Bond Behavior and Failure Mechanisms of the Interface between Engineered Cementitious Composites and Shaped Steel

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

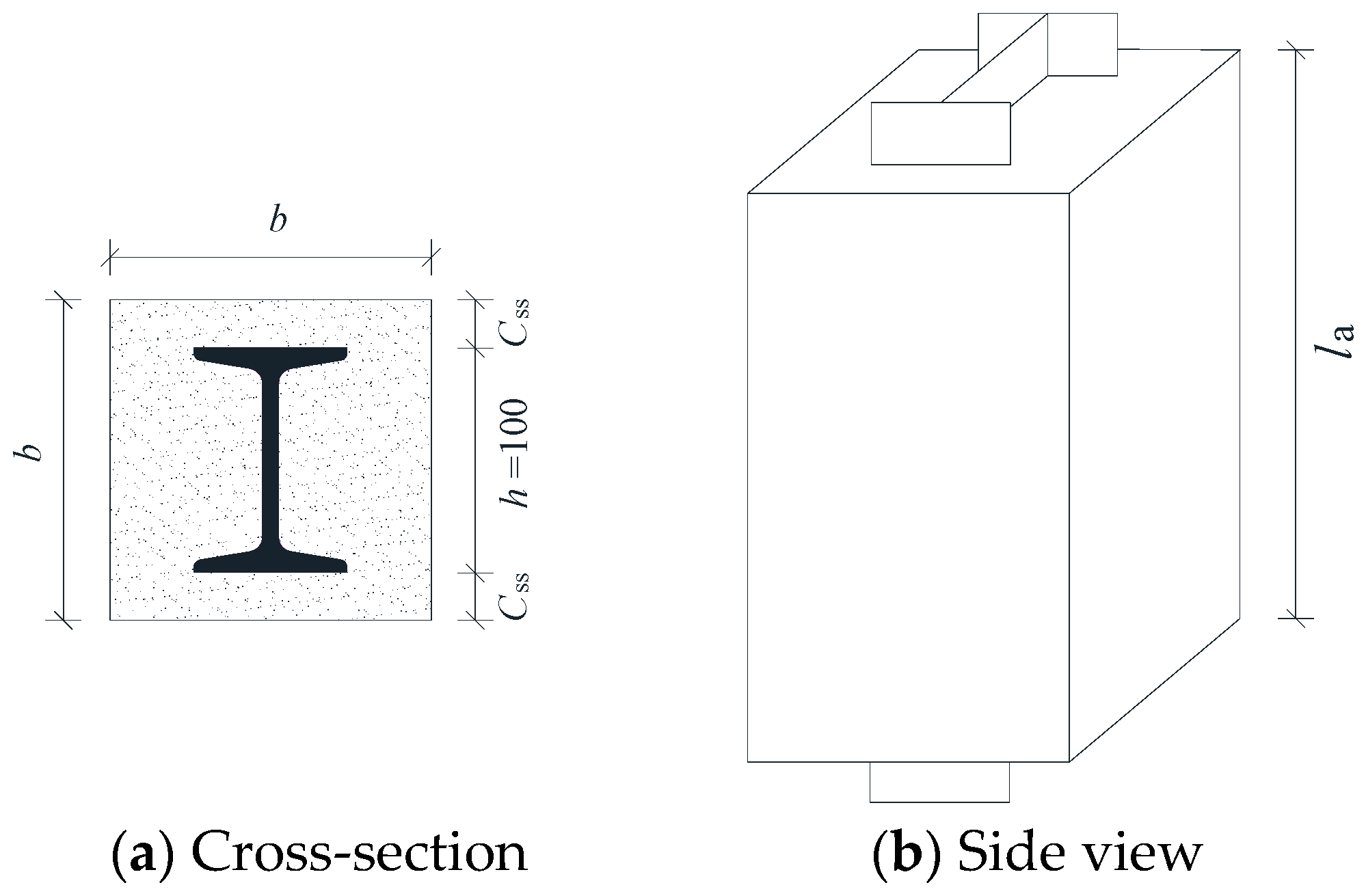

2.2. Specimen Design

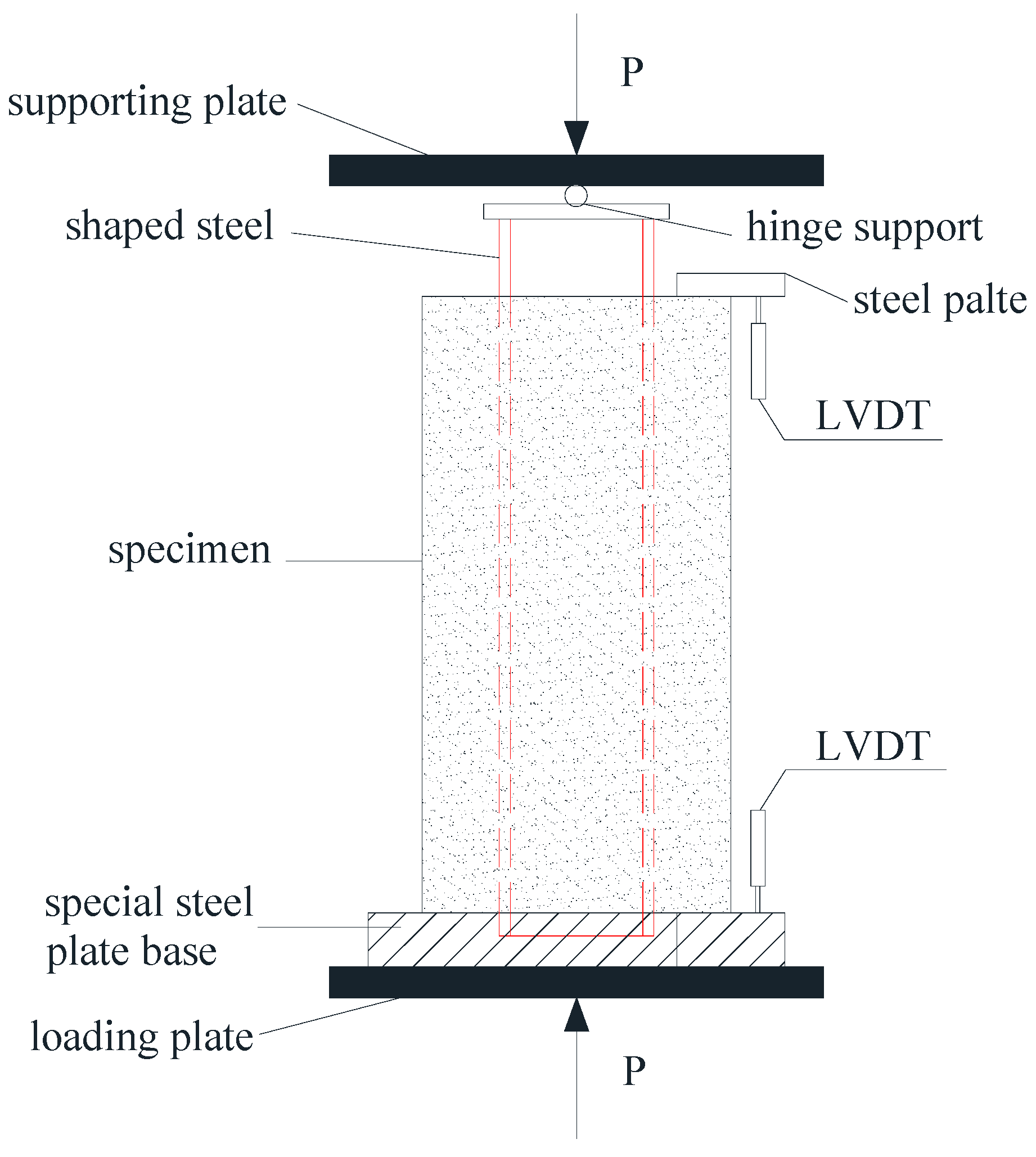

2.3. Test Setup and Measurement

3. Experimental Results and Discussion

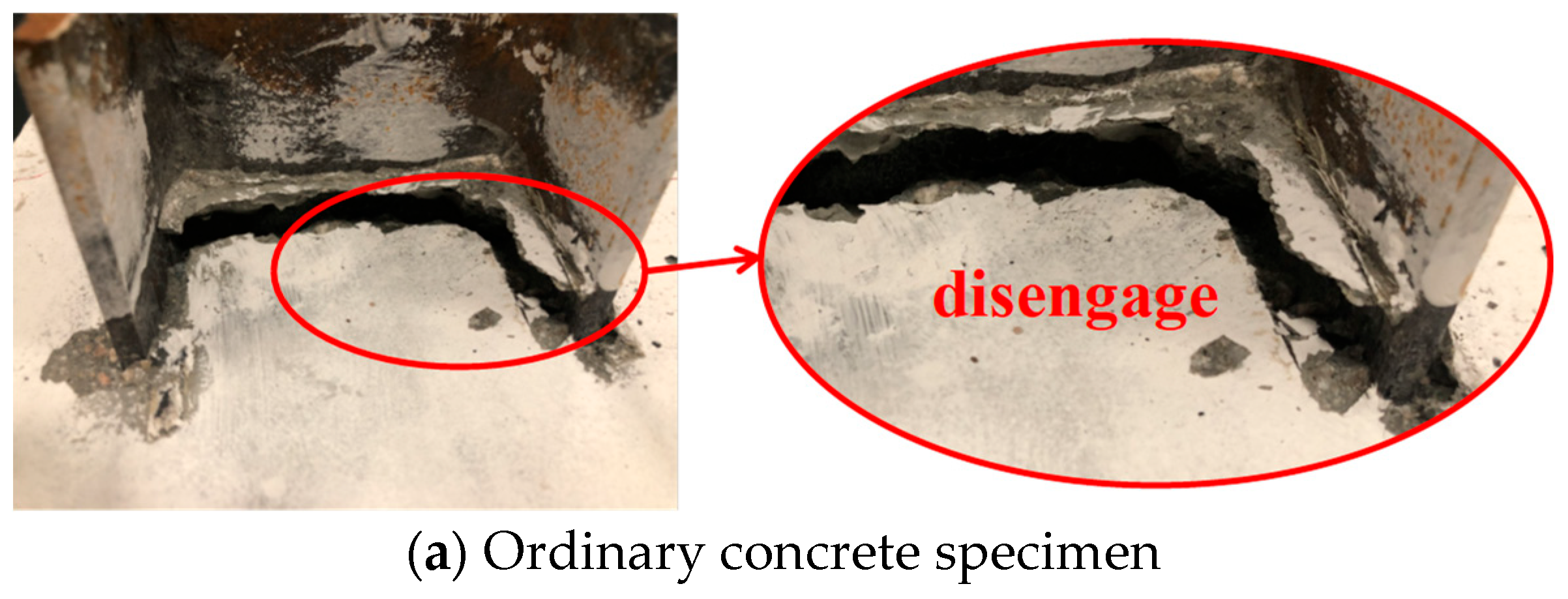

3.1. Failure Phenomena

- (1)

- Crack types

- (2)

- Failure mode

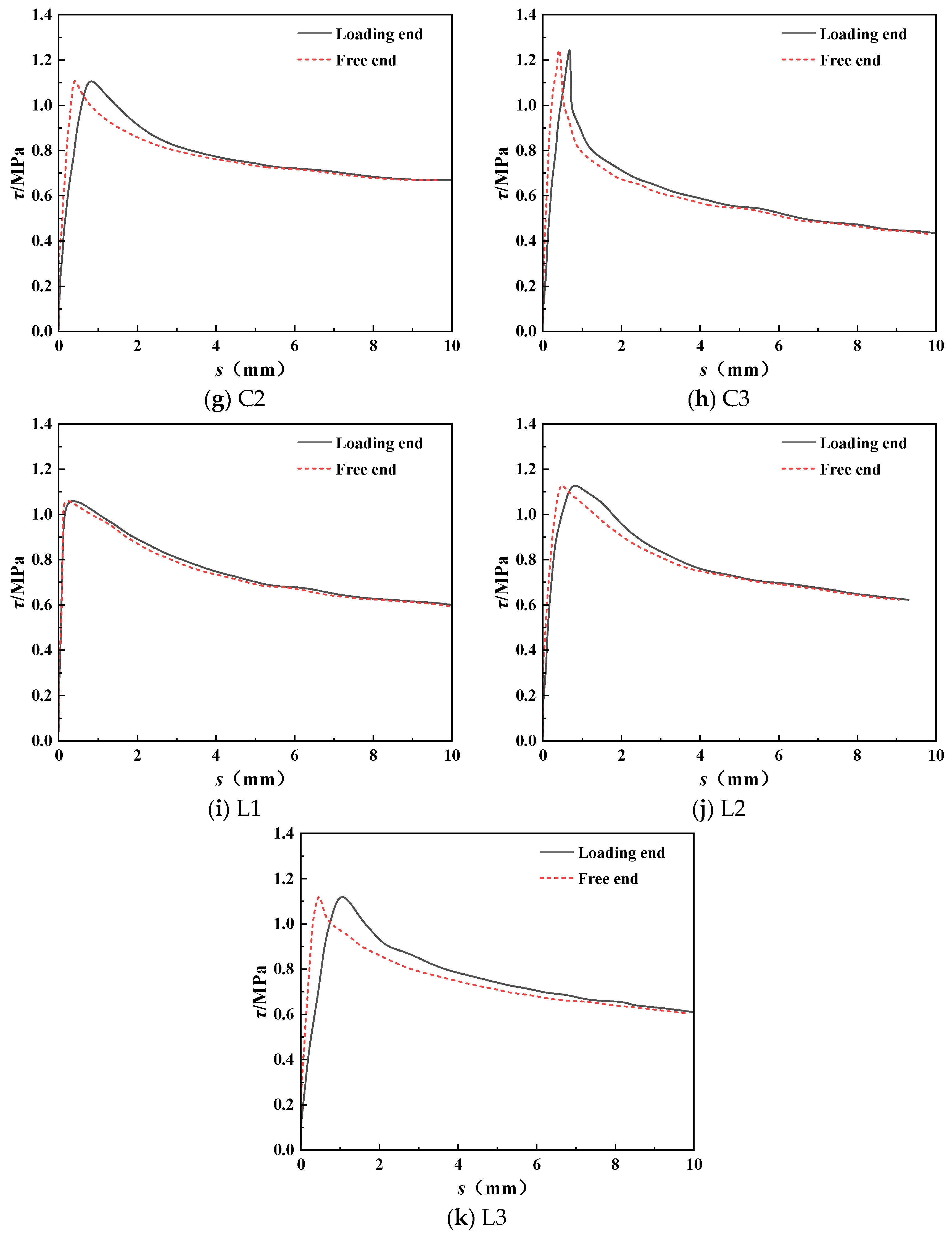

3.2. Bond Stress–Slip Curves

- (1)

- Non-slip stage

- (2)

- Linear ascent stage

- (3)

- Nonlinear ascent stage

- (4)

- Descent stage

- (5)

- Residual stage

4. Analysis of the Characteristic Points of the Bond Stress–Slip Curves

4.1. Comparison between ECC and the Ordinary Concrete

4.2. Effects of Various Parameters

- (1)

- ECC compressive strength

- (2)

- Fiber volume content

- (3)

- Cover thickness

- (4)

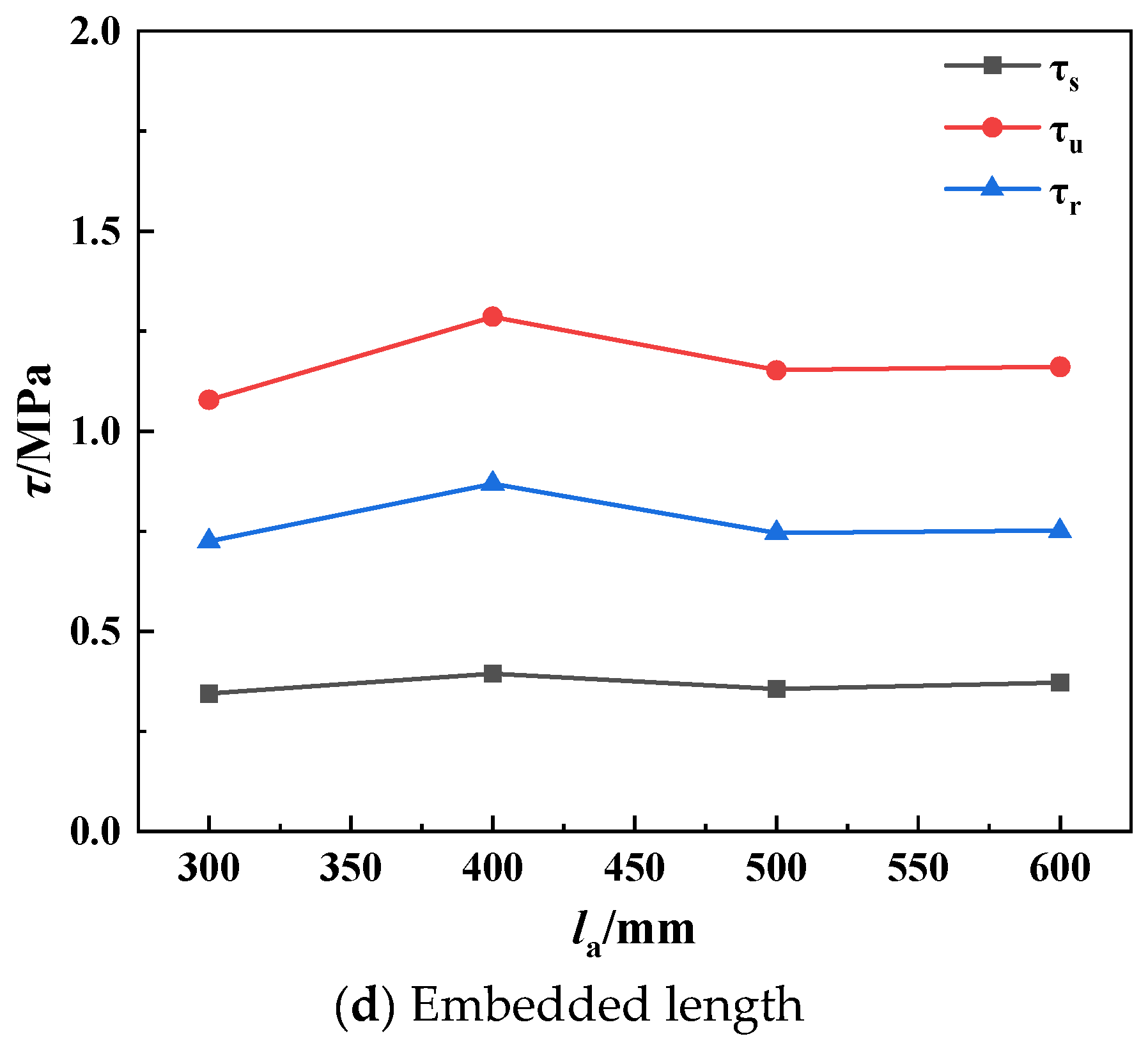

- Embedded length

5. Calculation Method of Bond Strength

6. Conclusions

- (1)

- The ordinary concrete specimen failed in brittle splitting. However, the fiber-bridging effect effectively controlled crack development and extension, allowing the surrounding matrix to maintain good integrity after testing. In contrast, ECC specimens exhibited splitting-bond or bond failure, demonstrating excellent ductility.

- (2)

- The bond stress–slip curves consisted of five stages: non-slip, linear ascent, nonlinear ascent, descent, and residual stages. During the initial loading stage, the bond resistance was primarily provided by the chemical adhesive force, with no slip occurring at both ends of the specimen. As the load further increased, the interface chemical adhesive force was destroyed and the bond resistance was mainly provided by sliding friction.

- (3)

- Compared to the ordinary concrete specimen, the standard ultimate and residual bond strength of the ECC specimen were enhanced by 37.9% and 27.4%, respectively, due to the reactivity of fly ash's main mineral component SiO2 with the cement hydration product Ca(OH)2, resulting in the formation of strong gelling C-S-H gel. Consequently, the chemical adhesive and sliding friction at the interface between ECC and the shaped steel were enhanced.

- (4)

- The increase in the ECC compressive strength, fiber volume content, and cover thickness had a positive influence on the initial, ultimate, and residual bond strength of ECC specimens. The maximum initial, ultimate, and residual bond strength was achieved when the embedded length of the shaped steel was 400 mm.

- (5)

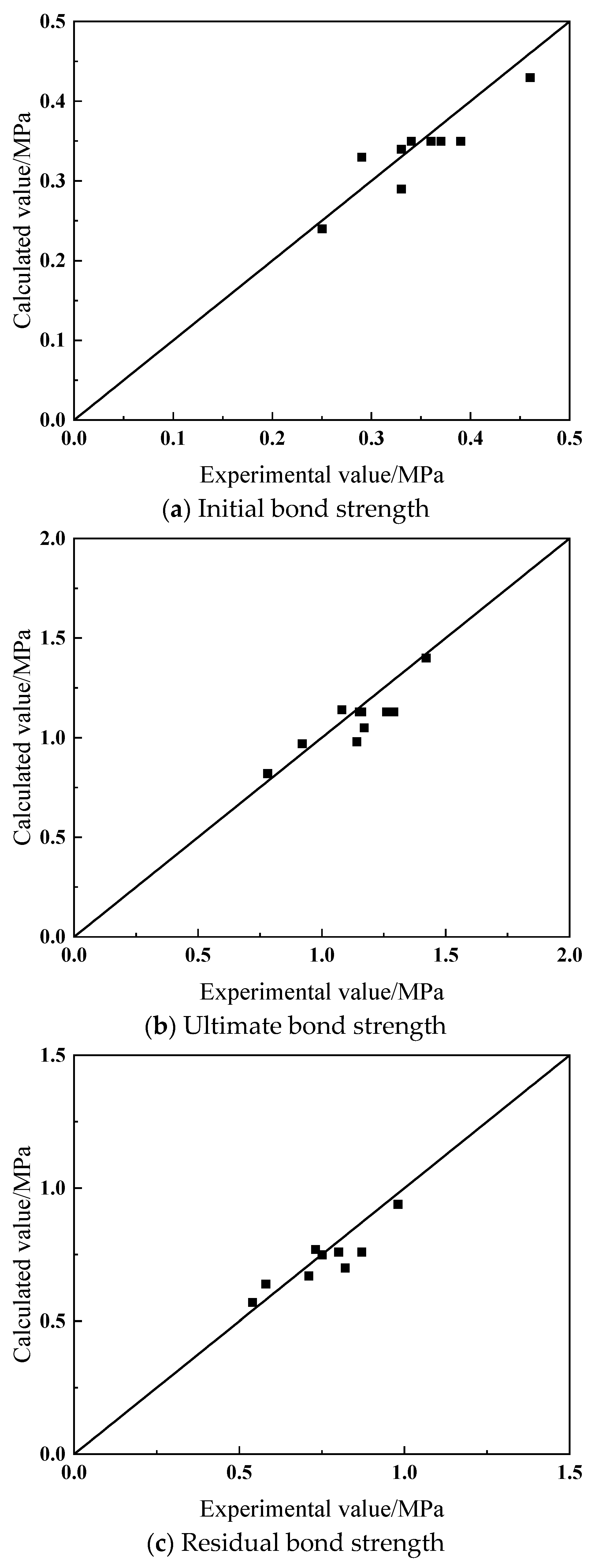

- The calculation equations for characteristic bond strengths were built through the regression analysis of experimental data. The comparison between the calculated and experimental values suggested that the proposed equations were capable of effectively predicting the characteristic bond strengths between the shaped steel and ECC.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gan, D.; Guo, L.; Liu, J.; Zhou, X. Seismic behavior and movement strength of tubed steel reinforced-concrete (SRC) beams-columns. J. Constr. Steel Res. 2011, 67, 1516–1524. [Google Scholar] [CrossRef]

- Hsu, H.L.; Hsieh, J.C.; Juang, J.L. Seismic performance of steel-encased composite members with strengthening cross-inclined bars. J. Constr. Steel Res. 2004, 60, 1663–1679. [Google Scholar] [CrossRef]

- Shi, X.M.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Boyd, P.F.; Cofer, W.F.; Mclean, D.I. Seismic performance of steel-encased concrete columns under flexural loading. ACI Struct. J. 1995, 92, 355–364. [Google Scholar]

- Yang, Y.; Yu, Y.L.; Guo, Y.X. Experimental study on shear performance of partially precast Castellated Steel Reinforced Concrete (CPSRC) beams. Steel Compos. Struct. 2016, 21, 289–302. [Google Scholar] [CrossRef]

- Wu, K.; Chen, F.; Lin, J.; Zhao, J.; Zheng, H. Experimental study on the interfacial bond strength and energy dissipation capacity of steel and steel fibre reinforced concrete (SSFRC) structures. Eng. Struct. 2021, 235, 112094. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, H.; Shi, N.; Chen, F.; Xu, J. Analysis of the bond behavior difference in steel and steel fiber reinforced concrete (SSFRC) composite member with circular section. Constr. Build. Mater. 2020, 264, 120142. [Google Scholar] [CrossRef]

- Prakash, A.; Srinivasan, S.M.; Rama, M.R.A. Application of steel fibre reinforced cementitious composites in high velocity impact resistance. Mater. Struct. 2017, 50, 6. [Google Scholar] [CrossRef]

- Paultre, P.; Eid, R.; Langlois, Y.; Levesque, Y. Behavior of steel fiber-reinforced highstrength concrete columns under uniaxial compression. J. Struct. Eng. 2010, 136, 1225–1235. [Google Scholar] [CrossRef]

- Wu, K.; Chen, F.; Chen, C.; Zheng, H.; Xu, J. Analysis of the Bearing and Damage Mechanism in Steel-Steel Fiber-Reinforced Concrete-Composite Member. J. Mater. Civ. Eng. 2020, 32, 04020274. [Google Scholar] [CrossRef]

- Li, V.C. From Micromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. Proc. Jpn. Soc. Civ. Eng. 1992, 10, 37–48. [Google Scholar]

- Wang, S.; Li, V.C. High early strength engineered cementitious composites. ACI Mater. J. 2006, 103, 97–105. [Google Scholar]

- Li, V.C. Interface Tailoring for Strain-hardening PVA-ECC. ACI Mater. J. 2011, 99, 463–472. [Google Scholar]

- Li, L.Z.; Cai, Z.W.; Yu, K.Q.; Zhang, Y.X.; Yao, Q. Performance-based design of all-grade strain hardening cementitious composites with compressive strengths from 40 MPa to 120 MPa. Cem. Concr. Comp. 2019, 97, 202–217. [Google Scholar] [CrossRef]

- Lu, C.; Yuan, Z.; Yang, C.; Hou, D.; Yao, Y. Tensile properties of PVA and PE fiber reinforced engineered cementitious composites containing coarse silica sand. J. Build. Eng. 2023, 75, 106913. [Google Scholar] [CrossRef]

- Kabir, M.I.; Lee, C.K.; Rana, M.M.; Zhang, Y.X. Flexural and bond-slip behaviours of engineered cementitious composites encased steel composite beams. J. Constr. Steel Res. 2019, 157, 229–244. [Google Scholar] [CrossRef]

- Fan, J.; Gou, S.; Ding, R.; Zhang, J.; Shi, Z. Experimental and analytical research on the flexural behaviour of steel-ECC composite beams under negative bending moments. Eng. Struct. 2020, 210, 110309. [Google Scholar] [CrossRef]

- Yan, Y.; Liang, H.; Lu, Y.; Huang, Y. Behaviour of concrete-filled steel-tube columns strengthened with high-strength CFRP textile grid-reinforced high-ductility engineered cementitious composites. Constr. Build. Mater. 2021, 269, 121283. [Google Scholar] [CrossRef]

- Rana, M.M.; Lee, C.K.; Al-Deen, S.; Zhang, Y.X. Flexural behaviour of steel composite beams encased by engineered cementitious composites. J. Constr. Steel Res. 2018, 143, 279–290. [Google Scholar] [CrossRef]

- Hung, C.C.; Chen, Y.S. Innovative ECC jacketing for retrofitting shear-deficient RC members. Constr. Build. Mater. 2016, 111, 408–418. [Google Scholar] [CrossRef]

- Deng, M.K.; Zhang, Y.X. Cyclic loading tests of RC columns strengthened with high ductile fiber reinforced concrete jacket. Constr. Build. Mater. 2017, 153, 986–995. [Google Scholar] [CrossRef]

- Parra-Montesinos, G.J.P.; Peterfreund, S.W.; Chao, S.H. Highly damage-tolerant beam-column joints through use of high-performance fiber-reinforced cement composites. ACI Struct. J. 2005, 102, 487–495. [Google Scholar]

- Fischer, G.; Li, V.C. Deformation Behavior of Fiber-Reinforced Polymer Reinforced Engineered Cementitious Composite (ECC) Flexural Members under Reversed Cyclic Loading Conditions. ACI Struct. J. 2003, 100, 25–35. [Google Scholar]

- Pan, J.J.; Deng, M.K.; Sun, H.Z. Bond behavior of plain round bar embedded in high ductile concrete under monotonic and cyclic loading. Struct. Concr. 2021, 22, 3446–3460. [Google Scholar] [CrossRef]

- Feldman, L.R.; Bartlett, F.M. Bond strength variability in pullout specimens with plain reinforcement. ACI Struct. J. 2005, 102, 860–867. [Google Scholar]

- Chao, S.H.; Naaman, A.E.; Parra-Montesinos, G.J. Bond Behavior of Reinforcing Bars in Tensile Strain-Hardening Fiber-Reinforced Cement Composites. ACI Struct. J. 2009, 106, 897–906. [Google Scholar]

- Toshiyuki, K.; Hiroshi, H. Bond-Splitting Strength of Reinforced Strain-Hardening Cement Composite Elements with Small Bar Spacing. ACI Struct. J. 2015, 112, 189–198. [Google Scholar]

- Choi, W.C.; Jang, S.J.; Yun, H.D. Bond and cracking behavior of lap-spliced reinforcing bars embedded in hybrid fiber reinforced strain-hardening cementitious composite (SHCC). Compos. Part B-Eng. 2017, 108, 35–44. [Google Scholar] [CrossRef]

- Lee, S.W.; Kang, S.B.; Tan, K.H.; Yang, E.H. Experimental and analytical investigation on bond-slip behaviour of deformed bars embedded in engineered cementitious composites. Constr. Build. Mater. 2016, 127, 494–503. [Google Scholar] [CrossRef]

- Bai, L.; Yu, J.; Zhang, M.; Zhou, T. Experimental study on the bond behavior between H-shaped steel and engineered cementitious composites. Constr. Build. Mater. 2019, 196, 214–232. [Google Scholar] [CrossRef]

- Tian, L.M.; Kou, Y.F.; Lin, H.L.; Li, T.J. Interfacial bond-slip behavior between H-shaped steel and engineered cementitious composites (ECCs). Eng. Struct. 2021, 231, 111731. [Google Scholar] [CrossRef]

- Deng, M.K.; Pan, J.J.; Sun, H.Z. Bond behavior of steel bar embedded in Engineered Cementitious Composites under pullout load. Constr. Build. Mater. 2018, 168, 705–714. [Google Scholar] [CrossRef]

| Fiber Type | Length /mm | Diameter /μm | Tensile Strength /MPa | Elastic Modulus /GPa | Density /g·cm−3 |

|---|---|---|---|---|---|

| PE | 12 | 43 | 1900 | 39 | 1.3 |

| Mixture | Binder | Water Binder Ratio | Sand Binder Ratio | PE Fibers | fcu (MPa) | ft (MPa) | εtu | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Mineral Powder | Silica Fume | |||||||

| E1–1.5 | 50% | 50% | - | - | 0.29 | 0.36 | 1.5% | 55.4 | 5.1 | 3.2% |

| E2–1.5 | 55% | 20% | 20% | 5% | 0.24 | 0.36 | 1.5% | 73.2 | 6.9 | 2.8% |

| E1–0.5 | 50% | 50% | - | - | 0.29 | 0.36 | 0.5% | 56.3 | 5.2 | 0.6% |

| E1–1.0 | 50% | 50% | - | - | 0.29 | 0.36 | 1.0% | 55.9 | 5.1 | 1.8% |

| Steel | Location | Yield Strength /MPa | Ultimate Strength /MPa | Specific Elongation /% |

|---|---|---|---|---|

| Shaped steel | Web | 275.56 | 409.26 | 36 |

| Flange | 298.87 | 437.59 | 34 |

| Specimen | Mixture | Vf (%) | Css (mm) | la (mm) | b (mm) |

|---|---|---|---|---|---|

| S1 | E1–1.5 | 1.5 | 50 | 400 | 200 |

| S2 | E2–1.5 | 1.5 | 50 | 400 | 200 |

| F1 | E1–0.5 | 0.5 | 50 | 400 | 200 |

| F2 | E1–1.0 | 1.0 | 50 | 400 | 200 |

| C1 | E1–1.5 | 1.5 | 30 | 400 | 160 |

| C2 | E1–1.5 | 1.5 | 40 | 400 | 180 |

| C3 | E1–1.5 | 1.5 | 60 | 400 | 220 |

| L1 | E1–1.5 | 1.5 | 50 | 300 | 200 |

| L2 | E1–1.5 | 1.5 | 50 | 500 | 200 |

| L3 | E1–1.5 | 1.5 | 50 | 600 | 200 |

| CC1 | N1 | – | 50 | 400 | 200 |

| Specimen | Ps/kN | Pu/kN | Pr/kN | τs/MPa | τu/MPa | τr/MPa | Number of Cracks | Failure Mode | Calculated Value/MPa | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tip of Flange | Middle of Flange | τs | τu | τr | ||||||||

| S1 | 92.12 | 300.45 | 202.77 | 0.39 | 1.29 | 0.87 | 0 | 1 | Bond | 0.35 | 1.13 | 0.76 |

| S2 | 107.66 | 331.59 | 228.28 | 0.46 | 1.42 | 0.98 | 0 | 2 | Bond | 0.43 | 1.40 | 0.94 |

| F1 | 68.51 | 215.24 | 135.62 | 0.29 | 0.92 | 0.58 | 3 | 2 | Splitting-bond | 0.33 | 0.97 | 0.64 |

| F2 | 77.98 | 274.22 | 191.62 | 0.33 | 1.17 | 0.82 | 4 | 2 | Splitting-bond | 0.34 | 1.05 | 0.70 |

| C1 | 57.98 | 182.55 | 125.62 | 0.25 | 0.78 | 0.54 | 1 | 1 | Bond | 0.24 | 0.82 | 0.57 |

| C2 | 77.15 | 266.02 | 165.57 | 0.33 | 1.14 | 0.71 | 0 | 1 | Bond | 0.29 | 0.98 | 0.67 |

| C3 | 85.64 | 293.69 | 186.62 | 0.37 | 1.26 | 0.80 | 1 | 1 | Splitting-bond | 0.35 | 1.13 | 0.76 |

| L1 | 60.27 | 188.79 | 127.04 | 0.34 | 1.08 | 0.73 | 1 | 1 | Splitting-bond | 0.35 | 1.14 | 0.77 |

| L2 | 103.81 | 336.35 | 217.69 | 0.36 | 1.15 | 0.75 | 3 | 1 | Bond | 0.35 | 1.13 | 0.75 |

| L3 | 130.23 | 406.77 | 263.03 | 0.37 | 1.16 | 0.75 | 2 | 2 | Bond | 0.35 | 1.13 | 0.75 |

| CC1 | 72.65 | 234.69 | 171.34 | 0.31 | 1.00 | 0.73 | 0 | 2 | Splitting | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, J.; Huang, Z.; Lu, T.; Deng, M. Bond Behavior and Failure Mechanisms of the Interface between Engineered Cementitious Composites and Shaped Steel. Buildings 2024, 14, 2233. https://doi.org/10.3390/buildings14072233

Pan J, Huang Z, Lu T, Deng M. Bond Behavior and Failure Mechanisms of the Interface between Engineered Cementitious Composites and Shaped Steel. Buildings. 2024; 14(7):2233. https://doi.org/10.3390/buildings14072233

Chicago/Turabian StylePan, Jiaojiao, Zhenbin Huang, Tingting Lu, and Mingke Deng. 2024. "Bond Behavior and Failure Mechanisms of the Interface between Engineered Cementitious Composites and Shaped Steel" Buildings 14, no. 7: 2233. https://doi.org/10.3390/buildings14072233

APA StylePan, J., Huang, Z., Lu, T., & Deng, M. (2024). Bond Behavior and Failure Mechanisms of the Interface between Engineered Cementitious Composites and Shaped Steel. Buildings, 14(7), 2233. https://doi.org/10.3390/buildings14072233