Analysis of Mechanical Properties during Construction Stages Reflecting the Construction Sequence for Long-Span Spatial Steel Structures

Abstract

:1. Introduction

2. Background

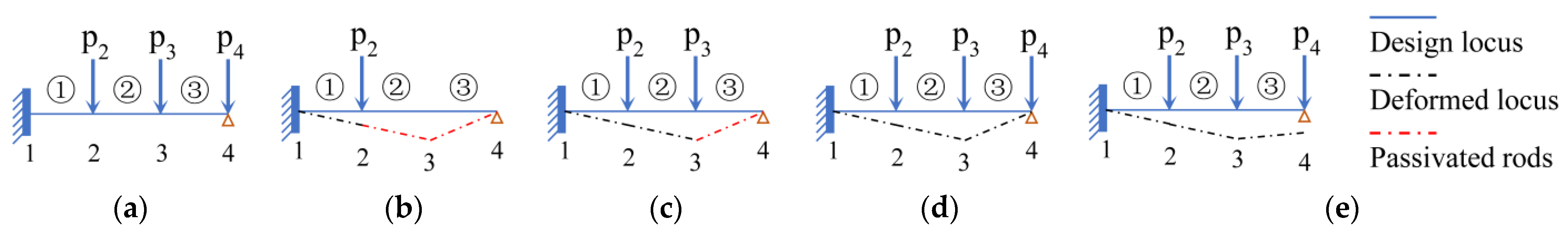

2.1. Nonlinear Time-Varying Analysis of CS

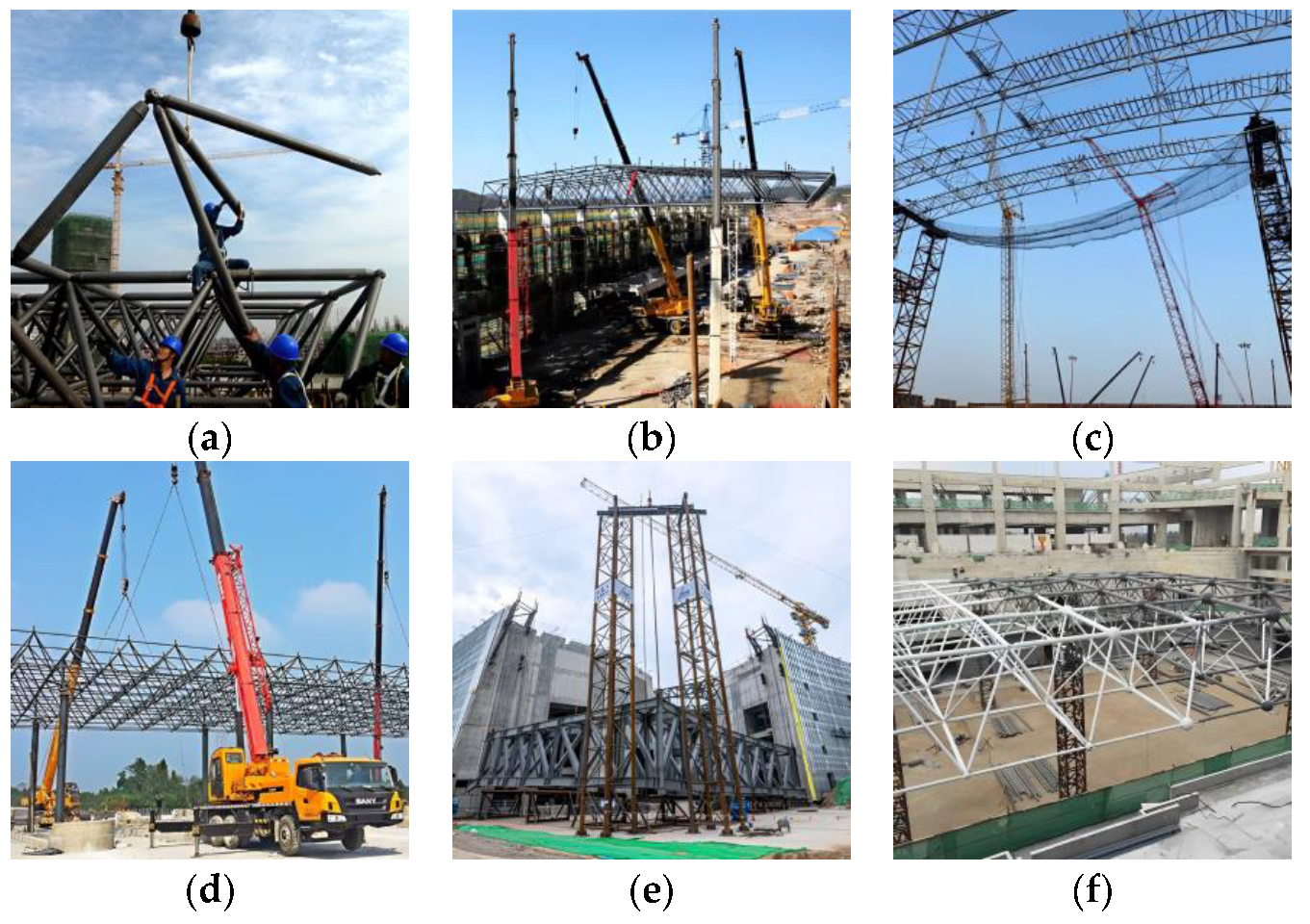

2.2. Construction Methods

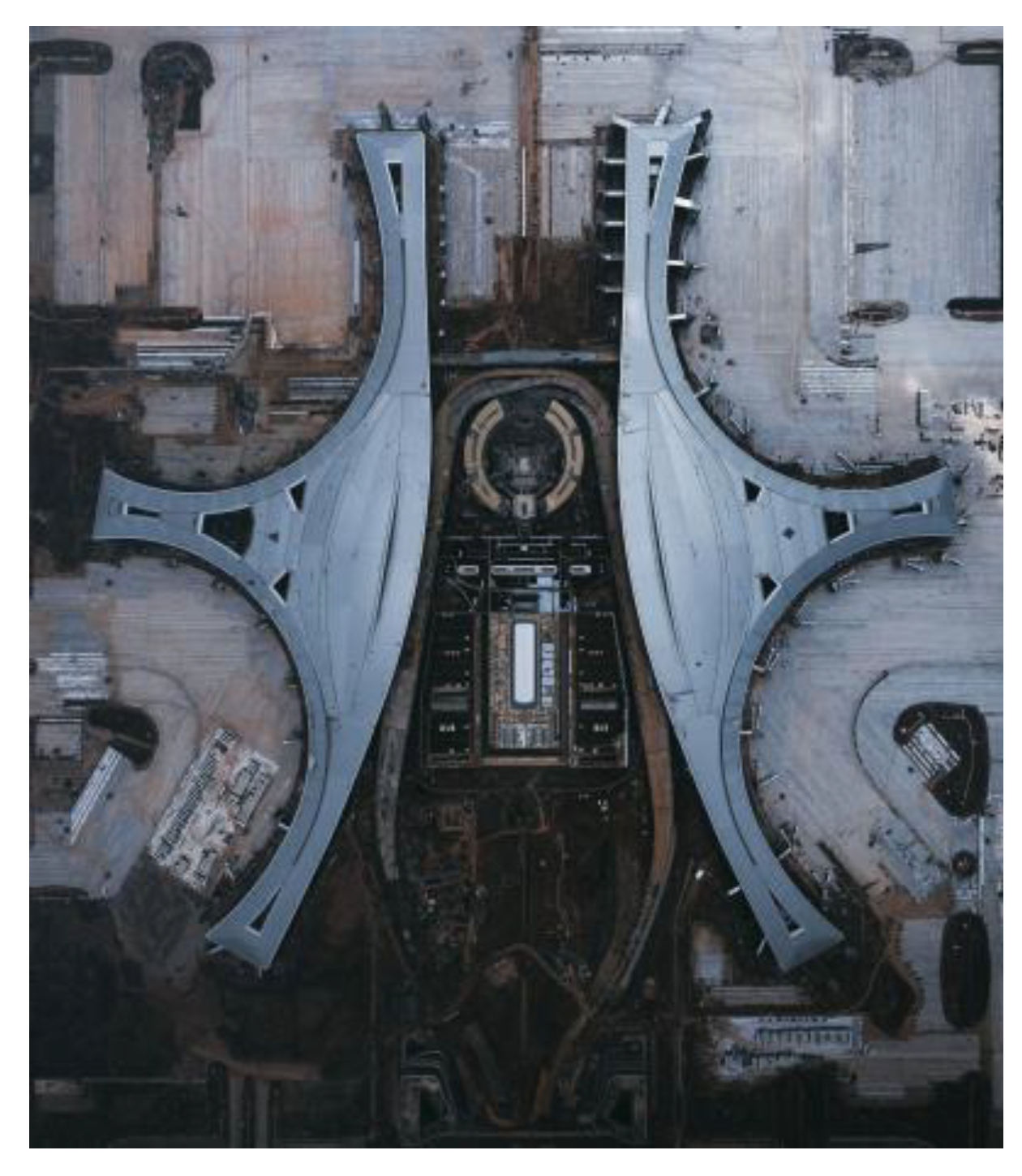

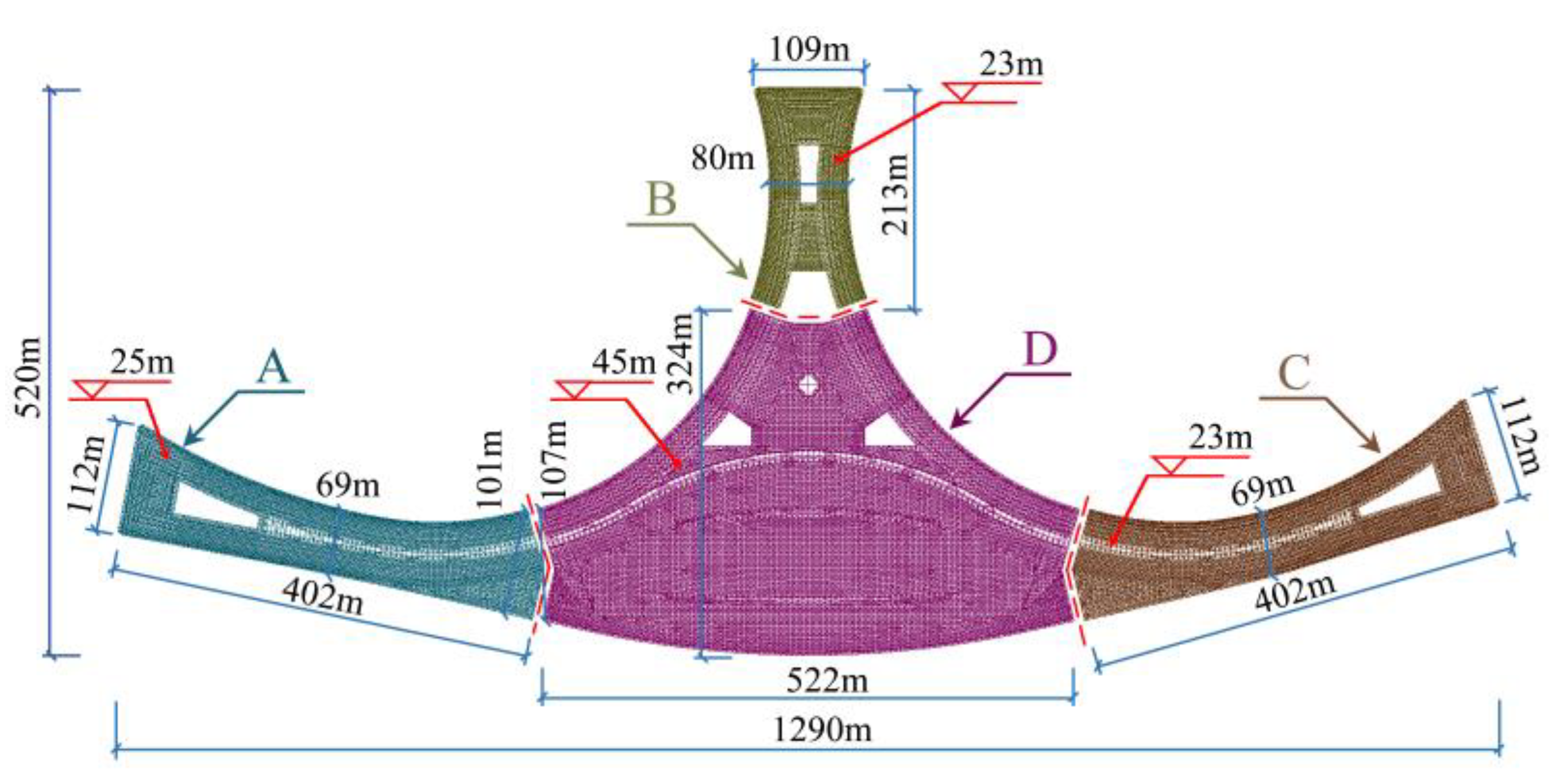

2.3. Engineering Background

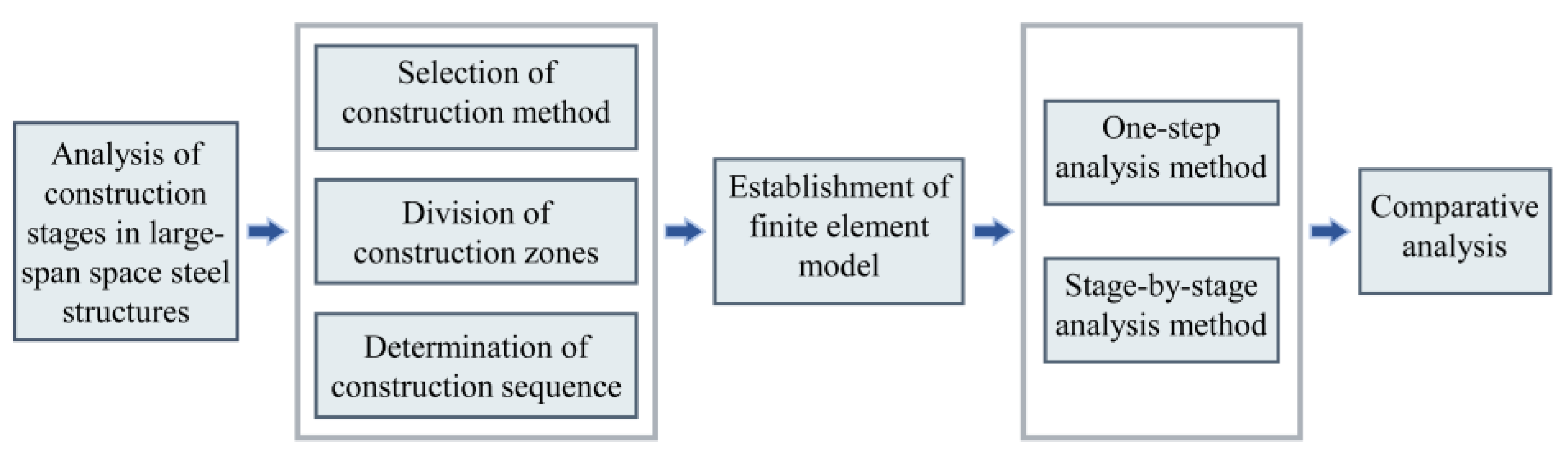

3. Methodology

3.1. Selection of Construction Methods

3.2. Division of Construction Zones

3.3. Determination of Construction Sequence

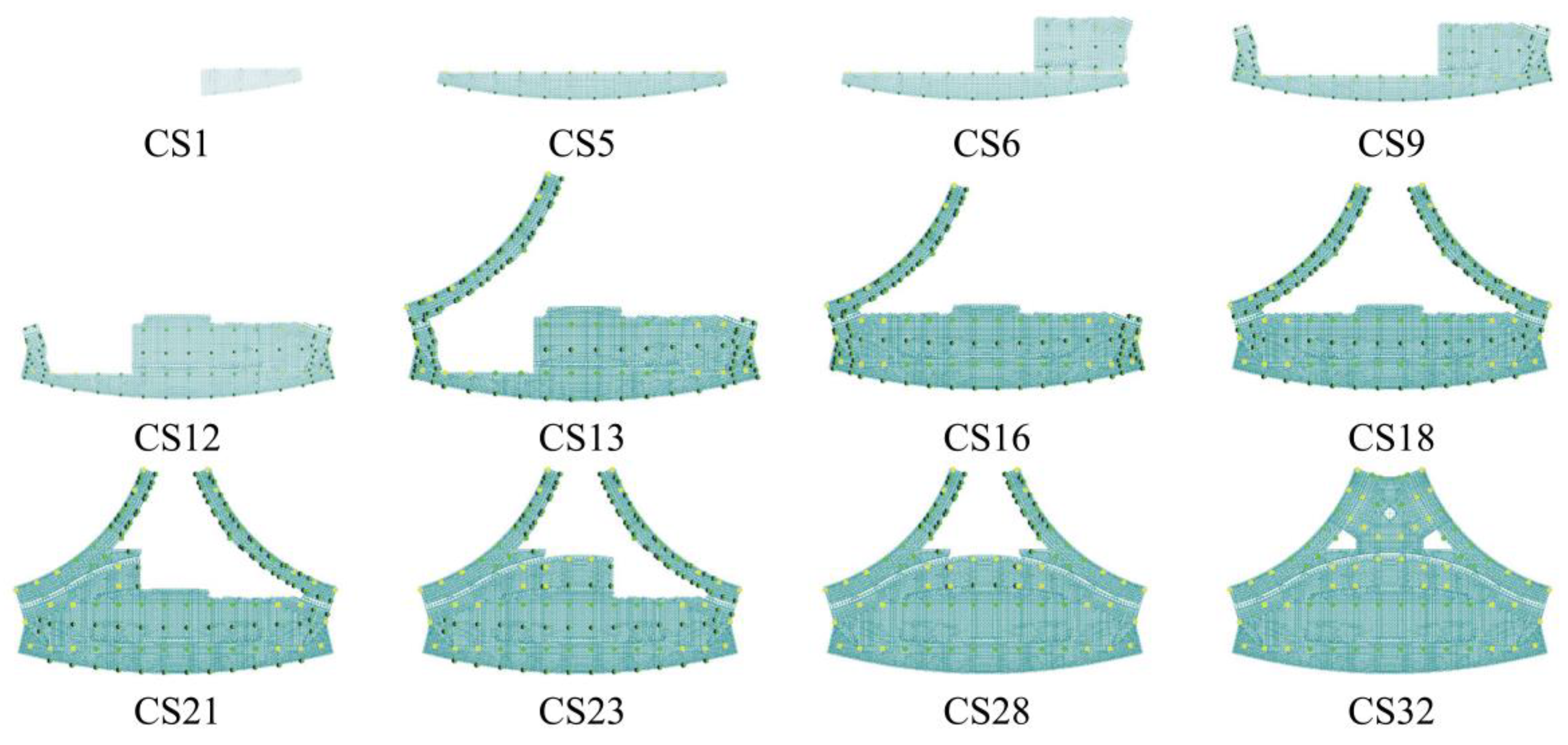

4. Experiments and Results

4.1. Establishment of the Model

- Load value. The load conditions involved in the construction process analysis include the constant load and live load. The constant load includes the self-weight of the steel structure and accessory structures. Considering the bolted ball nodes in the grid structure, the self-weight coefficient is enlarged to 1.05. The live load includes the construction loads, such as temporary personnel and machinery weight during construction;

- Power amplification factor. The structure is subjected to dynamic loads due to the action of lifting equipment during installation. Therefore, the dynamic load coefficient is set to 1.4;

- Unit type. The grid structure is simulated by a beam unit, considering the bending moment. The truss unit simulates the steel tie rods without considering the bending moment;

- Boundary conditions. Fixed supports simulate the connection between fixed supports at the top of columns and the mesh frame. Articulated bearing simulates the connection between a temporary support and the grid structure. The sliding bearing simulates the connection between the sliding bearing at the top of the column and the grid. The elasticity coefficients of the sliding bearing are set to 8 kN/mm, 6 kN/mm, and 4 kN/mm, respectively.

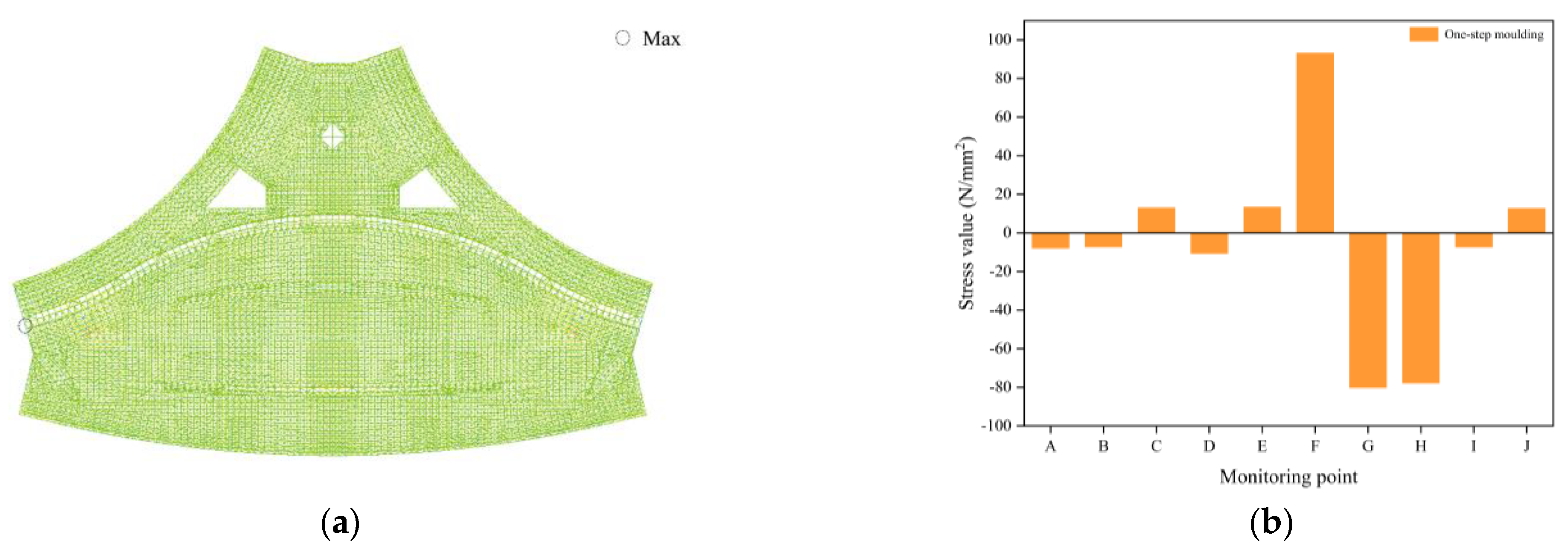

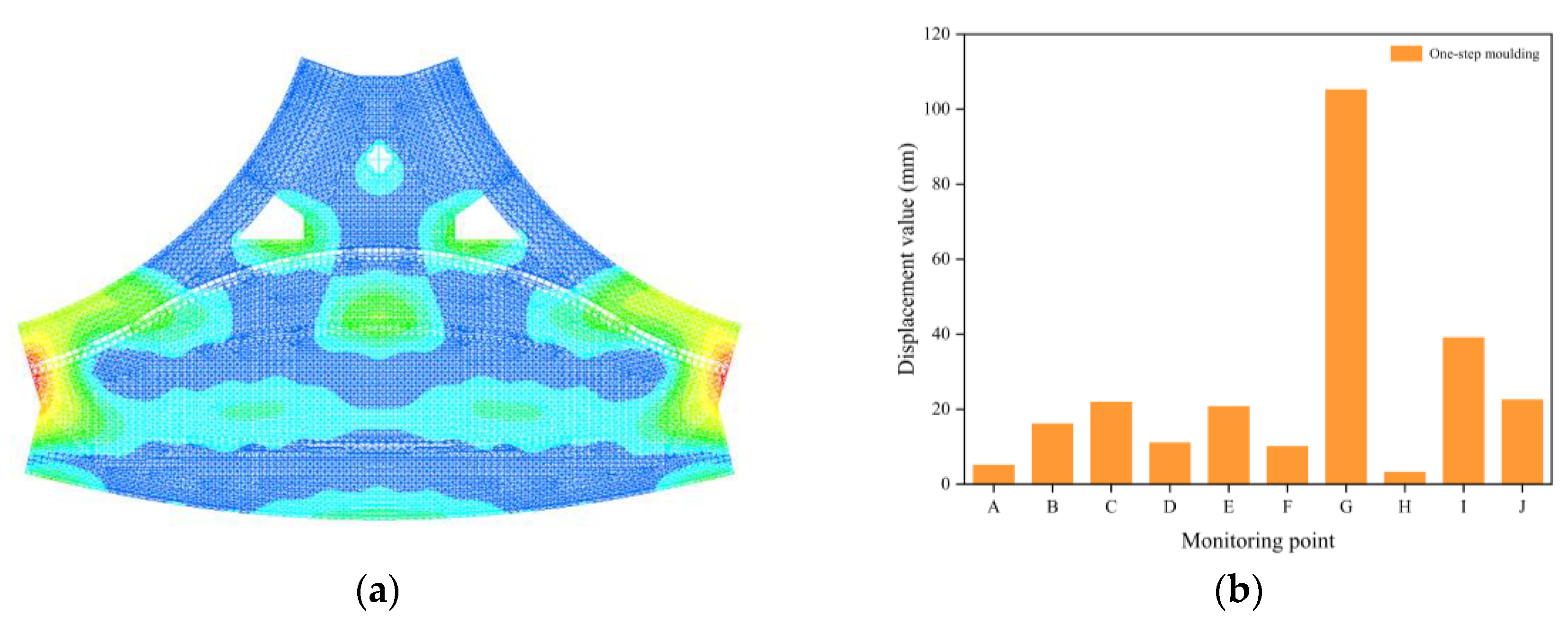

4.2. One-Step Analysis Method

4.2.1. Stress Analysis

4.2.2. Displacement Analysis

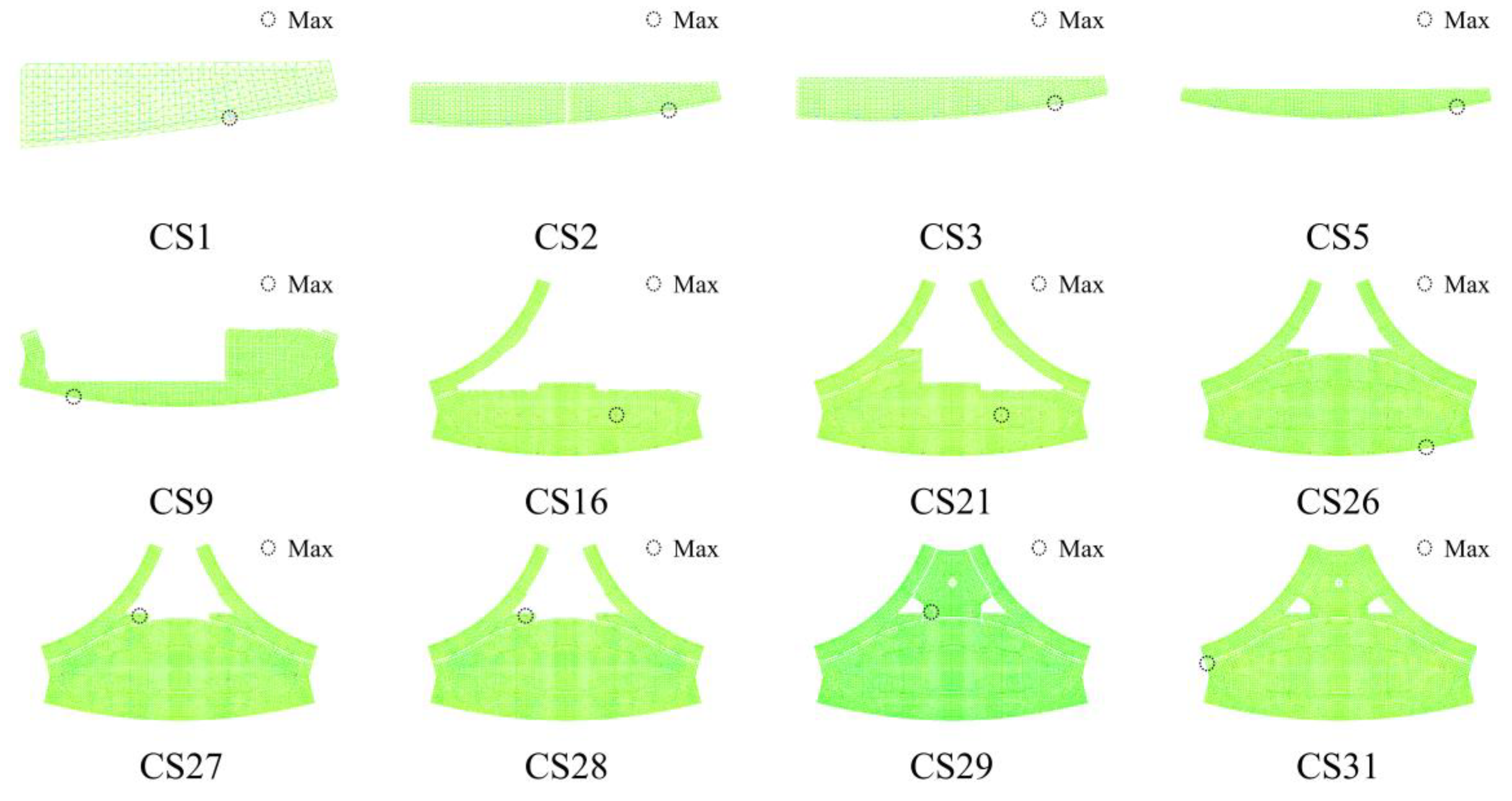

4.3. Stage-by-Stage Analysis Method

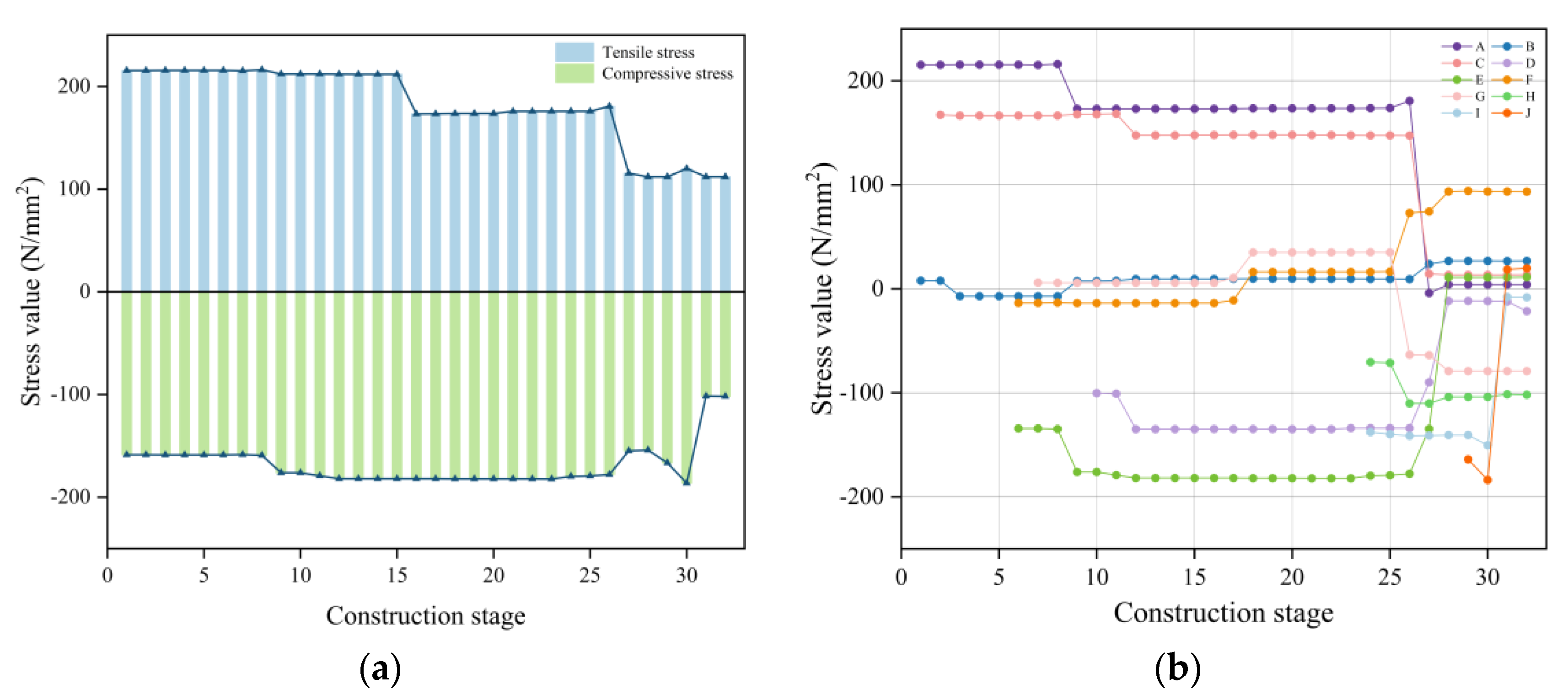

4.3.1. Stress Analysis

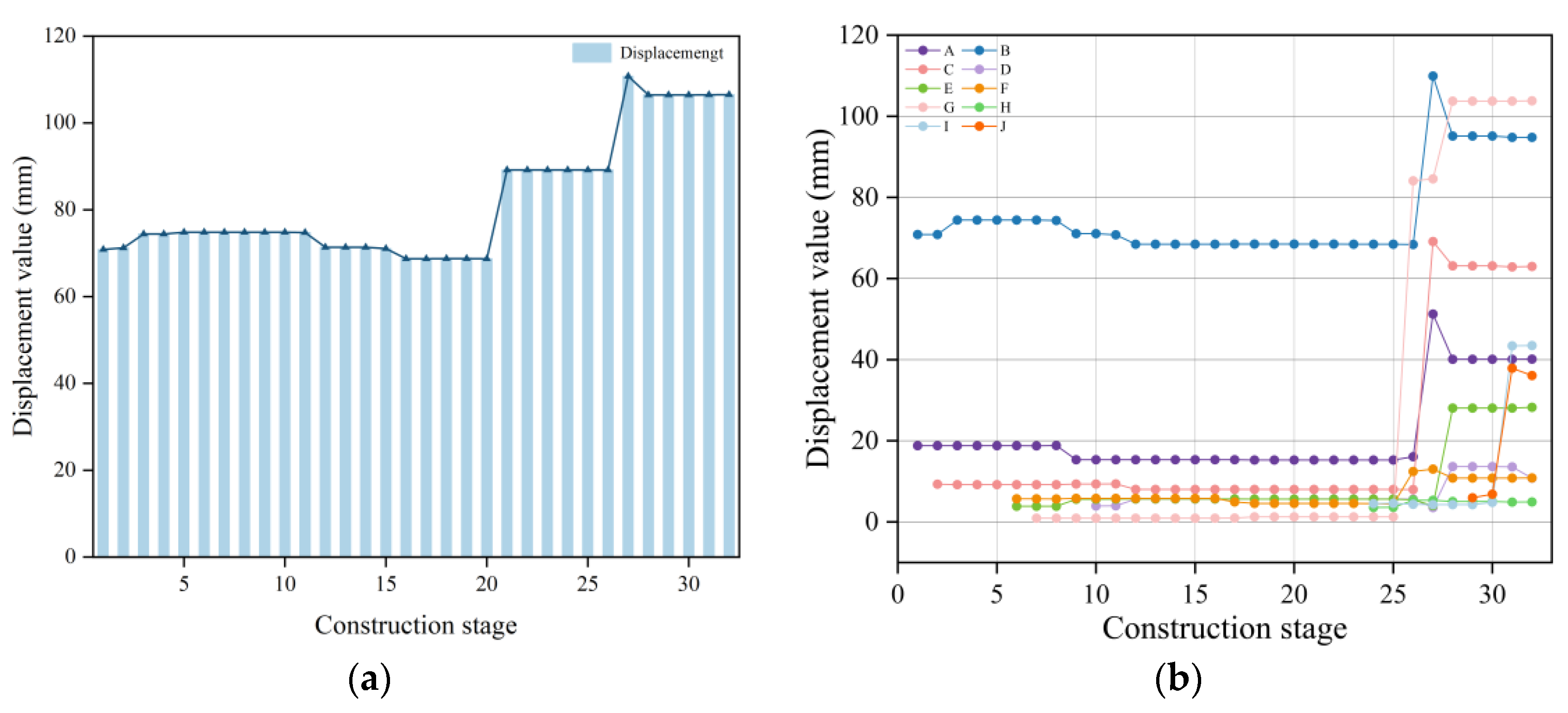

4.3.2. Displacement Analysis

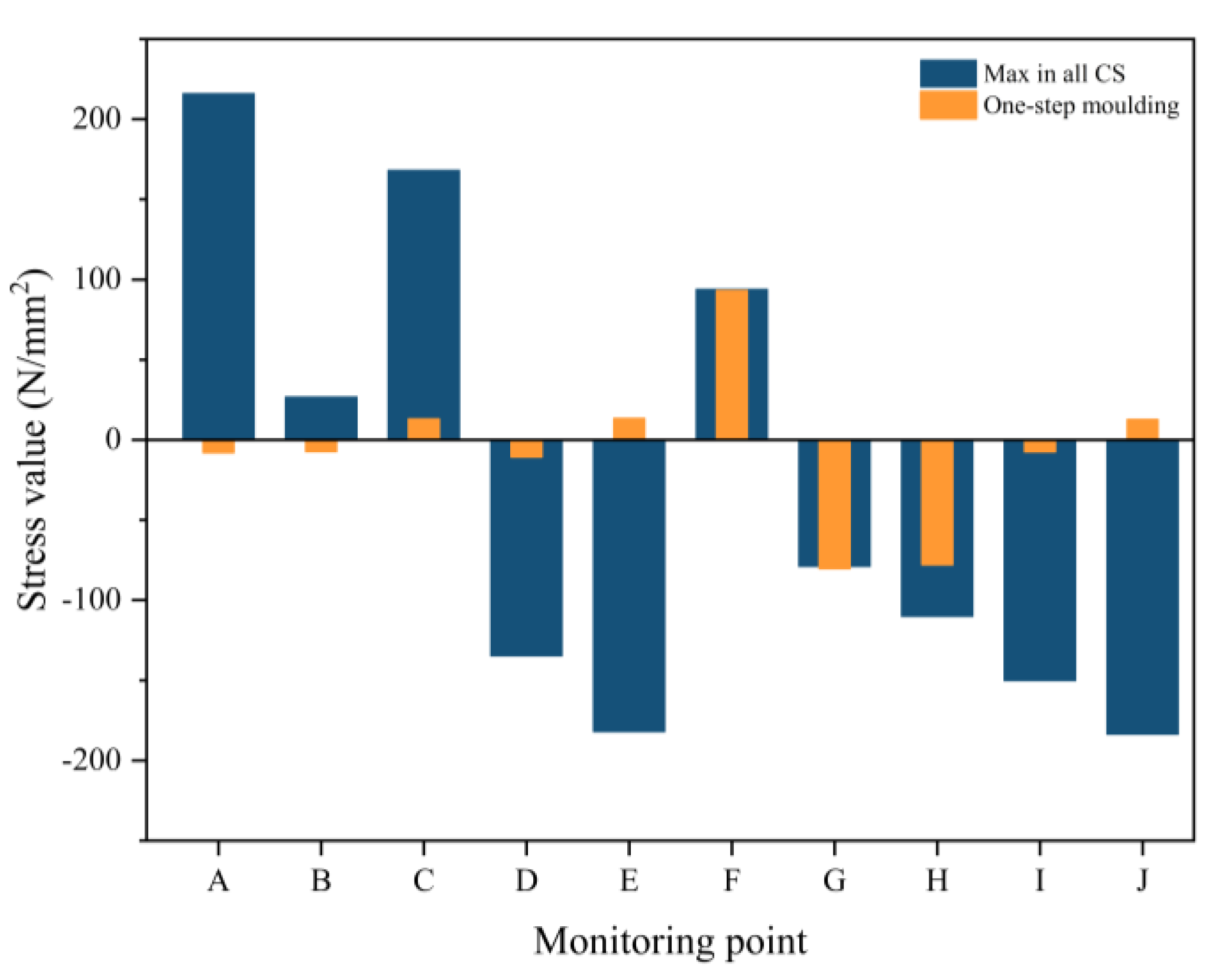

4.4. Construction Sequencing Impact Analysis

4.4.1. Stress Analysis

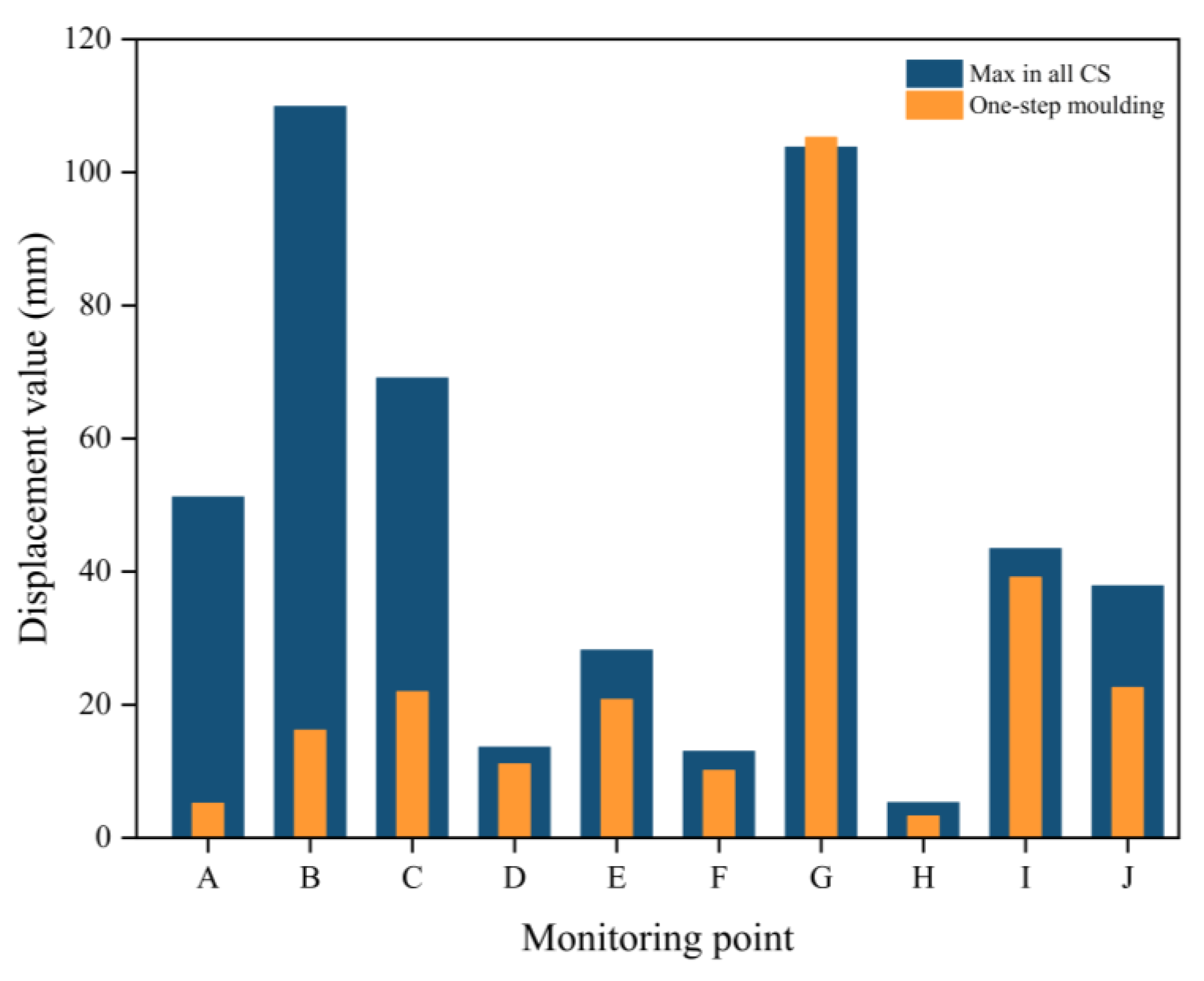

4.4.2. Displacement Analysis

5. Conclusions

- The initial installation and unloading process of the long-span spatial steel structure’s subsection is the turning point where the stress state and displacement changes often occur. During the construction process, the stress concentration phenomenon mainly occurs in the position of the temporary support frame, and the displacement maximum value is in the position of the structure’s outer overhang. Construction technicians should carry out targeted monitoring of the stress state and displacement deformation of the structure, which can quickly identify potential safety hazards.

- In the process of structural forming, the stress changes through the initial stress stage, stress adjustment stage, stress accelerated adjustment stage, and stress stabilization stage, showing a tendency to develop from high stress to low stress. The maximum tensile stress decreases from +215.53 N/mm2 to +111.97 N/mm2, and the maximum compressive stress decreases from −158.65 N/mm2 to −101.88 N/mm2. While the overall displacement is an accumulative process, the displacement change passes through the stages of displacement stabilization, fluctuation, and peak displacement. Compared with the initial displacement value of 70.86 mm for CS1, the maximum displacement value of the structure after forming reached 106.52 mm. For areas of stress concentration, construction workers should focus on monitoring. At peak displacements, counter-arches should be set up based on the displacement values.

- The one-step forming analysis method can quickly provide the structure’s stress state and displacement and deformation after forming. The stage-by-stage forming analysis method provides a detailed picture of the structural stresses and displacement deformations after each critical CS. During the construction process, most structures’ peak stresses and displacements occur at certain stages. Therefore, it is necessary for construction technicians to perform CS analyses that reflect the construction sequence.

- The construction of a long-span spatial steel structure is a complex and continuous gradual process of the structural system. Due to the mutual coupling of structural geometric nonlinearity, time-varying physical properties, and boundary condition changes, different construction sequences will lead to different stress and deformation paths in the construction process. The construction path effect leads to different final mechanical states of the same structure under different construction paths.

- Future research could explore different types of long-span structures, such as steel skywalks, steel truss bridges, and hybrid structural systems. Additionally, studying new construction techniques like modular construction, high-strength steel, or composite materials may further optimize construction efficiency and structural performance. By expanding the scope of research to include various structural forms and innovative construction methods, we hope to advance the safe and efficient construction of long-span spatial steel structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zucca, M.; Tattoni, S.; Di Castri, M.; Simoncelli, M. On the collapse of a post-tensioned reinforced concrete truss bridge during the construction phases. Eng. Fail. Anal. 2024, 158, 107999. [Google Scholar] [CrossRef]

- Pei, H.; Jia, L.; Li, J.; Li, K.; Xia, R. A Study of the Mechanical Behavior of a Steel-Concrete Hybrid Beam Bridge during Construction. Buildings 2023, 13, 1781. [Google Scholar] [CrossRef]

- Chen, H.; Yin, S.; Qiao, C.; He, J.; Hu, M. Construction Effects on the Mechanical States of a Truss Structure. J. Perform. Constr. Facil. 2022, 36, 1152. [Google Scholar] [CrossRef]

- Ding, L.; Sun, Y.-J.; Zhang, W.-Z.; Bi, G.; Xu, H.-Z. Stress Monitoring of Segment Structure during the Construction of the Small-Diameter Shield Tunnel. Sensors 2023, 23, 8023. [Google Scholar] [CrossRef] [PubMed]

- Yao, G.; Chen, Y.; Yang, Y.; Ma, X.; Men, W. Investigation on Buckling Performance of Prefabricated Light Steel Frame Materials under the Action of Random Defects during Construction. Materials 2023, 16, 5666. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Xin, J.; Yang, L.; Zhou, J.; Luo, C.; Zhou, Y.; Zhang, H. Optimization Method for the Length of the Outsourcing Concrete Working Plane on the Main Arch Rib of a Rigid-Frame Arch Bridge Based on the NSGA-II Algorithm. Structures 2024, 59, 105767. [Google Scholar] [CrossRef]

- Yao, H.; She, J.; Zhou, Y. Risk assessment of construction safety accidents based on association rule mining and Bayesian network. J. Intell. Constr. 2024. [Google Scholar] [CrossRef]

- Yao, G.; Wu, C.; Yang, Y. Scientometric Analysis for Mechanical Performance of Broken-Line Long-Span Steel Structure in Construction Considering Geometric Nonlinearity. Symmetry 2021, 13, 1229. [Google Scholar] [CrossRef]

- Hu, J.; Chen, W.; Ren, S.; Zhang, S.; Qu, Y.; Yin, Y.; Yang, D. Building performance monitoring and analysis of a large-span aerogel-membrane airport terminal. Eng. Struct. 2020, 219, 110837. [Google Scholar] [CrossRef]

- Deng, D.; Zou, J.; Cai, J.; Chen, Z.; Wang, H. Non-contact measurement method of displacement of spherical joints in long-span space steel structures. Structures 2024, 61, 106089. [Google Scholar] [CrossRef]

- Guo, S.; Xu, D.; Shang, K.; Yang, S.; Wang, D.; Li, G.; Zheng, B.; Jiao, Y. Analysis of progressive collapse of a super-long span latticed steel arch structure. J. Theor. Appl. Mech. 2023, 61, 103–117. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Dong, F.; Wang, J. Wind Resistance Performance Assessment of Long-Span Cable-Supported Bridges Based on Time-Varying Reliability Theory. Sustainability 2024, 16, 923. [Google Scholar] [CrossRef]

- Fu, R.-C.; Wang, H.-N.; Jiang, M.-J. Exact analytical solution for deep tunnels in viscoelastic-plastic rock considering the actual loading path. Appl. Math. Model. 2024, 128, 370–391. [Google Scholar] [CrossRef]

- He, Z.; Lu, Y.; Liu, F.; Pan, F.; He, S. An estimate on in-construction differential settlement of super high-rise frame core-tube buildings. Struct. Des. Tall Spec. Build. 2020, 29, e1737. [Google Scholar] [CrossRef]

- Hu, Y.; Lei, H.; Zheng, G.; Shi, L.; Zhang, T.; Shen, Z.; Jia, R. Ground movement induced by triple stacked tunneling with different construction sequences. J. Rock Mech. Geotech. Eng. 2022, 14, 1433–1446. [Google Scholar] [CrossRef]

- Ling, C.; Ruan, Y.; Wu, P.; Li, J.; Zhao, J.; Yuan, B. Influence of Different Excavation Sequence of Double-Side Heading Method on Supporting Structure. Adv. Civ. Eng. 2022, 2022, 2258594. [Google Scholar] [CrossRef]

- Yang, S.-S.; Zhang, D.-W.; Wang, M.; Xu, J.-M.; Shen, C.; Zhang, C.-Z. Ground settlement caused by pipe-roof pre-construction method: Effect of the sequence of jacking pipe groups. J. Cent. South Univ. 2024, 31, 576–588. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, F.; Zhang, H.; Shi, Z.; Zhu, H. Optimization of assembly sequence of building components based on simulated annealing genetic algorithm. Alex. Eng. J. 2023, 62, 257–268. [Google Scholar] [CrossRef]

- Soomro, M.A.; Mangi, N.; Xiong, H.; Kumar, M.; Mangnejo, D.A. Centrifuge and numerical modelling of stress transfer mechanisms and settlement of pile group due to twin stacked tunnelling with different construction sequences. Comput. Geotech. 2020, 121, 103449. [Google Scholar] [CrossRef]

- Yao, G.; Sun, W.; Yang, Y. Analysis and Identification of Building Construction Accident Risk in China basing Exclusively Database. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 072009. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Radu, D.; Ali, Z.; Almujibah, H.; Hadzima-Nyarko, M.; Khan, M.B. Modeling the Relation between Building Information Modeling and the Success of Construction Projects: A Structural-Equation-Modeling Approach. Appl. Sci. 2023, 13, 9018. [Google Scholar] [CrossRef]

- Mudiyanselage, S.T.; Wijesundara, K.; Venkatesan, S.; De Silva, S.; Dissanayake, R.; Neluwala, P. Significance of construction sequence and the initial behaviour in concrete-faced rockfill dams. Aust. J. Struct. Eng. 2024, 25, 125–143. [Google Scholar] [CrossRef]

- Jiao, Y.; Cao, P. Research on Optimization of Project Design Management Process Based on BIM. Buildings 2023, 13, 2139. [Google Scholar] [CrossRef]

- Mayouf, M.; Jones, J.; Elghaish, F.; Emam, H.; Ekanayake, E.M.A.C.; Ashayeri, I. Revolutionising the 4D BIM Process to Support Scheduling Requirements in Modular Construction. Sustainability 2024, 16, 476. [Google Scholar] [CrossRef]

- Yilmaz, G.; Akcamete, A.; Demirors, O. BIM-CAREM: Assessing the BIM capabilities of design, construction and facilities management processes in the construction industry. Comput. Ind. 2023, 147, 103861. [Google Scholar] [CrossRef]

- Tang, Q.; Xin, J.; Jiang, Y.; Zhang, H.; Zhou, J. Dynamic Response Recovery of Damaged Structures Using Residual Learning Enhanced Fully Convolutional Network. Int. J. Struct. Stab. Dyn. 2024, 2550008. [Google Scholar] [CrossRef]

- Zheng, X.; Li, W. Finite element simulation analysis of steel truss arch bridge jacking construction. Civ. Eng. J.-Staveb. Obz. 2023, 32, 519–532. [Google Scholar] [CrossRef]

- Liu, J.; Meng, F.; Chen, Y.; Chen, Z. The influence of coupling on the whole process of construction simulation of chord dome structure. E3S Web Conf. 2020, 143, 01046. [Google Scholar] [CrossRef]

- Qin, S.; Wei, K.; Qin, J.; Yuan, R.; Xu, L.; Dan, Q. Stress-free-state based structural analysis and construction control theory for staged construction bridges. Adv. Bridge Eng. 2020, 1, 1. [Google Scholar] [CrossRef]

- Li, Q.; Guo, H.; Guo, B. The Dual-Parameter Control of Synchronization in Steel Box Girder Incremental Launching Construction. Appl. Sci. 2023, 13, 12074. [Google Scholar] [CrossRef]

- Xin, Y.; Li, J.; Hao, H.; Yang, N.; Li, C. Time-Varying System Identification of Precast Segmental Columns Subjected to Seismic Excitations. J. Bridge Eng. 2022, 27, 1–18. [Google Scholar] [CrossRef]

- Sun, M.; Li, Q.; Li, Y. Investigation of time-varying natural frequencies of high-rise buildings under harsh excitations using a high-resolution combined scheme. J. Build. Eng. 2022, 57, 104859. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Yu, B. Time-varying behavior and its coupling effects with environmental conditions and cementitious material types on surface chloride concentration of marine concrete. Constr. Build. Mater. 2021, 303, 124578. [Google Scholar] [CrossRef]

- Huang, J.; Tan, P.; Zhang, Y.; Zhou, F. Endurance time analysis of seismic performances of long-span continuous rigid-frame bridges with corrugated steel webs. Structures 2022, 43, 990–1001. [Google Scholar] [CrossRef]

- Yu, L.; Xu, W.; Zhang, D.-B.; Ma, X.-M.; Wu, Y.-H. Strain Incremental Adjustment Method of Cable Force of Composite Saddle Anchor Span of Single-Tower Single-Span Ground-Anchored Suspension Bridge. Math. Probl. Eng. 2021, 2021, 2956496. [Google Scholar] [CrossRef]

- Gou, H.; Pu, Q.; Wang, J.; Chen, Z.; Qin, S. Spatial mechanical behaviors of long-span V-shape rigid frame composite arch bridges. Struct. Eng. Mech. 2013, 47, 59–73. [Google Scholar] [CrossRef]

- Ruan, R.; Chen, Y.; Lin, W.; Wei, L.; Huang, J. The Construction Technology of Column Replacement Integral Accumulation Sliding at Uneven Elevation for Steel Structures. Buildings 2023, 13, 1958. [Google Scholar] [CrossRef]

- Pei, B.; Chong, A.; Xia, H.; Kang, X. Design and key construction technology of steel-concrete-steel sandwich composite pylon for a large span cable-stayed bridge. Sci. Rep. 2023, 13, 6626. [Google Scholar] [CrossRef]

- Wen, F.; Liang, X.; Chen, C.; Xu, L.; Feng, Q. Construction Control and Monitoring Platform of a Large-Segment Steel Box Girder with Hoisting Installation. Appl. Sci. 2023, 13, 9573. [Google Scholar] [CrossRef]

- Wang, Y. In A closed coal yard grid construction simulation. In Proceedings of the 3rd International Conference on Civil, Architectural and Hydraulic Engineering (ICCAHE), Hangzhou, China, 30–31 July 2014; pp. 1672–1675. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Zhang, X.; Wang, Z.; Yan, J.; Chen, X. The Construction Technology of Roof Steel Structure in YanCheng NanYang Airport. Adv. Civ. Eng. 2018, 2018, 6386020. [Google Scholar] [CrossRef]

- Lu, C.; Yang, Z.; Li, P.; Xu, Q.; Chen, L.; Zhang, C. Integral sliding of a 800 T steel roof truss for a cultural and art center building. Case Stud. Constr. Mater. 2022, 17, e01345. [Google Scholar] [CrossRef]

- Yang, Y.; Du, H.; Yao, G.; Ma, X.; Men, W. Time-Varying Mechanical Analysis of Long-Span Spatial Steel Structures Integral Lifting in Construction Basing Building Information Model. Sustainability 2023, 15, 1256. [Google Scholar] [CrossRef]

- Ruan, R.; Lai, M.; Jiang, C.; Wang, J.; Lin, Y. Integral Lifting of Steel Structure Corridor between Two Super High-Rise Buildings under Wind Load. Buildings 2023, 13, 2441. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Z.; Wang, Z. Single-Side Accumulative Jacking Construction Method for Large-Span Arched Latticed Shells. J. Constr. Eng. Manag. 2022, 148, 06022001. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, J.; Feng, R.; Chen, H. Resistance of cold-formed sorbite stainless steel circular tubes under uniaxial compression. Thin-Walled Struct. 2022, 179, 109739. [Google Scholar] [CrossRef]

- Akduman, S.; Karalar, M.; Mert, N.; Ozturk, H. Investigation of the Post-Fire Behavior of Different End-Plated Beam-Column Connections. Buildings 2024, 14, 1013. [Google Scholar] [CrossRef]

- GB 50017-2017; Standard for Design of Steel Structures. Chinese Ministry of Housing and Urban-Rural Development, China Architecture & Building Press: Beijing, China, 2017.

| Construction Stage | Tensile Stress (N/mm2) | Compressive Stress (N/mm2) | Construction Stage | Tensile Stress (N/mm2) | Compressive Stress (N/mm2) |

|---|---|---|---|---|---|

| CS1 | +215.53 | −158.65 | CS17 | +173.37 | −181.97 |

| CS2 | +215.53 | −158.65 | CS18 | +173.65 | −182.15 |

| CS3 | +215.67 | −158.78 | CS19 | +173.65 | −182.15 |

| CS4 | +215.67 | −158.78 | CS20 | +173.66 | −182.15 |

| CS5 | +215.67 | −158.78 | CS21 | +175.70 | −182.18 |

| CS6 | +215.67 | −158.78 | CS22 | +175.70 | −182.18 |

| CS7 | +215.28 | −158.50 | CS23 | +175.71 | −182.21 |

| CS8 | +216.18 | −159.27 | CS24 | +175.71 | −179.74 |

| CS9 | +212.10 | −176.13 | CS25 | +175.71 | −179.27 |

| CS10 | +212.10 | −176.13 | CS26 | +180.77 | −177.82 |

| CS11 | +212.11 | −179.11 | CS27 | +115.38 | −154.87 |

| CS12 | +211.95 | −181.95 | CS28 | +112.03 | −154.07 |

| CS13 | +211.89 | −181.95 | CS29 | +112.03 | −166.54 |

| CS14 | +211.89 | −181.95 | CS30 | +120.09 | −186.28 |

| CS15 | +211.88 | −181.95 | CS31 | +111.99 | −101.48 |

| CS16 | +173.24 | −181.97 | CS32 | +111.97 | −101.88 |

| Construction Stage | Displacement (mm) | Construction Stage | Displacement (mm) |

|---|---|---|---|

| CS1 | 70.86 | CS17 | 68.72 |

| CS2 | 71.23 | CS18 | 68.74 |

| CS3 | 74.43 | CS19 | 68.74 |

| CS4 | 74.43 | CS20 | 68.72 |

| CS5 | 74.83 | CS21 | 89.18 |

| CS6 | 74.83 | CS22 | 89.18 |

| CS7 | 74.83 | CS23 | 89.18 |

| CS8 | 74.83 | CS24 | 89.19 |

| CS9 | 74.84 | CS25 | 89.19 |

| CS10 | 74.84 | CS26 | 89.17 |

| CS11 | 74.75 | CS27 | 110.76 |

| CS12 | 71.37 | CS28 | 106.47 |

| CS13 | 71.38 | CS29 | 106.47 |

| CS14 | 71.38 | CS30 | 106.47 |

| CS15 | 71.07 | CS31 | 106.48 |

| CS16 | 68.71 | CS32 | 106.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, G.; Li, R.; Yang, Y.; Cai, X.; Zhou, Y.; Zhou, C.; Lei, T. Analysis of Mechanical Properties during Construction Stages Reflecting the Construction Sequence for Long-Span Spatial Steel Structures. Buildings 2024, 14, 2389. https://doi.org/10.3390/buildings14082389

Yao G, Li R, Yang Y, Cai X, Zhou Y, Zhou C, Lei T. Analysis of Mechanical Properties during Construction Stages Reflecting the Construction Sequence for Long-Span Spatial Steel Structures. Buildings. 2024; 14(8):2389. https://doi.org/10.3390/buildings14082389

Chicago/Turabian StyleYao, Gang, Rui Li, Yang Yang, Xiaodong Cai, Yan Zhou, Canwei Zhou, and Ting Lei. 2024. "Analysis of Mechanical Properties during Construction Stages Reflecting the Construction Sequence for Long-Span Spatial Steel Structures" Buildings 14, no. 8: 2389. https://doi.org/10.3390/buildings14082389

APA StyleYao, G., Li, R., Yang, Y., Cai, X., Zhou, Y., Zhou, C., & Lei, T. (2024). Analysis of Mechanical Properties during Construction Stages Reflecting the Construction Sequence for Long-Span Spatial Steel Structures. Buildings, 14(8), 2389. https://doi.org/10.3390/buildings14082389