A Comparative Study of the Fire Properties of Chinese Traditional Timber Structural Components under Different Surface Treatments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Making

2.1.1. Choice of Wood Type and Specimen Size

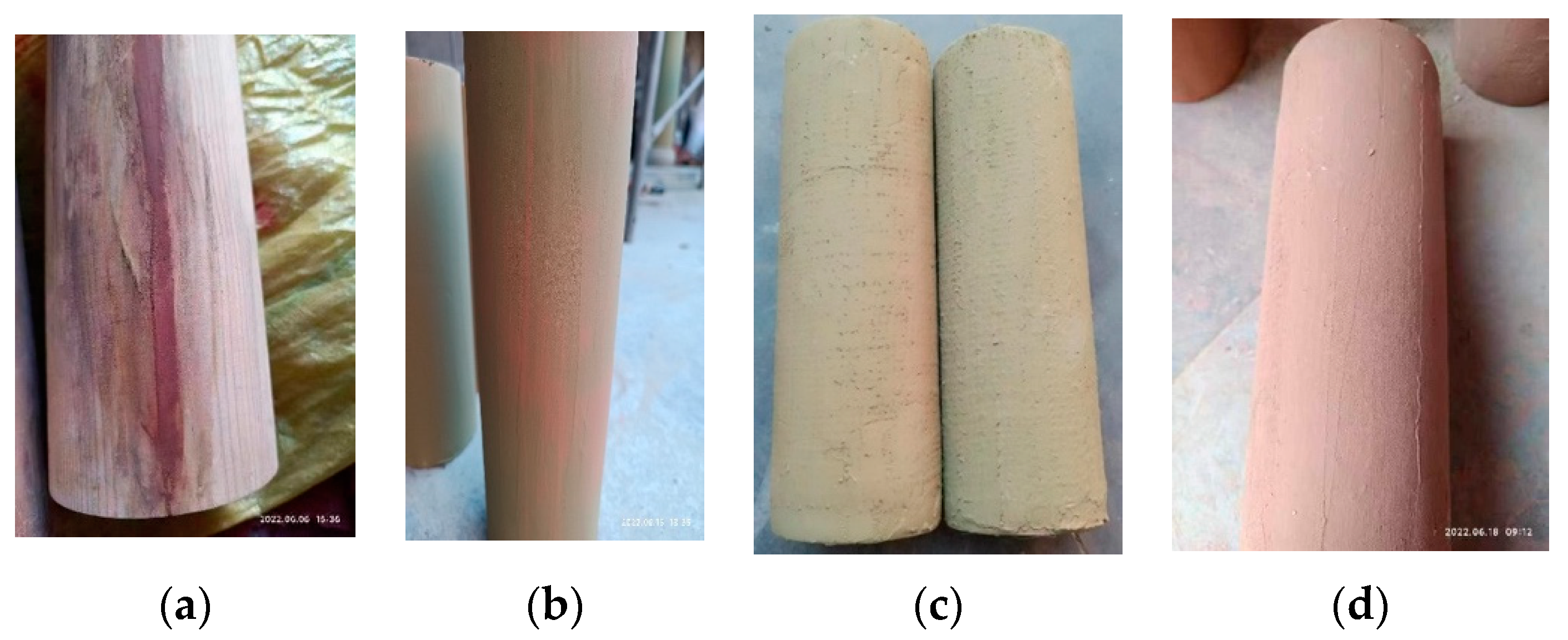

2.1.2. Choice of Surface Treatments

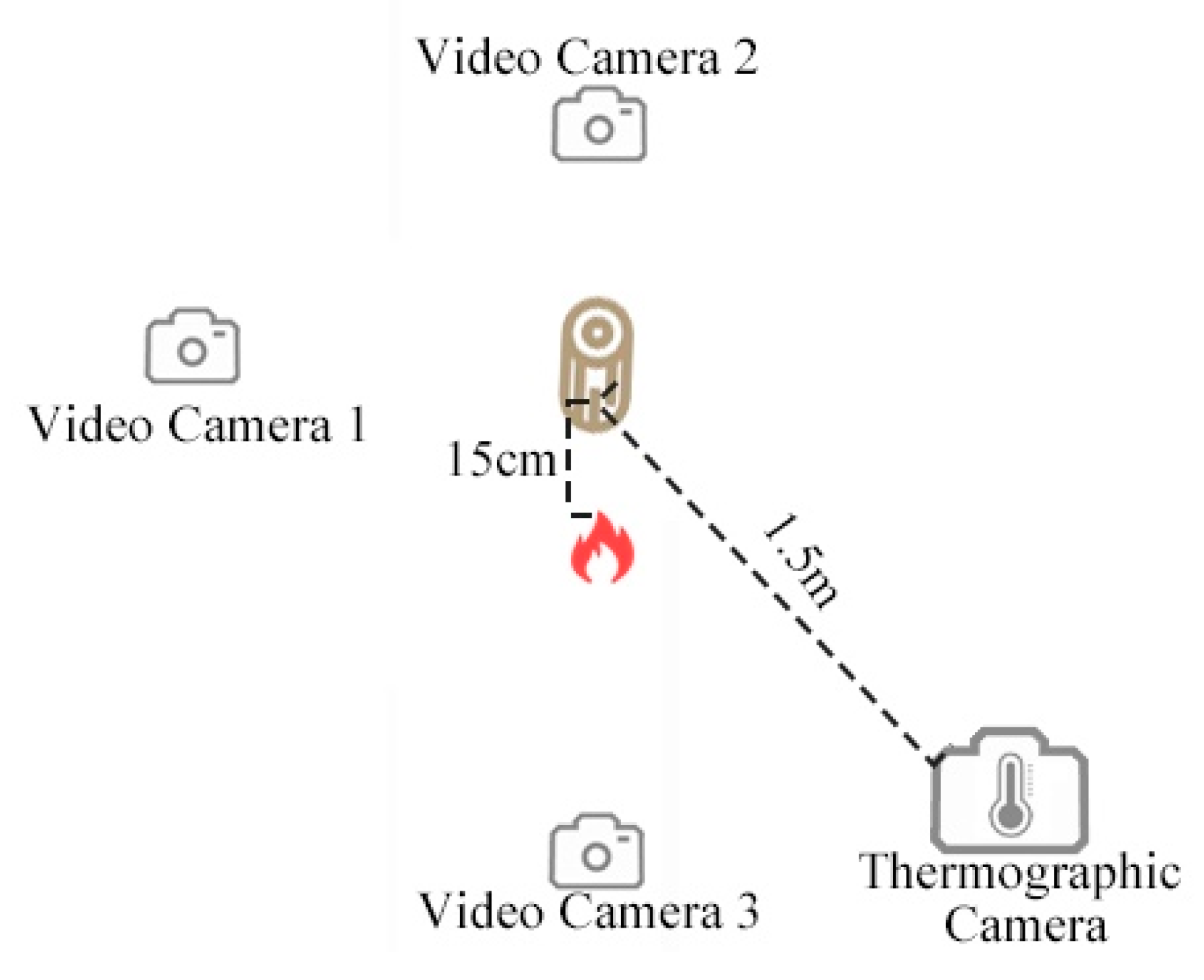

2.2. Single-Sided Fire Test

3. Results

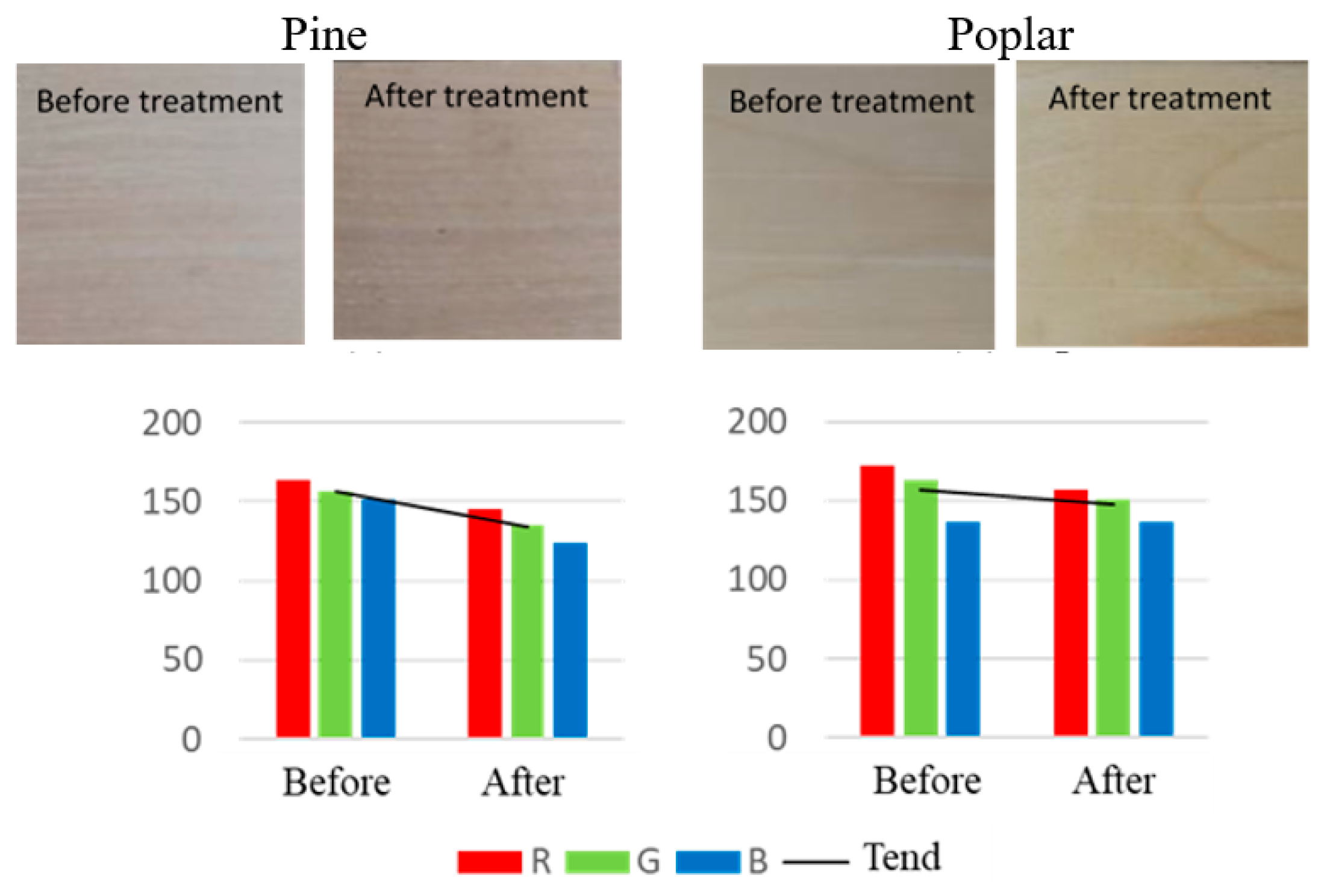

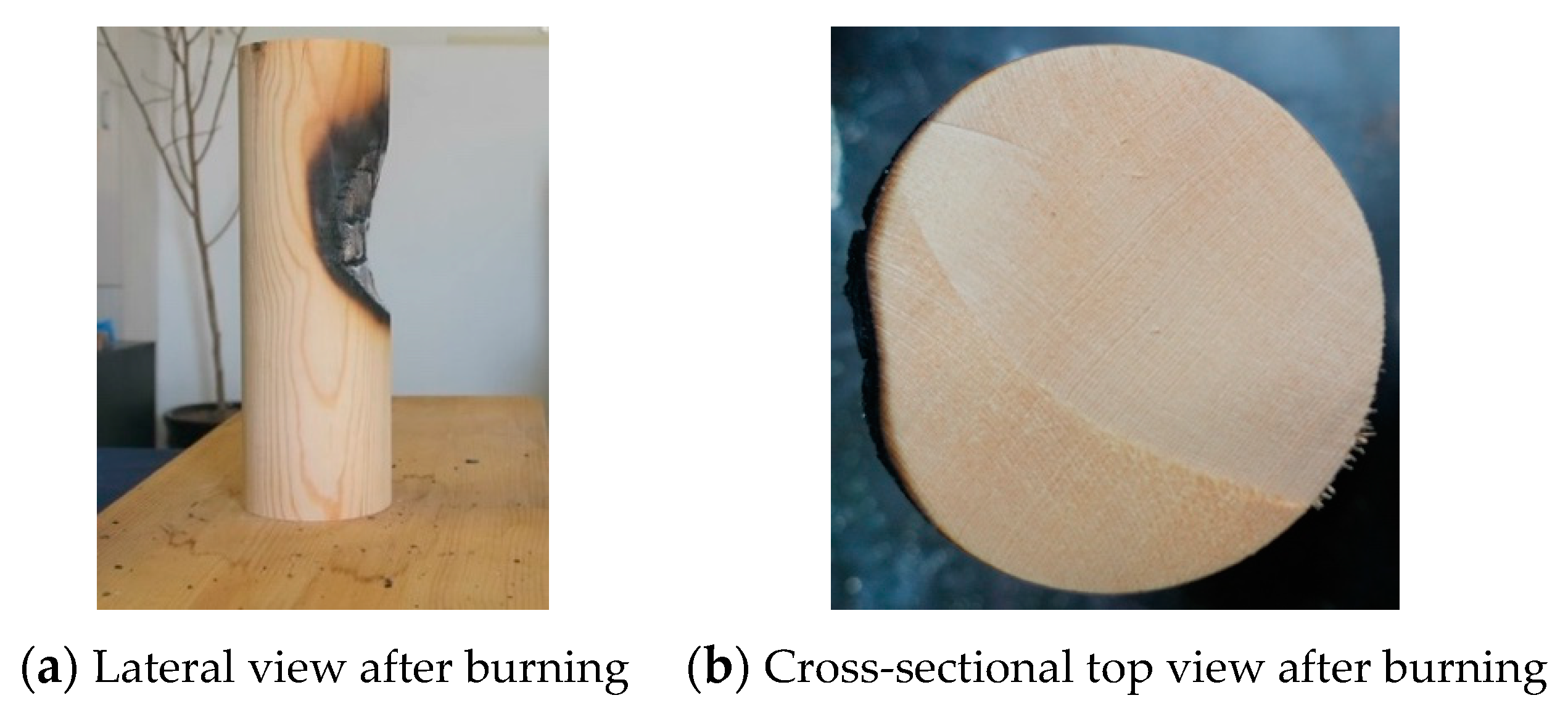

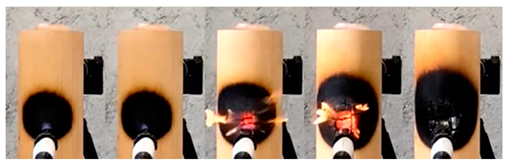

3.1. Visual Observation

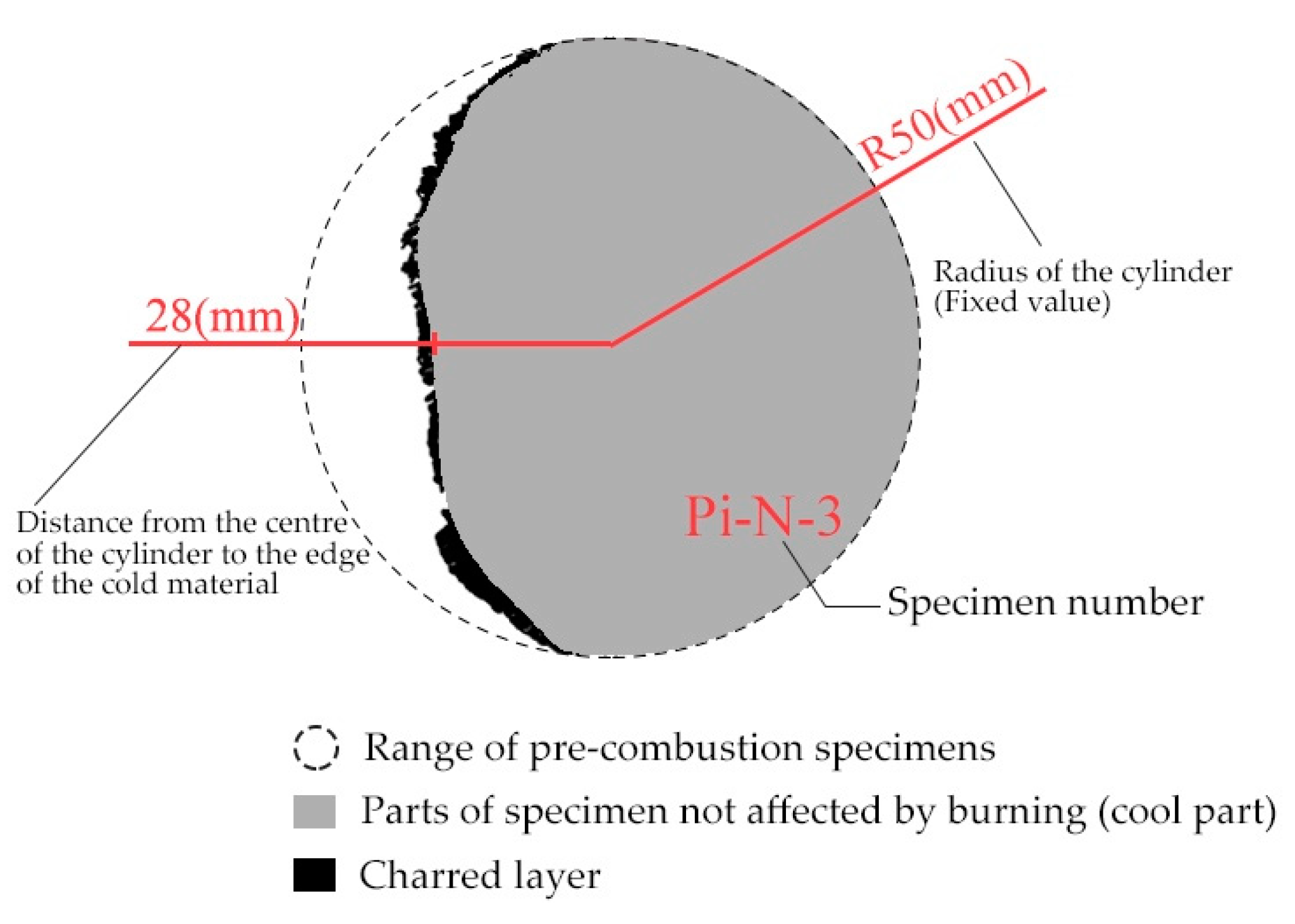

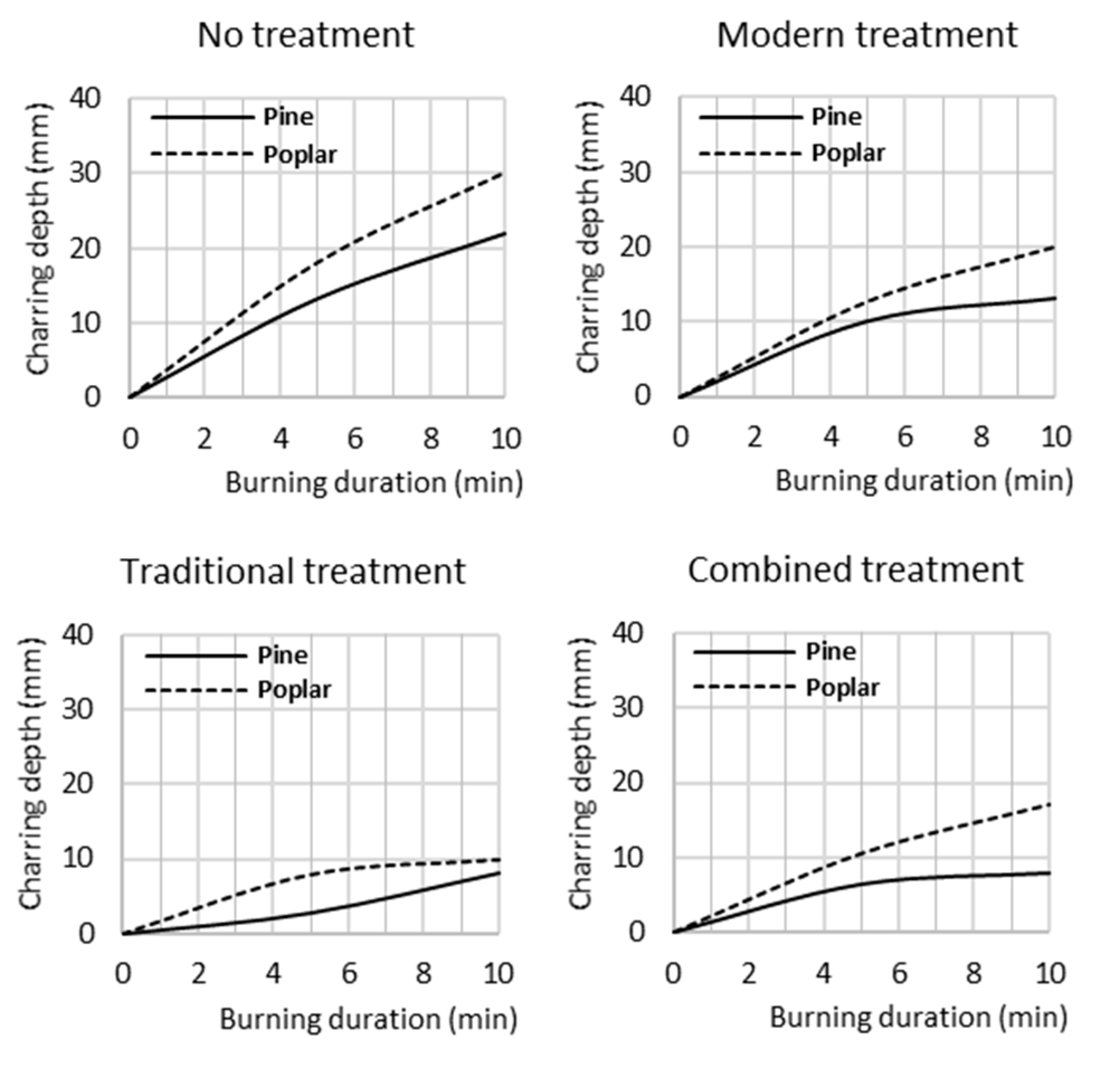

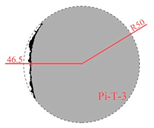

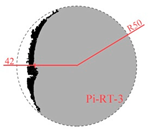

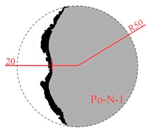

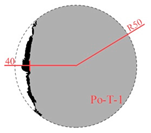

3.2. Charring Characteristics

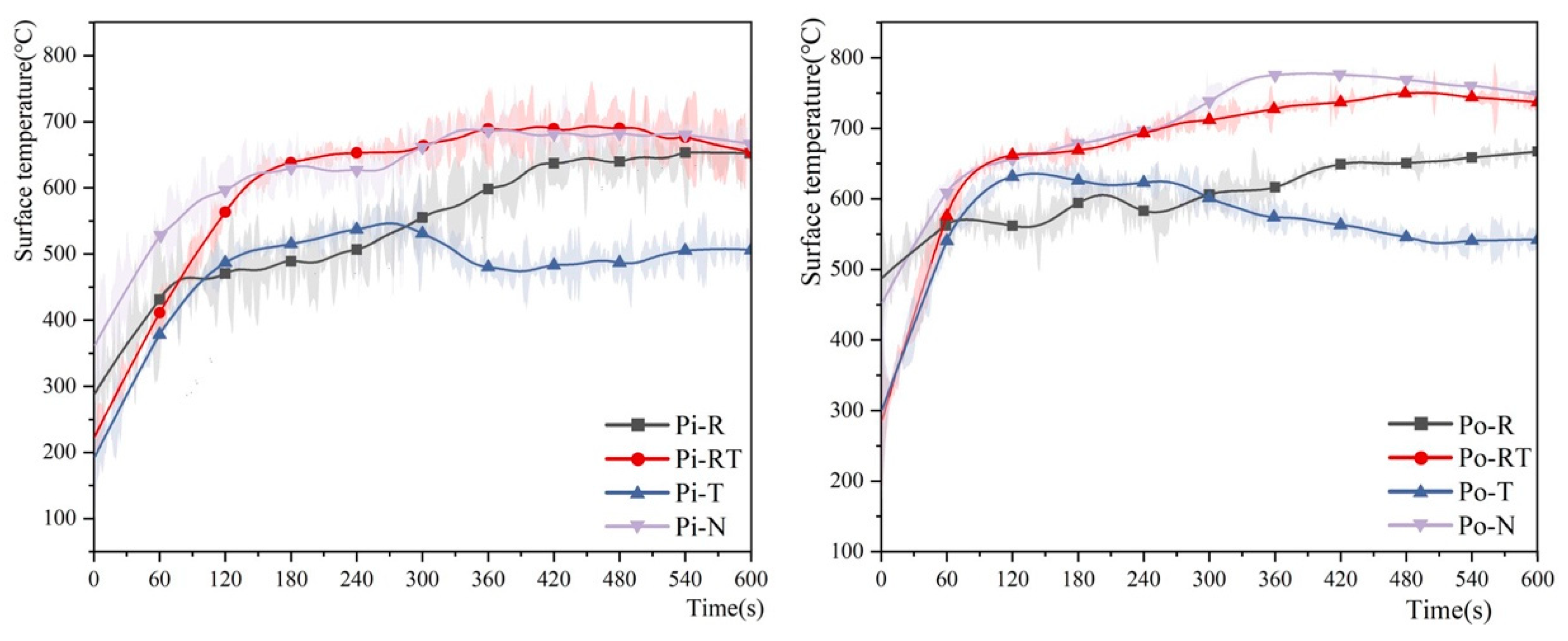

3.3. Surface Temperature Variations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.J.; Park, S. Tectonic traditions in ancient Chinese architecture, and their development. J. Asian Archit. Build. Eng. 2017, 16, 31–38. [Google Scholar] [CrossRef]

- Fang, D.P.; Iwasaki, S.; Yu, M.H.; Shen, Q.P.; Miyamoto, Y.; Hikosaka, H. Ancient Chinese timber architecture I: Experimental study. J. Struct. Eng. 2001, 127, 1348–1357. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, H.; Jiang, X.; Lu, Y.; Wang, W.; Yin, Y. Wood used in ancient timber architecture in Shanxi Province, China. IAWA J. 2017, 38, 182–200. [Google Scholar] [CrossRef]

- Zhang, X.C.; Xue, J.Y.; Zhao, H.T.; Sui, Y. Experimental study on Chinese ancient timber-frame building by shaking table test. Struct. Eng. Mech. 2011, 40, 453–469. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Mei, X.J. Fire Protection in Ancient Buildings; Chemical Industry Press: Beijing, China, 2010. [Google Scholar]

- Wang, Y.; Wang, W.; Zhou, H.; Qi, F. Burning Characteristics of Ancient Wood from Traditional Buildings in Shanxi Province, China. Forests 2022, 13, 190. [Google Scholar] [CrossRef]

- Yang, L.; Ran, Y.; Liu, T. Fire Risk Analysis of Wooden Ancient Buildings. Eng. Constr. 2016, 48, 91–94. [Google Scholar]

- Fu, P.; Teri, G.L.; Li, J.; Li, J.X.; Li, Y.H.; Yang, H. Investigation of ancient architectural painting from the Taidong tomb in the western qing tombs, hebei, china. Coatings 2020, 10, 688. [Google Scholar] [CrossRef]

- Li, J.; Zhao, R. A Multi-Method Analysis of a Color Painting on Ancient Architecture from Anyuan Temple in Chengde, China. Coatings 2024, 14, 559. [Google Scholar] [CrossRef]

- Xu, Q.F.; Han, C.Q.; Chen, L.Z.; Wang, Z.C.; Leng, Y.B. Experimental study of the mechanical properties of traditional ground battle protection roundwood posts after fire. China Civ. Eng. J. 2019, 52, 90–99. [Google Scholar]

- Xu, Q.F.; Han, C.Q.; Chen, L.Z.; Wang, Z.C.; Leng, Y.B. Experimental study of the mechanical properties of traditional ground warfare treated wooden beams after fire on three sides. Build. Struct. 2021, 51, 92–97+29. [Google Scholar]

- Mali, P.; Sonawane, N.S.; Patil, V.; Lokhande, G.; Mawale, R.; Pawar, N. Morphology of wood degradation and flame retardants wood coating technology: An overview. Int. Wood Prod. J. 2022, 13, 21–40. [Google Scholar] [CrossRef]

- Jiang, J.; Li, J.; Gao, Q. Effect of flame retardant treatment on dimensional stability and thermal degradation of wood. Constr. Build. Mater. 2015, 75, 74–81. [Google Scholar] [CrossRef]

- Li, S.; Wang, X.; Xu, M.; Liu, L.; Wang, W.; Gao, S.; Li, B. Effect of a biomass based waterborne fire retardant coating on the flame retardancy for wood. Polym. Adv. Technol. 2021, 32, 4805–4814. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, L.; Liu, S.; Zhang, C.; Xiang, T. The traditional wisdom in fire prevention embodied in the layout of ancient villages: A case study of high chair village in Western Hunan, China. Buildings 2022, 12, 1885. [Google Scholar] [CrossRef]

- Dong, L.L.; Lu, Y.H.; Chen, G. The Modern Green Technology Innovation of Bayu Traditional Wooden Building. Adv. Mater. Res. 2015, 1065, 1610–1617. [Google Scholar] [CrossRef]

- Lai, Y.; Liu, X.; Li, Y.; Leonidas, E.; Fisk, C.; Yang, J.; Zhang, Y.; Willmott, J. Investigating the fire-retardant efficiency of intumescent coatings on inclined timber: A study on application strategies and heat transfer mechanisms. Constr. Build. Mater. 2023, 407, 133586. [Google Scholar] [CrossRef]

- Liang, C.; Du, Y.; Wang, Y.; Ma, A.; Huang, S.; Ma, Z. Intumescent fire-retardant coatings for ancient wooden architectures with ideal electromagnetic interference shielding. Adv. Compos. Hybrid Mater. 2021, 4, 979–988. [Google Scholar] [CrossRef]

- Jiang, H.C.; Li, K.; Ma, Y.; Ma, X.M.; Hu, Z.Y. Combustion performance study of phosphorus-nitrogen-boron composite flame-retardant rubber wood. Chin. J. Trop. Crop 2020, 41, 787–792. [Google Scholar]

- Zhang, J.; Xu, Q.F.; Shang, J.X. Residual bearing capacity tests of wooden columns after fire on one side and two adjacent sides. J. Shenyang Univ. Technol. 2013, 35, 461–468. [Google Scholar]

- Zang, X.; Liu, W.; Wu, D.; Pan, X.; Zhang, W.; Bian, H.; Shen, R. Contemporary fire safety engineering in timber structures: Challenges and solutions. Fire 2023, 7, 2. [Google Scholar] [CrossRef]

- Garcia-Castillo, E.; Paya-Zaforteza, I.; Hospitaler, A. Fire in heritage and historic buildings, a major challenge for the 21st century. Dev. Built Environ. 2023, 13, 100102. [Google Scholar] [CrossRef]

- Mohammadiounotikandi, A.; Fakhruldeen, H.F.; Meqdad, M.N.; Ibrahim, N.; Jafari, B.F.; Navimipour, N.; Unal, M. A fire evacuation and control system in smart buildings based on the internet of things and a hybrid intelligent algorithm. Fire 2023, 6, 171. [Google Scholar] [CrossRef]

- Yun, W.C.; Ji, Q.; Tan, L.W. Flame retardant properties of magnesium oxide nanoparticles on wood. Appl. Chem. Ind. 2015, 44, 1057–1060. [Google Scholar]

- Yuan, C.; Zhai, S.C.; Zhang, Y.M.; Zhang, Y.L. Analysis of archaeological wood degradation by infrared spectroscopy combined with thermogravimetry. Spectrosc. Spect. Anal. 2020, 40, 2943–2950. [Google Scholar]

- Yuan, C.Y.; Lang, Y.J.; Wang, K.; Liu, X.; Wang, Q.L. Analysis on the fire spread law of brick-wood structured ancient buildings under different flow velocity. Fire Sci. Technol. 2021, 40, 643. [Google Scholar]

- Deng, C.; Liu, Y.; Jian, H.; Liang, Y.; Wen, M.; Shi, J.; Park, H. Study on the preparation of flame retardant plywood by intercalation of phosphorus and nitrogen flame retardants modified with Mg/Al-LDH. Constr. Build. Mater. 2023, 374, 130939. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, J.; Shen, Z.; Bi, H.; Shentu, B. Flame resistance and bonding performance of plywood fabricated by guanidine phosphate-impregnated veneers. Forests 2023, 14, 741. [Google Scholar] [CrossRef]

- Deng, C.; Ji, Y.; Zhu, M.; Liang, Y.; Jian, H.; Yan, Z.; Wen, M.; Park, H. Preparation of organic-inorganic phosphorus-nitrogen-based flame retardants and their application to plywood. Polymers 2023, 15, 3112. [Google Scholar] [CrossRef]

- Schnabl, S.; Turk, G.; Planinc, I. Buckling of timber columns exposed to fire. Fire Saf. J. 2011, 46, 431–439. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, D.; Yang, L. Influence of Fire-Retardant Coatings on the Hygroscopic Properties of Wood. J. Wood Sci. 2021, 67, 345–353. [Google Scholar]

- Chen, L.; Ye, X.; Zhou, M. Study on the Hygroscopicity of Fire-Retardant Treated Wood. Int. J. Fire Sci. Technol. 2018, 35, 289–299. [Google Scholar]

- Gao, B.; Wei, S.; Du, W.; Yang, H.; Chu, Y. Experimental Study on the Fire Resistance Performance of Partition Board under the Condition of Small Fire Source. Processes 2021, 9, 1818. [Google Scholar] [CrossRef]

- Lee, W.M.; Fragomeni, S.; Monckton, H.; Guerrieri, M. A review of test Methods, issues and challenges of Large-Scale fire testing of concrete tunnel linings. Constr. Build. Mater. 2023, 392, 131901. [Google Scholar] [CrossRef]

| Wood Species | Stage | RGB Value | ||

|---|---|---|---|---|

| R | G | B | ||

| Pine | Before | 164 | 157 | 151 |

| After | 145 | 135 | 124 | |

| Poplar | Before | 157 | 151 | 137 |

| After | 172 | 163 | 137 | |

| Wood Species | Dimension | Types of Surface Treatment | Specimen Numbering |

|---|---|---|---|

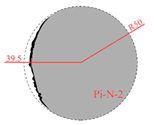

| Pine | ∅100 × 400 mm | No treatment (control) | Pi-N-1 |

| Pi-N-2 | |||

| Pi-N-3 | |||

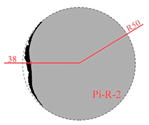

| Modern | Pi-R-1 | ||

| Pi-R-2 | |||

| Pi-R-3 | |||

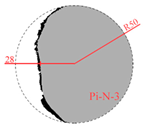

| Traditional | Pi-T-1 | ||

| Pi-T-2 | |||

| Pi-T-3 | |||

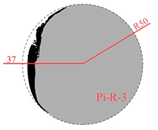

| Combined | Pi-RT-1 | ||

| Pi-RT-2 | |||

| Pi-RT-3 | |||

| Poplar | ∅100 × 400 mm | No treatment (control) | Po-N-1 |

| Po-N-2 | |||

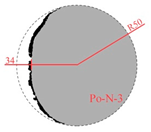

| Po-N-3 | |||

| Modern | Po-R-1 | ||

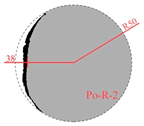

| Po-R-2 | |||

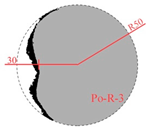

| Po-R-3 | |||

| Traditional | Po-T-1 | ||

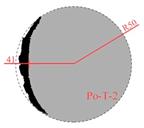

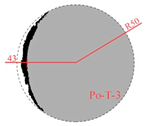

| Po-T-2 | |||

| Po-T-3 | |||

| Combined | Po-RT-1 | ||

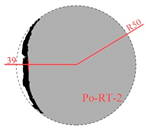

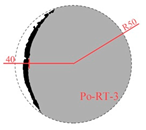

| Po-RT-2 | |||

| Po-RT-3 |

| Wood Species | Individual MC without Treatment | Average MC without Treatment | Treatment Type | Individual MC after Treatment | Average MC after Treatment | Average MC Difference after Treatment |

|---|---|---|---|---|---|---|

| Pine | 12.1% | 10.2% | Modern | 17.2% | 16.9% | +6.7% |

| 17.1% | ||||||

| 16.4% | ||||||

| 8.8% | Traditional | 8.9% | 8.7% | −1.5% | ||

| 8.5% | ||||||

| 8.7% | ||||||

| 9.6% | Combined | 8.8% | 8.7% | −1.5% | ||

| 8.5% | ||||||

| 8.7% | ||||||

| Poplar | 7.4% | 8.2% | Modern | 15.1% | 14.4% | +6.2% |

| 13.4% | ||||||

| 14.8% | ||||||

| 9.2% | Traditional | 7.6% | 7.0% | −1.2% | ||

| 5.8% | ||||||

| 7.6% | ||||||

| 8.0% | Combined | 7.1% | 7.4% | −0.6% | ||

| 7.2% | ||||||

| 7.8% |

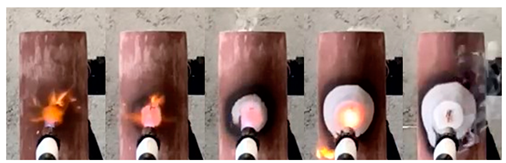

| Treatment | Time Recorded after Fire Ignition | T | ||||

|---|---|---|---|---|---|---|

| 10 s | 30 s | 60 s | 300 s | 600 s | ||

| Pi-N (Control) |  | 3.6 s | ||||

| Pi-R (Modern) |  | 0.6 s | ||||

| Pi-T (Traditional) |  | 2.3 s | ||||

| Pi-RT (Combined) |  | 4.3 s | ||||

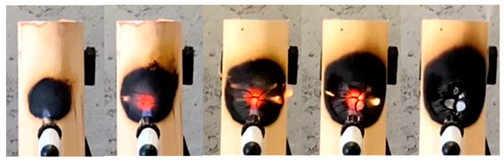

| Treatment | Time Recorded after Fire Ignition | T | ||||

|---|---|---|---|---|---|---|

| 10 s | 30 s | 60 s | 300 s | 600 s | ||

| Po-N (Control) |  | 14.0 s | ||||

| Po-R (Modern) |  | 9.1 s | ||||

| Po-T (Traditional) |  | 16.0 s | ||||

| Po-RT (Combined) |  | 27.0 s | ||||

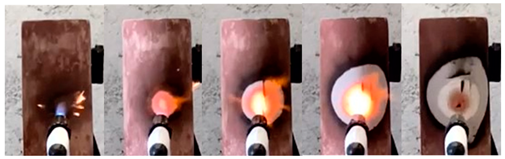

| Wood Species | No Treatment | Modern Treatment | Traditional Treatment | Combined Treatment |

|---|---|---|---|---|

| Pine |  |  |  |  |

| Pi-N-1 | Pi-R-1 | Pi-T-1 | Pi-RT-1 | |

|  |  |  | |

| Pi-N-2 | Pi-R-2 | Pi-T-2 | Pi-RT-2 | |

|  |  |  | |

| Pi-N-3 | Pi-R-3 | Pi-T-3 | Pi-RT-3 | |

| Poplar |  |  |  |  |

| Po-N-1 | Po-R-1 | Po-T-1 | Po-RT-1 | |

|  |  |  | |

| Po-N-2 | Po-R-2 | Po-T-2 | Po-RT-2 | |

|  |  |  | |

| Po-N-3 | Po-R-3 | Po-T-3 | Po-RT-3 |

| Specimen Number | Average MC after Treatment (%) | Burning Duration (min) | Charring Depth (mm) | Charring Rate (mm/min) | Mass Before Test (m0) (g) | Mass after Test (m1) (g) | Mass Loss (∆m) (g) |

|---|---|---|---|---|---|---|---|

| Pi-N-1 | 5 | 16.0 | 3.2 | 1015.2 | 992.8 | 22.4 | |

| Pi-N-2 | 10.2 | 5 | 10.5 | 2.1 | 1116.4 | 1106.3 | 10.1 |

| Pi-N-3 | 10 | 22.0 | 2.2 | 1126.7 | 1073.3 | 53.4 | |

| Pi-R-1 | 5 | 10.0 | 2.0 | 870.2 | 864.8 | 5.4 | |

| Pi-R-2 | 16.9 | 5 | 10.0 | 2.0 | 858.9 | 853.9 | 5.0 |

| Pi-R-3 | 10 | 13.0 | 1.3 | 1133.7 | 1119.4 | 14.3 | |

| Pi-T-1 | 5 | 2.0 | 0.4 | 1598 | 1590.8 | 7.2 | |

| Pi-T-2 | 8.7 | 5 | 3.5 | 0.7 | 1213.6 | 1208.6 | 5.0 |

| Pi-T-3 | 10 | 8.0 | 0.8 | 1439.5 | 1429.4 | 10.1 | |

| Pi-RT-1 | 5 | 8.5 | 1.7 | 1424.0 | 1410.4 | 13.6 | |

| Pi-RT-2 | 8.7 | 5 | 4.5 | 0.9 | 1192.0 | 1187.9 | 4.1 |

| Pi-RT-3 | 10 | 8.0 | 0.8 | 1368.5 | 1345.7 | 22.8 | |

| Po-N-1 | 5 | 16.0 | 3.2 | 1010.0 | 985.2 | 24.8 | |

| Po-N-2 | 8.2 | 5 | 20.0 | 4.0 | 1015.5 | 991.7 | 23.8 |

| Po-N-3 | 10 | 30.0 | 3.0 | 1013.3 | 958.7 | 54.6 | |

| Po-R-1 | 5 | 13.5 | 2.7 | 1116.1 | 1105.9 | 10.2 | |

| Po-R-2 | 14.4 | 5 | 12.0 | 2.4 | 1005.7 | 993.7 | 12.0 |

| Po-R-3 | 10 | 20.0 | 2.0 | 1119.0 | 1102.9 | 16.1 | |

| Po-T-1 | 5 | 7.0 | 1.4 | 1522.7 | 1506.5 | 16.2 | |

| Po-T-2 | 7.0 | 5 | 9.0 | 1.8 | 1306.6 | 1293 | 13.6 |

| Po-T-3 | 10 | 10.0 | 1.0 | 1592.6 | 1582.9 | 19.7 | |

| Po-RT-1 | 5 | 10.0 | 2.0 | 1376.0 | 1363.1 | 12.9 | |

| Po-RT-2 | 7.4 | 5 | 11.0 | 2.2 | 1430.9 | 1419.8 | 11.1 |

| Po-RT-3 | 10 | 17.0 | 1.7 | 1372.5 | 1353.2 | 19.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yeo, S.; Dai, S. A Comparative Study of the Fire Properties of Chinese Traditional Timber Structural Components under Different Surface Treatments. Buildings 2024, 14, 2439. https://doi.org/10.3390/buildings14082439

Li Y, Yeo S, Dai S. A Comparative Study of the Fire Properties of Chinese Traditional Timber Structural Components under Different Surface Treatments. Buildings. 2024; 14(8):2439. https://doi.org/10.3390/buildings14082439

Chicago/Turabian StyleLi, Yupeng, Sokyee Yeo, and Shibing Dai. 2024. "A Comparative Study of the Fire Properties of Chinese Traditional Timber Structural Components under Different Surface Treatments" Buildings 14, no. 8: 2439. https://doi.org/10.3390/buildings14082439