The Influences of Positive and Negative Resal Effects on the Shear Performance of Tapered Girders with Corrugated Steel Webs

Abstract

:1. Introduction

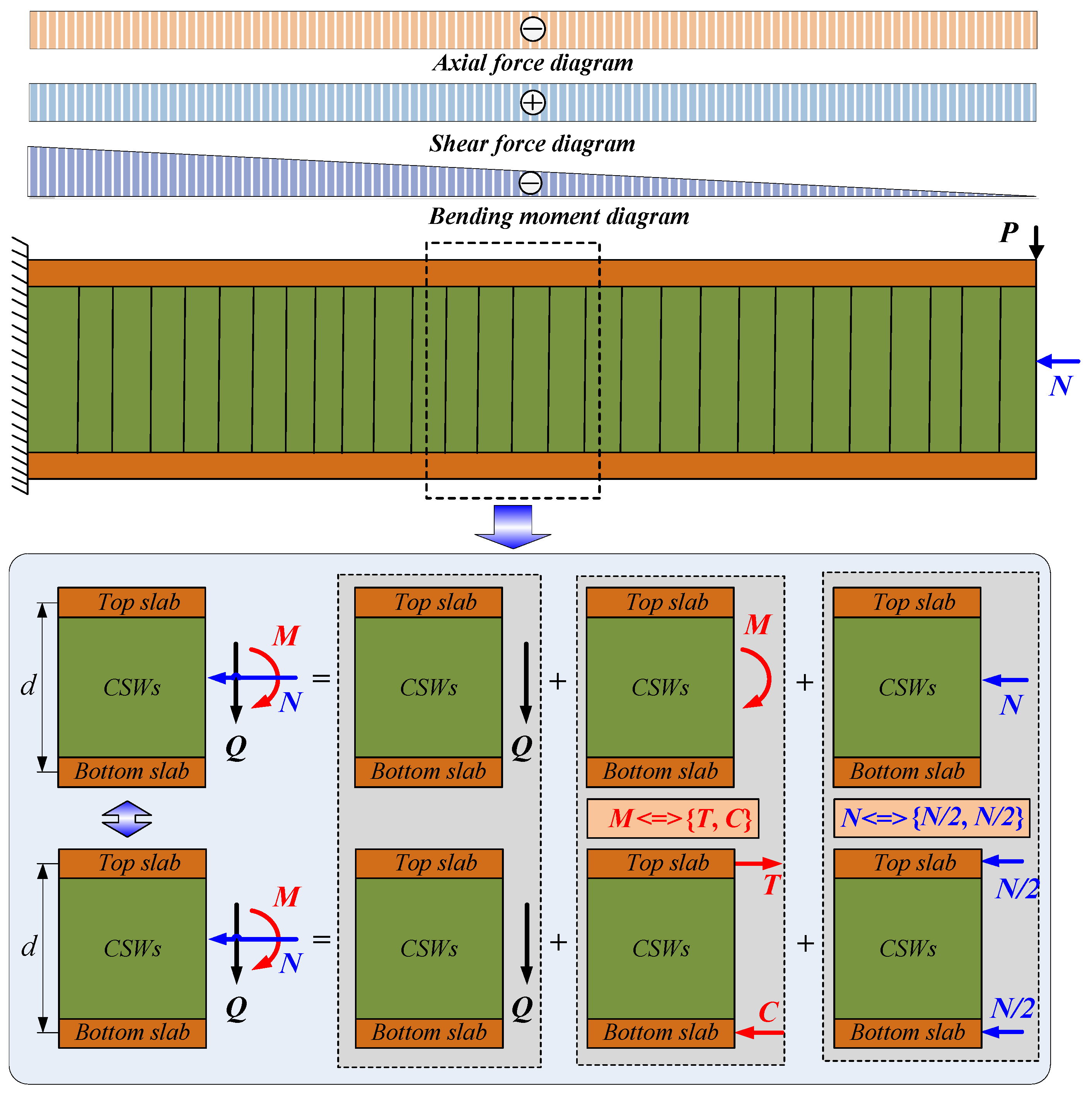

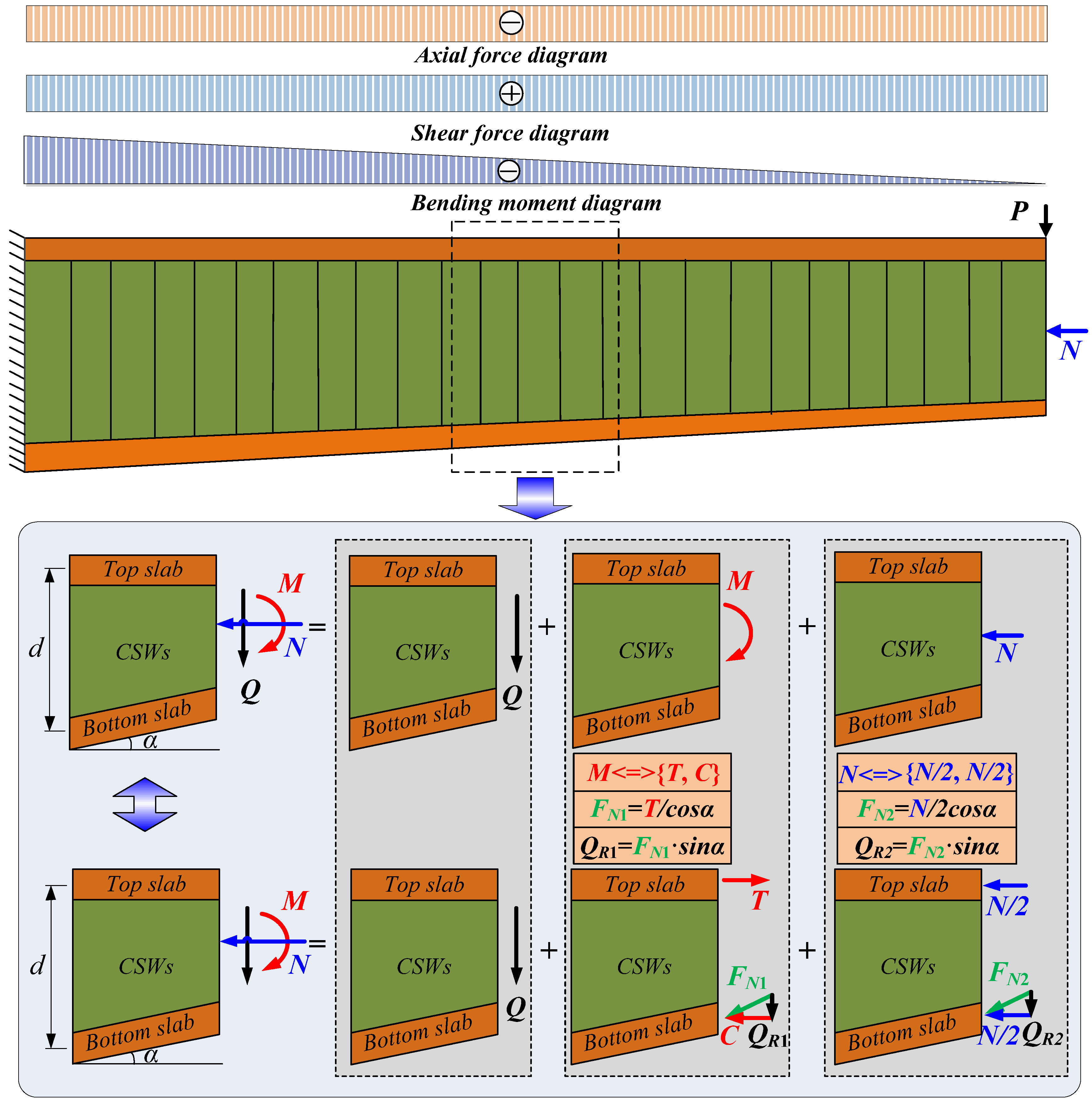

2. Shear Force Calculation of Girder Bridges with CSWs

2.1. Existing Shear Calculation Methods

2.2. Resal Effect

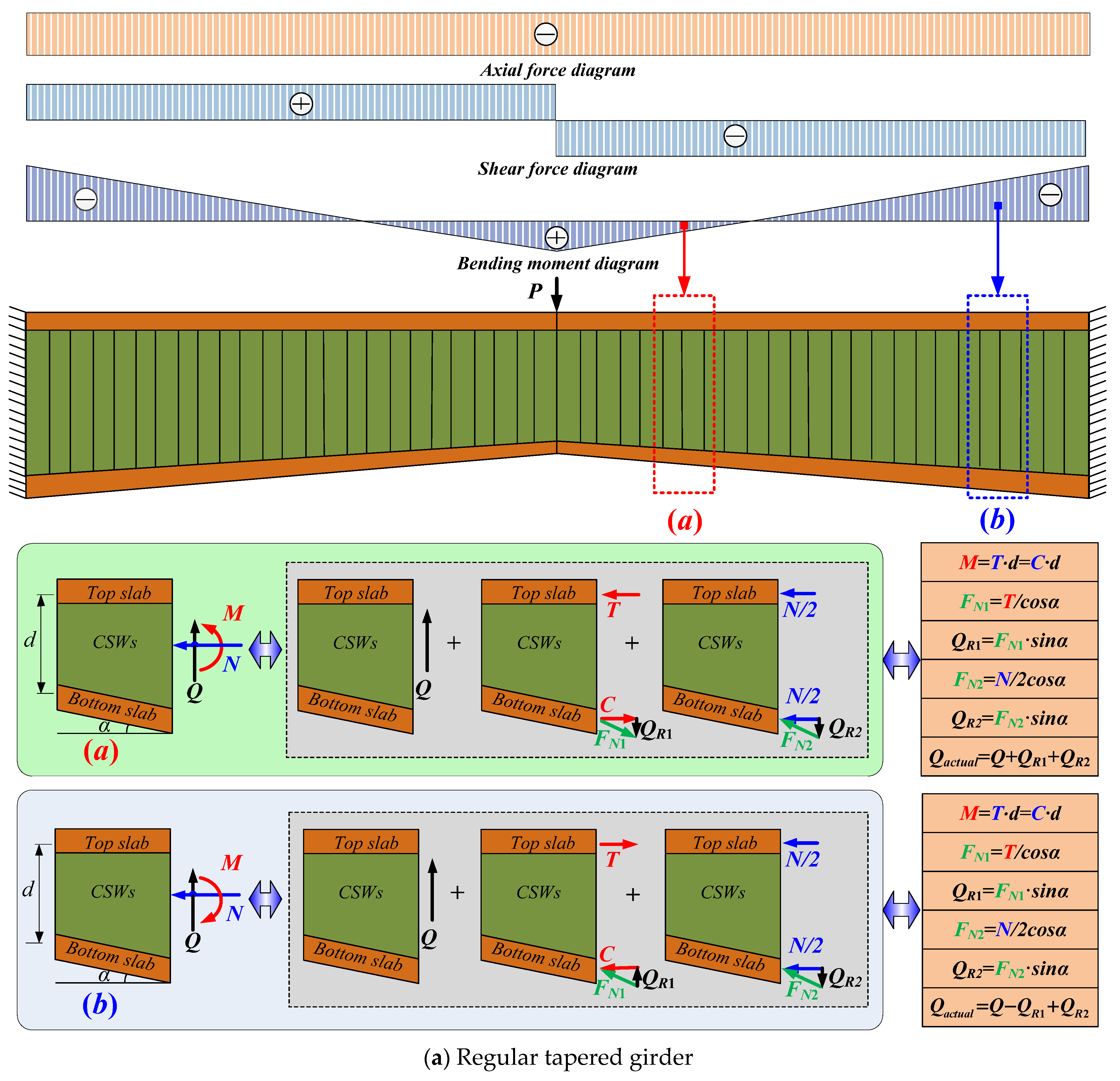

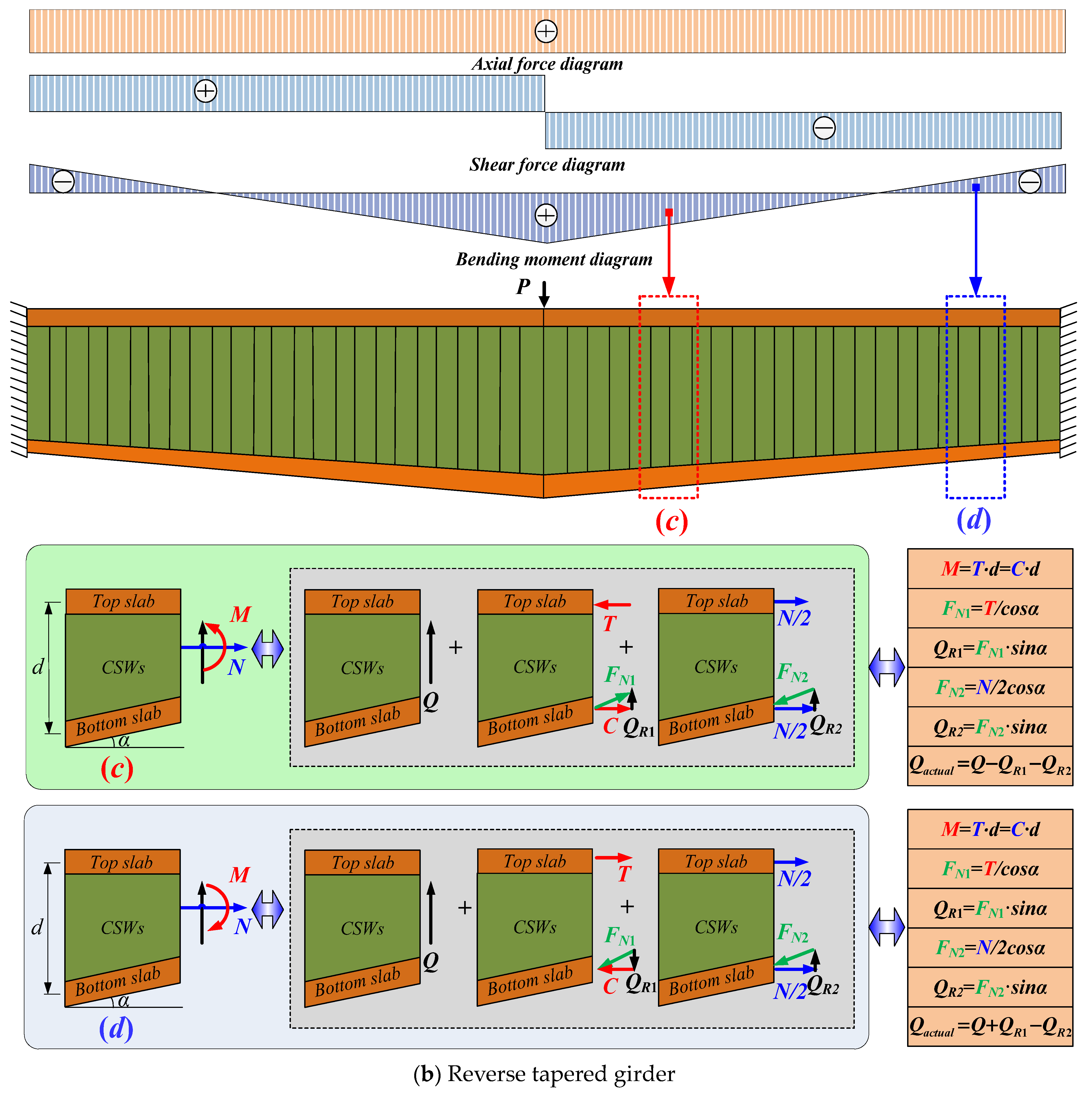

2.3. Improved Shear Method Considering Positive and Negative Resal Effects

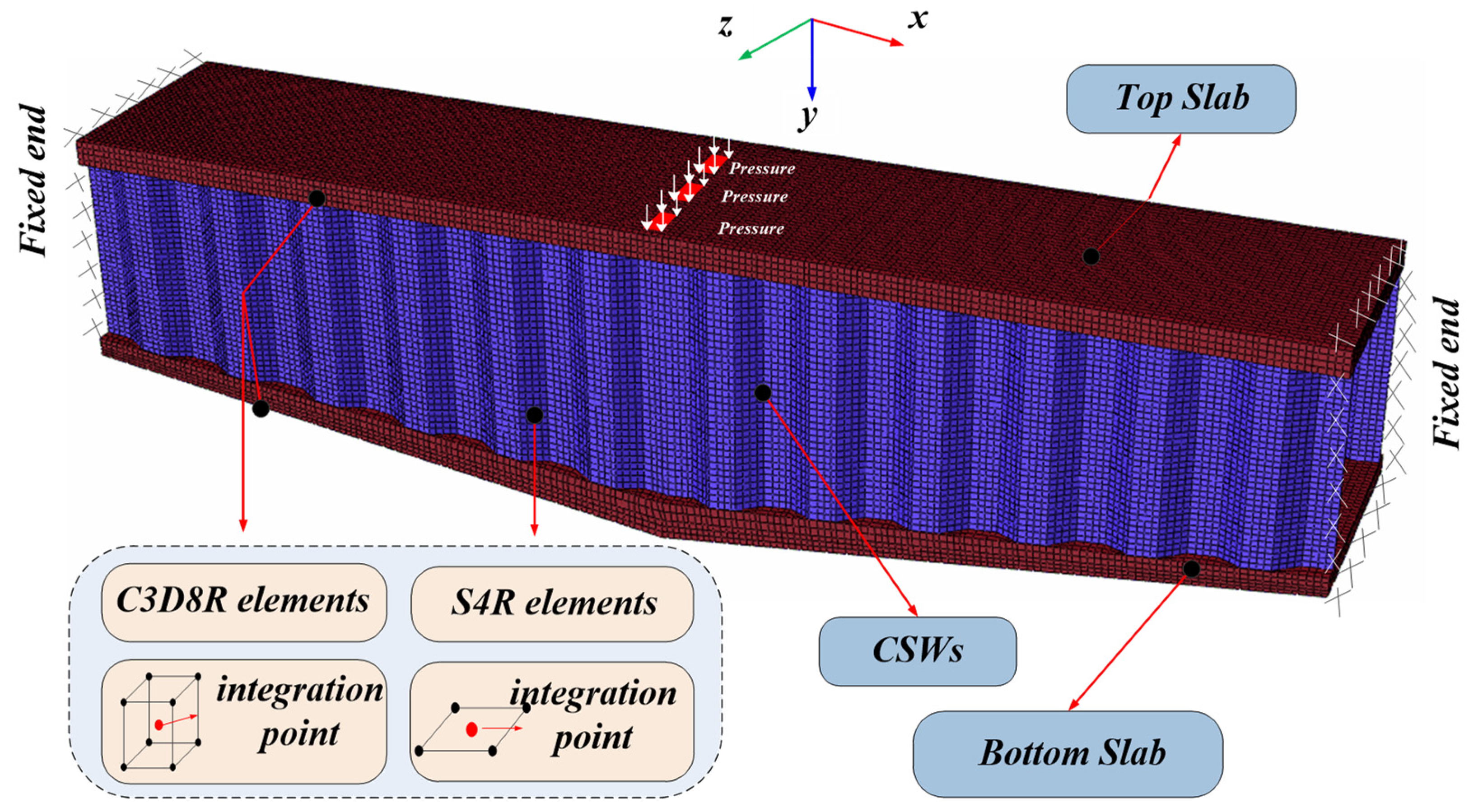

3. Finite Element Model

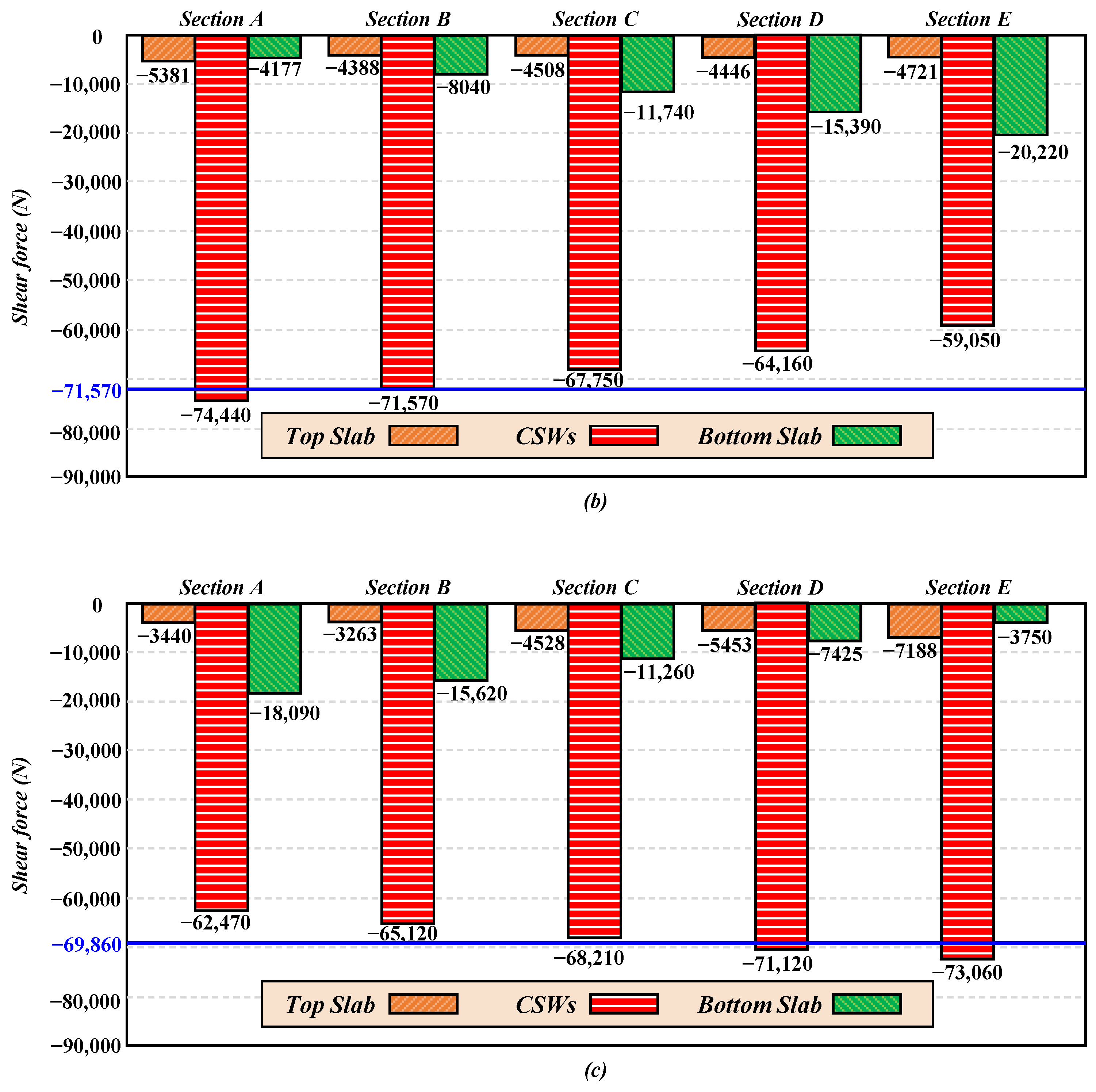

4. Results and Analysis

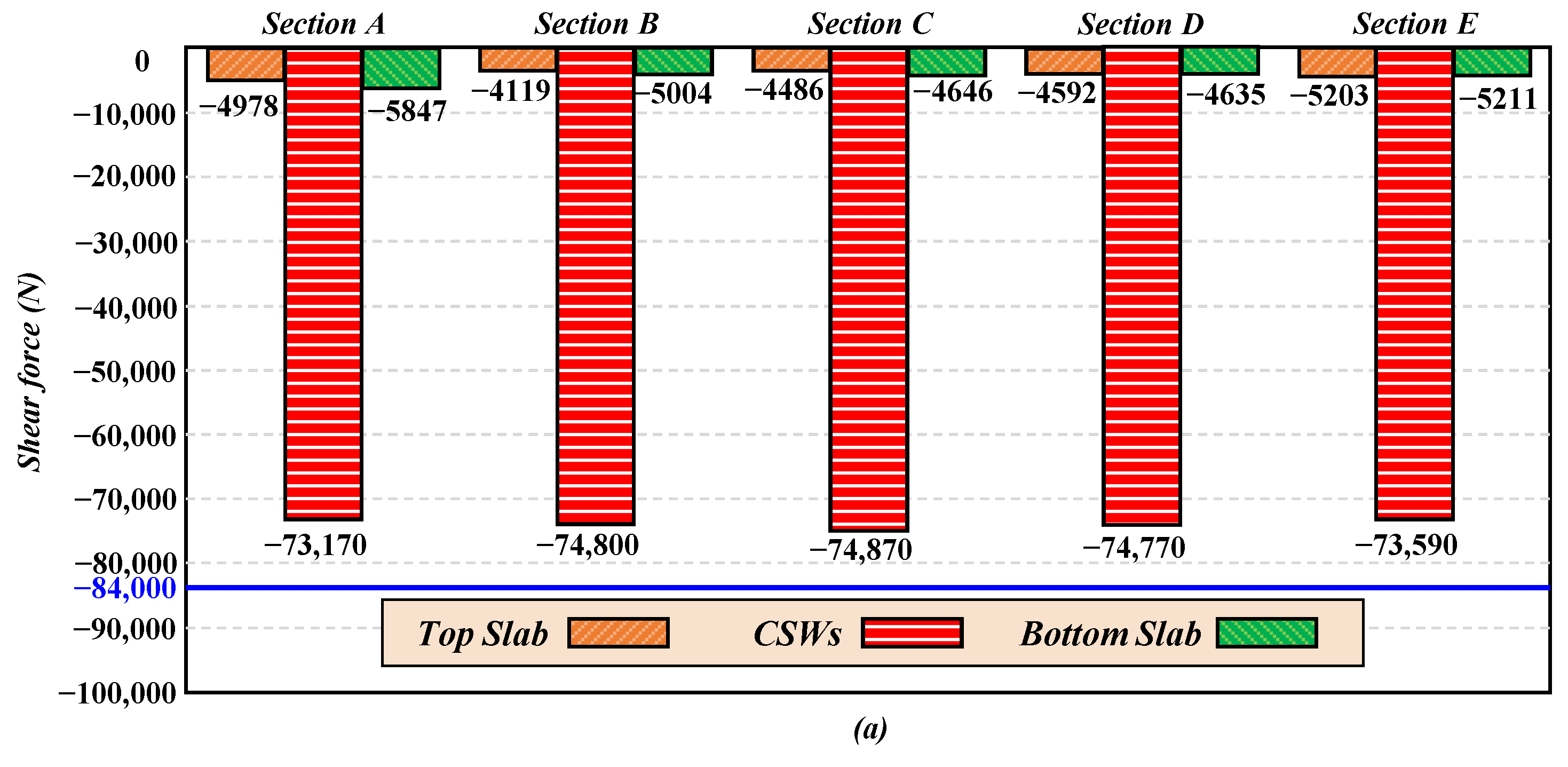

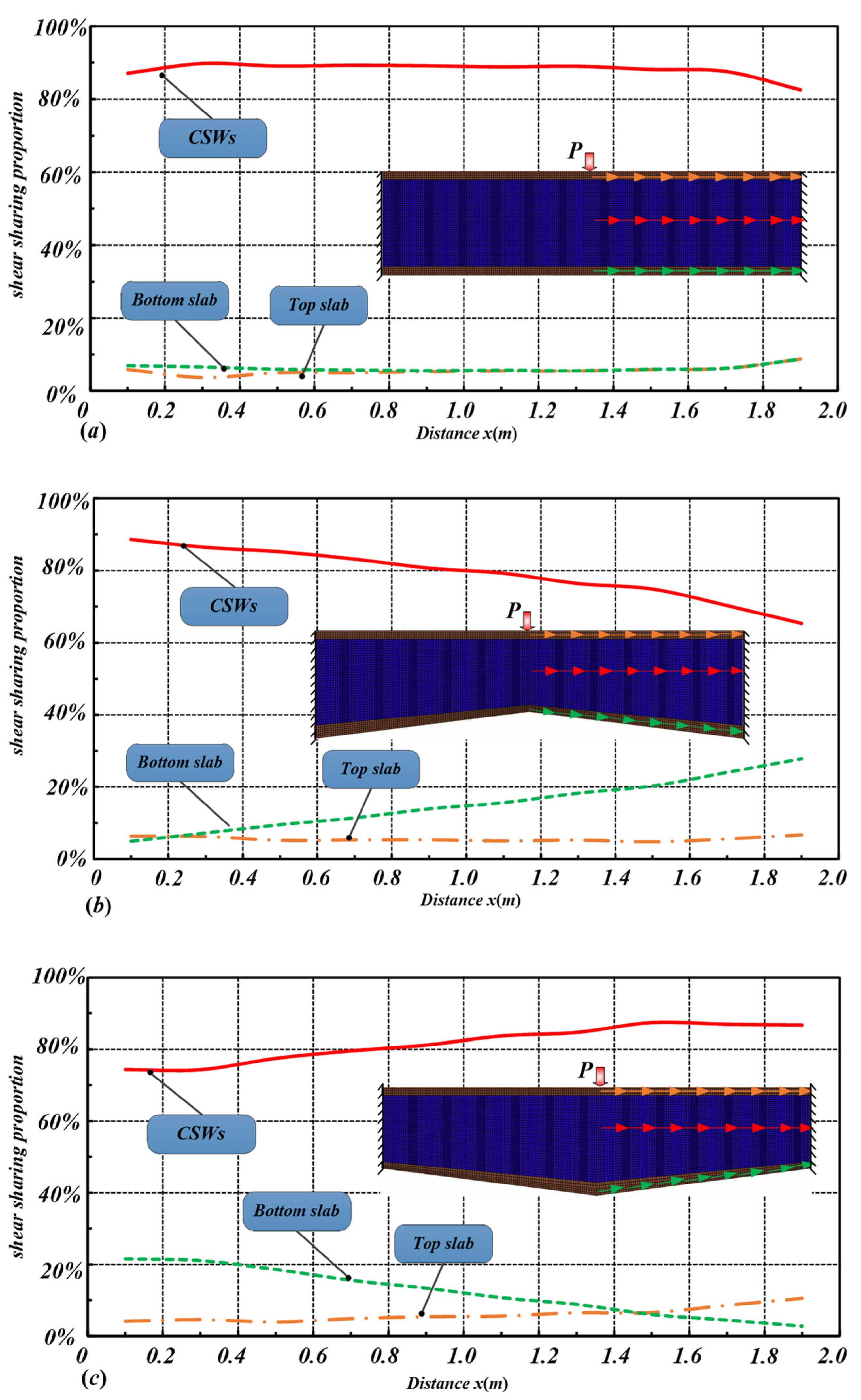

4.1. Shear Distribution between Concrete Slabs and CSWs

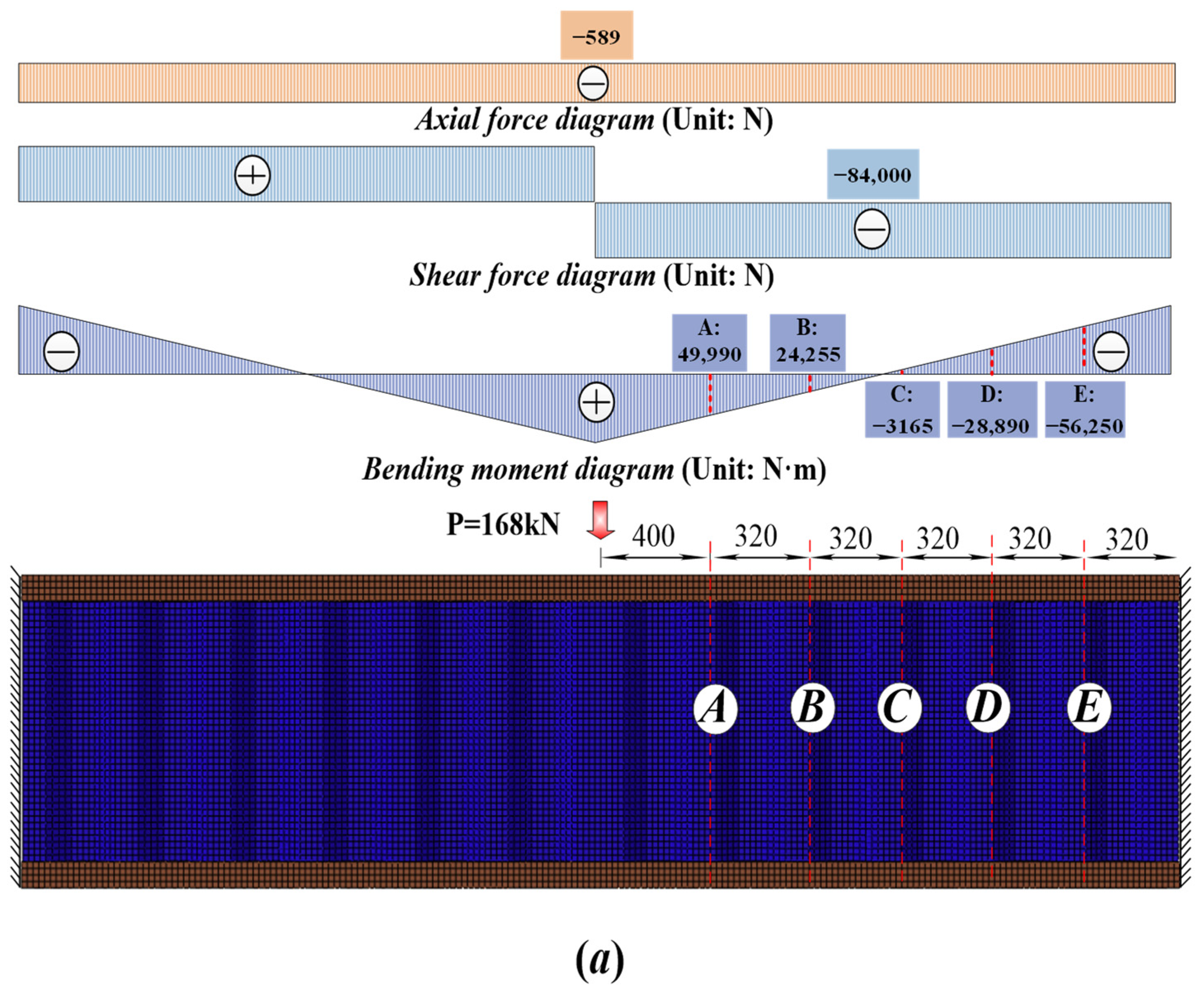

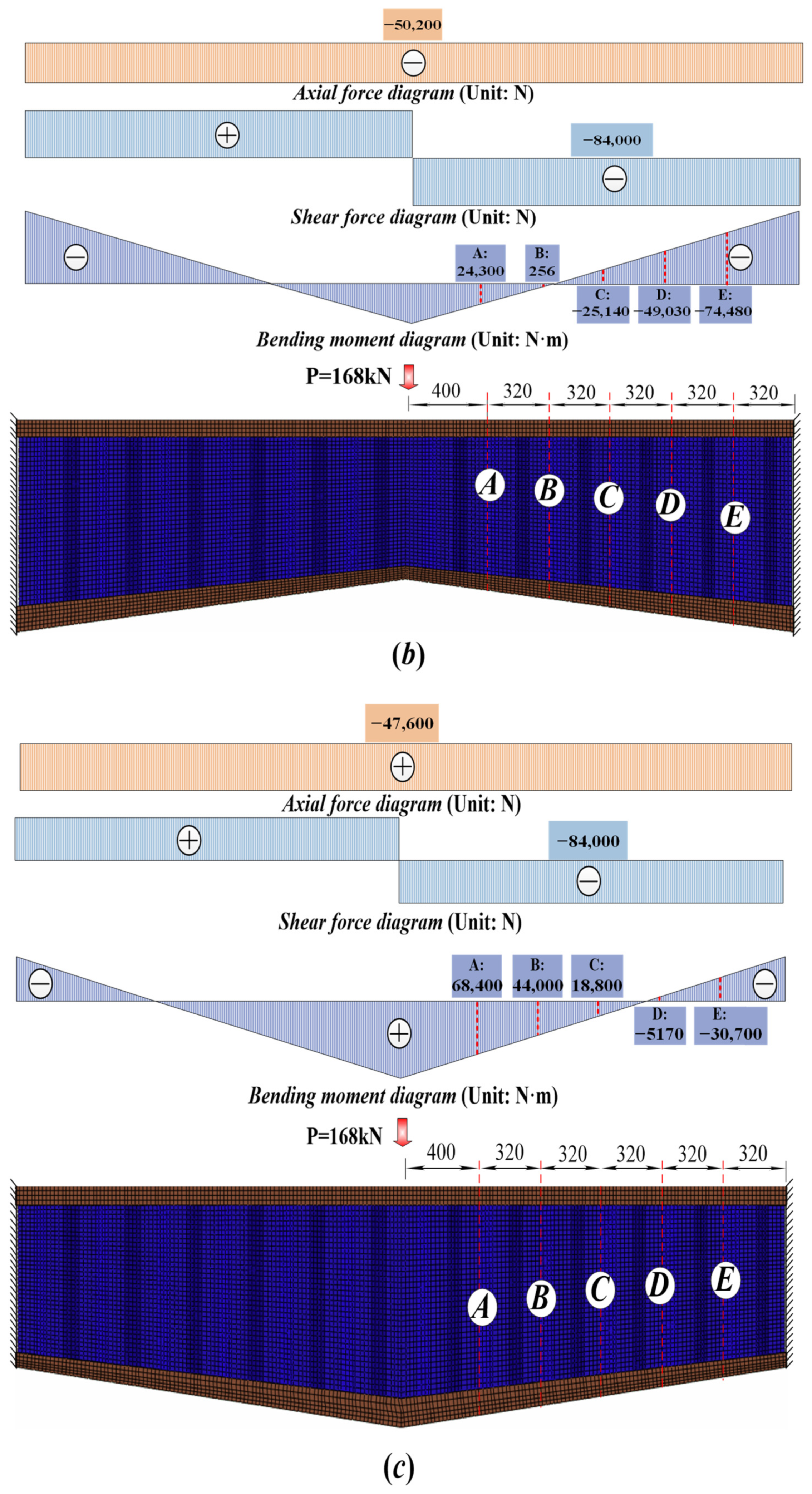

- Prismatic girder

- 2.

- Regular tapered girder

- 3.

- Reverse tapered girder

4.2. Shear-Sharing Proportions

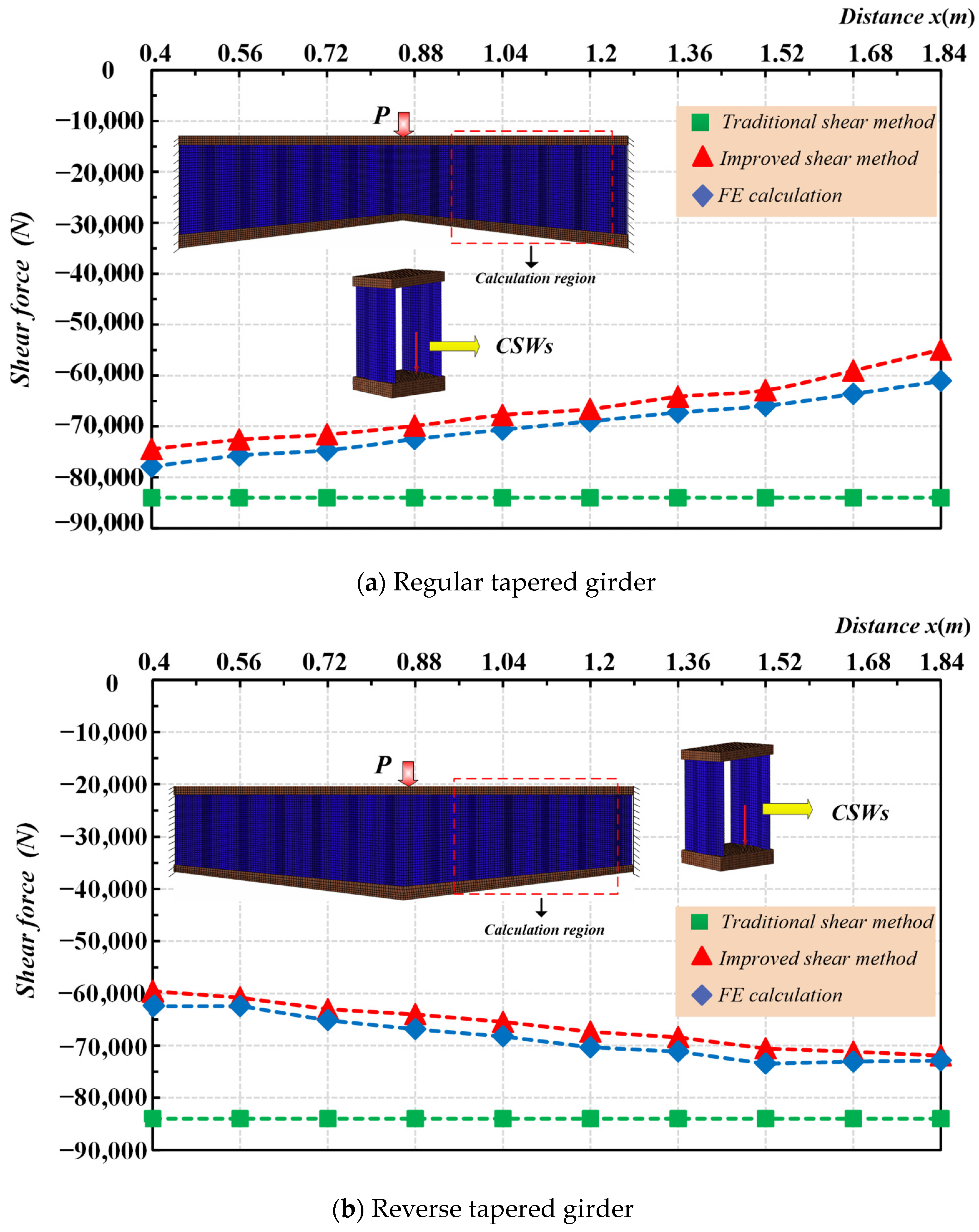

5. Verification of Improved Shear Method

6. Analysis of Calculation Errors

7. Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, W.; Zhou, M.; Hassanein, M.F.; Zhang, J.; Liu, D.; An, L. Growth of Prestressed Concrete Bridges with Corrugated Steel Webs in China. Proc. Inst. Civ. Eng.-Civ. Eng. 2018, 171, 77–84. [Google Scholar] [CrossRef]

- Jung, K.; Kim, K.; Sim, C.; Kim, J.J. Verification of Incremental Launching Construction Safety for the Ilsun Bridge, the World’s Longest and Widest Prestressed Concrete Box Girder with Corrugated Steel Web Section. J. Bridge Eng. 2011, 16, 453–460. [Google Scholar] [CrossRef]

- Chen, X.C.; Pandey, M.; Bai, Z.Z.; Au, F.T.K. Long-Term Behavior of Prestressed Concrete Bridges with Corrugated Steel Webs. J. Bridge Eng. 2017, 22, 04017040. [Google Scholar] [CrossRef]

- Moon, J.; Yi, J.-W.; Choi, B.H.; Lee, H.-E. Lateral–Torsional Buckling of I-Girder with Corrugated Webs under Uniform Bending. Thin-Walled Struct. 2009, 47, 21–30. [Google Scholar] [CrossRef]

- Khalid, Y.A.; Chan, C.L.; Sahari, B.B.; Hamouda, A.M.S. Bending Behaviour of Corrugated Web Beams. J. Mater. Process. Technol. 2004, 150, 242–254. [Google Scholar] [CrossRef]

- Rosignoli, M. Prestressed Concrete Box Girder Bridges with Folded Steel Plate Webs. Proc. Inst. Civ. Eng.-Struct. Build. 1999, 134, 77–85. [Google Scholar] [CrossRef]

- Luo, R.; Edlund, B. Shear Capacity of Plate Girders with Trapezoidally Corrugated Webs. Thin-Walled Struct. 1996, 26, 19–44. [Google Scholar] [CrossRef]

- Hassanein, M.F.; Kharoob, O.F. Behavior of Bridge Girders with Corrugated Webs: (II) Shear Strength and Design. Eng. Struct. 2013, 57, 544–553. [Google Scholar] [CrossRef]

- Ashrafi, H.R.; Beiranvand, P.; Pouraminian, M.; Moayeri, M.S. Examining the Impact of Sheet Placement and Changes in Waves Characteristics on Behavior of Wavy Steel Shear Wall. Case Stud. Constr. Mater. 2018, 9, e00180. [Google Scholar] [CrossRef]

- Amani, M.; Al-Emrani, M.; Khalili, S. Imperfection Sensitivity of Plastic Shear Buckling Behavior in Corrugated Web Stainless Steel Beams. ce/papers 2023, 6, 1793–1798. [Google Scholar] [CrossRef]

- Sause, R.; Braxtan, T.N. Shear Strength of Trapezoidal Corrugated Steel Webs. J. Constr. Steel Res. 2011, 67, 223–236. [Google Scholar] [CrossRef]

- Nie, J.-G.; Zhu, L.; Tao, M.-X.; Tang, L. Shear Strength of Trapezoidal Corrugated Steel Webs. J. Constr. Steel Res. 2013, 85, 105–115. [Google Scholar] [CrossRef]

- Zevallos, E.; Hassanein, M.F.; Real, E.; Mirambell, E. Shear Evaluation of Tapered Bridge Girder Panels with Steel Corrugated Webs near the Supports of Continuous Bridges. Eng. Struct. 2016, 113, 149–159. [Google Scholar] [CrossRef]

- Hassanein, M.F.; Kharoob, O.F. Shear Buckling Behavior of Tapered Bridge Girders with Steel Corrugated Webs. Eng. Struct. 2014, 74, 157–169. [Google Scholar] [CrossRef]

- Li, L.; Zhou, C.; Wang, L. Distortion Analysis of Non-Prismatic Composite Box Girders with Corrugated Steel Webs. J. Constr. Steel Res. 2018, 147, 74–86. [Google Scholar] [CrossRef]

- Lifeng, L.; Jindong, C.; Wei, F.; Zhou, C. Research on shear stress calculation in variable cross-section of composite box girder with corrugated steel webs. J. Railw. Sci. Eng. 2019, 16, 3024–3032. [Google Scholar] [CrossRef]

- Zhou, M.; Liao, J.; An, L. Shear Properties of Tapered Box Girders with Steel Trapezoidally Corrugated Webs Considering Resal Effect. J. Bridge Eng. 2020, 25, 04019126. [Google Scholar] [CrossRef]

- Zhou, M.; Liao, J.; Zhong, J.; An, L.; Wang, H. Unified Calculation Formula for Predicting the Shear Stresses in Prismatic and Non-Prismatic Beams with Corrugated Steel Webs. Structures 2021, 29, 507–518. [Google Scholar] [CrossRef]

- Shandong Administration Market Regulation Code for Long Span Prestressed Concrete Composite Girder Bridge with Corrugated Steel Webs 2019. Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://dbba.sacinfo.org.cn/attachment/downloadStdFile%3Fpk%3D28961f69dd68abf6be9e6f0b881b2ebeabdf82a67ac18a3fc73622f7bb7dfd1e&ved=2ahUKEwiqrJKEibKHAxU0aPUHHXyyHKgQFnoECBEQAQ&usg=AOvVaw2nn4_MLCigaEcDcWo8Ic5k (accessed on 12 June 2024).

- Ren, D.L.; Wan, S. Design and Application of PC Composite Box-Girder Bridge with Corrugated Steel Webs. Appl. Mech. Mater. 2011, 71–78, 1168–1172. [Google Scholar] [CrossRef]

- Sayed-Ahmed, E.Y. Behaviour of Steel and (or) Composite Girders with Corrugated Steel Webs. Can. J. Civ. Eng. 2001, 28, 656–672. [Google Scholar] [CrossRef]

- Jiang, R.J.; Kwong Au, F.T.; Xiao, Y.F. Prestressed Concrete Girder Bridges with Corrugated Steel Webs: Review. J. Struct. Eng. 2015, 141, 04014108. [Google Scholar] [CrossRef]

- Zhou, M.; Shang, X.; Hassanein, M.F.; Zhou, L. The Differences in the Mechanical Performance of Prismatic and Non-Prismatic Beams with Corrugated Steel Webs: A Comparative Research. Thin-Walled Struct. 2019, 141, 402–410. [Google Scholar] [CrossRef]

| Section | M | N | FE Result ① | Equation (1) ② | Equation (2) ③ | |①–③|/① | |①–②|/① |

|---|---|---|---|---|---|---|---|

| A | 24,300 | −50,200 | −74,440 | −84,000 | −77,909 | 4.66% | 12.84% |

| B | 0 | −50,200 | −71,570 | −84,000 | −74,707 | 4.38% | 17.37% |

| C | −25,140 | −50,200 | −67,750 | −84,000 | −70,631 | 4.25% | 23.99% |

| D | −49,030 | −50,200 | −64,160 | −84,000 | −67,260 | 4.83% | 30.92% |

| E | −74,480 | −50,200 | −59,050 | −84,000 | −63,602 | 7.71% | 42.25% |

| Section | M | N | FE Result ① | Equation (1) ② | Equation (2) ③ | |①–③|/① | |①–②|/① |

|---|---|---|---|---|---|---|---|

| A | 68,400 | 47,600 | −62,470 | −84,000 | −59,556 | 4.66% | 34.46% |

| B | 44,000 | 47,600 | −65,120 | −84,000 | −63,024 | 3.22% | 28.99% |

| C | 18,800 | 47,600 | −68,210 | −84,000 | −65,463 | 4.03% | 23.15% |

| D | −5170 | 47,600 | −71,120 | −84,000 | −68,391 | 3.84% | 18.11% |

| E | −30,700 | 47,600 | −73,060 | −84,000 | −71,160 | 2.60% | 14.97% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Cheng, Y.; Pei, H.; Wang, J.; Zhou, M. The Influences of Positive and Negative Resal Effects on the Shear Performance of Tapered Girders with Corrugated Steel Webs. Buildings 2024, 14, 2217. https://doi.org/10.3390/buildings14072217

Xu F, Cheng Y, Pei H, Wang J, Zhou M. The Influences of Positive and Negative Resal Effects on the Shear Performance of Tapered Girders with Corrugated Steel Webs. Buildings. 2024; 14(7):2217. https://doi.org/10.3390/buildings14072217

Chicago/Turabian StyleXu, Fen, Yikai Cheng, Huiteng Pei, Jixiang Wang, and Man Zhou. 2024. "The Influences of Positive and Negative Resal Effects on the Shear Performance of Tapered Girders with Corrugated Steel Webs" Buildings 14, no. 7: 2217. https://doi.org/10.3390/buildings14072217

APA StyleXu, F., Cheng, Y., Pei, H., Wang, J., & Zhou, M. (2024). The Influences of Positive and Negative Resal Effects on the Shear Performance of Tapered Girders with Corrugated Steel Webs. Buildings, 14(7), 2217. https://doi.org/10.3390/buildings14072217