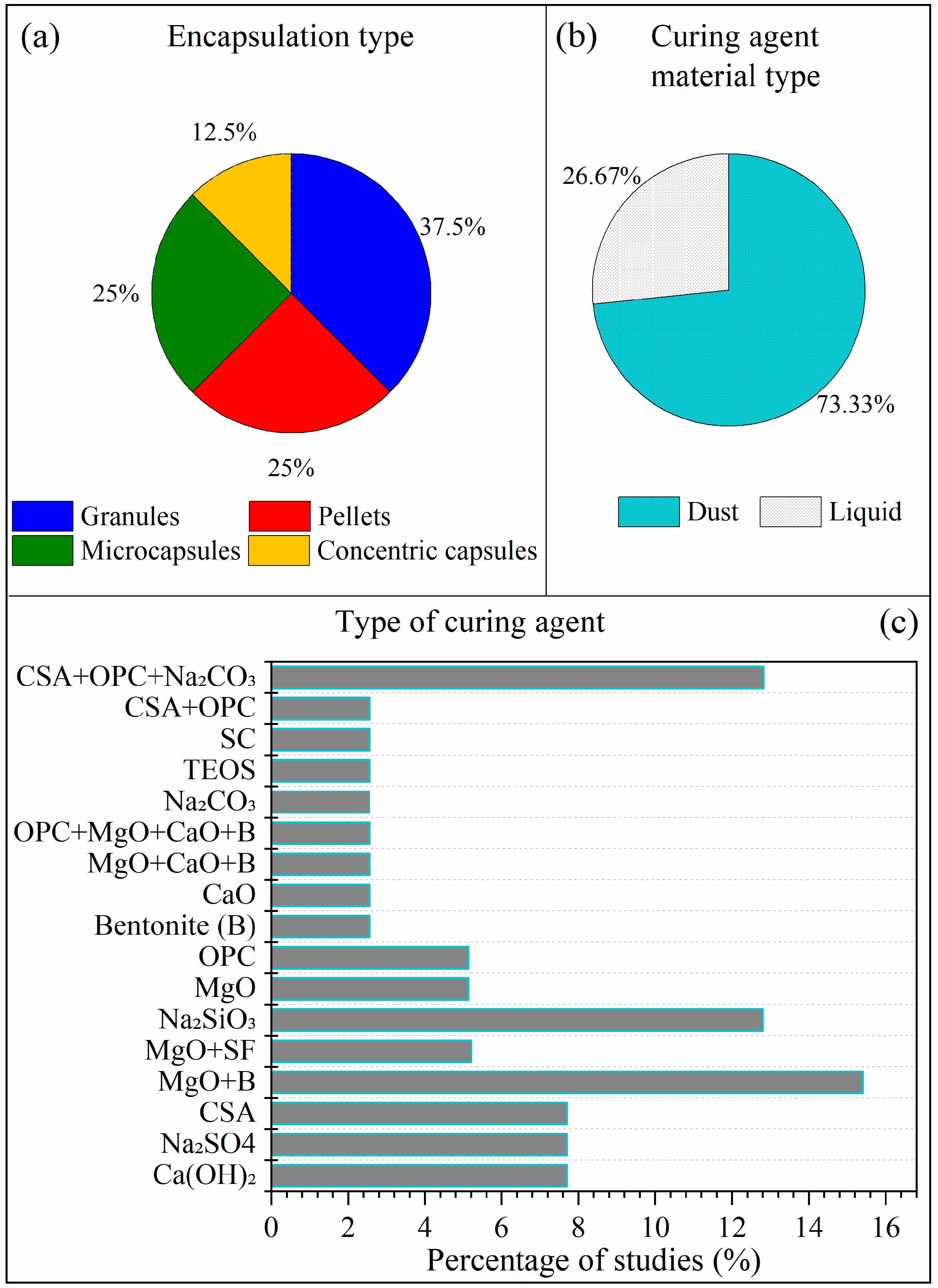

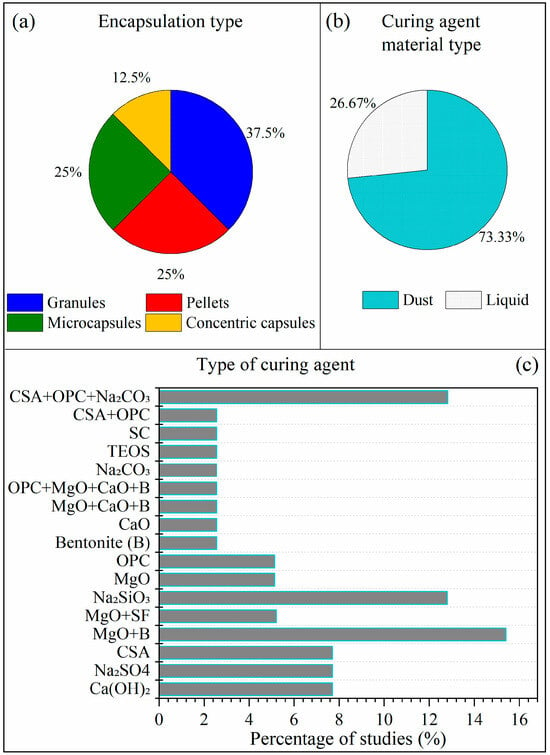

The analyzed studies found that the predominant encapsulation method for healing agents used granules, representing approximately 38% of the adopted approaches. Subsequently, a frequency of 25% for pellet usage was observed, along with the same percentage for the utilization of microcapsules/capsules. Lastly, concentric capsules were employed in about 13% of the investigations (Figure 6a).

Figure 6.

Survey of parameters adopted for (a) encapsulation type, (b) materials, (c) and curing agents.

It is worth noting that the employed healing agents are predominantly composed of powdered materials, accounting for approximately 73%, contrasting with 27% in liquid form, as evidenced in Figure 6b. This predominance is justified because, as observed, the encapsulation process is primarily carried out through granules and pellets, representing about 60% of the technique adopted in the analyzed studies.

In this context, the primary healing agents frequently employed in the research were identified as follows: the combination of reactive magnesium oxide (MgO) with bentonite was present in about 15.4% of the formulations; the joint utilization of calcium sulfoaluminate cement (CSA), ordinary Portland cement (OPC), and sodium carbonate (Na2CO3) as curing agents represented approximately 12.82% of the compositions adopted in the studies; and finally, the use of sodium silicate (Na2SiO3) was also the subject of several investigations (Figure 6c).

The strategy of combining reactive magnesium oxide (MgO) with bentonite was adopted to seal cracks and utilize highly reactive minerals, as mentioned by R. Alghamri [27,74]. The authors selected reactive MgO as the central agent in the self-healing process due to its expansive properties and the ability to generate irreversible hydration products, which are stable and compatible with the cementitious matrix. In turn, bentonite was chosen due to its binding properties, which remain effective over a wide range of temperatures, and its significant role in crack mitigation. This contribution is attributed to the remarkable expansion capacity of bentonite, which can increase its volume by up to 15 to 18 times when in contact with water. As indicated by Lee and Ryou [10], the use of CSA-based expansive agents in self-healing materials is associated with their characteristics that enable sealing through expansion induced by ettringite formation. Conversely, sodium carbonate can react with portlandite and produce calcium carbonate. Sodium silicate was employed due to its capacity to respond with portlandite and form significant amounts of hydrated calcium silicate (C-S-H) [35,51].

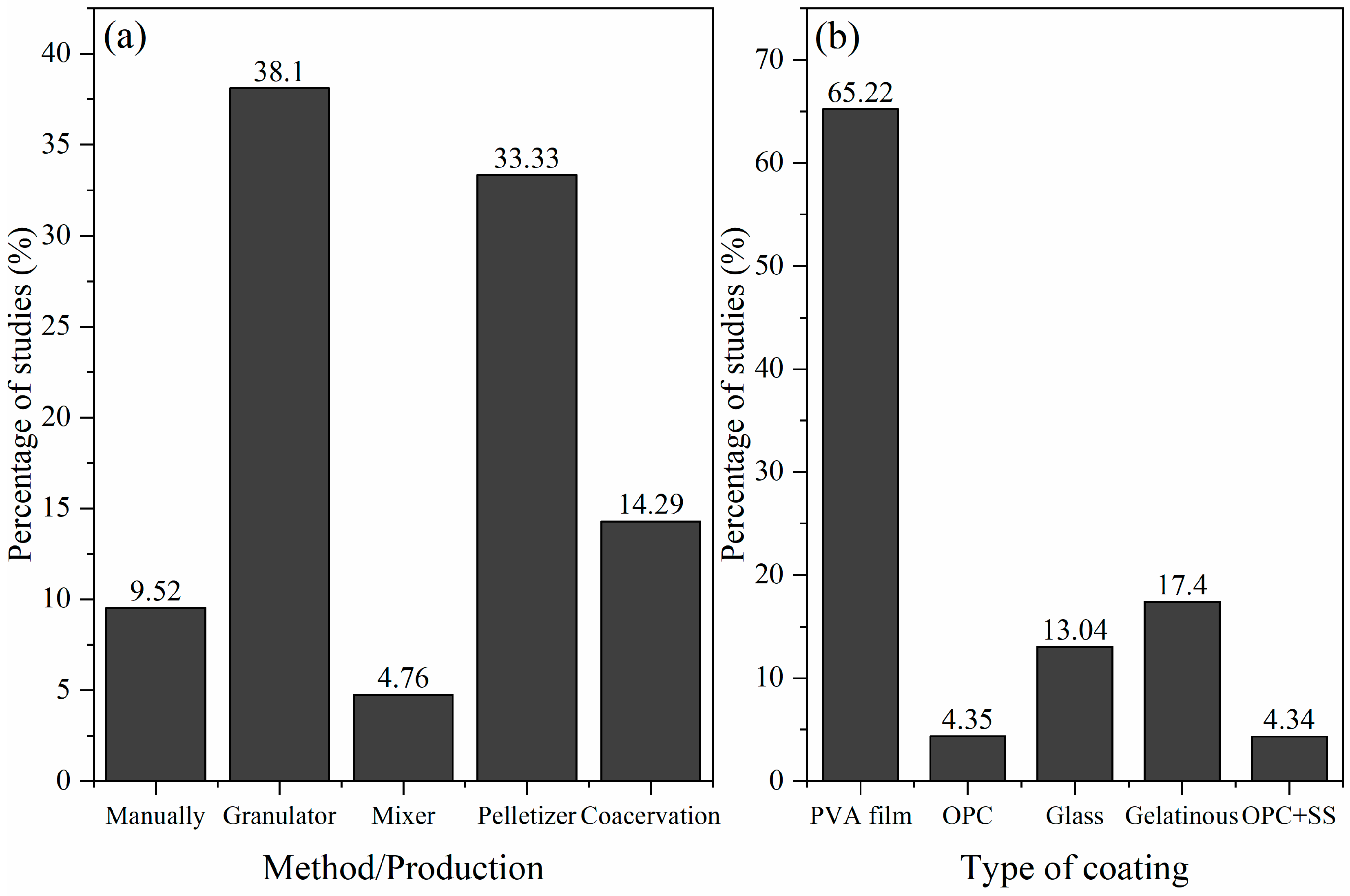

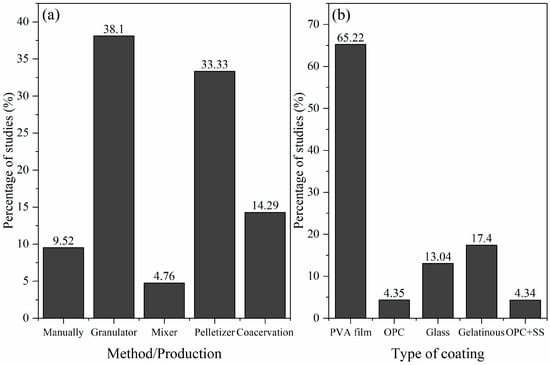

The primary techniques used in the studies for encapsulation production were granulation, accounting for 38% of the studies, and pelletization, which comprised 33% of the studies (Figure 7a). In the process of encapsulating the healing agent through pelletization, the powdered material is added to a pelletizer, which can be a shallow disk (40–60°) or a deep drum (0–30°), to produce pellets through the uniform spraying of water using a spray gun with adjustable air pressure. The pelletization process must adhere to specific temperature and relative humidity conditions of 20 ± 2 °C and 50 ± 5%, respectively. If the composition includes different self-healing materials, the powdered material should be manually dry-mixed for 3 min. After adding the powder to the pelletizer, it is usually sprayed with 10–30% distilled water relative to the total powder weight. However, this proportion may vary depending on each material’s chemical and physical composition. Subsequently, the pellets are dried at 40 °C and 60 °C for one day [79,95]. Regarding granulation, this can be accomplished through traditional methods, such as granule formation from moistened powder, or through fluidized bed granulation, where particles are suspended in an air stream, and a liquid is sprayed downward, forming more cohesive or agglomerated particles [31,33].

Figure 7.

Parameters adopted: (a) production method of capsules, pellets, and granules and (b) type of coating applied.

Kim et al. [33] and Lee and Ryou [31,32] present comparable methodologies with variations in the materials and methods they employed. Kim et al. [33] formed granules from powders, which were slightly moistened with a solution of water and ethanol in a 1:10 ratio, using Ca(OH)2 and Na2SO4 as activators. The powdered material was added to a granulator. For the coating of the granules, PVA was dissolved in water at a 1:11 ratio and sprayed onto the granules, repeating the process twice to improve the coating quality.

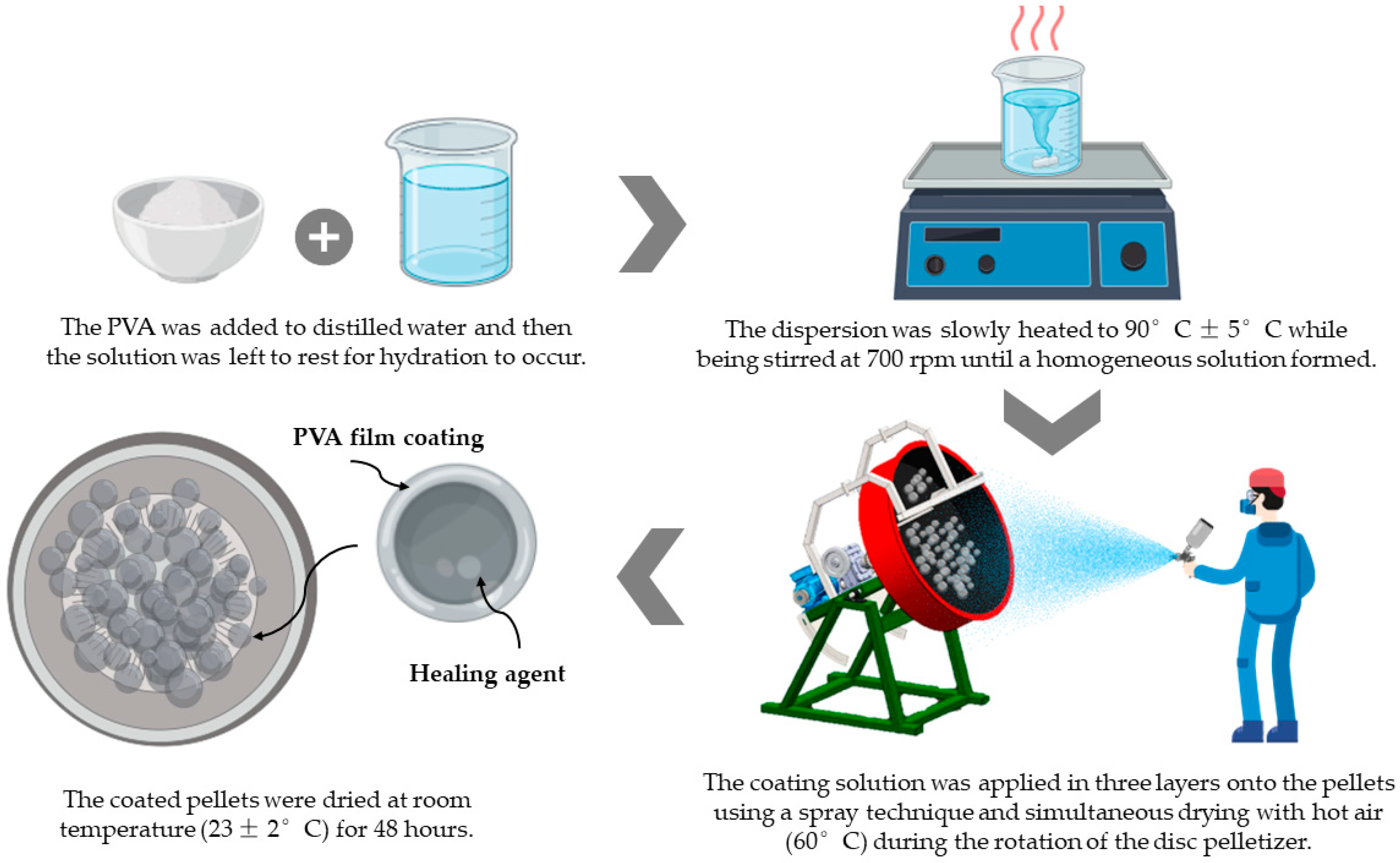

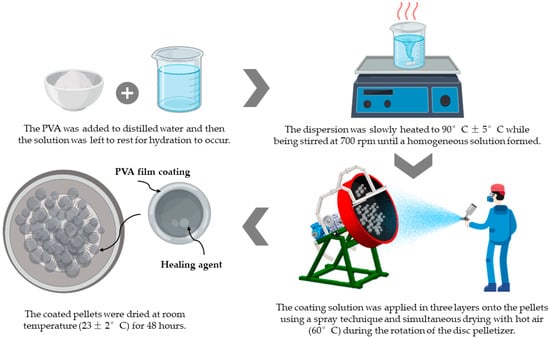

Lee and Ryou [31,32], on the other hand, used different compositions for the healing agents, including calcium sulfoaluminate (CSA), CSA combined with ordinary Portland cement (OPC), and Na2CO3. Granulation was carried out through kneading, wet granulation, and drying at 60 °C. The coating process of the granules followed these steps: Initially, PVA was dissolved in distilled water; then, the dispersion was heated to 90 °C ± 5 °C until a homogeneous solution was obtained. The coating solution was then applied in three layers on the granules using the spray technique, with simultaneous drying at 60 °C. During the rotation of the pelletizer, the granules were sprayed. After the coating application, the granules were dried for 48 h at room temperature (23 °C ± 2 °C) and stored in an airtight plastic container. Both studies demonstrated the effectiveness of encapsulating healing agents in PVA-coated granules using granulation and coating techniques that ensure the controlled release of the healing agents and the durability of structural repairs in self-healing mortars. The use of pelletizers and the detailed process of heating and drying the PVA coating are common points that contribute to the robustness of the encapsulated granules, ensuring their effectiveness in self-healing mortar applications. The studies employed the pan-coating technique, a traditional method extensively used in pharmaceuticals to encapsulate components. This process includes rotating pellets or tablets while applying a liquid coating through a high-pressure nozzle. The coating hardens upon heating, effectively sealing the inner material. However, its granular nature, often more significant than 1 mm, may restrict its suitability in applications where a precise encapsulation size impacts the mechanical properties [95,96,97].

Additionally, approximately 14.29% of studies employed the complex coacervation method for encapsulating active substances (Figure 7a). This process involves the formation of macromolecular coacervates through phase separation in aqueous polymer solutions, utilizing two polymers with opposite charges to create a polymer-rich liquid phase. This technique yields 10 to 1000 μm microcapsules, often incorporating gelatin and gum arabic as primary components. Studies such as those by Litina and Al-Tabbaa (2020) and Kanellopoulos et al. [35] have applied microcapsules obtained via complex coacervation in commercial and conventional repair mortars. The procedure used for obtaining microcapsules followed the methodology described in Ref. [95]. A 600 mL beaker in a water bath on a hot plate was used to produce the emulsion. A mechanical stirrer equipped with a four-blade Rushton turbine operating at a 15° angle relative to the vertical axis was used to mix two separately prepared phases: the external phase, composed of gelatin and gum arabic dissolved in deionized water at 45 °C and adjusted to pH 9 with sodium hydroxide and acetic acid added to achieve the target pH, and the internal phase, prepared with gelatin in water at 45 °C and sodium silicate in water, also at 45 °C [95,98]. The sodium silicate solution was gradually added to the gelatin solution under agitation, followed by emulsification in cooled mineral oil to form a stable water-in-oil (w/o) emulsion. After confirming the stability of the w/o emulsion, it was incorporated into the external phase in bulk. During the cooling of the mixture, monitoring the critical temperature of 26 °C was crucial to promote the controlled deposition of the coacervate forming the capsule wall, thereby avoiding irregular formation and permeability issues. Once 10 °C was reached, glutaraldehyde was added to cross-link the gelatin polymer, followed by overnight agitation at 40 °C to complete the cross-linking. The capsules were filtered, washed with deionized water, and dispersed in a preservative solution to maintain homogeneous suspension. The precise control of temperatures and pH throughout the process is essential to ensure the desired quality and morphology of the microcapsules. It is important to highlight that an overly alkaline pH forms long, narrow coacervate strands with poor deposition.

In contrast, an overly acidic pH forms tiny spherical droplets, leading to thin-walled capsules. An intermediate pH yields elongated oval coacervates with better wall quality. This fact is supported by the study by Gilford et al. [96], which observed that the shell thickness also increased as the pH increased from 3.0 to 3.7.

In most cases, the surface coating process follows the production of curing agent encapsulation in capsules, granules, and pellets. For granules and pellets, the primary coating mainly consists of a PVA film (polyvinyl alcohol) with a coating thickness ranging between 100 and 600 µm (~65%). In the case of microcapsules, the coating comprises a combination of cross-linked gelatine and gum arabic with a coating thickness of 50–200 µm (~17%). It is essential to highlight that a coating technique developed in recent years has shown promise due to its increased resistance to pellet surfaces. This technique involves using ordinary Portland cement (OPC) to create an outer layer beneath the curing agent core, which is sprayed with a solution composed of water and sodium silicate (SS) (Figure 7b).

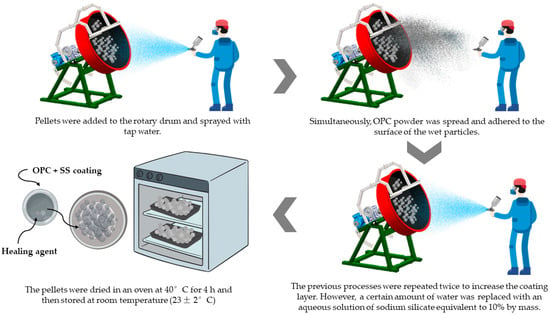

Figure 8 and Figure 9 illustrate the coating process with PVA film and OPC+SS, respectively, which were used to create a protective layer on wound healing agents exposed in the literature. The following steps were followed to carry out the coating of PVA film on pellets: (i) Initially, PVA was dissolved in distilled water. (ii) Next, the dispersion was heated to 90 °C ± 5 °C until a homogeneous solution was obtained. (iii) The coating solution was applied in three layers on the pellets using the spray technique with simultaneous drying at 60 °C. (iv) During the rotation of the pelletizer, the pellets were sprayed. After application, they were dried for 48 h at room temperature (23 °C ± 2 °C) and stored in an airtight plastic container (Figure 8) [74].

Figure 8.

The process of spraying the coating layer onto the pellets using PVA.

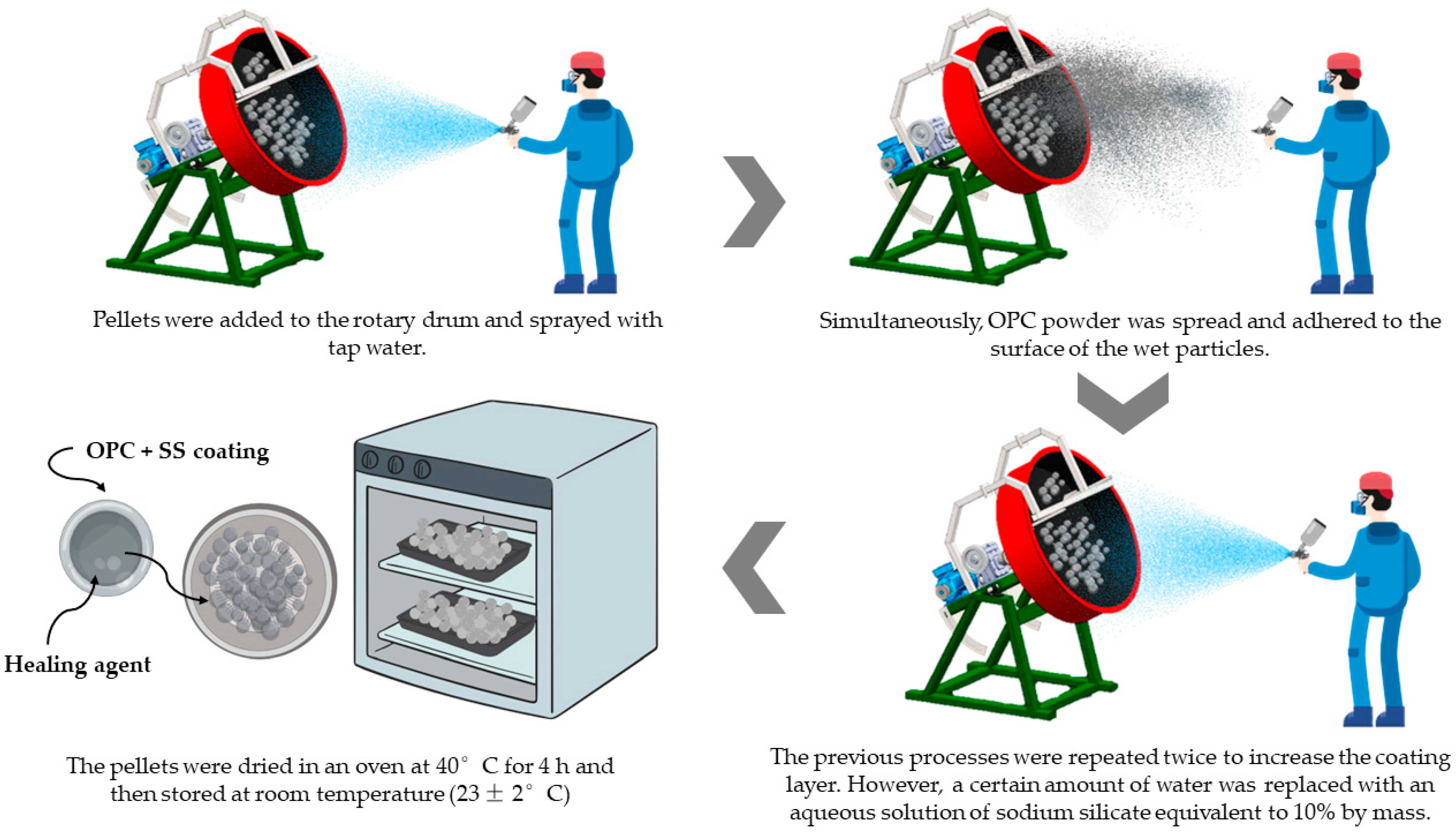

Figure 9.

The stages of the pellet coating process using OPC and SS.

The following steps were used to coat pellets with OPC and SS, as exemplified in Figure 9: (i) Initially, the pellets were introduced into the rotating drum and sprayed with water. At the same time, the OPC powder was spread to promote the adhesion of cement on the surface of the moist particles, aiming to create an outer layer. (ii) To ensure a uniform outer layer and avoid discontinuities, the coating thickness was increased by repeating this process twice and replacing water with an aqueous sodium silicate solution (10% by weight). Sodium silicate was used in this phase to accelerate the hardening of the coating shell through rapid reaction with OPC constituents. (iii) Finally, the samples were dried at 40 °C for 4 h and then stored at room temperature (23 ± 2 °C).

The authors described that introducing SS in the coating process contributed to the early development of envelope strength, allowing for the rotation of capsules inside the drum without losing material due to tensions and frictions [29].

Studies have shown that the coating methodology used can influence the properties of mortars, especially concerning their workability and mechanical properties, as discussed later in Section 3.4. It is essential to highlight that, in studies using the encapsulation technique of the healing agent through PVA film, it was found that a certain number of added pellets did not survive the mixing process, leading to the healing agent being hydrated earlier than expected, thus potentially reducing the crack sealing process. On the other hand, pellets coated with OPC and SS showed a high survival capacity during mixing, efficient protection of the healing agent, effective release during crack propagation, and high healing efficiency after cracking without negatively affecting the properties of the mortar.

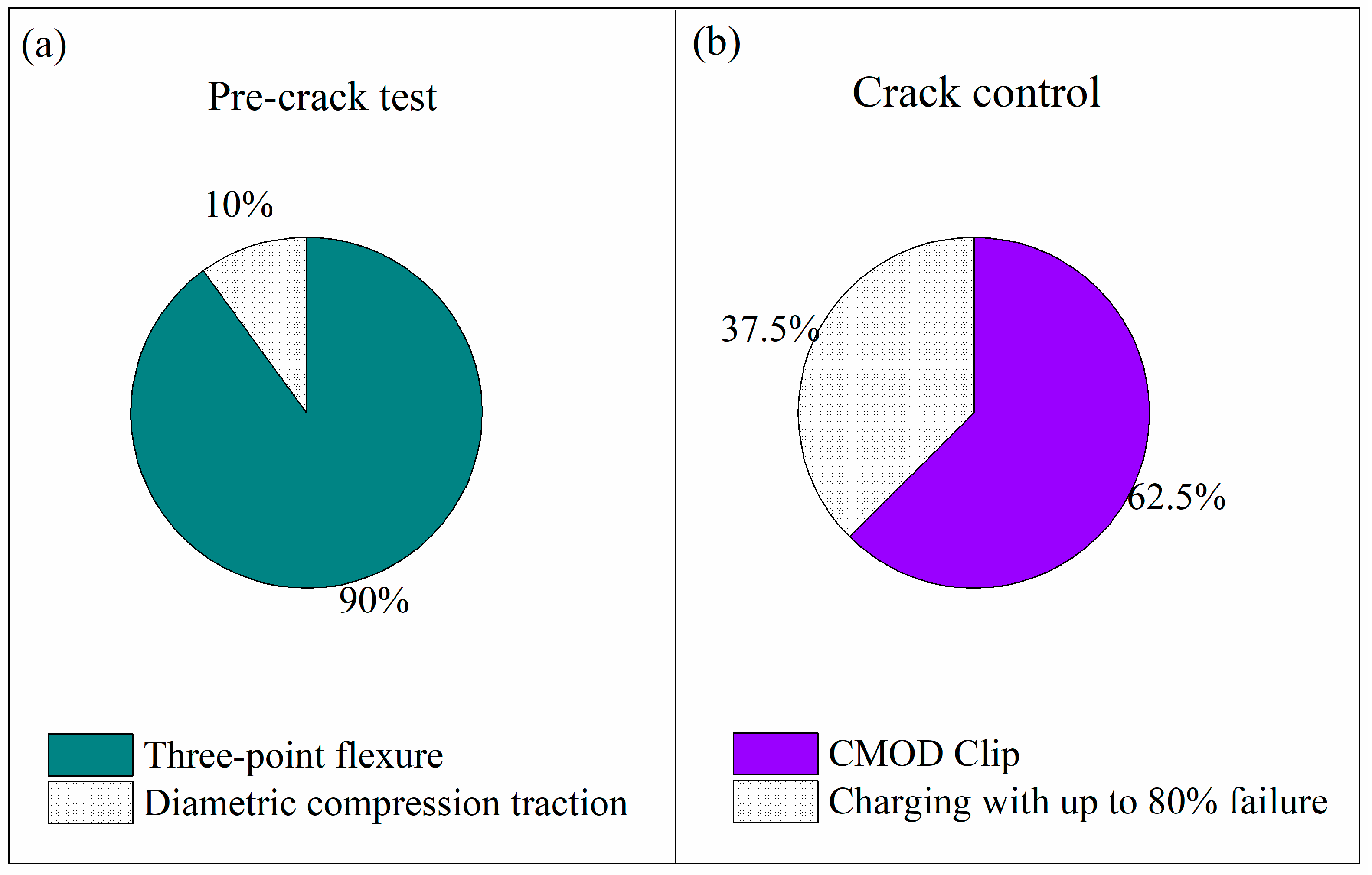

3.3. Parameters Adopted for Crack Control and Curing Environment

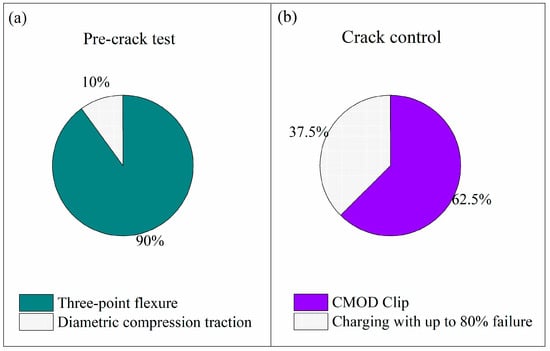

Approximately 90% of the analyzed studies employed the pre-crack test through the three-point flexural loading test (Figure 10a). Steel wires with an approximate diameter of 2 mm were incorporated into the surface of prismatic specimens to control crack formation, avoiding complete material rupture. Additionally, a notch with a depth of approximately 1.5 mm was created in the center of the bottom part of the mortar, inducing crack formation at this specific point. The most effective control method used by the authors was the use of the CMOD device (~63%), which stands for “Crack Mouth Opening Displacement” (Figure 10b). This device is employed to measure and quantify crack mouth opening displacement. The CMOD is fixed on the underside of the samples, allowing for the measurement and recording of the crack width variation as the load is applied during tests inducing crack formation.

Figure 10.

The parameters adopted for the type of test for crack control: (a) a pre-crack test and (b) a crack control device.

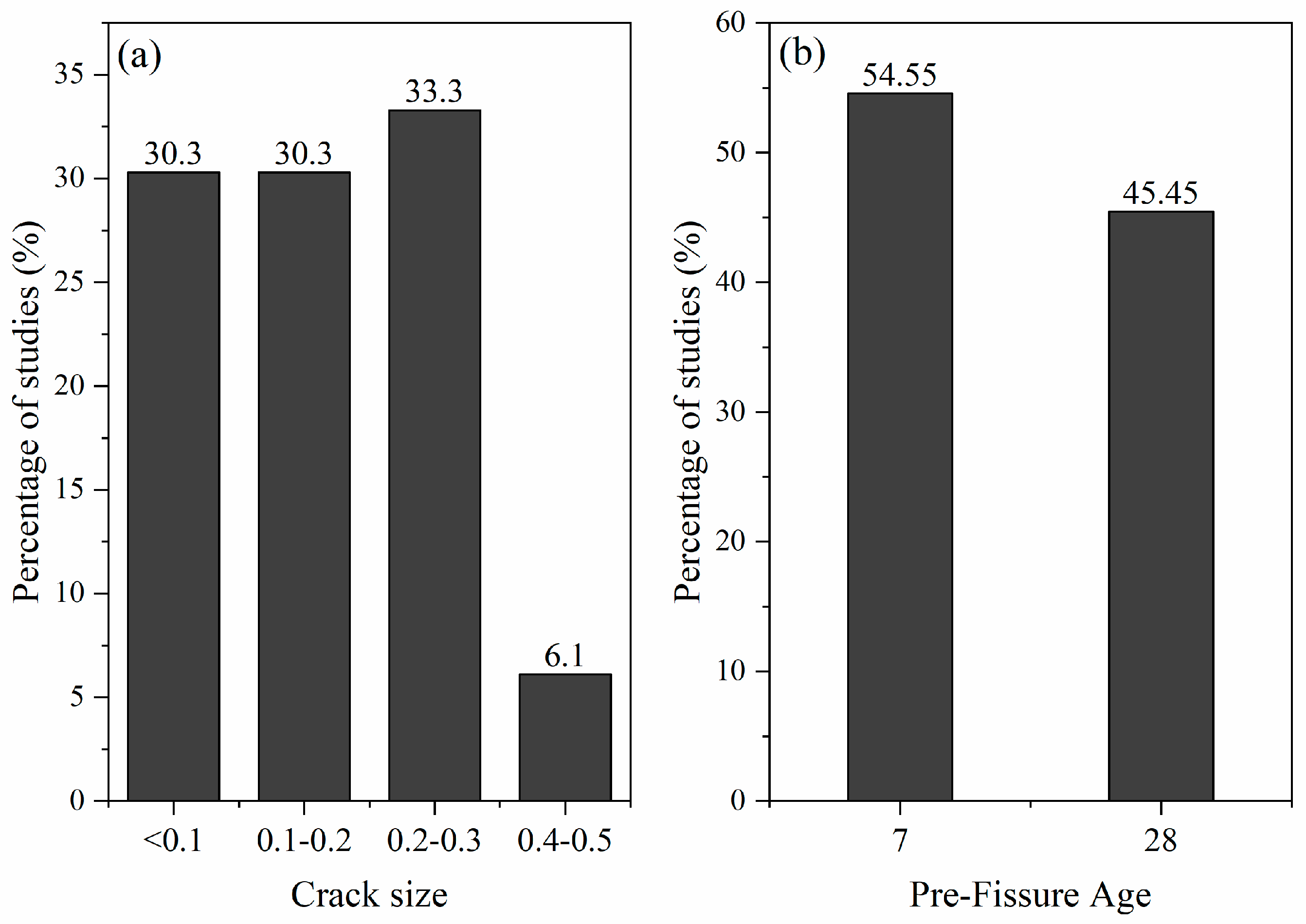

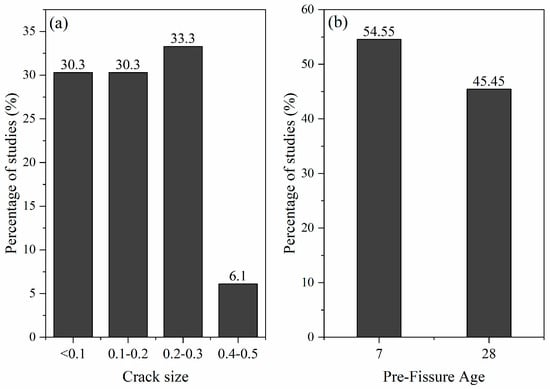

Regarding the size of the residual crack formed in self-healing materials through an autonomous mechanism, studies have revealed different ranges of dimensions. Approximately 33% of the cracks exhibited dimensions between 200 and 300 µm, followed by about 30% in the 100–200 µm range and approximately 30% with a size smaller than 100 µm. The age at which the pre-existing crack forms is related to the type of healing agent selected. Generally, when an expansive agent is used, the pre-existing crack is formed approximately seven days after molding (Figure 11a). However, when employing pozzolanic materials, such as blast furnace slag, which react more slowly in the self-healing process, pre-existing cracks are formed at 28 days (Figure 11b).

Figure 11.

The parameters adopted in the studies: (a) the crack size and (b) age.

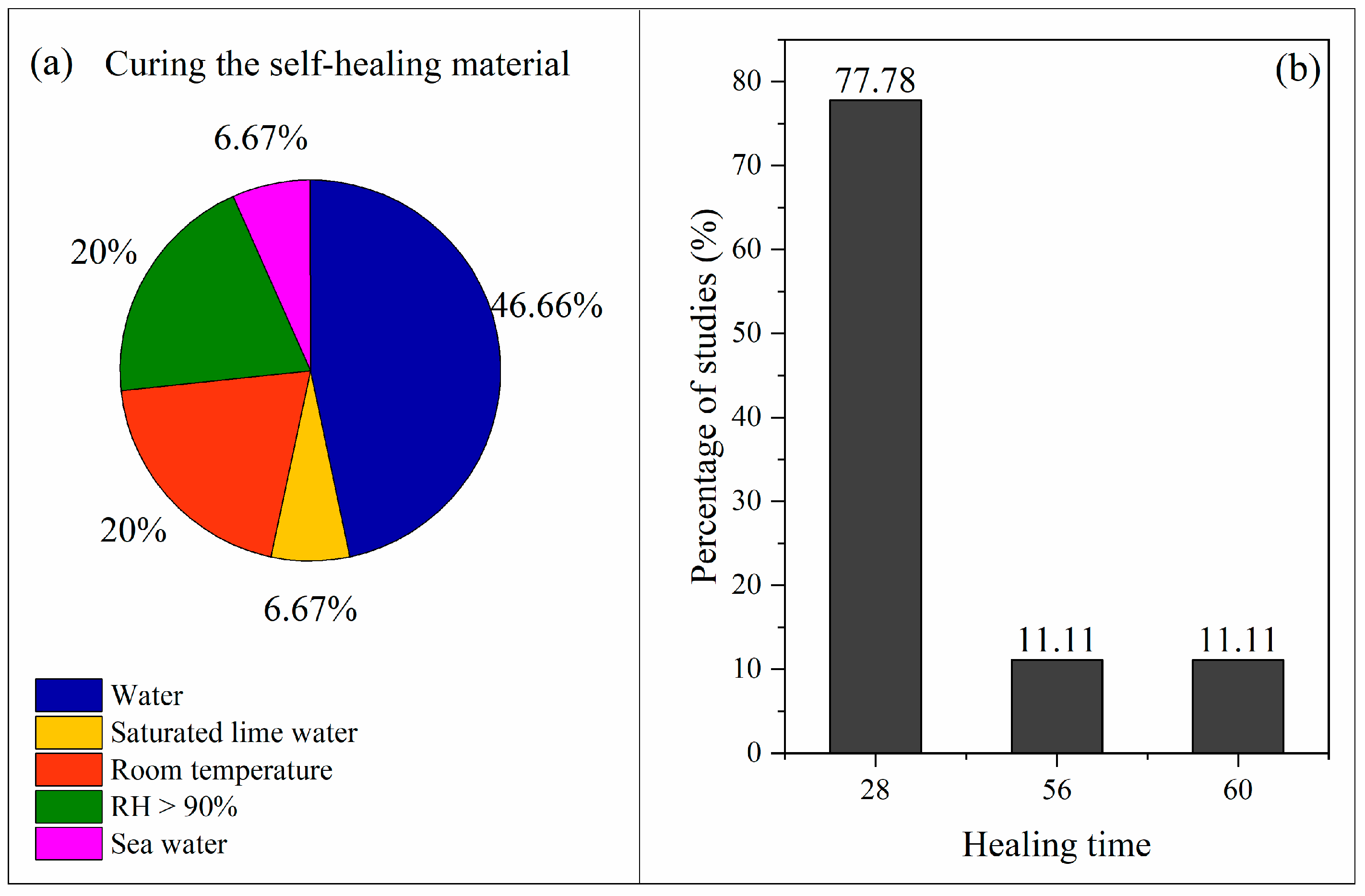

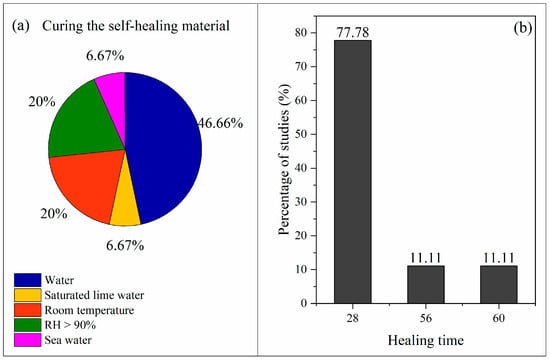

Studies have shown that the presence of water plays a crucial role in the evolution of the self-healing phenomenon. However, mere high humidity is not sufficient to seal the cracks. According to Kanellopoulos et al. [51], water plays a fundamental role in penetrating the cracks and accelerating the development of healing products. Therefore, approximately 50% of the studies adopted a controlled environment at a temperature of 21–23 °C, with water, to promote the self-healing of Portland cement-based composites (Figure 12a).

Figure 12.

The parameters adopted in the studies: (a) the curing environment used and (b) the duration of the self-healing process (b).

Like the pre-crack phase, the time required for self-healing is related to the type of self-healing material. For pellets and granules containing expansive agents, self-healing is typically evaluated over 28 days. On the other hand, when it comes to pozzolanic materials, the self-healing process can extend for up to 60 days depending on the material’s reactivity (Figure 12b).

3.4. The Influence of Pellets/Granules/Capsules on the Properties of Mortar

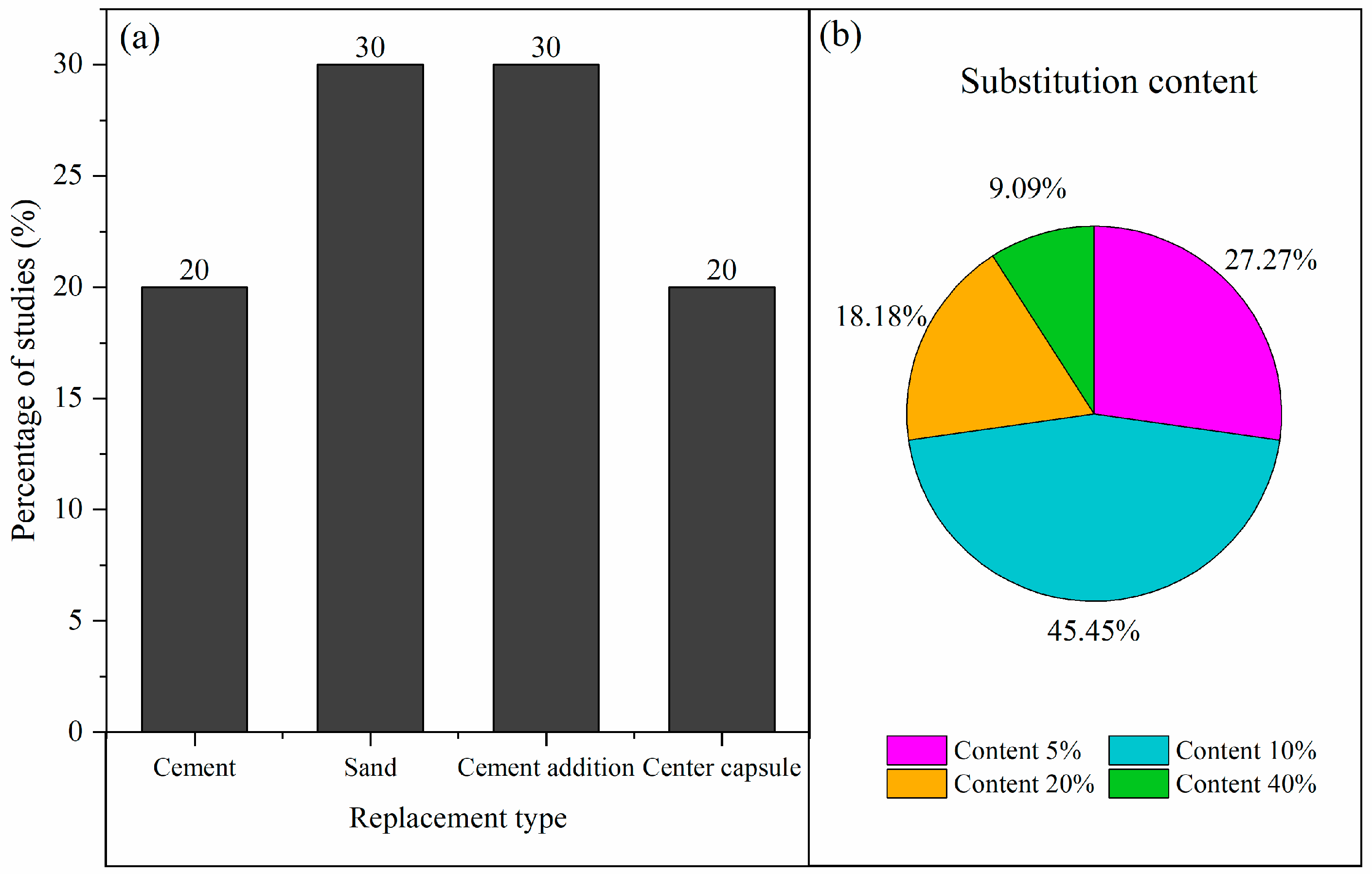

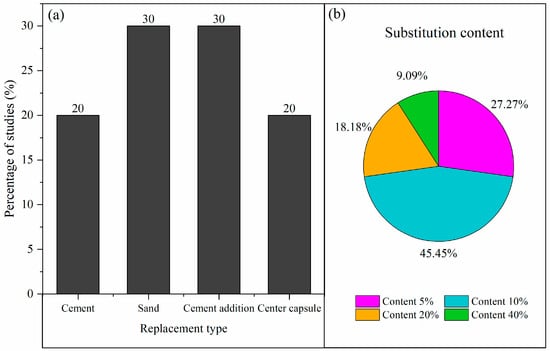

Self-healing agents are preferentially introduced into the cementitious matrix through mass substitution of sand (30%) and cement (20%), as well as by addition relative to the cement (30%), as illustrated in Figure 13a. Additionally, experimental procedures using samples containing concentric glass capsules manually inserted in the central region of the sample (20%) were identified as adopted parameters.

Figure 13.

The parameters adopted in the studies: (a) the type of replacement and (b) the replacement content of capsules, granules, or pellets in the cement matrix.

Approximately 73% of the studies employed a 5–10% substitution rate, as shown in Figure 13b. This preference is primarily associated with the finding that the incorporation of pellets, granules, and capsules above a content of 10% results in adverse impacts on the physical–mechanical properties of mortar [27,35]. The analyzed studies observed the effects of capsules, pellets, and granules on spread and compressive strength. The results indicate that capsules, pellets, and granules have a negative influence of approximately 80% for both evaluated properties.

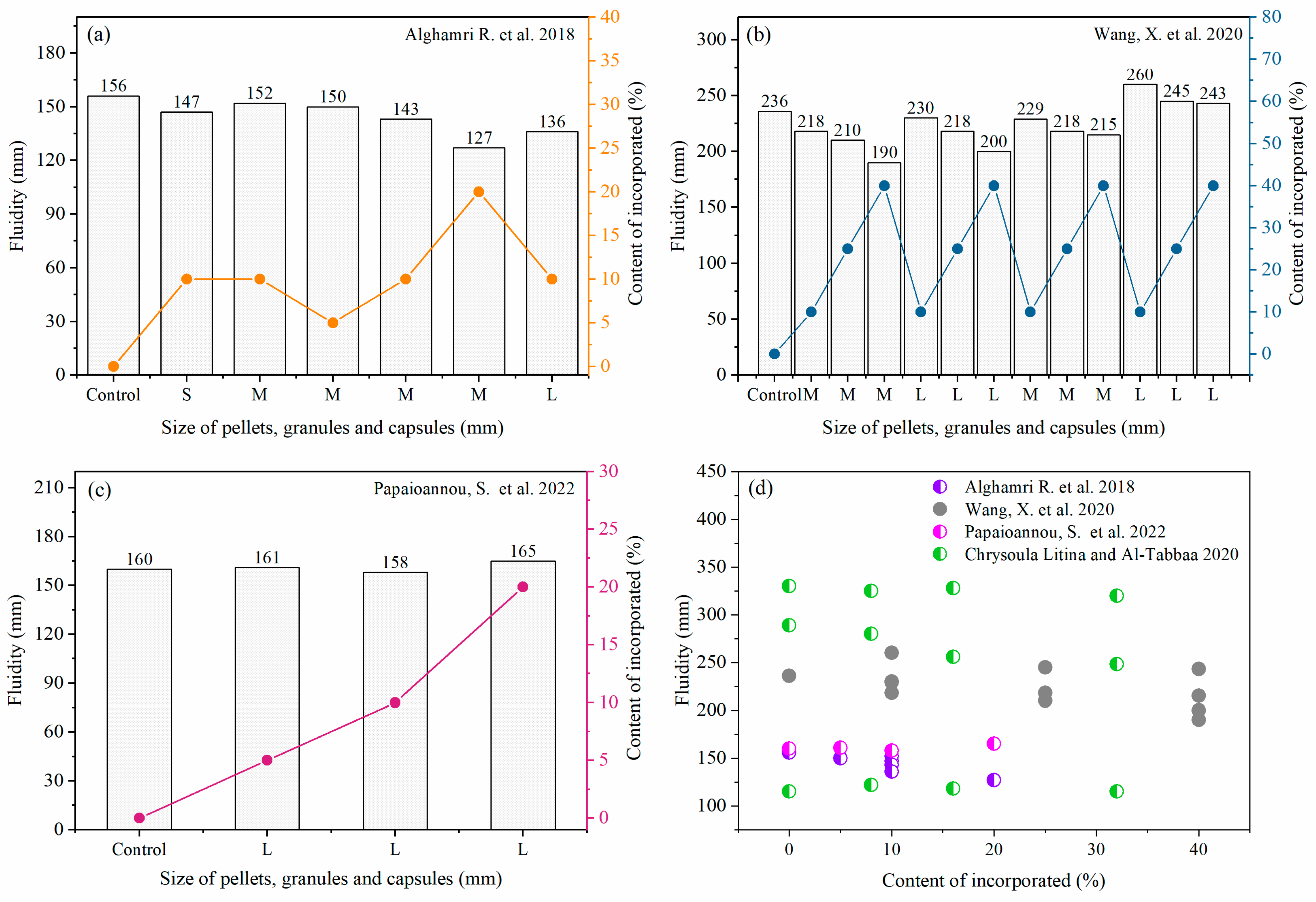

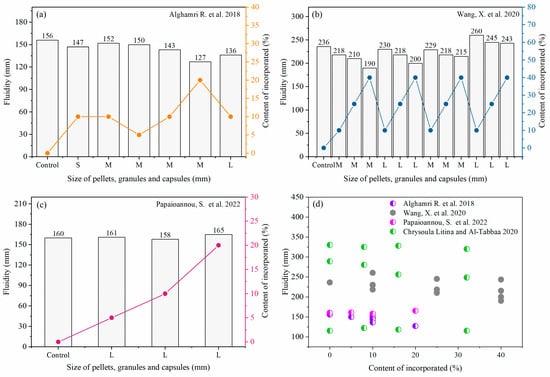

Figure 14 presents the influence of pellets on the fluidity results of mortars in the literature. Studies with PVA-coated pellets showed a reduction of approximately 19% in fluidity (Figure 14a). Additionally, as the incorporation content and the size of the pellets increase, workability significantly decreases [27]. Incorporating self-healing pellets into mortar decreased its workability due to two primary factors. Firstly, the lower density of the pellets compared to sand increased the sand volume by 33% to 115% depending on the pellet type. This raised the sand-to-cement ratio and reduced the available cement per unit volume. This led to decreased workability, as less cement was available to coat the aggregates, thus increasing friction during mixing. Secondly, the crush resistance of the pellets was less than 30% of that of sand, causing many pellets to break during mixing. This released the self-healing materials in the pellet cores, which consumed water early in the hydration process, further reducing the mixture’s workability.

Figure 14.

Influence of pellets, granules, or capsules on fresh state properties: (a) PVA-coated pellets, (b) Portland cement pellets, and (c) PC- and SS-coated capsules. (d) Flowability mapping versus incorporated content of pellets, granules, or capsules. Legend: small (S: 0.6–1 mm), medium (M: 1–2 mm), and large (L: 2–5 mm). (The mentioned references are Alghamri et al. 2018 [27], Wang 2020 [28], Papaioannou et al. 2022 [29], Litina and Al-Tabbaa 2020 [34]).

Rheological assessments, such as viscosity and yield stress evaluations, would be highly beneficial for discussing the impact of incorporating pellets, granules, or microcapsules on mortar flowability. In the study by Kanellopoulos et al. [35], it was observed that the gradual addition of microcapsules relative to the total cement mass significantly increased the cement paste’s viscosity, with notable variations depending on the microcapsule concentration. These findings align with previous studies on the behavior of spherical inclusions in concentrated suspensions, where an increase in particle volumetric fraction can lead to agglomeration phenomena, resulting in higher viscosities [99]. This effect is more pronounced with particles of varying sizes, as seen with non-monodimensional microcapsules, potentially compromising suspension flowability [100].

In the study conducted by Wang et al. [28], sodium carbonate (Na2CO3) at different concentrations was introduced into the mortar through Portland cement pellets (Figure 14b). The addition of pellets resulted in a notable decrease in workability as the substitution ratio of pellets for sand increased from 10% to 40%. Additionally, reducing the dimensions of the pellets also negatively influenced the properties, where larger pellets (L) approached or exceeded the values of the sample without pellets (~236 mm), showing an increase of 3 to 9%. Meanwhile, medium-sized pellets (M) led to a reduction in workability of up to 20%.

However, Papaioannou et al. [29] observed that the use of Portland cement capsules coated with Portland cement (PC) and sodium silicate (SS) at concentrations of up to 20% by volume as a substitute for sand resulted in a 3% increase in fluidity (Figure 14c). Generally, incorporation and growth in the content of capsules, pellets, and granules in cementitious material mixes are expected to modify the mixture’s viscosity, affecting the particle size distribution and packing density of the system (Figure 14d) [101]. Nevertheless, the study indicated that adding cement capsules coated with sodium silicate had an insignificant effect on the workability of mixes with incorporation concentrations of up to 20%.

These results show better compatibility in the workability of cementitious matrix mixtures containing PC and SS-coated pellets. The use of PVA film-coated pellets may lead to their rupture during the mixing process, reducing workability due to the influence of the healing agent.

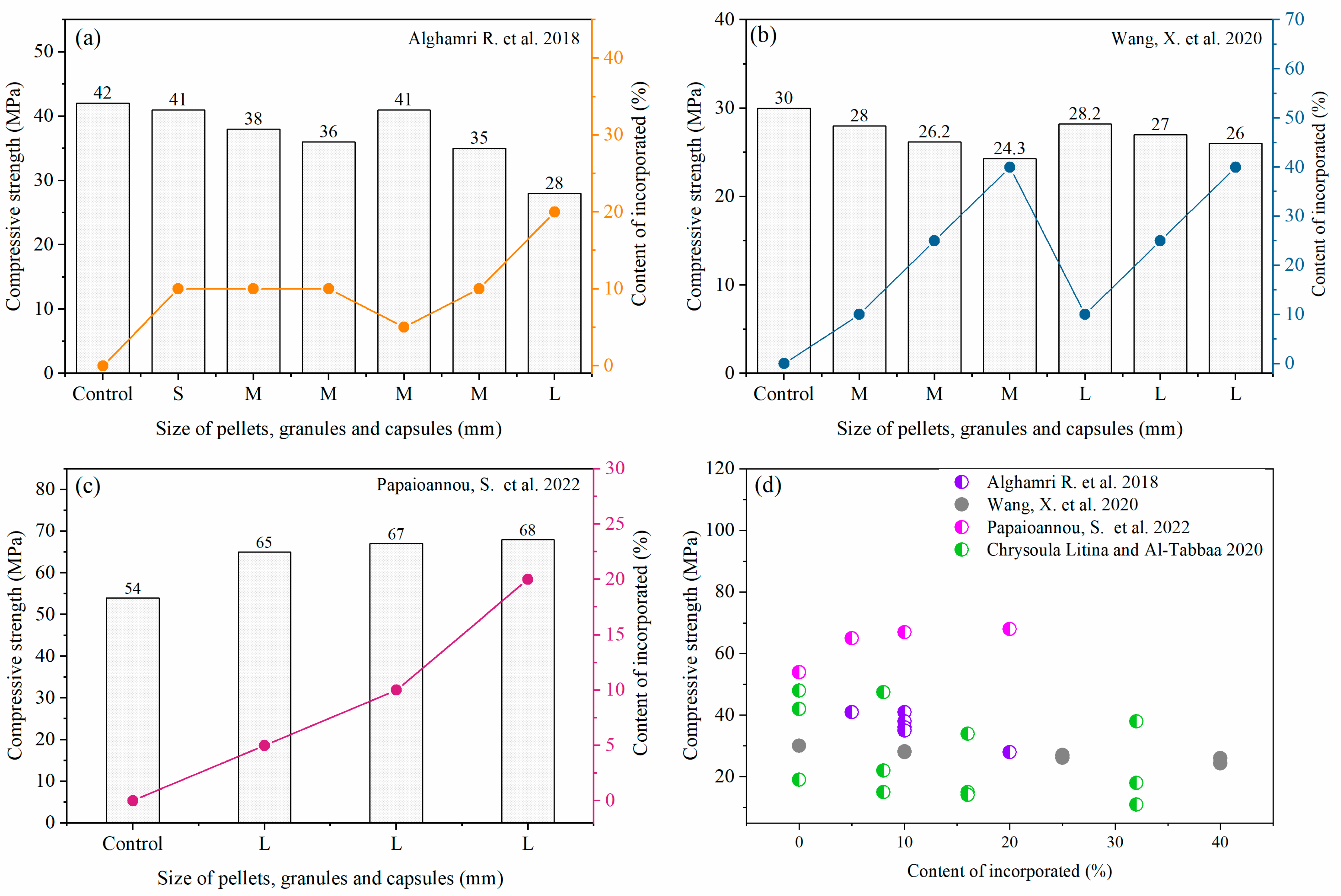

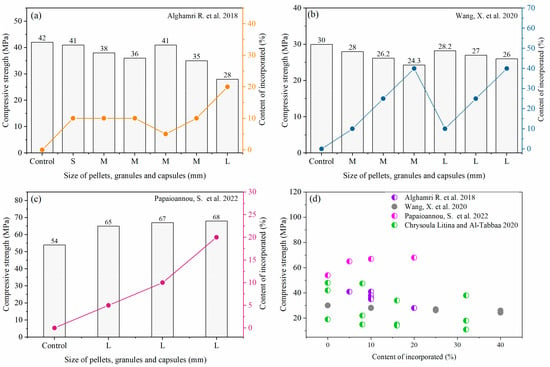

This trend is also evident in compressive strength at 28 days, as illustrated in Figure 15. A reduction in strength of up to 39% is observed in samples with larger-sized pellets and an incorporation content of 20% coated with PVA, as reported in ref. [27] (Figure 15a). Similarly, Wang et al. [28] observed a reduction in compressive strength ranging from 6% to 19% with Portland cement pellet incorporations between 10% and 40% (Figure 15b). Conversely, capsules coated with PC and SS exhibited compressive strengths close to 70 MPa, indicating an increase of up to 19% compared to the reference (Figure 15c). The literature generally suggests that incorporating pellets, capsules, and granules into cementitious materials significantly reduces strength, except for capsules coated with PC and SS (Figure 15d) [34].

Figure 15.

The influence of pellets of different sizes on the compressive strength of the mortar. (a) Pellets coated with PVA; (b) pellets coated with PC; (c) PC- and SS-coated capsules; (d) Compressive strength mapping versus incorporated content of pellets, granules, or capsules. Legend: small (S: 0.6–1 mm), medium (M: 1–2 mm), and large (L: 2–5 mm). (The mentioned references are Alghamri et al. 2018 [27], Wang 2020 [28], Papaioannou et al. 2022 [29], Litina and Al-Tabbaa 2020 [34]).

According to Papaioannou et al. [29], these positive outcomes stem from substituting sand volume with capsules and the enhanced strength provided by the sodium silicate coating. Their study also emphasizes the excellent adhesion between the capsules and the cementitious matrix.

Recent studies utilizing CSA as a healing agent and producing capsules through granulation with reactive powder coating via polyurethane spraying [102], with a 5% replacement of the total cement weight, confirm that these methods primarily have a negative impact on the fresh state of mortars [17]. There was a 22% reduction in workability compared to mortar without incorporated capsules. Regarding mechanical properties, a 12% decrease was observed; however, no statistically significant difference was found among the means of the different analyzed mixtures.

3.5. The Influence of Healing Agents on the Self-Healing Properties of Mortars

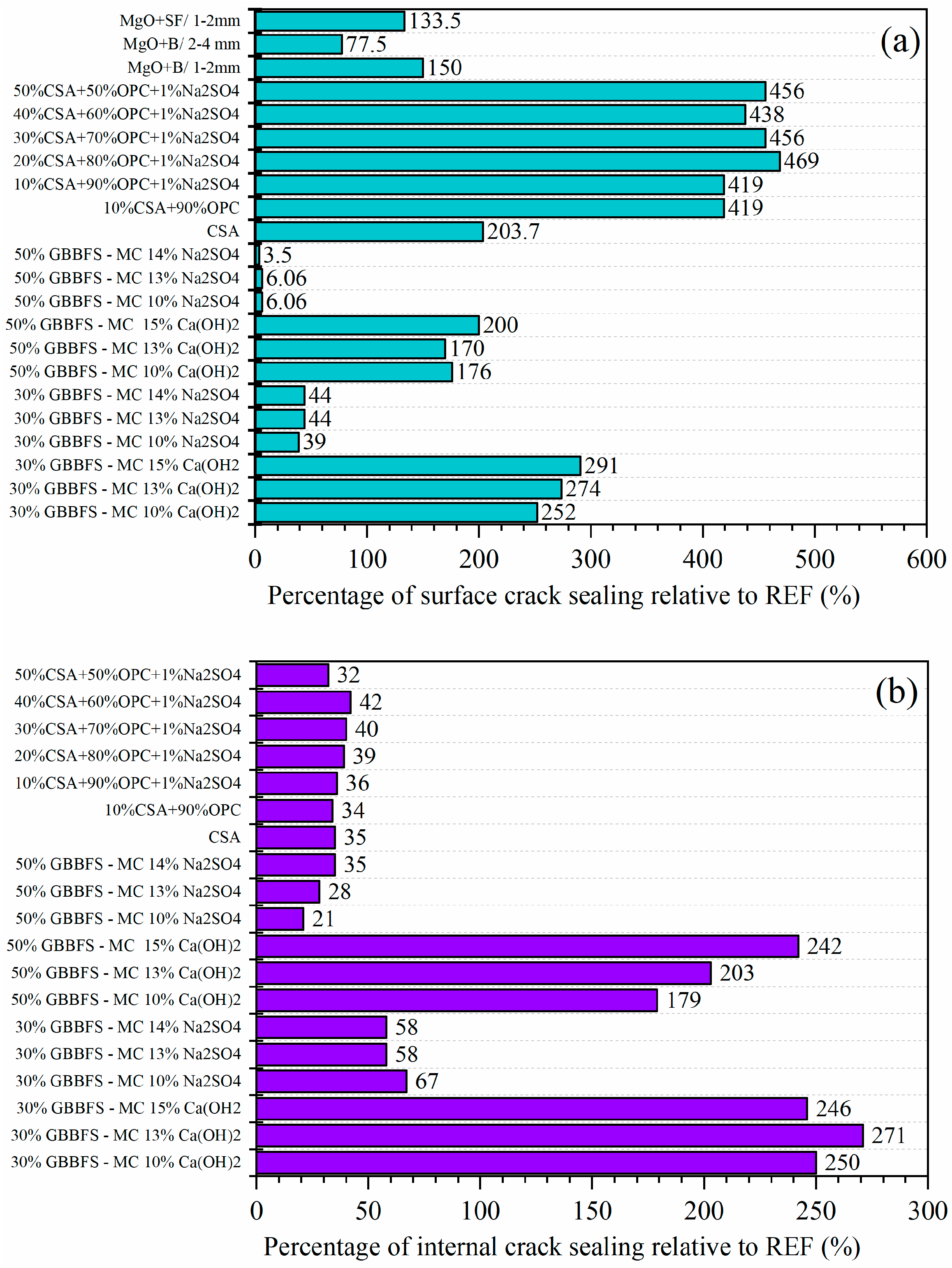

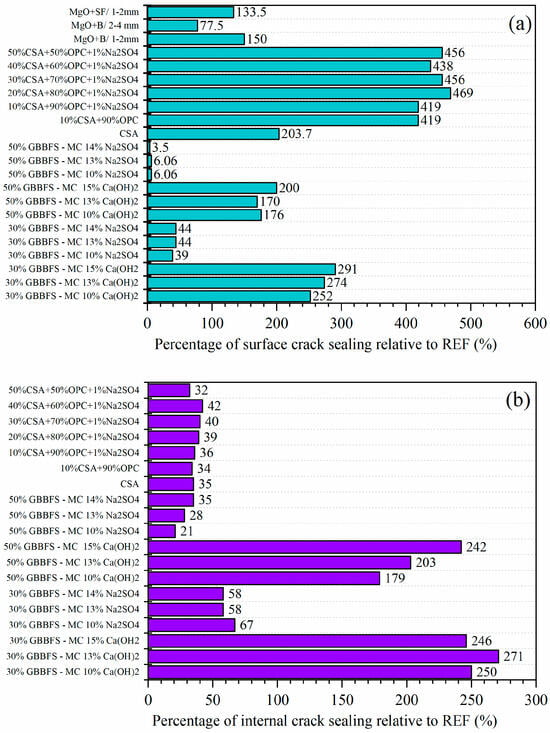

Figure 16 illustrates the impact of various curing agents encapsulated in pellets and granules on self-healing properties, addressing both superficial and internal crack sealing. Components containing expansive agents (CSA) demonstrated superior effectiveness in self-healing, especially concerning superficial crack sealing (Figure 16a).

Figure 16.

The influence of healing agents on the self-healing mechanism. (a) Superficial crack sealing; (b) internal crack sealing.

Regarding internal crack sealing, mixtures that replaced cement with up to 50% blast furnace slag (GGBFS) and incorporated granules containing calcium hydroxide [Ca(OH)2] obtained the best results (Figure 16b).

4. Conclusions and Research Gaps

A systematic literature review on the parameters adopted for incorporating pellets, granules, and capsules to evaluate the autonomous self-healing ability of cementitious materials, along with the influence of this incorporation on workability and compressive strength properties, indicated the following:

The cement-to-sand ratio of self-healing mortar ranges from 1:3.12 to 1:1.15 with a water-to-cement ratio between 0.4 and 0.5. The studies also incorporated fine aggregates with particle sizes smaller than 2 mm in the compositions, which can favor stable and uniform crack control.

- The predominant encapsulation method used for healing agents was the simultaneous use of granules and pellets in equipment designated as granulators and pelletizers, respectively. Additionally, the predominant surface coating mainly consists of a PVA film. However, cementitious materials incorporating pellets with a PVA film coating significantly reduced spreading and compressive strength properties.

- Adverse behavior was observed in these properties for capsules coated with Portland cement and sprayed with a water and sodium silicate solution. This indicates a trend towards their use, as it reduces the negative effect of pellet/capsule incorporation on mortar properties. Additionally, this type of coating, regarding the use of expansive agents through pellets/capsules as the core, may provide benefits in crack sealing and increase the incorporation content in cementitious materials to promote self-healing.

- It was observed in this systematic review that the preferred pre-crack test method is the three-point flexural test. Steel wires are used to prevent the complete rupture of the prismatic sample, and a small notch (1.5 mm) at the bottom center of the sample is made to induce a crack at a specific point. The CMOD device is the central apparatus for crack control to observe crack opening.

- Regarding the parameters for evaluating self-healing, it was observed that for pellets, granules, or capsules composed of expansive agents, the pre-crack test is generally conducted at 7 days, and the curing time and duration of the crack sealing monitoring process are both approximately 28 days. Additionally, the environment for conducting the autonomous healing of cement-based materials was water.

This review article mapped significant studies published on autonomous self-healing in mortars, focusing on various encapsulation types. It presented the main parameters adopted for self-healing mortar composition, the preparation of healing agents for encapsulation, crack opening, and control procedures, and evaluation environments that enable crack sealing. Additionally, it discussed the impact of incorporating encapsulated self-healing agents on mortars’ primary physical and mechanical properties. This survey substantially contributes to the field by identifying trends and critical parameters, which can guide new studies and facilitate the comparison of experimental results regarding autonomous self-healing.

This systematic literature review also identified gaps and trends in new studies related to autonomous self-healing. It is noteworthy that most studies in this review focused primarily on forming encapsulation agents, with few examining the impact of incorporating these agents on mortars’ physical and mechanical properties. Therefore, a key recommendation for future research is to conduct a comprehensive evaluation of self-healing, from the production of encapsulation agents to their final application in mortars, focusing on mechanical properties.

Additionally, another topic that warrants further investigation is the impact of healing agents on the fresh-state behavior of cementitious matrices, as there is a significant gap in the evaluation of the rheological properties of these composites. Furthermore, there is a growing trend of and an increasing need for studies on the simulation of composites produced with healing agents and the self-healing process in the presence of multiple cracks.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/buildings14072000/s1, Table S1: Bibliographic search on healing agents in self-healing materials, Figure S1: Networking visualization containing a color map of citations from the journal source.

Author Contributions

Conceptualization, G.T.d.S.L., L.S. and L.U.D.T.J.; methodology, G.T.d.S.L., L.S. and L.U.D.T.J.; formal analysis, G.T.d.S.L., L.S. and L.U.D.T.J.; investigation, G.T.d.S.L.; data curation, G.T.d.S.L.; writing—original draft preparation, G.T.d.S.L., L.S. and L.U.D.T.J.; writing—review and editing, G.T.d.S.L., L.S. and L.U.D.T.J.; supervision, M.C. and J.C.R.; project administration, M.C. and J.C.R.; funding acquisition, M.C. and J.C.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data will be made available upon request.

Acknowledgments

We would like to acknowledge CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gwon, S.; Ahn, E.; Shin, M. Water Permeability and Rapid Self-Healing of Sustainable Sulfur Composites Using Superabsorbent Polymer and Binary Cement. Constr. Build. Mater. 2020, 265, 120306. [Google Scholar] [CrossRef]

- Gwon, S.; Ahn, E.; Shin, M. Self-Healing of Modified Sulfur Composites with Calcium Sulfoaluminate Cement and Superabsorbent Polymer. Compos. Part B 2019, 162, 469–483. [Google Scholar] [CrossRef]

- Park, B.; Cheol, Y. Effect of Healing Products on the Self-Healing Performance of Cementitious Materials with Crystalline Admixtures. Constr. Build. Mater. 2021, 270, 121389. [Google Scholar] [CrossRef]

- Sinha, A.; Wang, Q.; Wei, J. Feasibility and Compatibility of a Biomass Capsule System in Self-Healing Concrete. Materials 2021, 14, 958. [Google Scholar] [CrossRef] [PubMed]

- Cheol, Y.; Park, B. Enhanced Autogenous Healing of Ground Granulated Blast Furnace Slag Blended Cements and Mortars. Integr. Med. Res. 2019, 8, 3443–3452. [Google Scholar] [CrossRef]

- Qureshi, T.; Kanellopoulos, A.; Al-Tabbaa, A. Autogenous Self-Healing of Cement with Expansive Minerals-I: Impact in Early Age Crack Healing. Constr. Build. Mater. 2018, 192, 768–784. [Google Scholar] [CrossRef]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; García Calvo, J.L.; Asensio, E.; et al. Evaluation of Methodologies for Assessing Self-Healing Performance of Concrete with Mineral Expansive Agents: An Interlaboratory Study. Materials 2021, 14, 2024. [Google Scholar] [CrossRef] [PubMed]

- Youssef Namnoum, C.; Hilloulin, B.; Grondin, F.; Loukili, A. Determination of the Origin of the Strength Regain after Self-Healing of Binary and Ternary Cementitious Materials Including Slag and Metakaolin. J. Build. Eng. 2021, 41, 102739. [Google Scholar] [CrossRef]

- Feng, J.; Qian, S. Accelerating Autonomic Healing of Cementitious Composites by Using Nano Calcium Carbonate Coated Polypropylene Fibers. Mater. Des. 2023, 225, 111549. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property Assessment of High-Performance Concrete Containing Three Types of Fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of Mix Composition on the Extent of Autogenous Crack Healing by Continued Hydration or Calcium Carbonate Formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-Healing of Surface Cracks in Mortars with Expansive Additive and Crystalline Additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Belie, N.D.; Gruyaert, E.; Al-tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jonkers, H.; Tittelboom, K.V.; Snoeck, D.; De Belie, N.; De Muynck, W.; Verstraete, W.; Wang, J.; Mechtcherine, V. Recovery against Environmental Action. In Self-Healing Phenomena in Cement-Based Materials: State-of-the-Art Report of RILEM Technical Committee; Springer: Dordrecht, The Netherlands, 2013; p. 240. [Google Scholar]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-Healing Cement Concrete Composites for Resilient Infrastructures: A Review. Compos. Part B 2020, 189, 107892. [Google Scholar] [CrossRef]

- Reinhardt, H.-W.; Jooss, M. Permeability and Self-Healing of Cracked Concrete as a Function of Temperature and Crack Width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- De Brabandere, L.; Van Mullem, T.; Lee, J.H.; Suh, J.-I.; Lee, K.-M.; De Belie, N. Comparative Analysis of Three Different Types of Self-Healing Concrete via Permeability Testing and a Quasi-Steady-State Chloride Migration Test. Constr. Build. Mater. 2024, 411, 134288. [Google Scholar] [CrossRef]

- Anglani, G.; Van Mullem, T.; Tulliani, J.M.; Van Tittelboom, K.; De Belie, N.; Antonaci, P. Durability of Self-Healing Cementitious Systems with Encapsulated Polyurethane Evaluated with a New Pre-Standard Test Method. Mater. Struct. Constr. 2022, 55, 143. [Google Scholar] [CrossRef]

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, Mechanical and Microstructural Properties of Alkali-Activated Composites Incorporating Nanomaterials: A Comprehensive Review. J. Clean. Prod. 2023, 384, 135390. [Google Scholar] [CrossRef]

- Wei, C.; Li, Y.; Liu, X.; Zhang, Z.; Wu, P.; Gu, J. Large-Scale Application of Coal Gasification Slag in Nonburnt Bricks: Hydration Characteristics and Mechanism Analysis. Constr. Build. Mater. 2024, 421, 135674. [Google Scholar] [CrossRef]

- Van Tittelboom, K.V.; Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef]

- Oh, S.; Choi, Y.W.; Yong, J.K. Effect of Cement Powder Based Self-Healing Solid Capsule on the Quality of Mortar. Constr. Build. Mater. 2019, 214, 574–580. [Google Scholar] [CrossRef]

- Ge, Y.; Hu, H.; Zhan, Q.; Zhang, X.; Su, Y.; Zhou, J. Study on Self-Healing Effect of Cement-Based Materials Cracks Based on Various Inorganic Minerals. J. Build. Eng. 2024, 82, 108202. [Google Scholar] [CrossRef]

- Wani, S.; Jan Gęca, M.; Selvaraj, T.; Shanmuga Priya, T. Assessing the Influence of Bacillus Megaterium and Bacillus Sphaericus in Cementitious Materials: Promoting Sustainability towards Strength, Durability and Crack Repair. Ain Shams Eng. J. 2024, 15, 102748. [Google Scholar] [CrossRef]

- Xiao, X.; Tan, A.C.Y.; Unluer, C.; Yang, E.-H. Development of a Functionally Graded Bacteria Capsule for Self-Healing Concrete. Cem. Concr. Compos. 2023, 136, 104863. [Google Scholar] [CrossRef]

- Lo Monte, F.; Repesa, L.; Snoeck, D.; Doostkami, H.; Roig-Flores, M.; Jackson, S.J.P.; Alvarez, A.B.; Nasner, M.; Borg, R.P.; Schröfl, C.; et al. Multi-Performance Experimental Assessment of Autogenous and Crystalline Admixture-Stimulated Self-Healing in UHPFRCCs: Validation and Reliability Analysis through an Inter-Laboratory Study. Cem. Concr. Compos. 2024, 145, 105315. [Google Scholar] [CrossRef]

- Alghamri, R.; Kanellopoulos, A.; Litina, C.; Al-Tabbaa, A. Preparation and Polymeric Encapsulation of Powder Mineral Pellets for Self-Healing Cement Based Materials. Constr. Build. Mater. 2018, 186, 247–262. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Jiang, Z. Preparation and Characterization of Self-Healing Mortar Based on “Build-In” Carbonation. Materials 2020, 13, 21. [Google Scholar] [CrossRef] [PubMed]

- Papaioannou, S.; Amenta, M.; Kilikoglou, V.; Gournis, D.; Karatasios, I. Synthesis and Integration of Cement-Based Capsules Modified with Sodium Silicate for Developing Self-Healing Cements. Constr. Build. Mater. 2022, 316, 125803. [Google Scholar] [CrossRef]

- Lima, G.T.d.S.; Oliveira, M.V.C.; Pinto, R.C.d.A.; Rocha, J.C. Is the Diffuse Ultrasound Method Reliable for Evaluating Autonomous Self-Healing in Cementitious Materials with Expansive Agent Pellets? Mater. Lett. 2023, 351, 135058. [Google Scholar] [CrossRef]

- Lee, Y.; Ryou, J. Self Healing Behavior for Crack Closing of Expansive Agent via Granulation/Film Coating Method. Constr. Build. Mater. 2014, 71, 188–193. [Google Scholar] [CrossRef]

- Lee, Y.S.; Ryou, J.S. Crack Healing Performance of PVA-Coated Granules Made of Cement, CSA, and Na2CO3 in the Cement Matrix. Materials 2016, 9, 555. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.G.; Atta-ur-Rehman; Qudoos, A.; Ryou, J.S. Self-Healing Performance of GGBFS Based Cementitious Mortar with Granulated Activators Exposed to a Seawater Environment. Constr. Build. Mater. 2018, 188, 569–582. [Google Scholar] [CrossRef]

- Litina, C.; Al-Tabbaa, A. First Generation Microcapsule-Based Self-Healing Cementitious Construction Repair Materials. Constr. Build. Mater. 2020, 255, 119389. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Al-Tabbaa, A. The Effect of Varying Volume Fraction of Microcapsules on Fresh, Mechanical and Self-Healing Properties of Mortars. Constr. Build. Mater. 2016, 122, 577–593. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Kanellopoulos, A. Encapsulation of Expansive Powder Minerals within a Concentric Glass Capsule System for Self-Healing Concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Restuccia, L.; Reggio, A.; Ferro, G.A.; Tulliani, J.M. New Self-Healing Techniques for Cement-Based Materials. Procedia Struct. Integr. 2017, 3, 253–260. [Google Scholar] [CrossRef]

- Tittelboom, K.V.; De Belie, N.; Van Loo, D.; Jacobs, P. Self-Healing Efficiency of Cementitious Materials Containing Tubular Capsules Filled with Healing Agent. Cem. Concr. Compos. 2011, 33, 497–505. [Google Scholar] [CrossRef]

- Perez, G.; Erkizia, E.; Gaitero, J.J.; Kaltzakorta, I.; Jiménez, I.; Guerrero, A. Synthesis and Characterization of Epoxy Encapsulating Silica Microcapsules and Amine Functionalized Silica Nanoparticles for Development of an Innovative Self-Healing Concrete. Mater. Chem. Phys. 2015, 165, 39–48. [Google Scholar] [CrossRef]

- Zhu, D.Y.; Rong, M.Z.; Zhang, M.Q. Self-Healing Polymeric Materials Based on Microencapsulated Healing Agents: From Design to Preparation. Prog. Polym. Sci. 2015, 49–50, 175–220. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, M.; Liu, R.; Li, X.; Yan, J.; Du, H. Enhancing Self-Healing Efficiency of Concrete Using Multifunctional Granules and PVA Fibers. J. Build. Eng. 2023, 76, 107314. [Google Scholar] [CrossRef]

- Shao, L.; Feng, P.; Liu, Q.; Chen, C.; Cai, Y.; Xu, G. A Review on Performance Improvement and Multi-Functionalization of Cement Composites Using Capsules. Constr. Build. Mater. 2023, 409, 133977. [Google Scholar] [CrossRef]

- Gupta, S.; Pang, S.D.; Kua, H.W. Autonomous Healing in Concrete by Bio-Based Healing Agents—A Review. Constr. Build. Mater. 2017, 146, 419–428. [Google Scholar] [CrossRef]

- Rajadesingu, S.; Palani, N.; Mendonce, K.C.; Vijayakumar, P.; Monisha, P.; Ayyadurai, S. State-of-the-Art Review on Advancements of Eco-Friendly Bacterial-Infused Self-Healing Concrete for Sustainable Constructions. J. Build. Eng. 2024, 91, 109669. [Google Scholar] [CrossRef]

- Silvestro, L.; Jean, P.; Gleize, P. Effect of Carbon Nanotubes on Compressive, Flexural and Tensile Strengths of Portland Cement-Based Materials: A Systematic Literature Review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Maes, M.; Van Tittelboom, K.; De Belie, N. The Efficiency of Self-Healing Cementitious Materials by Means of Encapsulated Polyurethane in Chloride Containing Environments. Constr. Build. Mater. 2014, 71, 528–537. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Tsangouri, E.; Van Hemelrijck, D.; De Belie, N. The Efficiency of Self-Healing Concrete Using Alternative Manufacturing Procedures and More Realistic Crack Patterns. Cem. Concr. Compos. 2015, 57, 142–152. [Google Scholar] [CrossRef]

- Perez, G.; Gaitero, J.J.; Erkizia, E.; Jimenez, I.; Guerrero, A. Characterisation of Cement Pastes with Innovative Self-Healing System Based in Epoxy-Amine Adhesive. Cem. Concr. Compos. 2015, 60, 55–64. [Google Scholar] [CrossRef]

- Mostavi, E.; Asadi, S.; Hassan, M.M.; Alansari, M. Evaluation of Self-Healing Mechanisms in Concrete with Double-Walled Sodium Silicate Microcapsules. J. Mater. Civ. Eng. 2015, 27, 04015035. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, H.G.; Song, T.H.; Ryou, J.S. The Control of Response Time in Self-Healing of Granulated Cementitious Material by Water-Soluble Film Coating. Procedia Eng. 2015, 125, 663–668. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Qureshi, T.S.; Al-Tabbaa, A. Glass Encapsulated Minerals for Self-Healing in Cement Based Composites. Constr. Build. Mater. 2015, 98, 780–791. [Google Scholar] [CrossRef]

- Formia, A.; Terranova, S.; Antonaci, P.; Pugno, N.M.; Tulliani, J.M. Setup of Extruded Cementitious Hollow Tubes as Containing/Releasing Devices in Self-Healing Systems. Materials 2015, 8, 1897–1923. [Google Scholar] [CrossRef] [PubMed]

- Gruyaert, E.; Van Tittelboom, K.; Sucaet, J.; Anrijs, J.; Van Vlierberghe, S.; Dubruel, P.; De Geest, B.G.; Remon, J.P.; De Belie, N. Capsules with Evolving Brittleness to Resist the Preparation of Self-Healing Concrete. Mater. Constr. 2016, 66, e092. [Google Scholar]

- Li, W.; Zhu, X.; Zhao, N.; Jiang, Z. Preparation and Properties of Melamine Urea-Formaldehyde Microcapsules for Self-Healing of Cementitious Materials. Materials 2016, 9, 152. [Google Scholar] [CrossRef] [PubMed]

- Feiteira, J.; Gruyaert, E.; De Belie, N. Self-Healing of Moving Cracks in Concrete by Means of Encapsulated Polymer Precursors. Constr. Build. Mater. 2016, 102, 671–678. [Google Scholar] [CrossRef]

- Araújo, M.; Van Vlierberghe, S.; Feiteira, J.; Graulus, G.J.; Van Tittelboom, K.; Martins, J.C.; Dubruel, P.; De Belie, N. Cross-Linkable Polyethers as Healing/Sealing Agents for Self-Healing of Cementitious Materials. Mater. Des. 2016, 98, 215–222. [Google Scholar] [CrossRef]

- Alghamri, R.; Kanellopoulos, A.; Al-Tabbaa, A. Impregnation and Encapsulation of Lightweight Aggregates for Self-Healing Concrete. Constr. Build. Mater. 2016, 124, 910–921. [Google Scholar] [CrossRef]

- De Nardi, C.; Bullo, S.; Ferrara, L.; Ronchin, L.; Vavasori, A. Effectiveness of Crystalline Admixtures and Lime/Cement Coated Granules in Engineered Self-Healing Capacity of Lime Mortars. Mater. Struct. Constr. 2017, 50, 191. [Google Scholar] [CrossRef]

- Dong, B.; Fang, G.; Wang, Y.; Liu, Y.; Hong, S.; Zhang, J.; Lin, S.; Xing, F. Performance Recovery Concerning the Permeability of Concrete by Means of a Microcapsule Based Self-Healing System. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Al-Ansari, M.; Abu-Taqa, A.G.; Hassan, M.M.; Senouci, A.; Milla, J. Performance of Modified Self-Healing Concrete with Calcium Nitrate Microencapsulation. Constr. Build. Mater. 2017, 149, 525–534. [Google Scholar] [CrossRef]

- Milla, J.; Hassan, M.M.; Rupnow, T. Evaluation of Self-Healing Concrete with Microencapsulated Calcium Nitrate. J. Mater. Civ. Eng. 2017, 29, 04017235. [Google Scholar] [CrossRef]

- Wang, X.; Sun, P.; Han, N.; Xing, F. Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite. Materials 2017, 10, 20. [Google Scholar] [CrossRef] [PubMed]

- Arce, G.A.; Hassan, M.M.; Mohammad, L.N.; Rupnow, T. Characterization of Self-Healing Processes Induced by Calcium Nitrate Microcapsules in Cement Mortar. J. Mater. Civ. Eng. 2017, 29, 04016189. [Google Scholar] [CrossRef]

- Araújo, M.; Van Tittelboom, K.; Feiteira, J.; Gruyaert, E.; Chatrabhuti, S.; Raquez, J.M.; Šavija, B.; Alderete, N.; Schlangen, E.; De Belie, N. Design and Testing of Tubular Polymeric Capsules for Self-Healing of Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012003. [Google Scholar] [CrossRef]

- Kim, D.M.; Song, I.H.; Choi, J.Y.; Jin, S.W.; Nam, K.N.; Chung, C.M. Self-Healing Coatings Based on Linseed-Oil-Loaded Microcapsules for Protection of Cementitious Materials. Coatings 2018, 8, 404. [Google Scholar] [CrossRef]

- Hu, Z.X.; Hu, X.M.; Cheng, W.M.; Zhao, Y.Y.; Wu, M.Y. Performance Optimization of One-Component Polyurethane Healing Agent for Self-Healing Concrete. Constr. Build. Mater. 2018, 179, 151–159. [Google Scholar] [CrossRef]

- Al-Ansari, M.; Abu Taqa, A.G.; Senouci, A.; Hassan, M.M.; Shaat, A. Effect of Calcium Nitrate Healing Microcapsules on Concrete Strength and Air Permeability. Mag. Concr. Res. 2019, 71, 195–206. [Google Scholar] [CrossRef]

- Milla, J.; Hassan, M.M.; Rupnow, T.; Daly, W.H. Measuring the Crack-Repair Efficiency of Steel Fiber Reinforced Concrete Beams with Microencapsulated Calcium Nitrate. Constr. Build. Mater. 2019, 201, 526–538. [Google Scholar] [CrossRef]

- Arce, G.A.; Hassan, M.M.; Mohammad, L.N.; Rupnow, T. Self-Healing of SMA and Steel-Reinforced Mortar with Microcapsules. J. Mater. Civ. Eng. 2019, 31, 04018366. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, Y.; Li, Y.; Han, X.; Liu, Q. Preparation and Application of Microcapsules Containing Toluene-Di-Isocyanate for Self-Healing of Concrete. Constr. Build. Mater. 2019, 202, 762–769. [Google Scholar] [CrossRef]

- Lv, L.; Guo, P.; Liu, G.; Han, N.; Xing, F. Light Induced Self-Healing in Concrete Using Novel Cementitious Capsules Containing UV Curable Adhesive. Cem. Concr. Compos. 2020, 105, 103445. [Google Scholar] [CrossRef]

- Feng, J.; Dong, H.; Wang, R.; Su, Y. A Novel Capsule by Poly (Ethylene Glycol) Granulation for Self-Healing Concrete. Cem. Concr. Res. 2020, 133, 106053. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; Du, W.; Zhang, Y.; Zou, Y. Preparation and Characterization of Nano-Fe3O4/Paraffin Encapsulated Isocyanate Microcapsule by Electromagnetic Controlled Rupture for Self-Healing Cementitious Materials. Constr. Build. Mater. 2020, 265, 120703. [Google Scholar] [CrossRef]

- Alghamri, R.; Al-Tabbaa, A. Self-Healing of Cracks in Mortars Using Novel PVA-Coated Pellets of Different Expansive Agents. Constr. Build. Mater. 2020, 254, 119254. [Google Scholar] [CrossRef]

- Wang, X.; Chen, S.; Yang, Z.; Ren, J.; Zhang, X.; Xing, F. Self-Healing Concrete Incorporating Mineral Additives and Encapsulated Lightweight Aggregates: Preparation and Application. Constr. Build. Mater. 2021, 301, 124119. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.; Lin, R.; Su, X. Preparation and Characterization of Microcrystalline Wax/Epoxy Resin Microcapsules for Self-Healing of Cementitious Materials. Materials 2021, 14, 1725. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Lin, Z.; Tang, C.; Hao, W. Preparation and Mechanical Properties of Microcapsule-Based Self-Healing Cementitious Composites. Materials 2021, 14, 4866. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Shi, X. Laboratory Assessment of Early-Age Durability Benefits of a Self-Healing Sytem to Cementitious Composites. J. Build. Eng. 2021, 44, 102602. [Google Scholar] [CrossRef]

- Beglarigale, A.; Eyice, D.; Seki, Y.; Yalçınkaya, Ç.; Çopuroğlu, O.; Yazıcı, H. Sodium Silicate/Polyurethane Microcapsules Synthesized for Enhancing Self-Healing Ability of Cementitious Materials: Optimization of Stirring Speeds and Evaluation of Self-Healing Efficiency. J. Build. Eng. 2021, 39, 102279. [Google Scholar] [CrossRef]

- Ren, J.; Wang, X.; Li, D.; Xu, S.; Dong, B.; Xing, F. Performance of Temperature Adaptive Microcapsules in Self-Healing Cementitious Materials under Different Mixing Temperatures. Constr. Build. Mater. 2021, 299, 124254. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Cao, Z.; He, P.; Liu, Q.; Han, X.; Wan, Y. Preparation and Application of Novel Microcapsules Ruptured by Microwave for Self-Healing Concrete. Constr. Build. Mater. 2021, 304, 124616. [Google Scholar] [CrossRef]

- Cao, B.; Al-Tabbaa, A. Reactive MgO-Based Self-Healing Slag-Cement-Bentonite Slurry Walls. Cem. Concr. Compos. 2022, 131, 104565. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, R.; Chen, M.; Li, X.; Zhu, Z. Coupled Effect of Self-Healing Granules and Permeable Crystalline Additive on Early-Age Cracks Repair in Cement Material. Mater. Lett. 2022, 323, 132560. [Google Scholar] [CrossRef]

- Du, W.; Li, E.; Lin, R. Preparation and Characterization of Nano-CaCO3/Ceresine Wax Composite Shell Microcapsules Containing E-44 Epoxy Resin for Self-Healing of Cement-Based Materials. Nanomaterials 2022, 12, 197. [Google Scholar] [CrossRef] [PubMed]

- Ying, Y.; Hu, M.; Han, J.; Liu, W.; Qi, B.; Guo, J. Self-Healing in Cementitious System Using Interface Enhanced Capsules Prepared at Room Temperature. J. Clean. Prod. 2023, 395, 136465. [Google Scholar] [CrossRef]

- Taqa, A.A.; Suleiman, G.; Senouci, A.; Mohsen, M.O. Using Aerosol OT in Hexane Solution to Synthesize Calcium Nitrate Self-Healing Refined Microcapsules for Construction Applications. Buildings 2022, 12, 751. [Google Scholar] [CrossRef]

- Mao, Q.; Chen, J.; Qi, W.; Liu, H.; Wang, Z.; Cui, S. Improving Self-Healing and Shrinkage Reduction of Cementitious Materials Using Water-Absorbing Polymer Microcapsules. Materials 2022, 15, 847. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.J.; Bae, S.H.; Ji, D.M.; Kim, S.H. Effects of Capsule Type on the Characteristics of Cement Mortars Containing Powder Compacted Capsules. Materials 2022, 15, 6773. [Google Scholar] [CrossRef] [PubMed]

- Mao, Q.; Chen, J.; Wu, W.; Li, R.; Shi, S.; Wang, Z.; Cui, S. Multiple Self-Healing Effects of Water-Absorbing Microcapsules in Cementitious Materials. Polymers 2023, 15, 428. [Google Scholar] [CrossRef]

- Arroyave, S.; Asensio, E.; Perilla, J.E.; Narváez-Rincón, P.C.; Cadavid, A.; Guerrero, A. Evaluation and Characterization of Autonomous Self-Healing Cementitious Materials with Low Carbon Footprint Using Hybrid Organic/Inorganic Microcapsules. Mater. Today Proc. 2023. In Press. [Google Scholar] [CrossRef]

- Du, W.; Liu, B.; Feng, Z.; Liu, Q.; Wu, M.; Zuo, D. Influence of Electromagnetic Inductive Microcapsules on Self-Healing Ability of Limestone Calcined Clay Cement (LC3) Mortar. Polymers 2023, 15, 3081. [Google Scholar] [CrossRef]

- Zamir, M.; Dvorkin, D.; Peled, A. Fabric Cement-Based Composites with Nanoparticles Filler, Interfacial Characteristics. In Proceedings of the 3rd International RILEM Conference on Strain Hardening Cementitious Composites (SHCC3), Dordrecht, The Netherlands, 3–5 November 2014; pp. 171–178. [Google Scholar]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. The Influence of MgO-Type Expansive Agent Incorporated in Self-Healing System of Engineered Cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A Review: Self-Healing in Cementitious Materials and Engineered Cementitious Composite as a Self-Healing Material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Palmer, D.; Kerr, A.; Al-Tabbaa, A. Polymeric Microcapsules with Switchable Mechanical Properties for Self-Healing Concrete: Synthesis, Characterisation and Proof of Concept. Smart Mater. Struct. 2017, 26, 045025. [Google Scholar] [CrossRef]

- Iii, J.G.; Hassan, M.M.; Asce, M.; Rupnow, T.; Asce, M.; Barbato, M.; Asce, M.; Okeil, A.; Asce, M.; Asadi, S. Dicyclopentadiene and Sodium Silicate Microencapsulation for Self-Healing of Concrete. J. Mater. Civ. Eng. 2014, 26, 886–896. [Google Scholar] [CrossRef]

- Ach, D.; Briançon, S.; Broze, G.; Puel, F.; Rivoire, A.; Galvan, J.; Chevalier, Y. Formation of Microcapsules by Complex Coacervation. Can. J. Chem. Eng. 2015, 93, 183–191. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A Review of Microencapsulation Methods of Phase Change Materials (PCMs) as a Thermal Energy Storage (TES) Medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Toda, K.; Furuse, H. Extension of Einstein’s Viscosity Equation to That for Concentrated Dispersions of Solutes and Particles. J. Biosci. Bioeng. 2006, 102, 524–528. [Google Scholar] [CrossRef] [PubMed]

- Faroughi, S.A.; Huber, C. Crowding-Based Rheological Model for Suspensions of Rigid Bimodal-Sized Particles with Interfering Size Ratios. Phys. Rev. E 2014, 90, 052303. [Google Scholar] [CrossRef] [PubMed]

- Papaioannou, S.; Amenta, M.; Kilikoglou, V.; Gournis, D.; Karatasios, I. Critical Aspects in the Development and Integration of Encapsulated Healing Agents in Cement and Concrete. J. Adv. Concr. Technol. 2021, 19, 301–320. [Google Scholar] [CrossRef]

- Oh, S.-R.; Lee, K.-M.; Choi, S.; Choi, Y.-W. Fundamental Properties and Self-Healing Performance of Repair Mortar with Solid Capsules Made Using Inorganic Reactive Powder. Materials 2022, 15, 1710. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).