Seismic Response and Collapse Analysis of a Transmission Tower Structure: Assessing the Impact of the Damage Accumulation Effect

Abstract

:1. Introduction

2. Methodology

2.1. Mixed Hardening Elastic–Plastic Constitutive Modeling

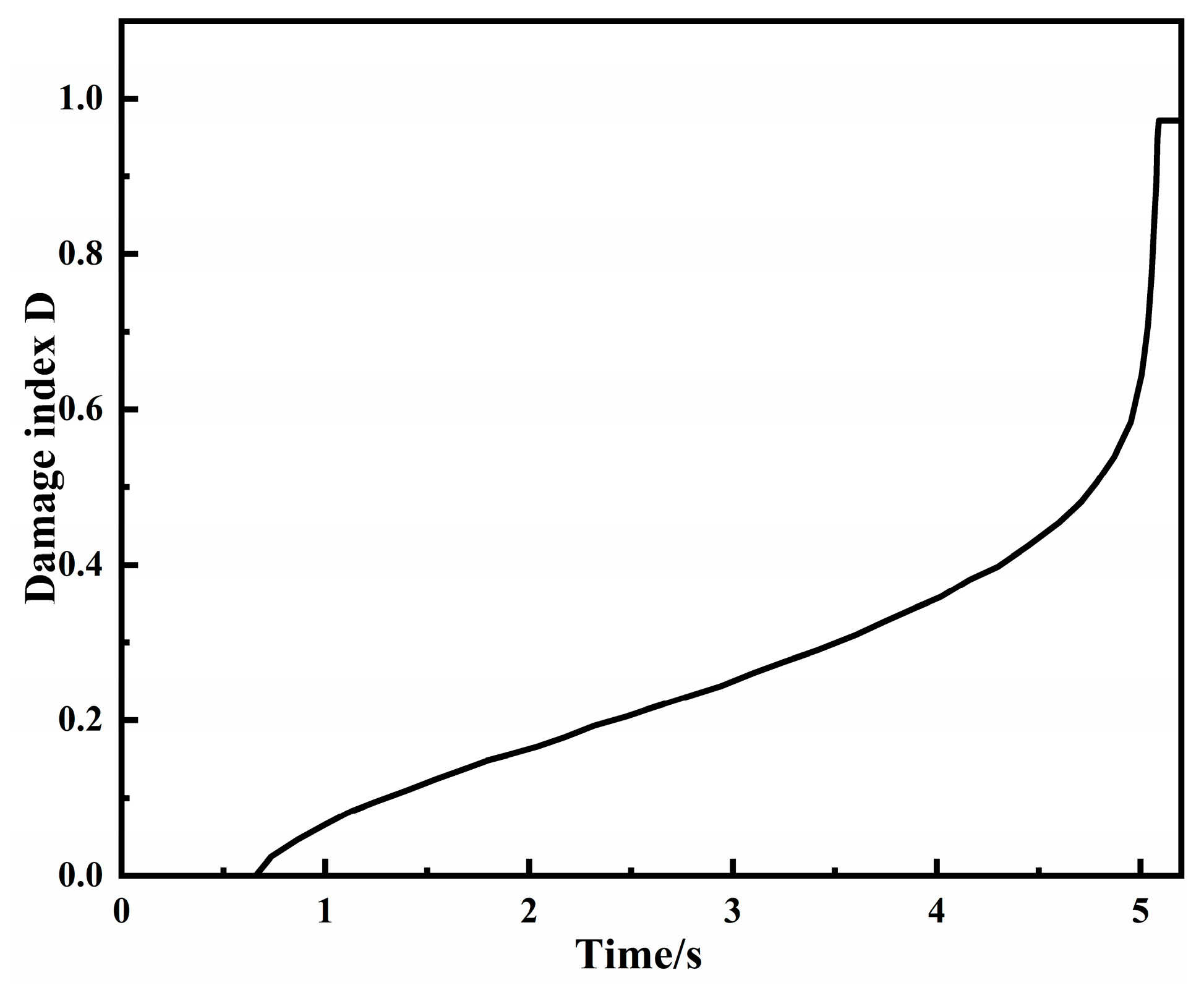

2.2. Damage Evolution

2.3. Definition of the Segment Damage Index (SDI)

3. Numerical Implementation of the Constitutive Model

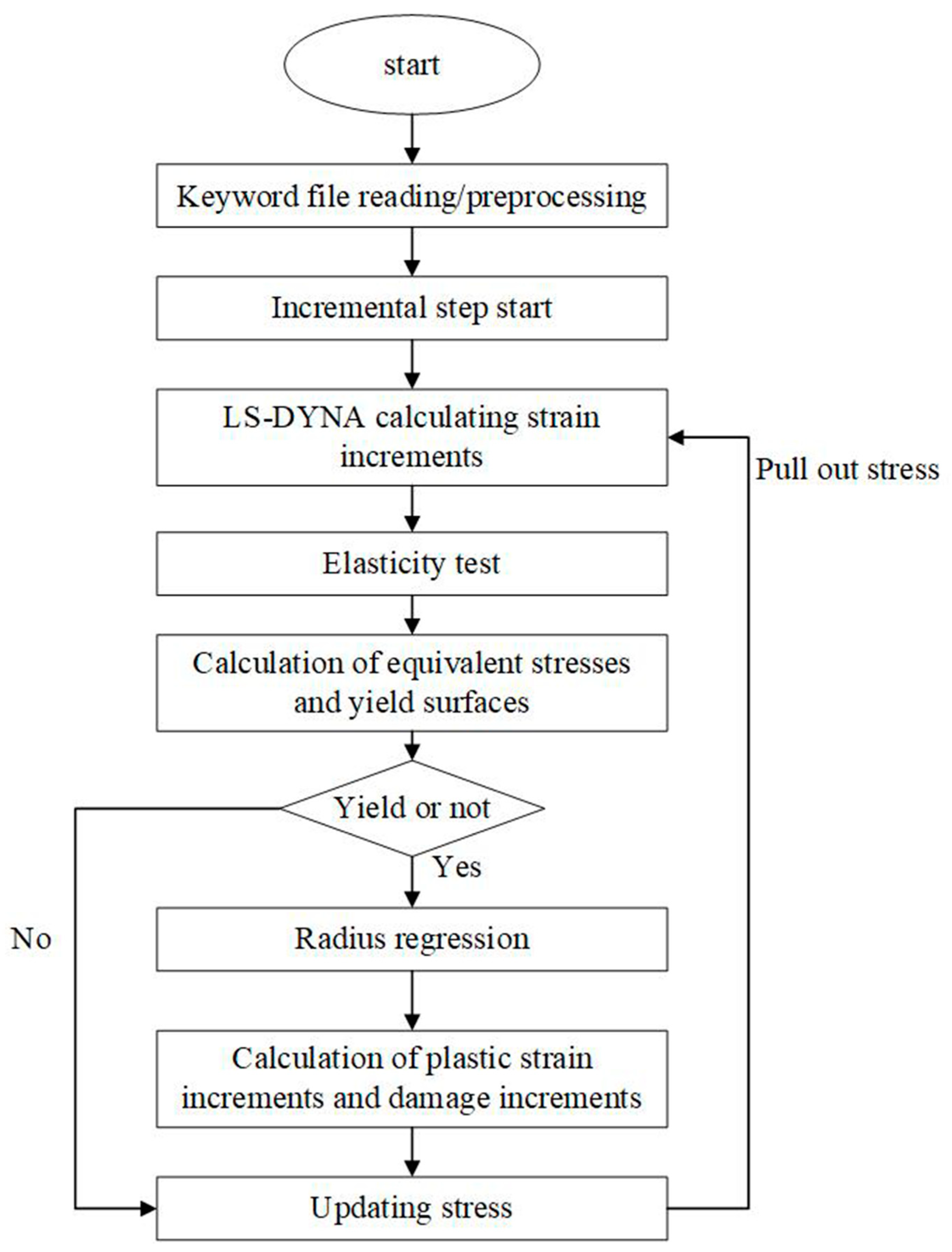

3.1. Stress–Updating Algorithm

3.2. Failure Strain Criterion

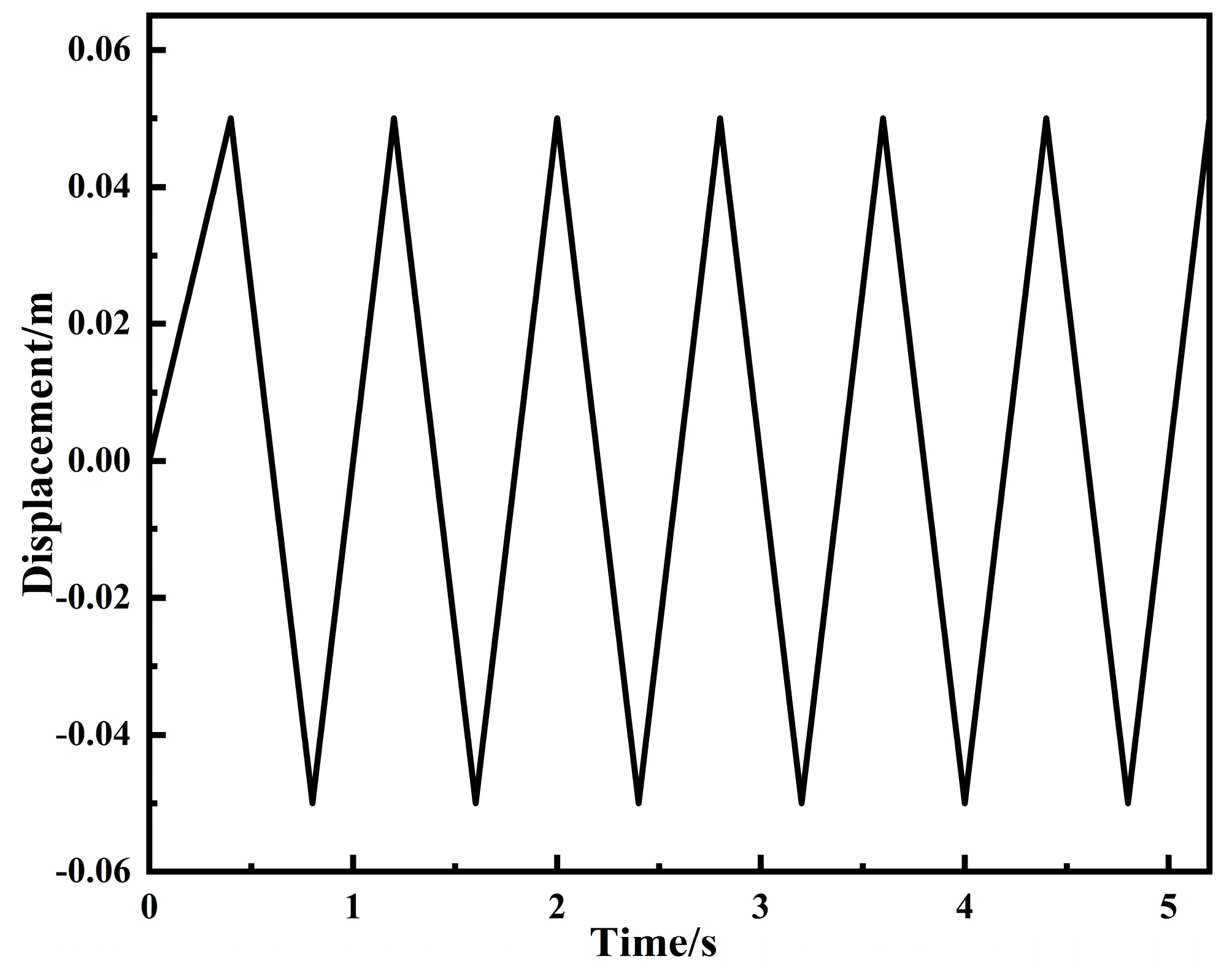

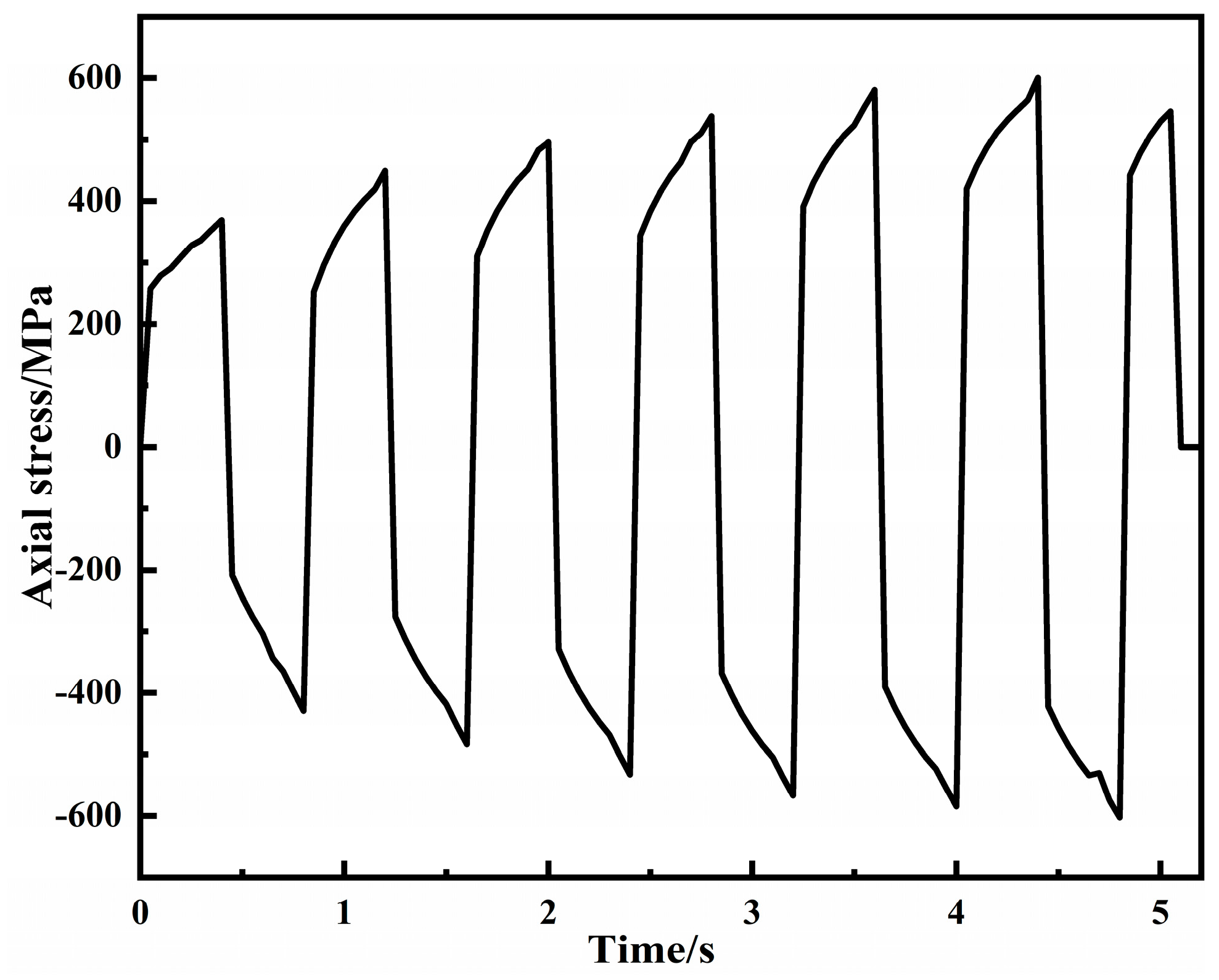

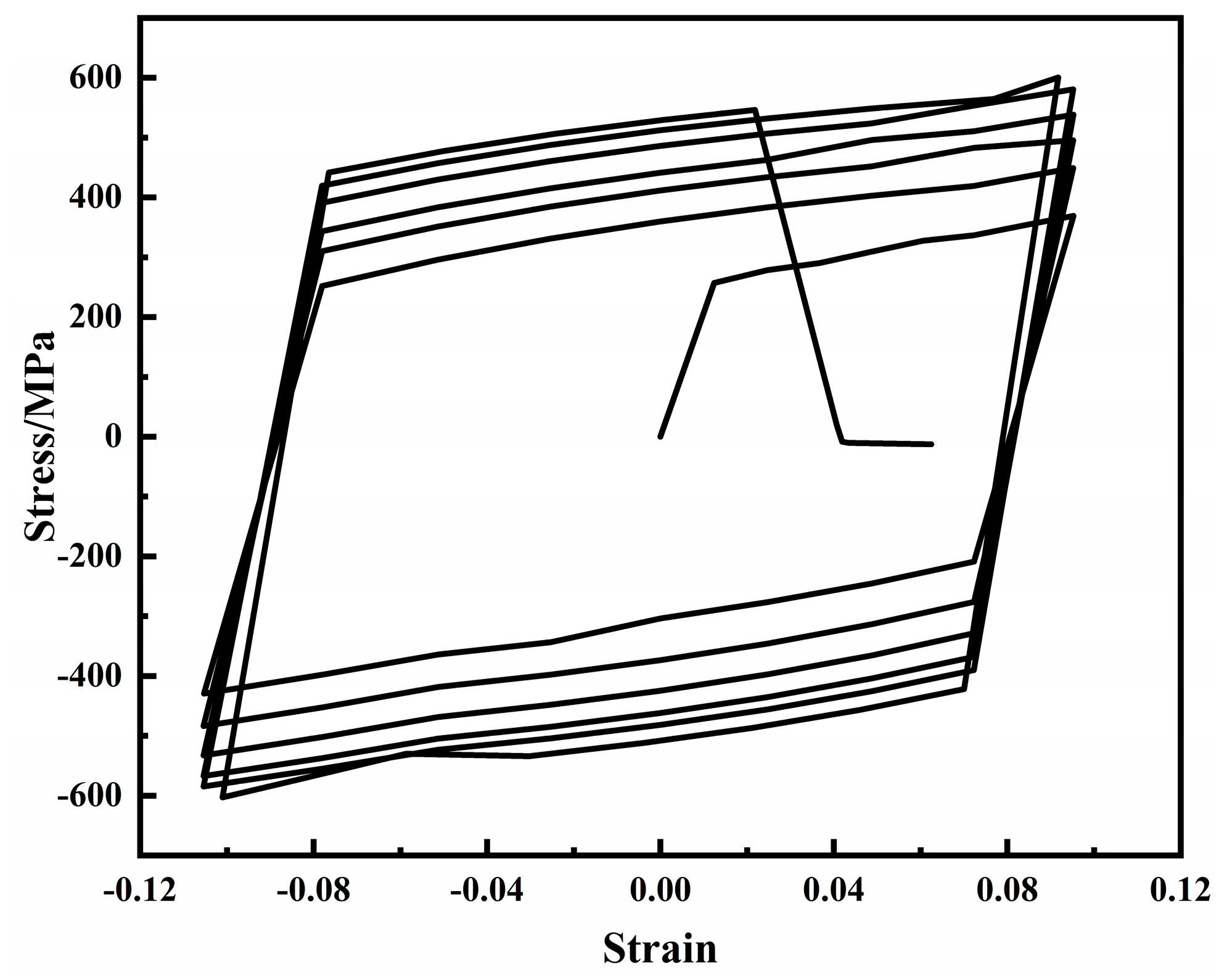

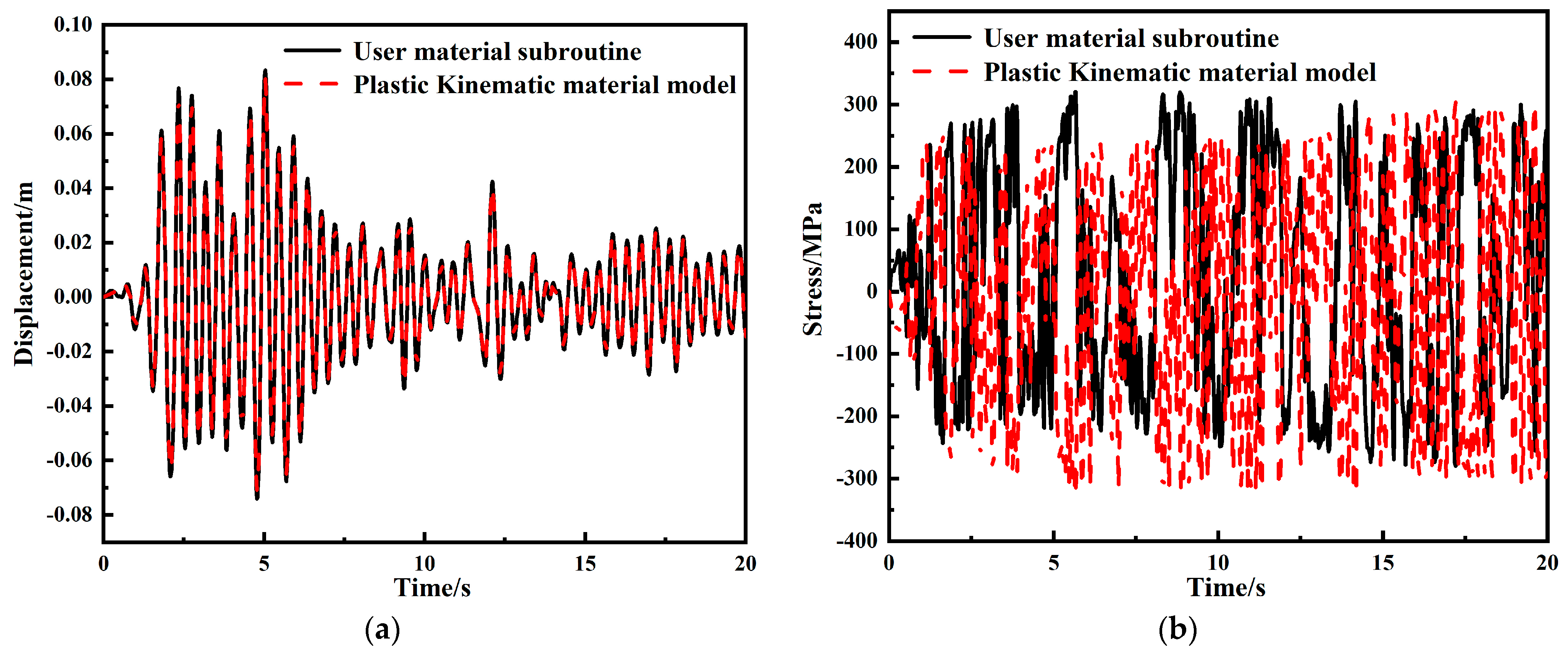

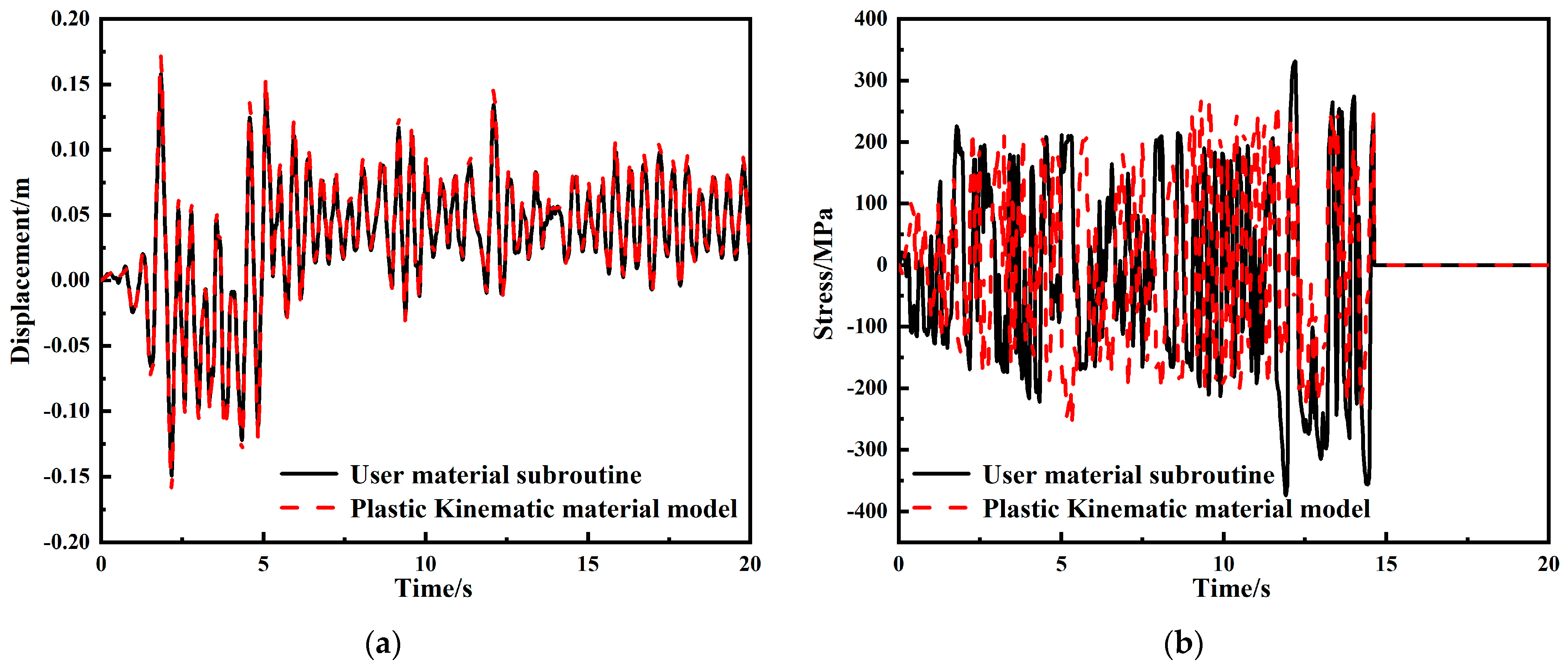

3.3. Subroutine Validation

3.4. Verification of Structural Examples

4. Simulation and Analysis of the Collapse of the Transmission Tower

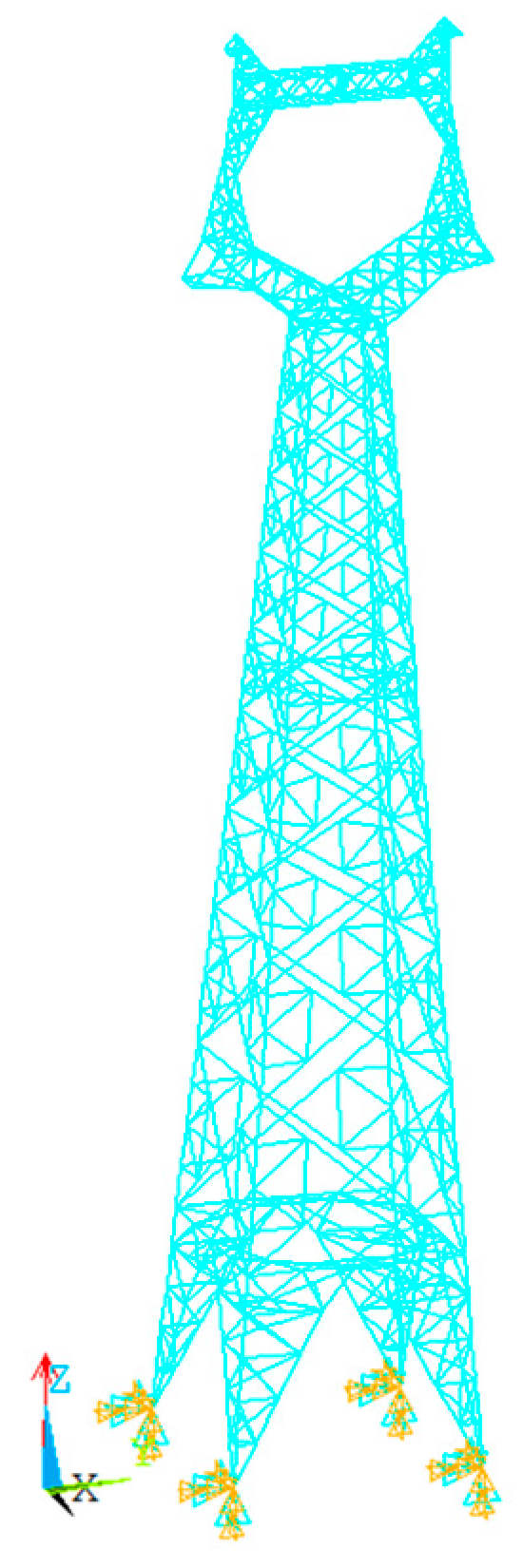

4.1. Establishment of a Computational Analysis Model

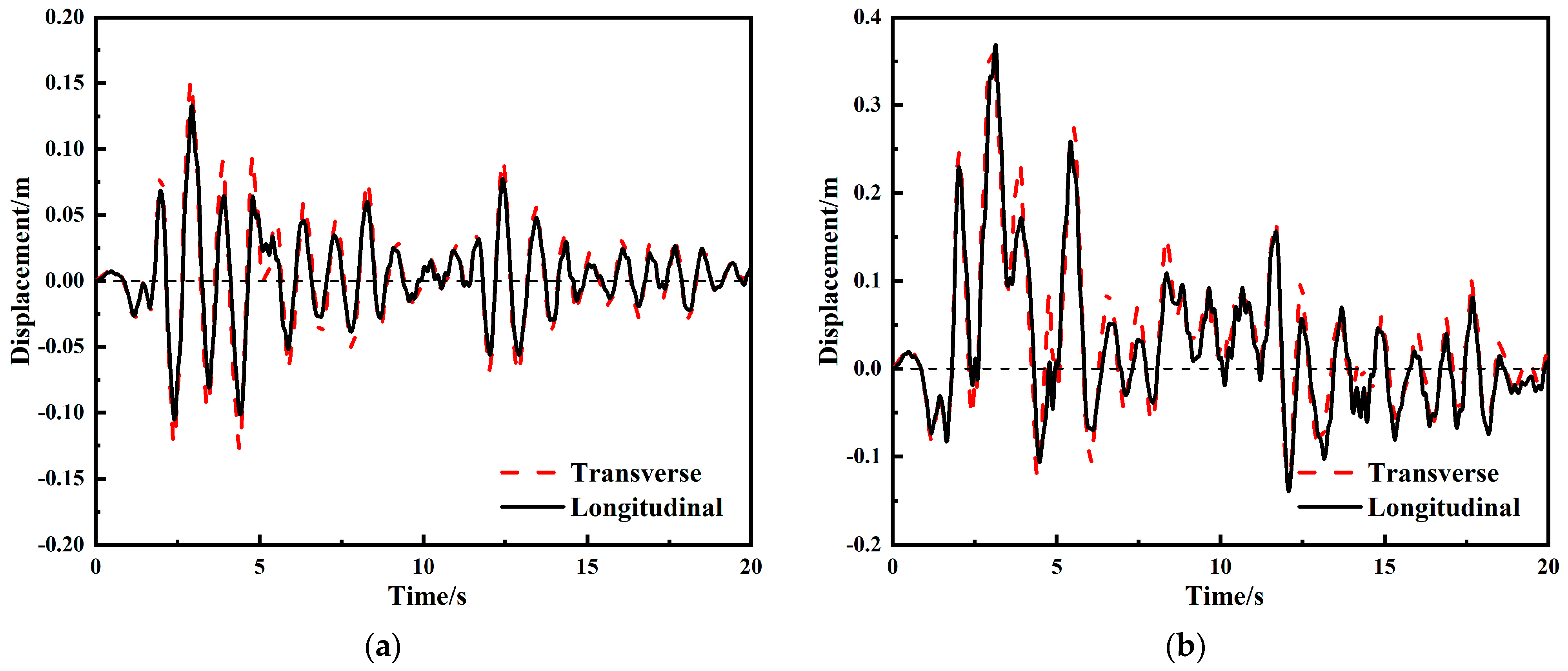

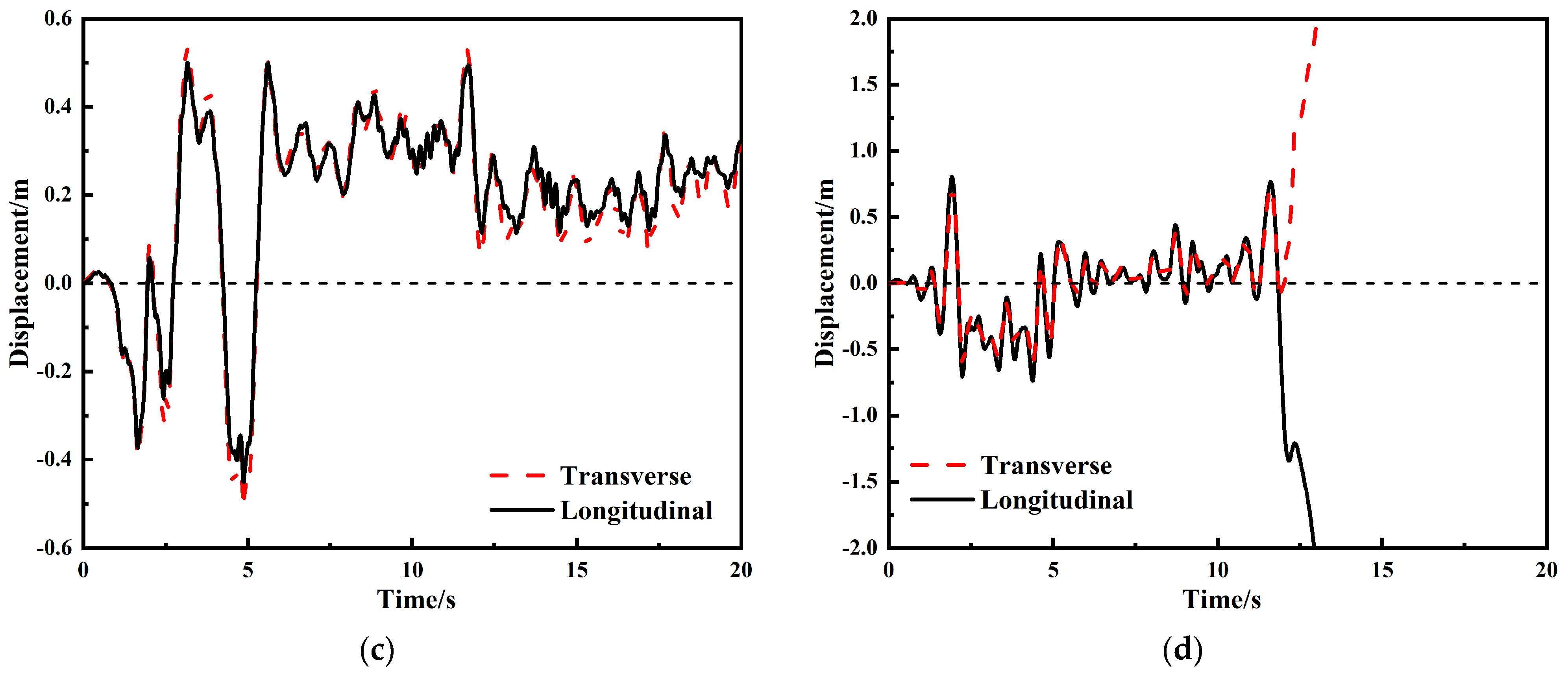

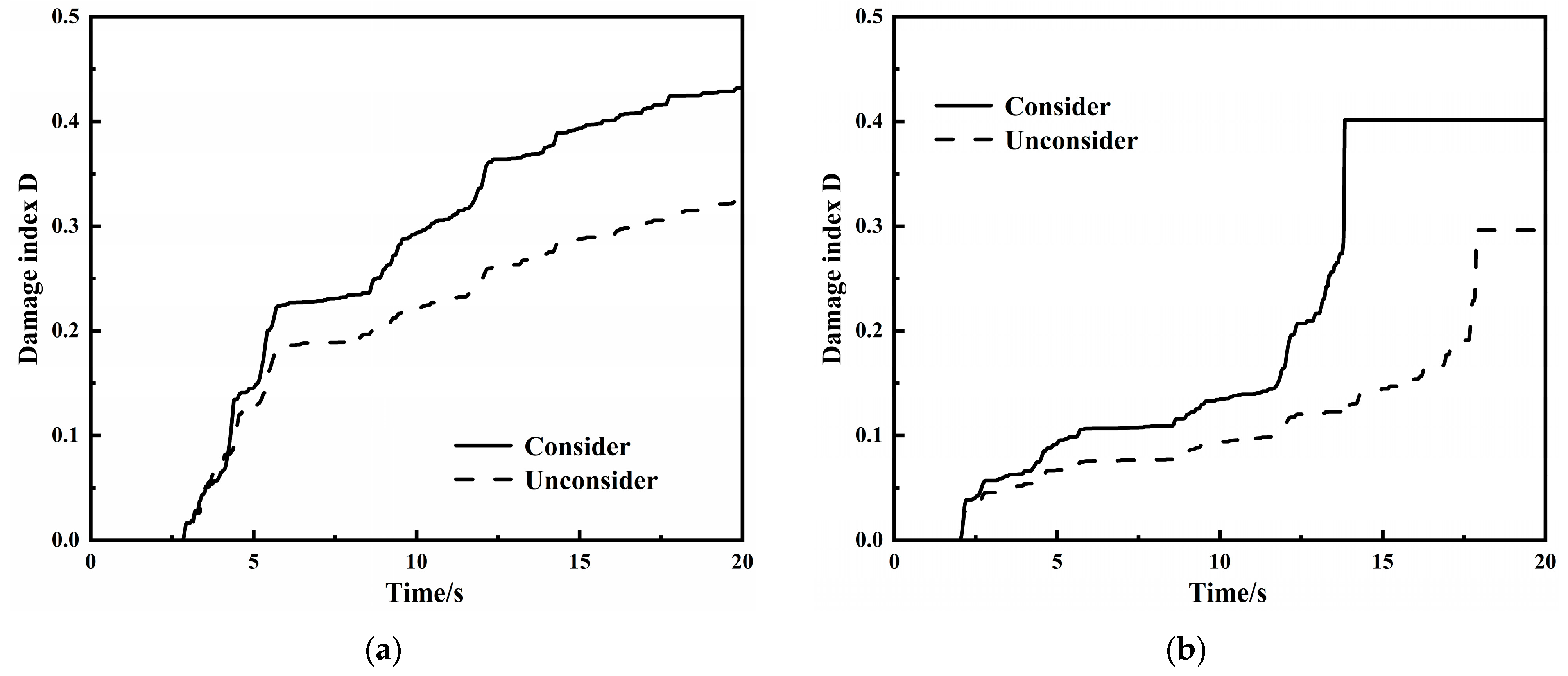

4.2. Dynamic Response Index Analysis

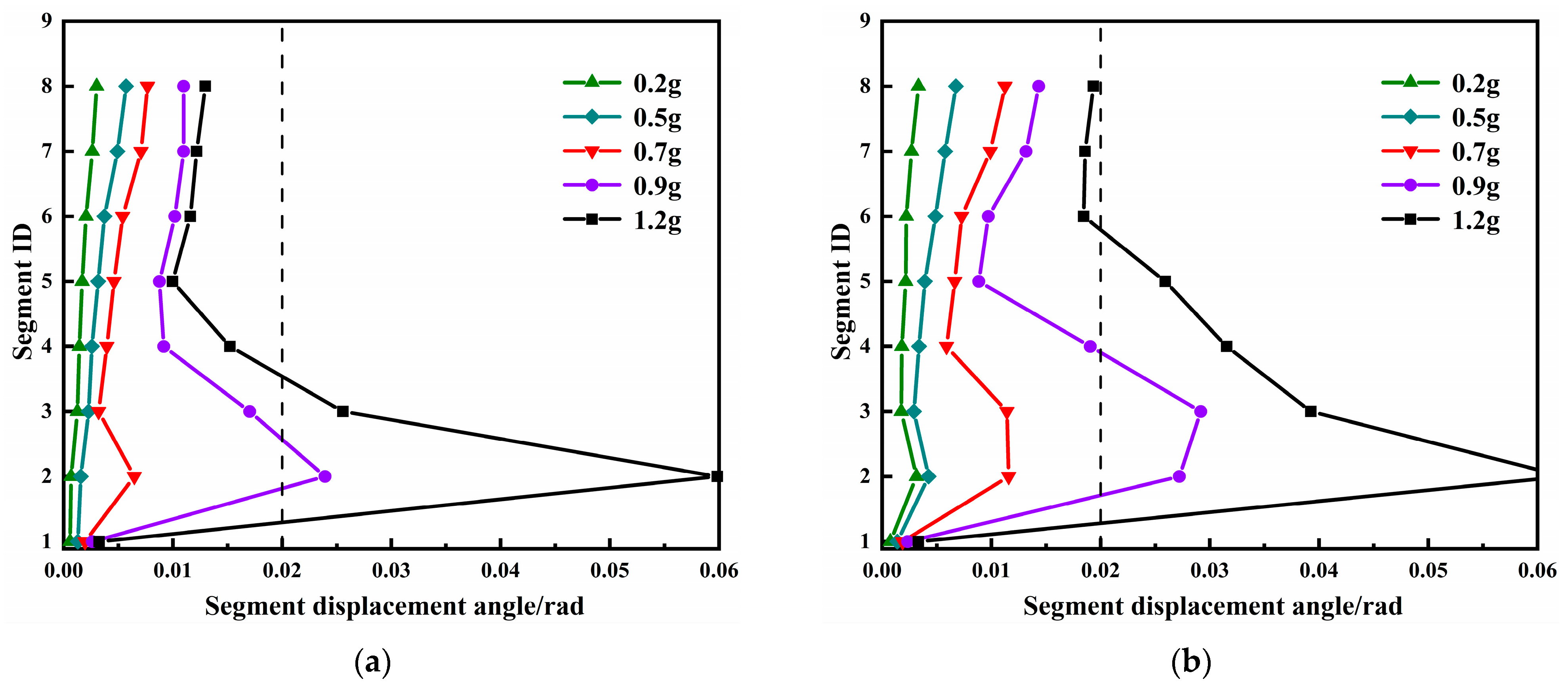

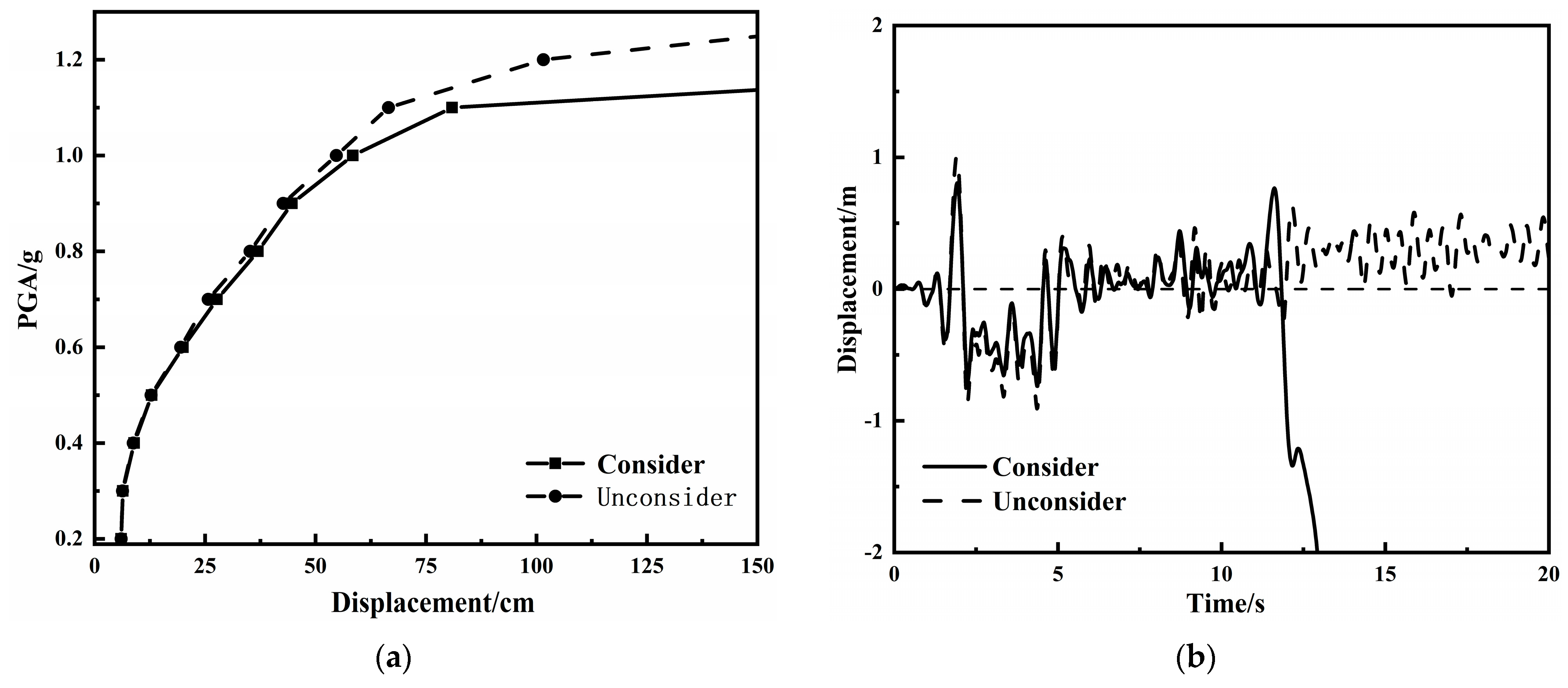

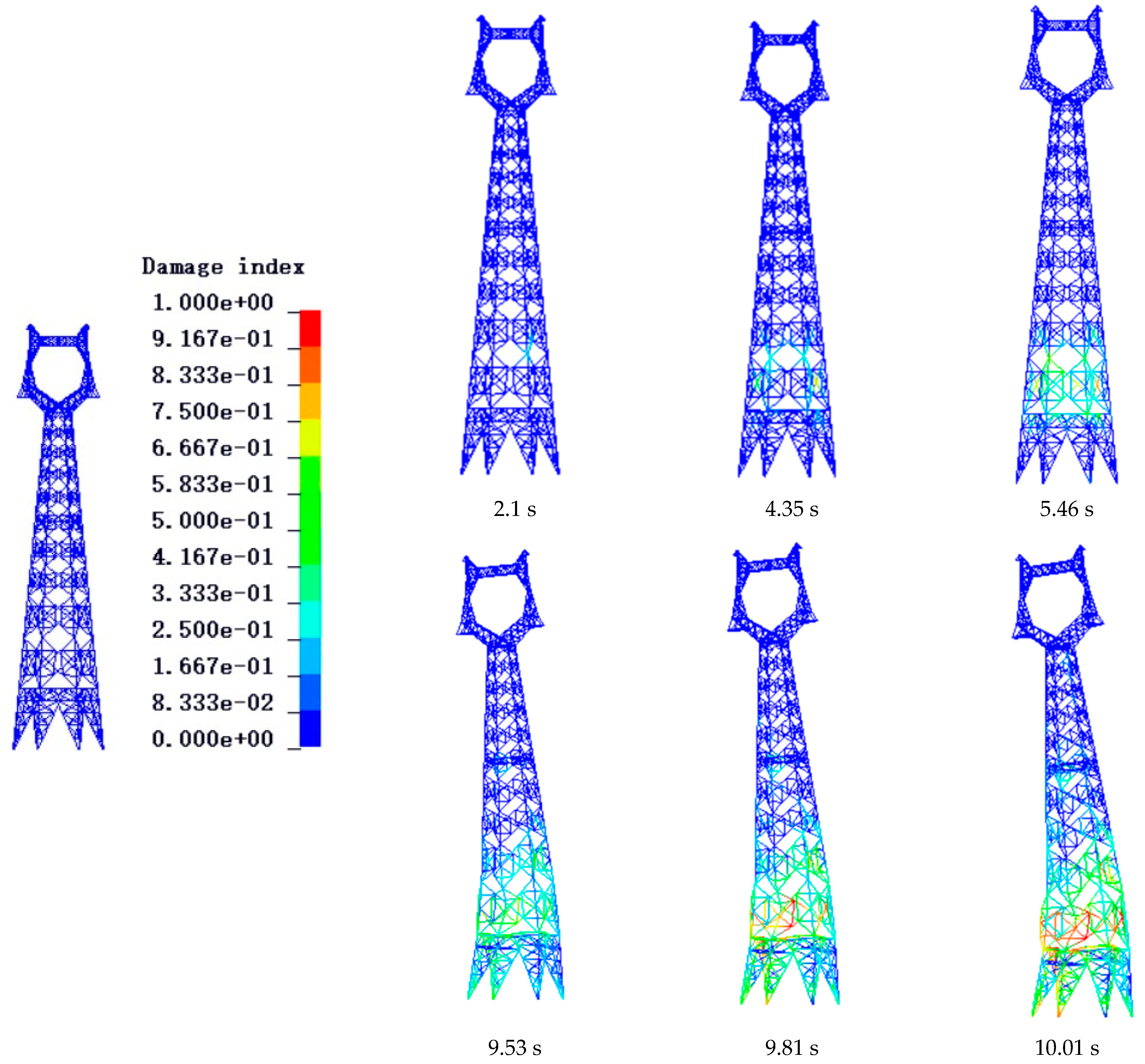

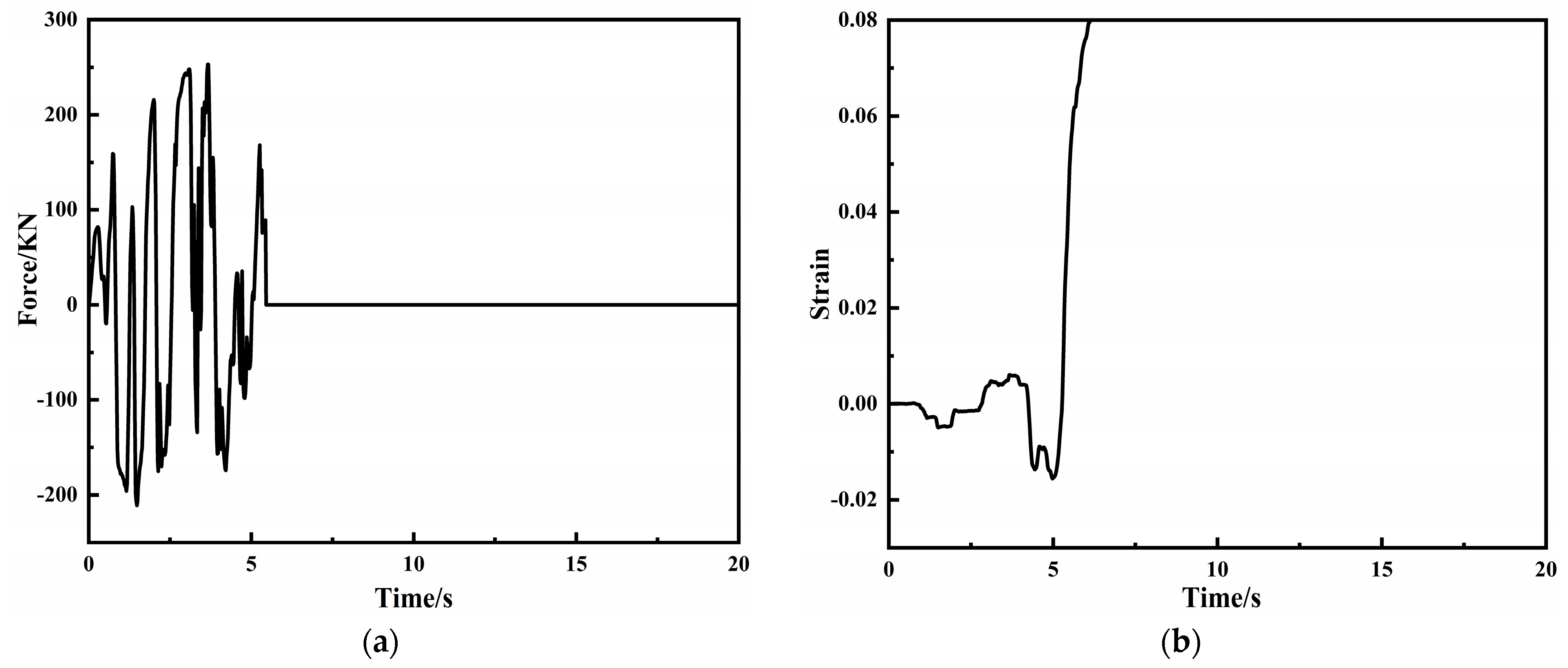

4.3. Mechanism of Transmission Tower Collapse Considering the Influence of the Cumulative Effect

4.4. Analysis of the Transmission Tower Collapse Mechanism

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alminhana, F.; Mason, M.; Albermani, F. A compact nonlinear dynamic analysis technique for transmission line cascades. Eng. Struct. 2018, 158, 164–174. [Google Scholar] [CrossRef]

- Albermani, F.; Kitipornchai, S.; Chan, R. Failure analysis of transmission towers. Eng. Fail. Anal. 2009, 16, 1922–1928. [Google Scholar] [CrossRef]

- Park, H.S.; Choi, B.H.; Kim, J.J.; Lee, T.H. Seismic performance evaluation of high voltage transmission towers in South Korea. Ksce. J. Civ. Eng. 2016, 20, 2499–2505. [Google Scholar] [CrossRef]

- Meek, J.L.; Lin, W.J. Geometric and material nonlinear analysis of thin-walled beam-columns. J. Struct. Eng. 1990, 116, 1473–1490. [Google Scholar] [CrossRef]

- Meek, J.L.; Loganathan, S. Geometric and material non-linear behaviour of beam-columns. Comput. Struct. 1990, 34, 87–100. [Google Scholar] [CrossRef]

- Rao, N.P.; Knight, G.M.S.; Mohan, S.J.; Lakshmanan, N. Studies on failure of transmission line towers in testing. Eng. Struct. 2012, 35, 55–70. [Google Scholar]

- Li, Q.W.; Li, H.N. Study on dynamic stability of transmission tower structures. J. Disa Prev. Mitig Eng. 2008, 28, 202–207. (In Chinese) [Google Scholar]

- Tian, L.; Ma, R.S.; Li, H.N.; Wang, Y. Progressive collapse of power transmission tower-line system under extremely strong earthquake excitations. Int. J. Struct. Stab. Dy. 2016, 16, 1550030. [Google Scholar] [CrossRef]

- Tian, L.; Pan, H.Y.; Ma, R.S.; Qiu, C.X. Collapse simulations of a long span transmission tower-line system subjected to near-fault ground motions. Earthq. Struct. 2017, 13, 211–220. [Google Scholar]

- Shin, M.; Kim, B. Effects of frequency contents of aftershock ground motions on reinforced concrete (RC) bridge columns. Soil. Dyn. Earthq. Eng. 2017, 97, 48–59. [Google Scholar] [CrossRef]

- Zhi, X.D.; Fan, F.; Shen, S.Z. Application of material damage cumulation in reticulated shells under severe earthquakes. J. Harbin. Inst. Tech. (in Chinese). 2008, 40, 169–173. [Google Scholar]

- Prager, W. A new method of analyzing stresses and strains in work-hardening plastic solids. J. Appl. Mech. 1956, 23, 493–496. [Google Scholar] [CrossRef]

- Axelsson, K.; Samuelsson, A. Finite element analysis of elastic–plastic materials displaying mixed hardening. Int. J. Numer. Meth. Eng. 1979, 14, 211–225. [Google Scholar] [CrossRef]

- Huang, K.Z.; Huang, Y.G. Solid-Constitutive Relations; Tsinghua University Press: Beijing, China, 1999; pp. 14–27. [Google Scholar]

- Chen, L.S.; Zhao, X.H. Theory of matter with elastic range and definition of backstress. Appl. Math. Mech. 1999, 50, 452–459. [Google Scholar]

- Bonora, N.; Gentile, D.; Pirondi, A.; Newaz, G. Ductile damage evolution under triaxial state of stress: Theory and experiments. Int. J. Plasticity. 2005, 21, 981–1007. [Google Scholar] [CrossRef]

- Li, Z.X.; Lu, Y.; Xu, L.H.; Ding, Y. Nonlinear seismic damage control of steel-concrete hybrid structure using MR dampers. China. Civ. Eng. J. 2013, 46, 38–45. (In Chinese) [Google Scholar]

- Shen, Z.Y.; Dong, B. An experiment-based cumulative damage mechanics moUdel of steel under cyclic loading. Adv. Struct. Eng. 1997, 1, 39–46. [Google Scholar] [CrossRef]

- Park, Y.J.; Ang, A.H.S. Mechanistic seismic damage model for reinforced concrete. J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Park, Y.J.; Ang, A.H.S.; Wen, Y.K. Seismic damage analysis of reinforced concrete buildings. J. Struct. Eng. 1985, 111, 740–757. [Google Scholar] [CrossRef]

- Ou, J.P.; Niu, D.T.; Wang, G.Y. Fuzzy dynamic reliability analysis and design of nonlinear seismic steel structures. J. Harbin Archit. 1991, 24, 9–20. [Google Scholar]

| Damage Degree | Basically Intact | Minor Damage | Medium Damage | Serious Damage | Collapse |

|---|---|---|---|---|---|

| Park [20] | – | 0~0.4 | – | 0.4~1.0 | ≥1.0 |

| Ou [21] | 0~0.1 | 0.1~0.25 | 0.25~0.45 | 0.45~0.65 | ≥0.9 |

| This paper | 0~0.2 | 0.2~0.4 | 0.4~0.6 | 0.6~0.8 | ≥0.8 |

| /MPa | /MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 248 | 0.3 | 0.75 | 0.2 | 1.0 | 0.1 | 0 | 0.19 | 0.5 |

| Defense Intensity | Seismic Subgroup | Site Type | Seismic Grade | Importance Factor |

|---|---|---|---|---|

| 8 (0.2 g) | Group II | Type II | Grade 2 | 1.0 |

| PGA | 0.2 g | 0.5 g | 0.7 g | 0.9 g | 1.2 g |

|---|---|---|---|---|---|

| SDI | 0 | 0.24486 | 0.52634 | 0.72615 | 0.82147 |

| Transverse | 0.00302 | 0.00572 | 0.00767 | 0.02393 | 0.05985 |

| Longitudinal | 0.00332 | 0.00676 | 0.01124 | 0.02918 | 0.06244 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, P.; Liu, H.; Wang, Y.; Han, S. Seismic Response and Collapse Analysis of a Transmission Tower Structure: Assessing the Impact of the Damage Accumulation Effect. Buildings 2024, 14, 2243. https://doi.org/10.3390/buildings14072243

Nie P, Liu H, Wang Y, Han S. Seismic Response and Collapse Analysis of a Transmission Tower Structure: Assessing the Impact of the Damage Accumulation Effect. Buildings. 2024; 14(7):2243. https://doi.org/10.3390/buildings14072243

Chicago/Turabian StyleNie, Pingping, Haiqing Liu, Yunlong Wang, and Siyu Han. 2024. "Seismic Response and Collapse Analysis of a Transmission Tower Structure: Assessing the Impact of the Damage Accumulation Effect" Buildings 14, no. 7: 2243. https://doi.org/10.3390/buildings14072243