Environment Assessment of Modified Red Mud Utilized in Roadbed

Abstract

1. Introduction

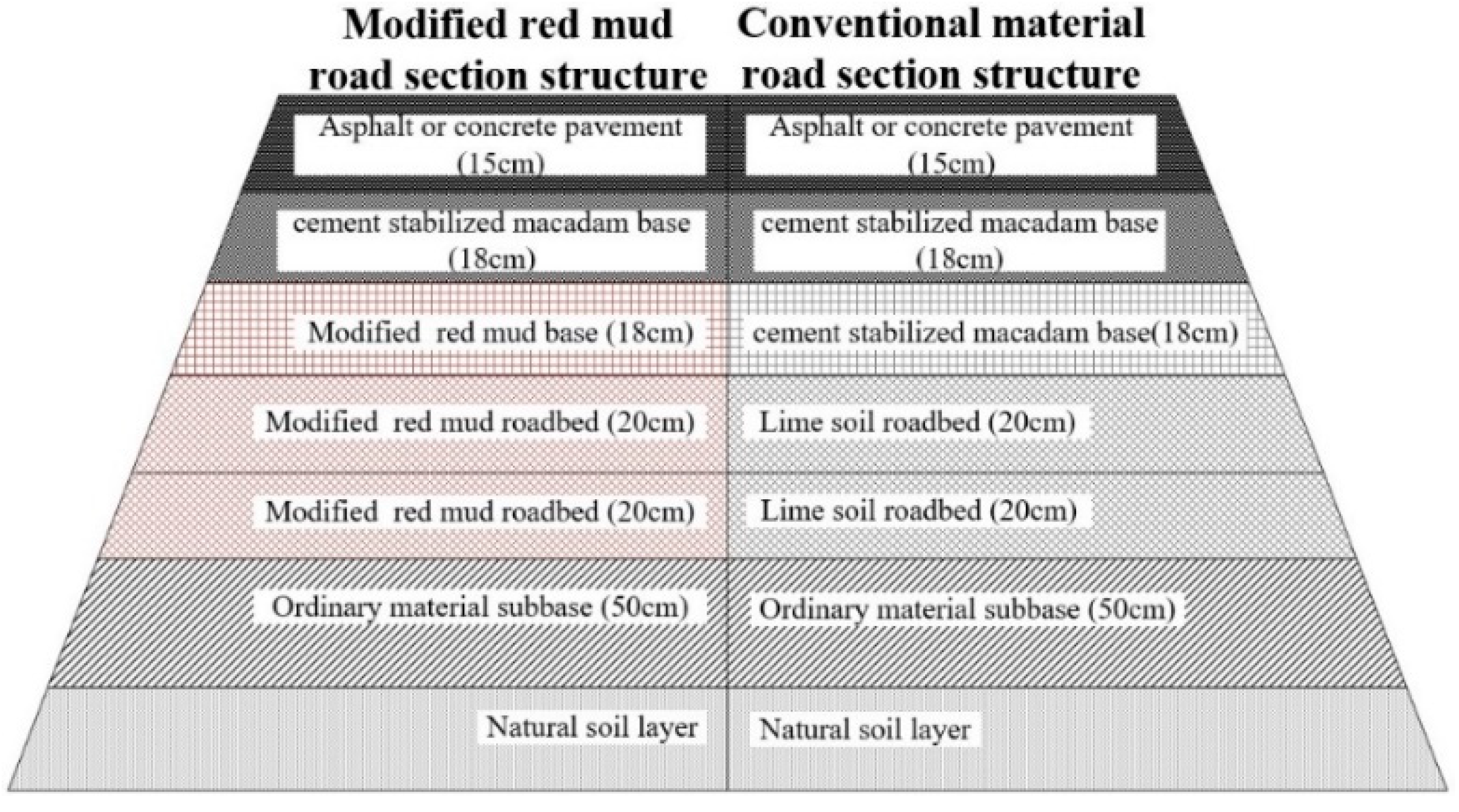

2. Materials and Methods

2.1. Sample and Specimen Preparation

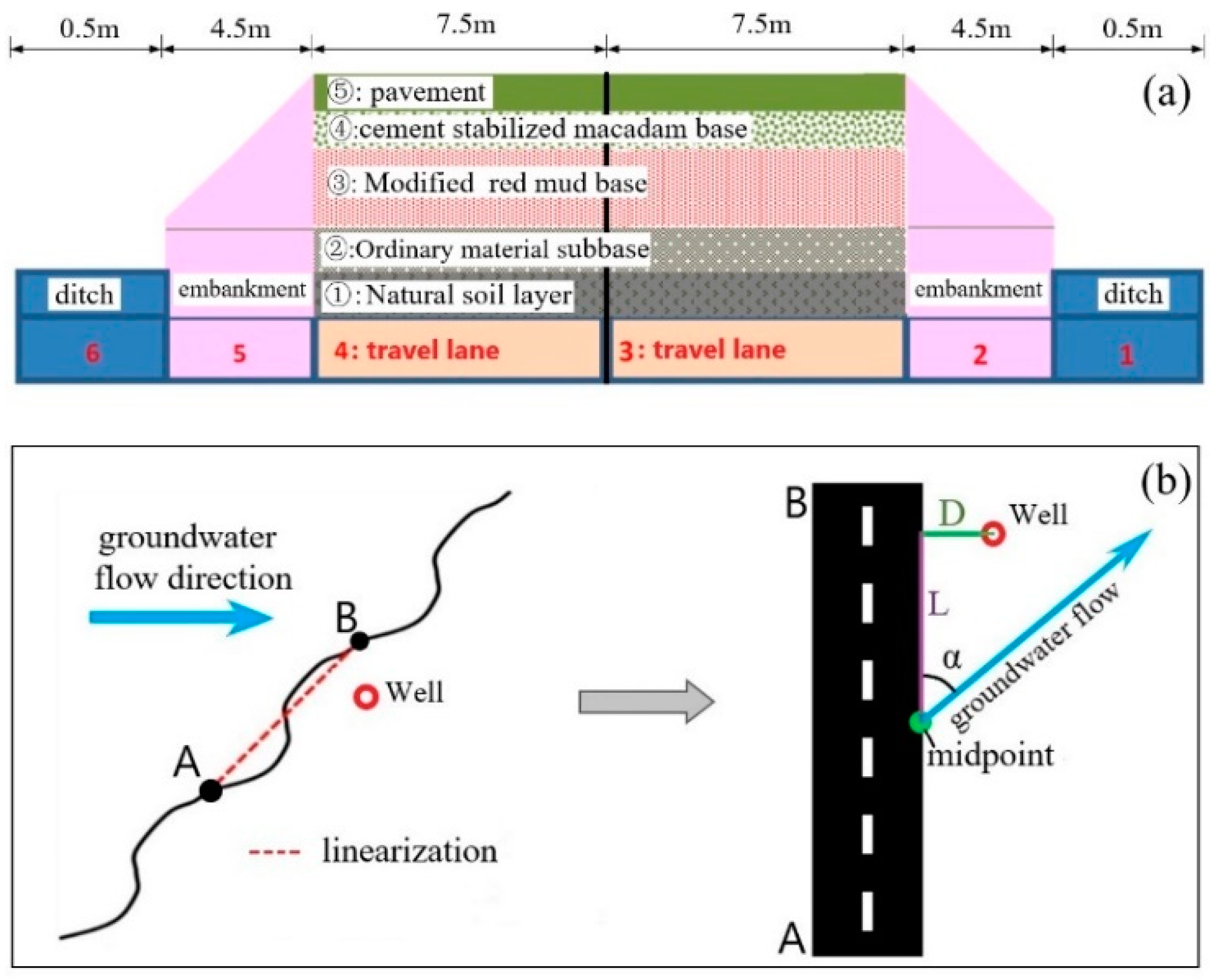

2.2. Exposure Scenario and Experimental Method

2.3. Risk Assessment Methods

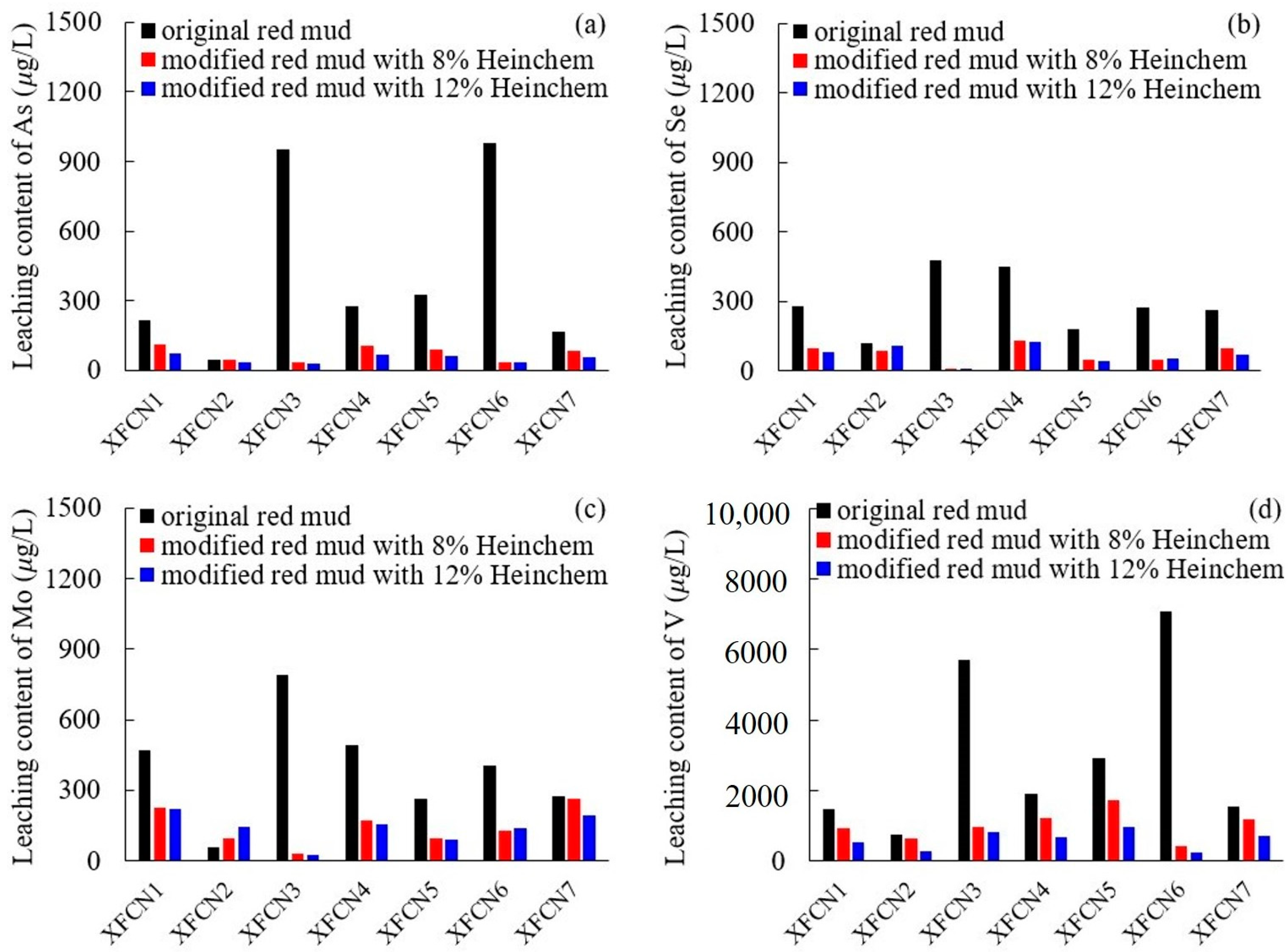

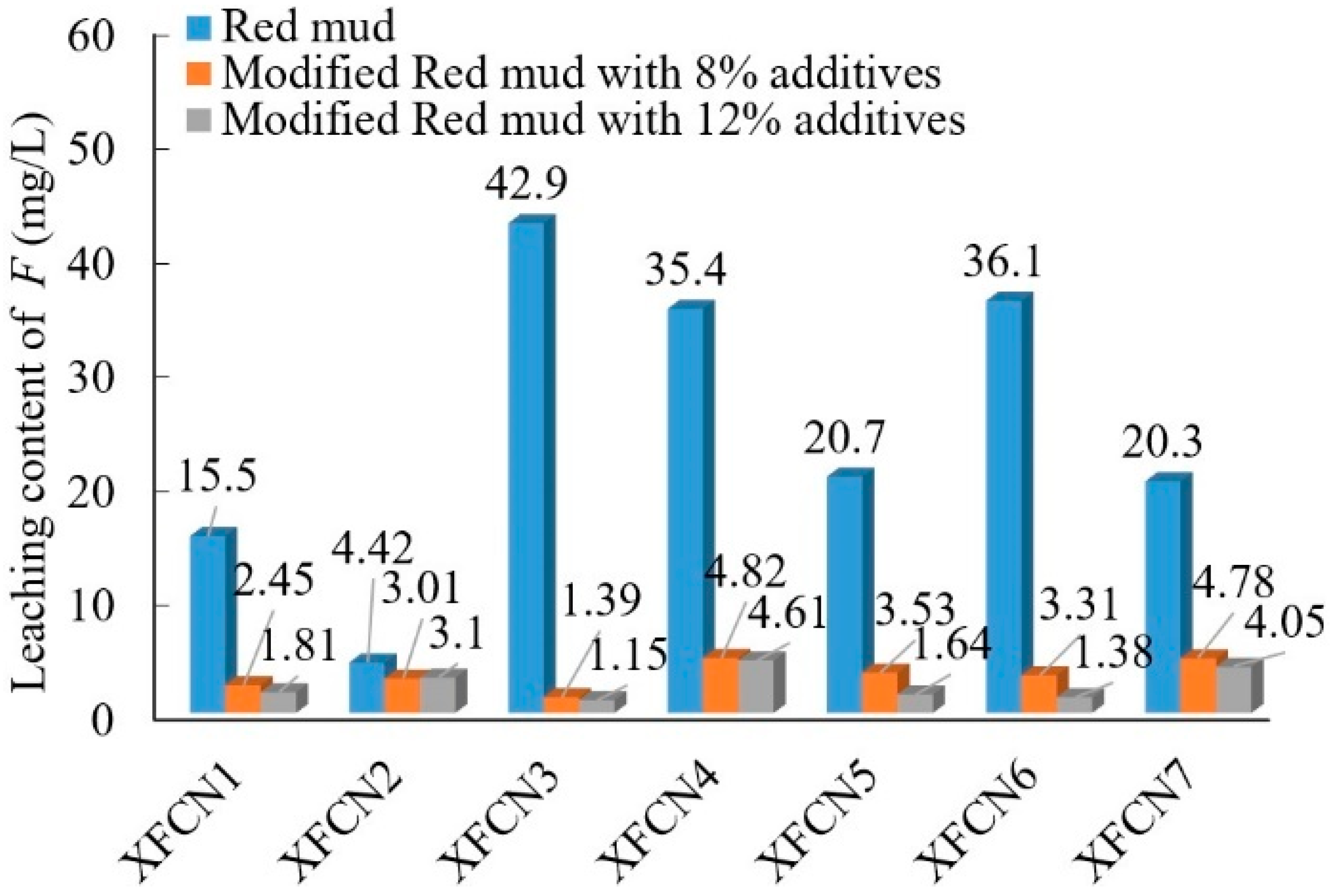

3. Identification of Characteristic Pollutants in Modified Red Mud

4. Environmental Risk Assessment of Modified Red Mud

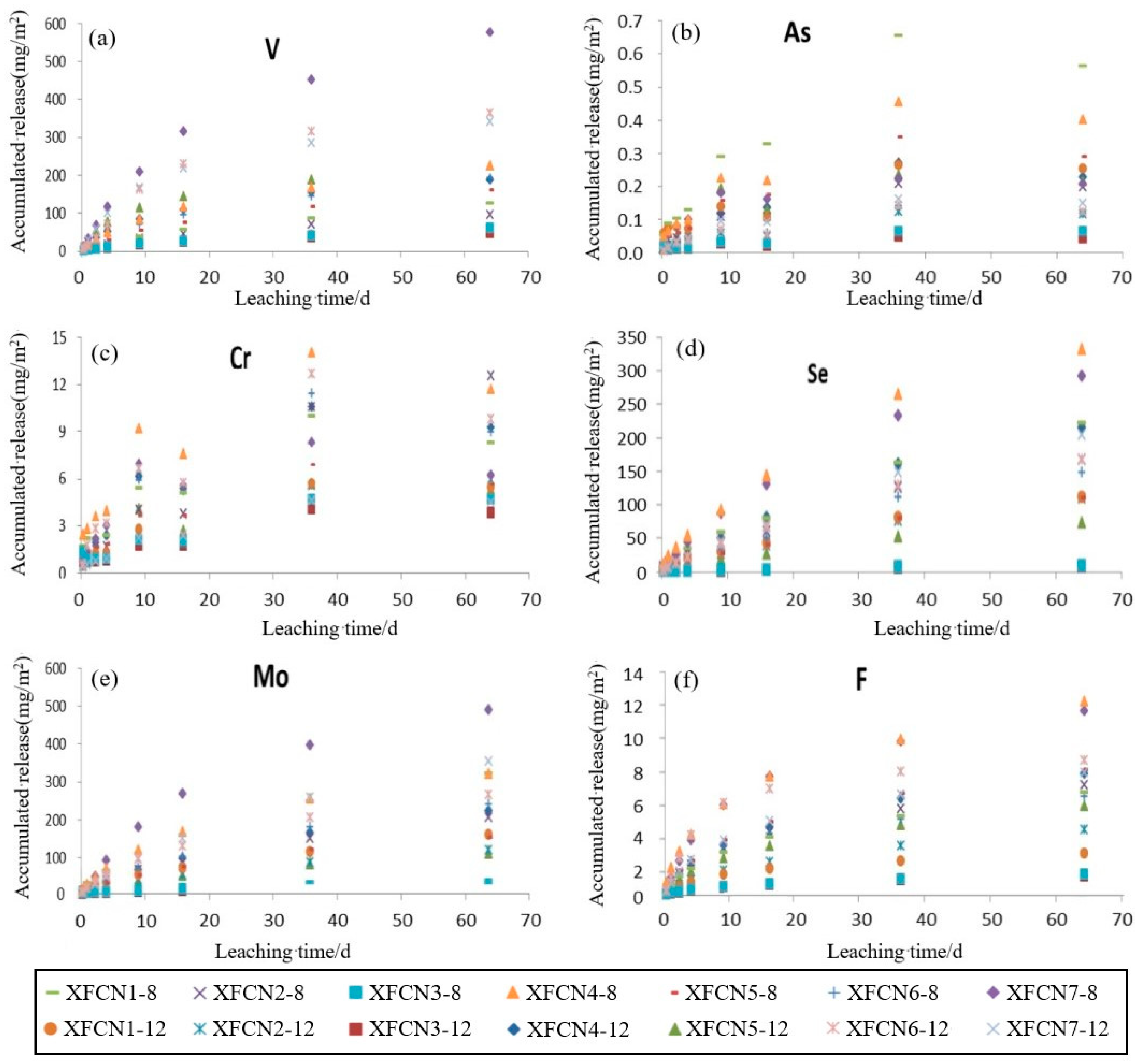

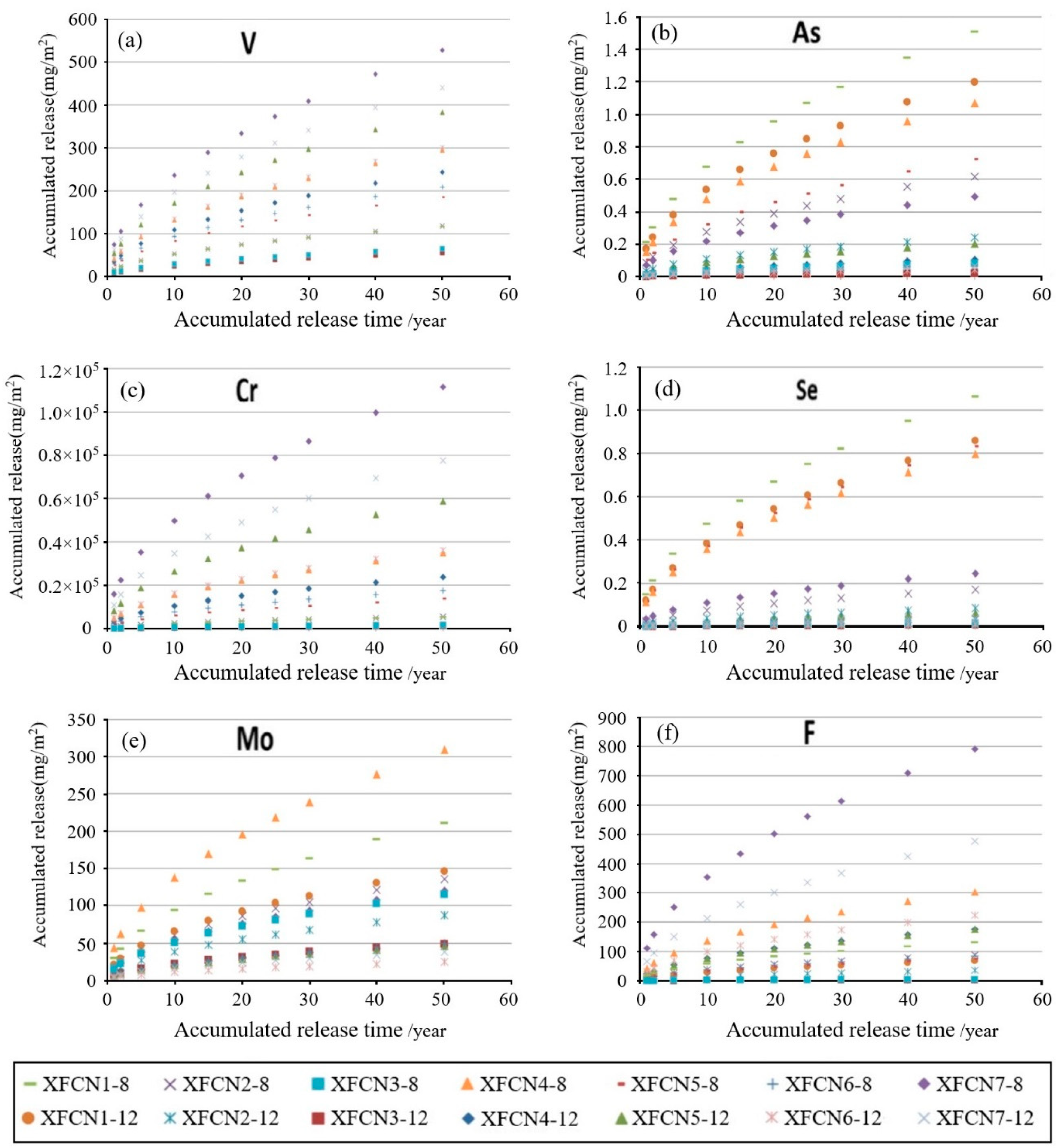

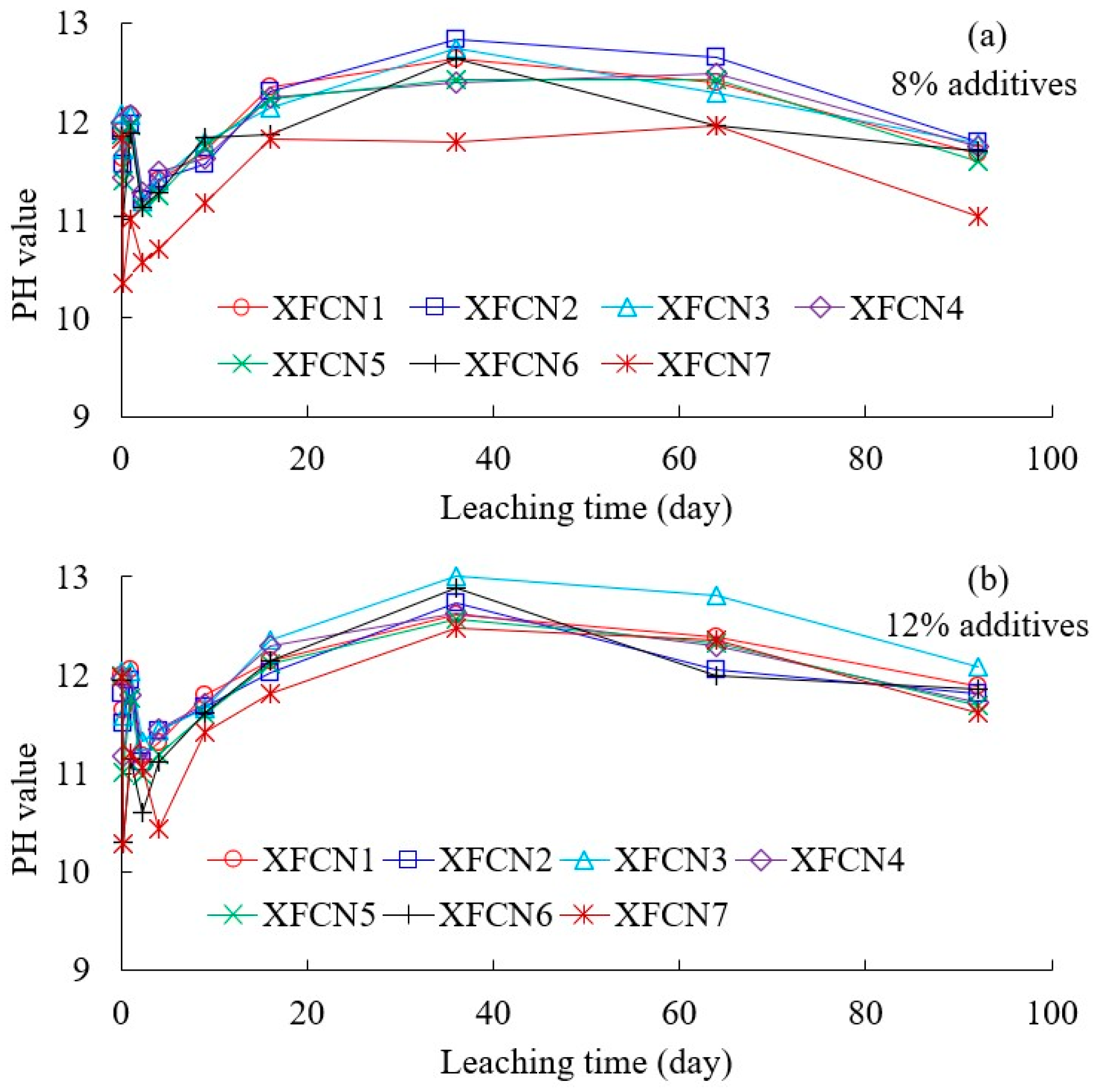

4.1. Release Patterns of Characteristic Pollutants in Modified Red Mud

4.2. Risk Assessment of Characteristic Pollutants

4.3. Impact on Farmland

5. Conclusions

- (1)

- Although the modified red mud has a significant solidification effect on F, V, As, Se, and Mo, the leaching contents of F, V, Cr, As, Se, and Mo in the modified red mud still cannot meet the requirement of groundwater quality, which should be considered in the groundwater environmental risk assessment when the modified red mud is used as a roadbed material. Moreover, the difference in leaching contents of F, V, Cr, As, Se, and Mo between the modified red mud with 8% and 12% modified materials is small.

- (2)

- When the leaching contents of V, Cr6+, Cr3+, As3+, Se4+, Se6+, Mo, and F in the modified red mud are lower than 0.15 mg/L, 0.1 mg/L, 0.2 mg/L, 0.012 mg/L, 0.012 mg/L, 0.012 mg/L, 0.075 mg/L, and 1.2 mg/L, respectively, the environmental risk of the modified red mud during long-term road use is acceptable.

- (3)

- The addition of a leaching solution of the modified red mud into the soil will slightly increase the soil pH value. The pH of the leaching solution of the modified red mud has little inhibitory effect on the growth of earthworms and Chinese cabbage.

- (4)

- The modified red mud for road use has little influence on the groundwater, this study provides a new way for the resource utilization of red mud. The replacement of traditional road materials by modified red mud has the potential to reduce material costs and improve road performance while conserving land resources. However, the technology of modified red mud is still in the developmental stage, and the composition of red mud may vary greatly depending on the source, requiring further research and standardization to ensure its reliability and consistency under different environmental and engineering conditions.

6. Prospects and Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Liu, X. Applications of Red Mud as an Environmental Remediation Material: A Review. J. Hazard. Mater. 2021, 408, 124420. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Chen, X.; Li, W.; Yu, Y.; Yan, K. Environmental Assessment, Management and Utilization of Red Mud in China. J. Clean. Prod. 2014, 84, 606–610. [Google Scholar] [CrossRef]

- Wang, K.; Dou, Z.; Liu, Y.; Li, X.; Lv, G.; Zhang, T.-A. Summary of Research Progress on Separation and Extraction of Valuable Metals from Bayer Red Mud. Environ. Sci. Pollut. Res. 2022, 29, 89834–89852. [Google Scholar] [CrossRef] [PubMed]

- Ujaczki, É.; Feigl, V.; Molnár, M.; Cusack, P.; Curtin, T.; Courtney, R.; O’Donoghue, L.; Davris, P.; Hugi, C.; Evangelou, M.W.; et al. Re-using Bauxite Residues: Benefits beyond (Critical Raw) Material Recovery. J. Chem. Technol. Biotechnol. 2018, 93, 2498–2510. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, S.; Dhawan, N. Evaluation of Red Mud as a Polymetallic Source—A Review. Miner. Eng. 2021, 171, 107084. [Google Scholar] [CrossRef]

- Liu, Y.; Naidu, R. Hidden Values in Bauxite Residue (Red Mud): Recovery of Metals. Waste Manag. 2014, 34, 2662–2673. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, Y.; Huang, J. Research Progress on Resource Comprehensive Utilization of Red Mud. Bull. Chin. Ceram. 2020, 39, 144–149. [Google Scholar]

- Sun, Z.; Tang, Q.; Xakalashe, B.S.; Fan, X.; Gan, M.; Chen, X.; Ji, Z.; Huang, X.; Friedrich, B. Mechanical and Environmental Characteristics of Red Mud Geopolymers. Constr. Build. Mater. 2022, 321, 125564. [Google Scholar] [CrossRef]

- Wu, P.; Liu, X.; Zhang, Z.; Wei, C.; Wang, J.; Gu, J. The Harmless and Value-Added Utilization of Red Mud: Recovering Iron from Red Mud by Pyrometallurgy and Preparing Cementitious Materials with Its Tailings. J. Ind. Eng. Chem. 2024, 132, 50–65. [Google Scholar] [CrossRef]

- Pei, J.; Pan, X.; Qi, Y.; Yu, H.; Tu, G. Preparation of Ultra-Lightweight Ceramsite from Red Mud and Immobilization of Hazardous Elements. J. Environ. Chem. Eng. 2022, 10, 108157. [Google Scholar] [CrossRef]

- Xue, S.; Huang, N.; Fan, J.; Liu, Z.; Ye, Y.; He, Y.; Hartley, W.; Zhu, F. Evaluation of Aggregate Formation, Stability and Pore Characteristics of Bauxite Residue Following Polymer Materials Addition. Sci. Total Environ. 2021, 765, 142750. [Google Scholar] [CrossRef] [PubMed]

- Sun, S. Experimental Study on Solid Waste Improved Soil and Its Environmental Impact, 1st ed.; Dong, A., Ed.; Science Publishing House: Beijing, China, 2010; Volume 73, ISBN 978-7-03-028823-3. [Google Scholar]

- Yu, H.; Ma, T.; Wang, D. Review on China’s Pavement Engineering Research 2020. China J. Highw. 2020, 33, 1–66. [Google Scholar]

- Zhang, J.; Li, P.; Liang, M.; Jiang, H.; Yao, Z.; Zhang, X.; Yu, S. Utilization of Red Mud as an Alternative Mineral Filler in Asphalt Mastics to Replace Natural Limestone Powder. Constr. Build. Mater. 2020, 237, 117821. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Yao, Z.; Wu, S.; Jiang, H.; Liang, M.; Qiao, Y. Environmental Aspects and Pavement Properties of Red Mud Waste as the Replacement of Mineral Filler in Asphalt Mixture. Constr. Build. Mater. 2018, 180, 605–613. [Google Scholar] [CrossRef]

- Ma, S.; Sun, Z.; Wei, J.; Zhang, X.; Zhang, L. Utilization of Modified Red Mud Waste from the Bayer Process as Subgrade and Its Performance Assessment in a Large-Sale Application. Coatings 2022, 12, 471. [Google Scholar] [CrossRef]

- Shandong Expressway Group: Red Mud-Based Cementitious Materials Successfully Applied to Highway—Civil Engineering Online. Available online: https://bbs.co188.com/thread-10507351-1-1.html (accessed on 1 July 2024).

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Jaf, D.K.I.; Abdulrahman, P.I.; Mohammed, A.S.; Kurda, R.; Qaidi, S.M.; Asteris, P.G. Machine Learning Techniques and Multi-Scale Models to Evaluate the Impact of Silicon Dioxide (SiO2) and Calcium Oxide (CaO) in Fly Ash on the Compressive Strength of Green Concrete. Constr. Build. Mater. 2023, 400, 132604. [Google Scholar] [CrossRef]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive Utilization Status of Red Mud in China: A Critical Review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Tan, Q.; Yang, Q.; Ye, C.; Wang, D.; Xie, N. Utilization of Red Mud in High-Performance Grouting Material for Semi-Flexible Pavement. J. Clean. Prod. 2024, 454, 142240. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Development of Early Strength of Lime Stabilized Expansive Soil: Effect of Red Mud and Egg Shell Ash. Acta Tech. Corviniensis-Bull. Eng. 2016, 9, 93. [Google Scholar]

- Cui, H.; Pei, G. Study on Road Performance of Silty Clay Improved by Soil Stabilizer Containing Red Mud. J. China Foreign Highw. 2018, 38, 301–306. [Google Scholar]

- Sun, J.; Li, Y.; Wei, J.; Sun, J. Research on engineering application of red mud casting materials for lightweight sintering method. Light Met. 2019, 8, 15–18. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Hou, Z.; Dong, Z. Improving Strength of Calcinated Coal Gangue Geopolymer Mortars via Increasing Calcium Content. Constr. Build. Mater. 2018, 166, 760–768. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, Y.; Zhao, R.; Zhang, J. Research status and development trend of mechanical properties of red mud geopolymer concrete. Mater. Her. 2020, 34, 15102–15109. [Google Scholar]

- Cheng, R.; Tian, G.; Mi, D.; Dong, X. Study on the basic engineering properties of red mud modified loess. Geotechnics 2018, 39, 89–97. [Google Scholar] [CrossRef]

- Palomo, A.; Palacios, M. Alkali-Activated Cementitious Materials: Alternative Matrices for the Immobilisation of Hazardous Wastes: Part II. Stabilisation of Chromium and Lead. Cem. Concr. Res. 2003, 33, 289–295. [Google Scholar] [CrossRef]

- Sore, S.O.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Synthesis and Characterization of Geopolymer Binders Based on Local Materials from Burkina Faso—Metakaolin and Rice Husk Ash. Constr. Build. Mater. 2016, 124, 301–311. [Google Scholar] [CrossRef]

- Fernandez Jiminez, A.M.; Lachowski, E.E.; Palomo, A.; Macphee, D.E. Microstructural Characterisation of Alkali-Activated PFA Matrices for Waste Immobilisation. Cem. Concr. Compos. 2004, 26, 1001–1006. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable Geopolymer Concrete Using Ground Granulated Blast Furnace Slag and Rice Husk Ash: Strength and Permeability Properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Perera, D.S.; Aly, Z.; Vance, E.R.; Mizumo, M. Immobilization of Pb in a Geopolymer Matrix. J. Am. Ceram. Soc. 2005, 88, 2586–2588. [Google Scholar] [CrossRef]

- Meddah, M.S.; Zitouni, S.; Belâabes, S. Effect of Content and Particle Size Distribution of Coarse Aggregate on the Compressive Strength of Concrete. Constr. Build. Mater. 2010, 24, 505–512. [Google Scholar] [CrossRef]

- Sun, Z. Study on the Engineering Technology and Environmental Impacts of the Bayer Method of Filling Roadbeds with Red Mud. Master’s Thesis, Shandong University, Jinan, China, 2018. [Google Scholar]

- JTG D30-2015; Announcement of the Ministry of Transportation and Communications on the Publication of the Design Specification for Highway Roadbeds. 3rd ed. People’s Transportation Press: Beijing, China, 2015.

- NEN 7375-2004; Leaching Characteristics—Determination of the Leaching of Inorganic Components from Moulded or Monolitic Materials with a Diffusion Test—Solid Earthy and Stony Materials. Milieukwaliteit: Amsterdam, The Netherlands, 2004.

- GB/T 15555.12-1995; Solid Waste-Glass Electrode Test-Method of Corrosively. 1st ed. Ministry of Ecological Environment of the People’s Republic of China: Beijing, China, 1995.

- HJ 766-2015; Solid Waste–Determination of Metals–Inductively Coupled Plasma Mass Spectrometry (ICP-MS). 1st ed. China Environmental Science Publishing House: Beijing, China, 2015.

- GB 5085.3-2007; Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity. 1st ed. China Environmental Science Publishing House: Beijing, China, 2007.

- GBT14848-2017; Groundwater Quality Standards. 2nd ed. China Quality Inspection Press: Beijing, China, 2017.

- GB 3838-2002; Environmental Quality Standards for Surface Water. 2nd ed. China Environmental Science Publishing House: Beijing, China, 2002.

- Yang, Z.; Chen, Q.; Guo, Q.; Dang, Y.; Li, X.; Qian, J. Phosphogypsum Application in Cement Production Status and Prospects. Silic. Bull. 2016, 35, 2860–2865. [Google Scholar] [CrossRef]

- GB2760-2014; National Standards for Food Safety Standards for the Use of Food Additives. 2nd ed. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2014.

- Cheng, S.; Grosse, W.; Karrenbrock, F.; Thoennessen, M. Efficiency of Constructed Wetlands in Decontamination of Water Polluted by Heavy Metals. Ecol. Eng. 2002, 18, 317–325. [Google Scholar] [CrossRef]

| Sample Number of Original Red Mud | Generation Time | Sample Number of Modified Red Mud | |

|---|---|---|---|

| With 8% Heinchem | With 12% Heinchem | ||

| XFCN1 | 2009 | XFCN1-8 | XFCN1-12 |

| XFCN2 | 2010 | XFCN2-8 | XFCN2-12 |

| XFCN3 | 2014 | XFCN3-8 | XFCN3-12 |

| XFCN4 | 2016 | XFCN4-8 | XFCN4-12 |

| XFCN5 | 2017 | XFCN5-8 | XFCN5-12 |

| XFCN6 | 2018 | XFCN6-8 | XFCN6-12 |

| XFCN7 | 2019 | XFCN7-8 | XFCN7-12 |

| Physical and Mechanical Index Parameters | Original Red Mud (XFCN1) | Modified Red Mud (XFCN1-12) | Remarks |

|---|---|---|---|

| Optimal moisture content (%) | 28.5 | 26.8 | Compaction test |

| Maximum dry density (g/cm3) | 1.74 | 1.71 | |

| Liquid limit (%) | 45.4 | 36.4 | Atterberg limits test |

| Plastic limit (%) | 29.6 | 21.5 | |

| Plasticity index | 15.8 | 14.9 | |

| Internal friction angle (°) | 24.2 | 36.8 | Undrained triaxial test |

| Cohesion force (kPa) | 31.0 | 143.2 | |

| 7-day non-immersion strength (kPa) | 506 | 3080.6 | Uniaxial compression test |

| 7-day immersion strength (kPa) | 0 (disintegration) | 3047.1 | |

| CBR2.5 (%) | 2.8 | 94 | CBR test |

| Compression coefficient a1-2 (MPa-1) | 0.19 | 0.07 | Oedometer test |

| Free swelling rate (%) | 17 | 5 | Soil swelling test |

| Swelling ratio without load (%) | 0.05 | 0 |

| Sample of Original Red Mud | Chemical Composition | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | TiO2 | Na2O | K2O | Loss | |

| XFCN1 | 28.09 | 25.54 | 19.81 | 1.71 | 0.29 | 2.15 | 10.17 | 0.31 | 11.43 |

| Distance LAB | Angle α | Distance D | Distance L |

|---|---|---|---|

| 0.5, 1.0 km | 10°, 15°, 30°, 60° | 1, 5, 10, 50 m | 1, 5, 10, 50 m |

| Toxicity Level | Seed Germination Rate (%) | Acute Mortality Rate of Earthworms (%) |

|---|---|---|

| Very toxic | ≥80 | ≥80 |

| High-toxic | 80~50 | 80~50 |

| Medium-toxic | 50~30 | 50~30 |

| Low-toxic | 30~10 | 30~10 |

| Non-toxic | ≤10 | ≤10 |

| Sample Number | Al (μg/L) | Cr (μg/L) | As (μg/L) | Se (μg/L) | Mo (μg/L) | V (μg/L) |

|---|---|---|---|---|---|---|

| XFCN1 | 15,432.5 | 18 | 217.5 | 280.9 | 470.8 | 1468 |

| XFCN1-8 | 58,925 | 446.4 | 107.8 | 96.1 | 226.8 | 928.1 |

| XFCN1-12 | 59,825 | 893.5 | 69.8 | 79.7 | 219.5 | 545.1 |

| XFCN2 | 12,212.5 | 70.65 | 46.39 | 118.79 | 55.46 | 734.3 |

| XFCN2-8 | 32,700 | 331.2 | 45.2 | 86.9 | 97.3 | 626.8 |

| XFCN2-12 | 50,850 | 787.1 | 34.4 | 106.6 | 142.7 | 291.4 |

| XFCN3 | 55,025 | 140.3 | 951.1 | 478.7 | 789.4 | 5704 |

| XFCN3-8 | 38,275 | 186 | 32.5 | 9.0 | 30.4 | 971.9 |

| XFCN3-12 | 45,625 | 171.5 | 27.0 | 7.9 | 27.2 | 834.4 |

| XFCN4 | 19,670 | 180 | 275.1 | 451.5 | 492.6 | 1912 |

| XFCN4-8 | 48,525 | 295 | 106.2 | 132.2 | 169.8 | 1235 |

| XFCN4-12 | 71,300 | 366 | 64.5 | 125.9 | 156.3 | 687.1 |

| XFCN5 | 39,250 | 53.34 | 326.9 | 178 | 263.9 | 2915 |

| XFCN5-8 | 60,650 | 171 | 87.3 | 47.9 | 94.9 | 1718 |

| XFCN5-12 | 52,175 | 202 | 58.8 | 43.4 | 87.9 | 947.5 |

| XFCN6 | 37,900 | 236.6 | 981.1 | 271.7 | 403.9 | 7069 |

| XFCN6-8 | 110,575 | 254.8 | 34.3 | 50.7 | 128.8 | 420.1 |

| XFCN6-12 | 110,150 | 302.9 | 31.2 | 52.3 | 136.9 | 253.9 |

| XFCN7 | 7,802.5 | 516.6 | 163.3 | 260.5 | 274.5 | 1542 |

| XFCN7-8 | 66,500 | 166.7 | 82.63 | 98.4 | 262.1 | 1184 |

| XFCN7-12 | 80,525 | 147.6 | 57.6 | 69.8 | 191.9 | 697.6 |

| Limit value | 200 | 5 | 10 | 10 | 70 | 50 |

| Types of Pollutants | D = 1 m, L = 1 m, α = 10° | D = 5 m, L = 5 m, α = 10° | D = 10 m, L = 10 m, α = 10° | ||||||

|---|---|---|---|---|---|---|---|---|---|

| LC (mg/L) | LAB 0.5 km | LAB 1 km | LC (mg/L) | LAB 0.5 km | LAB 1 km | LC (mg/L) | LAB 0.5 km | LAB 1 km | |

| EC (mg/L) | EC (mg/L) | EC (mg/L) | EC (mg/L) | EC (mg/L) | EC (mg/L) | ||||

| V | 0.16 | 0.0495 | 0.0494 | 0.15 | 0.0413 | 0.0409 | 0.18 | 0.0475 | 0.0352 |

| As3+ | 0.014 | 0.0096 | 0.01 | 0.012 | 0.0078 | 0.0078 | 0.015 | 0.0094 | 0.0068 |

| As5+ | 200 | 0.0037 | 0.0036 | 100 | 0.00028 | 0.00033 | 200 | 0.0021 | 0.0017 |

| Cr6+ | 0.1 | 0.0499 | 0.0486 | 0.1 | 0.0446 | 0.0458 | 0.12 | 0.0499 | 0.0363 |

| Cr3+ | 0.2 | 0.0296 | 0.0292 | 0.2 | 0.0263 | 0.0273 | 0.4 | 0.0944 | 0.0367 |

| Se4+ | 0.014 | 0.0094 | 0.0095 | 0.012 | 0.0077 | 0.0074 | 0.016 | 0.0099 | 0.0075 |

| Se6+ | 0.014 | 0.0094 | 0.0096 | 0.012 | 0.0077 | 0.0077 | 0.016 | 0.0099 | 0.0074 |

| Mo | 0.08 | 0.0538 | 0.0533 | 0.075 | 0.0494 | 0.0486 | 0.08 | 0.0494 | 0.0476 |

| F | 1.4 | 0.9325 | 0.9578 | 1.2 | 0.7719 | 0.7787 | 1.4 | 0.8318 | 0.6627 |

| Conditions | PH | Survival Rate of Earthworms | Standard Error | ||

|---|---|---|---|---|---|

| 7d | 14d | 7d | 14d | ||

| Modified red mud leaching solution | 12.63 | 80.0% | 75.0% | 14% | 21% |

| 12.62 | 100.0% | 86.7% | 0% | 15% | |

| 12.84 | 100.0% | 90.0% | 0% | 17% | |

| 12.74 | 93.3% | 93.3% | 12% | 12% | |

| 12.74 | 100.0% | 93.3% | 0% | 6% | |

| 13.00 | 96.7% | 96.7% | 6% | 6% | |

| 12.39 | 96.7% | 93.3% | 6% | 12% | |

| 12.63 | 90.0% | 90.0% | 10% | 10% | |

| 12.42 | 90.0% | 83.3% | 10% | 21% | |

| 12.56 | 93.3% | 93.3% | 12% | 12% | |

| 12.64 | 96.7% | 80.0% | 6% | 10% | |

| 12.89 | 96.7% | 93.3% | 6% | 17% | |

| 11.79 | 96.7% | 93.3% | 6% | 6% | |

| 12.48 | 96.7% | 90.0% | 6% | 17% | |

| Blank | 8.6 | 90% | 90% | 10% | 10% |

| Leaching Solution pH | Germination Ratio | Standard Error | Root Length | Standard Error | Inhibition Ratio |

|---|---|---|---|---|---|

| 12.06 | 100% | 0.00 | 6.91 | 1.38 | 15.1% |

| 12.06 | 96.7% | 0.06 | 7.01 | 2.08 | 16.8% |

| 12.06 | 96.7% | 0.06 | 7.36 | 1.66 | 9.8% |

| 12.04 | 96.7% | 0.06 | 6.54 | 2.01 | 16.7% |

| 12.06 | 93.3% | 0.06 | 7.69 | 1.93 | 22.7% |

| 12.35 | 96.7% | 5.8% | 7.86 | 2.02 | −6.6% |

| 12.31 | 96.7% | 5.8% | 7.95 | 2.21 | −5.5% |

| 12.35 | 96.7% | 5.8% | 7.97 | 1.41 | −5.2% |

| 12.29 | 93.3% | 11.5% | 7.75 | 1.28 | −7.8% |

| Blank 1 | 93.3% | 0.12 | 6.0 | 1.64 | - |

| Blank 2 | 95.0% | 7.1% | 8.41 | 2.01 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Jiang, N.; Wang, W.; Jin, L.; Yan, S. Environment Assessment of Modified Red Mud Utilized in Roadbed. Buildings 2024, 14, 2135. https://doi.org/10.3390/buildings14072135

Cheng Y, Jiang N, Wang W, Jin L, Yan S. Environment Assessment of Modified Red Mud Utilized in Roadbed. Buildings. 2024; 14(7):2135. https://doi.org/10.3390/buildings14072135

Chicago/Turabian StyleCheng, Yu, Na Jiang, Wentong Wang, Lu Jin, and Shiying Yan. 2024. "Environment Assessment of Modified Red Mud Utilized in Roadbed" Buildings 14, no. 7: 2135. https://doi.org/10.3390/buildings14072135

APA StyleCheng, Y., Jiang, N., Wang, W., Jin, L., & Yan, S. (2024). Environment Assessment of Modified Red Mud Utilized in Roadbed. Buildings, 14(7), 2135. https://doi.org/10.3390/buildings14072135