Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate

Abstract

1. Introduction

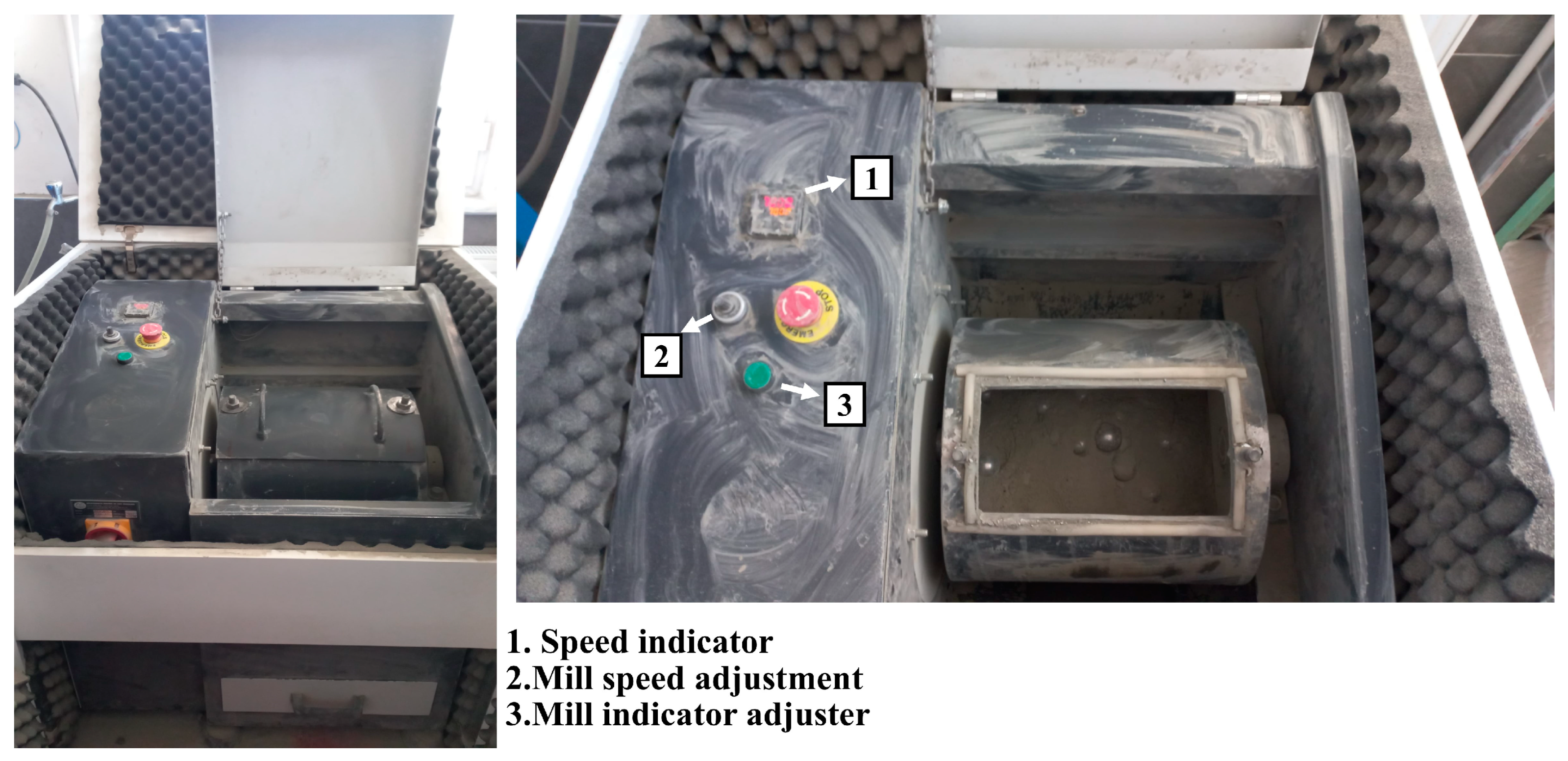

2. Materials and Methods

Design of Experiments with the Taguchi Method

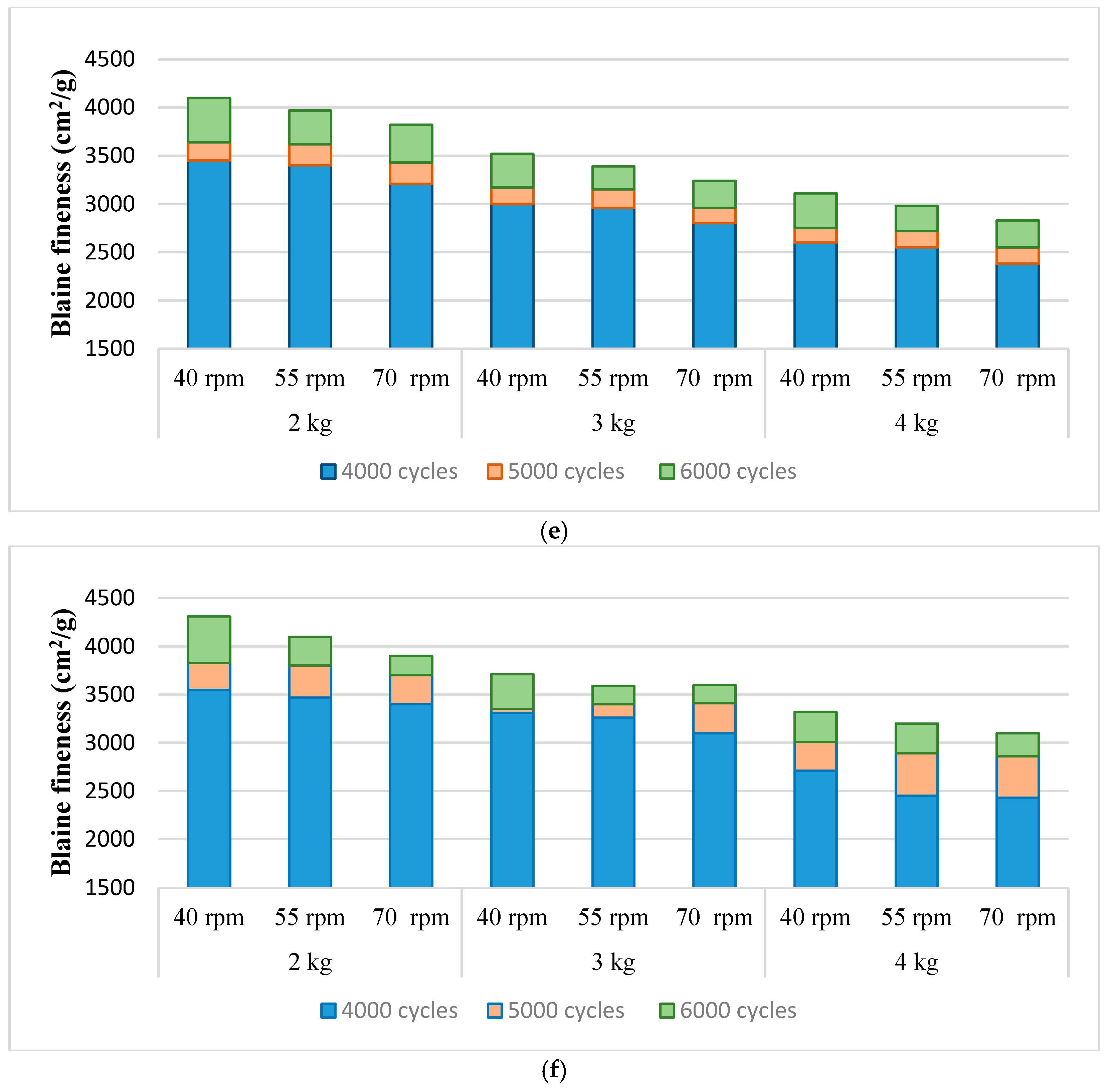

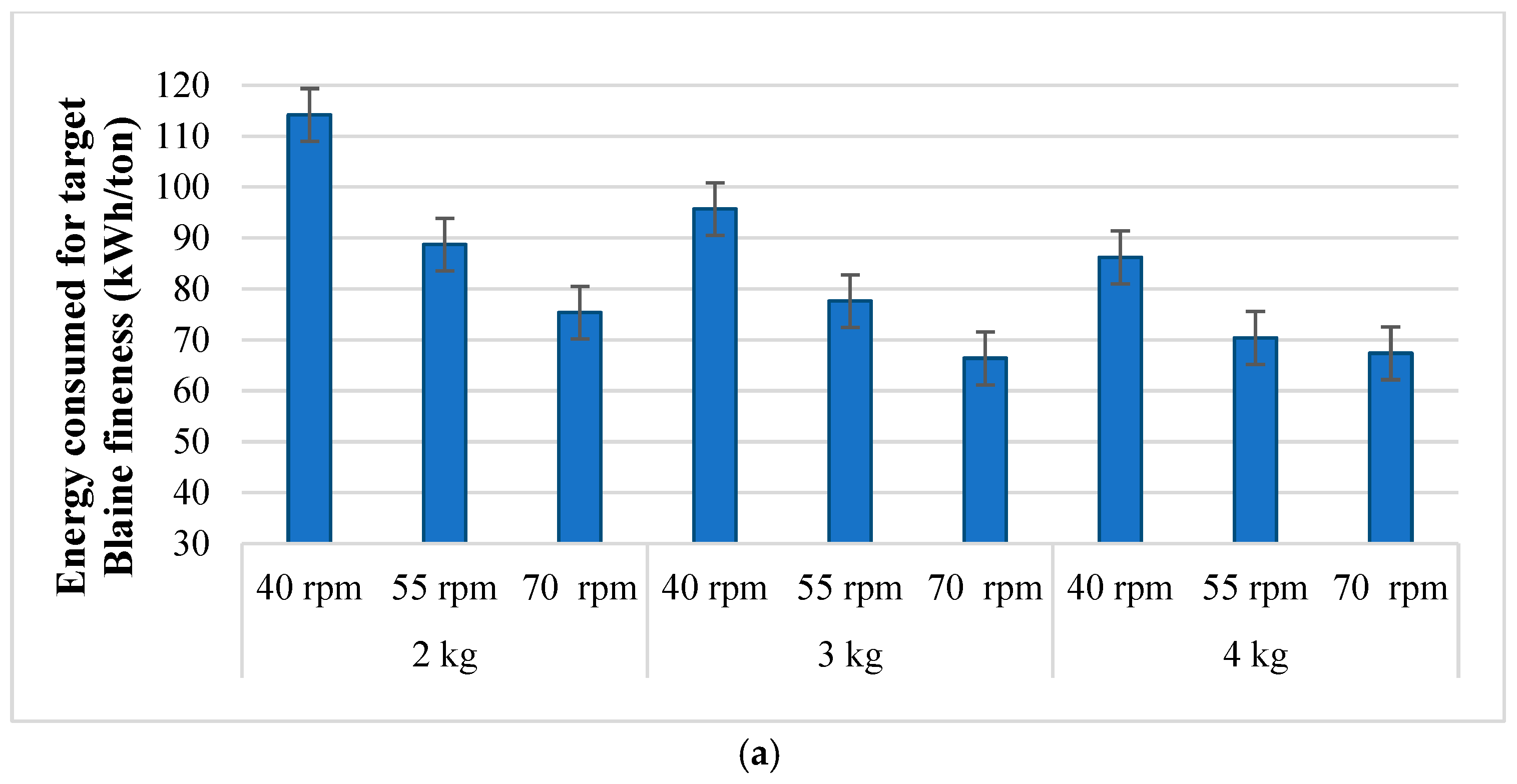

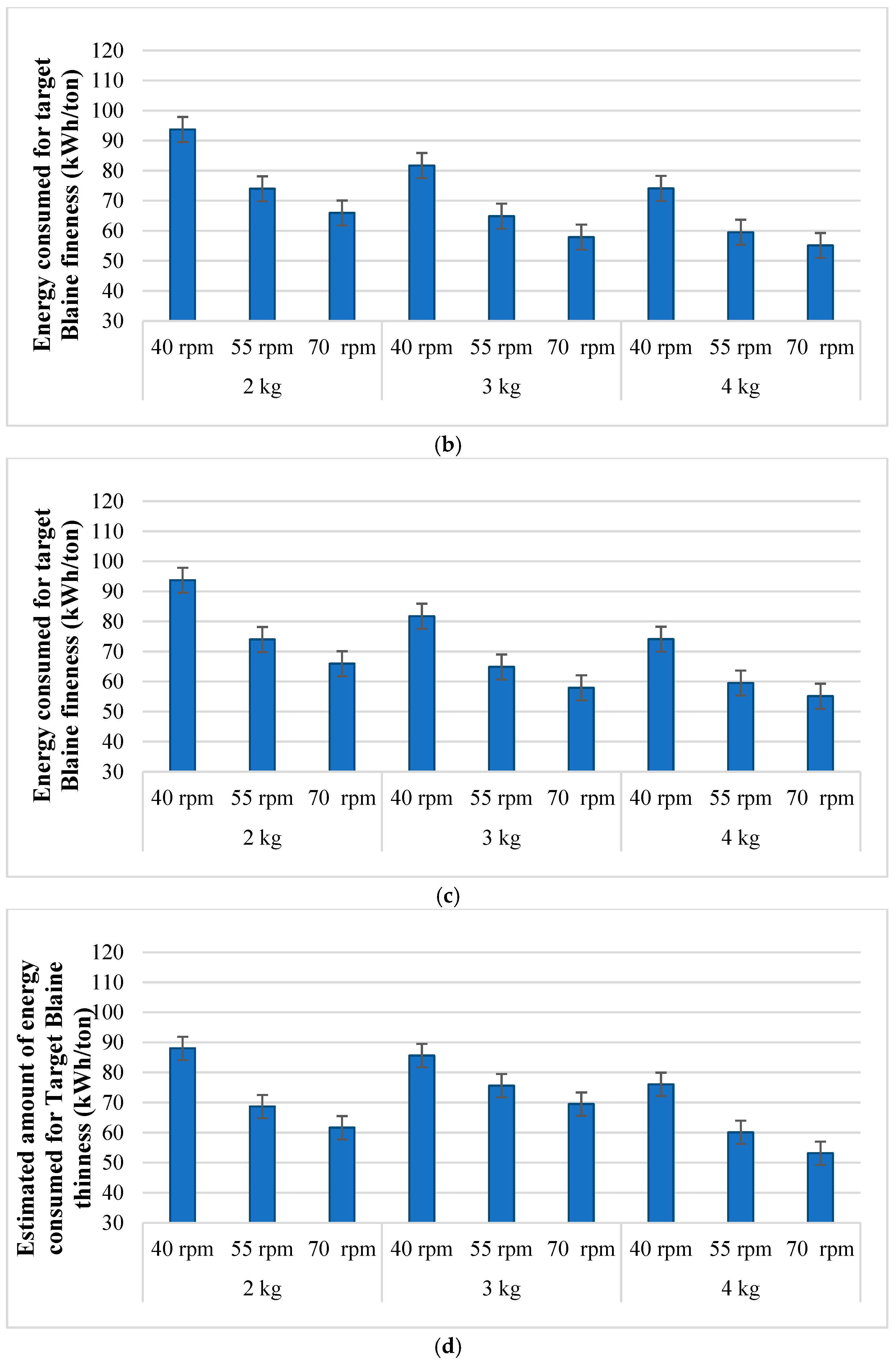

3. Results and Discussion

3.1. Experimental Results

3.2. Evaluation of the Experimental Results

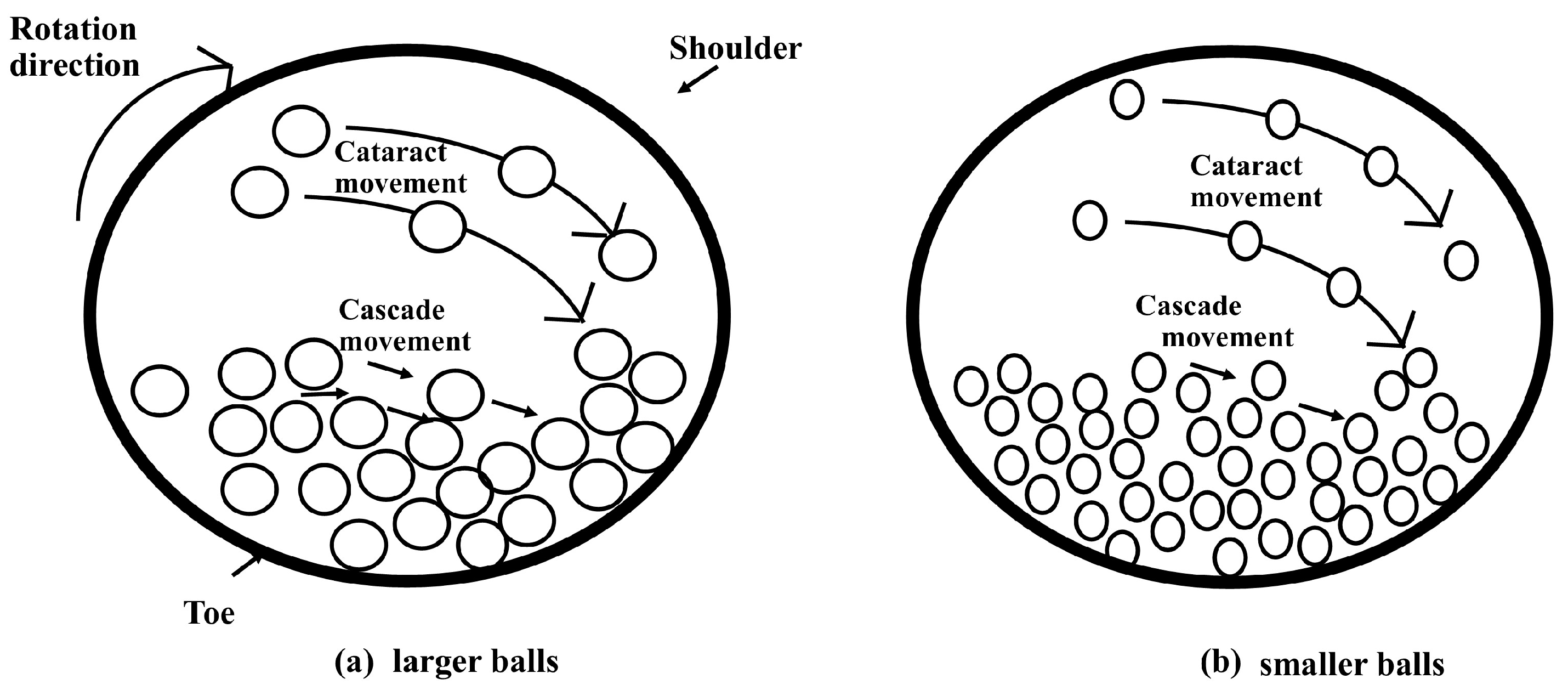

3.2.1. Effect of Ball Size Variation on Grinding Performance

3.2.2. Effect of Mill-Speed Variation on Grinding Performance

3.2.3. Effect of Feed-Rate Variation on Grinding Performance

3.3. General Evaluation

3.4. Evaluation of Analysis Results

3.4.1. Analysis of Signal-to-Noise (S/N) Ratio

3.4.2. ANOVA Method

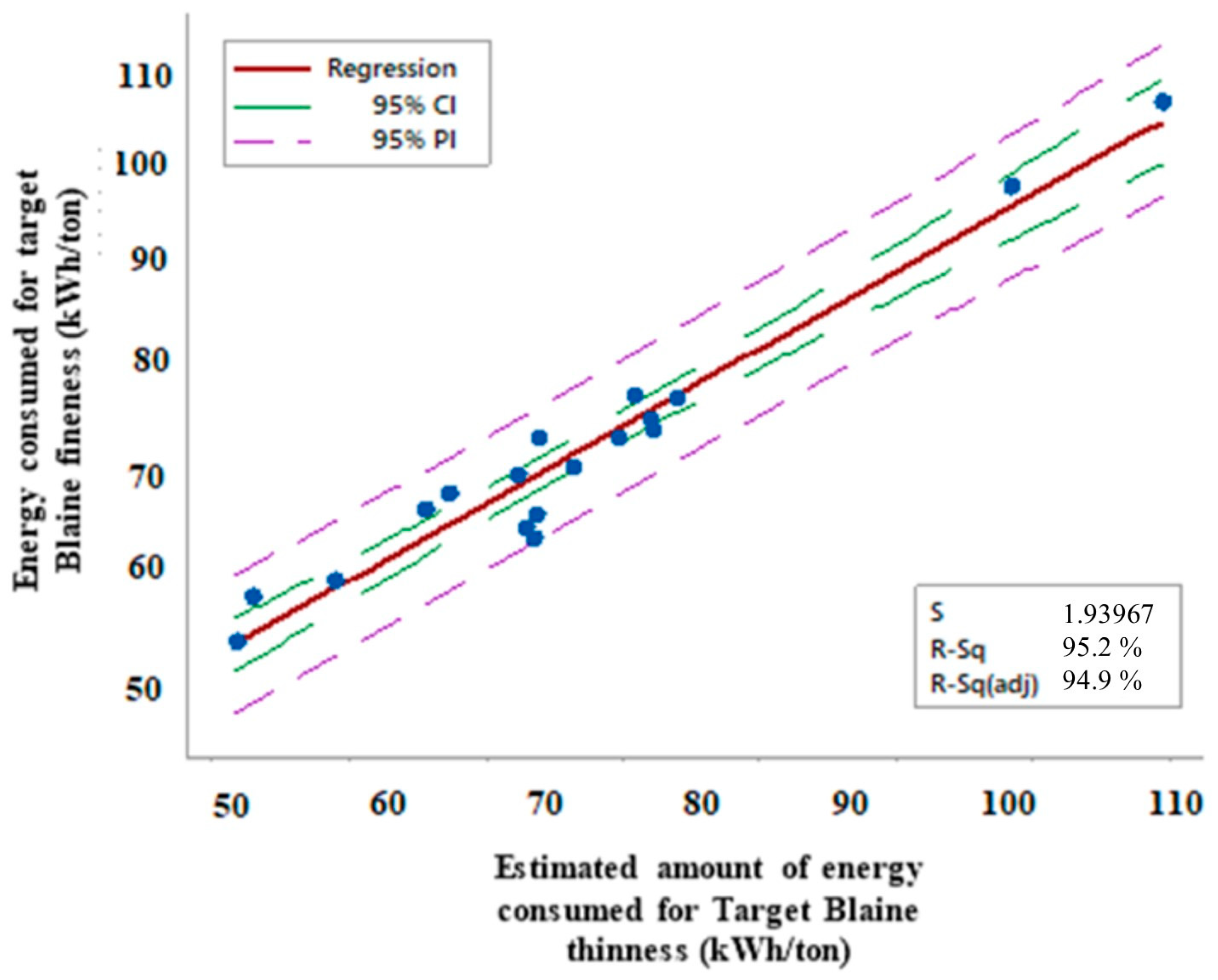

3.4.3. Regression Analysis

3.5. Estimation of Optimum Grinding Conditions by Taguchi Method, Linear Regression Equations, and Quadratic Regression Equation and Comparison with Experimental Results

4. Conclusions

- Ball size variation has a significant effect on grinding performance. It was observed that smaller diameter balls, especially the Bond type ball distribution no. 6, resulted in higher grinding efficiency and surface area. This is related to the abrasion effect and the formation of fines in the feed. As a result, considering the interactions of ball size, mill speed, and feed rate, the best grinding performance was obtained with Bond-type ball distribution no. 6. This distribution has a high surface area and ball density, but there are important factors to consider in terms of grinding time and energy efficiency;

- Increasing the mill speed resulted in a general decrease in grinding efficiency, especially increases up to 90% of the critical speed. This adversely affected the shoulder and foot angles of the balls, making it more difficult to crush the particle;

- An increase in the feed rate increased the material fill rate and void-filling capacity but showed different effects on the grinding performance depending on the ball distribution. At smaller ball distributions, especially in the mixtures numbered 3, 4, and 6, the increase in the material-filling ratio had a negative effect on the grinding performance;

- To minimize the energy consumed in grinding, the optimum levels of the effective parameters (ball distribution, grinding mass, and mill speed) were determined using the Taguchi method;

- According to the results of the statistical analysis, it was determined that the most important parameter for energy efficiency was ball distribution, with a contribution of 36.89%;

- The developed quadratic regression models showed a very good relationship between the measured and predicted values of the energy consumed in grinding with high correlation coefficients;

- As a result, considering the interactions of ball size, mill speed, and feed rate, the best grinding performance was obtained with Bond-type ball distribution no. 6. This distribution has a high surface area and ball density, but there are important factors to consider in terms of grinding time and energy efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mardani-Aghabaglou, A. Investigation of Cement-Superplasticizer Admixture Compatibility. Ph.D. Thesis, Ege University, Engineering Faculty, Civil Engineering Department, Izmir, Turkey, 2016. NO. 10103689. 290p. Available online: https://tez.yok.gov.tr/UlusalTezMerkezi/ (accessed on 16 May 2024).

- Kaya, Y.; Kobya, V.; Mardani, A. Evaluation of fresh state, rheological properties, and compressive strength performance of cementitious system with grinding aids. J. Appl. Polym. Sci. 2024, 141, e55212. [Google Scholar] [CrossRef]

- Kobya, V.; Kaya, Y.; Mardani-Aghabaglou, A. Effect of amine and glycol-based grinding aids utilization rate on grinding efficiency and rheological properties of cementitious systems. J. Build. Eng. 2022, 47, 103917. [Google Scholar] [CrossRef]

- Yiğit, B.; Salihoğlu, G.; Mardani-Aghabaglou, A.; Salihoğlu, N.K.; Özen, S. Recycling of sewage sludge incineration ashes as construction material. J. Fac. Eng. Archit. Gazi Univ. 2020, 35, 1647–1664. [Google Scholar]

- Qian, H.Y.; Kong, Q.G.; Zhang, B.L. The effects of grinding media shapes on the grinding kinetics of cement clinker in ball mill. Powder Technol. 2013, 235, 422–425. [Google Scholar] [CrossRef]

- Touil, D.; Belaadi, S.; Frances, C. The specific selection function effect on clinker grinding efficiency in a dry batch ball mill. Int. J. Miner. Process. 2008, 87, 141–145. [Google Scholar] [CrossRef][Green Version]

- Katubilwa, F.M.; Moys, M.H.; Glasser, D.; Hildebrandt, D. An attainable region analysis of the effect of ball size on milling. Powder Technol. 2011, 210, 36–46. [Google Scholar] [CrossRef]

- Santosh, T.; Eswaraiah, C.; Soni, R.K.; Kumar, S. Size reduction performance evaluation of HPGR/ball mill and HPGR/stirred mill for PGE bearing chromite ore. Adv. Powder Technol. 2023, 34, 103907. [Google Scholar] [CrossRef]

- Santosh, T.; Soni, R.K.; Eswaraiah, C.; Rao, D.S.; Venugopal, R. Optimization of stirred mill parameters for fine grinding of PGE bearing chromite ore. Part. Sci. Technol 2020, 39, 663–675. [Google Scholar]

- Abdelhaffez, G.S.; Ahmed, A.A.; Ahmed, H.M. Effect of grinding media on the milling efficiency of a ball mill. Rud.-Geološko-Naft. Zb. 2022, 38, 171–177. [Google Scholar] [CrossRef]

- Ipek, H. The effects of grinding media shape on breakage rate. Miner. Eng. 2006, 19, 91–93. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Özen, S.; Altun, M.G. Durability performance and dimensional stability of polypropylene fiber reinforced concrete. J. Green Build. 2018, 13, 20–41. [Google Scholar] [CrossRef]

- Danha, G.; Hlabangana, N.; Muzenda, E. Effect of ball and feed particle size distribution on the milling efficiency of a ball mill: An attainable region approach. S. Afr. J. Chem. Eng. 2018, 25, 79–84. [Google Scholar]

- Shahbazi, B.; Jafari, M.; Parian, M.; Rosenkranz, J.; Chelgani, S.C. Study on the impacts of media shapes on the performance of tumbling mills—A review. Miner. Eng. 2020, 157, 106490. [Google Scholar] [CrossRef]

- Erdem, A.S. Modelling of Effect of Ball Size on Grinding Model Parameters. Ph.D. Thesis, Hacettepe University, Engineering Faculty, Mining Engineering Department, Ankara, Turkey, 2009. [Google Scholar]

- Dong, H.; Moys, M.H. Load behavior and mill power. Int. J. Miner. Process. 2003, 69, 11–28. [Google Scholar] [CrossRef]

- Shi, F. Comparison of grinding media—Cylpebs versus balls. Miner. Eng. 2004, 17, 1259–1268. [Google Scholar] [CrossRef]

- Lameck, N.S.; Kiangi, K.K.; Moys, M.H. Effects of grinding media shapes on load behaviour and mill power in a dry ball mill. Miner. Eng. 2006, 19, 1357–1361. [Google Scholar] [CrossRef]

- Amiri, S.H.; Zare, S. Influence of grinding and classification circuit on the performance of iron ore beneficiation—A plant scale study. Miner. Process. Extr. Metall. Rev. 2021, 42, 143–152. [Google Scholar] [CrossRef]

- Sezer, A.; Boz, A.; Tanrinian, N. An investigation into strength and permittivity of compacted sand-clay mixtures by partial replacement of water with lignosulfonate. Acta Phys. Pol. A 2016, 130, 23–27. [Google Scholar] [CrossRef]

- Dökme, F.; Güven, O. Bilyalı değirmenlerde hızın performansa olan etkilerinin deneysel olarak incelenmesi. Mühendis Ve Makina 2014, 55, 38–50. [Google Scholar]

- Erdem, A.S.; Ergün, Ş.L. The effect of ball size on breakage rate parameter in a pilot scale ball mill. Miner. Eng. 2009, 22, 660–664. [Google Scholar] [CrossRef]

- Magdalinovic, N.; Trumic, M.; Trumic, M.; Andric, L. The optimal ball diameter in a mill. Physicochem. Probl. Miner. Process. 2012, 48, 329–339. [Google Scholar]

- Schnatz, R. Optimization of continuous ball mills used for finish-grinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time. Int. J. Miner. Process. 2004, 74, S55–S63. [Google Scholar] [CrossRef]

- Jayasundara, C.T.; Yang, R.Y.; Yu, A.B.; Rubenstein, J. Effects of disc rotation speed and media loading on particle flow and grinding performance in a horizontal stirred mill. Int. J. Miner. Process. 2010, 96, 27–35. [Google Scholar] [CrossRef]

- Fortsch, D.S. Ball charge loading-impact on specific power consumption and capacity. In Proceedings of the IEEE Cement Industry Technical Conference, Phoenix, AZ, USA, 9–14 April 2006; Conference Record. IEEE: New York, NY, USA, 2006; p. 11. [Google Scholar]

- Deniz, V. The effect of mill speed on kinetic breakage parameters of clinker and limestone. Cem. Concr. Res. 2004, 34, 1365–1371. [Google Scholar] [CrossRef]

- Simba, K.P.; Moys, M.H. Effects of mixtures of grinding media of different shapes on milling kinetics. Miner. Eng. 2014, 61, 40–46. [Google Scholar] [CrossRef]

- AmanNejad, M.; Barani, K. Effects of ball size distribution and mill speed and their interactions on ball milling using DEM. Miner. Process. Extr. Metall. Rev. 2021, 42, 374–379. [Google Scholar] [CrossRef]

- Göktaş, İ.; Altun, O.; Toprak, N.A.; Altun, D. Element-based ball mill and hydrocyclone modelling for a copper ore grinding circuit. Miner. Eng. 2023, 198, 108090. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Öztürk, H.T.; Kankal, M.; Ramyar, K. Assessment and prediction of cement paste flow behavior; Marsh-funnel flow time and mini-slump values. Constr. Build. Mater. 2021, 301, 124072. [Google Scholar] [CrossRef]

- Aslan, N.; Akçiçek, N. Optimization of clinker grinding using the Taguchi method. Int. J. Eng. Appl. Sci. 2011, 3, 101–108. [Google Scholar]

- Nas, E.; Altan Özbek, N. Optimization of the machining parameters in turning of hardened hot work tool steel using cryogenically treated tools. Surf. Rev. Lett. 2020, 27, 1950177. [Google Scholar] [CrossRef]

- Kıvak, T. Optimization of surface roughness and flank wear using the Taguchi method in milling of Hadfield steel with PVD and CVD coated inserts. Measurement 2014, 50, 19–28. [Google Scholar] [CrossRef]

- Mandal, N.; Doloi, B.; Mondal, B.; Das, R. Optimization of flank wear using Zirconia Toughened Alumina (ZTA) cutting tool: Taguchi method and Regression analysis. Measurement 2011, 44, 2149–2155. [Google Scholar] [CrossRef]

- Jankovic, A.; Valery, W.; Davis, E. Cement grinding optimisation. Miner. Eng. 2004, 17, 1075–1081. [Google Scholar] [CrossRef]

- Çalkaya, M. Analysıs of Fine Wet Grinding of Zeolite in Ball Mill. Master’s Thesis, Selçuk University, Engineering Faculty, Mining Engineering Department, Konya, Turkey, 2008. [Google Scholar]

- Sridhar, C.S.; Sankar, P.S.; Prasad, R.K. Grinding kinetics, modeling, and subsieve morphology of ball mill grinding for cement industry ingredients. Part. Sci. Technol. 2016, 34, 1–8. [Google Scholar] [CrossRef]

- Cetin, M.H.; Ozcelik, B.; Kuram, E.; Demirbas, E. Evaluation of vegetable based cutting fluids with extreme pressure and cutting parameters in turning of AISI 304L by Taguchi method. J. Clean. Prod. 2011, 19, 2049–2056. [Google Scholar] [CrossRef]

| Reference | [23] | [28] | [13] | [29] |

|---|---|---|---|---|

| Ball shape and size | 6, 11, 15 and 20 mm spherical balls | Spherical (40 mm), ellipsoids (40 mm), and cubic (32 mm), mix (total weight of balls kept constant) | 10 mm, 20 mm, 10 and 20 mm mix | 16 and 20 mm spherical balls |

| Feed material properties (size, quantity, type) | Quartz (1080–1168 g) and copper waste (792–949 g) | Quartz (0.3–1.6 mm size range) | Quartz (850–1700 microns and 300–850 microns) | |

| Mill Rotation Speed | 85% of critical speed | 75% of critical speed | 75% of critical speed | 60, 65, 70, 75, and 80% of critical speed |

| Results obtained | The optimum ball diameter depending on the diameter of the particle size of the milled material was related to an equation depending on the milling conditions and milled material properties | The optimum ratio of grinding performance was obtained by using 50% spherical and 50% cube balls | For coarser feeds, a mix of 50 mm, 20 mm, and 10 mm ball diameters tends to break the material faster than other ball combinations. For finer feeds, a binary mix of 20 mm and 10 mm diameter balls leads to a faster breakage rate | When 60% of the grinding media consists of small balls and 40% of the grinding media consists of large balls, the change in grinding speed is the parameter that most affects grinding efficiency for all mill fills |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 * | Na2O | K2O | Cl * | C3S | C2S | C3A | C4AF | Loss of Ignition | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clinker | 21.52 | 5.43 | 3.31 | 65.38 | 1.04 | 0.38 | 0.48 | 0.54 | 0.01 | 56.51 | 19.06 | 8.79 | 10.07 | 0.52 |

| Gypsum | 4.98 | 1.21 | 0.83 | 28.94 | 0.83 | 39.67 | 0.25 | 0.19 |

| Ball Diameter (mm) | Ball Weight (g/pcs) | 1. Ball Distribution (pcs) | 2. Ball Distribution (pcs) | 3. Ball Distribution (pcs) | 4. Ball Distribution (pcs)) | 5. Ball Distribution (pcs) | 6. Ball Distribution (Bond Type) (pcs) |

|---|---|---|---|---|---|---|---|

| 65 | 860 | 4 | 4 | 5 | 3 | ||

| 55 | 510 | 5 | 5 | 6 | 6 | 6 | |

| 43 | 260 | 12 | 12 | 12 | 22 | 20 | |

| 40 | 225 | 7 | 7 | 14 | 17 | 15 | |

| 37 | 190 | 3 | 8 | 9 | 13 | 10 | 43 |

| 30 | 110 | 6 | 12 | 22 | 22 | 22 | 67 |

| 25 | 70 | 5 | 12 | 17 | 17 | 17 | 10 |

| 20 | 30 | 3 | 71 | ||||

| 15 | 16 | 20 | 40 | 50 | 50 | 97 | |

| Total surface area (mm2) | 263,093 | 325,673 | 433,097 | 457,102 | 427,005 | 551,796 | |

| Total weight (g) | 12,675 | 15,005 | 19,750 | 19,485 | 19,725 | 19,922 | |

| 1. Ball Distribution (pcs) | 2. Ball Distribution (pcs) | 3. Ball Distribution (pcs) | 4. Ball Distribution (pcs) | 5. Ball Distribution (pcs) | 6. Ball Distribution (Bond Type) (pcs) | ||

|---|---|---|---|---|---|---|---|

| Mill volume (m3) | 0.0223 | ||||||

| Ball fill (J) | 0.122 | 0.144 | 0.189 | 0.187 | 0.189 | 0.191 | |

| Void fill (U) | For 2 kg feeding amount | 0.977 | 0.825 | 0.627 | 0.635 | 0.628 | 0.621 |

| For 3 kg feeding amount | 1.465 | 1.238 | 0.940 | 0.953 | 0.942 | 0.932 | |

| For 4 kg feeding amount | 1.954 | 1.650 | 1.254 | 1.271 | 1.255 | 1.243 | |

| Parameters | Symbol | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 |

|---|---|---|---|---|---|---|---|

| Ball Distribution | A | 1 | 2 | 3 | 4 | 5 | 6 |

| Mass (kg) | B | 2 | 3 | 4 | - | - | - |

| Speed (rpm) | C | 40 | 55 | 70 | - | - | - |

| Experiment No. | Factor A | Factor B | Factor C |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 |

| 3 | 1 | 3 | 3 |

| 4 | 2 | 1 | 1 |

| 5 | 2 | 2 | 2 |

| 6 | 2 | 3 | 3 |

| 7 | 3 | 1 | 2 |

| 8 | 3 | 2 | 3 |

| 9 | 3 | 3 | 1 |

| 10 | 4 | 1 | 3 |

| 11 | 4 | 2 | 1 |

| 12 | 4 | 3 | 2 |

| 13 | 5 | 1 | 2 |

| 14 | 5 | 2 | 3 |

| 15 | 5 | 3 | 1 |

| 16 | 6 | 1 | 3 |

| 17 | 6 | 2 | 1 |

| 18 | 6 | 3 | 2 |

| Experiment No. | Control Factors | Energy Consumed (kWh/ton) | S/N Ratio for Energy Consumed | Means for Energy Consumed | ||

|---|---|---|---|---|---|---|

| Ball Distribution (BD) | Feed Mass (m) | Mill Speed (v) | ||||

| 1 | 1 | 2 | 40 | 76.12 | −37.6300 | 76.12 |

| 2 | 1 | 3 | 55 | 56.9 | −35.1022 | 56.9 |

| 3 | 1 | 4 | 70 | 52.41 | −34.3883 | 52.41 |

| 4 | 2 | 2 | 40 | 70.63 | −36.9798 | 70.63 |

| 5 | 2 | 3 | 55 | 48.58 | −33.7292 | 48.58 |

| 6 | 2 | 4 | 70 | 49.68 | −33.9236 | 49.68 |

| 7 | 3 | 2 | 55 | 54.26 | −34.6896 | 54.26 |

| 8 | 3 | 3 | 70 | 45.03 | −33.0700 | 45.03 |

| 9 | 3 | 4 | 40 | 49.41 | −33.8763 | 49.41 |

| 10 | 4 | 2 | 70 | 47.91 | −33.6085 | 47.91 |

| 11 | 4 | 3 | 40 | 57.08 | −35.1297 | 57.08 |

| 12 | 4 | 4 | 55 | 44.07 | −32.8829 | 44.07 |

| 13 | 5 | 2 | 55 | 54.85 | −34.7835 | 54.85 |

| 14 | 5 | 3 | 70 | 50.83 | −34.1224 | 50.83 |

| 15 | 5 | 4 | 40 | 55.52 | −34.8890 | 55.52 |

| 16 | 6 | 2 | 70 | 51.92 | −34.3067 | 51.92 |

| 17 | 6 | 3 | 40 | 54.37 | −34.7072 | 54.37 |

| 18 | 6 | 4 | 55 | 41.09 | −32.2747 | 41.09 |

| Response Table for Signal-to-Noise Ratios | Response Table for Means | ||||||

|---|---|---|---|---|---|---|---|

| Level | BD | m | v | Level | BD | m | v |

| 1 | −35.71 | −35.33 | −35.54 | 1 | 61.81 | 59.28 | 60.52 |

| 2 | −34.88 | −34.31 | −33.91 | 2 | 56.30 | 52.13 | 49.96 |

| 3 | −33.88 | −33.71 | −33.9 | 3 | 49.57 | 48.70 | 49.63 |

| 4 | −33.87 | 4 | 49.69 | ||||

| 5 | −34.60 | 5 | 53.73 | ||||

| 6 | −33.76 | 6 | 49.13 | ||||

| Delta | 1.94 | 1.63 | 1.63 | Delta | 12.68 | 10.59 | 10.89 |

| Rank | 1 | 3 | 2 | Rank | 1 | 3 | 2 |

| Source | Degree of Freedom (DoF) | The Sum of Squares (SS) | Mean Square (MS) | F-Value | p-Value | Impact Rates (%) |

|---|---|---|---|---|---|---|

| BD | 5 | 460.64 | 230.32 | 30.61 | 0.000178 | 36.89 |

| m | 2 | 349.93 | 174.96 | 10.04 | 0.000464 | 28.02 |

| v | 2 | 377.91 | 75.58 | 23.25 | 0.002702 | 30.26 |

| Error | 8 | 60.20 | 7.53 | 4.82 | ||

| Total | 17 | 1248.67 | 100.00 |

| BD | |||

|---|---|---|---|

| 1 | energy consumed | = | 97.66 − 5.29 m − 0.3631 v |

| 2 | energy consumed | = | 92.14 − 5.29 m − 0.3631 v |

| 3 | energy consumed | = | 85.41 − 5.29 m − 0.3631 v |

| 4 | energy consumed | = | 85.53 − 5.29 m − 0.3631 v |

| 5 | energy consumed | = | 89.58 − 5.29 m − 0.3631 v |

| 6 | energy consumed | = | 84.97 − 5.29 m − 0.3631 v |

| Taguchi Methods | Linear Regression | Quadratic Regression | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Experimental Result | Prediction | Error (%) | Experimental Result | Prediction | Error (%) | Experimental Result | Prediction | Error (%) | |

| A6B3C3 (The best) | 49.37 | 52.34 | 6.02 | 49.37 | 50.56 | 3.02 | 49.37 | 49.26 | 0.23 |

| A3B2C3 (Random) | 57.90 | 61.04 | 5.42 | 57.90 | 59.06 | 2.01 | 57.90 | 45.12 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, Y.; Kobya, V.; Mardani, A.; Mardani, N.; Beytekin, H.E. Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate. Buildings 2024, 14, 2356. https://doi.org/10.3390/buildings14082356

Kaya Y, Kobya V, Mardani A, Mardani N, Beytekin HE. Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate. Buildings. 2024; 14(8):2356. https://doi.org/10.3390/buildings14082356

Chicago/Turabian StyleKaya, Yahya, Veysel Kobya, Ali Mardani, Naz Mardani, and Hatice Elif Beytekin. 2024. "Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate" Buildings 14, no. 8: 2356. https://doi.org/10.3390/buildings14082356

APA StyleKaya, Y., Kobya, V., Mardani, A., Mardani, N., & Beytekin, H. E. (2024). Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size, Mill Rotation Speed, and Feed Rate. Buildings, 14(8), 2356. https://doi.org/10.3390/buildings14082356