Advanced Fatigue Assessment of Riveted Railway Bridges on Existing Masonry Abutments: An Italian Case Study

Abstract

1. Introduction

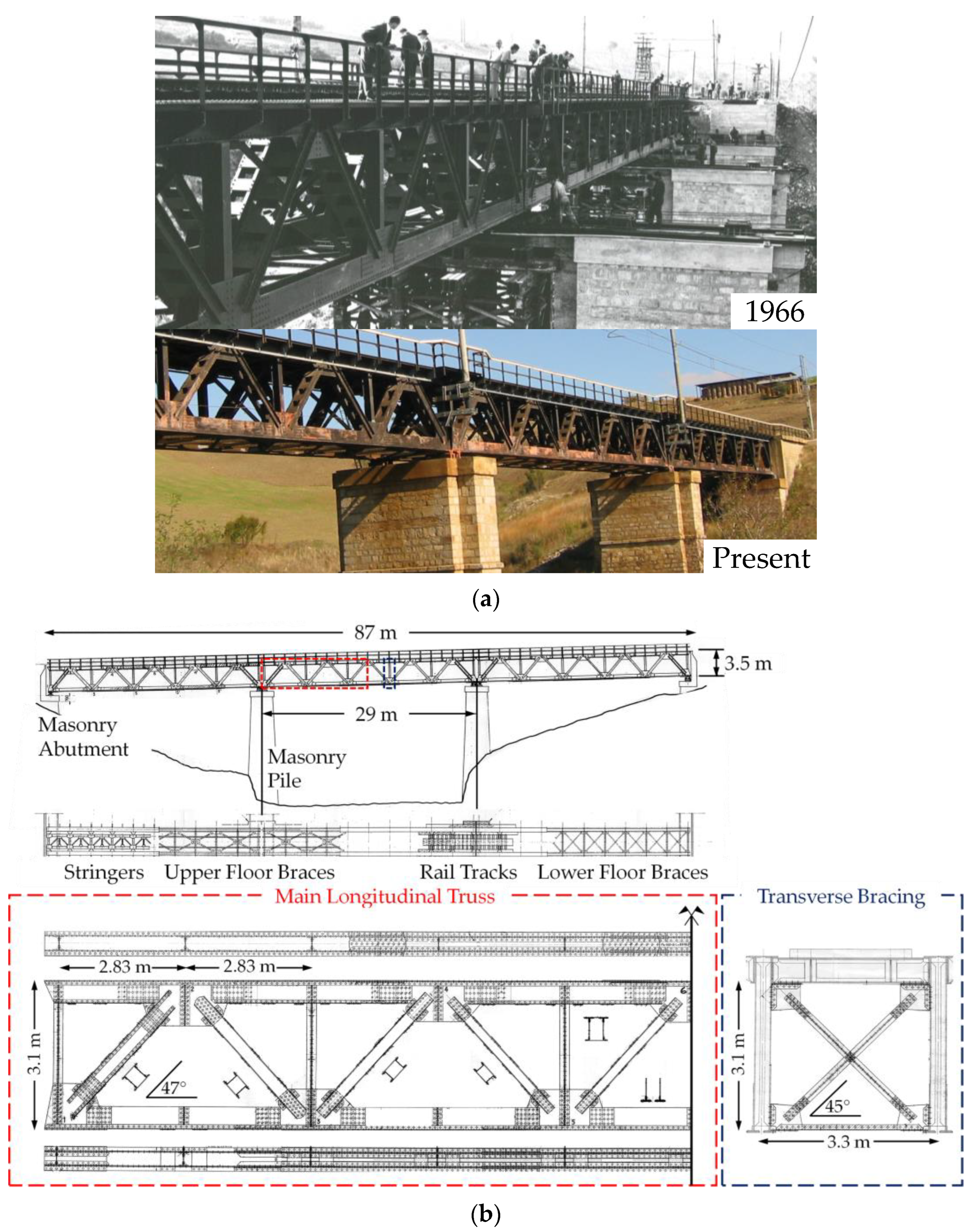

2. Main Features of the Selected Case Study

2.1. Generality

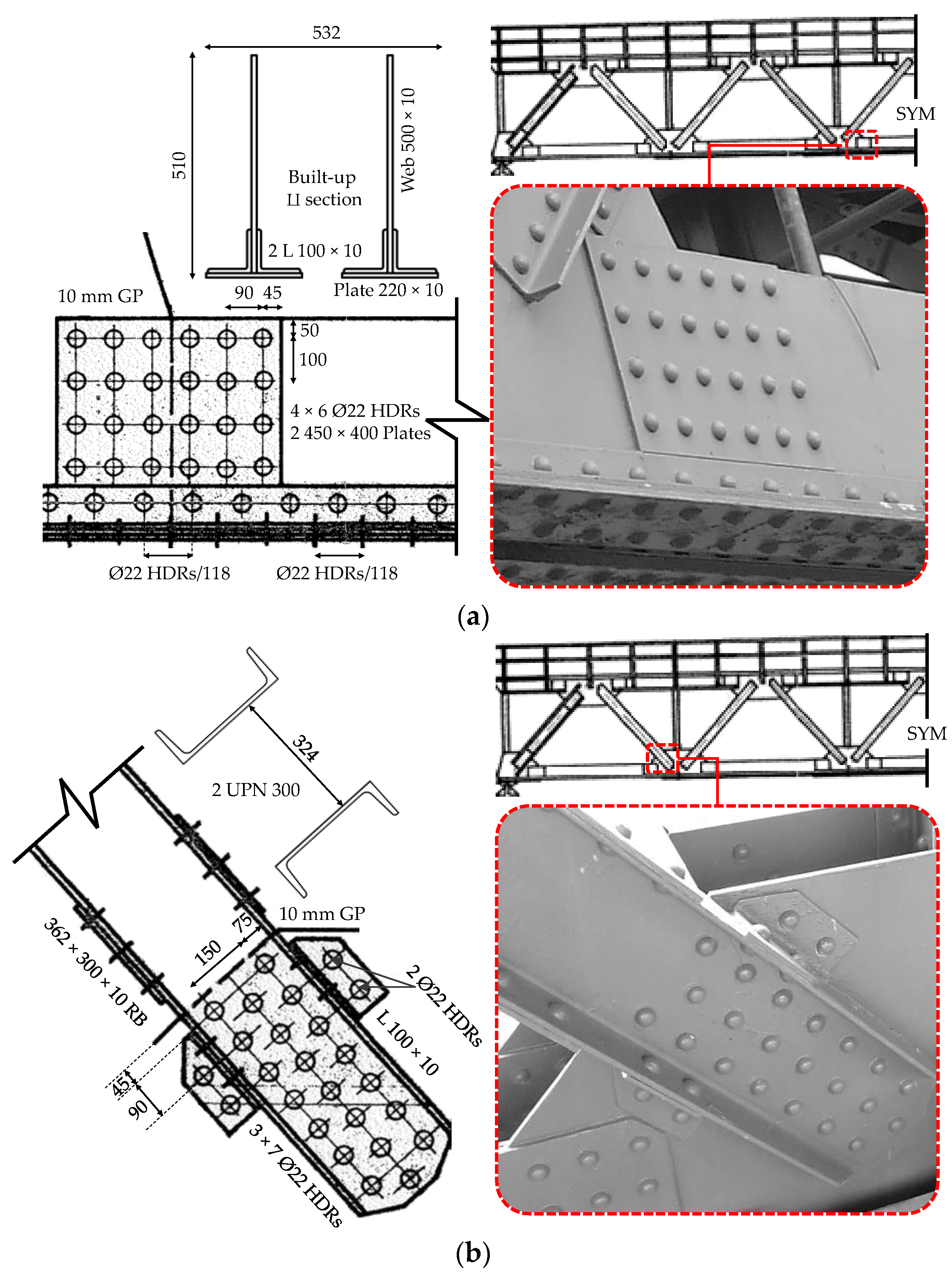

2.2. Description of Investigated Connections

3. Modelling Assumptions

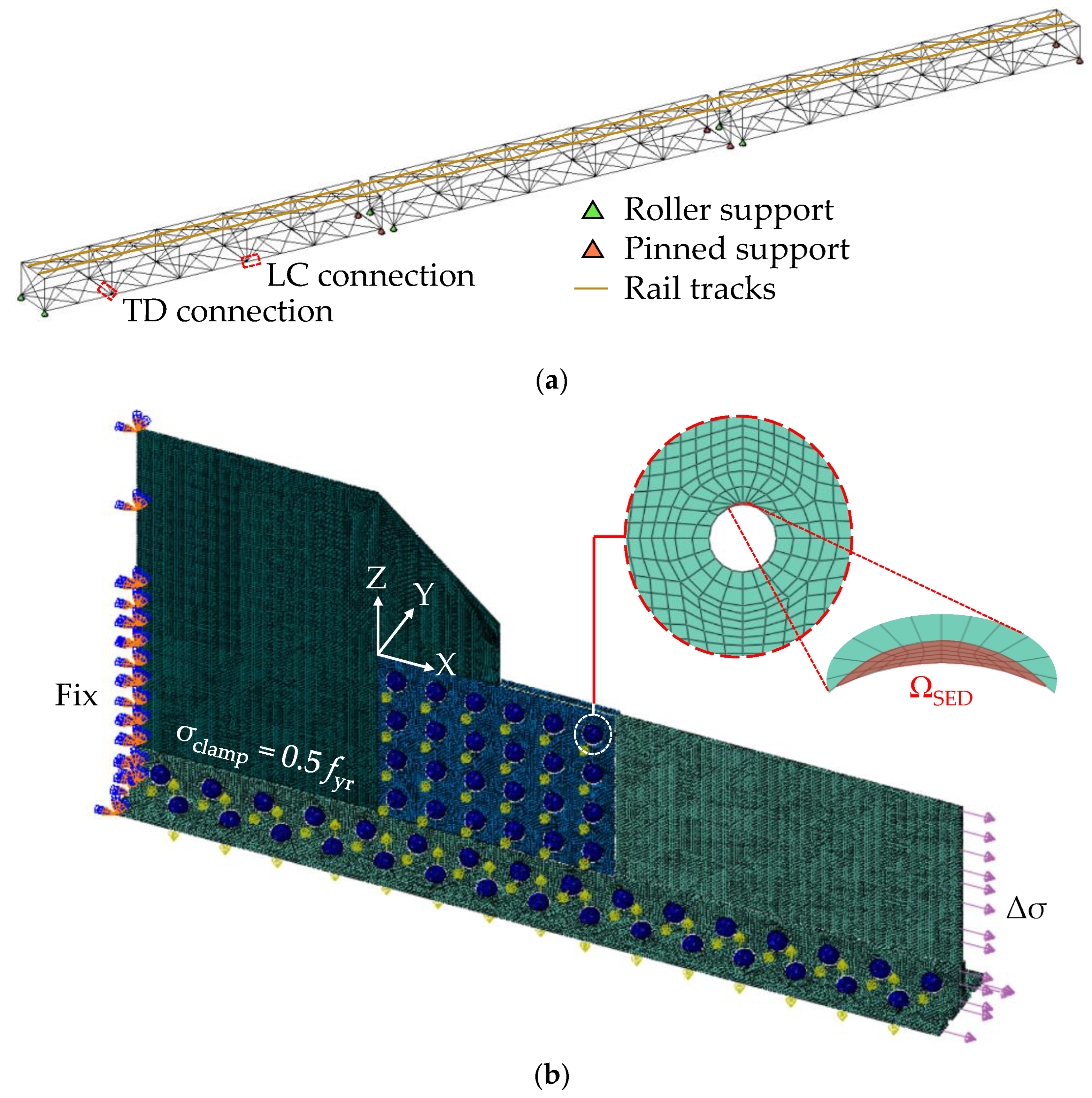

3.1. Global FEMs

- Ideal clockwise rotation of 90 degrees of the stress history;

- Identification of “water sources” in correspondence with each peak of the stress history;

- Counting the number of half-cycles by detecting flow terminations according to three stop criteria, i.e., (i) intersection with a flow started at an earlier peak, (ii) intersection with an opposite tensile peak of equal or greater magnitude, (iii) end of the stress history;

- Repetition of previous steps for compressive valleys;

- Definition of equivalent stress ranges for each half-cycle, i.e., equal to the stress difference between its start and termination.

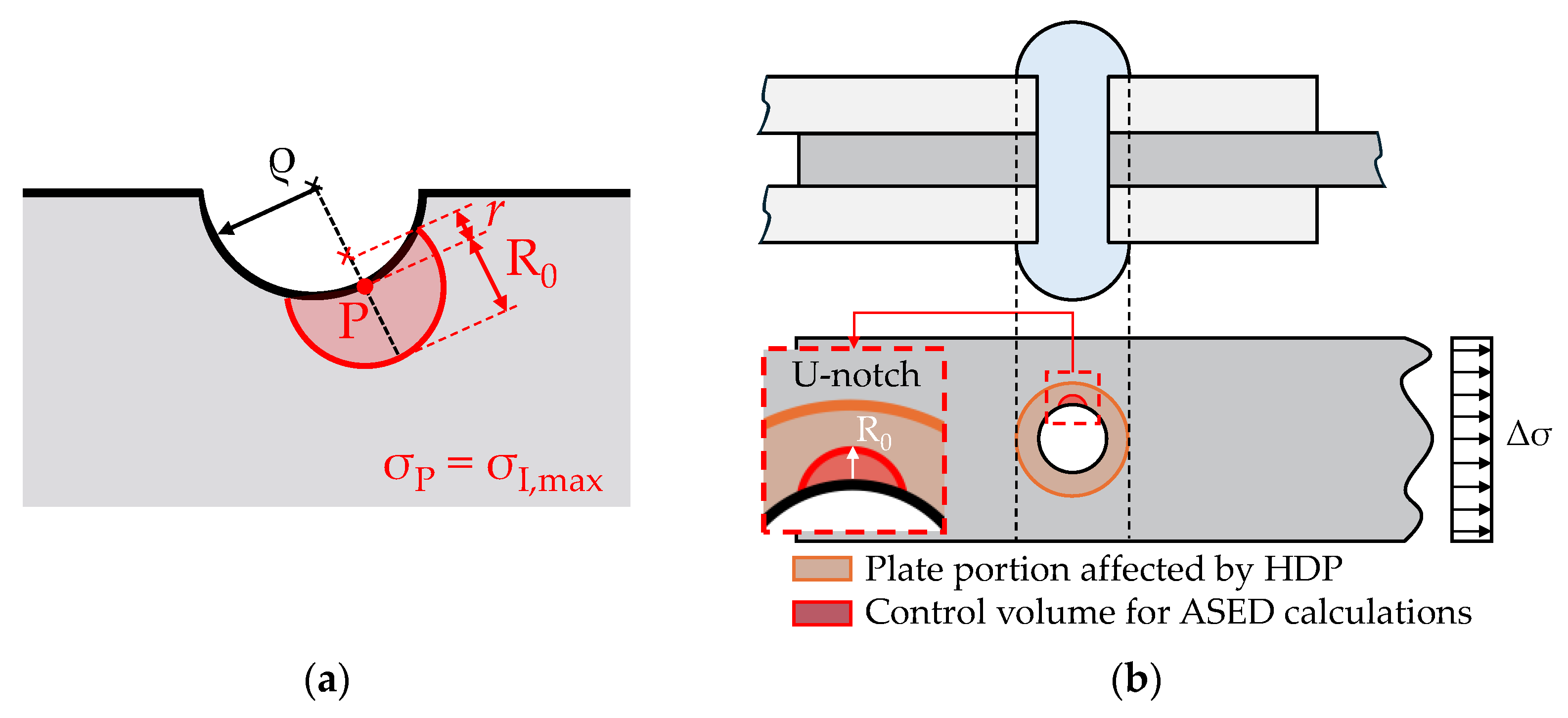

3.2. Principles of the Strain Energy Density Method

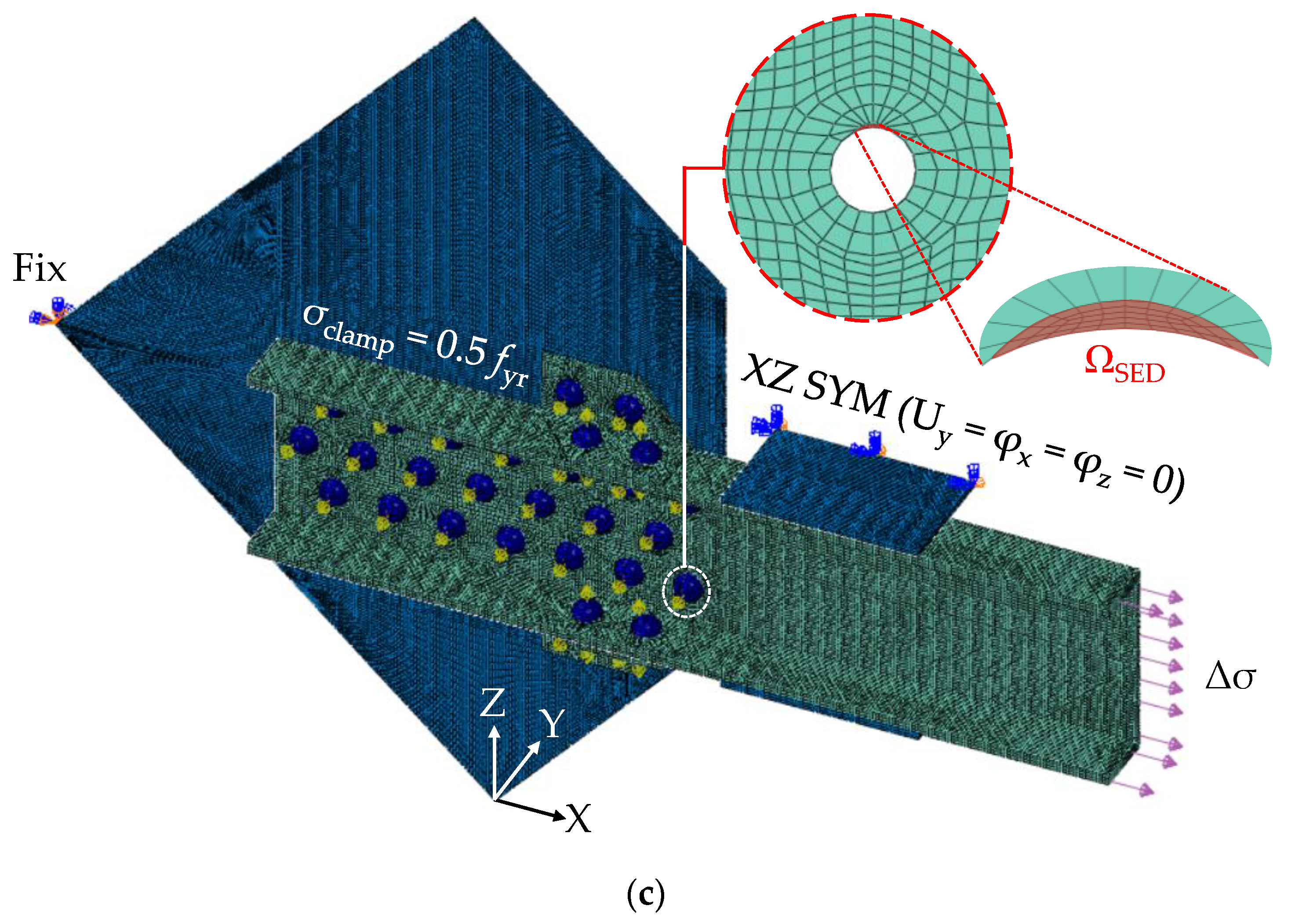

3.3. Local FEMs for SED Calculations

4. Results and Discussion

4.1. Global Scale FE Analyses

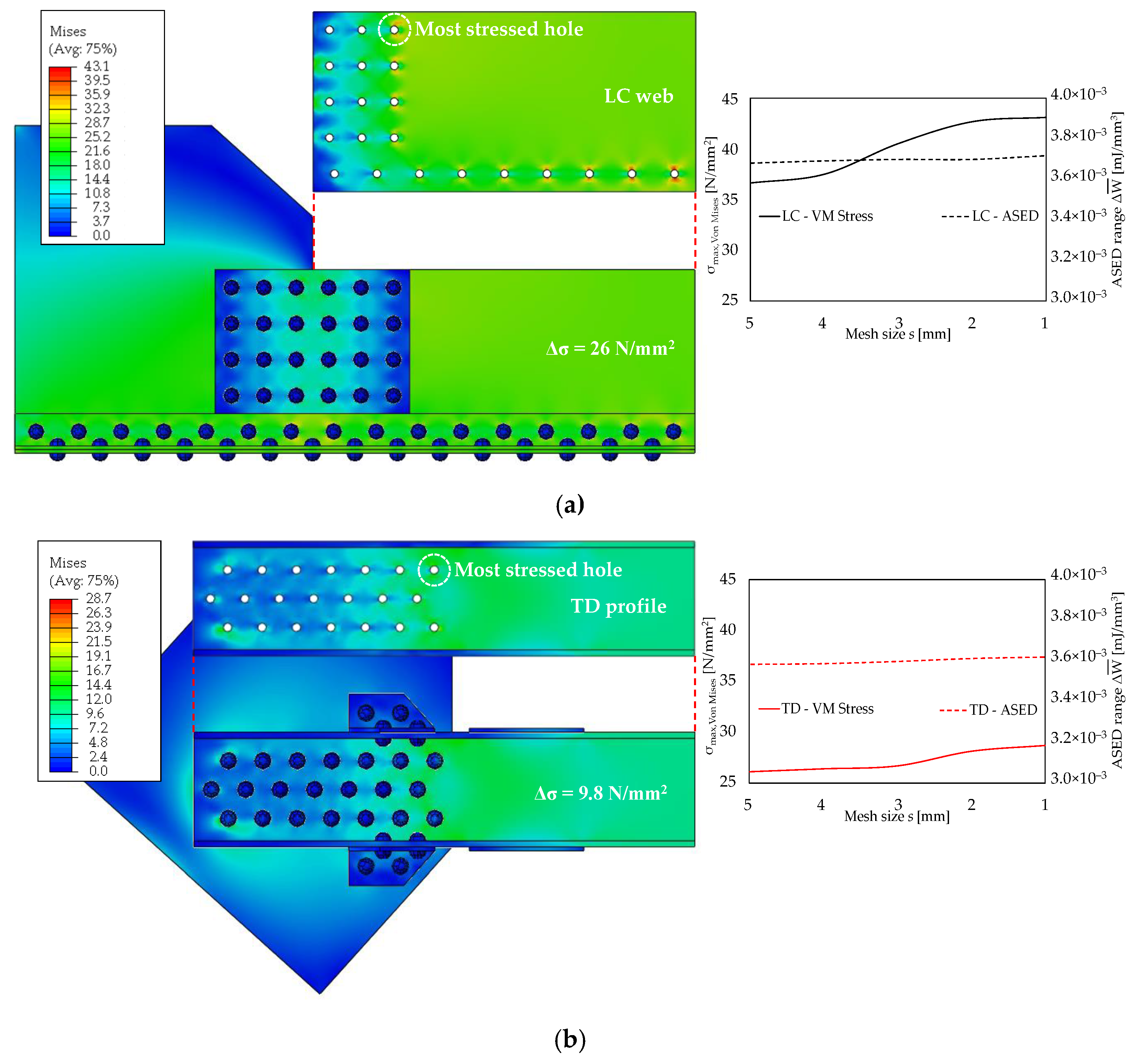

4.2. Local FE Analyses for ASED Calculations

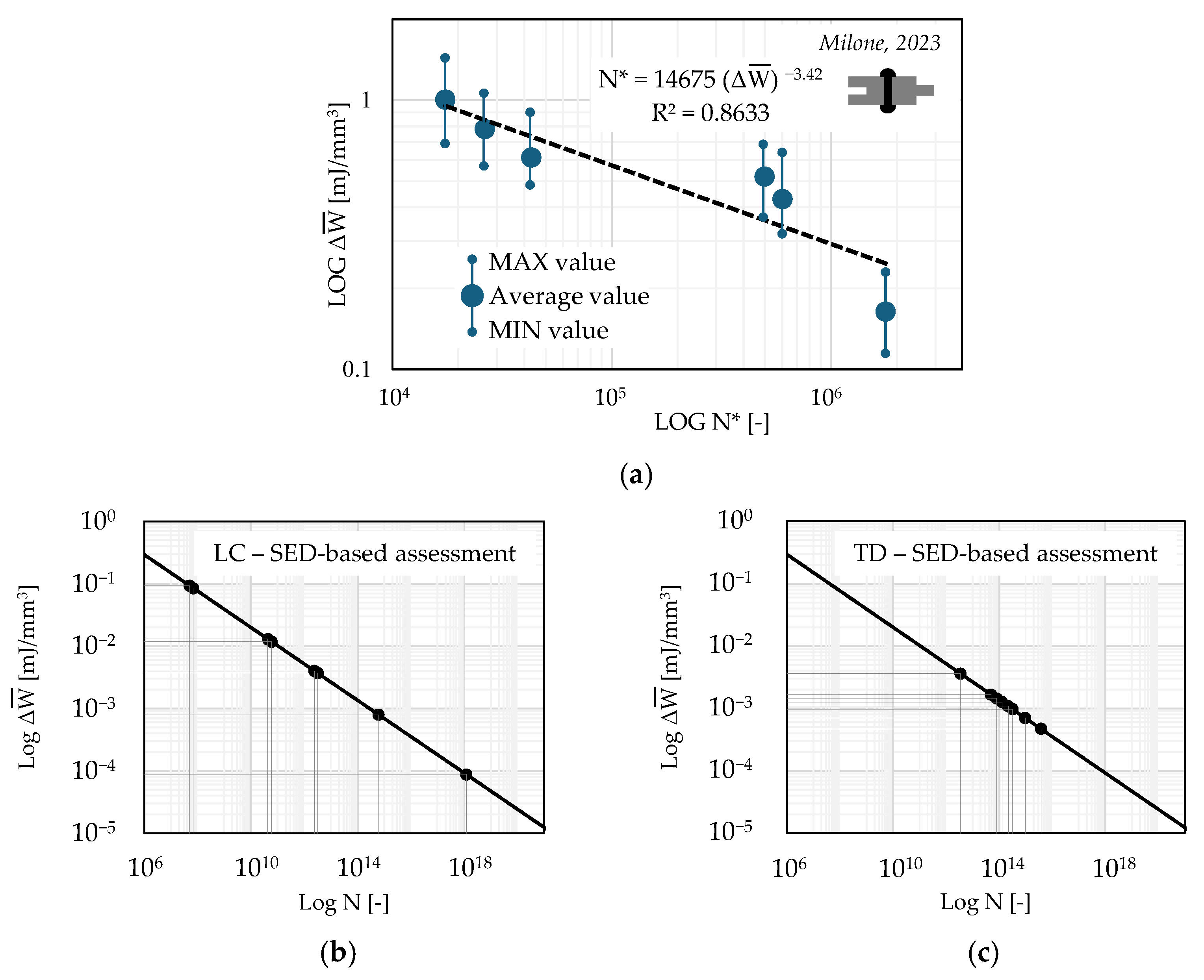

4.3. SED-Based Fatigue Assessment of Critical Details

5. Comparison with the Literature and Normative Fatigue Assessment Techniques

6. Conclusions

- Global-scale FE analyses of the 3D truss structure highlighted that most critical details from a fatigue perspective were represented by the lower chord (LC) midspan connection and by the most stressed tensile diagonal (TD) connection. This condition resulted from the adopted structural scheme and the presence of significant mean tensile stress;

- Local-scale FEMs were developed to accurately represent the geometric details. Subsequently, SED-based fatigue demand was derived with reference to equivalent stress cycles to be endured during the reference service life Lref = 100 years;

- According to the well-known Miner criterion, both connections were deemed safe with respect to fatigue issues, although with significantly different margins of safety (DTOT = 1.6 × 10−2 and 4.5 × 10−6, respectively);

- SED-based outcomes were compared against nominal stress-life approaches drawn from the literature and normative prescriptions. Accordingly, the SED method predicted higher fatigue damage in the LC compared with other methods, due to its ability to capture local stress amplification induced by secondary bending;

- Conversely, lower damage was observed for TD with respect to EN1993-1-9 and prEN1993-1-9:2023, due to the peculiar profiles and connection configuration in which out-of-plane bending was inhibited by longitudinal symmetry;

- Further studies will be carried out to assess the validity of SED-based fatigue assessment with reference to full-scale structures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Jesus, A.M.P.; da Silva, A.L.L.; Figueiredo, M.V.; Correia, J.A.F.O.; Ribeiro, A.S.; Fernandes, A.A. Strain-life and crack propagation fatigue data from several Portuguese old metallic riveted bridges. Eng. Fail. Anal. 2011, 18, 148–163. [Google Scholar] [CrossRef]

- Pedrosa, B.; Correia, J.A.F.O.; Rebelo, C.; Lesiuk, G.; de Jesus, A.M.P.; Fernandes, A.A.; Duda, M.; Calcada, R.; Veljkovic, M. Fatigue resistance curves for single and double shear riveted joints from old Portuguese metallic bridges. Eng. Fail. Anal. 2019, 96, 255–273. [Google Scholar] [CrossRef]

- Sieber, L.; Urbanek, R.; Bar, J. Crack-Detection in old riveted steel bridge structures. Procedia Struct. Integr. 2019, 17, 339–346. [Google Scholar] [CrossRef]

- Marmo, R. Numerical and Experimental Investigation on Shear Behaviour of Riveted Connections. Ph.D. Thesis, University of Naples “Federico II”, Naples, Italy, 2015. [Google Scholar]

- Milone, A. On the Performance of Lap-Shear Hot-Driven Riveted Connections: Experimental and Numerical Study. Ph.D. Thesis, University of Naples “Federico II”, Naples, Italy, 2023. [Google Scholar]

- Collette, Q.; Sire, S.; Wouters, I. Lap shear tests on repaired wrought-iron riveted connections. Eng. Struct. 2015, 85, 170–181. [Google Scholar] [CrossRef]

- Bertolesi, E.; Buitrago, M.; Adam, J.M.; Calderon, P.A. Fatigue assessment of steel riveted railway bridges: Full-scale tests and analytical approach. J. Constr. Steel Res. 2021, 182, 106664. [Google Scholar] [CrossRef]

- Liu, Z.; Hebdon, M.H.; Correia, J.A.F.O.; Carvalho, H.; Vilela, P.M.L.; de Jesus, A.M.P.; Calcada, R.A.B. Fatigue Assessment of Critical Connections in a Historic Eyebar Suspension Bridge. J. Perform. Constr. Facil. 2019, 33, 04018091. [Google Scholar] [CrossRef]

- Milone, A.; D’Aniello, M.; Landolfo, R. Influence of camming imperfections on the resistance of lap shear riveted connections. J. Constr. Steel Res. 2023, 203, 107833. [Google Scholar] [CrossRef]

- D’Aniello, M.; Fiorino, L.; Portioli, F.; Landolfo, R. Experimental investigation on shear behaviour of riveted connections in steel structures. Eng. Struct. 2011, 33, 516–531. [Google Scholar] [CrossRef]

- Kuzawa, M.; Kaminski, T.; Bien, J. Fatigue assessment procedure for old riveted road bridges. Arch. Civ. Mech. Eng. 2018, 18, 1259–1274. [Google Scholar] [CrossRef]

- Marques, F.; Correia, J.A.; de Jesus, A.M.; Cunha, A.; Caetano, E.; Fernandes, A.A. Fatigue analysis of a railway bridge based on fracture mechanics and local modelling of riveted connections. Eng. Fail. Anal. 2018, 94, 121–144. [Google Scholar] [CrossRef]

- EN1993-1-9; Eurocode 3: Design of Steel Structures—Part 1–9: Fatigue. CEN: Brussels, Belgium, 2005.

- EN1993-1-9; Background Document for EN1993-1-9. CEN: Brussels, Belgium, 2005.

- Leonetti, D.; Maljaars, J.; Pasquarelli, G.; Brando, G. Rivet clamping force of as-built hot-riveted connections in steel bridges. J. Constr. Steel Res. 2020, 167, 105955. [Google Scholar] [CrossRef]

- Landolfo, R.; Cascini, L.; D’Aniello, M.; Portioli, F. Gli effetti del degrado da fatica e corrosione sui ponti ferroviari in carpenteria metallica: Un approccio integrato per la valutazione della vita residua. Riv. Ital. Della Saldatura 2011, 3, 367–377. (In Italian) [Google Scholar]

- De Jesus, A.M.P.; Figueiredo, M.A.V.; Ribeiro, A.S.; de Castro, P.M.S.T.; Fernandes, A.A. Residual Lifetime Assessment of an Ancient Riveted Steel Road Bridge. Strain 2011, 47, 402–415. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zambardi, R. A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches. Int. J. Fract. 2001, 112, 275–298. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. Recent developments in brittle and quasi-brittle failure assessment of engineering materials by means of local approaches. Mater. Sci. Eng. R Rep. 2014, 75, 1–48. [Google Scholar] [CrossRef]

- Radaj, D.; Vormwald, M. Advanced Methods of Fatigue Assessment; Springer: New York, NY, USA, 2013. [Google Scholar]

- Taras, A.; Greiner, R. Development and Application of a Fatigue Class Catalogue for Riveted Bridge Components. Struct. Eng. Int. 2019, 20, 91–103. [Google Scholar] [CrossRef]

- prEN1993-1-9:2023; Eurocode 3: Design of Steel Structures—Part 1-9: Fatigue—2023 Draft. CEN: Brussels, Belgium, 2023.

- Mercuri, M.; Pathirage, M.; Gregori, A.; Cusatis, G. Influence of self-weight on size effect of quasi-brittle materials: Generalized analytical formulation and application to the failure of irregular masonry arches. Int. J. Fract. 2023, 246, 117–144. [Google Scholar] [CrossRef]

- Computer and Structures, Inc. (CSI). SAP200 v23 User’s Manual; CSI: Walnut Creek, CA, USA, 2021. [Google Scholar]

- D.M. 17/01/2018; Aggiornamento delle “Norme tecniche per le costruzioni”. MIT: Rome, Italy, 2018. (In Italian)

- Circolare 21/01/2019 n.7; Istruzioni per l’applicazione dell’«Aggiornamento delle “Norme Tecniche per le Costruzioni”. CSLLPP: Rome, Italy, 2019. (In Italian)

- RFI DTC INC PO SP IFS 003 A; Specifica per la Verifica a Fatica dei Ponti Ferroviari. RFI: Rome, Italy, 2011. (In Italian)

- Matsuishi, M.; Endo, T. Fatigue of metals subjected to varying stress. Jpn. Soc. Mech. Eng. 1968, 68, 37–40. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- European Convention for Constructional Steelwork (ECCS). Fatigue Design of Steel and Composite Structures, 2nd ed.; ECCS: Bruxelles, Belgium, 2018. [Google Scholar]

- Reis, A.J.; Oliveira Pedro, J.J. Bridge Design: Concepts and Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Milone, A.; Foti, P.; Filippi, S.; Landolfo, R.; Berto, F. Evaluation of the influence of mean stress on the fatigue behavior of notched and smooth medium carbon steel components through an energetic local approach. Fatigue Fract. Eng. Mater. Struct. 2024, 46, 4315–4332. [Google Scholar] [CrossRef]

- Milone, A.; Foti, P.; Viespoli, L.M.; Wan, D.; Mutignani, F.; Landolfo, R.; Berto, F. Influence of hot-dip galvanization on the fatigue performance of high-strength bolted connections. Eng. Struct. 2024, 299, 117136. [Google Scholar] [CrossRef]

- Simulia. ABAQUS v6.14 User’s Manual; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2014. [Google Scholar]

- Lazzarin, P.; Berto, F.; Zappalorto, M. Rapid calculations of notch stress intensity factors based on averaged strain energy density from coarse meshes: Theoretical bases and applications. Int. J. Fatigue 2010, 32, 1559–1567. [Google Scholar] [CrossRef]

- Foti, P.; Berto, F. Strain Energy Density evaluation with free coarse mesh model. Mater. Des. Process. Commun. 2020, 2, e116. [Google Scholar] [CrossRef]

- Foti, P.; Razavi, N.; Ayatollahi, M.R.; Marsavina, L.; Berto, F. On the application of the volume free strain energy density method to blunt V-notches under mixed mode condition. Eng. Struct. 2021, 230, 111716. [Google Scholar] [CrossRef]

- Miner, M.A. Cumulative Damage in Fatigue. J. Appl. Mech. 1945, 3, 159–164. [Google Scholar] [CrossRef]

- Maljaars, J.; Euler, M. Fatigue S-N curves of bolts and bolted connections for application in civil engineering structures. Int. J. Fatigue 2021, 151, 106355. [Google Scholar] [CrossRef]

- Pilkey, D.F.; Pilkey, W.D.; Bi, Z. Peterson’s Stress Concentration Factors, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

| Train Type [-] | Total Load [kN] | Total Length [m] | Number of Axes [-] | Nominal Speed [m/s] | Dynamic Factor φ [-] | Average Daily Passages [1/d] |

|---|---|---|---|---|---|---|

| 3 | 9400 | 385.5 | 60 | 70 | 1.31 | 7 |

| 4 | 5100 | 237.6 | 30 | 70 | 1.31 | 6 |

| 8 | 10,350 | 212.5 | 46 | 28 | 1.18 | 1 |

| 9 | 2960 | 134.8 | 24 | 33 | 1.16 | 1 |

| Lower Chord—Midspan (LC) | |||||

| Train Type [-] | Daily Passages [1/d] | Rainflow Method | |||

| n [-] | Δσeq [N/mm2] | σm,eq [N/mm2] | R [-] | ||

| 3 | 7 | 7 × 1 | 20.6 | 20.4 | 0.33 |

| 7 × 13 | 3.0 | 23.8 | 0.88 | ||

| 4 | 6 | 6 × 1 | 21.0 | 20.6 | 0.32 |

| 6 × 12 | 6.3 | 21.2 | 0.74 | ||

| 8 | 1 | 1 × 1 | 26.0 | 28.1 | 0.37 |

| 1 × 22 | 4.0 | 35.2 | 0.89 | ||

| 9 | 1 | 1 × 1 | 15.0 | 17.6 | 0.40 |

| 1 × 6 | 7.4 | 21.4 | 0.71 | ||

| Tensile Diagonal—Support (TD) | |||||

| Train Type [-] | Daily Passages [1/d] | Rainflow Method | |||

| n [-] | Δσeq [N/mm2] | σm,eq [N/mm2] | R [-] | ||

| 3 | 7 | 7 × 1 | 5.5 | 10.0 | 0.57 |

| 7 × 12 | 3.2 | 11.2 | 0.75 | ||

| 4 | 6 | 6 × 1 | 4.9 | 9.7 | 0.60 |

| 6 × 11 | 3.0 | 10.7 | 0.75 | ||

| 8 | 1 | 1 × 2 | 9.8 | 12.2 | 0.43 |

| 1 × 32 | 1.1 | 14.1 | 0.93 | ||

| 9 | 1 | 1 × 1 | 4.4 | 9.5 | 0.62 |

| 1 × 6 | 2.2 | 10.6 | 0.81 | ||

| Lower Chord—Midspan (LC) | Tensile Diagonal—Support (TD) | ||||

|---|---|---|---|---|---|

| Train Type [-] | SED Method | Train Type [-] | SED Method | ||

| n [-] | [mJ/mm3] | n [-] | [mJ/mm3] | ||

| 3 | 7 | 8.7 × 10–5 | 3 | 7 | 1.7 × 10–3 |

| 91 | 4.0 × 10–3 | 84 | 1.1 × 10–3 | ||

| 4 | 6 | 8.0 × 10–4 | 4 | 6 | 1.4 × 10–3 |

| 72 | 1.3 × 10–2 | 66 | 9.7 × 10–4 | ||

| 8 | 1 | 3.7 × 10–3 | 8 | 2 | 3.6 × 10–3 |

| 22 | 8.5 × 10–2 | 32 | 4.7 × 10–4 | ||

| 9 | 1 | 1.2 × 10–2 | 9 | 1 | 1.3 × 10–3 |

| 6 | 9.3 × 10–2 | 6 | 7.0 × 10–4 | ||

| Reference | Detail | DC [N/mm2] | Slope m1 [-] | Slope m2 [-] | Stress Parameter |

|---|---|---|---|---|---|

| EN1993-1-9 B.D. [13,14] | Two-sided joint | 90 | 3 | 5 | Δσnet |

| One-sided joint | 71 | 3 | 5 | Δσnet | |

| prEN1993-1-9:2023 [22]; Maljaars and Euler [39] | Two-sided joint | 90 | 5 | 5 | Δσ* (Equation (6)) |

| One-sided joint | 90 | 5 | 5 | Δσ* (Equation (6)) | |

| Taras et al. [21] | Two-sided joint | 90 | 5 | 5 | Δσgross |

| One-sided joint | 85 | 5 | 5 | Δσgross |

| Lower Chord (LC) | |||||||

| nTOT,i | ki [-] | 1.19 | 2.06 | di = nTOT,i/N*i | |||

| Δσ | Δσnet | Δσ* | SED | [13,14] | [22,39] | [21] | |

| [-] | [N/mm2] | [-] | |||||

| 2.6 × 105 | 20.6 | 24.5 | 50.6 | 2.2 × 10–13 | 2.6 × 10–3 | 7.2 × 10–3 | 8.0 × 10–5 |

| 3.3 × 106 | 3.0 | 3.6 | 7.4 | 1.4 × 10–6 | 1.0 × 10–4 | 6.1 × 10–6 | 6.8 × 10–8 |

| 2.2 × 105 | 21.0 | 25.0 | 51.6 | 3.7 × 10–10 | 2.3 × 10–3 | 6.7 × 10–3 | 7.6 × 10–5 |

| 2.6 × 106 | 6.3 | 7.5 | 15.5 | 6.2 × 10–5 | 7.6 × 10–4 | 2.0 × 10–4 | 2.2 × 10–6 |

| 3.7 × 104 | 26.0 | 31.0 | 63.9 | 1.2 × 10–8 | 7.4 × 10–4 | 3.3 × 10–3 | 3.7 × 10–5 |

| 8.0 × 105 | 4.0 | 4.8 | 9.8 | 1.2 × 10–2 | 5.9 × 10–5 | 6.2 × 10–6 | 7.0 × 10–8 |

| 3.7 × 104 | 15.0 | 17.9 | 36.9 | 6.6 × 10–7 | 1.4 × 10–4 | 2.1 × 10–4 | 2.3 × 10–6 |

| 2.2 × 105 | 7.4 | 8.8 | 18.2 | 4.4 × 10–3 | 1.0 × 10–4 | 3.7 × 10–5 | 4.1 × 10–7 |

| DTOT [-] | 1.6 × 10–2 | 6.8 × 10–3 | 1.7 × 10–2 | 2.0 × 10–4 | |||

| Variation [-] | - | ×2.37 | ×0.97 | >> | |||

| Tensile Diagonal (TD) | |||||||

| nTOT,i | ki [-] | 1.08 | 1.91 | di = nTOT,i/N*i | |||

| Δσ | Δσnet | Δσ* | SED | [13,14] | [22,39] | [21] | |

| [-] | [N/mm2] | [-] | |||||

| 2.6 × 105 | 5.5 | 5.9 | 11.3 | 5.7 × 10–7 | 7.5 × 10–5 | 4.1 × 10–6 | 1.4 × 10–7 |

| 3.3 × 106 | 3.2 | 3.5 | 6.6 | 1.7 × 10–6 | 1.9 × 10–4 | 3.5 × 10–6 | 1.3 × 10–7 |

| 2.2 × 105 | 4.9 | 5.3 | 10.1 | 2.5 × 10–7 | 4.5 × 10–5 | 1.9 × 10–6 | 7.0 × 10–8 |

| 2.6 × 106 | 3.0 | 3.2 | 6.2 | 8.6 × 10–7 | 1.3 × 10–4 | 2.0 × 10–6 | 7.2 × 10–8 |

| 3.7 × 104 | 9.8 | 10.6 | 20.2 | 1.1 × 10–6 | 6.1 × 10–5 | 1.0 × 10–5 | 3.7 × 10–7 |

| 8.0 × 105 | 1.1 | 1.2 | 2.3 | 2.2 × 10–8 | 1.9 × 10–6 | 4.1 × 10–9 | 1.5 × 10–10 |

| 3.7 × 104 | 4.4 | 4.8 | 9.1 | 3.3 × 10–8 | 5.5 × 10–6 | 1.9 × 10–7 | 6.8 × 10–9 |

| 2.2 × 105 | 2.2 | 2.4 | 4.5 | 2.3 × 10–8 | 4.1 × 10–6 | 3.6 × 10–8 | 1.3 × 10–9 |

| DTOT [-] | 4.5 × 10–6 | 5.1 × 10–4 | 2.2 × 10–5 | 7.9 × 10–7 | |||

| Variation [-] | - | << | ×0.20 | ×5.70 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milone, A.; D’Aniello, M.; Landolfo, R. Advanced Fatigue Assessment of Riveted Railway Bridges on Existing Masonry Abutments: An Italian Case Study. Buildings 2024, 14, 2271. https://doi.org/10.3390/buildings14082271

Milone A, D’Aniello M, Landolfo R. Advanced Fatigue Assessment of Riveted Railway Bridges on Existing Masonry Abutments: An Italian Case Study. Buildings. 2024; 14(8):2271. https://doi.org/10.3390/buildings14082271

Chicago/Turabian StyleMilone, Aldo, Mario D’Aniello, and Raffaele Landolfo. 2024. "Advanced Fatigue Assessment of Riveted Railway Bridges on Existing Masonry Abutments: An Italian Case Study" Buildings 14, no. 8: 2271. https://doi.org/10.3390/buildings14082271

APA StyleMilone, A., D’Aniello, M., & Landolfo, R. (2024). Advanced Fatigue Assessment of Riveted Railway Bridges on Existing Masonry Abutments: An Italian Case Study. Buildings, 14(8), 2271. https://doi.org/10.3390/buildings14082271