Mitigating Making-Do Practices Using the Last Planner System and BIM: A System Dynamic Analysis

Abstract

:1. Introduction

2. Literature Review

2.1. Theoretical Understanding of Making-Do Waste

2.2. Technical Understanding of Making-Do Waste

2.3. LPS-BIM Mitigation Strategies for MD Practices

2.4. System Dynamics Modeling

2.5. System Dynamics Applications in Lean Construction Research

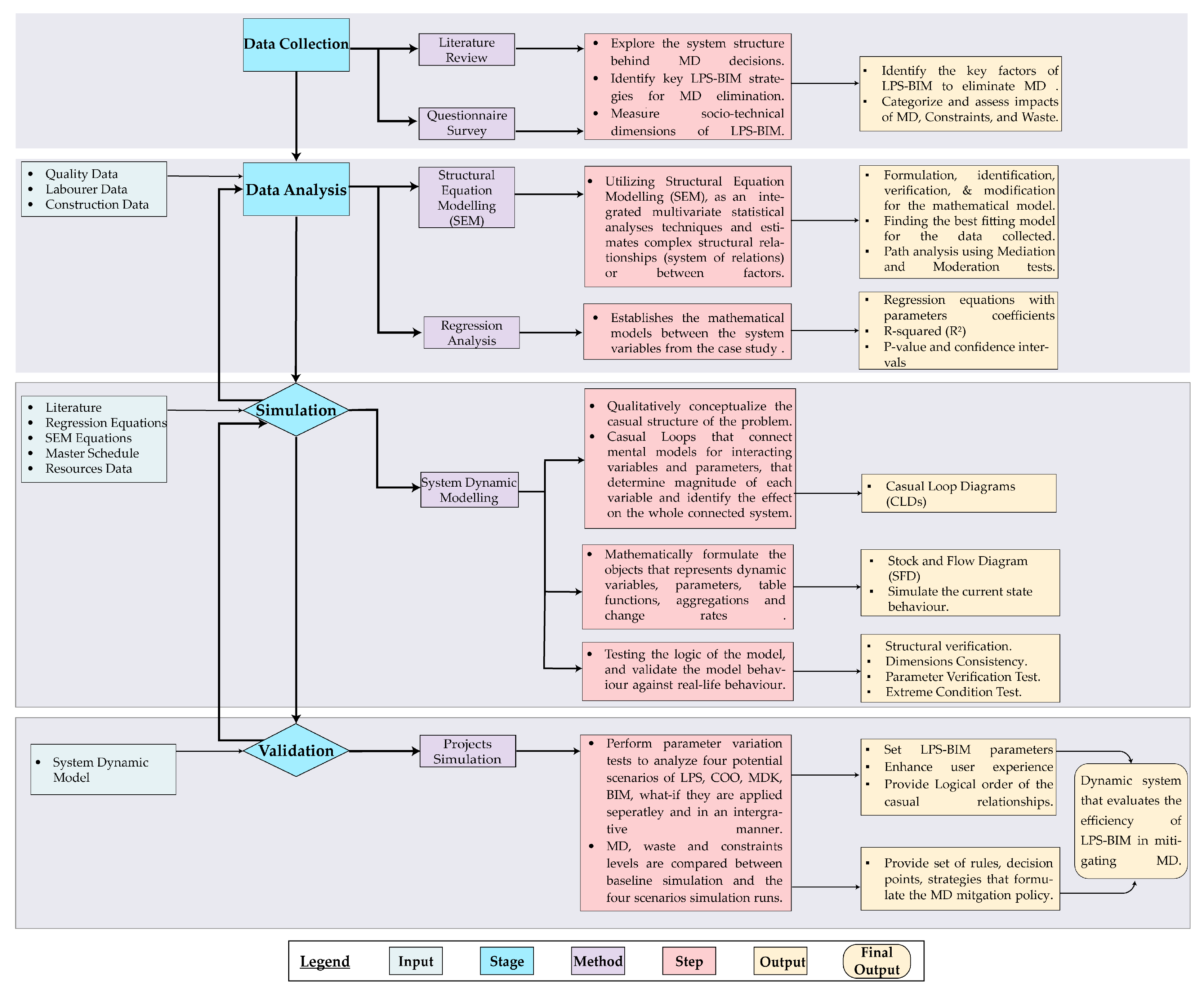

3. Materials and Methods

3.1. Data Collection for LPS-BIM (Questionnaire Survey)

3.2. Structural Equation Modeling

3.3. System Dynamic Modeling (SDM)

4. Results

4.1. Data Analysis

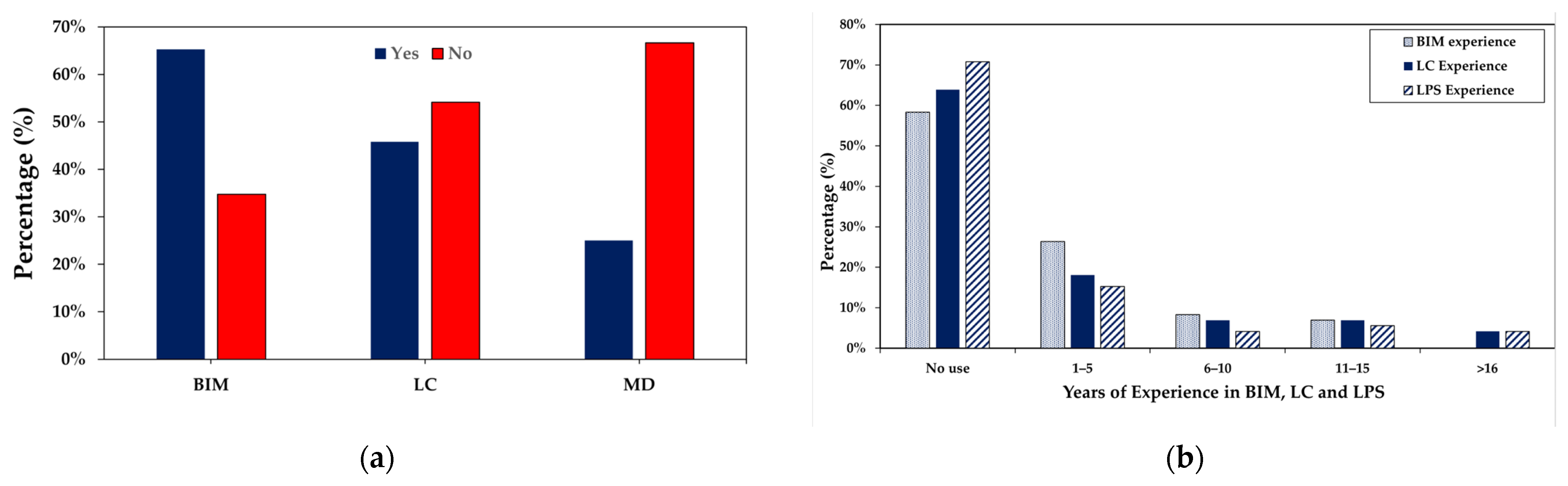

4.1.1. Descriptive Analysis for Questionnaire Data

4.1.2. Exploratory Factor Analysis (EFA)

4.1.3. Confirmatory Factor Analysis (CFA)

4.1.4. Structural Equation Model Assessment

4.2. Causal Loop Diagram (CLD)

4.3. Stock and Flow Diagrams

4.3.1. Work Progress

4.3.2. Productivity

* impactOfWorkSpaceLimitation[SUBSTAGES] * impactOfBIMonProductivity * impactofLPSonProductivity

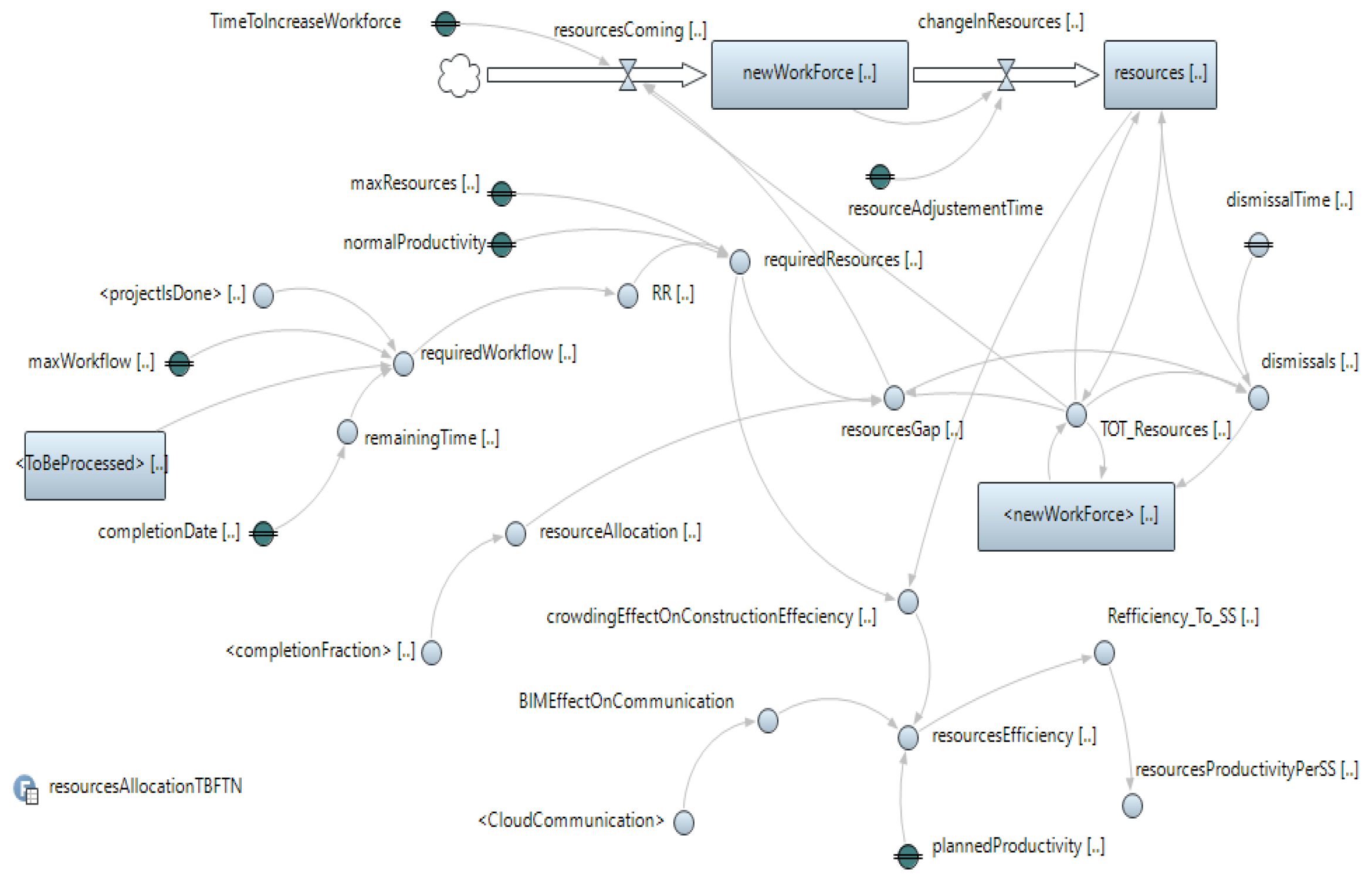

4.3.3. Resources

4.3.4. Cost and Location Subsystems

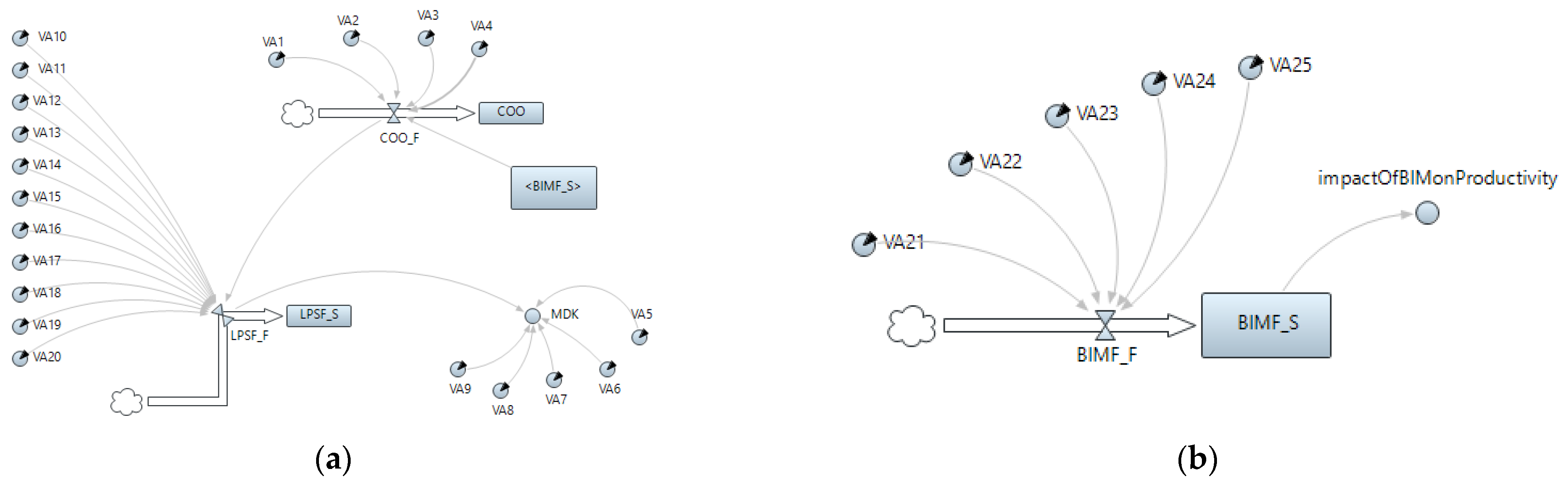

4.3.5. The Dynamic Interaction with LPS Functions and BIM Functionalities

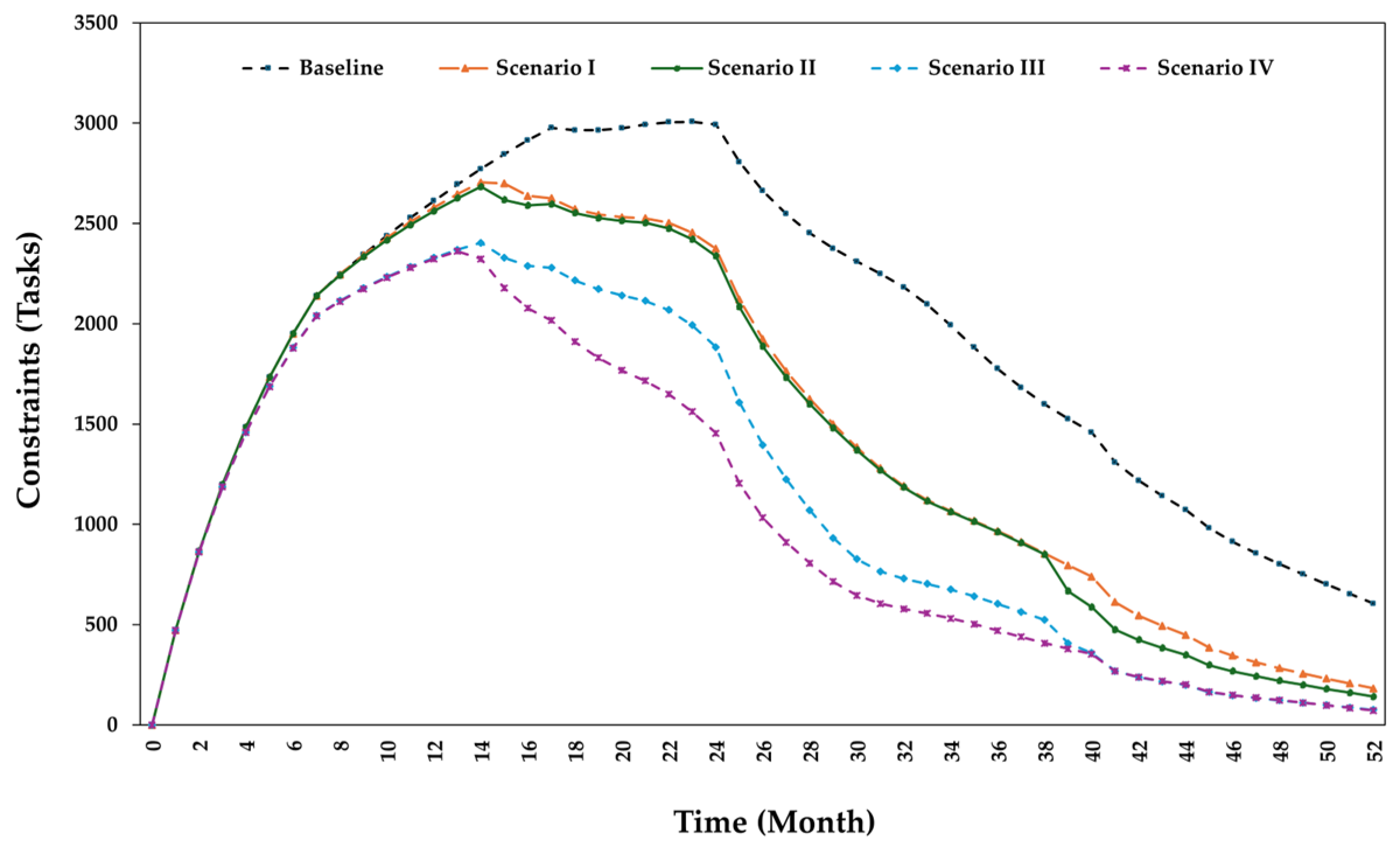

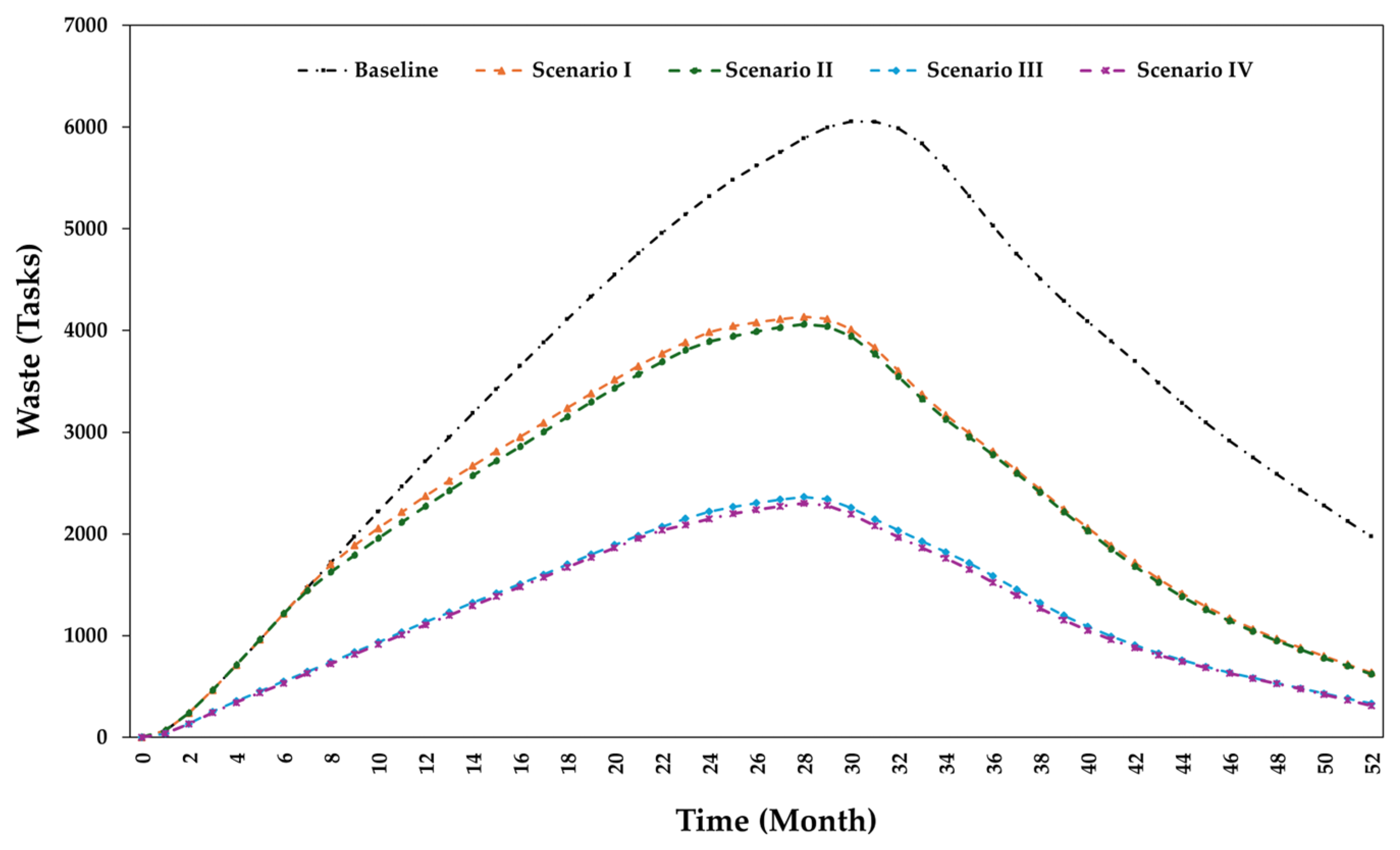

4.4. Simulations

4.4.1. Validation Projects

4.4.2. Model Assumptions

4.4.3. Testing for Model Unit Consistency

4.4.4. Model Stability Testing

4.4.5. Parameter Variation Testing

5. Discussion

6. Conclusions

- Social-technical factors directly influence MD in construction management systems. MD is a form of improvisation that masquerades in the short run as innovation, which reduces delivery time and related costs, but in the long run, several wastes could emerge and even snowball across the project delivery time; more than 80% of MDs are NVAs or a source of NVAs. This percentage can be prevented when proper production planning and control are employed, such as the LPS.

- This study investigates the impact of the integrated form of the LPS and BIM on Making-Do mitigation, using the system dynamics modeling method to strategically assist project stakeholders in assessing lean–BIM policy in tackling this waste and its impacts.

- The study found that MD is not widely known among professionals, and even some lean practitioners have not heard about it; similarly, construction management research has shown little interest in investigating MD, except for a few attempts from academics working in LC research.

- This research presents a novel MD model based on system thinking theory, which simulates the feedback mechanisms in construction management and measures the accumulation levels of construction constraints, Making-Do incidents, and emerging wastes.

- The accuracy of the simulation results of variables (MD, constraints, waste, cost, and completion rate) for the baseline scenario is considered acceptable compared to data collected from Projects A, B, and C. The average percentage of collected data divided by estimated data is MD 98.24%, constraints 99.52%, waste 98.80%, completion rate 95.99%, and additional costs 97.34%.

- Four scenarios have been applied: Scenario I with LPS technical factors, Scenario II with the application of LPS technical factors in addition to collaboration (COO) factors, Scenario III with the application of LPS socio-technical parameters, and Scenario IV with full LPS and BIM parameters.

- After a series of dynamic simulations for each scenario and compared to the baseline simulation. The dynamic simulation results show that after applying LPS-BIM, construction projects can reduce the number of unresolved constraints, MD decisions, and waste generated by MD, such as material waste, quality deviation, defects, and reworks.

- Schedule pressure impacts the level of pushing work without proper screening for constraints, which may lead to mishandling uncertainty. However, cost overruns and failure to meet pressures are not considered in the scope of this paper, which is planned for future research.

- BIM functionalities have a high impact on collaboration but a minimal impact on MDK, while MDK has the maximum value once LPS functions are implemented in integration with BIM.

- Practical implications include enhancing overall planning reliability, coordination, and control and avoiding wasting resources and time. BIM improves stakeholder communication, while SDM facilitates decision-makers and analyzes multiple outcomes. Thus, further research with interventions to offer construction professionals adequate training to increase their awareness of MD and encourage preventive management measures is needed.

- This study relies only on SDM, which entails analyzing the system at the strategic level with high levels of aggregation. Such a limitation may hinder a compelling discussion on the entire LPS hierarchy at the operation level. Further research is recommended to utilize SDM in coordination with ABM to incorporate advanced social interaction. Furthermore, there is an exception regarding validating the current SDM because it was validated using only residential projects. It is suggested that the findings be validated with other types of construction (e.g., industrial, healthcare, and transportation projects) to increase the study’s external validity.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Formoso, C.T.; Bølviken, T.; Viana, D.D. Understanding waste in construction. In Lean Construction Core Concepts and New Frontiers; Tzortzopoulos, P., Kagioglou, M., Koskela, L., Eds.; Routledge: London, UK, 2020; pp. 129–145. [Google Scholar]

- Koskela, L.; Ferrantelli, A.; Niiranen, J.; Pikas, E.; Dave, B. Epistemological Explanation of Lean Construction. J. Constr. Eng. Manag. 2019, 145, 04018131. [Google Scholar] [CrossRef]

- Horman, M.J.; Kenley, R. Quantifying Levels of Wasted Time in Construction with Meta-Analysis. J. Constr. Eng. Manag. 2005, 131, 52–61. [Google Scholar] [CrossRef]

- Daniel, E.I.; Garcia, D.; Marasini, R.; Kolo, S.; Oshodi, O. Improving construction management practice in the gibraltar construction industry. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 1–7 July 2019; pp. 539–550. [Google Scholar] [CrossRef]

- Nassri, S.; Talebi, S.; Elghaish, F.; Koohestani, K.; McIlwaine, S.; Hosseini, M.R.; Poshdar, M.; Kagioglou, M. Labor waste in housing construction projects: An empirical study. Smart Sustain. Built Environ. 2023, 12, 325–340. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; CRC Press: Boca Raton, FL, USA, 1988. [Google Scholar]

- Love, P.E.D.; Li, H. Quantifying the causes and costs of rework in construction. Constr. Manag. Econ. 2000, 18, 479–490. [Google Scholar] [CrossRef]

- Josephson, P.E.; Hammarlund, Y. The causes and costs of defects in construction: A study of seven building projects. Autom. Constr. 1999, 8, 681–687. [Google Scholar] [CrossRef]

- Kenley, R.; Harfield, T. Removing Hidden Waiting Time in Critical Path Schedules: A Location-Based Approach to Avoiding Waste. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 28–31 July 2015; pp. 203–210. [Google Scholar]

- Belayutham, S.; González, V.A.; Yiu, T.W. Clean-lean administrative processes: A case study on sediment pollution during construction. J. Clean. Prod. 2016, 126, 134–147. [Google Scholar] [CrossRef]

- Sarhan, S.; Pasquire, C.; Manu, E.; King, A. Contractual governance as a source of institutionalised waste in construction. Int. J. Manag. Proj. Bus. 2017, 10, 550–577. [Google Scholar] [CrossRef]

- Carvajal-Arango, D.; Bahamón-Jaramillo, S.; Aristizábal-Monsalve, P.; Vásquez-Hernández, A.; Botero, L.F.B. Relationships between lean and sustainable construction: Positive impacts of lean practices over sustainability during construction phase. J. Clean. Prod. 2019, 234, 1322–1337. [Google Scholar] [CrossRef]

- Golzarpoor, H.; González, V.; Shahbazpour, M.; O’Sullivan, M. An input-output simulation model for assessing production and environmental waste in construction. J. Clean. Prod. 2017, 143, 1094–1104. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of Lean Construction on Sustainability of Modular Homebuilding. J. Archit. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- Formoso, C.T.; Soibelman, L.; De Cesare, C.; Isatto, E.L. Material Waste in Building Industry: Main Causes and Prevention. J. Constr. Eng. Manag. 2002, 128, 316–325. [Google Scholar] [CrossRef]

- Grosskopf, J.; Menezes, A.S.; Santos, D.G. Proposal of Activities That Facilitate Work in Order to Avoid Workflow Interruptions Caused By Making-Do. In Proceedings of the IGLC-21, Fortaleza, Brazil, 29 July–2 August 2013; pp. 719–728. [Google Scholar]

- Koskela, L. An Exploration towards a Production Theory and Its Application to Construction; VTT Technical Research Centre of Finland: Espoo, Finland, 2000. [Google Scholar]

- Womack, J.; Jones, D. Lean Thinking-Banish Waste and Create Wealth in Your Corporation; Simon and Schuster: New York, NY, USA, 2003. [Google Scholar]

- Koskela, L.; Bølviken, T.; Rooke, J. Which are the wastes of construction? In Proceedings of the 21st Annual Conference of the International Group for Lean Construction 2013, IGLC 2013, Fortaleza, Brazil, 29 July–2 August 2013; pp. 905–914. [Google Scholar]

- Koskela, L. Making-do the eighth category of waste. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction, Helsingor, Denmark, 3–5 August 2004; p. 10. [Google Scholar]

- Formoso, C.T.; Sommer, L.; Koskela, L.; Isatto, E.L. An Exploratory Study on the Measurement and Analysis of Making-Do in Construction Sites. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction, Lima, Peru, 13–15 July 2011; pp. 1–10. [Google Scholar]

- Emmitt, S.; Pasquire, C.; Mertia, B. Is good enough “making do”?: An investigation of inappropriate processing in a small design and build company. Constr. Innov. 2012, 12, 369–383. [Google Scholar] [CrossRef]

- Fireman, M.C.T.; Formoso, C.T.; Isatto, E.L. Integrating Production and Quality Control: Monitoring Making-Do and Unfinished Work. In Proceedings of the 21th Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 515–525. [Google Scholar]

- do Amaral, T.G.; Braga, P.D.B.; Vieira, S.V.; Neto J de, P.B. Relations Between Preconditions, Categories and Impacts of Making-Do Wastes. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction (IGLC), Edmonton, AB, Canada, 25–31 July 2022; pp. 1111–1122. [Google Scholar] [CrossRef]

- Neve, H.H.; Wandahl, S. Towards identifying making-do as lead waste in refurbishment projects. In Proceedings of the IGLC 2018—Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; Volume 2, pp. 1354–1364. [Google Scholar] [CrossRef]

- Dos Santos, É.M.; Fontenele, A.D.; Lima Machado, A.M.; De Paula Barros Neto, J.; Do Amaral, T.G. Analysis of making-do waste at construction site in Fortaleza, CearÁ, Brazil. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 853–864. [Google Scholar] [CrossRef]

- Formoso, C.T.; Sommer, L.; Koskela, L.; Isatto, E.L. The identification and analysis of making-do waste: Insights from two Brazilian construction sites. Ambiente Construído 2017, 17, 183–197. [Google Scholar] [CrossRef]

- Alhava, O.; Rinne, V.; Laine, E.; Koskela, L. Can a takt plan ever survive beyond the first contact with the trades on-site? In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC 2019, Dublin, Ireland, 1–7 July 2019; pp. 453–464. [Google Scholar] [CrossRef]

- Pikas, E.; Sacks, R.; Priven, V. Go or No-Go Decisions at the Construction Workface: Uncertainty, Perceptions of Readiness, Making Ready and Making-Do. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Ko, C.H.; Chung, N.F. Making Design Process Lean Design. In Proceedings of the IGLC-22, Oslo, Norway, 25–27 June 2014; pp. 463–474. [Google Scholar]

- Leão, C.F.; Formoso, C.T.; Isatto, E.L. Integrating Production and Quality Control with the Support of Information Technology Waste in Construction. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 847–858. [Google Scholar]

- Leão, C.F.; Isatto, E.L.; Formoso, C.T. Proposta de modelo para controle integrado da produção e da qualidade com apoio da computação móvel. Ambiente Construído 2016, 16, 109–124. [Google Scholar] [CrossRef]

- Etges, B.M.; Reck, R.H.; Fireman, M.T.; Rodrigues, J.L.; Isatto, E.L. Using BIM with the Last Planner® System to improve constraints analysis. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 493–504. [Google Scholar] [CrossRef]

- Do Amaral, T.G.; Braga, P.B.; Barros Neto, J.P. Application of dynamic spreadsheets in the analysis of waste by making-do. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 829–840. [Google Scholar] [CrossRef]

- Hamzeh, F.R.; Abi Morshed, F.; Jalwan, H.; Saab, I. Is Improvisation Compatible with Lookahead Planning? An Exploratory Study. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Sacks, R.; Radosavljevic, M.; Barak, R. Requirements for building information modeling based lean production management systems for construction. Autom. Constr. 2010, 19, 641–655. [Google Scholar] [CrossRef]

- Ballard, G.; Tommelein, I.D. 2020 Current Process Benchmark for the Last Planner® System of Project Planning and Control; UC Berkeley: Berkeley, CA, USA, 2021. [Google Scholar]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Ronen, B. The complete kit concept. Int. J. Prod. Res. 1992, 30, 2457–2466. [Google Scholar] [CrossRef]

- Ballard, G. The Last Planner System of Production Control; University of Birmingham: Birmingham, UK, 2000. [Google Scholar] [CrossRef]

- Fireman, M.C.T.; Saurin, T.A. Chain of wastes: The moderating role of making-do. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 409–418. [Google Scholar] [CrossRef]

- MacOmber, H.; Gregory, G.A.; Reed, D. Managing promises with the last planner system: Closing in on uninterrupted flow. In Proceedings of the 13th International Group for Lean Construction Conference, Sydney, Australia, 19–21 July 2005; pp. 13–18. [Google Scholar]

- Sukster, R. A Integração Entre o Sistema de gestão da Qualidade e o Planejamento e Controle da Produção em Empresas Construtoras. Master’s Thesis, Universidade Federal do Rio Grande do Sul, Farroupilha, Brazil, 2005. [Google Scholar]

- Dave, B. Developing a Construction Management System Based on Lean Construction and Building Information Modelling; University of Salford: Salford, UK, 2013. [Google Scholar]

- Karaz, M.; Teixeira, J.M.C. A System Dynamic Modelling Approach for Integrated Lean-BIM Planning and Control Methods. In Proceedings of the 31st Annual Conference of the International Group for Lean Construction (IGLC31), Lille, France, 26 June–2 July 2023; pp. 1220–1231. [Google Scholar] [CrossRef]

- Forrester, J. Industrial Dynamics; MIT Press: Cambridge, MA, USA, 1961. [Google Scholar]

- Kirkwood, C.W. System Dynamics Methods: A Quick Introduction; College of Business, Arizona State University: Tempe, AZ, USA, 1998. [Google Scholar]

- Coyle, R.G. System dynamics modelling: A practical approach. J. Oper. Res. Soc. 1997, 48, 544. [Google Scholar] [CrossRef]

- Love, P.E.D.; Manual, P.; Li, H. Determining the causal structure of rework influences in construction. Constr. Manag. Econ. 1999, 17, 505–517. [Google Scholar] [CrossRef]

- Borshchev, A.; Grigoryev, I. The Big Book of Simulation Modeling Modeling with AnyLogic 8; AnyLogic North America: Oakbrook Terrace, IL, USA, 2020. [Google Scholar]

- Kedir, N.; Siraj, N.; Fayek, A.R. Application of System Dynamics in Construction Engineering and Management: Content Analysis and Systematic Literature Review. Adv. Civ. Eng. 2023, 2023, 1058063. [Google Scholar] [CrossRef]

- Zhan, Z.; Tang, Y.; Wang, C.; Yap, J.B.H.; Lim, Y.S. System Dynamics Outlook on BIM and LEAN Interaction in Construction Quantity Surveying. Iran. J. Sci. Technol.—Trans. Civ. Eng. 2022, 46, 3947–3962. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Sharmak, W. Hybrid Simulation for Value Stream Mapping to Improve the Environmental Performance of the Construction Phase. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction, IGLC 2022, Edmonton, AB, Canada, 25–31 July 2022; pp. 421–432. [Google Scholar] [CrossRef]

- Meshref, A.N.; Elkasaby, E.l.A.F.A.; Abdel Kader Mohamed Farid, A. Reducing construction waste in the construction life cycle of industrial projects during design phase by using system dynamics. J. Build. Eng. 2023, 69, 106302. [Google Scholar] [CrossRef]

- Omotayo, T.; Awuzie, B.; Egbelakin, T.; Obi, L.; Ogunnusi, M. AHP-systems thinking analyses for kaizen costing implementation in the construction industry. Buildings 2020, 10, 230. [Google Scholar] [CrossRef]

- Ko, C.H. Improving Formwork Design Using Lean Thinking. In Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 435–445. [Google Scholar] [CrossRef]

- Cano, S.; Rubiano, O. Dynamics model of the flow management of construction projects: Study of case. In Proceedings of the IGLC 28—28th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 6–12 July 2020; pp. 1045–1056. [Google Scholar] [CrossRef]

- Chinda, T. The Use of System Dynamics Modelling in Improving Construction Safety. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction, Taipei, Taiwan, 15–17 July 2009; pp. 91–100. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches; Sage Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Dusek, G.A.; Yurova, Y.V.; Ruppel, C.P. Using Social Media and Targeted Snowball Sampling to Survey a Hard-to-Reach Population: A Case Study. Int. J. Dr. Stud. 2015, 10, 279. [Google Scholar] [CrossRef]

- Hair, J.F.; Babin, B.J.; Black, W.C.; Anderson, R.E. Multivariate Data Analysis; Cengage: Boston, MA, USA, 2019. [Google Scholar]

- Singh, C.D.; Khamba, J.S. Structural Equation Modeling. In Manufacturing Competency and Strategic Success in the Automobile Industry; CRC Press: Boca Raton, FL, USA, 2019; pp. 171–188. [Google Scholar] [CrossRef]

- Collier, J.E. Applied Structural Equation Modeling Using AMOS; Routledge: London, UK, 2020. [Google Scholar] [CrossRef]

- Zlatanovic, D. System Dynamics Models in Management Problem Solving. Econ. Horiz. 2012, 14, 25–38. [Google Scholar]

- Wang, Y.; Zhao, J.; Gao, N.; Shen, F. A Dynamic Evaluation Method for the Development of Intelligent Construction Technology in the Construction Field Based on Structural Equation Model–System Dynamics Model. Buildings 2024, 14, 417. [Google Scholar] [CrossRef]

- Kaya, H.D.; Dikmen, I. Using System Dynamics to Support Strategic Digitalization Decisions. J. Constr. Eng. Manag. 2024, 150, 04024009. [Google Scholar] [CrossRef]

- Lakshmikantham, V.; Deo, S.G. Method of Variation of Parameters for Dynamic Systems; Routledge: London, UK, 2019. [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics Using SPSS, 2nd ed.; Sage Publications, Inc: London, UK, 2005. [Google Scholar]

- Bentler, P.M. Comparative fit indexes in structural models. Psychol. Bull. 1990, 107, 238–246. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Hu, L.; Bentler, P.M. Fit indices in covariance structure modeling: Sensitivity to underparameterized model misspecification. Psychol. Methods 1998, 3, 424–453. [Google Scholar] [CrossRef]

- Schumacker, R.E.; Lomax, R.G. A Beginner’s Guide to Structural Equation Modeling, 2nd ed.; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 2004. [Google Scholar]

- Nunnally, J.; Bernstein, I. Psychometric Theory, 3rd ed.; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Lyneis, J.M.; Cooper, K.G.; Els, S.A. Strategic management of complex projects: A case study using system dynamics. Syst. Dyn. Rev. 2001, 17, 237–260. [Google Scholar] [CrossRef]

- Thomas, H.R.; Maloney, W.F.; Horner, R.M.W.; Smith, G.R.; Handa, V.K.; Sanders, S.R. Modeling Construction Labor Productivity. J. Constr. Eng. Manag. 1990, 116, 705–726. [Google Scholar] [CrossRef]

- Garrido, M.C.; Mendes, R.; Scheer, S.; Campestrini, T.F. Using BIM for Last Planner System: Case Studies in Brazil. In Proceedings of the Computing in Civil Engineering (ASCE), Austin, TX, USA, 21–23 June 2015. [Google Scholar]

- Seppänen, O.; Modrich, R.; Ballard, G. Integration of Last Planner System and Location-Based Management System. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 28–31 July 2015; pp. 123–132. [Google Scholar]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Heigermoser, D.; García de Soto, B.; Abbott, E.L.S.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Seppänen, O. Location-based management system now and in the future. In Lean Construction; Routledge: London, UK, 2020; pp. 276–300. [Google Scholar]

- Kenley, R.; Seppänen, O. Location-Based Management for Construction: Planning, Scheduling and Control, 1st ed.; Spon Press by Taylor & Francis: Abingdon-on-Thames, UK, 2010. [Google Scholar]

- Koskela, L. Lean construction as a movement towards theory-based construction management. In Salford Centre for Research and Innovation International Symposium; SD Publishing: Hartlebury, UK, 2004; pp. 33–42. [Google Scholar]

| Responses | Percentage |

|---|---|

| Total questionnaires sent out | 336 |

| Total submitted responses | 118 (35.12%) |

| Discarded responses | 2 |

| Total usable responses | 116 (34.52%) |

| Years of experience in the construction industry | |

| 0–5 years | 23.61% |

| 6–10 years | 22.22% |

| 11–15 years | 19.44% |

| 16–20 years | 8.33% |

| Above 20 years | 12.50% |

| No | Variable | Mean | Cronbach’s Alpha | Rank |

|---|---|---|---|---|

| VA24 | Identify and resolve time and space clashes using BIM Clash Detection tools. | 3.736 | 0.945 | 1 |

| VA23 | Report task information in alignment with product specifications to ensure accuracy. | 3.722 | 0.945 | 2 |

| VA25 | Facilitate the exchange and communication of Making-Do practices through online BIM models. | 3.722 | 0.944 | 3 |

| VA22 | Utilize 4D planning to visualize constraints and their impact on project timelines. | 3.681 | 0.945 | 4 |

| VA5 | Provide coaching, training, and seminars for superintendents and forepersons. | 3.653 | 0.945 | 5 |

| VA11 | Ensure the availability of BIM models, design drawings, and site layout plans for reference during the Last Planner System implementation. | 3.611 | 0.944 | 6 |

| VA21 | Facilitate daily discussions between trades to address constraints and coordinate activities. | 3.583 | 0.945 | 7 |

| VA2 | Ensure high-level coordination among project stakeholders. | 3.542 | 0.946 | 8 |

| VA20 | Collaboratively design operations using BIM for digital prototyping. | 3.486 | 0.945 | 9 |

| VA12 | Maintain transparency by keeping all plans publicly accessible. | 3.472 | 0.945 | 10 |

| VA14 | Apply constraint analysis proactively to identify and address potential issues as a team. | 3.472 | 0.945 | 11 |

| VA9 | Facilitate knowledge exchange and the sharing of experiences among different companies. | 3.458 | 0.945 | 12 |

| VA3 | Facilitate discussions to address concerns and foster consensus. | 3.444 | 0.945 | 13 |

| VA7 | Establish a data bank to clarify misconceptions regarding lean construction, Making-Do, and Last Planner System principles. | 3.444 | 0.946 | 14 |

| VA1 | Handle disagreements and interests effectively to foster collaboration. | 3.431 | 0.947 | 15 |

| VA6 | Process and translate knowledge from experiential learning into actionable insights. | 3.403 | 0.946 | 16 |

| VA13 | Utilize guiding information across digital and physical environments to enhance understanding. | 3.403 | 0.946 | 17 |

| VA17 | Involve stakeholders in constraint management processes to enhance collaboration in mitigating MD. | 3.347 | 0.944 | 18 |

| VA8 | Learn from past incidents of Making-Do. | 3.306 | 0.946 | 19 |

| VA16 | Encourage stakeholders to communicate and share any constraints that may impede progress. | 3.278 | 0.945 | 20 |

| VA10 | Compare and analyze multiple cases to understand how Making-Do is managed. | 3.264 | 0.946 | 21 |

| VA4 | Adapt local adjustments to align with organizational requirements. | 3.181 | 0.947 | 22 |

| VA18 | Maintain a workable backlog of tasks to prioritize and manage the workload effectively. | 3.153 | 0.944 | 23 |

| VA15 | Delay tasks with uncertain constraints to avoid potential disruptions. | 2.931 | 0.947 | 24 |

| VA19 | Break down tasks from processes to operations and further to individual tasks for clarity of management and control. | 2.889 | 0.947 | 25 |

| Constraints | MD Categories | MD Impacts | |||

|---|---|---|---|---|---|

| P1 | External Conditions | CAT1 | Access and Movement | I1 | Decreased Productivity |

| P2 | Information | CAT2 | Component Adjustment | I2 | Material Waste |

| P3 | Interdependent Tasks | CAT3 | Equipment/Tools | I3 | Quality Deviation |

| P4 | Labor | CAT4 | Sequencing | I4 | Rework |

| P5 | Materials and Components | CAT5 | Workspace | I5 | Unfinished Works |

| P6 | Space |

| Project A | Project B | Project C | |

|---|---|---|---|

|  |  | |

| Enterprise Code | M | N | K |

| Country | Brazil | Brazil | France |

| Start and finish dates | March 2016–March 2021 | March 2020–September 2023 | February 2019–March 2021 |

| Project type | Construction | Construction | Rehabilitation |

| Building type | Multi-storey condominium | Multi-storey condominium | Multi-storey building |

| Description | Three towers | Two towers | One tower |

| Floors/tower | 20 | 15 | 7 |

| No. of units | 480 | 45 | 140 |

| Land use (m2) | 9445 | 2860 | 1223 |

| Category | Cost Increase ($) | Actual Completion Rate (%) | Total MD (Tasks) | Total Constraints (Tasks) | Total Waste (Tasks) |

|---|---|---|---|---|---|

| Baseline A | 76,849.337 | 82.540 | 209.126 | 1956.066 | 3600.587 |

| Project A data | 75,950.000 | 80.570 | 205 | 1951 | 3590 |

| Baseline B | 29,094.560 | 87.996 | 182.637 | 973.859 | 2427.597 |

| Project B data | 27,200.000 | 82.010 | 180 | 968 | 2350 |

| Baseline C | 11,134.500 | 85.652 | 180.345 | 865.970 | 1700.781 |

| Project C data | 11,100.000 | 83.213 | 177 | 861 | 1699 |

| Tested Variable | Involved Parameters | Values | |

|---|---|---|---|

| Scenario I | LPS technical factors enabled | VA10, VA11, VA12, VA13, VA14, VA15, VA16, VA17, VA18, VA19, VA20, VA21 | All values set to five |

| Scenario II | LPS technical factors enabled, associated with collaboration factors | VA6, VA7, VA8, VA9, VA10, VA11, VA12, VA13, VA14, VA15, VA16, VA17, VA18, VA19, VA20, VA21 | All values set to five |

| Scenario III | LPS socio-technical factors enabled with the association of Making-Do knowledge factors | VA1, VA2, VA3, VA5, VA6, VA7, VA8, VA9, VA10, VA11, VA12, VA13, VA14, VA15, VA16, VA17, VA18, VA19, VA20, VA21 | All values set to five |

| Scenario IV | LPS socio-technical factors + BIM enabled | VA1, VA2, VA3, VA5, VA6, VA7, VA8, VA9, VA10, VA11, VA12, VA13, VA14, VA15, VA16, VA17, VA18, VA19, VA20, VA21, VA22, VA23, VA24, VA25 | All values set to five |

| Variable | Baseline | Scenario I | Scenario II | Scenario III | Scenario IV | |

|---|---|---|---|---|---|---|

| MD Categories | CAT1 | 23.754 | 15.572 | 15.572 | 11.795 | 11.284 |

| CAT2 | 99.032 | 74.655 | 74.093 | 66.208 | 66.455 | |

| CAT3 | 11.760 | 7.351 | 7.194 | 5.159 | 4.629 | |

| CAT4 | 53.450 | 43.508 | 43.315 | 38.878 | 39.017 | |

| CAT5 | 21.130 | 15.760 | 15.366 | 12.315 | 11.587 | |

| Constraints | P1 | 49.814 | 39.381 | 38.622 | 33.528 | 30.993 |

| P2 | 158.584 | 142.457 | 141.579 | 135.694 | 125.442 | |

| P3 | 221.538 | 163.799 | 157.679 | 122.372 | 109.533 | |

| P4 | 572.133 | 457.476 | 446.363 | 381.997 | 344.119 | |

| P5 | 766.068 | 559.156 | 544.587 | 430.870 | 382.813 | |

| P6 | 187.928 | 124.644 | 121.702 | 85.208 | 75.007 | |

| MD Impacts | I1 | 292.140 | 199.919 | 194.741 | 97.086 | 92.304 |

| I2 | 322.522 | 213.900 | 209.476 | 129.549 | 124.458 | |

| I3 | 354.241 | 235.027 | 229.363 | 112.556 | 109.578 | |

| I4 | 1247.717 | 766.449 | 747.751 | 417.300 | 404.727 | |

| I5 | 1383.967 | 941.289 | 941.289 | 507.161 | 498.680 | |

| Completion Rate (%) | 82.540 | 94.845 | 94.794 | 95.351 | 98.962 | |

| Cost | $ | 76,849.337 | 73,566.85 | 69,040.08 | 61,036.00 | 60,893.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaz, M.; Teixeira, J.M.C.; Amaral, T.G.d. Mitigating Making-Do Practices Using the Last Planner System and BIM: A System Dynamic Analysis. Buildings 2024, 14, 2314. https://doi.org/10.3390/buildings14082314

Karaz M, Teixeira JMC, Amaral TGd. Mitigating Making-Do Practices Using the Last Planner System and BIM: A System Dynamic Analysis. Buildings. 2024; 14(8):2314. https://doi.org/10.3390/buildings14082314

Chicago/Turabian StyleKaraz, Mahmoud, José Manuel Cardoso Teixeira, and Tatiana Gondim do Amaral. 2024. "Mitigating Making-Do Practices Using the Last Planner System and BIM: A System Dynamic Analysis" Buildings 14, no. 8: 2314. https://doi.org/10.3390/buildings14082314