Investigation on Strength and Flexural Behavior of PVA Fiber-Reinforced and Cemented Clayey Soil

Abstract

1. Introduction

2. Materials and Experimental Program

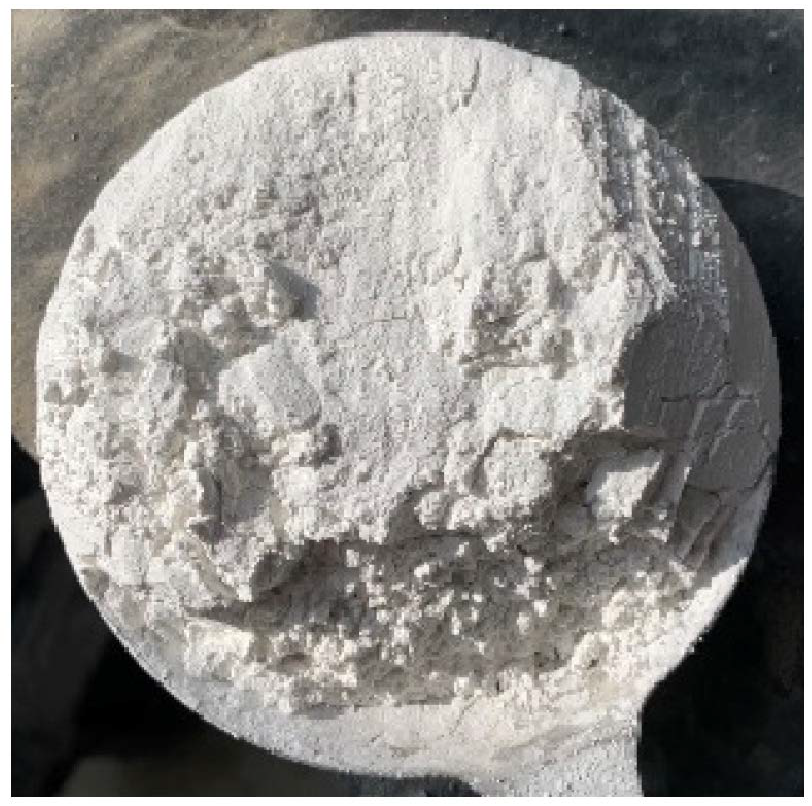

2.1. Materials

2.2. Preparation of Samples

2.3. Testing Program

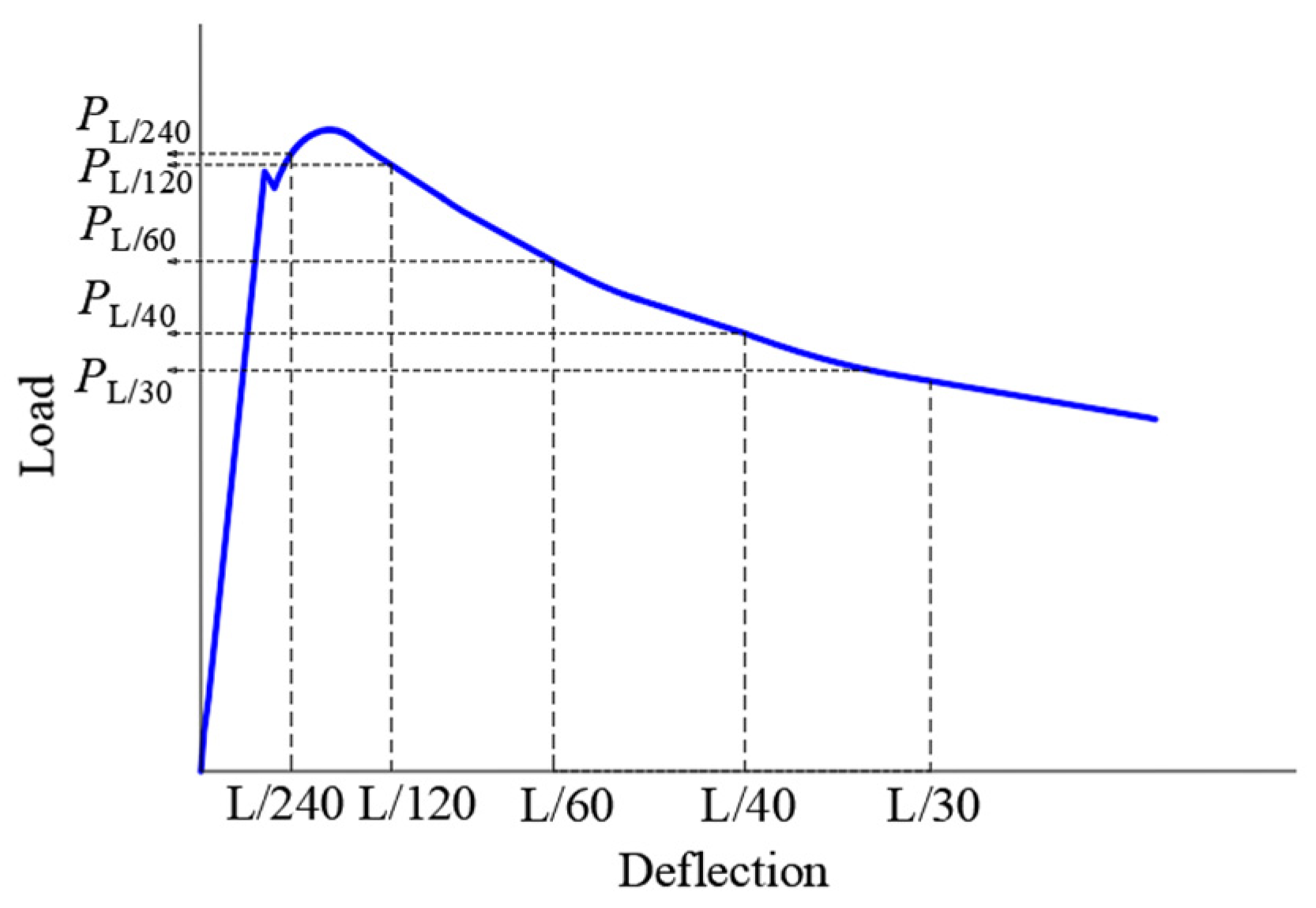

2.4. Parameters Describing the Behavior of FRCS

3. Results and Discussion

3.1. Effect of Cement and Moisture Content on Unconfined Compressive Strength

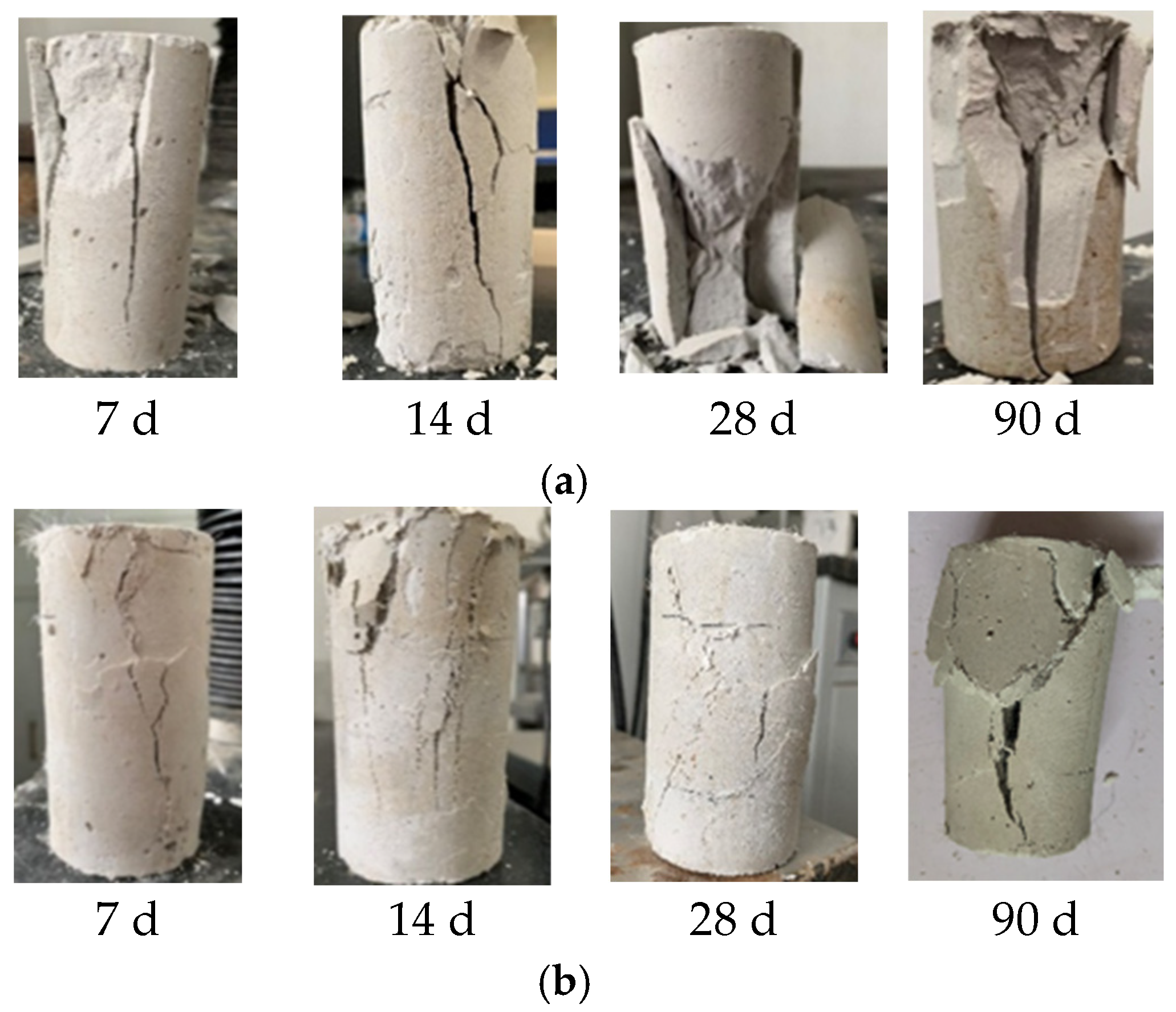

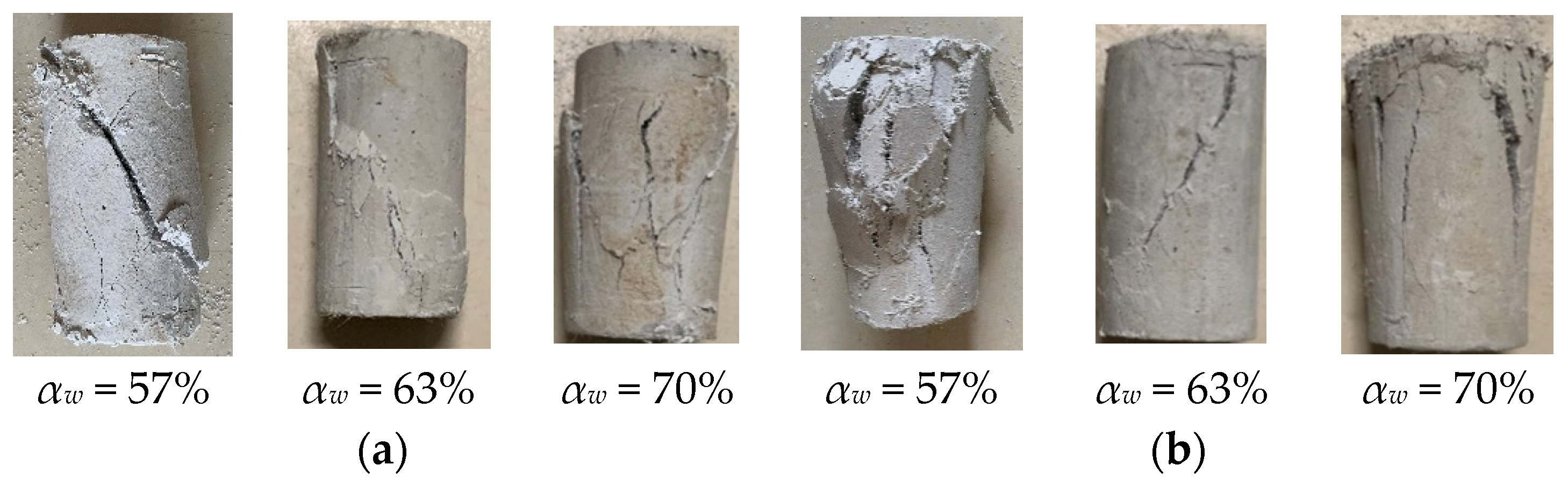

3.1.1. Failure Modes

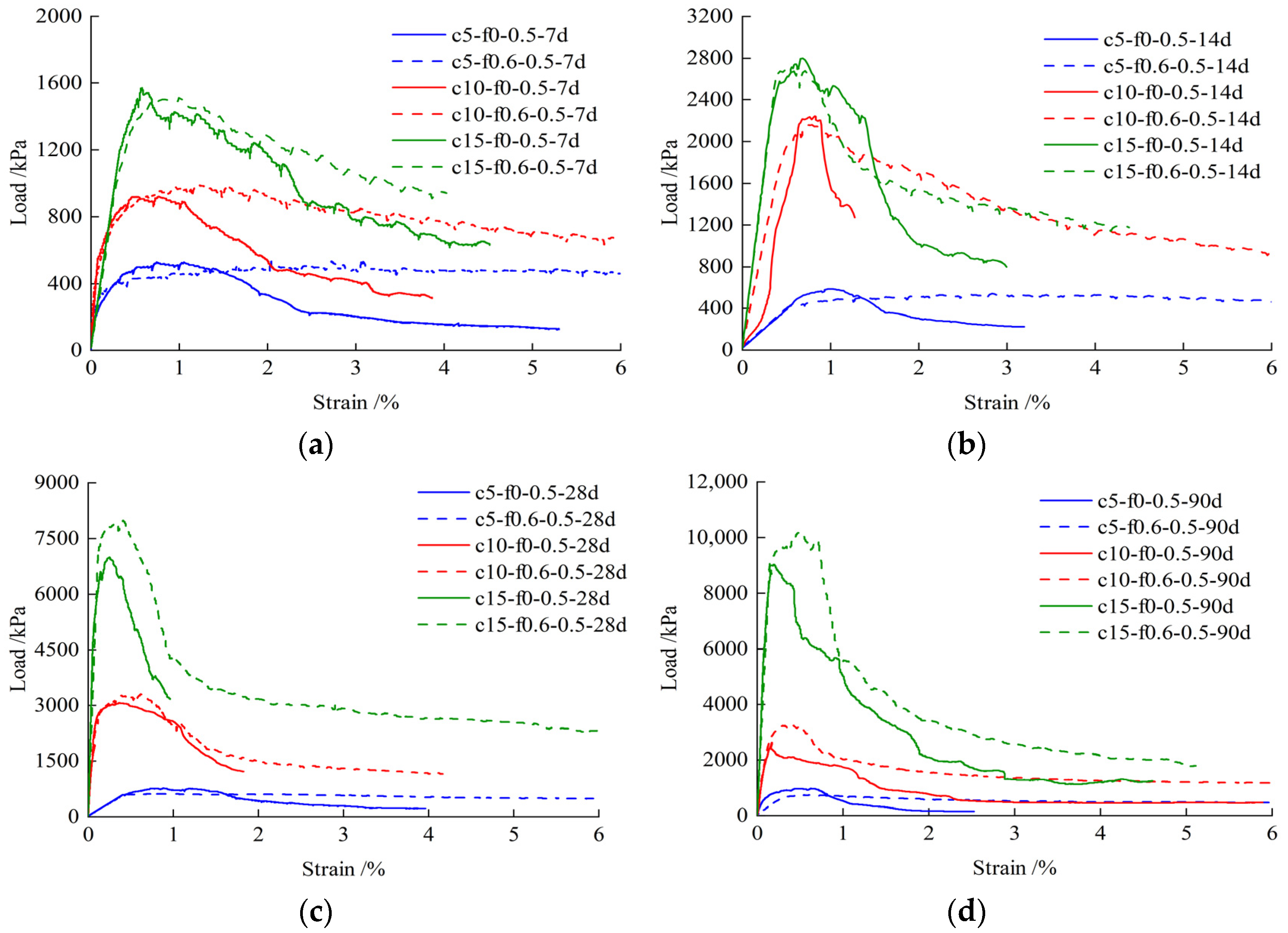

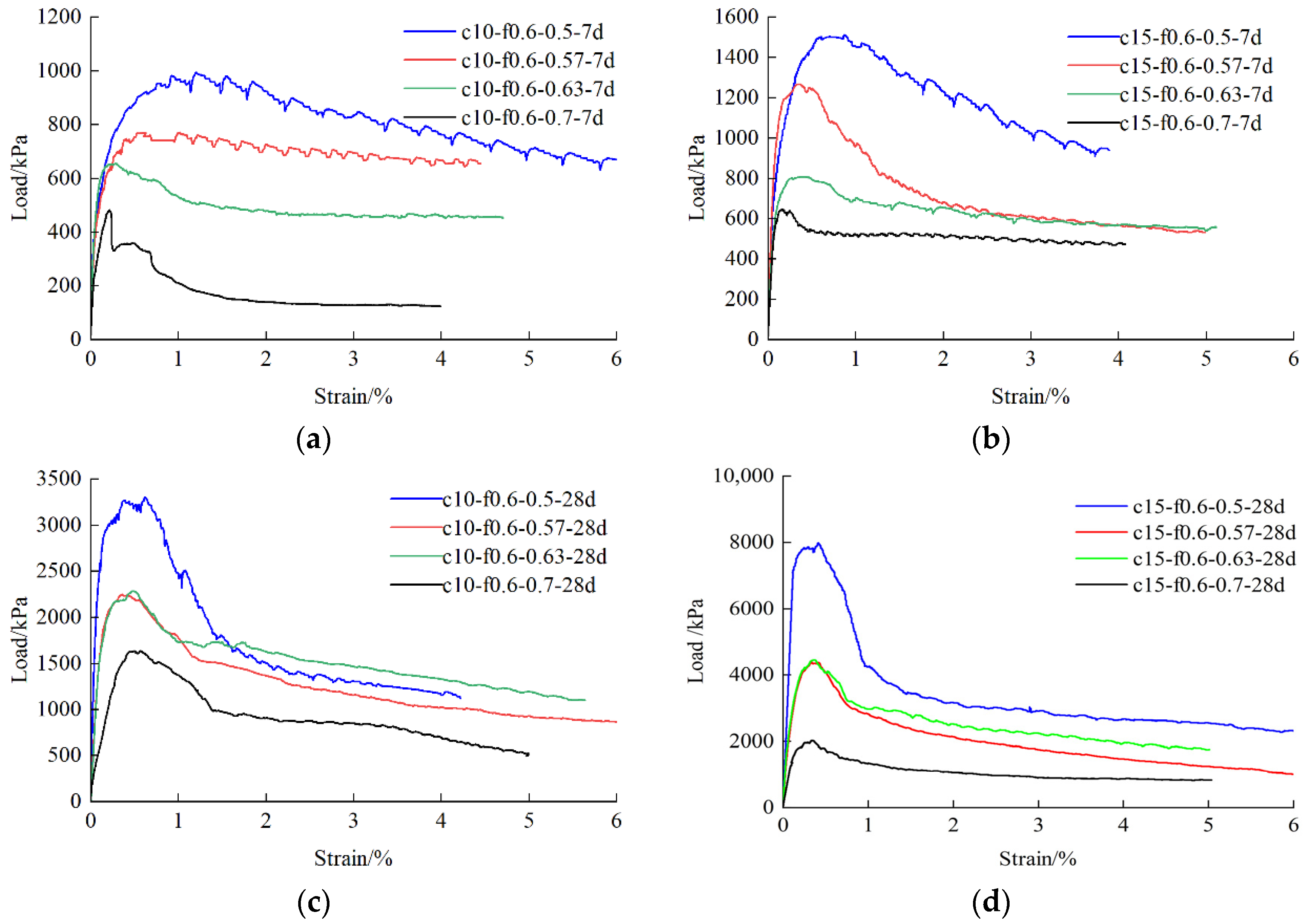

3.1.2. Stress-Strain Curves

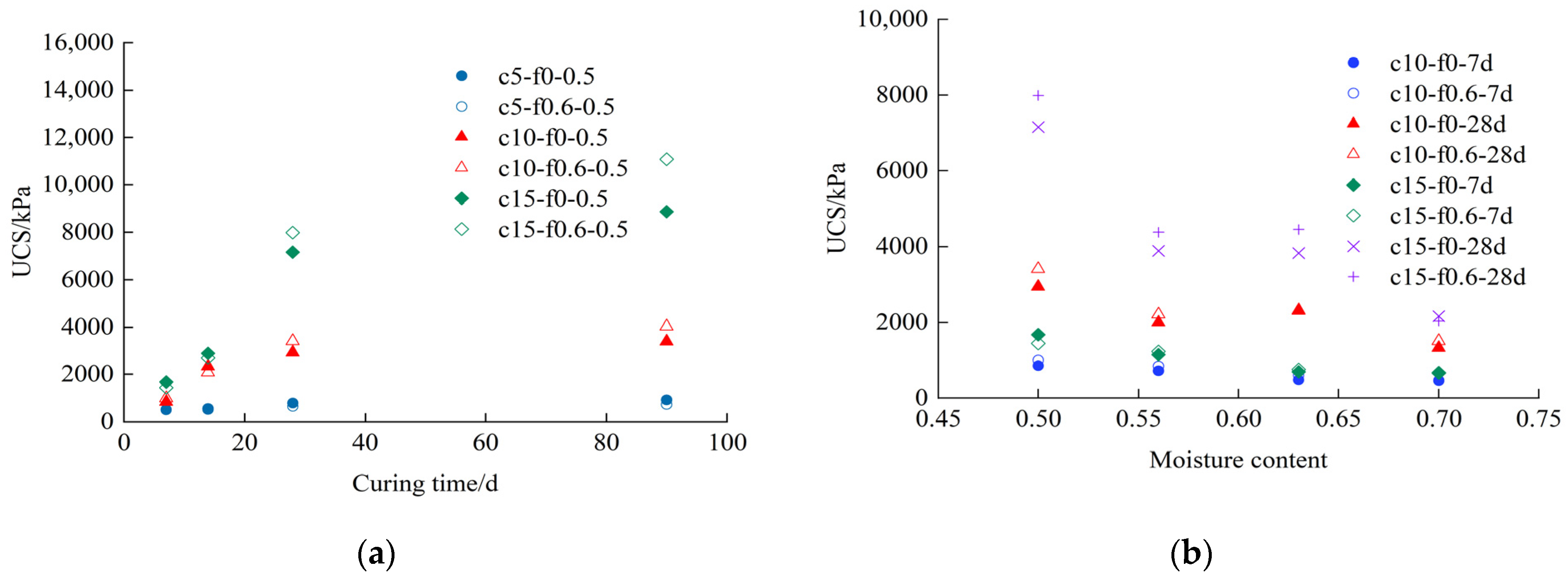

3.1.3. UCS

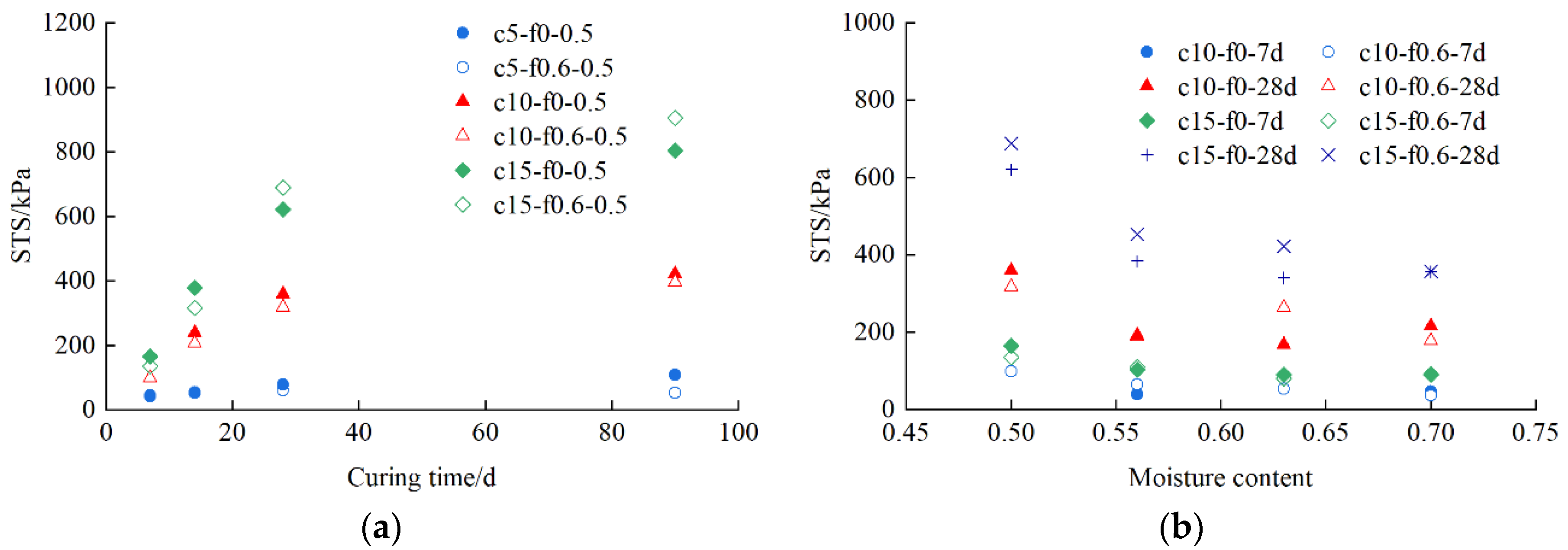

3.2. Effect of Cement and Moisture Contents on STS

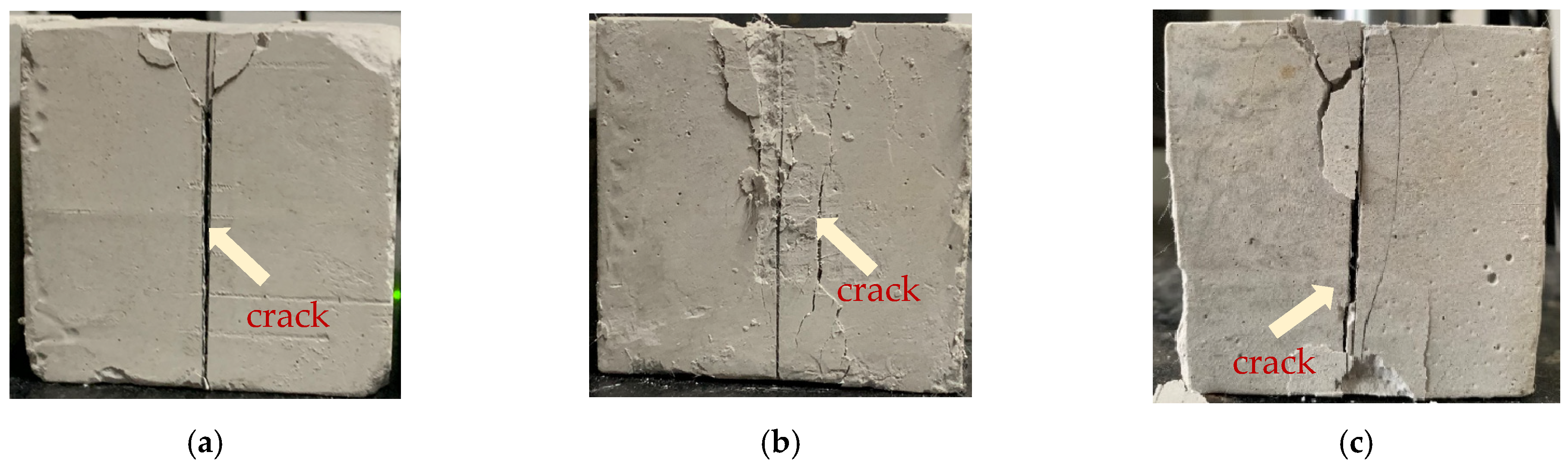

3.2.1. Failure Modes

3.2.2. STS

3.3. Effect of Cement and Moisture Content on Flexural Behavior

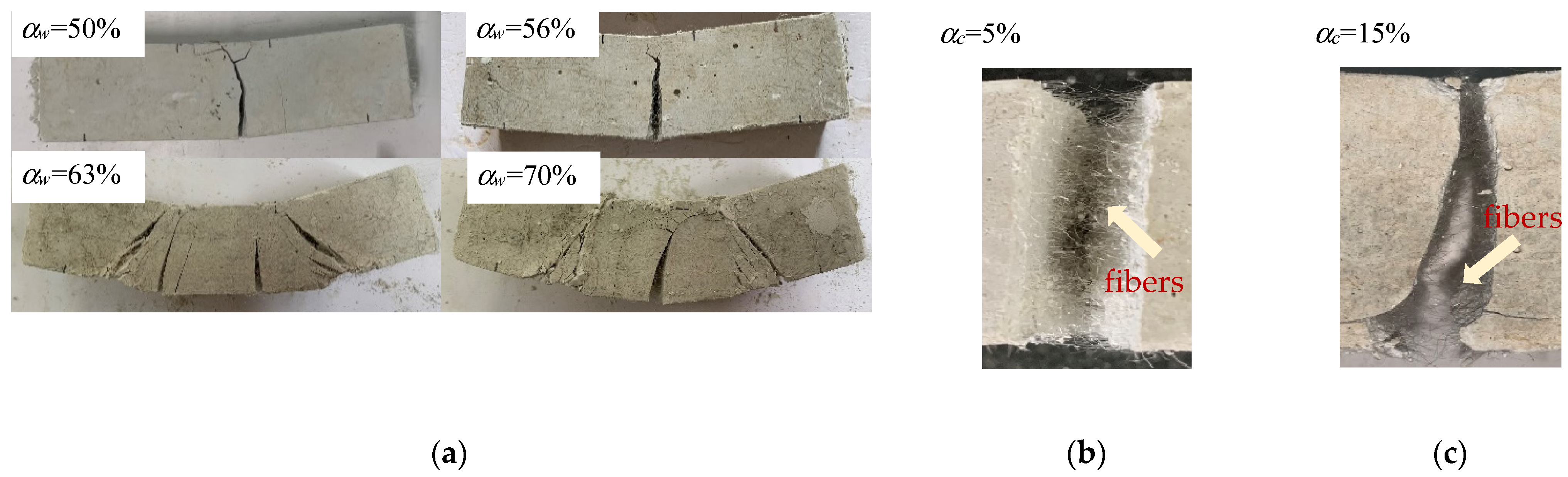

3.3.1. Failure Modes

3.3.2. Flexural Strength

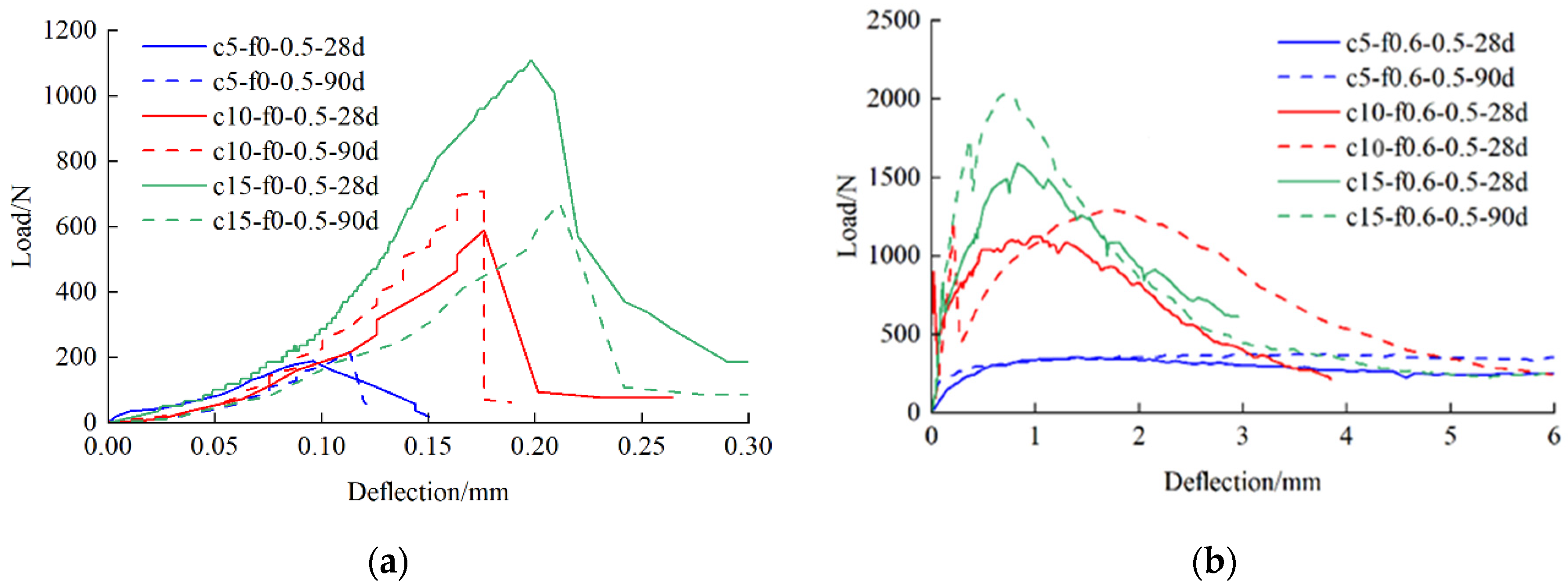

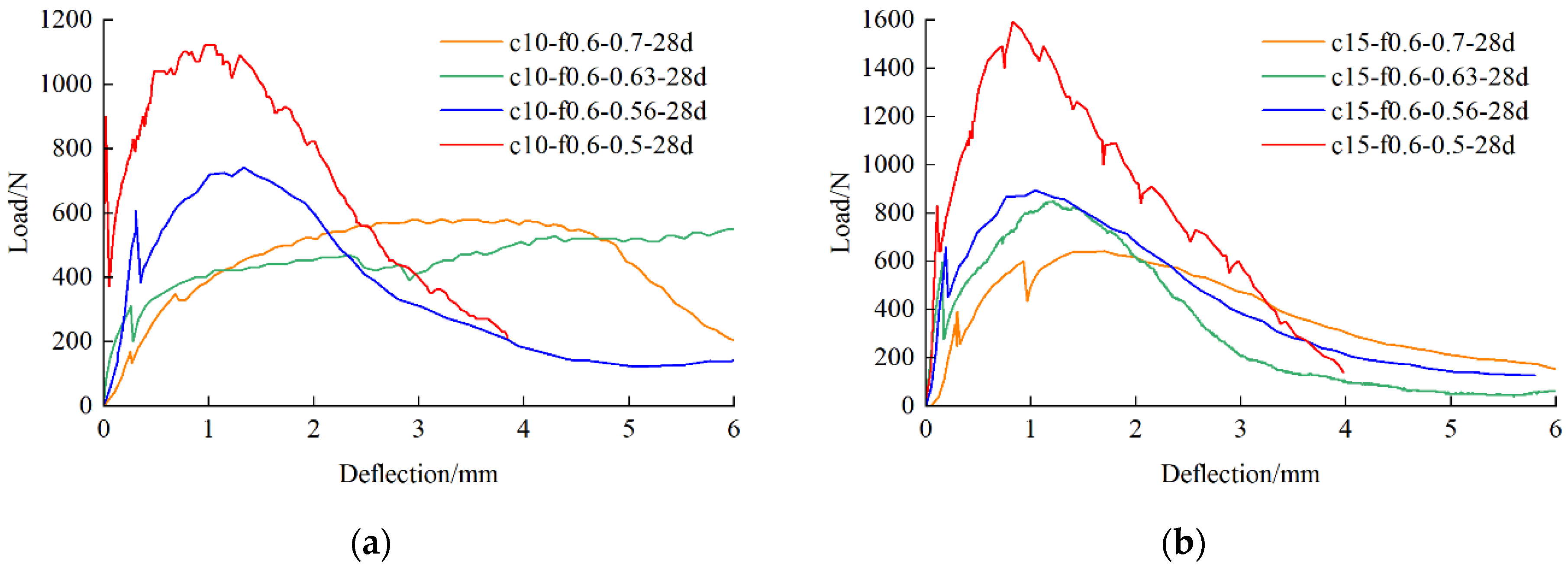

3.3.3. Load–Deflection Curves

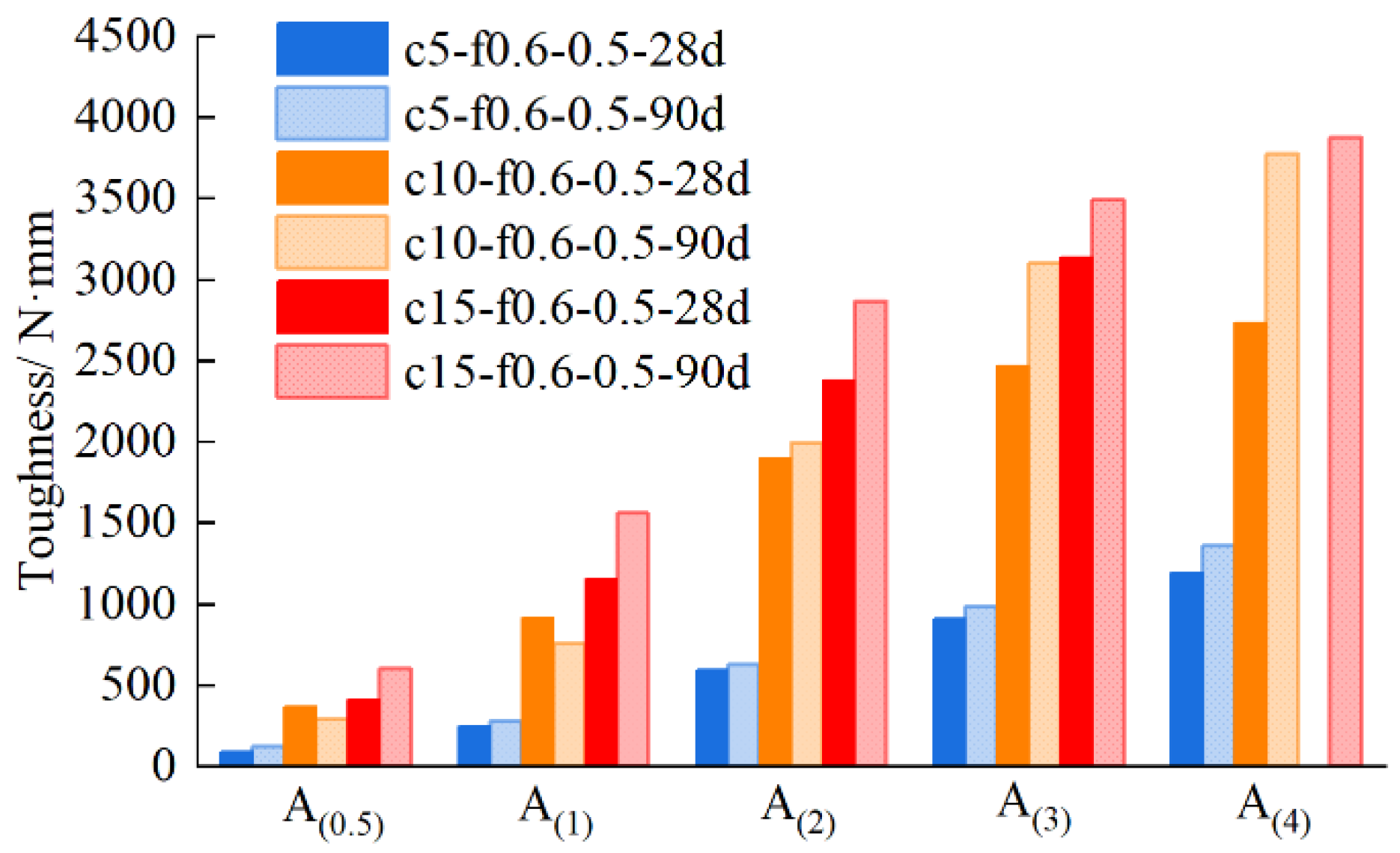

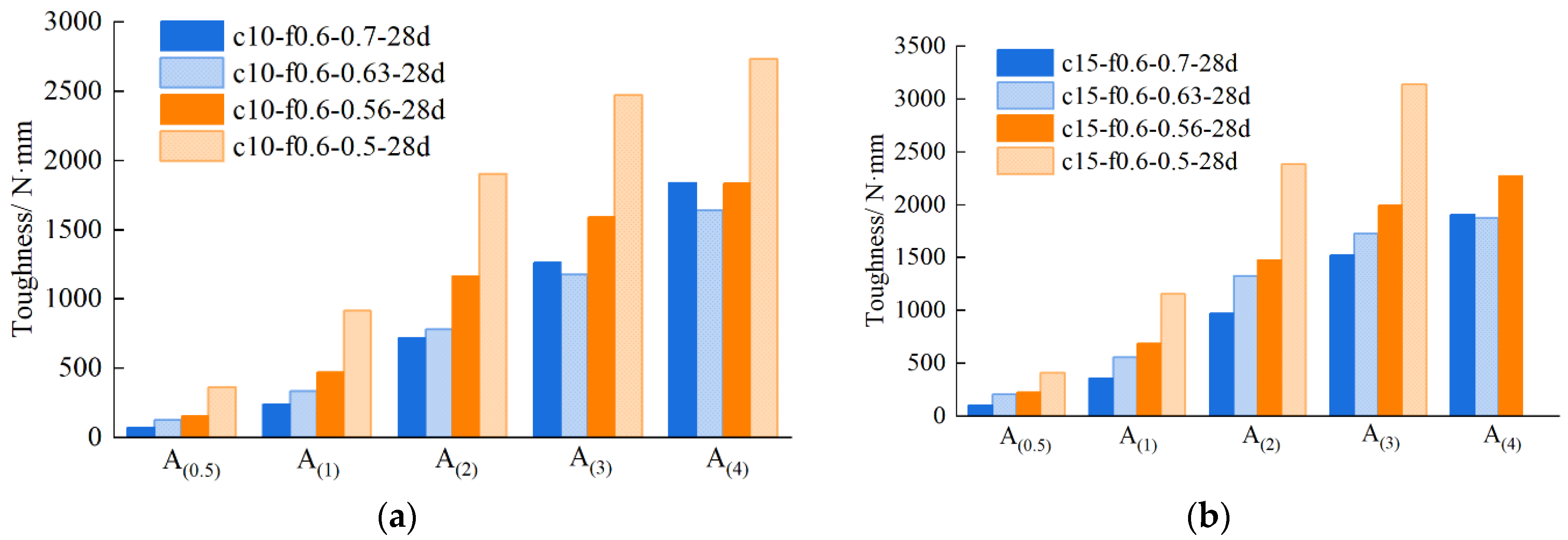

3.3.4. Toughness Analysis

4. Conclusions

- (a)

- The fibers can effectively improve the deformability of cement-cured soil during unconfined compression tests due to the bridging effect. With increasing cement content, the enhancement of peak and post-peak strength of UCS by fiber tended to become more significant with curing time, but ductility decreased. Simultaneously, the weakening effect of water content on UCS tended to become more obvious. The lower-strength specimens had better load-holding capacity;

- (b)

- The fiber-reinforced cemented specimens showed splitting cracks without brittle fracture. The fibers at the cracks were partially pulled or broken, but the specimen remained intact. STS of fiber-reinforced cemented specimens with αc = 15% increased by 11% compared to cemented soil when the curing time was increased to 28 d;

- (c)

- As the water content increased, the failure modes of the specimens changed from a single main crack to a multiple crack extension pattern in the bending process because of the low strength. Cracking load, peak, and post-peak strength gradually increased with the increase in cement content, but the deformability of the specimens became poor. Thus, 10% cement content is recommended for this soil;

- (d)

- Cement content and curing time improve the overall cracking resistance of fiber-reinforced cemented specimens under varies loading. Cement is the main factor affecting bending toughness. Especially in the interval of αc = 5% to αc = 10%, the growth of bending toughness was significant, and the enhancing effect of the fiber began to be seen. The toughness advantage of the specimen with αw = 50% is obvious, and the best reinforcement of the fiber is achieved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ling, H.I.; Leshchinsky, D.; Tatsuoka, F. Reinforced Soil Engineering: Advances in Research and Practice; Marcel Dekker Inc.: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Prabakar, J.; Dendorkar, N.; Morchhale, R.K. Influence of fly ash on strength behavior of typical soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.W.; Tang, C.S. Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

- Chen, D.; Liao, Y.D.; Jiang, C.H.; Feng, X.G. The Mechanical Properties of Coastal Soil Treated with Cement. J. Wuhan Univ. Technol. 2013, 28, 1155–1160. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Experimental study of impact of cement treatment on the shear behavior of loess and clay. Arab. J. Geosci. 2020, 13, 184–194. [Google Scholar] [CrossRef]

- Yazici, M.F.; Keskin, S.N. A review on soil reinforcement technology by using natural and synthetic fibers. J. Sci. Technol. 2021, 14, 631–663. [Google Scholar] [CrossRef]

- Aiban, S.A. A study of sand stabilization in eastern saudi arabia. Eng. Geol. 1994, 38, 65–97. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Allahverdi, A.; Mahinroosta, M. A model for prediction of compressive strength of chemically activated high phosphorous slag content cement. Int. J. Civ. Eng. 2014, 12, 481–487. [Google Scholar]

- Gumuşer, C.; Senol, A. Effect of fly ash and different lengths of polypropylene fibers content on the soft soils. Int. J. Civ. Eng. 2014, 12, 168–178. [Google Scholar]

- Kobayashi, M.; Issa, U.H.; Ahmed, A. On the compressive strength and geo-environmental properties of MC-clay soil treated with recycled bassanite. Int. J. Civ. Eng. 2015, 13, 54–61. [Google Scholar]

- Abdi, M.R.; Mirzaeifar, H. Effects of Discrete Short Polypropylene Fibers on Behavior of Artificially Cemented Kaolinite. Int. J. Civ. Eng. 2016, 14, 253–262. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Ren, W.X.; Yuan, B.X.; Yuan, H.P.; Zhao, Y.L.; Shan, S.B.; Cao, P. Laboratory Investigation on Strength Characteristics of Expansive Soil Treated with Jute Fiber Reinforcement. Int. J. Geomech. 2017, 17, 04017101. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Investigation of the Kenaf fiber hybrid length on the properties of the cement-treated sandy soil. Transp. Geotech. 2020, 22, 100301. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Park, S.S. Effect of fiber reinforcement and distribution on unconfined compressive strength of fiber-reinforced cemented sand. Geotext. Geomembr. 2009, 27, 162–166. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, R.; Cheng, Q.; Wang, X.K.; Liu, F.L. Research on Static Triaxial Mechanical Properties of New CementSoil Reinforced with Polypropylene Fiber. Adv. Mater. Sci. Eng. 2014, 2014, 532327. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Kazemian, S.; Huat, B.B.; Arun Prasad, A.P.; Barghchi, M. A review of stabilization of soft soils by injection of chemical grouting. 2010. Aust. J. Basic Appl. Sci. 2010, 4, 5862–5868. [Google Scholar]

- Wonglert, A.; Jongpradist, P. Impact of reinforced core on performance and failure behavior of stiffened deep cement mixing piles. Comput. Geotech. 2015, 69, 93–104. [Google Scholar] [CrossRef]

- Li, Q.; Chen, J.H.; Hu, H.X. The tensile and swelling behavior of cement-stabilized marine clay reinforced with short waste fibers. Mar. Georesour. Geotechnol. 2019, 37, 1236–1246. [Google Scholar] [CrossRef]

- Veylon, G.; Ghestem, M.; Stokes, A.; Bernard, A. Quantification of mechanical and hydric components of soil reinforcement by plant roots. Can. Geotech. J. 2015, 52, 1839–1849. [Google Scholar] [CrossRef]

- Wan, Y.; Xue, Q.; Liu, L.; Zhao, L.Y. The role of roots in the stability of landfill clay covers under the effect of dry-wet cycles. Environ. Earth Sci. 2016, 75, 71. [Google Scholar] [CrossRef]

- Ismail, S.; Yaacob, Z. Properties of laterite brick reinforced with oil palm empty fruit bunch fibres. Pertanika J. Sci. Technol. 2011, 19, 33–43. [Google Scholar]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Ramkrishnan, R.; Sruthy, M.R.; Sharma, A.; Karthik, V. Effect of random inclusion of sisal fibres on strength behavior and slope stability of fine grained soils. Mater. Today Proc. 2018, 5, 25313–25322. [Google Scholar] [CrossRef]

- Soleimani-Fard, H.; König, D.; Goudarzy, M. Plane strain shear strength of unsaturated fiber-reinforced fine-grained soils. Acta Geotech. 2022, 17, 105–118. [Google Scholar] [CrossRef]

- Maher, M.H. Static and Dynamic Force Response of Sands Reinforced with Discrete, Randomly Distributed Fibers. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 1988. [Google Scholar]

- Gray, D.H.; Maher, M.H. Admixture stabilization of sands with random fibers. In Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Brazil, 13–18 August 1989; A.A. Balkema: Rotterdam, The Netherland, 1989; pp. 1363–1366. [Google Scholar]

- Maher, M.H.; Gray, D.H. Static response of sands reinforced with randomly distributed fibers. J. Geotech. Engrg. 1990, 116, 1661–1677. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance evaluation of silty sand reinforced with fibres. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Marandi, M.; Bagheripour, H.; Rahgozar, R.; Zare, H. Strength and ductility of randomly distributed palm fibers reinforced silty-sand soils. Am. J. Appl. Sci. 2008, 5, 209–220. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Gao, W.; Chen, F.J.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Maher, M.; Ho, Y. Mechanical properties of kaolinite/fiber soil composite. Geotech. Eng. 1994, 120, 1381–1393. [Google Scholar] [CrossRef]

- Attom, M.F.; Al-Akhras, N.M.; Malkawi, A.I.H. Effect of fibres on the mechanical properties of clayey soil. Proc. Inst. Civ. Eng.-Geotech. 2009, 162, 277–282. [Google Scholar] [CrossRef]

- Park, S.S. Unconfined compressive strength and ductility of fiber-reinforced cemented sand. Constr. Build. Mater. 2011, 25, 1134–1138. [Google Scholar] [CrossRef]

- Pradhan, P.K.; Kar, R.K.; Naik, A. Effect of random inclusion of polypropylene fibers on strength characteristics of cohesive soil. Geotech. Geol. Eng. 2012, 30, 15–25. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. Shear modeling of fiber reinforced soil composite on the base of fiber pull-out test. Fibers Polym. 2013, 14, 277–284. [Google Scholar] [CrossRef]

- Jamei, M.; Villard, P.; Guiras, H. Shear Failure Criterion Based on Experimental and Modeling Results for Fiber-Reinforced Clay. Int. J. Geomech. 2013, 13, 882–893. [Google Scholar] [CrossRef]

- Kanchi, G.M.; Neeraja, V.S.; Babu, G.L.S. Effect of Anisotropy of Fibers on the Stress-Strain Response of Fiber-Reinforced Soil. Int. J. Geomech. 2015, 15, 06014016. [Google Scholar] [CrossRef]

- Qu, J.; Sun, Z. Strength behavior of shanghai clayey soil reinforced with wheat straw fibers. Geotech. Geol. Eng. 2016, 34, 515–527. [Google Scholar] [CrossRef]

- Devi, D.; Jempen, B. Shear strength behaviour of bamboo fiber reinforced soil. Int. Res. J. Eng. Technol. 2016, 3, 433–437. [Google Scholar]

- Wang, Y.X.; Guo, P.P.; Li, X.; Lin, H.; Liu, Y.; Yuan, H.P. Behavior of Fiber-Reinforced and Lime-Stabilized Clayey Soil in Triaxial Tests. Appl. Sci. 2019, 9, 900. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Oliveira, P.J.V.; Custódio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Syamsir, A.; Huat, B.B.K. Three point bending flexural strength of cement treated tropical marine soil reinforced by lime treated natural fiber. Measurement 2017, 111, 158–166. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Kitazume, M. Using fiber and liquid polymer to improve the behaviour of cement-stabilized soft clay. Geotext. Geomembr. 2017, 45, 592–602. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Consoli, N.C.; Zortéa, F.; de Souza, M.; Festugato, L. Studies on the Dosage of Fiber-Reinforced Cemented Soils. J. Mater. Civ. Eng. 2011, 23, 1624–1632. [Google Scholar] [CrossRef]

- Consoli, N.C.; de Moraes, R.R.; Festugato, L. Parameters Controlling Tensile and Compressive Strength of Fiber-Reinforced Cemented Soil. J. Mater. Civ. Eng. 2013, 25, 1568–1573. [Google Scholar] [CrossRef]

- Festugato, L.; Menger, E.; Benezra, F.; Kipper, E.A.; Consoli, N.C. Fibre-reinforced cemented soils compressive and tensile strength assessment as a function of filament length. Geotext. Geomembr. 2017, 45, 77–82. [Google Scholar] [CrossRef]

- Festugato, L.; da Silva, A.P.; Diambra, A.; Consoli, N.C.; Ibraim, E. Modelling tensile/compressive strength ratio of fibre reinforced cemented soils. Geotext. Geomembr. 2018, 46, 155–165. [Google Scholar] [CrossRef]

- Taha, M.M.M.; Feng, C.P.; Ahmed, S.H.S. Influence of Polypropylene Fibre (PF) Reinforcement on Mechanical Properties of Clay Soil. Adv. Polym. 2020, 2020, 9512839. [Google Scholar] [CrossRef]

- Soğanci, A. The effect of polypropylene fiber in the stabilization of expansive soils. World Acad. Sci. Technol. 2015, 9, 994–997. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Experimental Study of Combined Effects of Fibers and Nanosilica on Mechanical Properties of Cemented Sand. J. Mater. Civ. 2016, 28, 06016001. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Effects of Nanosilica Particles and Randomly Distributed Fibers on the Ultrasonic Pulse Velocity and Mechanical Properties of Cemented Sand. J. Mater. Civ. 2017, 29, 04016230. [Google Scholar] [CrossRef]

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. China Communications Press: Beijing, China, 2009.

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2002.

- ASTM C1609/C1609M-12; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2012.

| Characteristic | Value |

|---|---|

| Particle size (% by mass) | |

| <0.023 mm | 100% |

| Specific gravity | 2.69 |

| Consistency limit(%) | |

| Liquid limit | 49.0 |

| Plasticity index | 25.2 |

| Element | Result/% |

|---|---|

| SiO2 | 52.4 |

| Al2O3 | 46.3 |

| Fe2O3 | 0.30 |

| TiO2 | 0.06 |

| MgO | 0.18 |

| CaO | 0.3 |

| K2O | 0.25 |

| Na2O | 0.05 |

| Diameter /mm | Length /mm | Beak Extension /% | Tensile Strength /MPa | Elastic Modulus /MPa |

|---|---|---|---|---|

| 0.015 | 12 | 6.9 | 1620 | 40100 |

| Test No. | αc % | αf % | αw % | ρd g/m3 | ρ g/m3 |

|---|---|---|---|---|---|

| c5-f0-0.5 | 5 | 0 | 0.5 | 1.16 | 1.72 |

| c5-f0.6-0.5 | 5 | 0.6 | 0.5 | 1.17 | 1.72 |

| c10-f0-0.5 | 10 | 0 | 0.5 | 1.20 | 1.75 |

| c10-f0-0.57 | 10 | 0 | 0.57 | 1.12 | 1.70 |

| c10-f0-0.63 | 10 | 0 | 0.63 | 1.05 | 1.65 |

| c10-f0-0.7 | 10 | 0 | 0.7 | 0.98 | 1.61 |

| c10-f0.6-0.5 | 10 | 0.6 | 0.5 | 1.20 | 1.74 |

| c10-f0.6-0.57 | 10 | 0.6 | 0.57 | 1.12 | 1.69 |

| c10-f0.6-0.63 | 10 | 0.6 | 0.63 | 1.05 | 1.65 |

| c10-f0.6-0.7 | 10 | 0.6 | 0.7 | 0.99 | 1.61 |

| c15-f0-0.5 | 15 | 0 | 0.5 | 1.23 | 1.77 |

| c15-f0-0.57 | 15 | 0 | 0.57 | 1.15 | 1.72 |

| c15-f0-0.63 | 15 | 0 | 0.63 | 1.10 | 1.71 |

| c15-f0-0.7 | 15 | 0 | 0.7 | 1.01 | 1.63 |

| c15-f0.6-0.5 | 15 | 0.6 | 0.5 | 1.24 | 1.77 |

| c15-f0.6-0.57 | 15 | 0.6 | 0.57 | 1.15 | 1.72 |

| c15-f0.6-0.63 | 15 | 0.6 | 0.63 | 1.09 | 1.68 |

| c15-f0.6-0.7 | 15 | 0.6 | 0.7 | 1.01 | 1.63 |

| Cement Content/% | Water Content/% | Peak Bending Load/N | Nominal Flexural Strength/kPa | Growth Rate/% |

|---|---|---|---|---|

| 5 | 50 | 610 | 1143.8 | 370 |

| 10 | 1120 | 2100.0 | 262 | |

| 15 | 1590 | 2981.3 | 141 | |

| 10 | 56 | 710 | 1331.3 | 182 |

| 15 | 893 | 1674.4 | 62 | |

| 10 | 63 | 570 | 1068.8 | 138 |

| 15 | 729 | 1366.9 | 39 | |

| 10 | 70 | 581 | 1089.4 | 174 |

| 15 | 643 | 1205.6 | 59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, T.; Hou, L.; Dai, G.; Yang, Z.; Xiao, C. Investigation on Strength and Flexural Behavior of PVA Fiber-Reinforced and Cemented Clayey Soil. Buildings 2024, 14, 2433. https://doi.org/10.3390/buildings14082433

Huang T, Hou L, Dai G, Yang Z, Xiao C. Investigation on Strength and Flexural Behavior of PVA Fiber-Reinforced and Cemented Clayey Soil. Buildings. 2024; 14(8):2433. https://doi.org/10.3390/buildings14082433

Chicago/Turabian StyleHuang, Ting, Lijun Hou, Guoliang Dai, Zhekun Yang, and Chengbo Xiao. 2024. "Investigation on Strength and Flexural Behavior of PVA Fiber-Reinforced and Cemented Clayey Soil" Buildings 14, no. 8: 2433. https://doi.org/10.3390/buildings14082433

APA StyleHuang, T., Hou, L., Dai, G., Yang, Z., & Xiao, C. (2024). Investigation on Strength and Flexural Behavior of PVA Fiber-Reinforced and Cemented Clayey Soil. Buildings, 14(8), 2433. https://doi.org/10.3390/buildings14082433