Research on Carbon Emission Pre-Assessment of Residential Buildings in Xi’an City during the Scheme Design Stage

Abstract

1. Introduction

2. Methodology

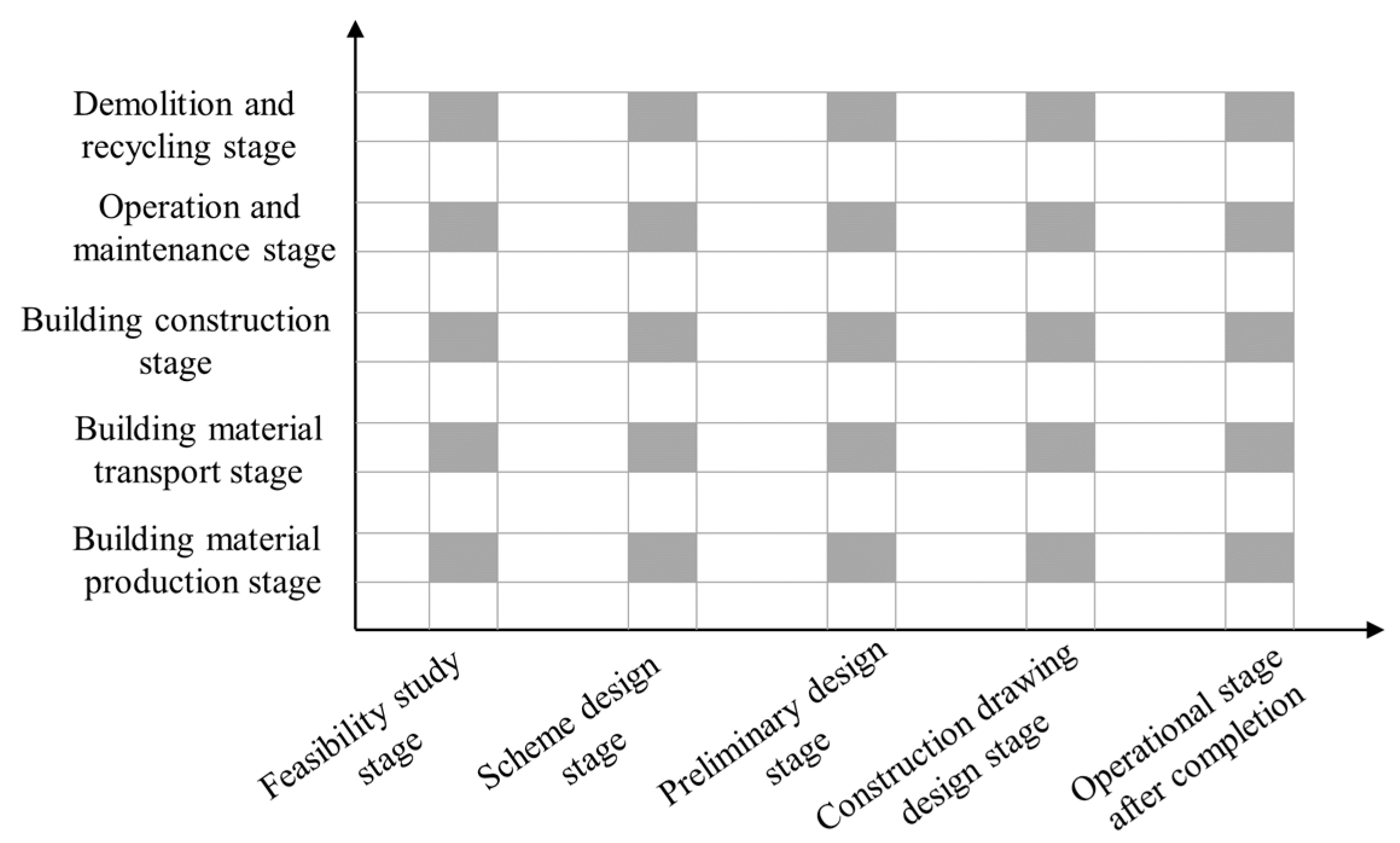

2.1. A Two-Dimensional Framework for Building Life Cycle Carbon Emissions

2.2. Building Carbon Emissions Accounting

2.2.1. Building Carbon Emission Factor

2.2.2. Building Carbon Emission Accounting Model

- Building material production stage

- 2.

- Building material transport stage

- 3.

- Building construction stage

- 4.

- Operation and maintenance stage

- 5.

- Building demolition and recycling stage

2.2.3. Functional Unit

2.3. Carbon Emission Prediction Model in the Design Stage of Building Scheme

2.3.1. Introduction to the Prediction Model

2.3.2. Evaluation Index

3. Data Collection

3.1. Data Source

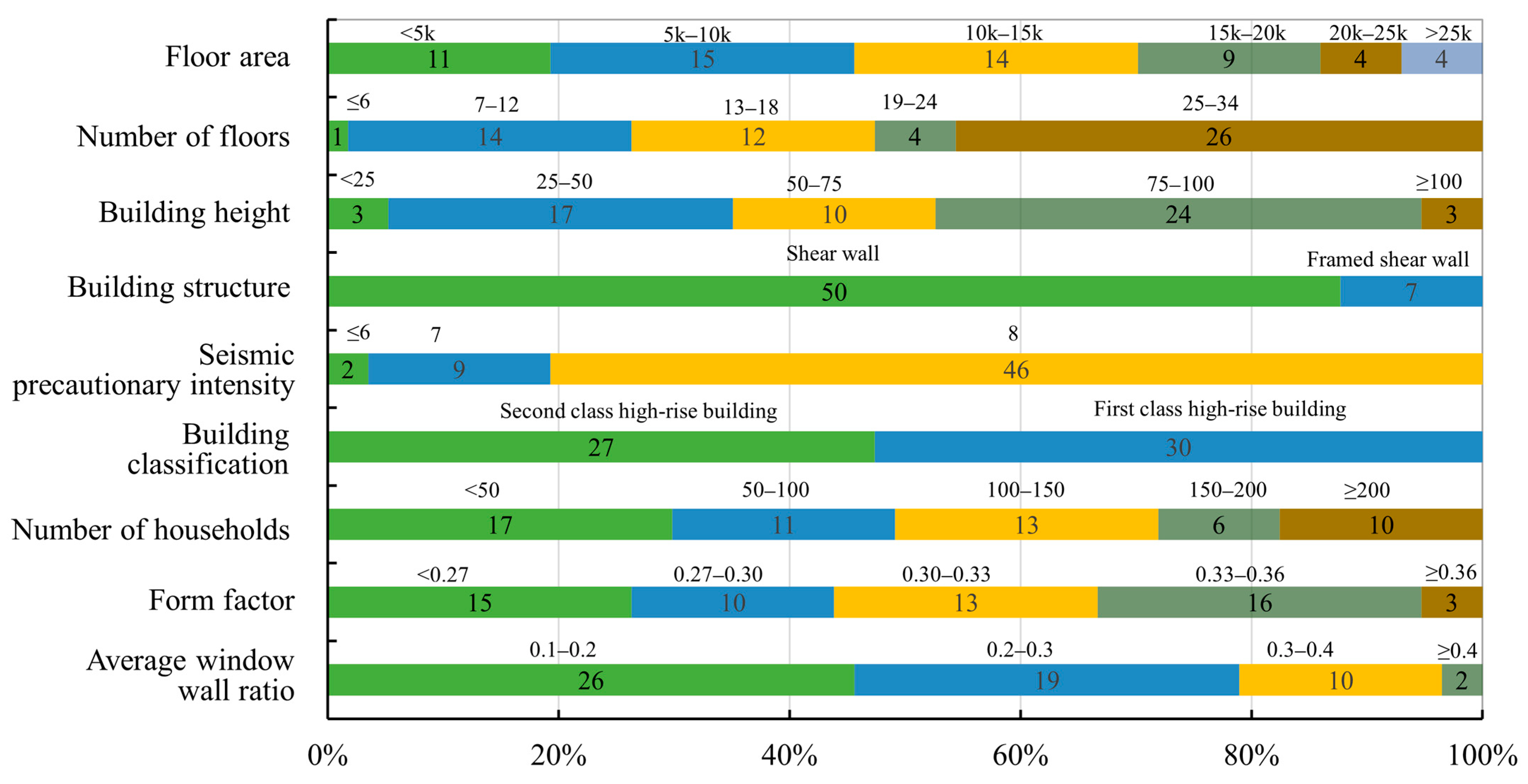

3.2. Data Description

4. Results and Discussion

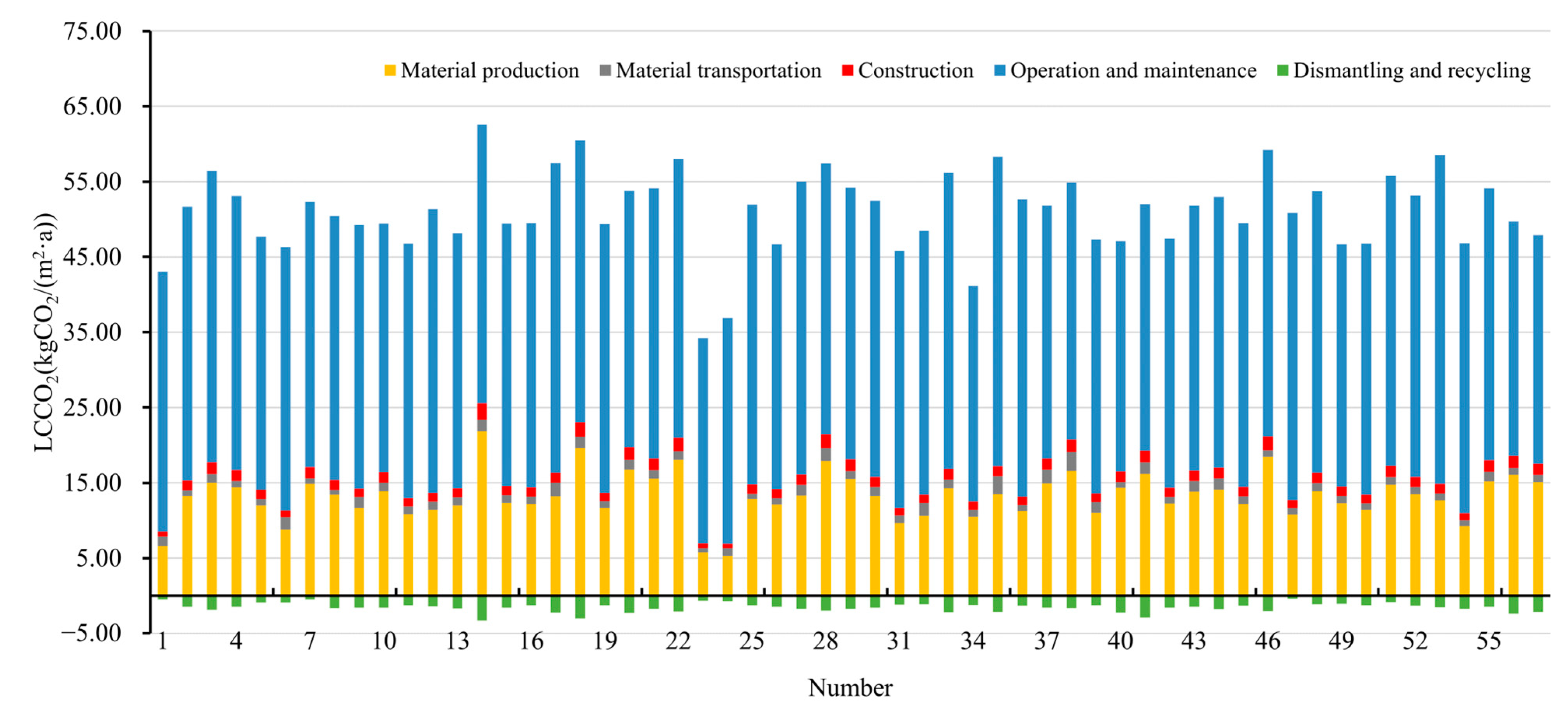

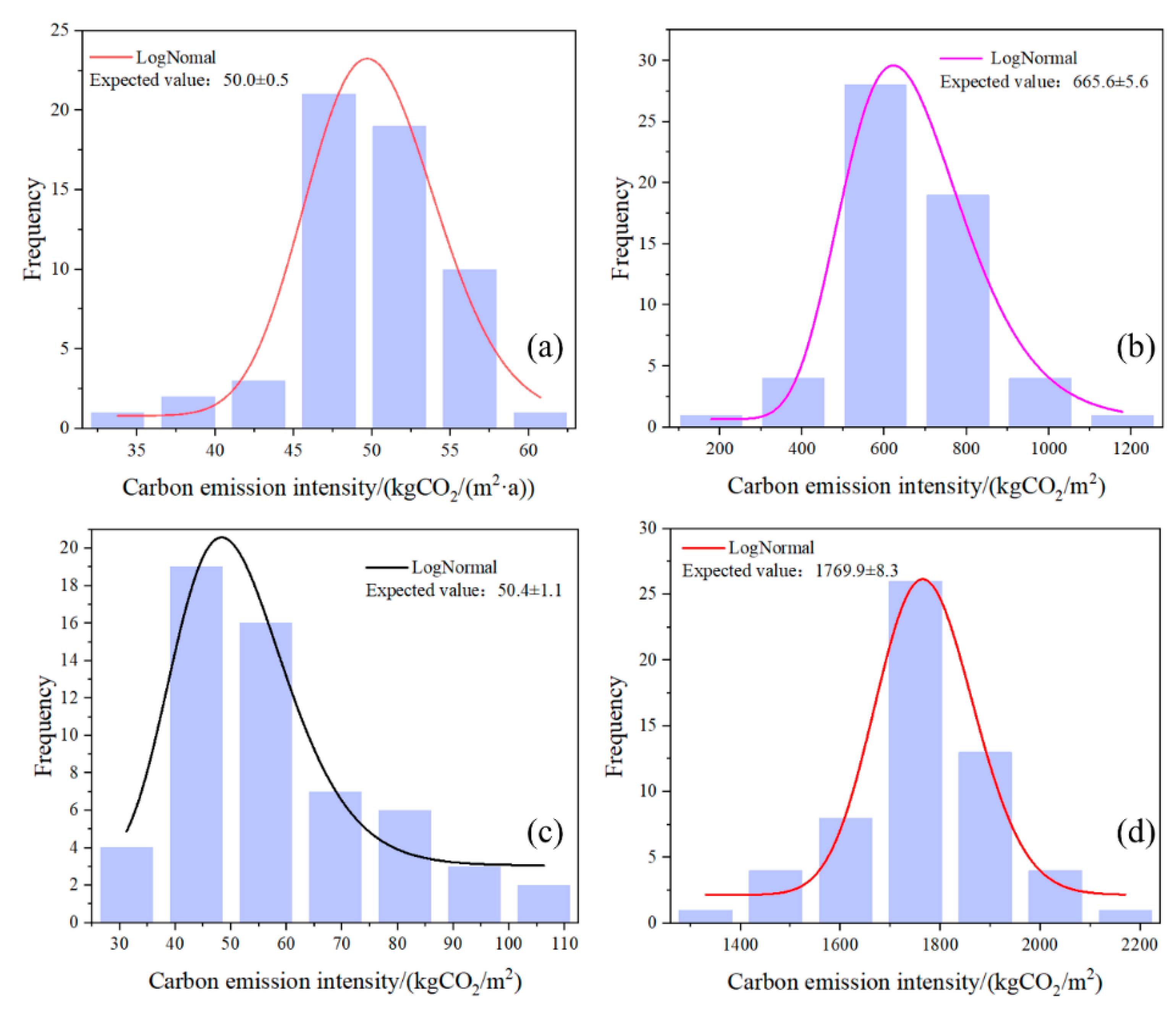

4.1. Analysis of Building Life Cycle Carbon Emission Characteristics

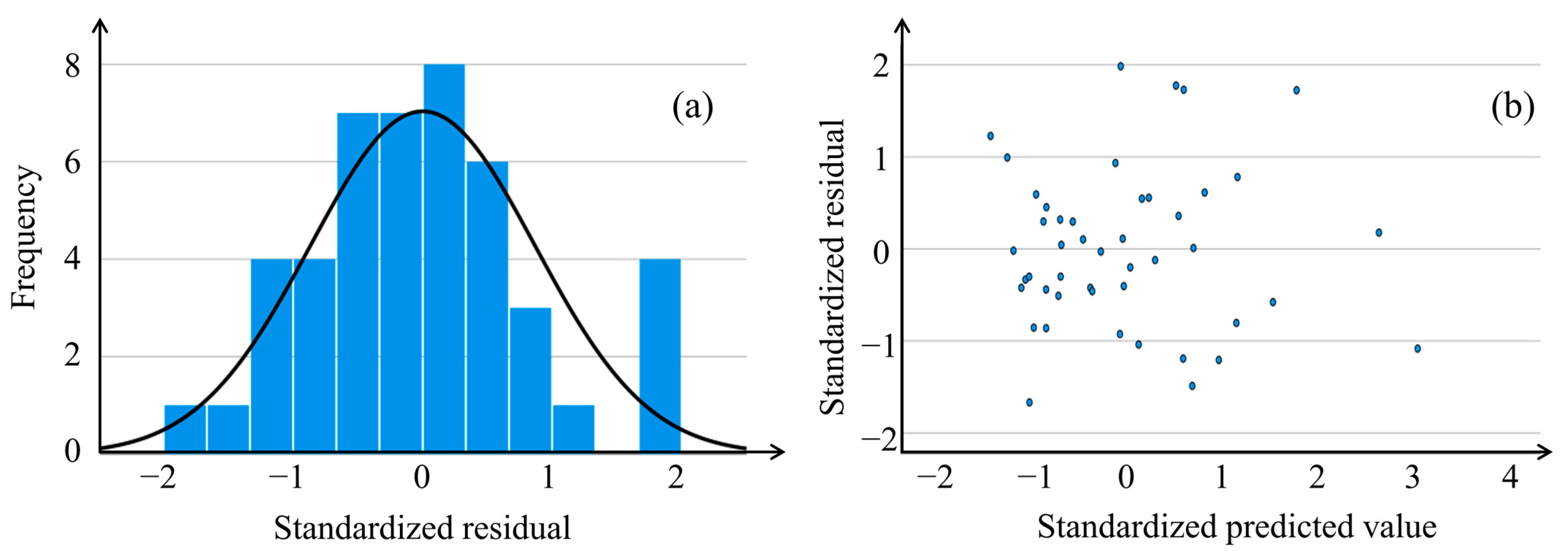

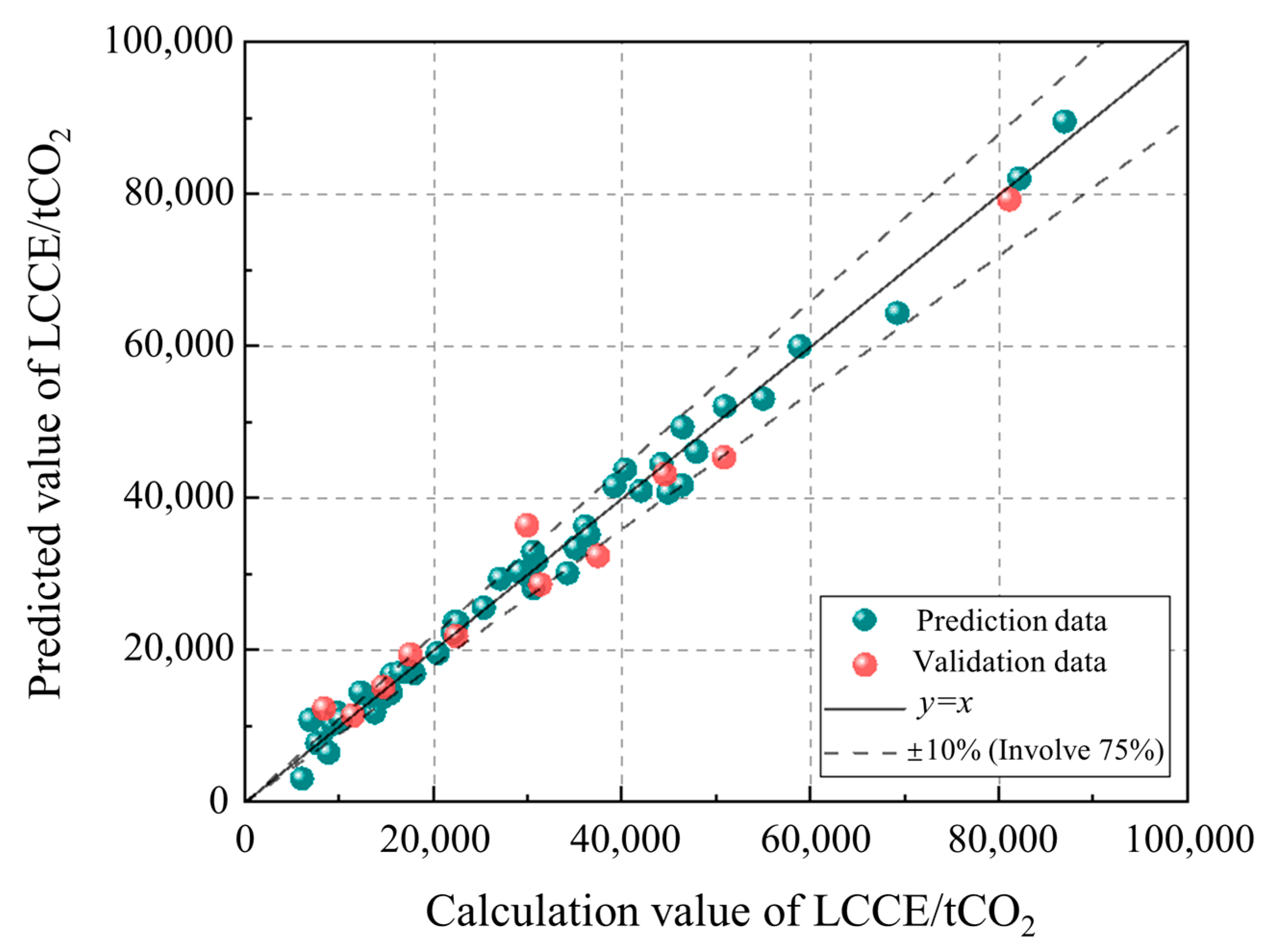

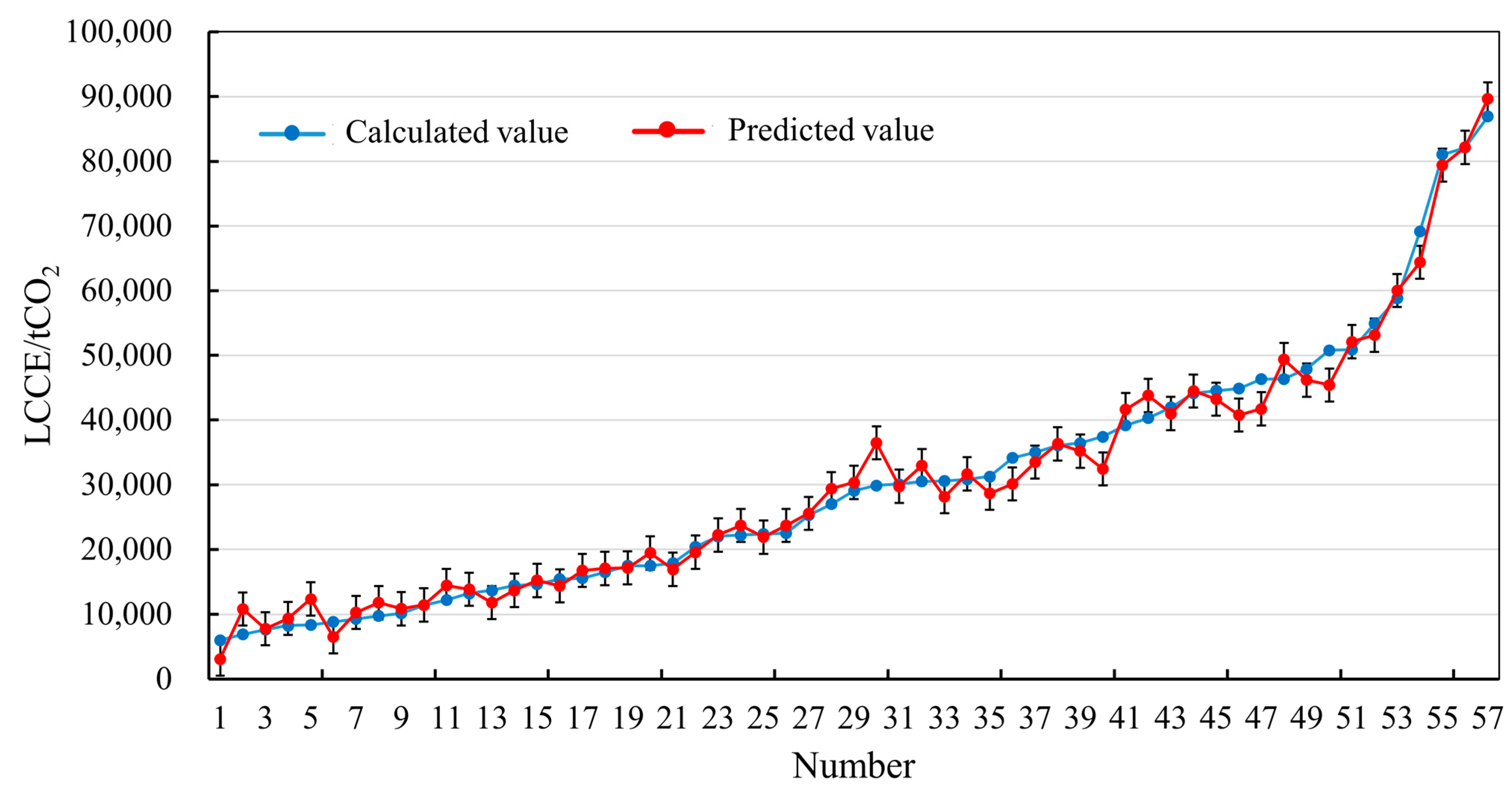

4.2. Construction of Prediction Model

4.2.1. Linear Analysis of Variables

4.2.2. Correlation Analysis and VIF Validation

4.2.3. Model Construction Result

4.3. Validation of Predictive Models

5. Conclusions

- (1)

- This study proposed a two-dimensional carbon emission framework for the building life cycle, which combines five project implementation stages, namely the feasibility study, scheme design, preliminary design, construction drawing design, and completed operation, with all stages of the building life cycle, and provided carbon emission pre-assessment methods for each building project implementation stage, so as to grasp the level of building carbon emission in the early stage of design. This study guided the selection of the design scheme and provided data support for the formulation of the carbon reduction scheme.

- (2)

- The life cycle carbon emissions of 57 residential buildings in Xi’an were calculated, and it was found that the life cycle carbon emission intensity was about 45~55 kgCO2/(m2·a). The operation and maintenance stage and building materials production stage contributed most of the carbon emissions, and the sum of the two stages contributed 92.3% of the carbon emissions. The distribution fitting graph based on the probability density function for the carbon emission intensity of the building life cycle, building material production and transportation, stage and building operation and maintenance stage is in line with the lognormal distribution on the whole, and its expected value can be used as a reference value for estimating building carbon emissions by the index method of the feasibility study stage.

- (3)

- Eleven independent variables affecting building carbon emissions, namely area, floor number, story height, number of households, shape factor, S-WWR, N-WWR, M-WWR, Wall-K, Windows-K, and Roof-K were studied and determined. On this basis, a multiple linear regression model was proposed for carbon emission pre-assessment in the design stage of building schemes. The model error is about 10%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Romero, J. Climate Change 2023: Synthesis Report. In Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2023; pp. 35–115. [Google Scholar] [CrossRef]

- Shu, Z.; Jin, J.; Zhang, J.; Wang, G.; Lian, Y.; Liu, Y.; Bao, Z.; Guan, T.; He, R.; Liu, C.; et al. 1.5°C and 2.0°C of global warming intensifies the hydrological extremes in China. J. Hydrol. 2024, 635, 131229. [Google Scholar] [CrossRef]

- Kabir, M.; Habiba, U.E.; Khan, W.; Shah, A.; Rahim, S.; Rios-Escalante, P.R.D.l.; Farooqi, Z.-U.-R.; Ali, L.; Shafiq, M. Climate change due to increasing concentration of carbon dioxide and its impacts on environment in 21st century; a mini review. J. King Saud Univ. Sci. 2023, 35, 102693. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, F.; Liu, J.; Li, Y.; Wang, M.; Luo, Y.; Ma, L.; Zhu, C.; Cai, W. Energy analysis and performance assessment of a hybrid deep borehole heat exchanger heating system with direct heating and coupled heat pump approaches. Energy Convers. Manag. 2023, 276, 116484. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Carbon footprint assessment of residential buildings, a review and a case study in Turkey. J. Clean. Prod. 2022, 340, 130691. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, Y.; Sun, H.; Wang, A. A real-time operational carbon emission prediction method for the early design stage of residential units based on a convolutional neural network: A case study in Beijing, China. J. Build. Eng. 2023, 75, 106994. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Yin, W.; Wang, Y.; Lv, J.; Wang, A. Deciphering carbon emissions in urban sewer networks: Bridging urban sewer networks with city-wide environmental dynamics. Water Res. 2024, 256, 121576. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Y.; Zhang, C. Forecasting CO2 emissions in Hebei, China, through moth-flame optimization based on the random forest and extreme learning machine. Environ. Sci. Pollut. Res. 2018, 25, 28985–28997. [Google Scholar] [CrossRef]

- Pan, W.; Li, K.; Teng, Y. Rethinking system boundaries of the life cycle carbon emissions of buildings. Renew. Sustain. Energy Rev. 2018, 90, 379–390. [Google Scholar] [CrossRef]

- Lu, W.; Chen, X.; Song, Z.; Li, Y.; Lu, J. A Fast Screening Method of Key Parameters from Coal for Carbon Emission Enterprises. Energies 2023, 16, 7592. [Google Scholar] [CrossRef]

- Maohu, L.; Huaxin, Z.; Shengnan, L. Comparative analysis of carbon emissions in Tianjin based on LMDI method and STIRPAT model. J. Environ. Eng. Technol. 2023, 13, 63–70. [Google Scholar] [CrossRef]

- Zhixing, L.; Liu, Y.; Jiaping, L. Carbon dioxide emissions of office buildings at embodied stage. J. Civ. Archit. Environ. Eng. 2014, 36, 37–43. [Google Scholar] [CrossRef]

- Li, H.; Li, B.; Niu, D. Prediction on the Energy Consumption Structure in Liaoning Province Based on System Dynamics. Pol. J. Environ. Stud. 2021, 30, 12. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, X.; Li, H. A random forest-based model for the prediction of construction-stage carbon emissions at the early design stage. J. Clean. Prod. 2021, 328, 129657. [Google Scholar] [CrossRef]

- Dou, R.; Hou, Y.; Wei, Y.; Liu, J. Dual carbon oriented optimization method for manufacturing industry chain based on BP neural network and clonal selection algorithm. Appl. Soft Comput. 2023, 148, 110887. [Google Scholar] [CrossRef]

- Hao, J.; Gao, J. Prediction Model of Urban Building Carbon Emissions and Reduction Based on the BP Neural Network Improved by NSGA-II. Build. Energy Effic. 2016, 44, 122–124. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-Vector Networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Yu, J.; Bai, L.; Wang, L. Prediction Model for Carbon Emissions of Life Cycle Assessment of High-rise Office Buildings Based on SVR: Take Tianjin as an Example. Build. Energy Effic. 2021, 49, 25–30. [Google Scholar] [CrossRef]

- Xu, A.; Song, M.; Wu, Y.; Luo, Y.; Zhu, Y.; Qiu, K. Effects of new urbanization on China’s carbon emissions: A quasi-natural experiment based on the improved PSM-DID model. Technol. Forecast. Soc. Chang. 2024, 200, 123164. [Google Scholar] [CrossRef]

- Saad, M.M.; Menon, R.P.; Eicker, U. Supporting Decision Making for Building Decarbonization: Developing Surrogate Models for Multi-Criteria Building Retrofitting Analysis. Energies 2023, 16, 6030. [Google Scholar] [CrossRef]

- Mao, X.; Wang, L.; Li, J.; Quan, X.; Wu, T. Comparison of regression models for estimation of carbon emissions during building’s lifecycle using designing factors: A case study of residential buildings in Tianjin, China. Energy Build. 2019, 204, 109519. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, Z.; Bi, W.; Ni, P.; Lei, F.; Yao, S.; Lang, J. Prediction and scenario simulation of the carbon emissions of public buildings in the operation stage based on an energy audit in Xi’an, China. Energy Policy 2023, 173, 113396. [Google Scholar] [CrossRef]

- Xu, A.; Yang, Q.; Yang, L.; Fan, R.; Liu, C.; Xie, N.; Yang, S.; Deng, C. Life cycle assessment and carbon footprint evaluation of a PEMFC system integrated with different hydrogen production routes. Energy Convers. Manag. 2024, 312, 118586. [Google Scholar] [CrossRef]

- Gerhardt-Mörsdorf, J.; Incer-Valverde, J.; Morosuk, T.; Minke, C. Exergetic life cycle assessment for green hydrogen production. Energy 2024, 299, 131553. [Google Scholar] [CrossRef]

- GB/T 51366-2019; Standard for Building Carbon Emission Calculation. China Architecture & Building Press: Beijing, China, 2019.

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Need for an embodied energy measurement protocol for buildings: A review paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Li, X.; Xie, Y.; Li, C.; Wang, Z.; Hopke, P.K.; Xue, C. Using the carbon balance method based on fuel-weighted average concentrations to estimate emissions from household coal-fired heating stoves. Chemosphere 2022, 307, 135639. [Google Scholar] [CrossRef]

- Shan, Y.; Guan, D.; Zheng, H.; Ou, J.; Li, Y.; Meng, J.; Mi, Z.; Liu, Z.; Zhang, Q. China CO2 emission accounts 1997–2015. Sci. Data 2018, 5, 170201. [Google Scholar] [CrossRef]

- Shan, Y.; Liu, J.; Liu, Z.; Xu, X.; Shao, S.; Wang, P.; Guan, D. New provincial CO2 emission inventories in China based on apparent energy consumption data and updated emission factors. Applied Energy 2016, 184, 742–750. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, L.; Liu, J. Embodied carbon emissions of office building: A case study of China’s 78 office buildings. Build. Environ. 2016, 95, 365–371. [Google Scholar] [CrossRef]

- Jialin, L.; Peng, M. A study on forecasting model of the carbon emissions in the process of building construction and its application. J. Anhui Jianzhu Univ. 2017, 25, 61–69. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, X.; Liu, K. Assessment of operational carbon emissions for residential buildings comparing different machine learning approaches: A study of 34 cities in China. Build. Environ. 2024, 250, 111176. [Google Scholar] [CrossRef]

- Jing, L.; Yan, L. The Carbon Emission Accounting Model Based on Building Life cycle. J. Eng. Manag. 2015, 29, 12–17. [Google Scholar] [CrossRef]

- Liu, K.; Zheng, J.; Dong, S.; Xie, W.; Zhang, X. Mixture optimization of mechanical, economical, and environmental objectives for sustainable recycled aggregate concrete based on machine learning and metaheuristic algorithms. J. Build. Eng. 2023, 63, 105570. [Google Scholar] [CrossRef]

| Name | Material Unit | EF | EF Unit | MCC | Replacement | Recovery |

|---|---|---|---|---|---|---|

| rock wool insulation board | m3 | 89.1 | kgCO2/m3 | 0.008 | 1 | — |

| Polyethylene foam strip | m | 0.281 | kgCO2/m | 0 | — | — |

| 3 mm flat glass | m2 | 8.475 | kgCO2/m2 | 0.008 | 1 | — |

| ceramic floor tile | m2 | 18.33 | kgCO2/m2 | 0.002 | 1 | — |

| grade III reinforcement | t | 2340 | kgCO2/t | 1 | — | 0.4 |

| bolt | kg | 2.14 | kgCO2/kg | 0.001 | — | 0.1 |

| steel security door | m2 | 73.48 | kgCO2/m2 | 0.036 | 1 | 0.5 |

| cement-steel nail | kg | 8.57 | kgCO2/kg | 0.001 | — | 0.1 |

| concrete C25 | m3 | 343 | kgCO2/m3 | 2.361 | — | — |

| concrete C30 | m3 | 295 | kgCO2/m3 | 2.367 | — | — |

| concrete C35 | m3 | 426 | kgCO2/m3 | 2.372 | — | — |

| clay standard brick | one thousand | 442.863 | kgCO2/one thousand | 1.6 | — | — |

| aerated concrete block | m3 | 191.5 | kgCO2/m3 | 0.6 | — | — |

| cement | t | 735 | kgCO2/t | 1 | — | — |

| slaked lime | t | 1190 | kgCO2/t | 1 | — | — |

| latex paint | kg | 4.12 | kgCO2/kg | 0.001 | — | — |

| Independent Variable | Name | VIF |

|---|---|---|

| X1 | Floor area | 5.177 |

| X2 | Floor Number | 4.934 |

| X3 | Story height | 1.359 |

| X5 | Household number | 5.451 |

| X8 | Form factor | 1.907 |

| X10 | S-WWR | 1.648 |

| X11 | N-WWR | 2.184 |

| X14 | M-WWR | 2.567 |

| X15 | Wall-K | 3.879 |

| X16 | Window-K | 3.752 |

| X17 | Roof-K | 4.06 |

| Model | R2adj | Mean Value | MAE | RMSE | MAE Error | RMSE Error |

|---|---|---|---|---|---|---|

| LCCE prediction model | 0.985 | 30,505 | 2684 | 3418 | 8.80% | 11.20% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Yang, L.; Wang, X.; Zhang, L.; Wang, Q.; Wu, K. Research on Carbon Emission Pre-Assessment of Residential Buildings in Xi’an City during the Scheme Design Stage. Buildings 2024, 14, 2171. https://doi.org/10.3390/buildings14072171

Gao H, Yang L, Wang X, Zhang L, Wang Q, Wu K. Research on Carbon Emission Pre-Assessment of Residential Buildings in Xi’an City during the Scheme Design Stage. Buildings. 2024; 14(7):2171. https://doi.org/10.3390/buildings14072171

Chicago/Turabian StyleGao, Huan, Lu Yang, Xinke Wang, Lisha Zhang, Qize Wang, and Kang Wu. 2024. "Research on Carbon Emission Pre-Assessment of Residential Buildings in Xi’an City during the Scheme Design Stage" Buildings 14, no. 7: 2171. https://doi.org/10.3390/buildings14072171

APA StyleGao, H., Yang, L., Wang, X., Zhang, L., Wang, Q., & Wu, K. (2024). Research on Carbon Emission Pre-Assessment of Residential Buildings in Xi’an City during the Scheme Design Stage. Buildings, 14(7), 2171. https://doi.org/10.3390/buildings14072171