Abstract

Natural and bio-based construction materials such as bamboo, cork, or natural fiber composites offer a promising solution for enhancing the environmental sustainability of buildings. In this sense, the paper presents an experimental thermo-acoustic characterization of four common Ecuadorian natural fibers, abaca (Musa textilis), cabuya (Furcraea andina), coir (Cocos nucifera), and totora (Schoenoplectus californicus). Different densities were considered, from 85 kg/m3 (Cabuya) to 244 kg/m3 (totora), to thermo-acoustically characterize the samples built with these fibers, by means of the guarded-hot-plate (GHP) and impedance tube methods in-lab experimental benches. The exhaustive original characterization of the evaluated natural fiber composites showed a promising overall thermo-acoustic behavior. The thermal conductivity of the fibers was around 0.04–0.06 W/m·K and, therefore, comparable to other materials such as polystyrene, polyurethane, or aerogel that are already utilized for similar applications. On the other hand, the sound-absorption properties of the evaluated fibers are also very competitive, but strongly affected by the thickness of the sample, with noise reduction coefficient NRC ranging from 0.12 to 0.53. Consequently, the production and distribution of these materials in the Ecuadorian market for thermal insulation and acoustic conditioning constitute an alternative characterized by good technical performance, which, compared to synthetic composites used in the construction industry for similar duties, is ecological, sustainable, and has low built-in energy consumption.

1. Introduction

In recent years, the international community has been more sensitive to the escalating pollution issue produced by the construction industry. This is due, in large part, to the fact that the amounts of waste produced by the construction sector, regardless of the social or cultural economic characteristics of the region, are devastating: In Hong Kong, 23% of total waste in 2022 came from construction [] with an increase of 7% disposed of at landfills; in Japan, the construction industry contributed 20% of the total waste in 2003 []; in Kuwait, 15–30% of solid waste is from construction, with over 90% landfilled []; in 2018, Mainland China made up 30–40% of its total waste from construction []; and the European Union (EU) reported 35% of total waste from construction in 2024 [], while in the USA, construction waste represents 29% of solid waste and covers 35% of landfill site []. The construction waste in São Paulo accounts for 55% of total waste [].

Addressing this issue, many countries have established policies to reduce construction waste and promote sustainable development. For instance, Hong Kong introduced incentives for green building technologies in 2001 and 2002 [], issued guidelines for using recycled aggregates in 2003 [], implemented a waste management plan for public projects in 2003, started a pilot recycling plan in 2004, and introduced landfill charges in 2005 []. The European Community implemented various legislative and strategic planning measures to promote the efficient use of resources in the construction sector []. One of the significant achievements in this area was the approval of the Waste Directive, which establishes a framework for waste management in the EU []. The Circular Economy Package proposed by the EU in 2015 aimed to transform how wastes are managed from the point of view of efficient and sustainable use of natural resources []. A key objective of this package was to increase the recycling and reuse of construction waste to 70% by 2020. However, according to Islam et al. [], by 2019, some European countries were still far from achieving these targets. This delay has led to the formulation of a new directive on construction materials in Europe, which has generated debate due to the perception that solutions for waste treatment were not adequately being addressed [].

The circular economy in the construction sector focuses on waste reduction and the reuse and recycling of construction materials. This practice can lead to a significant reduction in environmental impact and the conservation of natural resources. Furthermore, implementing circular economy strategies can stimulate innovation in creating more sustainable and durable construction materials. Within this circular economy, numerous sources suggest that using natural raw materials in construction makes waste not only reusable but also biodegradable if they are not given a second life []. Some initiatives promote the extraction of these materials from cultivated plants, such as the ones cited by Hebel et al. [], which can be used, for example, as effective thermal insulation materials or reinforcement constructive components [,]. The aforementioned aspects are also aligned with the United Nations-Sustainable Development Goals (UN-SDG) [].

Sound absorbers are commonly used for acoustic conditioning in industrial, entertainment, and residential contexts to reduce radiated sound energy through acoustic-thermal transformation. These materials are applied to overcome noise effects on health such as annoyance and sleep disturbance and to improve acoustic quality inside rooms where there is speech intelligibility []. Porous fibrous materials are the most available sound-absorbing materials. Fibers can be classified as natural (vegetable, animal, or mineral) and synthetic []. Due to some issues concerning life cycle assessment (LCA), it is important to develop new eco-friendly materials instead of synthetic fibrous materials such as foam, glass, and rock wool [], whose negative impacts on the environment are evident.

The LCA approach evaluates the entire life history of products and their potential impacts derived from extraction, production, transport, construction, de-construction, disposal, recycling, and reuse []. The production of synthetic materials requires more energy and has a significant global footprint []. In contrast, the production of natural-based materials does not depend on fossil fuels and petrochemicals.

Sound absorption properties of vegetation and leaves have been researched in several studies [,,,,], especially considering the availability of many “local” natural materials. Thus, giant reed [], kenaf [], pineapple [], tea-leaf [], and typha fibers [] have been reported, among others. Similarly, many types of wastes deriving from industry, garbage, or agricultural work have been researched in terms of compound properties based on cardboard [], sunflower residuals [], sugarcane waste [], olive [], and orange pruning [], coffee chaff [] and cigarettes []. The pores and cavities in their structures constitute the key element to ensure the sound absorption properties. These materials have a natural origin or the potential to recycle wastes and present a lower environmental impact compared to synthetic materials.

Table 1 shows the density, thickness, sound absorption coefficients, and noise reduction coefficient (NRC) of materials commonly used in room acoustics, such as glass wool and rock wool (with a high environmental impact during production) []. It also includes fibers extracted from plants, such as kenaf, hemp, coconut, cane, pineapple, tea, typha and wood fiber [,,,]. The NRC is the average of the mid-frequency sound absorption coefficients at 250, 500, 1000, and 2000 Hz.

Table 1.

Density, thickness, sound absorption coefficient of the 125, 250, 500, 1000, and 2000 Hz one-octave bands, and noise reduction coefficient (NRC) of inorganic (glass wool and rock wool) and organic fibers (kenaf, wood, hemp, coconut, cane, pineapple leaf, tea-leaf, and typha fibers). NP means that these data are not provided in the study. This table partially reproduces Table 1 and Table 2 of reference [] with permission from Elsevier (See the Acknowledgements section).

The results indicate that the highest sound absorption coefficient occurs at the 2000 Hz frequency band for all the natural fibers analyzed, but for Cane, that occurs at 1000 Hz. Kenaf and pineapple leaves exhibit superior performance at this frequency, with absorption coefficients of 0.94 and 0.98, respectively. When considering overall performance, the material made from Typha fibers performs the highest NRC at 0.72.

Researchers are promoting the interest in alternative uses of sustainable, natural, and recycled materials, or wastes derived from other production processes also for thermal isolation []; many sources propose the use of materials with an environmental commitment that replace industrial materials, which generate waste that is difficult to manage, before during and after construction, and do so with a considerable carbon footprint. The external envelope of a building is crucial as it significantly impacts the surrounding microclimate and acts as a barrier between the internal and external environments, affecting both the thermal comfort of occupants and energy loss [,]. Notably, thermal losses through opaque walls constitute a significant portion of a building’s total energy loss, making proper insulation essential []. The insulation material, with its specific thermo-physical properties, is key to the thermal performance of opaque walls in both winter and summer []. Using thermal insulation materials is a common method for reducing energy demand and improving thermal comfort in buildings, and consequently, it is another research field concerning sustainable building materials [].

Table 2 presents the density (kg/m3) and thermal conductivity (W/m·K) of glass wool and rock wool (with a high environmental impact during production) [,,]. The table also includes fibers extracted from jute, rice, hemp, bagasse, coconut, pineapple, and reeds [,,,]. The findings from several studies indicate that jute and pineapple fibers exhibit highly competitive thermal conductivity ranges of 0.038–0.055 (W/m·K) and 0.035–0.041(W/m·K), respectively, demonstrating performance comparable to that of synthetic materials.

Table 2.

Density and thermal conductivity of different inorganic (glass wool and rock wool) and organic fibers (jute, rice, hemp, bagasse, coconut, pineapple, reeds). This table partially reproduces Table 6 of reference [] with permission from Elsevier (See the Acknowledgments section).

Table 2.

Density and thermal conductivity of different inorganic (glass wool and rock wool) and organic fibers (jute, rice, hemp, bagasse, coconut, pineapple, reeds). This table partially reproduces Table 6 of reference [] with permission from Elsevier (See the Acknowledgments section).

| Fibrous Insulation Material | Density (kg/m3) | Thermal Conductivity (W/m·K) | Ref. |

|---|---|---|---|

| Glass wool (inorganic) | 13–100 | 0.030–0.045 | [,,] |

| Rock wool (inorganic) | 30–180 | 0.033–0.045 | [,,] |

| Jute | 35–100 | 0.038–0.055 | [,] |

| Rice straw | 154–168 | 0.046–0.056 | [,] |

| Hemp | 20–68 | 0.04–0.05 | [,] |

| Bagasse | 70–350 | 0.046–0.055 | [,] |

| Coir | 70–125 | 0.04–0.05 | [,,] |

| Pineapple leaves | 178–232 | 0.035–0.042 | [,] |

| Reeds | 190 | 0.056 | [] |

Not only the thermal but also tensile properties of natural fiber materials are also required for specific applications of heat-insulating materials used in the construction sector. Symington et al. [] conducted tensile tests of seven fibers (jute, kenaf, flax, abaca, sisal, hemp, and coir) with several moisture conditions. The thermal conductivity of pressed composites from polylactic acid and bamboo fibers was assessed and compared to other conventional composites and woods []. Stanković et al. [] developed a method to assess the thermal properties of textile fabrics crafted from natural and regenerated cellulose fibers. The study’s findings demonstrate that the heat transfer through these fabrics is significantly influenced by their capillary structure, yarn surface characteristics, and the distribution of air within the fabrics. Patnaik et al. conducted tests on waste wool and recycled polyester fibers to evaluate their thermal insulation capabilities, as well as their sound and moisture absorption and flame resistance properties [].

While the revised literature has explored the use of natural fibers in construction for thermal insulation and sound absorption, there is a scarcity of studies focusing on the mentioned referred attributes of the fibers extracted from abaca, cabuya, coir, and totora, which are part of the vegetal diversity in Ecuador. Even though there are some review articles on conventional and unconventional natural, recycled, and composited materials for building applications [,,], they only mention one out of the four fibers evaluated in the present research for acoustic applications.

This study was motivated by the increasing push towards sustainable development and the circular economy, where the need to find eco-friendly and efficient alternatives to traditional construction materials has been identified.

This study aims to investigate the mechanical attributes, thermal conductivity properties, and sound absorption coefficients derived from abaca, cabuya, coir, and totora fibers, which are available in Ecuador and present great potential for the development of the building industry. Thus, this research offers a comparative analysis of the mechanical, thermal, and acoustic properties of all four fibers, emphasizing their potential as sustainable alternatives in the construction industry. The UN-SDGs related to the development and use of the natural fibers of the study were also identified.

2. Materials and Methods

2.1. Materials Description and Importance in the Ecuadorian Economy

In this section, a brief description of the plants from which the fibers of the papers are extracted, and their importance in the Ecuadorian traditional culture are presented.

Figure 1 shows the plants from which the assessed fibers were extracted.

Figure 1.

Plants from which the studied fibers were extracted: (a) abaca (Musa textilis), (b) cabuya (Furcraea andina), (c) coir (Cocos nucifera), and (d) totora (Schoenoplectus californicus).

2.1.1. Abaca (Musa textilis)

The abaca is a Musaceae plant (Musa textilis) from which a highly resistant fiber is extracted and has traditionally been used for making artisanal products. The fiber is extracted using decortication methods, which consist of the fiber separation process using either manual or mechanical methods. Traditional manual decortication involves removing the pulp from the material by manually crushing it with a knife. Mechanical decortication is more efficient and involves the use of a decorticator. This device crushes the material using a spiked wheel set with blunt knives, which scrapes the pulp from the material. The material is typically fed into the decorticator manually, and after decortication, the fibers must be cleaned and dried []. This drying process, which can be done with mechanical dryers or sunlight for 48 h, is essential to remove any remaining pulp and moisture that could interfere with fiber cleaning. However, mechanical decortication is less efficient at removing cementing substances present between the fibers [].

The Philippines is the top producer of abaca worldwide while Ecuador ranks as the second-largest producer. In Ecuador, abaca is cultivated in expansive areas and its production is increasingly mechanized. Abaca thrives in fertile soils of volcanic or alluvial origin that retain humidity. The plant can grow at altitudes up to 1000 m, and requires an annual rainfall of 2000–3000 mm, and temperatures ranging from 20 to 27 °C []. Ecuador produces high-quality abaca fiber, benefiting from the country’s diverse regions and climates. Considered a traditional product, abaca has seen steady growth in development, production, and marketing in Ecuador due to its challenging cultivation in other parts of the world [].

The main abaca-producing regions in Ecuador are Santo Domingo de los Tsáchilas, Esmeraldas, and Manabí, which account for 75% of the national abaca plantation area. This includes 640 production units and 14,831 hectares of cultivated land nationwide []. Between 2009 and 2013, exports ranged from 10,000 to 11,000 MT []. Abaca is distinguished by its strong mechanical resistance, buoyancy, durability in saltwater, and fiber length exceeding in many cases 3 m. The finest grades of abaca are noted for being fine, light, and exceptionally strong. Its ability to grow on less fertile land makes it a sustainable fiber production option. Besides its economic benefits, abaca holds cultural and traditional significance in some Ecuadorian communities []. The cultivation and harvesting of abaca foster rural development by creating jobs in production areas, thereby improving the living conditions of local communities. For family businesses in abaca production, this activity is a crucial source of income and employment [].

Different research studies can be found in the literature that uses abaca fibers as reinforcing material for mortars [] and concrete [] and as composite materials and nanomaterials [] in construction, and furniture industries []. Abaca shows significant potential to replace glass fibers in various automotive components [] and is widely recognized as a material for paper products []. A recent study has tested a composite material made of abaca and polyester, with an acoustic absorption coefficient of 0.58 at 6300 Hz [].

2.1.2. Cabuya (Furcraea andina)

Cabuya fiber is obtained from the fique plant (Furcraea andina) native to the Andean regions []. It belongs to the Asparagaceae family which has about twenty species of succulent plants native to the Andean regions []. Primarily grown in Ecuador and Peru, it can be also found along the lakes and marshes from California down to Chile, as well as on several Pacific islands []. It grows at altitudes ranging from 1000 to 3500 m above sea level in xerophytic ecosystems such as spiny steppes []. It thrives in well-drained soil and can survive in soil with low nutrient levels. It is suited to mildly acidic to neutral pH levels and can also grow in highly acidic conditions. It has a good tolerance for drought conditions []. Cabuya has large, fleshy leaves with small tips and is a large, perennial, monocarpic succulent with a short central stem that is unbranched and covered with many spiny-edged leaves that form a rosette at the top of the stem [].

This plant is grown to produce fibers called Cabuya which have many traditional uses. The Cabuya plant has had numerous and varied applications among the indigenous Andean societies of Ecuador, which used its roots, stems, leaves, flower scapes, and flowers []. It has been used for making cordage, textiles, construction materials (beams and ropes), fuels (fire starters and firewood), detergents (shampoos and soaps), environmental uses (agroecological barriers and fertilizers), as well as food, medicine, and fodder. These uses have been prevalent throughout the history of these indigenous societies (e.g., Panzaleos, Cayambes, Kitu-kara, and Kañaris) [], some of them dating from pre-Hispanic times to the 21st century.

Recent studies have addressed the use of Cabuya fiber as an automotive reinforcement material [,].

2.1.3. Coir Fiber (Cocos nucifera)

Coir fiber is extracted from the husk of ripe coconuts (Cocos nucifera), which is very rich in lignin, making this product very strong and hard [].

Coconuts are grown in 93 countries, with the majority of cultivation occurring in Indonesia, the Philippines, and India []. In Ecuador, most of the crops can be found in coastal areas or on islands in the provinces of Manabí, Esmeraldas, Guayas, and El Oro. The coconut in these areas constitutes 85% of the country’s production []. Most coconut shells are thrown away, with the wastes either ending up in landfills or being burned. This is primarily due to a lack of awareness and insufficient resources to manage the production and distribution processes needed to deliver recycled waste materials to consumers [].

The coconut palm thrives in the intertropical zone, especially along seacoasts, due to its minimal requirements for water and light. Optimal conditions for its growth include temperatures between 25 °C and 30 °C, relative humidity around 75%, and altitudes below 400 m. Deep soils are preferred to support extensive root systems. While coconut palms can tolerate some salinity, excessively saline soils should be avoided [].

Brown coir, made from the husks of fully ripened coconuts, is processed to be UV light resistant, making it strong and abrasion resistant. It is a dark brown material commonly used in brushes, floor mats, and upholstery padding. The traditional method of producing fibers from coconut husks is lengthy and labor intensive. After separating the nut, the husks undergo retting in brackish water ponds, backwaters, or lagoons for 3–6 months, followed by anaerobic fermentation for 10–12 months. The fibers are then extracted by hand-beating, hackled, washed, ventilated, and cleaned manually [].

Coir fiber possesses odorless, anti-electrostatic, moisture-resistant, and antifungal properties, along with low heat diffusion and thermal conductivity []. These characteristics make it an ideal natural product for use in construction. The use of coconut fiber has been investigated for curing bricks, reinforcing mortars [,], and concrete [], or as an acoustic absorbent material [,].

2.1.4. Totora (Schoenoplectus californicus)

Totora is an annual-cycled bulrush from the Cyperaceae family that grows in lakes and marshes. It presents smooth stems and spongy and fibrous internal tissue and has high levels of mechanical-physical resistance []. It is a fast-growing plant that has been predominantly used in the Americas since ancient times to create a wide variety of objects. Its versatility and potential make it suitable for modern construction systems, offering benefits in the realm of sustainable building [].

It grows from Argentina to Florida along the Pacific Coast, and from Chile to California along the Atlantic Coast. It is also present in Hawaii, the Austral Islands, and Easter Island, and has been naturalized in New Zealand []. In South America, the term “totora” refers to the reed species Schoenoplectus californicus. Typha shares some characteristics with Schoenoplectus californicus, but the primary difference is that the useful part of Schoenoplectus is the stem, while for Typha, it is the leaves. Consequently, the fibers differ in their sectional shapes, sizes, and strengths. Totora thrives in freshwater wetlands and estuarine areas, exhibiting good resistance to water level changes and droughts [].

Ecuadorian collectors employ a distinctive method for gathering totora plants, cutting them diagonally 8 to 10 cm above the water’s surface. This traditional practice highlights their commitment to sustainability and their deep understanding of the totora’ ecological and cultural significance []. The hand-made process of material manipulation begins by moistening the cattail culms with water and leaving them in the shade for an hour so that they soften and increase flexibility. After softening, the culms are flattened with a stone to reduce volume and increase density, improving the resilience of the fibers. This process also helps achieve rigidity as the culms harden the finished material [].

Recently, totora has been used in traditional architecture as construction materials and for insulating roofs and walls [].

2.2. Non-Woven Sample Preparations

Abaca, cabuya, coir, and totora fibers were provided by local producers from the Intag, Manabí, Riobamba, and Imbabura areas, respectively. Abaca and cabuya fibers were extracted from the plant leaves using the decortication technique, which can be manual or mechanical []. Afterward, through a drying procedure, 4 to 5% of the mass of leaves was obtained as large fibers. These fibers were cut manually and became tangled (non-woven) mechanically using a studded rotating drum. Coir fiber was obtained from recyclers which sell the fiber already tangled.

Each fiber was submerged in a liquid binder composed of water (50%), wood glue (35%), and calcium hydroxide Ca(OH)2 (15%). This was carried out to eliminate the biological constituents, dirt, and any other particles attached to the fibers. After that, the fibers were placed in 30 × 30 cm wooden-made frames with different thicknesses between 20 and 60 mm, and once they were drained off, the fibers were totally dried using a stove at 70 degrees Celsius for about 8 h, obtaining homogeneous samples.

Figure 2 shows the process followed from the extraction of the fibers to the preparation of the samples. The process for extracting abaca, cabuya, coir, and totora fibers is explained in Section 2.1.1, Section 2.1.2, Section 2.1.3 and Section 2.1.4 of the Methodology. The procedure shown in the figure can be applied to the preparation of abaca, cabuya, and coir samples (considering that the local farmers sold the coir fibers already tangled).

Figure 2.

Process followed from the extraction of the fiber till the obtention of the definite samples to be tested in the guarded hot plate and the impedance tube.

Due to the different dimensions of the totora fiber, the sample preparation was set as an oriented strand totora board (OSTB). Totora was harvested by local communities in the proximity of San Pablo Lake in Ecuador. Stems were submerged in a liquid composed of water (96%), borax salt (2%), and boric acid (2%) for healing purposes and dried by at least 10 days of sun exposure. Dried stems were cut into 5–9 cm lengths and shredded to obtain totora pulp [,]. Two specimens were obtained binding the totora pulp (65%) with: (1) ATV29 glue (25%) and water (10%), and (2) hot silicone resin (35% polyvinyl acetate), as an OSTB. The composites were pressed into a wooden frame and dried.

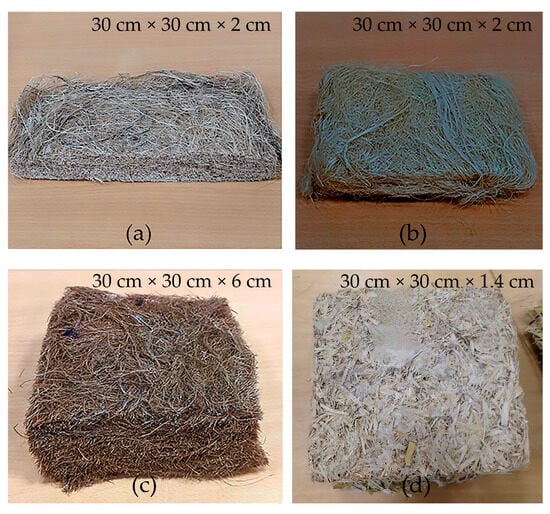

Tensile strength and stress were evaluated with a 50% specific deformation according to the ASMT D575-91 standard []. The assessed samples are shown in Figure 3.

Figure 3.

Examples of the samples made with the assessed fibers: (a) abaca (Musa textilis), (b) cabuya (Furcraea andina), (c) coir (Cocos nucifera), and (d) totora (Schoenoplectus californicus).

The diameter of the fibers was variable, with a width of the fibers ranging between abaca 100 and 300 micron (µm) []; cabuya: 10 and 200 µm [] and coir: 70 and 500 (µm) [,]. The totora samples are composed of pressed pieces of the stem of the cattail plant, with the fibers joined together, and the thickness variability can reach 1.5 mm []. The length of the fibers was variable because farmers sold them with the maximum length that they could extract from the plant. The length of fiber samples is the result of cutting or folding the fibers after the nonwoven forming process, so can vary between approximately 15 and 45 cm.

2.3. Thermal Conductivity

Thermal insulation materials are designed to reduce temperature flow transmission and are typically assessed via thermal conductivity (λ). This parameter, expressed in W/m·K, measures the steady-state heat flow through a unit area of material and is determined following the ISO 8302:1991 [] standard using the guarded hot plate method for homogeneous composites. In this study, thermal conductivity was measured with the Lambda Messtechnik hot plate thermal conductivity meter, model λ-Meter EP500e (Messtechnik, Dresden, Germany). The measurement is obtained under steady-state conditions by evaluating the material’s thickness, heat flow, and surface temperature. Most heat flux passes perpendicularly through the sample, calculated via the Joule effect by monitoring the electricity in the cartridge heaters []. The thermal conductivity is calculated according to Fourier’s law. Guarded hot-plate measurements yield an equivalent thermal conductivity value for fiber samples, considering the solid phase and air cavities within a sample panel. Despite being designed for homogeneous materials, the guarded hot-plate method is also reliable for analyzing materials with non-homogeneous but consistent geometric structures [].

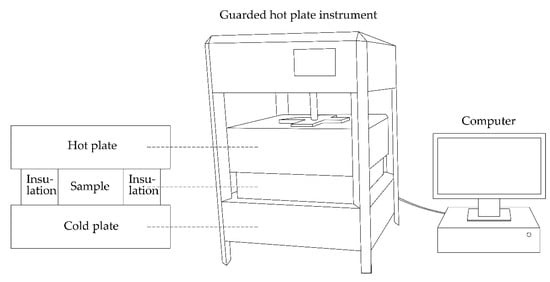

Figure 4 shows the Lambda-Messtechnik guarded hot-plate measurements apparatus employed to measure the thermal conductivity precisely under controlled conditions.

Figure 4.

Guarded hot plate instrument to measure the thermal conductivity of the samples.

The thermal conductivity was determined under steady-state conditions by measuring the sample’s thickness, heat flow, and constant surface temperatures. To get a thermal balance, the measurement was conducted for one hour. Four squared-shaped samples of each material were measured. The mean and standard deviation of the thermal evaluation were calculated. The procedure allows measuring a range of conductivities from 0.002 to 2.5 W/m·K. According to laboratory data, the results were obtained at average temperatures between 10 °C and 50 °C, with a temperature differential between plates of 15 °C []. A material is typically deemed a thermal insulator if its conductivity is less than 0.07 W/m·K. The measurement device evaluates the energy flow through the sample by considering the surface temperatures of the sensor plates and the sample thickness. From these measurements, it directly calculates thermal conductivity and thermal resistance, regardless of the material type and thickness. Before testing, all samples were conditioned for 24 h in an environment maintained at 23 °C with humidity below 60%. The conditions of the environment meet the recommendations of the ISO 8302:1991 [] and the ASTM C518-23 [].

2.4. Sound Absorption Coefficient

Sound absorption properties are related to the ability of materials to dissipate the incident acoustic energy. This parameter can be measured using an impedance tube for small samples in compliance with ISO 10534-2:1998 [] and for large samples in a reverberation room according to ISO 354:2003 []. These methods identify two different kinds of sound absorption coefficients for normal incidence and random incidence, respectively.

Kundt’s tube testing, also known as the impedance tube method, is a well-established technique for determining the sound absorption coefficient of materials. This method operates on the principle of measuring the standing wave ratio in a tube to quantify the interaction of sound waves with a sample material placed inside the tube. The sound absorption coefficient (α) is a crucial parameter representing the efficiency of a material in absorbing incident sound energy.

The sound absorption coefficient can be defined as follows:

where R is the reflection coefficient, calculated as the ratio of the reflected sound pressure amplitude () to the incident sound pressure amplitude () [,].

α = 1 − ∣R∣2

To measure these pressure amplitudes accurately, the impedance tube setup utilizes two microphones positioned at specific locations along the tube. These microphones capture the sound pressure levels, which are then used to determine the complex acoustic impedance () of the material []. The specific acoustic impedance at the sample surface is given by the following:

where and are the incident and reflected sound pressures, respectively, and and are the particle velocities of the incident and reflected waves, respectively [].

The normal incidence sound absorption coefficient is derived from the specific acoustic impedance using the following:

Here, represents the characteristic impedance of air, typically 413 Ns/m3 [].

In practice, the measurements conform to standards such as ISO 10534-2:1998, which specifies the procedures for obtaining the sound absorption coefficient and acoustic impedance in an impedance tube []. According to ISO 10534-2, the transfer function method is employed to accurately capture the sound pressure data, which involves calculating the transfer function between the two microphone signals [].

The complex reflection coefficient R is then determined by the following:

where is the transfer function between the two microphones, k is the wavenumber, and and are the positions of the two microphones [].

By incorporating these formulations and adhering to standardized procedures, the impedance tube method provides precise measurements of the sound absorption coefficient, enabling researchers and engineers to evaluate and enhance the acoustic properties of materials effectively [,]. Measurements were carried out in 2019. Consequently, the sound absorption coefficient of normal incident measurement was conducted using the impedance tube testing according to ISO 10524-2: 1998 []. Fiber samples were inserted into a 33 mm sample holder at the end of the impedance tube, ensuring no air gaps behind the sample. A loudspeaker at the opposite end emitted a white noise signal. According to the standard, the sound absorption coefficient is defined as the ratio of sound power not reflected by the sample to the incident sound power. The noise signal was perpendicularly incident on the sample’s circular surface. Two ½’’ pre-polarized free-field microphones (GRAS 46AO (Gras, Holte, Denmark)) were placed between the loudspeaker and the sample to capture the sound pressure within the impedance tube. The Spectronics ACUPRO measurement set was used to conduct the measurements. The ACUPRO 4.5 software facilitated calibration, data acquisition, signal recording, and the derivation of transfer functions between the microphones. For this study, frequencies from 500 Hz to 5 kHz were used. The ACUPRO 4.5 software was configured so that each measurement set value was the average of 100 measurements performed. However, these data are not provided by the software.

Each fiber sample was tested three times, with the sample being removed and reinserted into the holder after each measurement. The averaged results of these measurements were recorded for each fiber sample. For the acoustic measurements, repeated measures ANOVA within samples (between the sound absorption coefficient resulting from the three measurements of each sample) were conducted. It is a statistical technique used to evaluate whether significant differences exist between the means of three or more conditions, where the same samples are tested under each condition multiple times. The non-rejection of the null hypothesis (p-valor > 0.05) denotes that the measurements did not show any statistically significant difference, thereby assisting in validating the significance and reliability of the results.

Figure 5 illustrates the setup for measuring the sound absorption coefficient.

Figure 5.

Spectronics impedance tube (a), with microphones (b), sample holder (c), data acquisition system (d), amplifier (e), speaker (f), and PC connection (g).

The categorization of the tested samples as acoustic porous materials can be justified based on the structural configuration of the samples which permits the establishment of interconnected pores allowing the transmission of acoustic waves. The dissipation of acoustic energy can be attributed to the effects of the viscous boundary layer and thermal conduction from the ambient air to the sample []. The sound absorption capabilities of porous materials are subject to the influence of factors associated with the intrinsic properties of the material (such as flow resistivity, open porosity, and tortuosity) as well as considerations relating to the manufacturing process and installation procedures (including thickness, positioning within the acoustic field, and the angle of incidence of the acoustic wave).

The quantification of the flow resistivity involves comparing the pressure differential across a sample of material to the normal flow velocity within the material. This evaluation allows for the determination of the degree of air penetration in a porous material and the level of resistance that airflow encounters within a structure.

Open porosity pertains to the comparison between the interconnected pores and the total material volume. The ability to accommodate diverse porosity levels enables the enhancement of sound absorption capabilities, particularly at lower frequencies []. Tortuosity is described as the ratio between the average acoustic path length and the overall thickness of the sample. This metric assists in defining the frequency at which the most pronounced dissipative effects manifest, thereby leading to peak sound absorption values.

The dissipative effect of porous absorbers is primarily due to the conversion of sound energy into heat through viscous and thermal losses. The speed of air particles within the material significantly influences the absorption efficiency, with higher particle velocities leading to greater energy dissipation. These principles are critical in designing effective acoustic treatments that optimize the sound absorption properties of porous materials. Sound absorption is most effective when the material thickness is approximately one-quarter of the wavelength of the target frequency.

3. Results and Discussion

3.1. Mechanical Sample Properties

Table 3 shows the thickness, density, and tensile properties of the four fibers under study. It is worth noting that fibers of lower densities provide a voluminous fibrous structure compared to high-density fibers. This allows better sound absorption and thermal insulation applications [].

Table 3.

Bulk density (kg/m3), tensile strength (N), and tensile stress (kPa) of the samples made for the study. The acronyms used are AB30 and AB20 for the abaca fiber samples of 30 and 20 mm, CB45 and CB20 for the cabuya fibers samples of 45 mm and 20 mm, CN60, and CN40, for the coir samples of 60 mm and 40 mm, TV14 for the totora fiber sample of 14 mm with a random fiber disposition, and OSTB20 for the oriented strand totora sample of 20 mm.

The fibers with lower tensile stress are the ones of abaca, with 70.58 kPa and 56.56 kPa, respectively, for the samples of 30 mm (AB30) and 20 mm (AB20). The highest tensile stress corresponds to the OSTB20 totora sample, probably because the ordered distribution of the fibers together with the silicone resin used as binder confers the sample a higher cohesion and elasticity between the different components, and a better behavior when the material is subjected to tensile forces. Since silicon is more elastic than glue, OSTB20 has a better tensile stress than the TV14 totora sample, composed also of oriented fibers (but bound with glue). As the OSTB20 totora sample has a higher cohesion between particles, it also presents the best tensile strength (6110.00 N) even though it has a small thickness. The sample with the second-best tensile strength is also the one made of oriented strand totora fibers, probably because both samples (TV14 and OSTB20) have higher compacity than other materials, and consequently a greater resistance to compressive stress. This can be seen in the high density, 155.0 kg/m3 and 244.0 kg/m3, respectively, of the samples TV14 and OSTB20. Consequently, the samples with better performance are the ones of the totora fiber since they have small thicknesses with the best mechanical properties.

The comparison of mechanical attributes between sample thicknesses of the same type of fiber shows notable differences in performance. Considering, for example, the cabuya fiber, the mechanical analysis demonstrates that thicker cabuya fiber specimens exhibit significantly better mechanical performance, with higher tensile strength and stress values, compared to thinner specimens. This enhanced performance is due to increased fiber–fiber interaction, better load distribution, and more efficient stress transfer within thicker samples. Consequently, thicker fiber samples (except for the totora, which present different settings) are more suitable for high-stress applications such as structural reinforcements, while thinner fibers are better suited for applications with lower mechanical demands or where weight and space are limiting factors.

3.2. Thermal Conductivity Assessment

The effective thermal conductivity (Keff) allows the evaluation of the effectiveness of the thermal insulation of the fibers. The lower the Keff, the more effective the thermal insulator. The core of the abaca, cabuya, and coir fibers is porous, and the air is entrapped. The heat transfers through both the solid and porous components. However, the thermal conductivity of the air within the pores is lower than that of the solid component. It results in a lower overall thermal conductivity [].

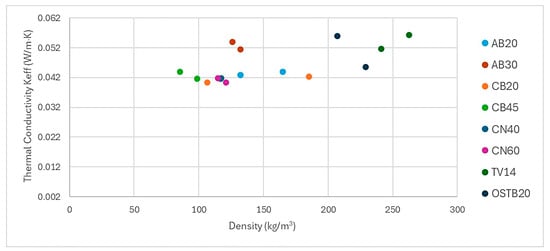

As is observed, Keff increases with the increase in the thickness of the specimens, but it is not appreciated in the relationship between Keff and bulk density, against Mehrzad et al. [] for sugarcane bagasse waste fiber. However, the obtained Keff for all the samples allows for classifying the assessed fibers as thermal insulators. Hence, these materials may be considered as potential building components to reduce heat transfer in air-conditioned buildings to decrease energy consumption. The almost constant thermal behavior of the fibers suggested the possibility of large use of this material without its preliminary selection for buildings’ thermal insulation scope. Table 4 reports a comparison between the thermal conductivity of the samples evaluated with other natural fibers. It can be appreciated that the fibers of the study present similar performance to the ones of other research based on the thermal conductivity of natural fibers. The standard deviations of the thermal conductivity are notably small, indicating the reliability of the results. In addition, the density standard deviations fall within acceptable margins for studies involving natural fibers.

Table 4.

Comparison of the thermal conductivity (Keff, W/m·K) of our study’s samples (abaca, cabuya, coir, and totora) with natural thermal insulators from other research (Bagasse, Buriti foam, Hemp, Pineapple leaf, Bamboo fiber, and Flax). The standard deviation of each measurement is shown between brackets.

Figure 6 shows the relation between Keff (W/m·K) and density (kg/m3) of the samples. It is important to note that the samples are made from natural materials and handcrafted, resulting in non-uniform samples. This may cause some variation in the data. Generally, there is a trend of increasing density leading to higher thermal conductivity, as the gas conduction contribution within these structures becomes insignificant due to smaller pores []. This can be observed in the abaca sample AB20, where an increase in density of 32 kg/m3 results in an increase in thermal conductivity of 0.0011 W/m·K. Similarly, for the cabuya sample CB20, an increase in density of 79 kg/m3 leads to a slight increase in thermal conductivity of 0.021 W/m·K, thus making them less effective insulators.

Figure 6.

Thermal conductivity (Keff (W/m·K)) vs. density (density (kg/m3).

In the coir samples (CN40 and CN60), the thermal conductivities and densities are very similar. The differences, as initially mentioned, are due to irregularities in the manufacturing process of the composite material and even in the fibers themselves. Comparing the conductivity between both sample thicknesses, the CN60 has a higher density, and consequently, higher conductivity.

Totora is a much denser material with smaller pores due to the inherent structure of OSTB, resulting in fewer interconnected pores and reduced thermal conductivity.

3.3. Sound Absorption Coefficient

The sound absorption coefficient of any material is the ratio between the incidence and total acoustic energy, and its mechanism is a thermal effect due to the friction of air molecules with pores. It refers to the ability of materials to reduce sound reflections, and it is used to reduce reverberation time and ensure speech intelligibility. The typical sound absorption coefficient of fibrous material is characterized by a maximum absorption peak, whose position depends on the density and thickness of the material. In any case, it is important to note that the structure of natural fibers allows the use of more diversified modes to attenuate the sound wave energy. Due to the low flow resistivity of the porous samples, the attenuation of the acoustic energy caused by the internal friction is negligible. For the totora samples with higher density, the sound absorption is lower due to the surface reflection and low acoustic permeation.

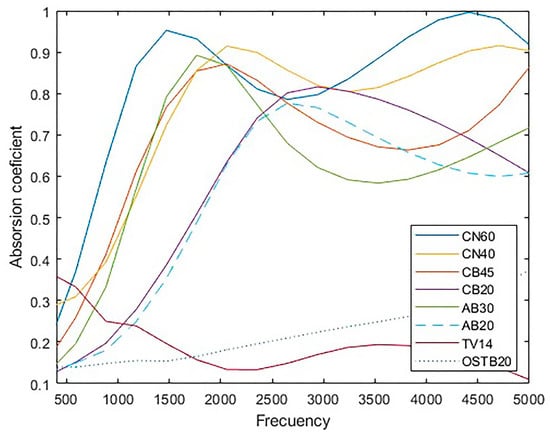

To illustrate the behavior of the different samples, the sound absorption coefficients were measured at normal incidence and plotted in Figure 7.

Figure 7.

Sound absorption coefficients of the natural fibers assessed. The acronyms used in the graphic are CN60 and CN40, for the coir fiber samples of 60 mm and 40 mm, CB45 and CB20 for the cabuya fibers sample of 45 mm and 20 mm, AB30, and AB20 for the abaca fiber samples of 30 and 20 mm, TV14 for the totora fiber sample of 14 mm with a random fiber disposition, and OSTB20 for the oriented strand totora sample of 20 mm.

For the porous fibers, both coir fibers and thicker cabuya and abaca samples present sound absorption coefficients above 0.5 for frequencies higher than 1 kHz. Thinner samples of cabuya and abaca are very efficient for sound absorption (>0.5) for frequencies above 2 kHz, and hence represent excellent sound absorption properties for high frequencies.

The fiber with the best acoustic performance is 60 mm thick coconut fiber (CN60), with an acoustic coefficient value of 0.95 at 1600 Hz, and 0.90 and 0.88 at the previous (1250 Hz). and posterior (2000 Hz) third-octave band; a second peak of 0.96 can be observed at 4000 Hz, with values of the absorption coefficients at the anterior and posterior frequencies bands of 0.82 (3150 Hz) and 0.92 (5000 Hz). The minimum values are given at 500 Hz and 630 Hz, with sound absorption coefficients of 0.30 and 0.40, respectively. The 40 mm coir sample (CN40) also presents very good acoustic performance, with a peak in the distribution of the absorption coefficient in the frequency range shown in Figure 7 of 0.92 at 2000 Hz, and values in the anterior (1600 Hz) and posterior (2500 Hz) frequency bands of 0.87 and 0.85, respectively; there is also a second peak at 5000 Hz of 0.92.

Figure 7 shows that the maximum sound absorption peak depended on the thickness; the low-frequency position of the maximum absorption peak corresponded to the 60 mm thick sample. When the thickness of the samples was increased, the maximum absorption peak was displaced to lower frequencies, and it is an effect that can be observed for the paired samples of the cabuya, abaca and coir fibers.

For totora fibers, the sound absorption coefficients were discreet, ranging from 0.12 to 0.36 within the frequency range of the study, which is explained by the lack of porosity in the samples assessed. It is worth noting that the TV14 (totora) sample performs a singular sound absorption curve compared to the other materials evaluated. It can be explained due to its thickness (14 mm), which can be considered a frequency-selecting sound absorber around 500 Hz.

It can be observed that mechanical properties and sound absorption coefficients do not keep a positive relationship with the acoustic absorption, since the fibers with better mechanical materials (totora) have the worst sound absorption coefficients.

Even though the frequency response of the sound absorption coefficient at different frequencies is important to understand the material behavior, its properties can also be defined through a single index for direct and easy comparisons between materials. The Noise Reduction Coefficient (NRC) is the average sound absorption coefficient in 250 Hz, 500 Hz, 1000 Hz, and 2000 Hz octave frequency bands, and it is widely used commercially to represent the sound absorption properties.

Table 5 shows the outcomes of the Repeated measures ANOVA within subjects. The test evaluates whether there are statistically significant differences between the sound absorption coefficients of the samples. According to the results, the null hypothesis cannot be rejected for any of the ANOVA tests conducted, since all p-values exceed 0.05. Consequently, it cannot be concluded that there are statistically significant differences between the acoustic absorption coefficients of any of the samples evaluated, underscoring the reliability of the results. Furthermore, the standard deviation of the sound absorption coefficients ranges from 0.001 to 0.026, demonstrating minimal variation across the different frequency bands evaluated (500 Hz to 5000 Hz). This minimal variation further indicates the high consistency of the results

Table 5.

Repeated measures ANOVA (within-subjects) results, conducted with the sound absorption coefficients of the measurements of each sample. Min Sd and Max Sd refer, respectively, to the minimum and maximum standard deviations of the acoustic frequencies evaluated (from 500 Hz to 5000 Hz).

Table 6 shows a comparison of NRC values of the fibers of the present study and other natural fibers, from the studies of Iannace et al. [], Siqueira et al. [], Mehrzad et al. [], Iannace et al. [] and Tabal et al. []. Although the different thicknesses of the samples make the comparison difficult, the highest NRC of our study is 0.53, which corresponds to the 60 mm sample of coir. The 45 mm sample of cabuya also has a very competitive NRC = 0.46. However, the samples of Bagasse and Kenaff also show very good performance in the metric evaluated, and just with 40 mm have an NRC of 0.62 and 0.52, respectively. Although the NRC are not the best in comparison with other natural fibers, the peak values of absorption are very high, presenting themselves as excellent acoustic absorbers, and as a natural alternative to the use of industrial acoustic absorbing materials in room acoustics for responsible and sustainable use of natural resources, and easier management of waste materials from construction sector.

Table 6.

Comparison of Noise reduction coefficient (NRC) of the samples under study (coir, cabuya, abaca and totora) with other natural thermal insulators, as Cocoa, Buriti, Bagasse, Sisal and Kenaf.

The production and distribution of these materials are ecological and sustainable, since they use natural components, fibers, which come from native plants from Ecuador and can be cultivated without affecting natural ecosystems, or in the case of coir, obtained from wastes of the agri-food industry. They have low built-in energy consumption since the fibers are obtained by hand or using mechanical methods. Furthermore, given that the raw materials and production would be carried out in Ecuador, the energy consumption and pollution associated with the transportation and distribution of these products to be used in national regions would be lower than synthetic materials normally used in the construction sector. This can also be applied to other countries in which the plants (from which the fibers of the study are obtained) grow.

Using natural fibers as thermal and acoustic insulators can offer significant social benefits, including improved health and comfort, job creation, economic development, sustainable living, cultural preservation, and affordable housing solutions, which should be demonstrated in further research. Industrial applications span various sectors such as building and construction, automotive, consumer electronics, furniture, aerospace, and packaging, highlighting the versatility and potential of natural fibers in contributing to a more sustainable and eco-friendly future.

3.4. Alignment with the United Nations Sustainable Development Goals

The use of natural fibers like the ones of the present study for acoustic and thermal insulation in the construction sector aligns with several United Nations Sustainable Development Goals (SDGs). The following aspects linked with the United Nations SDGs [] have been highlighted:

- ○

- SDG 1: No poverty. The production and installation of insulation materials made from natural fibers can create jobs in rural and underdeveloped regions, helping to reduce poverty. Additionally, the use of these materials can make construction and building maintenance more affordable, benefiting low-income communities.

- ○

- SDG 3: Good health and well-being is supported by the fact that insulation materials made from natural fibers generally do not contain harmful chemicals, improving indoor air quality and reducing health issues related to indoor pollution. Furthermore, the effective soundproofing provided by these fibers can reduce noise pollution, creating quieter and more restful living and working environments, which positively impacts mental and physical health.

- ○

- SDG 7: Affordable and clean energy, natural fibers possess excellent thermal insulation properties, significantly reducing the need for heating and cooling. This results in lower energy demand and associated costs, promoting more affordable and sustainable energy use.

- ○

- SDG 8: Decent work and economic growth benefits from the sustainable employment generated in the production, processing, and application of natural fiber insulation materials, particularly in the agricultural and manufacturing sectors. This type of employment promotes inclusive and sustainable economic growth.

- ○

- SDG 9: Industry, innovation, and infrastructure is supported by encouraging the use of natural fibers, which promotes innovation in building materials and more sustainable construction techniques. Additionally, buildings insulated with natural fibers can be more energy efficient and resilient to environmental changes, supporting long-term infrastructure development.

- ○

- SDG 11: Sustainable cities and communities is directly impacted by the use of eco-friendly building materials, such as natural fibers, which help create sustainable and resilient buildings, reducing the environmental footprint of urban development. Moreover, improved living conditions resulting from better acoustic and thermal insulation make homes and workplaces more comfortable and energy efficient.

- ○

- SDG 12: Responsible consumption and production is promoted through the use of natural fibers, which are renewable resources. Their use in insulation encourages responsible consumption by reducing reliance on synthetic materials and fostering sustainable production methods. Additionally, since natural fibers are biodegradable, waste is reduced at the end of the insulation’s lifecycle compared to synthetic materials.

- ○

- SDG 13: Climate action, using natural fibers for insulation can lower greenhouse gas emissions associated with heating and cooling buildings, contributing to climate change mitigation. Furthermore, the plants used to produce these fibers absorb CO2 during their growth, helping to offset carbon emissions.

- ○

- SDG 15: Life on land is supported by sustainable land use in cultivating natural fibers, which can aid in sustainable land management practices and biodiversity conservation. Crops like cabuya or abaca can improve soil health and prevent erosion, promoting sustainable agriculture.

- ○

- Finally, SDG 17: Partnerships for the goals underscores the importance of collaboration among governments, the private sector, academia, and civil society to promote natural fiber insulation. These partnerships are crucial for driving research, policy development, and market adoption of sustainable materials.

Consequently, the use of natural fibers for acoustic and thermal insulation in the construction sector aligns with and promotes several SDGs by enhancing sustainability, supporting economic growth, and may improve health and well-being, and reduce environmental impact.

3.5. Study Limitations and Future Lines of Research

The experiment was conducted using natural fiber coming from several locations in Ecuador. Different types of terrain, climatic conditions, height above sea level, or water salinity can affect the characteristics of the fibers, so these are limitations that can affect the repeatability of the study.

The sound absorption coefficient has been measured in an Impedance tube using samples. To do this, it is necessary to build panels from which to extract these samples. The values shown in the study are the result of the average acoustic absorption calculated from several samples of each material and thickness extracted from the panels; however, given the heterogeneous nature of the material, if a sample is taken from another part of the panel, or from a panel built using the same procedure but by different researchers, the results might be slightly different. Consequently, for optimizing the sample performance, the acoustic requirements should be the panel design drivers, given the high influence of the panel layout on the acoustic features.

It is worth noting that the flammability and fungal growth may limit the widespread usage of the assessed fibers in construction projects. Therefore, these fibers must be treated before installation to achieve acceptable levels of resistance to combustion and fungi.

The disappearance of many handmade products and traditional construction elements due to industrialization highlights the need to find new applications for these natural materials, which are deeply rooted in Ecuadorian culture. The materials used in this study are naturally sourced and have the potential to be biodegradable or recyclable, significantly reducing environmental impact compared to conventional artificial materials used in thermo-acoustic isolation. Utilizing these natural materials near their collection and production sites further minimizes the environmental footprint, promoting sustainability in the construction sector. This is achieved through eco-friendly manufacturing processes and the reduction of pollution associated with the transportation and distribution of construction materials. Additionally, adopting these materials can stimulate the growth of small family businesses, thereby enhancing the economic stability of low- and middle-income countries.

Implementing a circular economy, which encourages the recycling and reuse of materials, is crucial for maximizing efficiency and sustainability. Plants specifically cultivated for construction materials, do not harm the natural ecosystems, and represent a renewable option that can be continuously replenished, further integrating sustainability into the construction supply chain. Promoting the use of planted materials conserves natural resources and supports sustainable agricultural practices, closing the loop between production and consumption in a responsible and eco-friendly manner.

Future research on the use of natural fibers as thermal and acoustical insulation in the construction industry should focus on several key areas to fully realize their potential. One critical aspect is the long-term durability of these fibers, including their resistance to moisture, pests, and microbial growth, which could affect performance over time. Additionally, studies should assess the behavior of natural fiber insulators under different environmental conditions, such as varying humidity, temperature fluctuations to ensure reliability across diverse climates. Integration with various building elements, including walls, roofs, and floors, must also be explored to understand how natural fibers interact with other materials and contribute to overall building performance. Furthermore, comprehensive cost-benefit analyses are essential to compare the economic feasibility of natural fibers against traditional insulation materials, considering not only initial costs but also long-term savings from improved energy efficiency and potential maintenance reductions. Future research can support the wider adoption of natural fibers, promoting sustainability and innovation in the construction field.

4. Conclusions

In this work, thermal conductivities, mechanical and sound absorption properties of four traditional Ecuadorian fibers were investigated: abaca, cabuya, coir and totora. Their mechanical properties, together with their thermal and acoustic insulation were evaluated. After collection from local communities, fibrous samples of different thicknesses and densities were fabricated, as eco-friendly and cost-effective materials. The hot guarded plate technique and the impedance tube method were used for thermal conductivity assessment, and sound absorption coefficients, respectively. The main conclusions obtained in this study are the following:

- The tensile strength values of the fiber samples range from 593.33 (N) of the AB20 to 6110.00 (N) of the OSTB20. The tensile stress varies from 56.55 (kPa) (AB20) to 669.33 (kPa) (OSTB20).

- The thermal conductivity of the fiber samples varied from 0.0439 W/m·K (CB20) to 0.0564 W/m·K (OSTB20), performing good thermal insulation attributes for building applications.

- The NRC of the fiber samples ranges from 0.12 (OSTB20) to 0.53 (CN60). The fibers’ samples have an average sound absorption coefficient of 0.84 above 2 kHz for thicknesses of 40–60 mm and of 0.69 for thicknesses of 20–30 mm. The fibers also have comparable sound absorption coefficients with other natural fibers.

- The results suggest that the assessed fibers can be used as natural and sustainable materials to replace traditional synthetic thermo-acoustic absorbers. The materials of the study have a natural origin and potential to be biodegradable or recycled after use, which means that they will have a low environmental impact compared to artificial materials traditionally used in construction for thermoacoustic applications. The use of these natural materials near collection and production sites also reduces the environmental footprint, not only because their manufacturing processes are environmentally friendly, but also because they can reduce pollution due to the transportation and distribution of the construction materials. They can also promote the creation of small family industries at the local or regional level, promoting the economic strengthening of low- or middle-income countries. The use of natural fibers as thermal and acoustic insulators can offer significant social benefits, including improved health and comfort, job creation, economic development, sustainable living, cultural preservation, and affordable housing solutions, which should be demonstrated in further research. Industrial applications span various sectors such as building and construction, automotive, consumer electronics, furniture, aerospace, and packaging, highlighting the versatility and potential of natural fibers in contributing to a more sustainable and eco-friendly future.

- The use of natural fibers as thermal and acoustical insulators also aligns with the UN- SDGs. Leveraging natural fibers directly supports SDG 9 (Industry, Innovation, and Infrastructure) by promoting innovative, eco-friendly construction materials that advance sustainable industrial practices. This also aligns with SDG 11 (Sustainable Cities and Communities) by enhancing building efficiency and comfort, leading to healthier living environments. The production and use of natural fibers bolster SDG 8 (Decent Work and Economic Growth) by creating jobs in rural areas and stimulating local economies, thus supporting SDG 1 (No Poverty) and SDG 10 (Reduced Inequalities). Furthermore, natural fibers contribute to SDG 12 (Responsible Consumption and Production) by reducing reliance on non-renewable resources and minimizing environmental impact, and SDG 13 (Climate Action) by lowering greenhouse gas emissions through sustainable agricultural practices and the use of biodegradable materials. Integrating these fibers into building practices not only improves thermal and acoustic performance but also fosters a holistic approach to sustainable development.

Author Contributions

Conceptualization, L.B.-M., M.A.-G. and V.P.-R.; samples fabrication, V.P.-R., M.A.-G., L.B.-M. and O.J.; sample measurements, M.A.-G., L.B.-M., V.P.-R. and V.H.G.; formal analysis, L.B.-M., V.P.-R., V.H.G. and G.C.; writing—original draft preparation, L.B-M., V.P-R. and G.C.; writing—review and editing, L.B.-M., V.P.-R., V.H.G., O.J. and G.C.; funding acquisition, L.B.-M. and V.P.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universidad de Las Américas, under the grant numbers SOA.LBM.19.04 and 531.B.XV.24.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors are grateful to José Macías, Efraín Pulloquinga, Orlando Campaña, Jean Pierre Buenaño, and Mateo Castro for their valuable contribution to the project. Table 1 and Table 2 were partially reprinted from [], pages No. 843-844, Copyright 2015 and [], page No. 994, Copyright 2016, respectively, with permission from Elsevier.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Environmental Protection Department. Monitoring of Solid Waste in Hong Kong—Waste Statistics for 2021; Environment and Ecology Bureau: Tamar, Hong Kong, 2022. [Google Scholar]

- Li, Y.; Zhang, X. Comparison and Analysis of International Construction Waste Management Policies. In Construction Research Congress ASCE 2012; ASCE: Reston, VA, USA, 2012; pp. 1672–1681. [Google Scholar]

- Kartam, N.; Al-Mutairi, N.; Al-Ghusain, I.; Al-Humoud, J. Environmental Management of Construction and Demolition Waste in Kuwait. Waste Manag. 2004, 24, 1049–1059. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and Demolition Waste Management in China through the 3R Principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- European Commission. Buildings and Construction—European Commission. Available online: https://single-market-economy.ec.europa.eu/industry/sustainability/buildings-and-construction_en (accessed on 30 May 2024).

- Kofoworola, O.F.; Gheewala, S.H. Estimation of Construction Waste Generation and Management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef]

- Lordsleem Júnior, A.C.; Fucale, S.P. Quantitative Assessment of Waste Management in Brazilian Construction Sites. In Proceedings Sardinia 2009, Twelfth International Waste Management and Landfill Symposium; RILEM Publications SARL: Descartes, France, 2009. [Google Scholar]

- Buildings Lands and Planning Departments. Second Package of Incentives to Promote Green and Innovative Buildings Introduction Joint Practice Note No. 2; Planning Department: Hong Kong, China, 2002. [Google Scholar]

- Hao, J.L.; Hills, M.J.; Tam, V.W.Y. The Effectiveness of Hong Kong’s Construction Waste Disposal Charging Scheme. Waste Manag. Res. 2008, 26, 553–558. [Google Scholar] [CrossRef]

- Commission to the European Parliament and the Council. Strategy for the Sustainable Competitiveness of the Construction Sector and Its Enterprises. COM 2012, 66, 37–39. [Google Scholar]

- The European Parliament and the Council of the European Union—Official Journal of the European Union. Directive 2008/98/EC of 19 November 2008 on Waste and Repealing Certain Directives; European Sources Online: Cardiff, UK, 2008; pp. 3–30. [Google Scholar]

- Regions Commission to the European Parliament and the Council—The European Economic and Social Committee. A New Circular Economy Action Plan For a Cleaner and More Competitive Europe; Publications Office of the European Union Luxembourg: Luxembourg, 2020. [Google Scholar]

- Islam, R.; Hassan, T.; Yuniarto, A.; Uddin, A.S.M.S.; Salmiati, S. An Empirical Study of Construction and Demolition Waste Generation and Implication of Recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Commission to the European Parliament and the Council. Reglamento Europeo Sobre Productos de Construcción. P9_TA(2023)0253. 2024. Available online: https://www.europarl.europa.eu/doceo/document/TA-9-2023-0253_EN.pdf (accessed on 17 July 2024).

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Hebel, D.E.; Heisel, F. Cultivated Building Materials: Industrialized Natural Resources for Architecture and Construction; Birkhäuser: Basel, Switzerland, 2017. [Google Scholar]

- Sahat, S.; Ahmad, N.F.; Razali, S.N.A.M.; Kaamin, M.; Mokhtar, M.; Hamid, N.B.; Nyadiman, N. Effectiveness of Corn Cob as a Thermal Isolation Material. AIP Conf. Proc. 2018, 2016, e020127. [Google Scholar]

- Dewi, S.M.; Wijaya, M.N.; Christin Remayanti, N. The Use of Bamboo Fiber in Reinforced Concrete Beam to Reduce Crack. In AIP Conference Proceedings. Green Construction and Engineering Education for Sustainable Future; AIP Publishing: Melville, NY, USA, 2021; Volume 020003. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs. Sustainable Development Goals. Available online: https://sdgs.un.org/goals (accessed on 5 July 2024).

- Gramez, A.; Boubenider, F. Acoustic Comfort Evaluation for a Conference Room: A Case Study. Appl. Acoust. 2017, 118, 39–49. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent Trends in Porous Sound-Absorbing Materials. Sound Vib. 2010, 44, 12–18. [Google Scholar]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of Natural Fibers. Part I—Vegetable Fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- Abd Rashid, A.F.; Yusoff, S. A Review of Life Cycle Assessment Method for Building Industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Horoshenkov, K.V.; Khan, A.; Benkreira, H. Acoustic Properties of Low Growing Plants. J. Acoust. Soc. Am. 2013, 133, 2554–2565. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.S.; Kang, J.; Cheal, C. Random-Incidence Absorption and Scattering Coefficients of Vegetation. Acta Acust. United Acust. 2013, 99, 379–388. [Google Scholar] [CrossRef]

- D’Alessandro, F.; Asdrubali, F.; Mencarelli, N. Experimental Evaluation and Modelling of the Sound Absorption Properties of Plants for Indoor Acoustic Applications. Build. Environ. 2015, 94, 913–923. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Membrane-Type Acoustic Metamaterial Using Cork Sheets and Attached Masses Based on Reused Materials. Appl. Acoust. 2022, 189, 108605. [Google Scholar] [CrossRef]

- Ciaburro, G.; Puyana-Romero, V.; Iannace, G.; Jaramillo-Cevallos, W.A. Characterization and Modeling of Corn Stalk Fibers Tied with Clay Using Support Vector Regression Algorithms. J. Nat. Fibers 2021, 19, 7141–7156. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Puyana-Romero, V.; Trematerra, A. A Comparison between Numerical Simulation Models for the Prediction of Acoustic Behavior of Giant Reeds Shredded. Appl. Sci. 2020, 10, 6881. [Google Scholar] [CrossRef]

- Lim, Z.Y.; Putra, A.; Nor, M.J.M.; Yaakob, M.Y. Sound Absorption Performance of Natural Kenaf Fibres. Appl. Acoust. 2018, 130, 107–114. [Google Scholar] [CrossRef]

- Putra, A.; Or, K.H.; Selamat, M.Z.; Nor, M.J.M.; Hassan, M.H.; Prasetiyo, I. Sound Absorption of Extracted Pineapple-Leaf Fibres. Appl. Acoust. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Ersoy, S.; Küçük, H. Investigation of Industrial Tea-Leaf-Fibre Waste Material for Its Sound Absorption Properties. Appl. Acoust. 2009, 70, 215–220. [Google Scholar] [CrossRef]

- Moghaddam, M.K.; Safi, S.; Hassanzadeh, S.; Mortazavi, S.M. Sound Absorption Characteristics of Needle-Punched Sustainable Typha /Polypropylene Non-Woven. J. Text. Inst. 2015, 107, 145–153. [Google Scholar] [CrossRef]

- Asdrubali, F.; Pisello, A.L.; D’Alessandro, F.; Bianchi, F.; Fabiani, C.; Cornicchia, M.; Rotili, A. Experimental and Numerical Characterization of Innovative Cardboard Based Panels: Thermal and Acoustic Performance Analysis and Life Cycle Assessment. Build. Environ. 2016, 95, 145–159. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; de Baynast, H.; Michaud, P.; Dupont, T.; Leclaire, P. Sound Absorption Properties of a Sunflower Composite Made from Crushed Stem Particles and from Chitosan Bio-Binder. Appl. Acoust. 2016, 111, 179–187. [Google Scholar] [CrossRef]

- Othmani, C.; Taktak, M.; Zain, A.; Hantati, T.; Dauchez, N.; Elnady, T.; Fakhfakh, T.; Haddar, M. Acoustic Characterization of a Porous Absorber Based on Recycled Sugarcane Wastes. Appl. Acoust. 2017, 120, 90–97. [Google Scholar] [CrossRef]

- Martellotta, F.; Cannavale, A.; De Matteis, V.; Ayr, U. Sustainable Sound Absorbers Obtained from Olive Pruning Wastes and Chitosan Binder. Appl. Acoust. 2018, 141, 71–78. [Google Scholar] [CrossRef]

- Reixach, R.; Del Rey, R.; Alba, J.; Arbat, G.; Espinach, F.X.; Mutjé, P. Acoustic Properties of Agroforestry Waste Orange Pruning Fibers Reinforced Polypropylene Composites as an Alternative to Laminated Gypsum Boards. Constr. Build. Mater. 2015, 77, 124–129. [Google Scholar] [CrossRef]

- Ricciardi, P.; Torchia, F.; Belloni, E.; Lascaro, E.; Buratti, C. Environmental Characterisation of Coffee Chaff, a New Recycled Material for Building Applications. Constr. Build. Mater. 2017, 147, 185–193. [Google Scholar] [CrossRef]

- Gómez Escobar, V.; Maderuelo-Sanz, R. Acoustical Performance of Samples Prepared with Cigarette Butts. Appl. Acoust. 2017, 125, 166–172. [Google Scholar] [CrossRef]

- Yeon, J.O.; Kim, K.W. Analysis of Absorption Coefficient for Eco-Friendly Acoustical Absorbers. Adv. Mater. Res. 2014, 831, 58–61. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic Characterization of Natural Fibers for Sound Absorption Applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 989–1011. [Google Scholar] [CrossRef]

- Madhumathi, A.; Sundarraja, M.C.; Shanthipriya, R. A Comparative Study of the Thermal Comfort of Different Building Materials in Madurai. Int. J. Earth Sci. Eng. 2014, 7, 1004–1018. [Google Scholar]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life Cycle Analysis in the Construction Sector: Guiding the Optimization of Conventional Italian Buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Gori, P.; Bisegna, F. Thermophysical Parameter Estimation of Multi-Layer Walls with Stochastic Optimization Methods. Int. J. Heat Technol. 2010, 28, 109–116. [Google Scholar]

- Ingeli, R.; Gašparík, J.; Paulovičová, L. Impact of an Innovative Solution for the Interruption of 3-D Point Thermal Bridges in Buildings on Sustainability. Sustainability 2021, 13, 11561. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance Characteristics and Practical Applications of Common Building Thermal Insulation Materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Berardi, U.; Naldi, M. The Impact of the Temperature Dependent Thermal Conductivity of Insulating Materials on the Effective Building Envelope Performance. Energy Build. 2017, 144, 262–275. [Google Scholar] [CrossRef]

- Harish, S.; Michael, D.P.; Bensely, A.; Lal, D.M.; Rajadurai, A. Mechanical Property Evaluation of Natural Fiber Coir Composite. Mater. Charact. 2008, 60, 44–49. [Google Scholar] [CrossRef]

- Tangjuank, S. Thermal Insulation and Physical Properties of Particleboards from Pineapple Leaves. Int. J. Phys. Sci. 2011, 6, 4528–4532. [Google Scholar] [CrossRef]

- Symington, M.C.; Banks, W.M.; West, O.D.; Pethrick, R.A. Tensile Testing of Cellulose Based Natural Fibers for Structural Composite Applications. J. Compos. Mater. 2009, 43, 1083–1108. [Google Scholar] [CrossRef]

- Takagi, H.; Kako, S.; Kusano, K.; Ousaka, A. Thermal Conductivity of PLA-Bamboo Fiber Composites. Adv. Compos. Mater. 2007, 16, 377–384. [Google Scholar] [CrossRef]

- Stanković, S.B.; Popović, D.; Poparić, G.B. Thermal Properties of Textile Fabrics Made of Natural and Regenerated Cellulose Fibers. Polym. Test. 2008, 27, 41–48. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and Sound Insulation Materials from Waste Wool and Recycled Polyester Fibers and Their Biodegradation Studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Mohammadi, M.; Taban, E.; Tan, W.H.; Din, N.B.C.; Putra, A.; Berardi, U. Recent Progress in Natural Fiber Reinforced Composite as Sound Absorber Material. J. Build. Eng. 2024, 84, 108514. [Google Scholar] [CrossRef]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of Using Natural Fiber for Building Acoustic Absorber: A Review. J. Phys. Conf. Ser. 2019, 1262, 012017. [Google Scholar] [CrossRef]

- Divya, D.; Devi, S.Y.; Indran, S.; Raja, S.; Sumesh, K.R. Chapter 2—Extraction and Modification of Natural Plant Fibers—A Comprehensive Review. In Plant Fibers, Their Composites and Applications; The Textile Institute Book Series; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ozbakkaloglu, T., Wang, H., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 25–50. [Google Scholar] [CrossRef]

- Bande, M.M.; Grenz, J.; Asio, V.B.; Sauerborn, J. Morphological and Physiological Response of Abaca (Musa Textilis Var. Laylay) to Shade, Irrigation and Fertilizer Application at Different Stages of Plant Growth. Int. J. AgriScience 2013, 3, 157–175. [Google Scholar]

- Torres-Guillen, E.N. Production and Exportation of Abacá in Ecuador. 2021. Available online: https://cia.uagraria.edu.ec/Archivos/TORRES%20GUILLEN%20ELENA%20NARCISA.pdf (accessed on 18 July 2024). (In Spanish).

- Yaguachi-Andrade, F.M. Agronomic Management of Abaca (Musa Textilis) Cultivation in Ecuador. 2024. Available online: http://dspace.utb.edu.ec/handle/49000/16096?show=full (accessed on 18 July 2024). (In Spanish).