1. Introduction

With the rapid development of the construction industry, the problems of productivity and costs caused by the aging of the labor force are gradually highlighted. Due to the challenges and transformation demands in the current industry, the research and application of construction robots are particularly urgent and important. Moreover, the construction robot can effectively solve the supply–demand contradiction and problems of construction safety because of their excellent automation efficiency and reliable protection mechanism, which are driving the construction industry to a new stage of high efficiency, safety and intelligence [

1]. Currently, the application of construction robot technology in the world has profoundly changed the construction industry. Examples of these applications include the prefabricated house manufacturing robot of Randek in Sweden, the elevator installation robot of Schindler in Switzerland, the autonomous rebar strapping robot of Advanced Construction Robotics in the USA, etc.

In the construction industry, the continuous growth of global steel production has promoted the wide application of steel structures, and large-scale steel structure construction has led to numerous complex and strict technical requirements for welding operations. However, traditional manual welding faces the problems of modern welding, which makes it urgent to develop a welding robot to achieve high-efficiency, automatic welding operation, thereby promoting the modernization process of the industry [

2,

3,

4,

5]. Additionally, in the welding process, the traditional, manual, or semi-automatic welding method is often accompanied by high energy consumption and exhaust emissions such as welding fumes, harmful gases, etc., which pose a threat to the environment and workers’ health. The welding robot can significantly reduce energy consumption and reduce welding spatter and harmful gas emissions by accurately controlling welding parameters, optimizing welding paths, and adopting advanced welding processes. The welding robot can also achieve efficient and stable welding operations and reduce material waste and repeated processing caused by improper human operation, thereby reducing the negative impact on the environment at the source. Currently, the welding robot of ABB in Switzerland is utilized in welding operations for modular housing construction, which increases productivity by 15% and speed by 38%; in addition, it reduces waste by 30%. The welding robot of RoboticPlus play a significant role in indoor steel structure processing and improves the production efficiency of light workpieces by more than 10% and heavy workpieces by more than 33%. The welding robot of Jinggong Steel Building participated in on-site welding construction of the Nest-type Beijing Olympic Stadium. The ARCMANTM welding robot is suitable for complete joint penetration welding techniques, which demonstrates its broad adaptability in steel plate welding. The fully automatic welding of the welding robot improves production efficiency by 30%.

Although welding robots shows enormous application potential in the construction industry, their efficient and high-quality operation in complex and variable environments still faces multiple technical difficulties. Firstly, in the construction environment, due to the limitation of light conditions during the all-weather continuous operation and the interference of smoke and splashes, welding robots experience the technical bottlenecks of identification and tracking of weld seams under the harsh construction environment. Then, in the construction space, due to the influence of structures and shapes, welding robots faces the technical bottleneck of path planning under a variable construction structure. Next, in construction quality, due to unstable welding quality under the influences of the environment, structure, and weld seams, welding robots faces the technical bottleneck of weld quality control under the complex construction conditions. Despite numerous studies aimed at improving the application efficiency of welding robots in the construction industry, the existing literature still falls short in terms of the adaptability of weld seam tracking, the flexibility of trajectory planning, and the stability of quality control. As such, a comprehensive analysis of the latest research advancements in these areas, coupled with an exploration of their future development trends, holds crucial significance for advancing the widespread adoption of welding robots in the construction sector. The investigations of intelligent welding robots are systematically reviewed in this paper according to the above technical difficulties. The future trend of welding robot application in the construction industry is deeply analyzed, which provides a useful reference for subsequent research.

2. Bibliometric Analysis

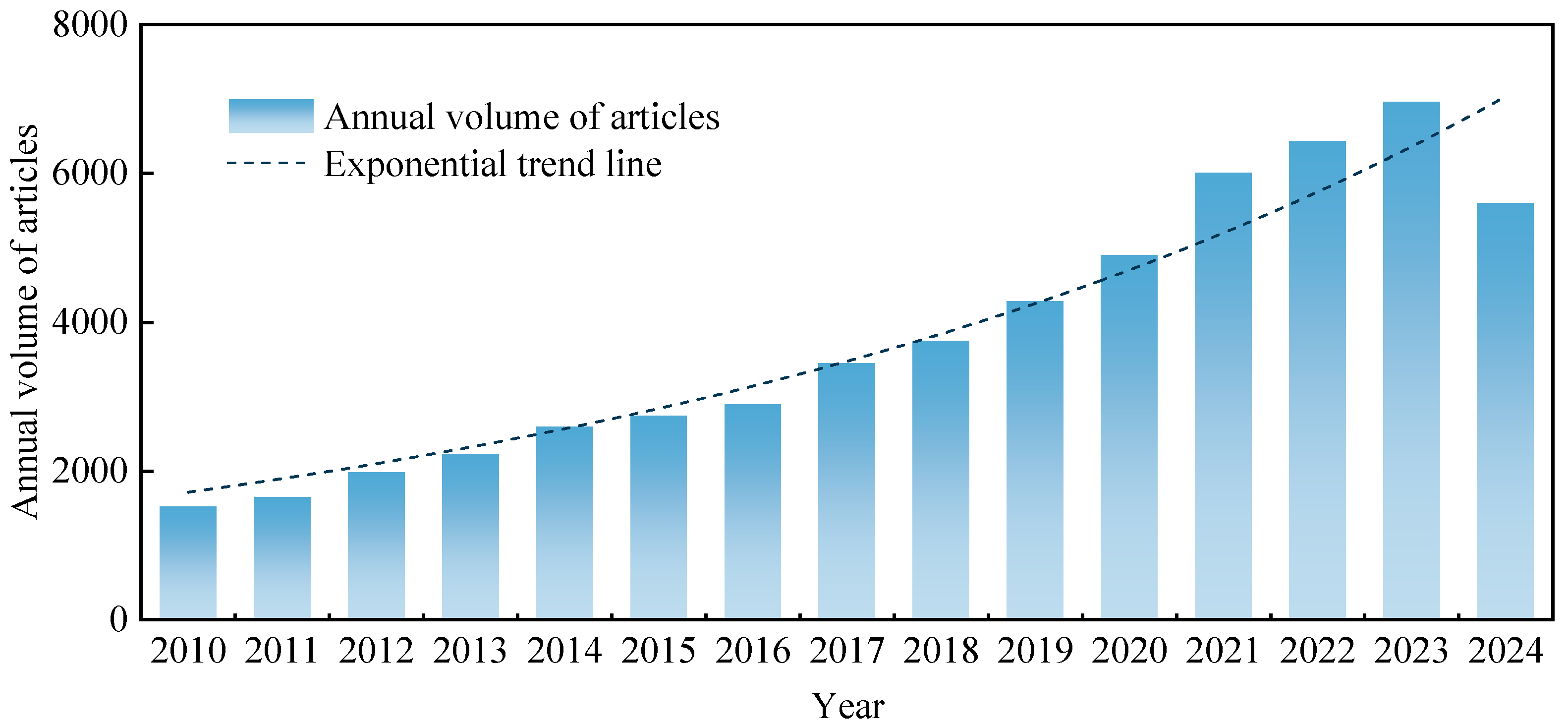

The bibliometric data are derived from the ELSEVIER database by precisely targeting keywords such as “welding robot”, “weld seam tracking”, “weld trajectory planning”, and “weld quality control”. Published articles in the past 15 years, from 2010 to 2024, were searched in depth, covering various types of research papers, publicly published books, meeting minutes, and news reports.

Figure 1 intuitively shows the number of articles published each year during this period and clearly reflects the change in research activity in this field. The data in the figure reveal that the number of 1518 papers published since 2010 has shown a significant exponential growth trend. By 2017, the annual publication volume had exceeded 3000 and continued to rise, exceeding 6000 by 2021. This series of data not only highlight the increasing research interest of researchers in this field but also indicate the broad development prospects and unlimited potential in the field of welding robot technology.

3. The Weld Seam Tracking Technology of Welding Robots

In steel structure, bridge, and building construction, the weld seam tracking ability of welding robots is crucial for the weld quality. On one hand, strict construction period pressure requires all-weather welding by welding robots. In order to ensure the continuity of the welding work and the high efficiency of the construction, the welding robot must have the ability to accurately identify and stably track the welding seam in limited light conditions or even in a dark environment. On the other hand, the welding process generates a large amount of smoke and high temperature splashes, which not only pose a threat to the health of the operator but also constitute a serious disturbance to the visual system of the welding robot. The above factors may cause the loss or misjudgment of the weld characteristics, thus seriously affecting the timeliness and accuracy of weld seam tracking. The position of the welding torch is detected by sensor technology, which can ensure the accuracy and stability of welding [

6]. According to sensing methods, the sensing technology for seam tracking can be divided into arc sensing, vision sensing, and laser sensing.

3.1. Arc Sensing

Voltage and current vary with welding torch height. Arc sensing relies on these arc characteristics to identify the weld seam center [

7,

8]. Arc sensing has the merit of convenient operation, high sensitivity, and continuous operability [

9].

Arc sensing is widely applied in robot arc welding. In the research on the development of arc sensing and experiments related to arc sensing, Pan [

10] considered the static and dynamic characteristics of arc sensing and established an arc sensing model using the control theory and experimental method. Le et al. [

11] conducted research on tracking algorithms for circular, right angle, and rectangular fillet weld seams by rotating arc sensing, as shown in

Figure 2. Fabry et al. [

12] combined arc sensing with the optical measurement of grooves to develop an arc sensing model which is used for estimating the gap width in automatic narrow-gap gas metal arc welding. Wang et al. [

13] proposed an automatic seam tracking method based on keyhole monitoring for plasma arc welding; this method effectively ensured weld quality and improved the work efficiency.

3.2. Vision Sensing

Vision sensing is widely applied in the welding process and possesses unique advantages [

14]. Traditional visual sensing consists of a lens and an optical processing system which is classified into active and passive depending on the conditions of the light source that it provides [

15,

16]. Moreover, vision sensing is widely used in all aspects of robotic welding [

17,

18,

19,

20].

The current research on vision sensing is primarily divided into research of the system and of algorithms. In their research on the weld seam tracking system, Zhang et al. [

21] designed an image acquisition system; the schematic is shown in

Figure 3a. Nele et al. [

22] and Ye et al. [

23] developed an image acquisition and weld seam tracking system by vision sensing; these are applied in robot welding. In the research algorithms, Park et al. [

24] designed a welding system for an offshore pipeline and proposed a moving average algorithm, as shown in

Figure 3b. Baek et al. [

25] proposed an automatic interweaving control algorithm which utilizes vision sensing to accurately predict the width and position of weld seams. He et al. [

26] proposed a weld feature point detection method which was applied to multichannel trajectory planning in MAG welding, as shown in

Figure 4.

3.3. Laser Sensing

Traditional vision sensing faces the problems of complexity, accuracy, and time consumption in extracting weld features [

5]. Therefore, vision sensing with a structured light emitter was developed to improve the accuracy and efficiency of weld seam tracking. Conventional laser sensing comprises the laser diode, lens, and optical processing system [

27]. Based on the triangulation principle, the laser stripe is projected by laser diode to the weldment, and the laser projection is recognized by the camera to obtain the 3D information of the weld seam [

28]. Additionally, laser sensing has the characteristics of simple image processing and strong anti-jamming [

29].

In the application and development of laser sensors, Sung et al. [

30] developed a prototype for multi-line laser vision sensing employing the multi-laser mode, which can process multiple range data. Others developed different weld seam tracking systems to improve the accuracy of weld seam tracking by laser sensing [

31,

32,

33,

34], as shown in

Figure 5. Zhang et al. [

35] proposed a laser vision recognition method using three-line structured light on the large splicing seam. This method can accurately calculate seam deviation, which possesses strong anti-interference ability and abundant information. Additionally, when dealing with weld detection in a complex workspace, the recognition accuracy of laser sensing is promoted through the application of optimization algorithms [

36]. Nguyen et al. [

37] developed a real-time weld seam tracking algorithm to process small-gap square-groove docking to shorten processing time and ensure accuracy. Fan et al. [

38] proposed an accurate tracking method for the narrow butt weld seam based on laser sensing, which can achieve accurate weld tracking control, as shown in

Figure 6. Huang et al. [

39] developed a double-sided seam tracking and error compensation control algorithm that leverages laser sensing.

The weld seam tracking of the construction welding robot provides a foundation to guarantee quality and efficiency in the of construction steel structures, bridges, and high-rise building. However, confronted with the challenges of harsh construction environments, the advantages and limitations of the above sensing technologies are manifested. Future research in weld seam tracking should focus on technical optimization to overcome the performance limitations of a single sensor, thereby achieving adaptive weld seam tracking.

4. The Trajectory Planning Technology of Welding Robots

With the increasing complexity of steel structure construction, variable construction structures pose strict track planning requirements for welding robots. Variable structure in a welding object and the high uncertainty of a welding seam position make the welding robot not only have the ability to accurately weld the standard prefabricated components but also quickly adapt to the weld seams of various sizes, shapes, and positions in a variety of construction spaces. A collision-free welding path is instantly generated and executed through the trajectory planning technology, which can safely and efficiently complete the welding operation [

40]. Currently, the focus of trajectory planning research can be summarized as the improvement of the welding robot in terms of motion performance and environmental adaptability.

4.1. The Motion Performance Improvement

In the application of welding robots in steel structure construction, the optimization of motion performance is very important. Its purpose is to ensure the efficient operation and the smooth transition of torch displacement, velocity, and acceleration. Thus, the existing research primarily delves into global path optimization and local joint stability.

Firstly, the research on global motion path optimization focuses on motion time and energy consumption as the key performance evaluation indicators. Xidias et al. [

41] realized the time-optimal planning of end-effector motion trajectory through a multi-group genetic algorithm and significantly improved the welding rate. Luo et al. [

42] achieved the minimum energy consumption for a robot trajectory by utilizing Lagrange interpolation and the numerical iterative method combined with the optimization objective of motion energy. In addition, Saravanan et al. [

43] established a comprehensive optimization system to optimize impact, time, and energy consumption. This method enables the balanced optimization of various performance aspects during the movement of robots. REYNOSO-MORA et al. [

44] employed a numerical method to conduct time-optimal trajectory planning for a six-axis serial robot; this method effectively reduced tracking errors. Secondly, research on local joint stability focuses on reducing the impact of robotic joint motion, thereby improving the continuity and smoothness of motion trajectory. The curve between adjacent nodes is further constructed by discretizing the joint time-position nodes of the robot [

45]. Curve interpolation and sequential quadratic programming are then applied to the time-position node [

46,

47], which reduces the joint motion impact and achieves trajectory smoothing. Chettibi et al. [

48] obtained a smooth joint space trajectory using the genetic algorithm with optimum time and energy as the objective function, as shown in

Figure 7.

4.2. The Environmental Adaptability Improvement

With the increasing complexity and diversity in steel structure construction, the environmental adaptability demands of welding robots are become stronger. Especially for the construction of large, complex steel structures, construction welding robots should have the ability to avoid obstacles and operate cooperatively.

Firstly, in the research of the obstacle avoidance function, Sudhakara et al. [

49] improved the existing A-star algorithm to realize collision-free operation along a predetermined line. Pack et al. [

50] proposed a fast-searching method for configuration space using a genetic alienation algorithm. Kim et al. [

51] proposed a trajectory planning method for the differential drive WMR. Gao et al. [

52] proposed an offline collision-free motion planning algorithm. These studies improved robots’ obstacle-avoidance effect, helping to cope with the challenge posed by complex space. In addition, by treating all components and obstacles of the robot as ellipsoids [

53] and simulating the obstacle avoidance algorithms based on various robot parameter limitations [

54], the obstacle avoidance operation was effectively achieved in a complex environment. Secondly, in the research on multi-robot collaborative work, a multi-robot collaborative optimization model was established and combined with the corresponding welding trajectory planning algorithm, thereby increasing the probability of a global optimal solution [

55]. This method can achieve efficient operation of multi-robot collaboration carrying out welding tasks for a complex structure [

56], as shown in

Figure 8.

Confronted with the complex construction space constraints of steel structure construction, the automation and intelligence of current welding robots are insufficient. The autonomous decision-making ability should be improved in subsequent research to realize automatic and efficient welding trajectory planning in complex construction spaces.

5. The Quality Control Technology of Welding Robots

As the core equipment in steel structure construction, the weld quality of welding robots directly affects the safety and stability of constructed structures. Given the fluctuations in construction conditions, such as complex environmental factors, diverse workpiece shapes, and unfixed weld positions, faced by construction welding operation, weld quality requires real-time control of welding robots. Currently, research of quality control primarily focuses on the optimization of weld process parameters before welding, monitoring of the weld pool during welding, and inspection of weld quality after welding.

5.1. Process Parameter Optimization before Welding

In the welding process, parameters such as the current, voltage, welding speed, and shielding gas flow play decisive roles in the weld pool feature, the heat-affected zone width, and the mechanical properties of the weld joint [

3,

57,

58]. Currently, the pre-welding process guarantee is mainly studied in terms of the influence of various process parameters on the strength and hardness of the weld joint [

59,

60,

61]. Moreover, the effects of different shielding gas mixtures and the distance between the nozzle and workpiece in the welding process are compared [

62]. Based on the above research, the welding process parameters were optimized, and it was found that the welding current is a more important parameter [

63].

5.2. Weld Pool Monitoring during Welding

Weld quality is determined by the stability of the weld pool, and the state of droplet transition determines the shape and size of the weld pool. Il’yashchenko et al. [

64] conducted a detailed analysis of the impact of the dynamic characteristics of the inverter and diode power supply on electrode metal transfer droplets. Han et al. [

65] studied the influence of arc mode on the welding process and found that the molten pool is more stable, and the splash is smaller, when the arc is in cold metal transfer mode. When faced with the construction of complex steel components, different weld pool filling states can easily be led by the dynamic change in the weld seam, which can induce welding defects such as welding deviations and incomplete penetration. By monitoring the key information, such as the shape contour, size characteristics, and temperature distribution of the weld pool, the quality and defects of weld seams can be judged. In order to benefit from the development of sensor technology and image processing technology, a technical basis is provided for the monitoring of the weld pool in the welding process.

In recent years, passive vision sensing technology is widely applied in image acquisition for weld pool monitoring, which is simple in structure design and installation [

15]. The intense arc light during the welding process serves as the light source for image acquisition. However, the intense arc light makes it difficult to extract information from the direct image. The core problem of passive sensors lies in employing light reduction and light filtering to eliminate arc light interference, thus obtaining high-quality images of the weld pool [

66]. In response to the above problems, passive vision sensing technology is applied for real-time acquisition and information processing of the weld pool image during the welding process. The weld pool area is illuminated by the arc light, and then the image is captured by a CCD camera after optical filtering [

15,

67,

68,

69,

70,

71,

72], as shown in

Figure 9. In addition, Hu et al. [

73,

74,

75] employed an infrared camera in a laser-based adaptive manufacturing system for image acquisition of the weld pool. Through filtering and other operations, a clear image of the weld pool was successfully captured. Fan et al. [

76] designed a set of three light-path weld seam image acquisition systems which realized the simultaneous monitoring of the front, back, and gap of the weld pool.

After obtaining the weld pool image, the geometric features are extracted by image filtering, noise reduction, and image segmentation to determine weld quality. However, there are significant uncertainties in the acquired image because of the interference of arc light and the dynamic adjustment of weld posture. The traditional image processing method exhibited limitations due to parameter sensitivity. In response to the above problems, we gradually shifted from traditional single-process technology to a method integrating multiple advanced image processes. This approach forms a comprehensive image processing framework characterized by strong adaptability and high robustness.

Figure 10 is a typical welding image processing flow, which shows the whole process from the acquisition of the original image to feature extraction [

77]. In the research on filtering and noise reduction for images, Liu et al. [

78] proposed an open operation method using specific structural elements to measure the weld pool’s geometric shape. Chen et al. [

79] calculated the width of a weld pool through an improved homomorphic filtering algorithm. In their research on image segmentation, Liu et al. [

80] studied six different traditional differential operators for edge extraction and concluded that the ideal weld pool edge feature is obtained by the Canny operator. Xia et al. [

81] employed the adaptive Wiener filtering algorithm and the Canny algorithm to extract edge features; in addition, their process obtained weld pool width information.

5.3. Weld Quality Inspection after Welding

Quality inspection post-welding can further ensure weld quality on the basis of the optimization of process pre-welding and the monitoring of the weld pool during welding [

82]. It mainly includes appearance inspection, nondestructive testing, and mechanical testing. Nondestructive testing technology is widely applied because it can detect the weld seam without affecting joint performance [

83,

84].

Visual inspection of the weld seam can be performed after the welding operation to identify surface defects such as undercuts, welding slags, pores, and cracks. The surface quality of the weld seam can be evaluated objectively and depending on the relevant specification requirements. Secondly, to further improve the accuracy of surface defect detection, optical measurement tools can be used to accurately measure the parameters of weld seam width and residual height to ensure that the weld quality meets requirements. As the first step in post-weld inspection, visual and measurement control is of great significance for ensuring weld quality and improving production efficiency.

Currently, nondestructive testing technology for weld defects mainly includes X-ray detection, ultrasonic detection, and magnetic particle detection, as shown in

Figure 11. The internal structure can be nondestructively evaluated by high penetration of X-ray detection technology. This method can precisely reveal the location, shape, and size of the weld defect, which can provide strong support for qualitative and quantitative analysis of weld quality [

85]. Bogdan-Dorel et al. [

86], Zhang et al. [

85], and Li et al. [

87] carried out a lot of studies on X-ray detection of the weld defect and summarized the influence of welding parameters on weld defects. Then, combining neural networks and deep learning, the accuracy of the X-ray detection model was optimized. Ultrasonic testing technology uses high-frequency ultrasonic probing to emit and receive ultrasonic pulses. The internal structure and potential defect of the weld are nondestructively detected by analyzing the characteristics of the reflected echo. The method is not affected by the workpiece surface and the external environment. Ghafarallahi et al. [

88] combined acoustic simulation and neural network to forecast weld quality. Then, the actual welding sample was verified by ultrasonic testing. Dhayalan et al. [

89] studied ultrasonic high-frequency-guided wave detection of dissimilar metal welds through experimentation and simulation. Amiri et al. [

90] proposed an integrated search system for the mechanical properties of spot weld joints using a neural network and ultrasonic testing. Magnetic particle testing technology can achieve nondestructive testing of the workpiece based on the principle of interaction between the magnetic field and the surface defects of the ferromagnetic material. Therefore, for specific materials or special types of defects, the integration of other nondestructive testing techniques is required to ensure that quality assessment is comprehensive and accurate. Pydi et al. [

91] examined weld quality by combining radiographic and magnetic particle detection. In summary, the above nondestructive testing methods can detect the internal defects of weld joints with unique advantages. However, due to the scope and limitations of their application, it is imperative that various techniques are combined in order to comprehensively and accurately assess weld joint quality in a practical manner.

The efficiency and quality of steel structure construction are improved by the use of construction welding robots. However, the stability of weld quality is vulnerable to the influence of complex construction conditions. Future research should focus on the deep integration of interdisciplinary technology and the development of an intelligent weld pool monitoring system. Moreover, the whole process of quality assurance in construction structure welding can be realized through its combination with nondestructive testing.

6. Conclusions

Against the backdrop of the rapid development of steel structure building in the construction industry, welding robots encounter multiple technical challenges while possessing vast application prospects. These challenges, more specifically, include weld seam tracking under harsh construction environments, weld trajectory planning under variable construction structures, and weld quality control under complex construction conditions. The latest studies focus on the three core technologies of welding robots outlined in this paper. The real-time performance and accuracy of weld seam tracking have been significantly improved through the application of advanced sensor technology. The efficiency and adaptability of welding robots in complex construction spaces have been enhanced through the application of trajectory planning technology. The high-quality output of welding robots is effectively ensured by the entire process of quality control of welds. However, at present, the autonomous decision making and the degree of intelligence of welding robots are insufficient, and it is difficult to use them widely on a construction site.

In the future, the following research directions of construction welding robots can be considered:

- (1)

Improvement of construction environment adaptability. The performance limitation of single sensors should be overcome by integrating multi-sensor technology. The reliability and stability of weld seam tracking should be enhanced to ensure accurate operation of construction robots in harsh construction site environments.

- (2)

Enhancement of autonomous control capability. The development of autonomous learning and decision-making capabilities should be strengthened so that robots can flexibly respond to structure diversity and different conditions, improving efficiency and precision.

- (3)

Improvement of intelligent quality prediction. The application of machine learning in steel structure weld quality prediction should be deepened. Thus, the accurate prediction of the geometric characteristics of weld joints can be realized to ensure high quality and safety in welding operations.

Author Contributions

Writing—original draft preparation, data curation, H.B.; visualization, X.C. and B.H.; conceptualization, writing—review and editing, S.P. and J.W.; supervision, H.B. and X.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the support of this research and project provided by Chongqing Technology Innovation and Application Development Project (CSTB2022TIAD-KPX0205).

Data Availability Statement

The reader can request the related data from the corresponding author.

Conflicts of Interest

The authors declare that they have no known competitive financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Irani, Z.; Kamal, M. Intelligent Systems Research in the Construction Industry. Expert Syst. Appl. 2014, 41, 934–950. [Google Scholar] [CrossRef]

- Zhang, G.; Yun, T.J.; Oh, W.B.; Lee, B.R.; Kim, I.S. A study on seam tracking in robotic GMA welding process. Mater. Today Proc. 2020, 22, 1771–1777. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, K.; Islam, A.; Roy, d. Effect of welding parameters on automated robotic arc welding process. Mater. Today Proc. 2020, 26, 2363–2367. [Google Scholar] [CrossRef]

- Muhammad, J.; Altun, H.; Abo-Serie, E. Welding seam profiling techniques based on active vision sensing for intelligent robotic welding. Int. J. Adv. Manuf. Technol. 2017, 88, 127–145. [Google Scholar] [CrossRef]

- Rout, A.; Deepak, B.; Biswal, B. Advances in weld seam tracking techniques for robotic welding: A review. Robot. Comput.-Integr. Manuf. 2019, 56, 12–37. [Google Scholar] [CrossRef]

- Lu, X.Q.; Liu, W.M.; Wu, Y.X. Review of sensors and its applications in the welding robot. Robot. Weld. Intell. Autom. 2014, 363, 337–349. [Google Scholar]

- Liu, W.J.; Gu, Z.Y.; Xiao, J.; Li, L.Y.; Yue, J.F. Research on the seam tracking of narrow gap P-GMAW based on arc sound sensing. Sens. Actuators A Phys. 2019, 292, 205–216. [Google Scholar]

- Shi, Y.H. Present situation and Prospect of seam tracking technology based on arc sensor. Weld Technol. 2008, 37, 1–5. [Google Scholar]

- Ushio, M.; Mao, W. Modelling of an arc sensor for dc mig/mag welding in open arc mode: Study of improvement of sensitivity and reliability of arc sensors in GMA welding (1st report). Weld. Int. 1996, 10, 622–631. [Google Scholar] [CrossRef]

- Pan, J.L. Arc sensing system for automatic weld seam tracking-mathematic model. Sci. China 2001, 44, 251–257. [Google Scholar] [CrossRef]

- Le, J.; Zhang, H.; Chen, X.Q. Realization of rectangular fillet weld tracking based on rotating arc sensors and analysis of experimental results in gas metal arc welding. Robot. Comput.-Integr. Manuf. 2018, 49, 263–276. [Google Scholar] [CrossRef]

- Fabry, C.; Pittner, A.; Rethmeier, M. Design of neural network arc sensor for gap width detection in automated narrow gap GMAW. Weld. World 2018, 62, 819–830. [Google Scholar] [CrossRef]

- Wang, W.X.; Wang, Q.; Yamane, S.; Hirano, T.; Hosoya, K.; Nakajima, T.; Yamamoto, H. Tracking using pattern matching of keyhole in visual robotic plasma welding. Int. J. Adv. Manuf. Technol. 2018, 98, 2127–2136. [Google Scholar] [CrossRef]

- Ding, Y.Y.; Huang, W.; Kovacevic, R. An on-line shape-matching weld seam tracking system. Robot. Comput.-Integr. Manuf. 2016, 42, 103–112. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Chen, J.; Feng, Z.L. Welding penetration prediction with passive vision system. J. Manuf. Process. 2018, 36, 224–230. [Google Scholar] [CrossRef]

- Shao, W.J.; Liu, X.F.; Wu, Z.J. A robust weld seam detection method based on particle filter for laser welding by using a passive vision sensor. Int. J. Adv. Manuf. Technol. 2019, 104, 2971–2980. [Google Scholar] [CrossRef]

- Chen, S.B. On the key technologies of intelligentized welding robot. Lect. Notes Control. Inf. Sci. 2007, 362, 105–115. [Google Scholar]

- Chen, S.B.; Wu, J. Real-time control of weld Pool dynamics during robotic GTAW. In: Intelligentized methodology for arc welding dynamical processes. Lect. Notes Electr. Eng. 2009, 29, 221–273. [Google Scholar]

- Xiao, R.Q.; Xu, Y.L.; Hou, Z.; Chen, C.; Chen, S.B. An adaptive feature extraction algorithm for multiple typical seam tracking based on vision sensor in robotic arc welding. Sens. Actuators A Phys. 2019, 297, 111533. [Google Scholar] [CrossRef]

- Xu, F.J.; Xu, Y.L.; Zhang, H.J.; Chen, S.B. Application of sensing technology in intelligent robotic arc welding: A review. J. Manuf. Process. 2022, 79, 854–880. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wen, G.G.; Chen, S.B. Weld image deep learning-based on-line defects detection using convolutional neural networks for Al alloy in robotic arc welding. J. Manuf. Process. 2019, 45, 208–216. [Google Scholar] [CrossRef]

- Nele, L.; Sarno, E.; Keshari, A. An image acquisition system for real-time seam tracking. Int. J. Adv. Manuf. Technol. 2013, 69, 2099–2110. [Google Scholar] [CrossRef]

- Ye, Z.; Fang, G.; Chen, S.B.; Zou, J.J. Passive vision based seam tracking system for pulse-MAG welding. Int. J. Adv. Manuf. Technol. 2018, 67, 1987–1996. [Google Scholar] [CrossRef]

- Park, J.H.; Moon, H.S. Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function. Appl. Sci. 2020, 10, 324. [Google Scholar] [CrossRef]

- Baek, D.Y.; Moom, H.S.; Park, S.H. Development of an automatic orbital welding system with robust weaving width control and a seam-tracking function for narrow grooves. Int. J. Adv. Manuf. Technol. 2017, 93, 767–777. [Google Scholar] [CrossRef]

- He, Y.S.; Xu, Y.L.; Chen, Y.X.; Chen, H.B.; Chen, S.B. Weld seam profile detection and feature point extraction for multi-pass route planning based on visual attention model. Robot. Comput.-Integr. Manuf. 2016, 37, 251–261. [Google Scholar] [CrossRef]

- Zou, Y.B.; Wei, X.Z.; Chen, J.X. Conditional generative adversarial network-based training image inpainting for laser vision seam tracking. Opt. Lasers Eng. 2020, 134, 106140. [Google Scholar] [CrossRef]

- He, Y.S.; Chen, Y.X.; Xu, Y.L.; Huang, Y.M.; Chen, S.B. Autonomous detection of weld seam profiles via a model of saliency-based visual attention for robotic arc welding. J. Intell. Robot. Syst. 2016, 81, 395–406. [Google Scholar] [CrossRef]

- Wilson, M. The role of seam tracking in robotic welding and bonding. Ind. Robot. 2002, 29, 132–137. [Google Scholar] [CrossRef]

- Sung, K.; Lee, H.; Choi, Y.; L Rhee, S. Development of a multiline laser vision sensor for joint tracking in welding. Weld. J. 2009, 4, 79–85. [Google Scholar]

- Fridenfalk, M.; Bolmsjö, G. Design and validation of a universal 6d seam tracking system in robotic welding based on laser scanning. Adv. Robot. 2003, 30, 437–448. [Google Scholar] [CrossRef]

- Kos, M.; Arko, E.; Kosler, H.; Jezeršek, M. Remote-laser welding system with in-line adaptive 3D seam tracking and power control. Procedia CIRP 2019, 81, 1189–1194. [Google Scholar] [CrossRef]

- Zou, Y.B.; Zhou, W.L. Automatic seam detection and tracking system for robots based on laser vision. Mechatronics 2019, 63, 102261. [Google Scholar] [CrossRef]

- Hou, Z.; Xu, Y.L.; Xiao, R.Q.; Chen, S.B. A teaching-free welding method based on laser visual sensing system in robotic GMAW. Int. J. Adv. Manuf. Technol. 2020, 109, 1755–1774. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.X.; Gui, H.; Li, D.Y.; Li, Z.G. Identification of the deviation of seam tracking and weld cross type for the derusting of ship hulls using a wall-climbing robot based on three-line laser structural light. J. Manuf. Process 2018, 35, 295–306. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Yang, J.N.; Zhou, F.Q.; Sun, J.H.; Li, X.S.; Xie, W.T. A robust laser stripe extraction method for structured-light vision sensing. Sensors 2020, 20, 4544. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, Q.; Hua, H.Q.B.; Pham, P. Development of a vision system integrated with industrial robots for online weld seam tracking. J. Manuf. Process. 2024, 119, 414–424. [Google Scholar] [CrossRef]

- Fan, J.F.; Jing, F.S.; Yang, L.; Long, T.; Tan, M. A precise seam tracking method for narrow butt seams based on structured light vision sensor. Opt. Laser Technol. 2019, 109, 616–626. [Google Scholar] [CrossRef]

- Huang, Y.; Li, G.; Shao, W.J.; Gong, S.H. A novel dual-channel weld seam tracking system for aircraft T-joint welds. Int. J. Adv. Manuf. Technol. 2017, 91, 751–761. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, X.W.; Xie, Z.H.; Li, F.; Gu, X.S. Online obstacle avoidance path planning and application for arc welding robot. Robot. Comput.-Integr. Manuf. 2022, 78, 102413. [Google Scholar] [CrossRef]

- Xidias, E.K. Time-optimal trajectory planning for hyper-redundant manipulators in 3Dworkspaces. Robot. Comput.-Integr. Manuf. 2018, 50, 286–298. [Google Scholar] [CrossRef]

- Luo, L.P.; Yuan, C.; Yan, R.J.; Yuan, Q.; Wu, J.; Shin, K.; Han, C. Trajectory planning for energy minimization of industry robotic manipulators using the Lagrange interpolation method. Int. J. Precis. Eng. Manuf. 2015, 16, 911–917. [Google Scholar] [CrossRef]

- Saravanan, R.; Ramabalan, S.; Balamurugan, C. Evolutionary optimal trajectory planning for industrial robot with payload constraints. Int. J. Adv. Manuf. Technol. 2008, 38, 1213–1226. [Google Scholar] [CrossRef]

- Reynoso-Mora, P.; Chen, W.J.; Tomizuka, M. On the Time-Optimal Trajectory Planning and Control of Robotic Manipulators along Predefined Paths. In Proceedings of the American Automatic Control Council, American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 371–377. [Google Scholar]

- Tan, G.; Wang, Y. Theoretical and experimental research on time-optimal trajectory planning and control of industrial robots. Control. Theory Appl. 2003, 20, 185–192. [Google Scholar]

- Gasparetto, A.; Zanotto, V. A new method for smooth trajectory planning of robot manipulators. Mech. Mach. Theory 2007, 42, 455–471. [Google Scholar] [CrossRef]

- Boryga, M.; Graboś, A. Planning of manipulator motion trajectory with higher-degree polynomials use. Mech. Mach. Theory 2009, 44, 1400–1419. [Google Scholar] [CrossRef]

- Chettibi, T. Synthesis of dynamic motions for robotic manipulators with geometric path constraints. Mechatronics 2006, 16, 547–563. [Google Scholar] [CrossRef]

- Sudhakara, P.; Ganapathy, V. Trajectory planning of a mobile robot using enhanced A-star algorithm. Indian J. Sci. Technol. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Pack, D.J.; Toussaint, G.J.; Haupt, R.L. Robot trajectory planning using a genetic algorithm. Adaptive Computing: Mathematical and Physical Methods for Complex Environments. Int. Soc. Opt. Photonics 1996, 2824, 171–182. [Google Scholar]

- Kim, Y.; Kim, B. Time optimal trajectory planning based on dynamics for differential-wheeled mobile robots with a geometric corridor. IEEE Trans. Ind. Electron. 2017, 64, 5502–5512. [Google Scholar] [CrossRef]

- Gao, W.X.; Tang, Q.; Yao, J.; Yang, Y. Automatic motion planning for complex welding problems by considering angular redundancy. Robot. Comput.-Integr. Manuf. 2020, 62, 101862. [Google Scholar] [CrossRef]

- Korayem, M.H.; Nazemizadeh, M.; Azimirad, V. Optimal trajectory planning of wheeled mobile manipulators in cluttered environments using potential functions. Sci. Iran. 2011, 18, 1138–1147. [Google Scholar] [CrossRef][Green Version]

- Sathiya, V.; Murugaiyan, C. Evolutionary algorithms-based multi-objective optimal mobile robot trajectory planning. Robotica 2019, 37, 1363–1382. [Google Scholar] [CrossRef]

- Tang, Q.C.; Ma, L.; Zhao, D.; Sun, Y.K.; Wang, Q.Y. A Dual-Robot Cooperative Arc Welding Path Planning Algorithm based on Multi-Objective Optimization. IFAC-PapersOnLine 2023, 56, 3048–3053. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Sun, Y.K.; Tang, Q.C.; Ma, L.; Zhao, D.; Yang, J.P.; Xu, J. A Dual-Robot Cooperative Welding Path Planning Algorithm Based on Improved Ant Colony Optimization. IFAC-PapersOnLine 2022, 55, 7–12. [Google Scholar] [CrossRef]

- SCHMIDT, A.; MARTIN, C.; DIETZ, T.; Pott, A. A generic data structure for the specific domain of robotic arc welding. Procedia CIRP 2018, 72, 322–327. [Google Scholar] [CrossRef]

- Sen, M.; Mukherjee, M.; Pal, T. Evaluation of correlations between DP-GMAW process parameters and bead geometry. Weld. J. 2015, 94, 265–279. [Google Scholar]

- Shahazad, A.; Agrawal, A.P.; Ahamad, N.; Singh, T.; Wahid, A. Robotic MIG welding process parameter optimization of steel EN24T. Mater. Today Proc. 2022, 62, 239–244. [Google Scholar]

- Ghosh, N.; Pal, P.K.; Nandi, G. Parametric Optimization of MIG Welding on 316L Austenitic Stainless Steel by Grey-based Taguchi Method. Procedia Technol. 2016, 25, 1038–1048. [Google Scholar] [CrossRef]

- Osman, M.H.; Nasrudin, N.F. Experimental Study of Single Pass Welding Parameter Using Robotic Metal Inert Gas (MIG) Welding Process. In Advances in Mechatronics, Manufacturing, and Mechanical Engineering; Springer: Singapore, 2020; pp. 10–21. [Google Scholar] [CrossRef]

- Suban, M. Determination of stability of MIG/MAG welding processes. Qual. Reliab. Eng. Int. 2001, 17, 345–353. [Google Scholar] [CrossRef]

- Tyagi, A.; Kumar, G.; Kumar, M.; Neha, E.; Wahid, M.A. Experimental investigation for optimization of robot spot welding parameters on low carbon steel JSC 590RN. Mater. Today Proc. 2022, 51, 1211–1216. [Google Scholar] [CrossRef]

- Il’yashchenko, D.P.; Chinakhov, D.A.; Lavrova, E.V. The Effect of Energy Parameters Power Sources on the Structure and Properties of Permanent Joints at Manual Arc Welding. Metals 2024, 14, 759. [Google Scholar] [CrossRef]

- Han, X.H.; Yang, Z.B.; Ma, Y.; Shi, C.Y.; Xin, Z.B. Comparative study of laser-arc hybrid welding for AA6082-T6 aluminum alloy with two different arc modes. Metals 2020, 10, 407. [Google Scholar] [CrossRef]

- Pietrzak, K.A.; Packer, S.M. Vision-Based Weld Pool Width Control. ASME J. Eng. Ind. 1994, 116, 86–92. [Google Scholar] [CrossRef]

- Zhang, G.J.; Yan, Z.H.; Wu, L. Visual Sensing of Weld Pool in Variable Polarity TIG Welding of Aluminum Alloy. Trans. Nonferrous Met. Soc. China 2006, 16, 522–526. [Google Scholar] [CrossRef]

- Li, L.P.; Chen, S.B.; Lin, T. The Modeling of Welding Pool Surface Reflectance of Aluminum Alloy Pulse GTAW. Mater. Sci. Eng. A 2005, 394, 320–326. [Google Scholar]

- Balfour, C.; Smith, J.S.; AI-Shamma, A.I. A novel edge feature correlation algorithm for real-time computer vision-based molten weld pool measurements. Weld. J. 2006, 1, 1–8. [Google Scholar]

- Liu, J.; Fan, Z.; Olsen, S.I.; Christensen, K.H.; Kristensen, J.K. A real-time passive vision system for robotic arc welding. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering, Gothenburg, Sweden, 24-28 August 2015; pp. 389–394. [Google Scholar]

- Wang, Z.S.; Shi, Y.H.; Hong, X.B.; Zhang, B.; Chen, X.Y.; Zhan, A. Weld pool and keyhole geometric feature extraction in K-TIG welding with a gradual gap based on an improved HDR algorithm. J. Manuf. Process. 2022, 73, 409–427. [Google Scholar] [CrossRef]

- Chen, S.B.; Zhang, Y.; Qiu, T.; Lin, T. Robotic Welding Systems with Vision-Sensing and Self-learning Neuron Control of Arc Welding Dynamic Process. J. Intell. Robot. Syst. 2003, 36, 191–208. [Google Scholar] [CrossRef]

- Hu, D.; Kovacevic, R. Modelling and measuring the thermal behaviour of the molten pool in closed-loop controlled laser-based additive manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 441–452. [Google Scholar] [CrossRef]

- Hu, D.; Kovacevic, R. Sensing modeling and control for laser-based additive manufacturing. Int. J. Mach. Tools Manuf. 2003, 43, 51–60. [Google Scholar] [CrossRef]

- Hu, D.; Mei, H.; Kovacevic, R. Improving solid freeform fabrication by laser-based additive manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 1253–1264. [Google Scholar] [CrossRef]

- Fan, C.J.; Lv, F.L.; Chen, S.B. Visual sensing and penetration control in aluminum alloy pulsed GTA welding. Int. J. Adv. Manuf. Technol. 2009, 42, 126–137. [Google Scholar] [CrossRef]

- Xu, Y.L.; Fang, G.; Lv, N.; Chen, S.B.; Zou, J.J. Computer vision technology for seam tracking in robotic GTAW and GMAW. Robot. Comput.-Integr. Manuf. 2015, 32, 25–36. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Wu, B.; Frakes, D.; Wang, Y. A specific structuring element-based opening method for rapid geometry measurement of weld pool. Int. J. Adv. Manuf. Technol. 2017, 90, 1465–1477. [Google Scholar] [CrossRef]

- Chen, Z.; Gao, X. Detection of weld pool width using infrared imaging during high-power fiber laser welding of type 304 austenitic stainless steel. Int. J. Adv. Manuf. Technol. 2014, 74, 1247–1254. [Google Scholar] [CrossRef]

- Liu, X.G.; Zhao, B. Based on the CO2 gas shielded welding molten pool image edge detection algorithm. Applied Mechanics and Materials. Appl. Mech. Mater. 2013, 437, 840–844. [Google Scholar] [CrossRef]

- Xia, C.Y.; Pan, Z.X.; Zhang, S.Y.; Polden, J.; Wang, L.; Li, H.J.; Xu, Y.L.; Chen, S.B. Model predictive control of layer width in wire arc additive manufacturing. J. Manuf. Process. 2020, 58, 179–186. [Google Scholar] [CrossRef]

- Li, W.T.; Zhang, W.B.; Yang, G.P. Research on ultrasonic phased array detection algorithm for TA15/Ti2AlNb multi-layer gradient material structure. Appl. Acoust. 2023, 204, 109240. [Google Scholar] [CrossRef]

- Deepak, J.R.; Bupesh Raja, V.K.; Srikanth, D.; Surendran, H.; Nickolas, M.M. Nondestructive testing (NDT) techniques for low carbon steel welded joints: A review and experimental study. Mater. Today Proc. 2021, 44, 3732–3737. [Google Scholar] [CrossRef]

- Xiao, Z.; Song, K.Y.; Gupta, M.M. Development of a CNN edge detection model of noised X-ray images for enhanced performance of non-destructive testing. Measurement 2021, 174, 109012. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, D.H.; Bai, Q.F.; Fu, L.H.; Hu, J.; Song, J.L. Research on X-ray weld seam defect detection and size measurement method based on neural network self-optimization. Eng. Appl. Artif. Intell. 2024, 133, 108045. [Google Scholar] [CrossRef]

- Bogdan-Dorel, C.; Ana Virginia, S.; Vasile George, C.; Amalia Ana, D.; Marius, A. Analysis of electric flux arc welding parameters influence using visual X-ray inspection. Mater. Today Proc. 2023, 78, 214–220. [Google Scholar] [CrossRef]

- Li, L.L.; Wang, P.; Ren, J.; Lv, Z.G.; Li, X.Y.; Gao, H.; Di, R.H. Synthetic data augmentation for high-resolution X-ray welding defect detection and classification based on a small number of real samples. Eng. Appl. Artif. Intell. 2024, 133, 108379. [Google Scholar] [CrossRef]

- Ghafarallahi, E.; Farrahi, G.H.; Amiri, N. Acoustic simulation of ultrasonic testing and neural network used for diameter prediction of three-sheet spot welded joints. J. Manuf. Process. 2021, 64, 1507–1516. [Google Scholar] [CrossRef]

- Dhayalan, R.; Rajkumar, K.V.; Kumar, A. Ultrasonic high frequency guided waves for testing of dissimilar metal welds. Mater. Today Proc. 2021, 44, 2978–2984. [Google Scholar] [CrossRef]

- Amiri, N.; Farrahi, G.H.; Kashyzadeh, K.R.; Chizari, M. Applications of ultrasonic testing and machine learning methods to predict the static & fatigue behavior of spot-welded joints. J. Manuf. Process. 2020, 52, 26–34. [Google Scholar]

- Pydi, H.P.; Pradeep, A.D.; Vijayakumar, S.; Srinivasan, R. Examination of various weld process parameters in MIG welding of carbon steel on weld quality using radiography & magnetic particle testing. Mater. Today Proc. 2022, 62, 1909–1912. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).