Experiment on Freeze–Thaw Resistance of Tunnel Portal-Lining Concrete with Silicone Coating in Cold Regions

Abstract

:1. Introduction

2. Study on Strength Deterioration Characteristics of Lining Concrete of High-Elevation Tunnels

3. Experimental Study on Freeze–Thaw of Lining Concrete with Different Silicone Coatings

3.1. Specimen Fabrication

3.2. Experimental Results and Analysis

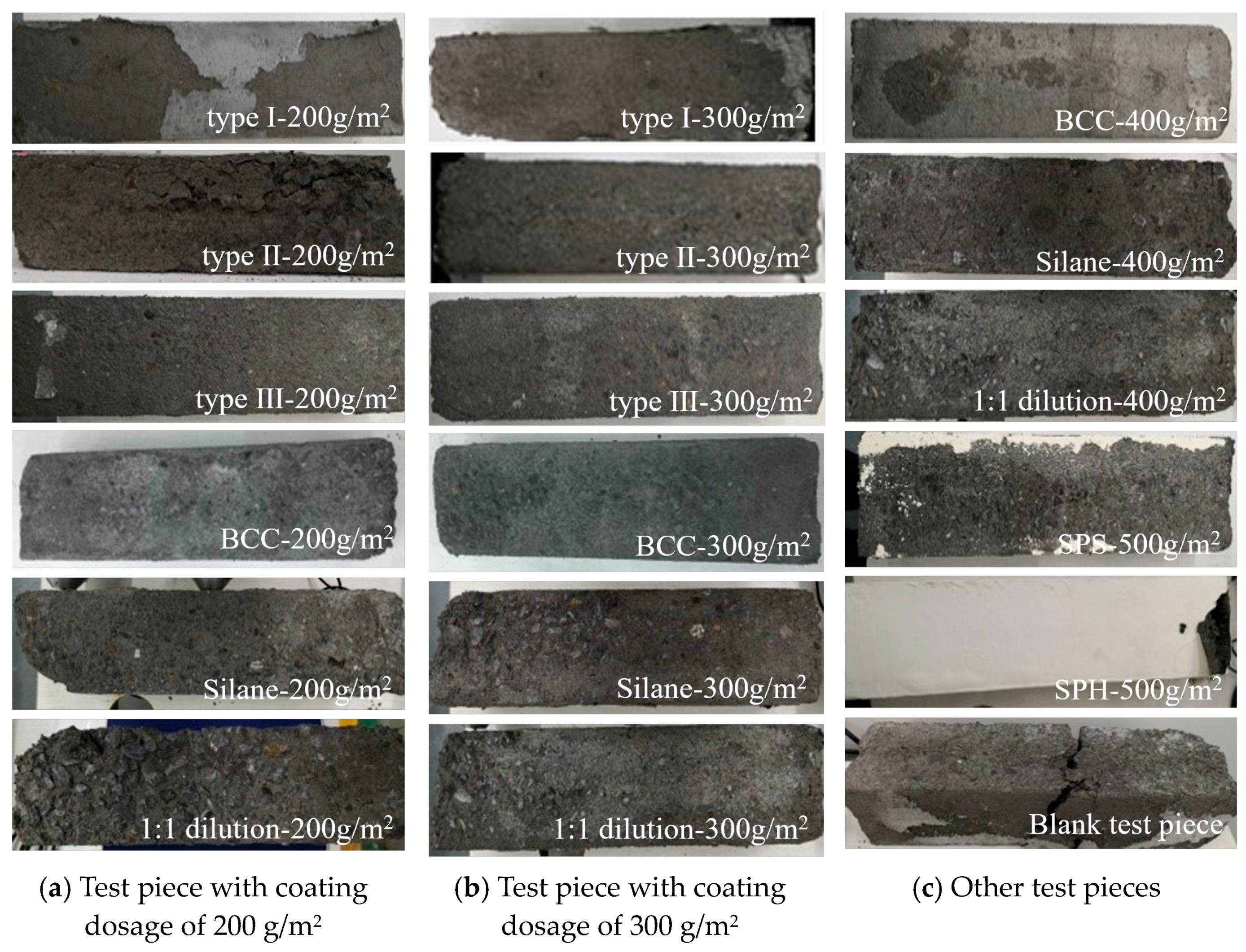

3.2.1. Freeze–Thaw Test Results and Analysis

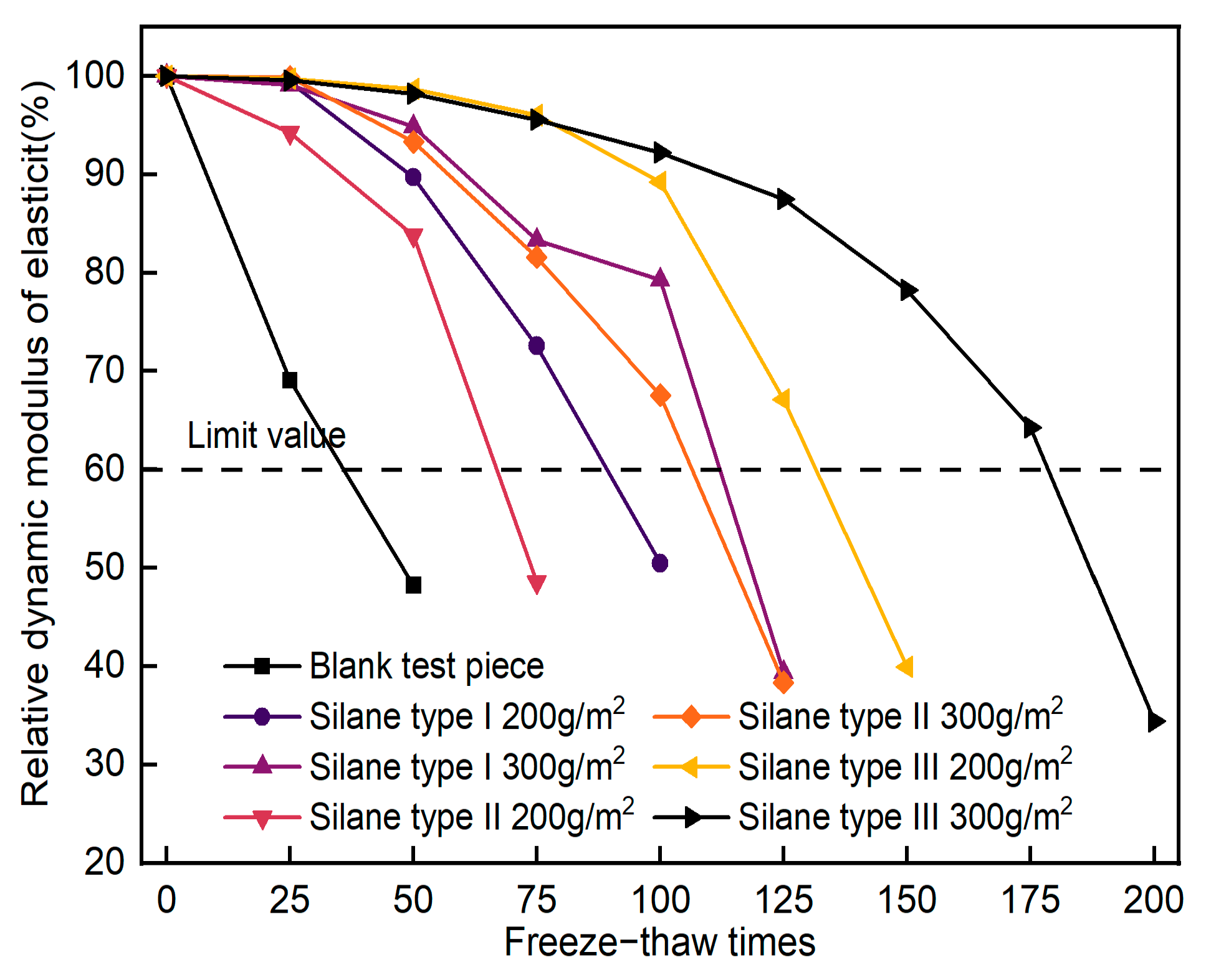

3.2.2. Test Results and Analysis of Dynamic Elastic Modulus

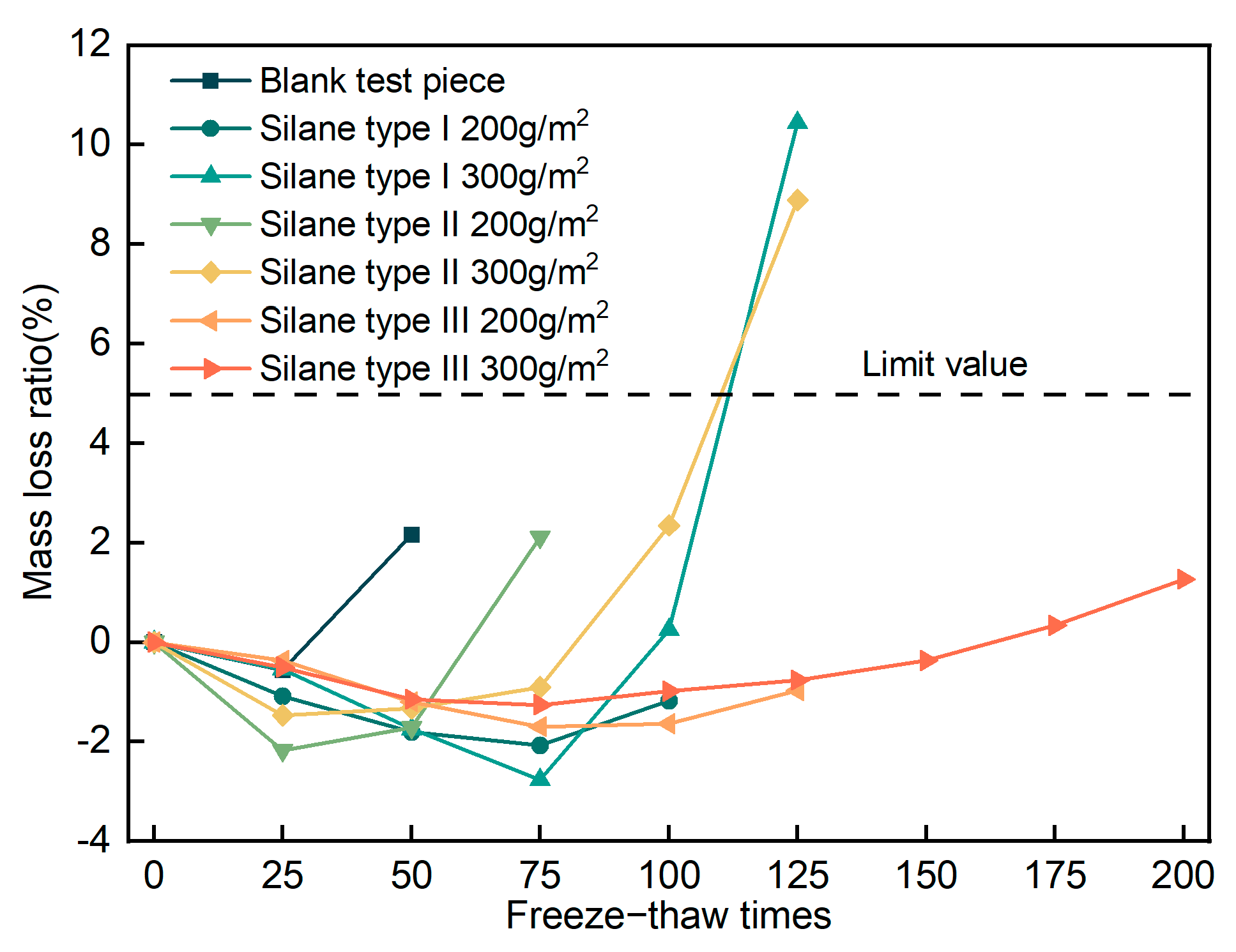

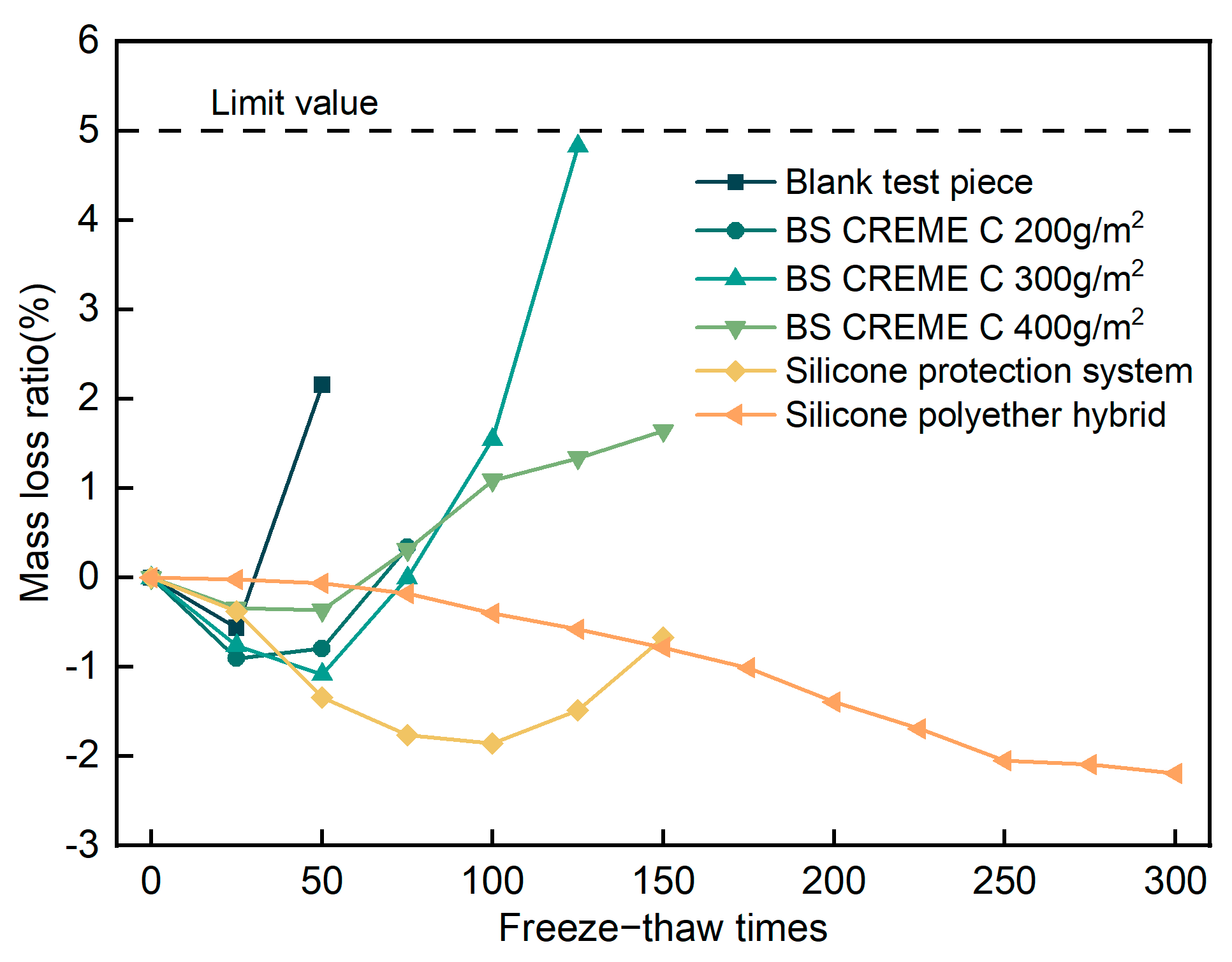

3.2.3. Mass Loss Test Results and Analysis

4. Research on the Conversion of Freeze–Thaw Cycles of Concrete

4.1. Freeze–Thaw Failure Mechanism and Influencing Factors of Concrete

4.2. Difference and Relationship between Indoor and Outdoor Freeze–Thaw Process

4.3. Equivalent Freezing–Thawing Cycle Conversion Model

4.4. Engineering Application Examples

5. Conclusions

- (1)

- The strength deterioration of tunnel concrete was greatly affected by freeze–thaw action. As the tunnel length increased, the greater the temperature difference between the entrance and the tunnel, coupled with the sunny–shady slope effect at both ends of the entrance, the overall concrete strength of the tunnel showed asymmetric characteristics where the entrance area was smaller than the middle area. It was stated that the lining concrete deterioration law was similar to the temperature change. Special attention should be paid to the freeze–thaw durability of lining concrete in high-altitude tunnel entrance areas.

- (2)

- Silicon coatings can prevent moisture and corrosive substances from entering concrete, thereby enhancing durability. When the coating was 200 g/m2, silane type III antifreeze had the best effect, and the freeze–thaw resistance cycles reached 125 times. When the coating dosage was 300 g/m2, the freeze–thaw resistance cycles of silane type I, silane type II, silane type III, and BS CREME C increased by 33%, 100%, 40%, and 100%, respectively. When the coating dosage was 400 g/m2, the freeze–thaw resistance cycles of BS CREME C and silane reached 125. When the coating dosage was 500 g/m2, the freeze–thaw resistance cycles of silicone polyether hybrid antifreeze reached 300. The damage laws of the specimens during freeze–thaw cycles were basically the same, and the strength reduction rate of the specimens was much greater than the mass loss rate of concrete.

- (3)

- An equivalent freeze–thaw cycle conversion model was established. It contained the two important factors of the on-site cooling rate and water richness. The freeze–thaw resistance of concrete specimens was closely related to the water environment they were exposed to. Considering the impact of moisture content on the freeze–thaw resistance of concrete, the concrete saturation coefficient S was used. For highly saturated concrete, the saturation coefficient S was taken as 1; for moderately saturated concrete, the saturation coefficient S was taken as 0.8.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Ye, G.; Schlangen, E.; Chen, H.; Qian, Z.; Sun, W.; Van Breugel, K. Modeling of the internal damage of saturated cement paste due to ice crystallization pressure during freezing. Cem. Concr. Compos. 2011, 33, 562–571. [Google Scholar] [CrossRef]

- Rosenqvist, M.; Oxfall, M.; Fridh, K.; Hassanzadeh, M. A test method to assess the frost resistance of concrete at the waterline of hydraulic structures. Mater. Struct. 2015, 48, 2403–2415. [Google Scholar] [CrossRef]

- Qin, X.C.; Meng, S.P.; Cao, D.F.; Tu, Y.M.; Sabourova, N.; Grip, N.; Ohlsson, U.; Blanksvärd, T.; Sas, G.; Elfgren, L. Evaluation of freeze-thaw damage on concrete material and prestressed concrete specimens. Constr. Build. Mater. 2016, 125, 892–904. [Google Scholar] [CrossRef]

- Chen, F.; Qiao, P. Probabilistic damage modeling and service-life prediction of concrete under freeze—Thaw action. Mater. Struct. 2015, 48, 2697–2711. [Google Scholar] [CrossRef]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, Q.; Dai, X.; Xiang, G. Improving the freeze-thaw resistance of mortar by a combined use of superabsorbent polymer and air entraining agent. J. Build. Eng. 2022, 52, 104471. [Google Scholar] [CrossRef]

- Deng, X.H.; Gao, X.Y.; Wang, R.; Zhao, C.J. Study on Frost Resistance and Pore Distribution Change of Recycled Concrete. Mater. Rep. 2021, 35, 16028–16034. [Google Scholar]

- Ma, Z.M.; Zhao, T.J.; Yang, J. Fracture Behavior of Concrete Exposed to the Freeze-Thaw Environment. J. Mater. Civ. Eng. 2017, 29, 04017071. [Google Scholar] [CrossRef]

- Lund, M.S.; Kevern, J.T.; Schaefer, V.R.; Hansen, K.K. Mix design for improved strength and freeze—Thaw durability of pervious concrete fill in Pearl-Chain Bridges. Mater. Struct. 2017, 50, 42. [Google Scholar] [CrossRef]

- Ruizhen, W.; Sai, W. Performance evolution of fiber reinforced concrete under freeze-thaw cycles. Cryogenics 2020, 34, 38–41+67. [Google Scholar]

- Hao, G. Study on mechanical properties and frost resistance of basalt fiber/resin matrix composite concrete. J. Funct. Mater. 2024, 55, 2148–2154. [Google Scholar]

- Ma, N.; Wang, B.; Miao, F.-S.; Wang, Y.-D. Study on Frost Resistance of Lined Channels Based on Vitrified Fiber Concrete. Water Sav. Irrig. 2024, 4, 58–64. [Google Scholar]

- Yang, Y.; Yan, C. Effect of Straw Fiber on Frost Resistance of Concrete Composites. Plast. Sci. Technol. 2024, 52, 75–77. [Google Scholar]

- Duan, G.Z.; Fang, C.Q. Research progress and new thinking of destruction of concrete due to freeze-thaw cycles. Concrete 2013, 5, 16–20. [Google Scholar]

- Cheng, X.; Zhu, P.; Wang, X.; Liu, H.; Wang, H.; Wang, Y.; Chen, C. Effects of Mineral Admixtures on Frost Resistance and Renewability of Recycled Aggregate Concrete. Bull. Chin. Ceram. Soc. 2024, 43, 956–964. [Google Scholar]

- Shanqing, S.; Aimin, G.; Fulai, W. Study of damage to alkali-inspired fly ash concrete under the coupling effect of freeze-thaw by acid salt erosion. Yangtze River 2024, 55, 222–230. [Google Scholar]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Zhao, C.; Ma, Z. Properties of integral waterproofing concrete under the coupling effect of freeze-thaw and chloride. Concrete 2016, 9, 12–15+20. [Google Scholar]

- Zhao, W.; Huang, W.; Song, Q.; Xu, J. Studying on the permeability of waterproofing concrete processed with silane emuslion under freezing-thawing environment. Concrete 2016, 8, 39–42. [Google Scholar]

- Zhu, M.; Weng, X.; Gao, R.; Jiang, L.; Li, W.; Li, M. Study on Performance of Reinforced Concrete Material for Airport Pavement. J. Shandong Agric. Univ. (Nat. Sci. Ed.) 2018, 49, 295–302. [Google Scholar]

- Lihai, S.; Yan, L.; Xungao, J. Research on frost resistance of airport pavement concrete enhanced by surface material. Concrete 2019, 3, 30–34+39. [Google Scholar]

- Gong, L.; Guan, H.; Yang, X. Effect of methylsilane waterproof agent on frost resistance of foam concrete. J. Harbin Eng. Univ. 2018, 39, 2075–2079. [Google Scholar]

- Xie, Y.; Weng, X.; Liu, P.; Gao, R.; Zhao, W. Study on frost resistance durability of surface-strengthened concrete. J. Railw. Sci. Eng. 2017, 14, 1878–1885. [Google Scholar]

- Zou, D.; Wang, Z.; Shen, M.; Liu, T.; Zhou, A. Improvement in freeze-thaw durability of recycled aggregate permeable concrete with silane modification. Constr. Build. Mater. 2021, 268, 121097. [Google Scholar] [CrossRef]

- Ma, Z.M.; Zhu, F.Z.; Zhao, T.J. Effects of surface modification of silane coupling agent on the properties of concrete with freeze-thaw damage. Ksce J. Civ. Eng. 2018, 22, 657–669. [Google Scholar] [CrossRef]

- Kang, S.; Wu, H.; Lu, H.; Li, N.; Liu, C.; Shu, Z. Improvement of Freeze-Thaw Resistance of Concrete by Polyvinyl Alcohol Membrane and Silane. Adv. Eng. Mater. 2023, 25, 2300396. [Google Scholar] [CrossRef]

- Taheri, B.M.; Ramezanianpour, A.M.; Sabokpa, S.; Gapele, M. Experimental evaluation of freeze-thaw durability of pervious concrete. J. Build. Eng. 2021, 33, 101617. [Google Scholar] [CrossRef]

- JGJ/T 23-2011; Technical Specification for Inspecting of Concrete Compressive Strength by Rebound Method. Evaluation Standard of Industrialized Building. Shaanxi Academy of Building Sciences Co., Ltd: Xi’an, China, 2011; 68P. B5.

- GB/T 50082-2009; Standard for Test Methods of Long-TERM performance and Durability of Ordinary Concrete. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009; 176P. B5.

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. Proc. 1945, 41, 245–272. [Google Scholar]

- Powers, T.C.; Willis, T. The air requirement of frost-resistant concrete. Highw. Res. Board Proc. 1949, 29, 184–211. [Google Scholar]

- Powers, T.C.; Helmuth, R. Theory of volume changes in hardened portland-cement paste during freezing. In Proceedings of the Thirty-Second Annual Meeting of the Highway Research Board, Highway Research Board Proceedings, Washington, DC, USA, 13–16 January 1953. [Google Scholar]

- Powers, T. Freezing effects in concrete. Spec. Publ. 1975, 47, 1–12. [Google Scholar]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Bresme, F.; Cámara, L.G. Computer simulation studies of crystallization under confinement conditions. Chem. Geol. 2006, 230, 197–206. [Google Scholar] [CrossRef]

- Fagerlund, G. The critical degree of saturation method of assessing the freeze/thaw resistance of concrete. Matériaux Constr. 1977, 10, 217–229. [Google Scholar]

- Yiben, Z.; Fei, X.; Shansuo, Z. Review of research on freeze–thaw damage concrete. Concrete 2021, 3, 10–14. [Google Scholar]

- Sun, H.; Fang, C.; Cai, W.; Guo, B. Study on the influence factors of thermal stress of concrete under freezing and thawing cycles. Concrete 2017, 5, 29–32+38. [Google Scholar]

- Yuan, L. Study on Stochastic Predicting Method for the Freeze Proof Durability of Concrete Based on Damage Theory. Master’s Thesis, Zhejiang University, Hangzhou, China, 2006. [Google Scholar]

- Liu, X.; Tang, G. Research on Prediction Method of Concrete Freeze-thaw Durability under Field Environments. Chin. J. Rock Mech. Eng. 2007, 12, 2412–2419. [Google Scholar]

- Cai, H. Prediction Model of Concrete Freeze-Thaw Durability. Ph.D. Thesis, Tsinghua University, Beijing, China, 1998. [Google Scholar]

- Kefei, L.; Huizhen, L.; Xiaotan, D. Durability design of concrete structures: Principle, method and standard. China Civ. Eng. J. 2021, 54, 64–71+96. [Google Scholar]

| Tunnel Name | Full Length (m) | Altitude (m) | Whether to Lay Insulation Board | Location of Tests along the Tunnel (m) |

|---|---|---|---|---|

| Balangshan Tunnel | 7954 | 3800 | 750 m at both ends | 0, 750, 1500, 2300, 3500, 4000, 5000, 6000, 7000 |

| Gaoersi Tunnel | 5682 | 3900 | 800 m at both ends | 0, 750, 1500, 2500, 3500, 4000, 5000, 5682 |

| Queershan Tunnel | 7060 | 4341 | 820 m at both ends | 0, 750, 1500, 2500, 3500, 4500, 5000, 6000, 7000 |

| Lanashan Tunnel | 3450 | 2980 | Unpaved | 0, 250, 1000, 1500, 2000, 2500, 3000 |

| Frost Resistant Material | Test Items | Frost Resistant Material | Test Items |

|---|---|---|---|

| Silane antifreeze | Silane antifreeze-200 g/m2 | Silane impermeability antifreeze agent | Type II-300 g/m2 |

| Silane antifreeze-300 g/m2 | Type III-200 g/m2 | ||

| Silane antifreeze-400 g/m2 | Type III-300 g/m2 | ||

| Silane (1:1 dilution)-200 g/m2 | BS CREME C, silicone | BS CREME C-200 g/m2 | |

| Silane (1:1 dilution)-300 g/m2 | BS CREME C-300 g/m2 | ||

| Silane (1:1 dilution)-400 g/m2 | BS CREME C-400 g/m2 | ||

| Silane impermeability antifreeze agent | Type I-200 g/m2 | Silicone protection system-500 g/m2 | |

| Type I-300 g/m2 | Silicone polyether hybrid-500 g/m2 | ||

| Type II-200 g/m2 | —— | Blank test piece |

| Dosage | Specimen Name | Freeze-Thaw Cycles | Dosage | Specimen Name | Freeze-Thaw Cycles |

|---|---|---|---|---|---|

| 200 g/m2 | Silane type I-200 g/m2 | 75 | 300 g/m2 | Silane type I-300 g/m2 | 100 |

| Silane type II-200 g/m2 | 50 | Silane type II-300 g/m2 | 100 | ||

| Silane type III-200 g/m2 | 125 | Silane type III-300 g/m2 | 175 | ||

| BS CREME C-200 g/m2 | 50 | BS CREME C-300 g/m2 | 100 | ||

| Silane-200 g/m2 | 100 | Silane-300 g/m2 | 100 | ||

| Silane (1:1 dilution)-200 g/m2 | 50 | Silane (1:1 dilution)-300 g/m2 | 75 | ||

| 400 g/m2 | BS CREME C-400 g/m2 | 125 | 500 g/m2 | Silicone protection system-500 g/m2 | 125 |

| Silane-400 g/m2 | 125 | Silicone polyether hybrid-500 g/m2 | 300 | ||

| Silane (1:1 dilution)-400 g/m2 | 75 | —— | Blank test piece | 25 |

| Serial Number | Degree of Saturation | Environment Condition | Saturation Coefficient S |

|---|---|---|---|

| 1 | High saturation | Long-term or frequent contact with water before freezing, high water saturation in concrete | 1.0 |

| 2 | Moderately saturated | It is wet before freezing or occasionally in contact with rain and water, and the degree of water saturation in the concrete is not high | 0.8 |

| Freeze–Thaw Cycles | Temperature Range °C | Freeze–Thaw Cycles | Temperature Range °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Maximum Temperature °C | Minimum Temperature °C | Maximum Temperature °C | Minimum Temperature °C | ||||||

| 1 | 15.94 | −7.0 | 1.09 | 0.09 | 49 | 1.44 | −8.00 | 0.79 | 0.06 |

| 3 | 3.00 | −12.31 | 0.85 | 0.07 | 51 | 4.56 | −3.88 | 0.70 | 0.06 |

| 5 | 4.94 | −5.56 | 0.70 | 0.06 | 53 | 6.44 | −3.06 | 0.79 | 0.06 |

| 7 | 4.88 | −8.44 | 0.83 | 0.07 | 55 | 4.94 | −2.44 | 0.49 | 0.04 |

| 9 | 1.63 | −6.25 | 0.66 | 0.05 | 57 | 3.19 | −3.56 | 0.45 | 0.04 |

| 11 | 0.94 | −7.88 | 0.74 | 0.06 | 59 | 3.19 | −5.38 | 0.71 | 0.06 |

| 13 | 2.69 | −7.5 | 0.68 | 0.05 | 61 | 6.88 | −2.38 | 0.62 | 0.05 |

| 15 | 1.94 | −10.81 | 0.85 | 0.07 | 63 | 4.00 | −2.00 | 0.40 | 0.03 |

| 17 | 1.75 | −3.63 | 0.36 | 0.03 | 65 | 6.81 | −2.25 | 0.76 | 0.06 |

| 19 | 5.81 | −2.25 | 0.90 | 0.07 | 67 | 5.25 | −3.81 | 0.76 | 0.06 |

| 21 | 4.13 | −1.69 | 0.97 | 0.08 | 69 | 4.38 | −2.56 | 0.46 | 0.04 |

| 23 | 0.44 | −7.81 | 0.46 | 0.04 | 71 | 3.81 | −3.69 | 0.42 | 0.03 |

| 25 | 1.63 | −10.00 | 0.65 | 0.05 | 73 | 3.88 | −2.38 | 0.52 | 0.04 |

| 27 | 3.06 | −4.63 | 0.43 | 0.03 | 75 | 5.00 | −2.31 | 0.61 | 0.05 |

| 29 | 1.69 | −4.94 | 0.37 | 0.03 | 77 | 1.88 | −2.63 | 0.75 | 0.06 |

| 31 | 2.38 | −4.19 | 0.55 | 0.04 | 79 | 5.31 | −1.94 | 0.48 | 0.04 |

| 33 | 0.50 | −9.50 | 0.67 | 0.05 | 81 | 4.63 | −3.69 | 0.69 | 0.06 |

| 35 | 5.19 | −4.75 | 0.55 | 0.04 | 83 | 2.81 | −4.81 | 0.64 | 0.05 |

| 37 | 0.81 | −9.31 | 0.67 | 0.05 | 85 | 2.44 | −6.19 | 0.72 | 0.06 |

| 39 | 4.31 | −3.88 | 0.55 | 0.04 | 87 | 2.19 | −6.56 | 0.73 | 0.06 |

| 41 | 1.25 | −8.00 | 0.62 | 0.05 | 89 | 3.69 | −6.88 | 0.59 | 0.05 |

| 43 | 4.44 | −7.31 | 0.78 | 0.06 | 91 | 1.19 | −8.38 | 0.64 | 0.05 |

| 45 | 8.75 | −2.31 | 0.74 | 0.06 | 93 | 4.06 | −3.06 | 0.47 | 0.04 |

| 47 | 8.31 | −1.31 | 0.64 | 0.05 | 95 | 3.88 | −5.63 | 0.63 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zheng, J.; Zheng, B.; Yang, F.; Guo, R.; Huang, H. Experiment on Freeze–Thaw Resistance of Tunnel Portal-Lining Concrete with Silicone Coating in Cold Regions. Buildings 2024, 14, 2330. https://doi.org/10.3390/buildings14082330

Zhou Y, Zheng J, Zheng B, Yang F, Guo R, Huang H. Experiment on Freeze–Thaw Resistance of Tunnel Portal-Lining Concrete with Silicone Coating in Cold Regions. Buildings. 2024; 14(8):2330. https://doi.org/10.3390/buildings14082330

Chicago/Turabian StyleZhou, Yuanfu, Jinlong Zheng, Bo Zheng, Feng Yang, Rui Guo, and Hongyu Huang. 2024. "Experiment on Freeze–Thaw Resistance of Tunnel Portal-Lining Concrete with Silicone Coating in Cold Regions" Buildings 14, no. 8: 2330. https://doi.org/10.3390/buildings14082330

APA StyleZhou, Y., Zheng, J., Zheng, B., Yang, F., Guo, R., & Huang, H. (2024). Experiment on Freeze–Thaw Resistance of Tunnel Portal-Lining Concrete with Silicone Coating in Cold Regions. Buildings, 14(8), 2330. https://doi.org/10.3390/buildings14082330