Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review

Abstract

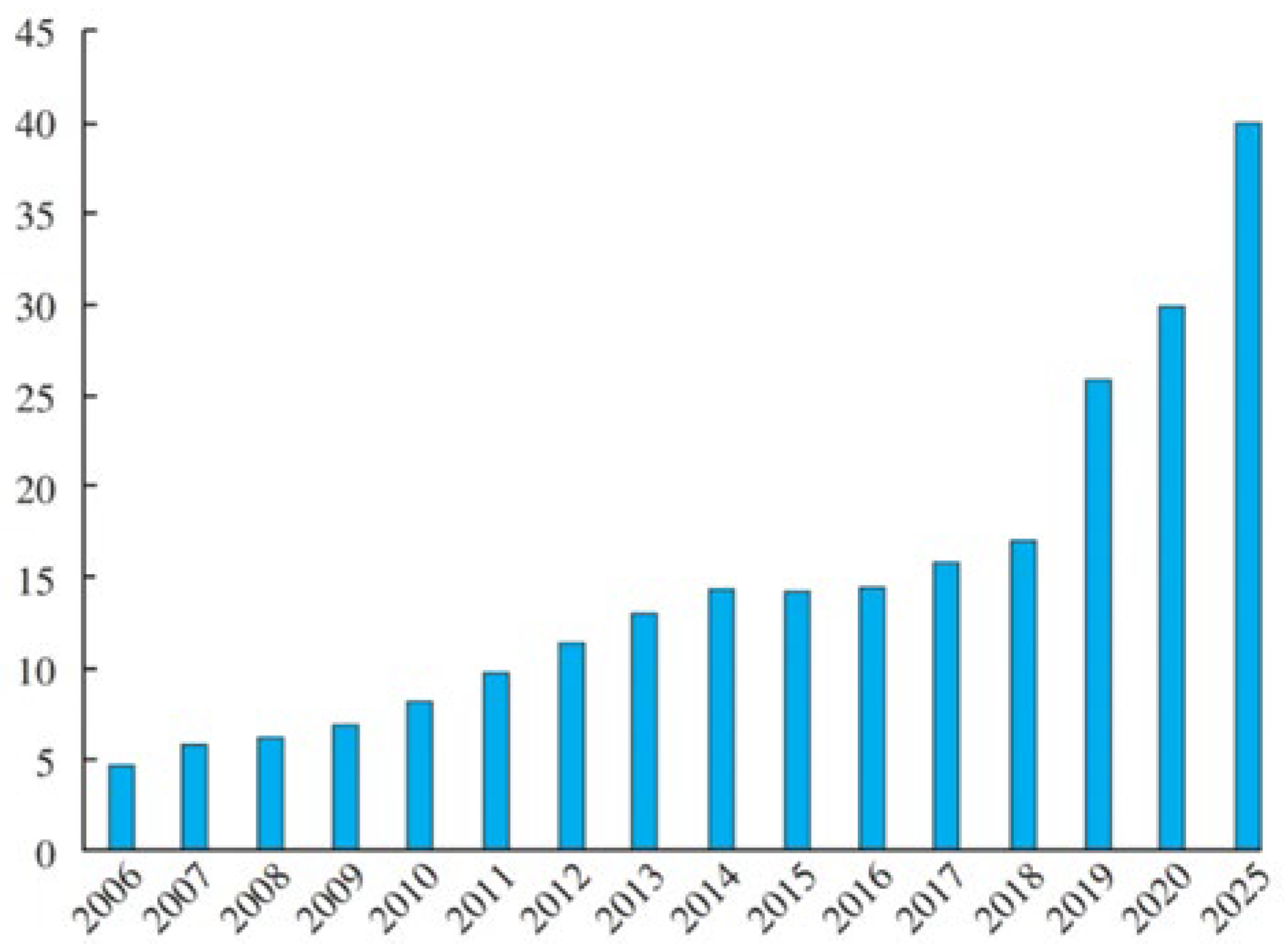

1. Introduction

2. The Benefits of Using RCA

2.1. Environmental Benefits

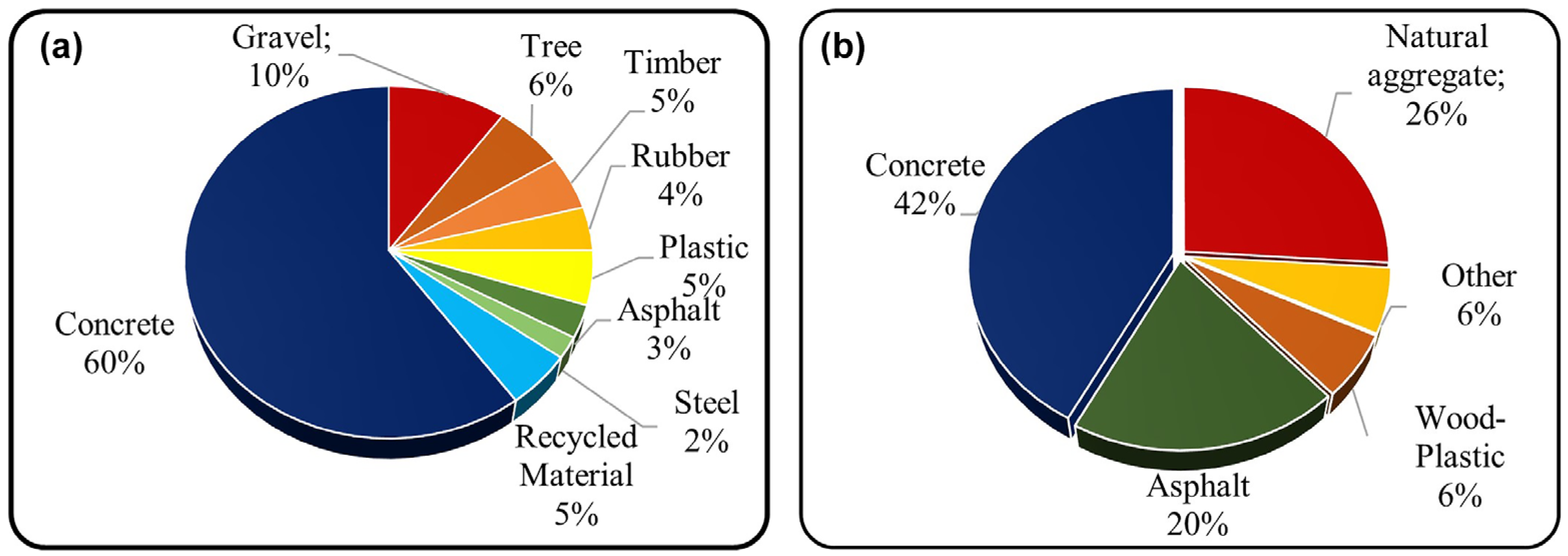

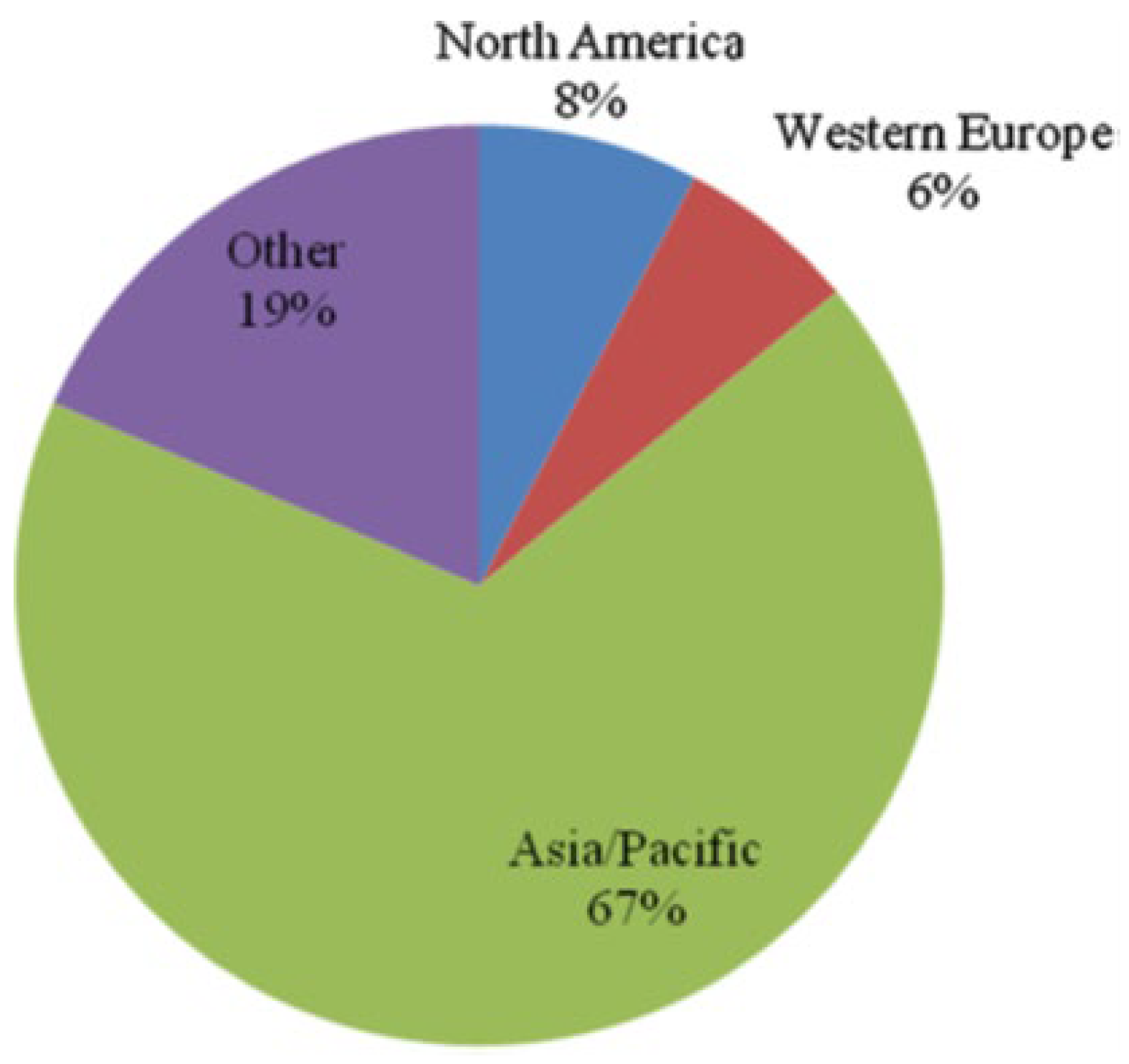

2.1.1. Reduction in CDW Landfill

2.1.2. Conservation of Natural Resources

2.1.3. Lower Carbon Footprint

2.2. Economic Benefits

- Lower waste disposal costs: less waste sent to landfills reduces fees, transportation costs, and long-term monitoring expenses.

- Material cost savings: recycled aggregates are typically cheaper than natural aggregates, leading to significant cost savings in construction.

- Job creation: the recycling industry expands with increased demand for recycled aggregates, creating more job opportunities.

2.3. Social Benefits

- Improving welfare by generating jobs: expanding the recycling industry generates new employment opportunities, supporting community welfare and the local economy.

- Public health: reduced greenhouse gas emissions and pollutants from the use of recycled aggregates improve public health outcomes.

- Resource conservation: using recycled aggregates preserves natural resources for future generations, promoting intergenerational fairness and stewardship.

- Civic pride and satisfaction: sustainable building practices enhance community satisfaction and pride in resource management and environmental care.

2.4. Technological Benefits

3. The Replacement Ratio of RCA of Structural RAC in Standards and Guidelines

3.1. Australia

3.2. Brazil

3.3. China

3.4. Germany

3.5. RILEM

3.6. United Kingdom (U.K.)

3.7. United States of America (U.S.A.)

4. A Brief Review of the Mechanical Properties of RAC

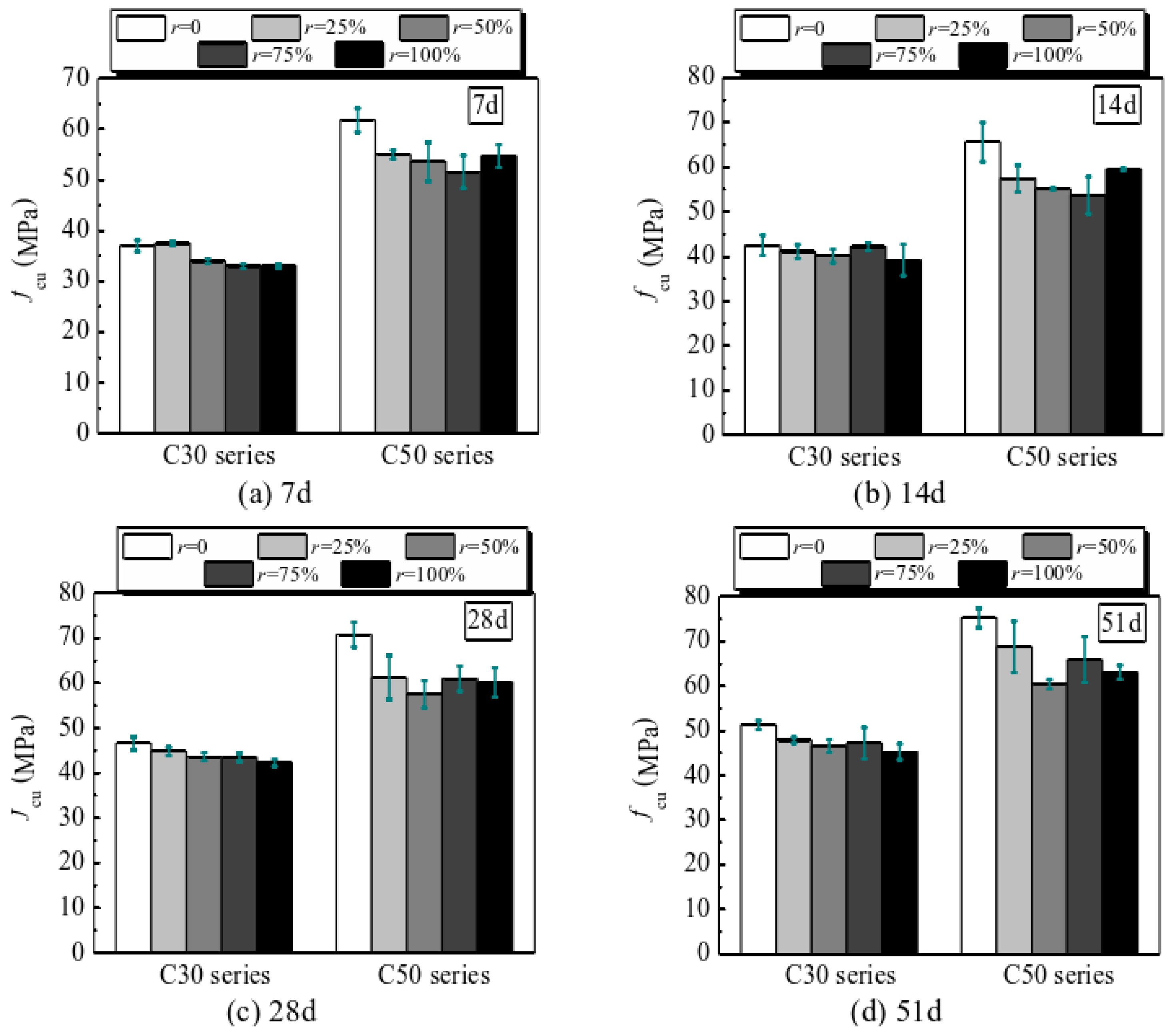

4.1. Compressive Strength

4.2. Tensile Strength

- The increased water-to-cement ratio due to the RCA particles’ absorption of the attached mortar.

- Forming a new interfacial transition zone creates a stronger link between the aggregate and cement paste.

4.3. Flexural Strength

4.4. Elastic Modulus

5. A Brief Review of the Durability Properties of RAC

5.1. Shrinkage and Creep

5.2. Abrasion Resistance

5.3. Permeability

5.4. Freeze and Thaw Resistance

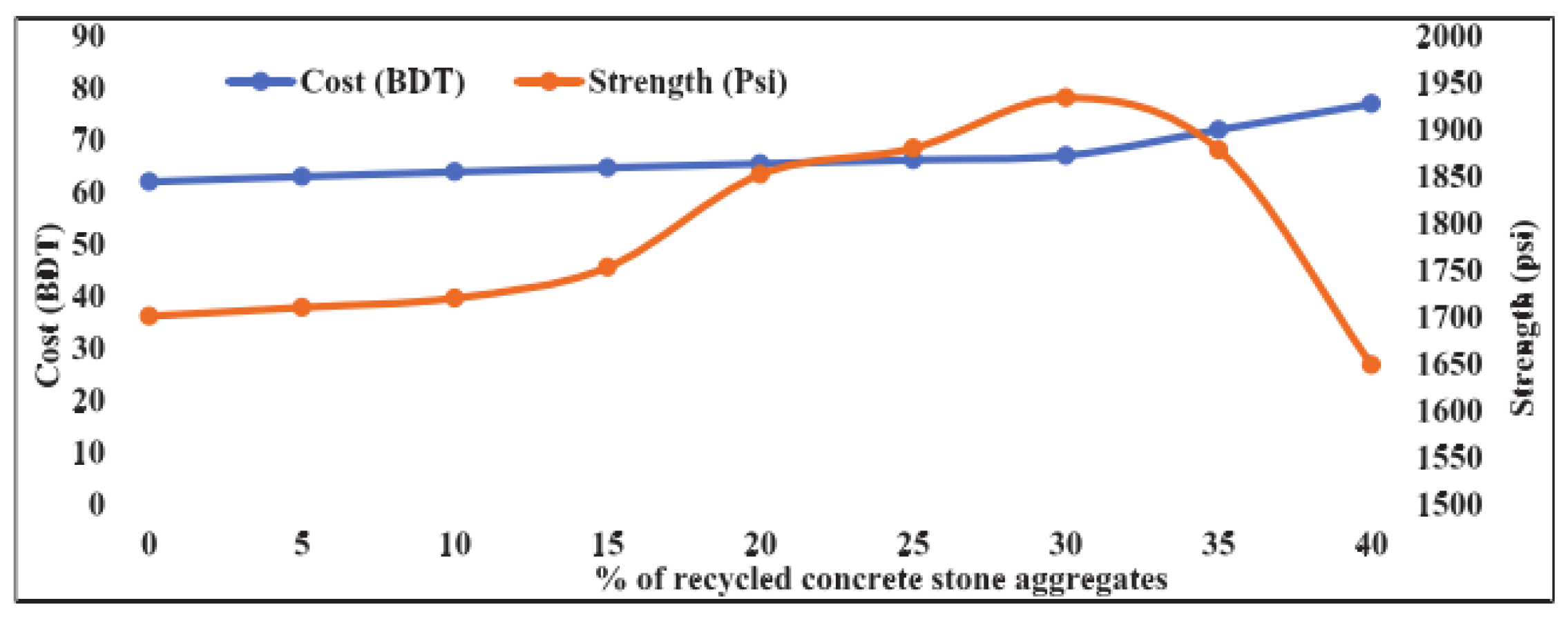

6. A Brief Review of the Cost-Benefit of RAC

7. The Optimal Replacement Ratio of RAC in Structural RAC

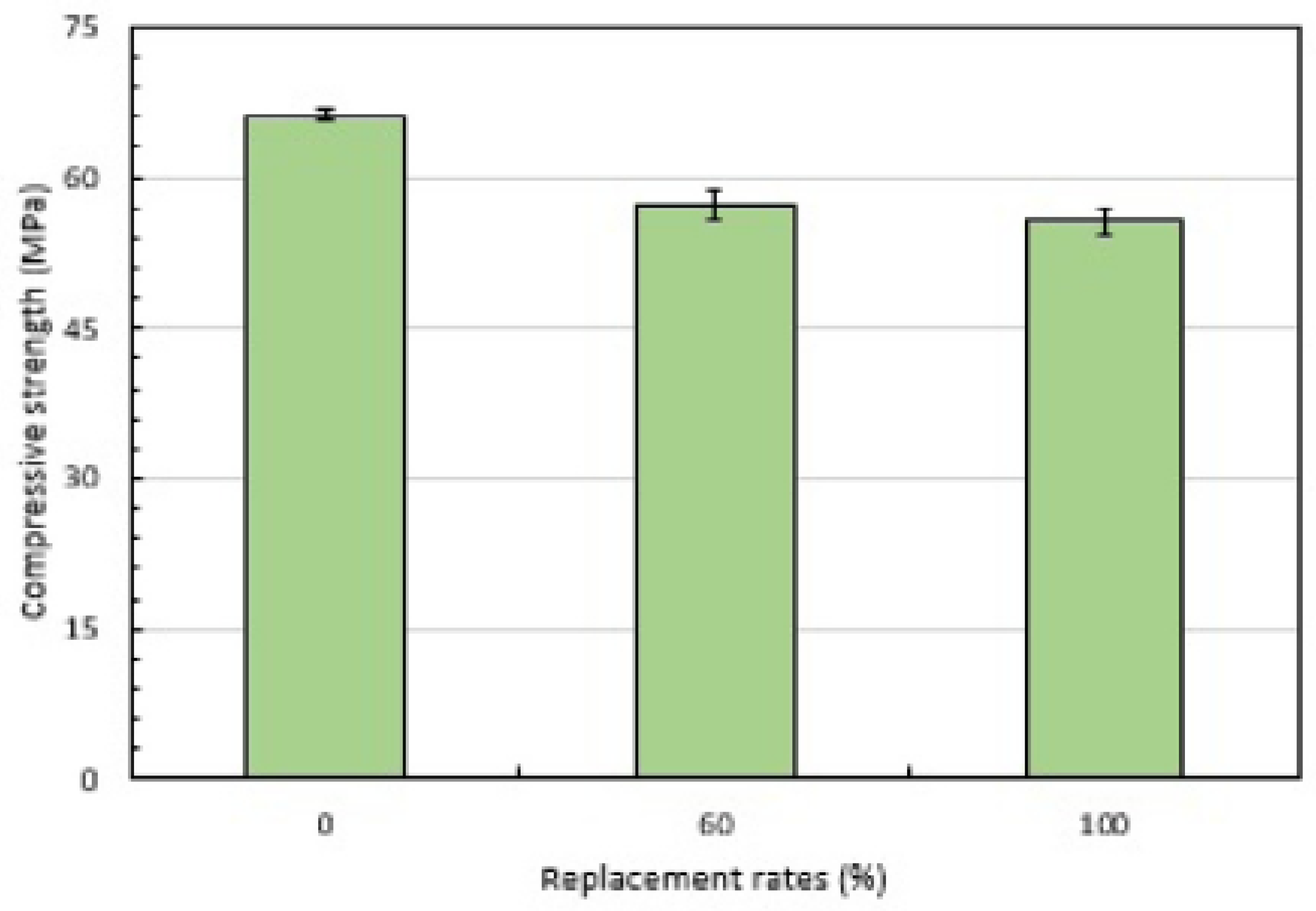

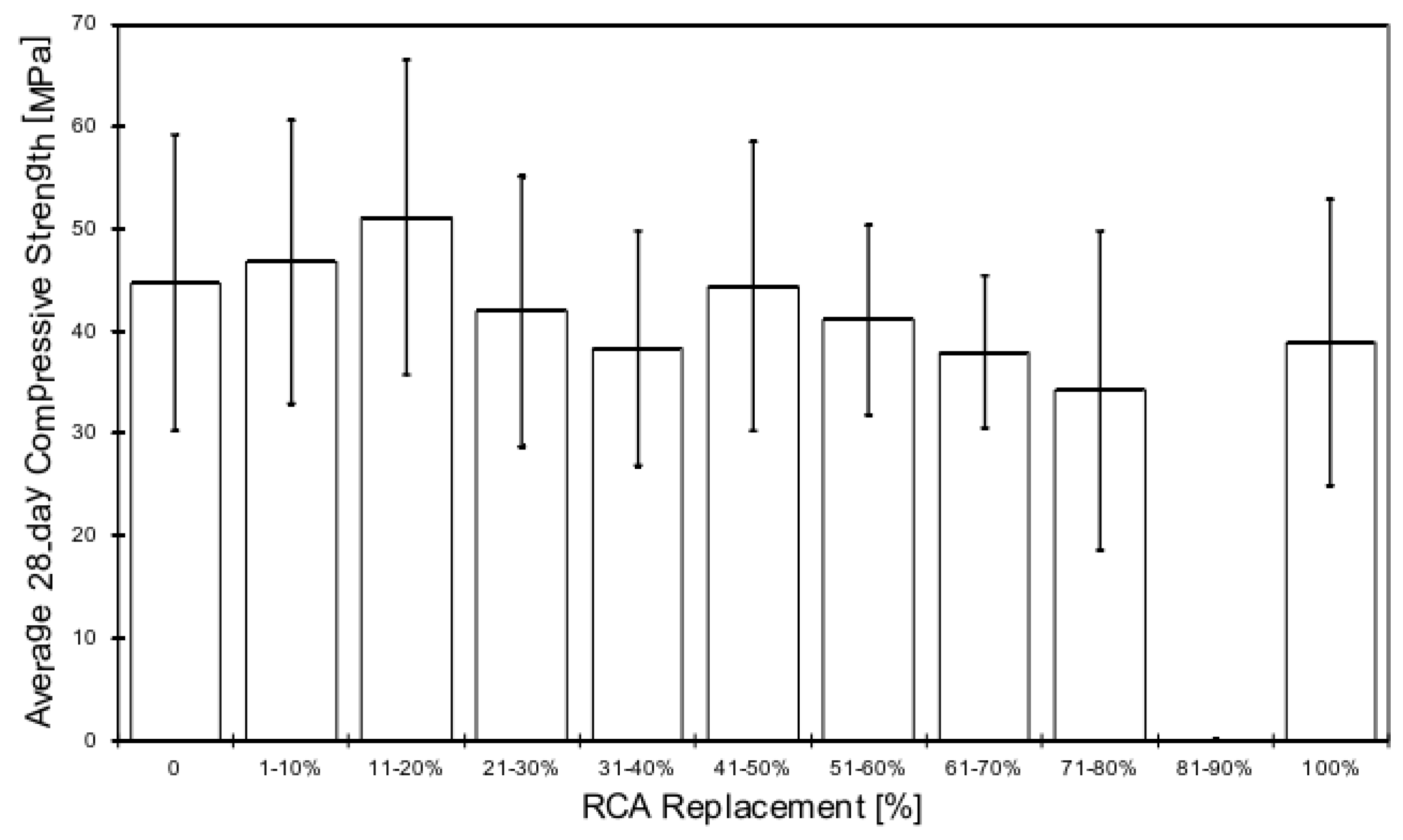

7.1. Variation in Compressive Strength

7.2. Variation in Splitting Tensile Strength

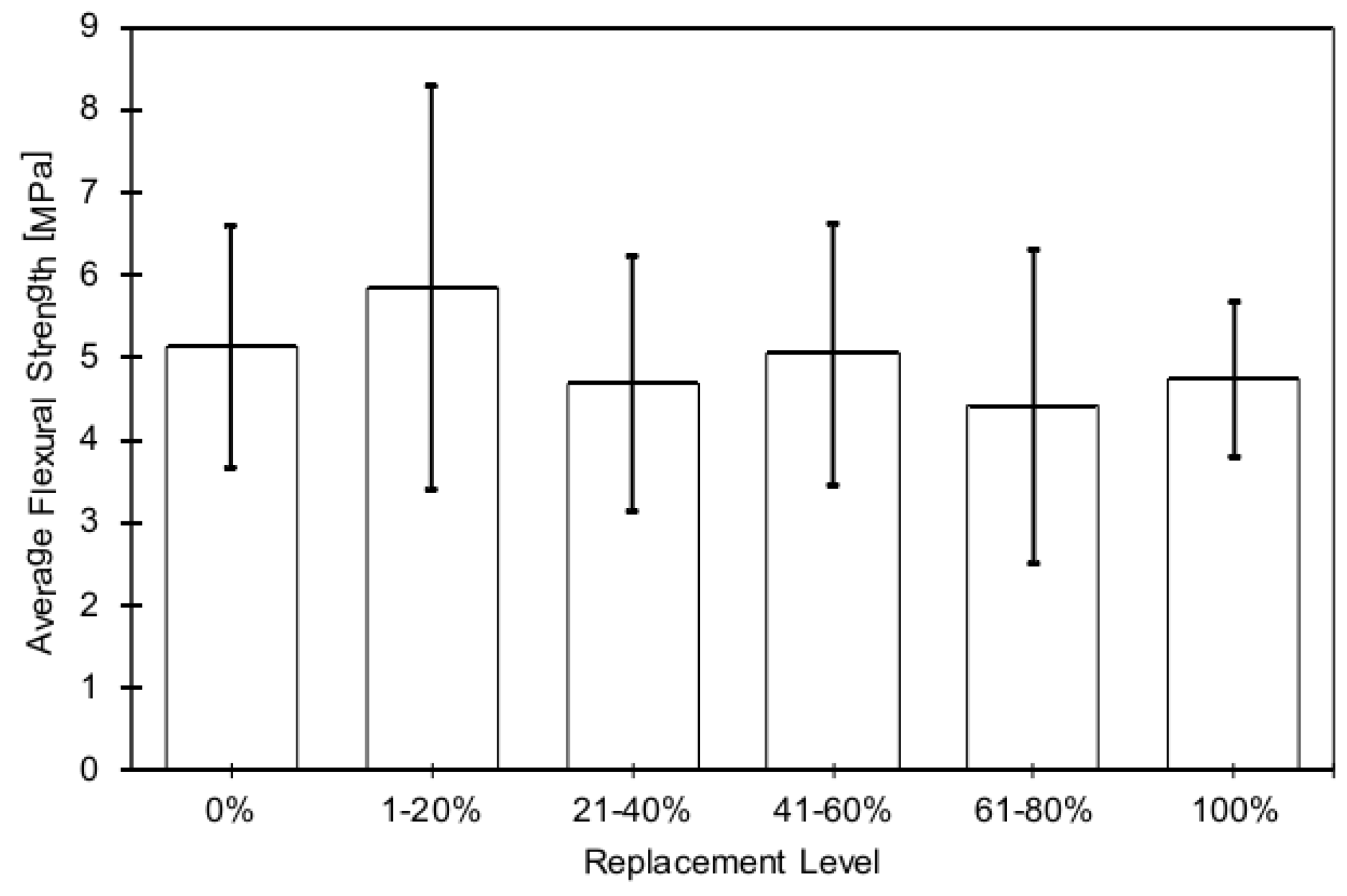

7.3. Variation in Flexural Strength

7.4. Variation in Elastic Modulus

7.5. Discussion on the Optimal RR of RCA

8. Challenges and Thinking

8.1. Challenges to Using Recycled Aggregate Concrete (RAC)

8.1.1. Technical Challenges

8.1.2. Economic Challenges

8.1.3. Regulatory and Standardization Challenges

8.1.4. Perceptual and Behavioral Challenges

8.2. Thinking

8.2.1. Balancing Performance and Sustainability

8.2.2. Technological Advancements

8.2.3. Economic and Environmental Impact

8.2.4. Standardization and Guidelines

8.2.5. Comprehensive Testing and Data Collection

8.2.6. Education and Awareness

8.2.7. Future Research Directions

9. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Assessing Trends in Materials Generation and Management in the United States, United States Environmental Protection Agency. 2015; pp. 1–22. Available online: https://www.epa.gov/sites/production/files/2020-11/documents/2018_ff_fact_sheet.pdf (accessed on 8 February 2022).

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Analysis of the Background and Current Development of China’s Construction Waste Recycling Industry. 2024. Available online: https://baijiahao.baidu.com/s?id=1788121838971865911&wfr=spider&for=pc (accessed on 15 January 2024).

- Aytekin, B.; Mardani-Aghabaglou, A. Sustainable Materials: A Review of Recycled Concrete Aggregate Utilization as Pavement Material. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 468–491. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Vivian, W.; Tam, M.; Jorge Evangelista, A. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; et al. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Hossain, M.; Poon, C.; Lo, I.; Cheng, J. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Nixon, P. Recycled concrete as an aggregate for concrete—A review. Matér. Constr. 1978, 11, 371–378. [Google Scholar] [CrossRef]

- Hansen, T.; Henrik, N. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int. 1983, 5, 79–83. [Google Scholar]

- Nassar, R.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Suryawanshi, S.; Singh, B.; Bhargava, P. Characterization of RAC. In Advances in Structural Engineering; Springer: New Delhi, India, 2015; pp. 1813–1822. [Google Scholar]

- Go’mez-Sobero’n, J. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with RA from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of RAs construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Spanish Minister of Public Works. Instrucción de Hormigón Estructural EHE-08 (Spanish Structural Concrete Code). 2008. Available online: https://www.boe.es/eli/es/rd/2008/07/18/1247 (accessed on 18 July 2008).

- Hansen, T.; Boegh, E. Elasticity and Drying Shrinkage Concrete of Recycled-Aggregate. ACI J. 1985, 82, 648–652. [Google Scholar]

- Yoshikane, T. Present Status of Recycling Waste Cement Concrete in Japan; Private Communication Research Laboratory, Taiyu Kensetsu Co., Ltd.: Nagoya, Japan, 1988. [Google Scholar]

- Nagatakia, S.; Gokceb, A.; Saekic, T.; Hisada, M. Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 965–971. [Google Scholar] [CrossRef]

- Fanijo, E.; Kolawole, J.; Babafemi, A.; Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: Properties, performance, and sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Varshney, H.; Khan, R.; Khan, I. Quality improvement techniques for recycled aggregates concrete incorporating fibers and Bacillus species bacteria—A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zaidi, S.; Khan, M.; Naqvi, T. A review on the properties of recycled aggregate concrete (RAC) modified with nano-silica. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Gu, L.; Liu, Y.; Zeng, J.; Zhang, Z.; Pham, P.; Liu, C.; Zhuge, Y. The synergistic effects of fibres on mechanical properties of recycled aggregate concrete: A comprehensive review. Constr. Build. Mater. 2024, 436, 137011. [Google Scholar] [CrossRef]

- Liu, K.; Fu, K.; Sang, Y.; Yang, Y.; Zou, C.; Xie, T.; Zhao, X. Frost resistance of recycled aggregate concrete: A critical review. J. Build. Eng. 2024, 90, 109450. [Google Scholar] [CrossRef]

- Muhammad, F.; Harun, M.; Ahmed, A.; Kabir, N.; Khalid, H.; Hanif, A. Influence of bonded mortar on recycled aggregate concrete properties: A review. Constr. Build. Mater. 2024, 432, 136564. [Google Scholar] [CrossRef]

- Wu, L.; Sun, Z.; Gao, Y. Modification of recycled aggregate and conservation and application of recycled aggregate concrete: A review. Constr. Build. Mater. 2024, 431, 136567. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Q.; Lin, W.; Ou, J. Material and structural properties of recycled coarse aggregate concrete made with seawater and sea-sand: A review. J. Build. Eng. 2024, 87, 109042. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, Y.; Lu, Y.; Ji, C.; Lin, C.; Yao, L.; Pu, Z.; Brito, J. Prediction of properties of recycled aggregate concrete using machine learning models: A critical review. J. Build. Eng. 2024, 90, 109516. [Google Scholar] [CrossRef]

- Statistics About Waste Generation: Global, US, UK & European Union. Available online: https://www.stonecycling.com/news/statistics-about-waste-generation/ (accessed on 3 September 2021).

- Croatia: Proposed Circular Economy Action Plan on Construction and Demolition Waste. Available online: https://thedocs.worldbank.org/en/doc/c22f85216d0d23a3287250b550d05935-0080012022/original/Deliverable1bCroatiaProposedCEactionPlan.pdf (accessed on 13 December 2022).

- Qiao, L.; Liu, D.; Yuan, X.; Wang, Q.; Ma, Q. Generation and Prediction of Construction and Demolition Waste Using Exponential Smoothing Method: A Case Study of Shandong Province, China. Sustainability 2020, 12, 5094. [Google Scholar] [CrossRef]

- Available online: https://baijiahao.baidu.com/s?id=1780537992583861155&wfr=spider&for=pc (accessed on 23 October 2023).

- Construction and Demolition Produce Large Amounts of Waste. Available online: https://www.level.org.nz/material-use/minimising-waste/ (accessed on 23 May 2024).

- Department of Design and Construction, Construction & Demolition Waste Manual. Available online: http://www.nyc.gov/html/ddc/downloads/pdf/waste.pdf (accessed on 7 March 2019).

- Barhmaiah, B.; Leela Priyanka, M.; Padmakar, M. Strength analysis and validation of recycled aggregate concrete. Mater. Today Proc. 2020, 37, 2312–2317. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Global Waste Management Outlook; United Nations: Vienna, Austria, 2015. [Google Scholar]

- Alexander, M.; Mindess, S. Aggregates in Concrete; Taylor & Francis: London, UK, 2005. [Google Scholar]

- World Construction Aggregates; The Freedonia Group: Cleveland, OH, USA, 2012.

- Mohammed, S.; Najim, K. Mechanical strength, flexural behavior and fracture energy of Recycled Concrete Aggregate self-compacting concrete. Structures 2020, 23, 34–43. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.; Nayak, S.; Dutta, S. Critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Nayana, A.; Kavitha, S. Evaluation of CO2 emissions for green concrete with high volume slag, recycled aggregate, recycled water. Int. J. Civ. Eng. Technol. 2017, 8, 703–708. [Google Scholar]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.; Klyuev, S.; Chulkova, I.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Azevedo, A. Design Strategy for Recycled Aggregate Concrete: A Review of Status and Future Perspectives. Crystals 2021, 11, 695. [Google Scholar] [CrossRef]

- Rossi, E.; Sales, A. Carbon footprint of coarse aggregate in Brazilian construction. Constr. Build. Mater. 2014, 72, 333–339. [Google Scholar] [CrossRef]

- Bampanis, I.; Vasilatos, C. Recycling Concrete to Aggregates. Implications on CO2 Footprint. Mater. Proc. 2023, 15, 28. [Google Scholar] [CrossRef]

- Groves, S.; Initiatives, S. Standards to Facilitate the Use of Recycled Material in Road Construction; Standards Australia: Sydney, Australia, 2023. [Google Scholar]

- Plaza, P.; Sáez del Bosque, I.; Frías, M.; Sánchez de Rojas, M.; Medina, C. Use of recycled coarse and fine aggregates in structural eco-concretes. Physical and mechanical properties and CO2 emissions. Constr. Build. Mater. 2021, 285, 122926. [Google Scholar] [CrossRef]

- Del Ponte, K.; Madras Natarajan, B.; Pakes Ahlman, A.; Baker, A.; Elliott, E.; Edil, T. Life-Cycle Benefits of Recycled Material in Highway Construction. Transp. Res. Rec. 2017, 2628, 1–11. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Huang, Y.; Guo, H.; Zhang, W.; Zhu, J. Enhancement technologies of recycled aggregate—Enhancement mechanism, influencing factors, improvement effects, technical difficulties, life cycle assessment. Constr. Build. Mater. 2022, 317, 126168. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Liang, J.; Meng, Y.; Rong, H.; Li, D.; Chen, Y.; Lv, J.; Jiang, Y.; Liu, Y. Straightening methods for RCA and RAC—A review. Cem. Concr. Compos. 2023, 141, 105145. [Google Scholar] [CrossRef]

- Nikmehr, B.; Kafle, B.; Al-Ameri, R. A review of the advanced treatment techniques for enriching the recycled concrete aggregates for recycled-based concrete: Economic, environmental and technical analysis. Smart Sustain. Built Environ. 2024, 13, 560–583. [Google Scholar] [CrossRef]

- Alvi, I.; Li, Q.; Hou, Y.; Onyekwena, C.; Zhang, M.; Ghaffar, A. A critical review of cement composites containing recycled aggregates with graphene oxide nanomaterials. J. Build. Eng. 2023, 69, 105989. [Google Scholar] [CrossRef]

- Gao, S.; Guo, X.; Ban, S.; Ma, Y.; Yu, Q.; Sui, S. Influence of supplementary cementitious materials on ITZ characteristics of recycled concrete. Constr. Build. Mater. 2023, 363, 129736. [Google Scholar] [CrossRef]

- Wang, J.; Che, Z.; Zhang, K.; Fan, Y.; Niu, D.; Guan, X. Performance of recycled aggregate concrete with supplementary cementitious materials (fly ash, GBFS, silica fume, and metakaolin): Mechanical properties, pore structure, and water absorption. Constr. Build. Mater. 2023, 368, 130455. [Google Scholar] [CrossRef]

- Arandara, K.; Paranavithana, G.; Priyadarshana, S.; Pitawala, H.; Dissanayake, R. Evaluation of coconut shell biochar on recycled aggregate concrete through petrographic studies. Constr. Build. Mater. 2024, 428, 136342. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, H.; Liang, Y.; Shen, J.; Yang, H. Study on fracture characteristics and fracture mechanism of fully recycled aggregate concrete using AE and DIC techniques. Constr. Build. Mater. 2024, 419, 135540. [Google Scholar] [CrossRef]

- Ying, J.; Jian, Y.; Gan, X.; Chen, B.; Xiao, J. Three-dimensional aggregate modelling method and damage analysis of recycled aggregate concrete. Compos. Struct. 2024, 343, 118286. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Y.; Ma, L.; Lin, S. Review on high-strength recycled aggregate concrete: Mix design, properties, models and structural behaviour. Structures 2024, 64, 106598. [Google Scholar] [CrossRef]

- Rais, M.; Khan, R. Development of sustainable admixture-based recycled aggregate concrete using ureolytic bacteria. Innov. Infrastruct. Solut. 2022, 7, 182. [Google Scholar] [CrossRef]

- Tošić, N.; Torrenti, J.; Sedran, T.; Ignjatović, I. Toward a codified design of recycled aggregate concrete structures: Background for the new fib Model Code 2020 and Eurocode 2. Struct. Concr. 2021, 22, 2916–2938. [Google Scholar] [CrossRef]

- Knapcová, V.; Pacheco, J.; Brito, J.; Sonnenschein, R. Eurocode 2 design of recycled aggregate concrete elements under compression: Evaluation through model uncertainties from tests on columns. Struct. Concr. 2024. [Google Scholar] [CrossRef]

- Johannessen, D.; Xu, A.; Garton, D.; Rae, S.; Roberts, W. S51: Suitability of the Use of Recycled Aggregate in Concrete (2020–2021); ARRB Project No.: 015699; Queensland Department of Transport and Main Roads: Brisbane, Australia, 2021.

- Adams, M.P. ACI CRC 18.517: Guideline Development for Use of Recycled Concrete Aggregates in New Concrete; Final Report; New Jersey Institute of Technology: Newark, NJ, USA, 2019. [Google Scholar]

- Ohemeng, E.; Ekolu, S. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A South African case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Mohammed, S.; Ahmed, A.; Sofiane, A.; Leonid, D.; Elhem, G.; Said, K.; Jamal, K.; Nataliya, L.; Arnaud, P. Trends and opportunities of using local sustainable building materials in the Middle East and North Africa region. RILEM Tech. Lett. 2022, 7, 127–138. [Google Scholar]

- CSIRO-HB 155:2002; Guide to the Use of Recycled Concrete and Masonry Materials. Standards Australia: Sydney, Australia, 2002.

- AS 2758.1:2014; Aggregates and Rock for Engineering Purposes: Concrete Aggregates. Standards Australia: Sydney, Australia, 2014.

- ABNT NBR 15116; Recycled Aggregates for Uses in Mortar and Concrete―Requirements and Test Methods. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2021.

- GB/T25177-2010; Recycled Coarse Aggregate for Concrete. China Standards Publication: Beijing, China, 2011.

- JGJ/T 443-2018; Technical Standard for Recycled Concrete Structures. China Construction Industry Press: Beijing, China, 2018.

- DAfStb. DAfStb 2010; Concrete in Accordance with DIN EN 206-1 and DIN 1045-2 with Recycled Aggregates in Accordance with DIN EN 12620. Deutscher Ausschuss für Stahlbeton e. V.: Berlin, Germany, 2010.

- DIN-4226-100; Aggregates for Mortar and Concrete—Part 100: Recycled Aggregates. Deutsches Institut fur Normung (German Institute for Standardization): Berlin, Germany, 2002.

- Hendriks, C.; Pietersen, H. Sustainable Raw Materials: Construction and Demolition Waste; State-of-the-Art Report; RILEM Technical Committee 165-SRM; RILEM Publications s.a.r.l.: Cachan, France, 2000. [Google Scholar]

- BS 8500-2:2015+A1:2016; Concrete–Complementary British Standard to BS EN 206 Part 2: Specification for Constituent Materials and Concrete. BSI Standards Limited: London, UK, 2016.

- ACI Committee. 555-01; Removal and Reuse of Hardened Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2001.

- ACI 221R-96; Guide for Use of Normal Weight and Heavyweight Aggregates in Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2001.

- ASTM Standard C33; Standard Specification for Concrete Aggregates. ASTM International, No. C: West Conshohocken, PA, USA, 2018.

- AASHTO M80-13; Standard Specification for Coarse Aggregate for Hydraulic Cement Concrete in American Association of State Highway and Transportation Officials (Ed.). AASHTO: Washington, DC, USA, 2013.

- AASHTO MP-16; Standard Specification for Reclaimed Concrete Aggregate for Use as Coarse Aggregate in Hydraulic Cement Concrete: American Association of State Highway and Transportation Officials (Ed.). AASHTO: Washington, DC, USA, 2013.

- ACI Education Bulletin E1-07; Aggregates for Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2007.

- Adnan, S.; Loon, L.; Rahman, I.; Saman, H.; Soejoso, M. Compressive strength of recycled aggregate concrete with various percentage of recycled aggregate. In Proceedings of the Conference National Seminar on Civil Engineering Research (SEPKA 2007), Johor Bahru, Malaysia, 11–12 December 2007. [Google Scholar]

- Chang, Y.; Wang, Y.; Zhang, H.; Chen, J.; Geng, Y. Different influence of replacement ratio of recycled aggregate on uniaxial stress-strain relationship for recycled concrete with different concrete strengths. Structures 2022, 42, 284–308. [Google Scholar] [CrossRef]

- Adessina, A.; Fraj, A.; Barthélémy, J. Improvement of the compressive strength of recycled aggregate concretes and relative effects on durability properties. Constr. Build. Mater. 2023, 384, 131447. [Google Scholar] [CrossRef]

- Ngo, T.; Bouvet, A.; Debieb, F.; Aggoun, S. Effect of cement and admixture on the utilization of recycled aggregates in concrete. Constr. Build. Mater. 2017, 149, 91–102. [Google Scholar]

- Li, B.; Hou, S.; Duan, Z.; Li, L.; Guo, W. Rheological behavior and compressive strength of concrete made with recycled fine aggregate of different size range. Constr. Build. Mater. 2021, 268, 121172. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Cimentada, A.; Medina, C. Influence of curing conditions on recycled aggregate concrete. Constr. Build. Mater. 2018, 172, 618–625. [Google Scholar] [CrossRef]

- Akhtar, M.; Halahla, A.; Almasri, A. Experimental study on compressive strength of recycled aggregate concrete under high temperature. Struct. Durab. Health Monit. 2021, 15, 335. [Google Scholar] [CrossRef]

- Xiao, J.; Li, L.; Shen, L.; Poon, C. Compressive behaviour of recycled aggregate concrete under impact loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Kikuchi, M.; Miura, T.; Dosho, Y.; Narikawa, M. Application of recycled aggregate concrete for structural concrete. Part 1—Experimental study on the quality of recycled aggregate and recycled aggregate concrete. In Sustainable Construction: Use of Recycled Concrete Aggregate, Proceedings of the International Symposium; Thomas Telford Publishing: London, UK, 1998; pp. 55–68. [Google Scholar]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L.; Fok, H.; Kou, S. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Li, B.; Jiang, G.; Hu, J.; Li, Y.; Wu, F.; Qin, Z.; Wang, S. Specimen size effect on compressive and splitting tensile strengths of sustainable geopolymeric recycled aggregate concrete: Experimental and theoretical analysis. J. Clean. Prod. 2024, 434, 140154. [Google Scholar] [CrossRef]

- Hansen, T. Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945–1985. Mater. Struct. 1986, 19, 201–246. [Google Scholar] [CrossRef]

- Padmini, A.; Ramamurthy, K.; Mathews, M. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Etxeberria, M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

- Safiuddin, M.; Alengaram, U.; Salam, A.; Jumaat, M.; Jaafar, F.; Saad, H. Properties of high-workability concrete with recycled concrete aggregate. Mater. Res. 2011, 14, 248–255. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Abou-Zeid, M.; Shenouda, M.; McCabe, S.; El-Tawil, F. Reincarnation of concrete. Concr. Int. 2005, 27, 53–59. [Google Scholar]

- Yaba, H.; Naji, H.; Younis, K.; Ibrahim, T. Compressive and flexural strengths of recycled aggregate concrete: Effect of different contents of metakaolin. Mater. Today Proc. 2021, 45, 4719–4723. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.; Darwin, D. Concrete, 2nd ed.; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Mehta, P.; Monteiro, P. Concrete Microstructure, Properties and Materials; McGraw Hill Professional: New York, NY, USA, 2017. [Google Scholar]

- Ravindrarajah, R. Effects of using recycled concrete as aggregate on the engineering properties of concrete. In National Symposium on the Use of Recycled Materials in Engineering Construction (1st: 1996: Sydney, NSW); ACT: Institution of Engineers: Barton, Australia, 1996; pp. 147–152. [Google Scholar]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F.; Serrano-López, M.; Serna, P.; Castaño-Tabares, J. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Khatib, J. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Lv, Z.; Liu, C.; Zhu, C.; Bai, G.; Qi, H. Experimental study on a prediction model of the shrinkage and creep of recycled aggregate concrete. Appl. Sci. 2019, 9, 4322. [Google Scholar] [CrossRef]

- Adams, M.; Fu, T.; Cabrera, A.; Morales, M.; Ideker, J.; Isgor, O. Cracking susceptibility of concrete made with coarse recycled concrete aggregates. Constr. Build. Mater. 2016, 102, 802–810. [Google Scholar] [CrossRef]

- Jayasuriya, A.; Bandelt, M.; Adams, M. Simulation of cracking susceptibility in recycled concrete aggregate systems. In Computational Modelling of Concrete Structures; CRC Press: Boca Raton, FL, USA, 2018; pp. 421–428. [Google Scholar]

- Gomez-Soberon, J. Creep of concrete with substitution of normal aggregate by recycled concrete aggregate. In Innovations in Design with Emphasis on Seismic, Wind, and Environmental Loading: Quality Control and Innovations in Materials/Hot-Weather Concreting; American Concrete Institute: Farmington Hills, MI, USA, 2002; Volume 209, pp. 461–474. [Google Scholar]

- Dhir, R.; Limbachiya, M.; Leelawat, T. Suitability of recycled concrete aggregate for use in BS 5328 designated mixes. Struct. Build. 1999, 34, 257–274. [Google Scholar] [CrossRef]

- Limbachiya, M.; Leelawat, T.; Dhir, R. RCA concrete: A study of properties in the fresh state, strength development and durability. In Sustainable Construction: Use of Recycled Concrete Aggregate, Proceedings of the International Symposium; Thomas Telford Publishing: London, UK, 1998; pp. 227–237. [Google Scholar]

- Kumar, R. Influence of recycled coarse aggregate derived from construction and demolition waste (CDW) on abrasion resistance of pavement concrete. Constr. Build. Mater. 2017, 142, 248–255. [Google Scholar] [CrossRef]

- Levy, S.; Helene, P. Durability of recycled aggregates concrete: A safe way to sustainable development. Cem. Concr. Res. 2004, 34, 1975–1980. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.; Brown, T.; Taylor, A. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Performance and properties of structural concrete made with recycled concrete aggregate. ACI Mater. J. 2003, 100, 371–380. [Google Scholar]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Tam, V.; Soomro, M.; Evangelista, A.; Haddad, A. Deformation and permeability of recycled aggregate concrete -A comprehensive review. J. Build. Eng. 2021, 44, 103393. [Google Scholar] [CrossRef]

- Gokce, A.; Nagataki, S.; Saeki, T.; Hisada, M. Freezing and thawing resistance of air-entrained concrete incorporating recycled coarse aggregate: The role of air content in demolished concrete. Cem. Concr. Res. 2004, 34, 799–806. [Google Scholar] [CrossRef]

- Zhang, H.; Luo, G.; Bao, J.; Zhang, P.; Lv, H.; Li, Y.; Sun, J.; Song, Q. Improving the salt frost resistance of recycled aggregate concrete modified by air-entraining agents and nano-silica under sustained compressive loading. Case Stud. Constr. Mater. 2024, 20, e03170. [Google Scholar] [CrossRef]

- Tam, V. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Makul, N. Cost-benefit analysis of the production of ready-mixed high-performance concrete made with recycled concrete aggregate: A case study in Thailand. Heliyon 2020, 6, e04135. [Google Scholar] [CrossRef]

- Lu, L.; Gao, M.; Guo, Y.; Wang, W.; Yan, H.; Jiang, T. Experiments on flexural behavior of the prefabricated RAC and NWC composite slab. Ain Shams Eng. J. 2022, 13, 101789. [Google Scholar] [CrossRef]

- Lu, L.; Ding, Y.; Guo, Y.; Hao, H.; Ding, S. Flexural performance and design method of the prefabricated RAC composite slab. Structures 2022, 38, 572–584. [Google Scholar] [CrossRef]

- Jayasuriya, A.; Adams, M.; Bandelt, M. Understanding variability in recycled aggregate concrete mechanical properties through numerical simulation and statistical evaluation. Constr. Build. Mater. 2018, 178, 301–312. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J. Reinforced recycled aggregate concrete slabs: Structural design based on Eurocode 2. Eng. Struct. 2020, 204, 110047. [Google Scholar] [CrossRef]

- Zaki, Z.; Khalid, F.; Guntor, N.; Meng Siang, A. The Optimum Replacement of Fine Recycled Concrete Aggregate on the Compressive and Splitting Tensile Strength of the Concrete. Int. J. Integr. Eng. 2020, 12, 18–26. [Google Scholar] [CrossRef]

- Basit, M.; Hasan, N.; Miah, M.; Paul, S. Strength and cost analysis of concrete made from three different recycled coarse aggregates. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

| Requirement | AS 2758.1:2014 | HB 155:2002 |

|---|---|---|

| Water absorption | No hard limit. | Class 1A: ≤6% Class 1B: ≤8% |

| Saturated dry density (kg/m3) | ≥2.1, <3.2 t/m3 (normal weight aggregate) | Class 1A: ≥2100 kg/m3 Class 1B: ≥1800 kg/m3 |

| Chloride content | Combined chloride salt content <0.04% in reinforced concrete Total water-soluble chloride salt content <0.03% | |

| Sulfate content | Sulfate content of concrete mix ≤5% by mass of Portland cement | |

| Deleterious fines index | ≤150 | |

| Soundness | 6% (Exposure class C) | |

| Light particles | ≤1% (fine) ≤3% for vesicular aggregates | |

| Material finer than 75 μm | Coarse: ≤2%; Fine: ≤20% | |

| Material finer than 2 μm | ≤1% (fine) | |

| Flakiness index | ≤35% | |

| Replacement ratio | Class 1A: ≤30% |

| Requirement | Limitation |

|---|---|

| Undesirable materials content | <1% |

| Clay in lumps content | <3% |

| Sulfate content | <0.1% |

| Chloride content for simple concrete | <0.2% |

| Chloride content for reinforced concrete | <0.1% |

| Chloride content for prestressed concrete | <0.01% |

| Water absorption | <7% |

| Fine (<0.075 mm) content for concrete protected from surface wear | <12% |

| Fine (<0.075 mm) content for concrete subjected to surface wear | <10% |

| Unpolished red or white ceramic content | 0% |

| Replacement ratio | Structural Portland cement concrete: ≤20% |

| Requirement | Class I | Class II | Class III |

|---|---|---|---|

| Water absorption | <3% | <5% | <8% |

| Apparent density (kg/m3) | >2450 | >2350 | >2250 |

| Content of clay by mass | <1% | <2% | <3% |

| Content of clay lumps by mass | <0.5% | <0.7% | <1.0% |

| Porosity | <47% | <50% | <53% |

| Content of elongated and flaky particles | <10% | ||

| Content of organic | Standard | ||

| Sulfide and sulfate by mass | <2% | ||

| Chloride by mass | <0.06% | ||

| Other impurities | <1% | ||

| Mass loss | <5% | <10% | <15% |

| Crushing Index | <12% | <20% | <30% |

| Replacement ratio | 50~100% | 30~50% for multi-story and high-rise recycled concrete buildings 50~100% for low-rise recycled concrete houses | |

| Requirement | Constituent by Mass [%] | |

|---|---|---|

| Type 1 | Type 2 | |

| Concrete and natural aggregates | ≥90 | ≥70 |

| Clinker, no porous clay bricks | ≤10 | ≤30 |

| Calcium silicate bricks | ≤10 | ≤30 |

| Other mineral materials (e.g., porous brick, lightweight concrete, plaster, mortar, porous slag) | ≤2 | ≤3 |

| Asphalt | ≤10 | ≤30 |

| Foreign substances (e.g., glass, plastic, metal, wood) | ≤0.2 | ≤0.5 |

| Oven dry density | ≥2000 kg/m3 | ≥2000 kg/m3 |

| Maximum water absorption (in 10 min) | 10% | 15% |

| Aggregate composition | Aggregate > 90% Bricks + Sandstone < 10 | Aggregate ≥ 70% Bricks + Sandstone ≤ 30% |

| Replacement ratio | ≤25%, with concrete strength ≤ 35 MPa ≤35%, with concrete strength ≤ 25 MPa | |

| Requirement | Class I | Class II | Class III |

|---|---|---|---|

| Water absorption | 20% | 10% | 3% |

| Saturated dry density (kg/m3) | 1500 | 2000 | 2400 |

| Maximum content of material with SSD * < 2200 kg/m3 | - | 10% | 10% |

| Maximum content of material with SSD * < 1800 kg/m3 | 10% | 1% | 1% |

| Maximum content of material with SSD * < 1000 kg/m3 | 1% | 0.5% | 0.5% |

| Maximum content of foreign materials (metals, glass, soft materials, bitumen) | 5% (by volume) | 1% (by volume) | 1% (by volume) |

| Maximum content of metals | 1% (by mass) | 1% (by mass) | 1% (by mass) |

| Maximum content of organic material | 1% (by mass) | 0.5% (by mass) | 0.5% (by mass) |

| Maximum sulfate content | 1% (by mass) | 1% (by mass) | 1% (by mass) |

| Replacement ratio | ≤100% (Coarse > 4 mm) | ≤20% (Coarse > 4 mm) | ≤100% (Coarse > 4 mm) |

| Requirement | Limitation |

|---|---|

| Maximum fines | ≤4% by mass of particles passing the 0.063 mm sieve |

| Maximum acid-soluble sulfate (SO3) | ≤0.8% by mass acid-soluble sulfate |

| Content of: concrete, concrete products, mortar, concrete masonry units | ≥90% by mass |

| Content of: concrete, concrete products, mortar, concrete masonry units, unbound aggregate, natural stone, hydraulically bound aggregate | ≥90% by mass |

| Content of: clay masonry units (i.e., bricks and tiles), calcium silicate masonry units, aerated non-floating concrete | ≤10% by mass |

| Content of bituminous materials | ≤5% by mass |

| Content of other materials: Cohesive (i.e., clay and soil) Miscellaneous metals, ferrous and non-ferrous Non-floating wood, plastic, and rubber Gypsum plaster and glass | ≤1% by mass |

| Floating material by volume | ≤2 cm3/kg |

| Replacement ratio | ≤20% |

| Impurities | Lime Plaster | Soil | Wood | Hydrated Gypsum | Asphalt | Paint Made Vinyl Acetate |

|---|---|---|---|---|---|---|

| Percentage of aggregate by volume | 7% | 5% | 4% | 3% | 2% | 0.2% |

| Requirement | Limitation |

|---|---|

| Maximum LA abrasion loss | 50% |

| Soundness loss | 12% (under sodium sulfate) |

| 18 (under magnesium sulfate) | |

| Amount of material passing No. 200 sieve | 1.5% |

| Chlorite ion content | 0.6 lb/yd3 of concrete |

| The Current Method (USD 1000/Year) | The Concrete Recycling Method (USD 1000/Year) | |

|---|---|---|

| Total cost | 44,097.16 | 6738.06 |

| Total benefit | 20.30 | 37,654.61 |

| Net benefit | −44,076.84 | +30,916.55 |

| NA (USD per ton) | RCA (USD per ton) | |

|---|---|---|

| Total cost | −76.30 | −45.77 |

| Total benefit | 0.73 | 22.36 |

| Net benefit | −75.57 | −23.41 |

| RCA Replacement (%) | FEL | OB |

|---|---|---|

| 20 | 0 to 7.5 | 5.5 to 16.0 |

| 40 | 7.5 to 9.5 | 7.5 to 16.5 |

| 60 | 8.5 to 10.5 | 9.5 to 17.5 |

| 80 | 4.5 to 12.5 | 9.5 to 18.0 |

| 100 | 5.5 to 12.0 | 9.0 to 18.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings 2024, 14, 2204. https://doi.org/10.3390/buildings14072204

Lu L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings. 2024; 14(7):2204. https://doi.org/10.3390/buildings14072204

Chicago/Turabian StyleLu, Linfeng. 2024. "Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review" Buildings 14, no. 7: 2204. https://doi.org/10.3390/buildings14072204

APA StyleLu, L. (2024). Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings, 14(7), 2204. https://doi.org/10.3390/buildings14072204