Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review

Abstract

1. Introduction

2. Methodology

2.1. Review Framework

2.2. Literature Search

2.3. Inclusion and Exclusion Criteria

2.4. Data Extraction and Analysis

2.5. Need for a Consistent Methodological Framework

3. E-Waste and Its Composition

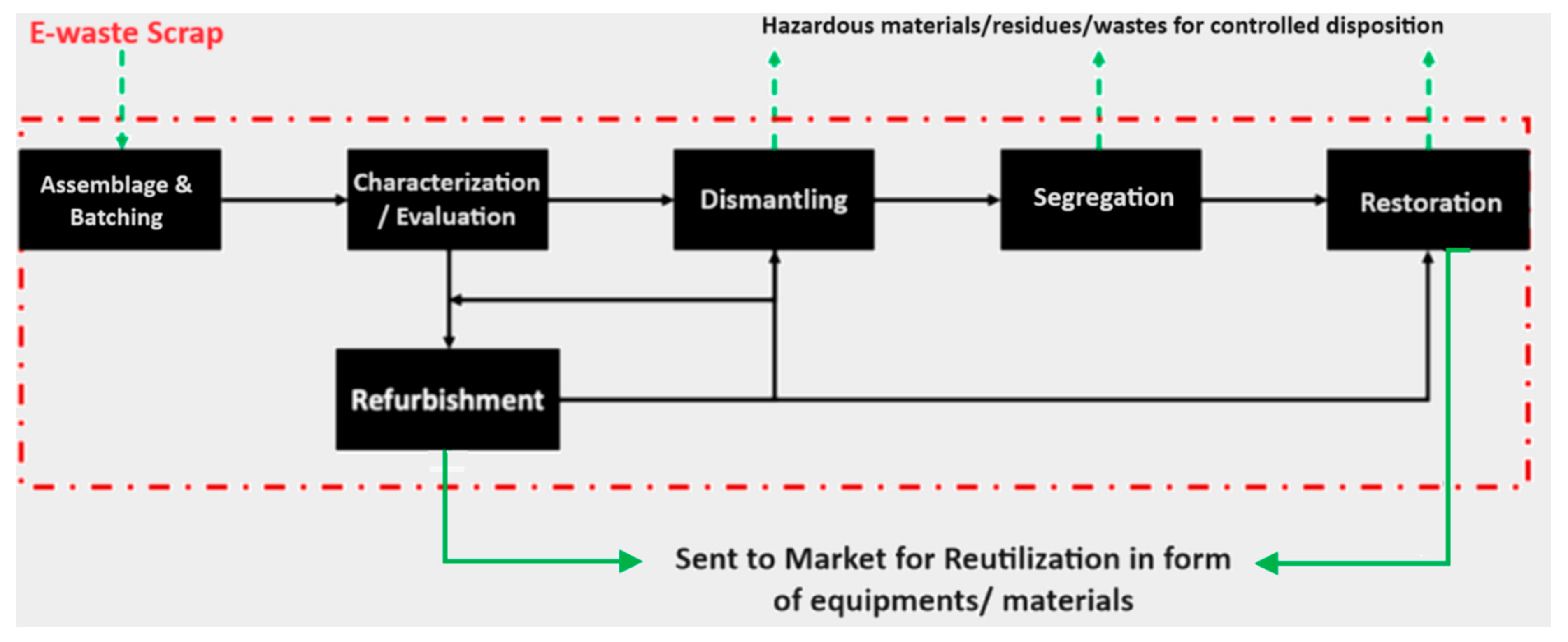

4. E-Waste to Construction Materials: Production Techniques

5. Properties of Concrete with Recycled E-Waste

5.1. Colour, Shape, Size, Aggregate Crushing Value, and Water Absorption of E-Waste Concrete

5.2. Workability of E-Waste Concrete

5.3. Characteristic Strength of E-Waste Concrete

- Physical properties (as E-waste plastic aggregates are lighter and stiffer in contrast to natural coarse aggregates): this difference induces stress concentration zones in the bulk of the concrete, which leads to the formation and propagation of cracks and, as a result, reduces the compressive performance of the material as a whole [30].

- Hydrophobic nature: As E-waste plastic aggregates exhibit a hydrophobic nature, this will not allow sufficient moisture to penetrate and hydrate the aggregate during the curing process, totally drying up the excess moisture, hence allowing dry out over time, meaning that the concrete becomes less dense and has a lower compressive strength [57].

- Surface texture: the smooth surface texture of E-waste plastic aggregates leads to a relatively poor bond formation between the mortar and the aggregates [45].

- Density and segregation: E-waste plastic aggregates have a lower density than the normal aggregate and tend to migrate towards the top surface during the casting process, including vibration for compaction. This form of segregation causes a non-homogeneous distribution of aggregates in the specimen, which reduces the compressive strength [58].

5.4. Flexural Strength of E-Waste Concrete

5.5. Tensile Strength of E-Waste Concrete

5.6. Thermal Resistance of E-Waste Concrete

6. Discussion

6.1. Workability of E-Waste Concrete

6.2. Mechanical Properties of E-Waste Concrete

6.3. Durability of E-Waste Concrete

6.4. Environmental and Health Impacts

6.5. Practical Implications and Feasibility

6.6. Economic Aspects

7. Conclusions

8. Future Recommendations

Funding

Conflicts of Interest

References

- Yang, K.-H.; Seo, E.-A.; Tae, S.-H. Carbonation and CO2 Uptake of Concrete. Environ. Impact Assess. Rev. 2014, 46, 43–52. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global Perspectives on E-Waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-waste Monitor—2017, United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Vienna. Available online: https://www.itu.int/en/ITU-D/Climate-Change/Documents/GEM%202017/Global-E-waste%20Monitor%202017%20-%20Executive%20Summary.pdf (accessed on 7 August 2024).

- Solving the E-Waste Problem (Step) White Paper One Global Definition of E-Waste 1 Solving the E-Waste Problem (Step) Initiative White Paper One Global Definition of E-Waste; United Nations University: Bonn, Germany, 2014.

- Garlapati, V.K. E-Waste in India and Developed Countries: Management, Recycling, Business and Biotechnological Initiatives. Renew. Sustain. Energy Rev. 2016, 54, 874–881. [Google Scholar] [CrossRef]

- Ylä-Mella, J.; Poikela, K.; Lehtinen, U.; Keiski, R.L.; Pongrácz, E. Implementation of Waste Electrical and Electronic Equipment Directive in Finland: Evaluation of the Collection Network and Challenges of the Effective WEEE Management. Resour. Conserv. Recycl. 2014, 86, 38–46. [Google Scholar] [CrossRef]

- Fuzail Hashmi, A.; Haq, M.U. Indian Based Fly Ash & International Based Fly Ash: A Review Paper. IOP Conf. Ser. Mater. Sci. Eng. 2018, 404, 012035. [Google Scholar] [CrossRef]

- Khan, R.A.; Haq, M. Long-Term Mechanical and Statistical Characteristics of Binary- and Ternary-Blended Concrete Containing Rice Husk Ash, Metakaolin and Silica Fume. Innov. Infrastruct. Solut. 2020, 5, 1–14. [Google Scholar] [CrossRef]

- Haq, M.; Khan, M.A.; Ali, S.; Ali, K.; Yusuf, M.; Kamyab, H.; Irshad, K. Enhancing Clayey Soil Performance with Lime and Waste Rubber Tyre Powder: Mechanical, Microstructural, and Statistical Analysis. Environ. Res. 2024, 256, 119217. [Google Scholar] [CrossRef]

- Singh, R.; Haq, M.; Khan, R.A. Influence of Industrial Waste and Mineral Admixtures on Durability and Sustainability of High-Performance Concrete. Environ. Sci. Pollut. Res. 2024, 31, 25567–25588. [Google Scholar] [CrossRef] [PubMed]

- Bansal, T.; Visalakshi, T.; Bhalla, S.; Bansal, T.; Talakokula, V.; Bhalla, S. Model Based Corrosion Assessment in Rebars of Different Fly Ash Blended Concrete Using Piezo Sensors. In Proceedings of the 7th Asia-Pacific Workshop on Structural Health Monitoring, APWSHM, Hong Kong, China, 12–15 November 2018. [Google Scholar]

- Bansal, T.; Talakokula, V.; Saravanan, T.J. Monitoring of Prestressed Concrete Beam under Corrosion Using Embedded Piezo Sensor Based on Electro-Mechanical Impedance Technique. Sci. Talks 2022, 4, 100095. [Google Scholar] [CrossRef]

- Gomasa, R.; Talakokula, V.; Kalyana Rama Jyosyula, S.; Bansal, T. A Review on Health Monitoring of Concrete Structures Using Embedded Piezoelectric Sensor. Constr. Build. Mater. 2023, 405, 133179. [Google Scholar] [CrossRef]

- Joseph, K. Electronic Waste Management in India–Issues and Strategies. In Proceedings of the 11th International Waste Management and Landfill Symposium, Cagliari, Sardinia, Italy, 1–5 October 2007. [Google Scholar]

- Raut, S.R.; Dhapudkar, R.S.; Mandaokar, M.G. Experimental Study on Utilization of E-Waste in Cement Concrete. Int. J. Eng. Sci. 2018, 5, 82–86. [Google Scholar]

- Ganesh, S.; Danish, P.; Bhat, K.A. Utilization of Waste Printed Circuit Board Powder in Concrete over Conventional Concrete. Mater. Today Proc. 2021, 42, 745–749. [Google Scholar] [CrossRef]

- Loganath, R.; Mohammed Bin Zacharia, K.; Kumar, A.; Singh, E.; Varma, V.S.; Sharma, D. System Optimization Models for Solid Waste Management. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2021; pp. 349–371. [Google Scholar] [CrossRef]

- Sharma, D.; Nema, A.; Prasad, R.; Sweta, K.; Sonaviya, D.R.; Karmakar, S. Global E-Waste Management: Consolidated Information Showcasing Best Available Practices. In Global E-Waste Management Strategies and Future Implications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 289–314. [Google Scholar] [CrossRef]

- Radhakrishnan, L.; Mary, J.S.; Sweta, K.; Jee, A.A.; Maurya, N.S.; Nema, A.; Sharma, D. Occupational Health Hazards Associated with E-Waste Handling, Treatment, Management, and Case Studies. In Global E-Waste Management Strategies and Future Implications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 153–181. [Google Scholar] [CrossRef]

- Sharma, R.; Jha, P.; Bansal, T.; Sharma, D.; Pathak, A. Sustainable Construction: Unveiling the Potential of Hempcrete in the Modern Era. Asian J. Civil. Eng. 2024, 25, 4157–4167. [Google Scholar] [CrossRef]

- Gavhane, M.A.; Soni, M.S.; Dinesh Sutar, M.; Patil, M.P. Utilisation of E—Plastic Waste in Concrete. Int. J. Eng. Res. Technol. 2016, 5, 594–601. [Google Scholar]

- Parliament, T.E. Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on Waste Electrical and Electronic Equipment (WEEE). J. Eur. Union 2003, 37, 24–39. [Google Scholar]

- Grant, K.; Goldizen, F.C.; Sly, P.D.; Brune, M.-N.; Neira, M.; van den Berg, M.; Norman, R.E. Health Consequences of Exposure to E-Waste: A Systematic Review. Lancet Glob. Health 2013, 1, e350–e361. [Google Scholar] [CrossRef]

- Perkins, D.N.; Brune Drisse, M.N.; Nxele, T.; Sly, P.D. E-Waste: A Global Hazard. Ann. Glob. Health 2014, 80, 286–295. [Google Scholar] [CrossRef]

- Ahmed, I. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal: A Legal Misfit in Global Ship Recycling Jurisprudence. Wash. Int’l LJ 2019, 29, 411. [Google Scholar]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and Structural Performance Evaluation of Recycled PET Fiber Reinforced Concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of Post-Consumer Waste Plastic in Cementitious Concrete Composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Effects of Particle Size of Treated CRT Funnel Glass on Properties of Cement Mortar. Mater. Struct. 2013, 46, 25–34. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Ferdous, W.; Kamchoom, V. Microplastics in Construction and Built Environment. Dev. Built Environ. 2023, 15, 100188. [Google Scholar] [CrossRef]

- Ullah, Z.; Qureshi, M.I.; Ahmad, A.; Khan, S.U.; Javaid, M.F. An Experimental Study on the Mechanical and Durability Properties Assessment of E-Waste Concrete. J. Build. Eng. 2021, 38, 102177. [Google Scholar] [CrossRef]

- Ghosh, B.; Ghosh, M.K.; Parhi, P.; Mukherjee, P.S.; Mishra, B.K. Waste Printed Circuit Boards Recycling: An Extensive Assessment of Current Status. J. Clean. Prod. 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Yonghua, L.I.U.; Xinlang, H.U.; Limin, S.H.I.; Yingli, G.A.O. Influence of Waste Circuit Board Non-Metallic Powder on Properties of Alkali-Activated Slag/Fly Ash Cementitious Material. Bull. Chin. Ceram. Soc. 2023, 42, 4456. [Google Scholar]

- Arulrajah, A.; Perera, S.; Wong, Y.C.; Maghool, F.; Horpibulsuk, S. Stabilization of PET Plastic-Demolition Waste Blends Using Fly Ash and Slag-Based Geopolymers in Light Traffic Road Bases/Subbases. Constr. Build. Mater. 2021, 284, 122809. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2021, 15, 175. [Google Scholar] [CrossRef] [PubMed]

- Bakhoum, E.S.; Mater, Y.M. Decision Analysis for the Influence of Incorporating Waste Materials on Green Concrete Properties. Int. J. Concr. Struct. Mater. 2022, 16, 63. [Google Scholar] [CrossRef]

- Nadhim, S.; Shree, P.N.; Kumar, G.P. A Comparative Study on Concrete Containing E-Plastic Waste and Fly Ash Concrete with Conventional Concrete. J. Sci. Technol. 2016, 6. [Google Scholar]

- Rohini, I.; Padmapriya, R. Effect of Bacteria Subtilis on E-Waste Concrete. Mater. Today Proc. 2021, 42, 465–474. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and Present Techniques of Self-Healing in Cementitious Materials: A Critical Review on Efficiency of Implemented Treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Santhanam, N.; Anbuarasu, G. Experimental Study on High Strength Concrete (M60) with Reused E-Waste Plastics. Mater. Today Proc. 2020, 22, 919–925. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Ajede, A. The Use of Granulated Plastic Waste in Structural Concrete. Afr. J. Sci. Technol. Innov. Dev. 2018, 10, 169–175. [Google Scholar] [CrossRef]

- Suchithra, S.; Kumar, M.; Indu, V.S. Study on Replacement of Coarse Aggregate by E-Waste in Concrete. Int. J. Tech. Res. Appl. 2015, 3, 266–270. [Google Scholar]

- Ling, T.-C.; Poon, C.-S. Utilization of Recycled Glass Derived from Cathode Ray Tube Glass as Fine Aggregate in Cement Mortar. J. Hazard. Mater. 2011, 192, 451–456. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.J.; Youm, K.-S.; Taha, M.M.R. Extracting Concrete Thermal Characteristics from Temperature Time History of Rc Column Exposed to Standard Fire. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Pinoteau, N.; Pimienta, P.; Guillet, T.; Rivillon, P.; Rémond, S. Effect of Heating Rate on Bond Failure of Rebars into Concrete Using Polymer Adhesives to Simulate Exposure to Fire. Int. J. Adhes. Adhes. 2011, 31, 851–861. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Recycling of E-Plastic Waste as a Construction Material in Developing Countries. J. Mater. Cycles Waste Manag. 2015, 17, 718–724. [Google Scholar] [CrossRef]

- Pauzi, N.N.M.; Jamil, M.; Hamid, R.; Abdin, A.Z.; Zain, M.F.M. The Effects of Using Cathode Ray Tube (CRT) Glass as Coarse Aggregates in High-Strength Concrete Subjected to High Temperature. J. Mater. Cycles Waste Manag. 2019, 21, 1414–1425. [Google Scholar] [CrossRef]

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Fire Resistance of Concrete Slabs Reinforced with FRP Bars. Part I: Experimental Investigations on the Mechanical Behavior. Compos. B Eng. 2011, 42, 1739–1750. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Hamid, R.; Taha, M.R. Fire Resistance of High-Volume Fly Ash Mortars with Nanosilica Addition. Constr. Build. Mater. 2012, 36, 779–786. [Google Scholar] [CrossRef]

- Lakshmi, R.; Nagan, S. Studies on Concrete Containing E Plastic Waste. Int. J. Environ. Sci. 2010, 1, 270–281. [Google Scholar]

- Manjunath, B.T.A. Partial Replacement of E-Plastic Waste as Coarse-Aggregate in Concrete. Procedia Environ. Sci. 2016, 35, 731–739. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Wang, M.; Wang, Z.; Awasthi, M.K.; Li, J. E-Waste Management in India: A Mini-Review. Waste Manag. Res. 2018, 36, 408–414. [Google Scholar] [CrossRef]

- Needhidasan, S.; Samuel, M.; Chidambaram, R. Electronic Waste–an Emerging Threat to the Environment of Urban India. J. Environ. Health Sci. Eng. 2014, 12, 1–9. [Google Scholar] [CrossRef]

- Arivalagan, S. Experimental Study on the Properties of Green Concrete by Replacement of E-Plastic Waste as Aggregate. Procedia Comput. Sci. 2020, 172, 985–990. [Google Scholar]

- Sabău, M.; Vargas, J.R. Use of E-Plastic Waste in Concrete as a Partial Replacement of Coarse Mineral Aggregate. Comput. Concr. 2018, 21, 377–384. [Google Scholar]

- Santhanam, N.; Ramesh, B.; Pohsnem, F.K. Concrete Blend with E-Waste Plastic for Sustainable Future. Mater. Today Proc. 2020, 22, 959–965. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Lim, N.H.A.S.; Tahir, M.M.; Alyousef, R.; Samadi, M. Performance Evaluation of Green Mortar Comprising Ceramic Waste as Cement and Fine Aggregates Replacement. SN Appl. Sci. 2019, 1, 557. [Google Scholar] [CrossRef]

- Needhidasan, S.; Ramesh, B.; Prabu, S.J.R. Experimental Study on Use of E-Waste Plastics as Coarse Aggregate in Concrete with Manufactured Sand. Mater. Today Proc. 2020, 22, 715–721. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Development of Ecofriendly Concrete Incorporating Recycled High-Impact Polystyrene from Hazardous Electronic Waste. J. Hazard. Toxic. Radioact. Waste 2015, 19, 04014042. [Google Scholar] [CrossRef]

- Needhidasan, S.; Vigneshwar, C.R.; Ramesh, B. Amalgamation of E-Waste Plastics in Concrete with Super Plasticizer for Better Strength. Mater. Today Proc. 2020, 22, 998–1003. [Google Scholar] [CrossRef]

- Rohini, I.; Padmapriya, R. Properties of Bacterial Copper Slag Concrete. Buildings 2023, 13, 290. [Google Scholar] [CrossRef]

- Rathore, V.; Rawat, A. Effective Utilization of Electronic Waste in Concrete Mixture as a Partial Replacement to Coarse Aggregates. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2019; Volume 2158. [Google Scholar]

- Štefan, R.; Foglar, M.; Fladr, J.; Horníková, K.; Holan, J. Thermal, Spalling, and Mechanical Behaviour of Various Types of Cementitious Composites Exposed to Fire: Experimental and Numerical Analysis. Constr. Build. Mater. 2020, 262, 119676. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Baskar, K. Effect of Temperature and Thermal Shock on Concrete Containing Hazardous Electronic Waste. J. Hazard. Toxic. Radioact. Waste 2018, 22, 04017028. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Use of Plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: A Review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Zeng, X.; Mathews, J.A.; Li, J. Urban Mining of E-Waste Is Becoming More Cost-Effective Than Virgin Mining. Environ. Sci. Technol. 2018, 52, 4835–4841. [Google Scholar] [CrossRef]

| Category | Description | Examples |

|---|---|---|

| Large Home Appliances | Major household appliances and electronics | Refrigerators, washing machines, air conditioners, dishwashers, microwave ovens |

| Small Home Electronics | Minor household gadgets and electronics | TVs, DVD/Blu-ray players, stereo systems, alarm clocks, blenders, coffee makers |

| IT & Telecom Equipment | Information technology and telecommunication devices | Computers, laptops, modems, routers, mobile phones, landline phones |

| Consumer Electronics | Electronic devices for entertainment and personal use | Radios, MP3 players, digital cameras, camcorders, game consoles |

| Lighting Products | Lamps and lighting equipment | LED bulbs, fluorescent tubes, halogen lamps, neon signs |

| Electronic Components | Individual electrical and electronic parts | Transistors, capacitors, resistors, printed circuit boards, wires, cables |

| Toys & Recreation | Electronic toys, leisure, and sports equipment | Remote-controlled toys, drones, fitness trackers, electronic games |

| Medical Devices | Medical and biomedical equipment | Thermometers, blood pressure monitors, diagnostic tools, imaging scanners |

| Control Systems | Monitoring and control instruments | Industrial control systems, thermostats, sensors, relays, microcontrollers |

| Automated Dispensers | Automatic dispensing machines | Soap dispensers, water dispensers, vending machines, ATMs |

| Contaminant | Origins |

|---|---|

| Halogenated Flame Suppressants (BFRs: PBDEs, PBBs) | Electronic devices |

| Polychlorinated Biphenyls (PCBs) | Dielectric liquids, lubricants, coolants in generators, capacitors, transformers, luminescent illumination, rotary aerators, dish cleaning machines, electric motors |

| Dioxins (PCDDs, PCDFs) Dioxin-analogous PCBs | Combustion derivatives Dielectric liquids, lubricants, coolants in generators, capacitors, transformers, luminescent illumination, rotary aerators, dish cleaning machines, electric motors |

| Polycyclic Aromatic Hydrocarbons (PAHs) | Combustion derivatives |

| Plumbum (Pb) | Printed circuit boards, cathode ray tubes (CRTs), illumination bulbs, televisual displays, solder, galvanic cells |

| Chromium (Cr) | Anticorrosive coatings, data tapes, floppy disks |

| Cadmium (Cd) | Switches, connectors, printed circuit boards, galvanic cells, infrared detectors, semiconductor chips, ink or toner photocopying machines, cathode ray tubes, mobile communication devices |

| Hydrargyrum (Hg) | Thermostats, sensors, monitors, cells, printed circuit boards, cold cathode luminescent lamps, liquid crystal display (LCD) backlights |

| Zinc (Zn) | Cathode ray tubes, metallic coatings |

| Nickel (Ni) | Galvanic cells |

| Lithium (Li) | Galvanic cells |

| Barium (Ba) Beryllium (Be) | Cathode ray tubes, luminescent lamps Power supply units, computing machines, X-ray apparatuses, ceramic components of electronics |

| Reference | CS | FS | SPS | TR | D | W |

|---|---|---|---|---|---|---|

| [37] | ✓ | ✓ | ✓ | .. | .. | .. |

| [38] | ✓ | .. | .. | .. | ✓ | ✓ |

| [39] | ✓ | .. | ✓ | .. | ✓ | .. |

| [40] | ✓ | .. | .. | ✓ | ✓ | .. |

| [41] | ✓ | .. | ✓ | .. | .. | .. |

| [42] | ✓ | .. | .. | ✓ | ✓ | .. |

| [43] | .. | .. | .. | ✓ | ✓ | .. |

| [44] | .. | .. | .. | ✓ | .. | .. |

| [45] | ✓ | .. | .. | ✓ | .. | .. |

| [46] | ✓ | .. | .. | ✓ | .. | .. |

| [47] | ✓ | .. | .. | ✓ | ✓ | .. |

| [48] | ✓ | .. | .. | ✓ | ✓ | .. |

| [49] | ✓ | .. | ✓ | .. | ✓ | .. |

| [16] | ✓ | .. | ✓ | .. | ✓ | .. |

| Study Reference | % E-Waste Plastic Aggregates | Aggregate Size (mm) | Change in 28-Day Flexural Strength (%) | Additional Comments |

|---|---|---|---|---|

| [61] | 5%, 10%, 15%, 20%, 25%, 30% | <10, 10–15, >15 | +15% (for <10 and 10–15 mm) | Compared to control |

| [50] | 10% | Not specified | +1.14% | Similar tensile strength with 20% |

| [57] | 12%, 17%, 22% | Not specified | −7.48%, −11.67%, −15.41% | Compared to control |

| [45] | 10–50% | Not specified | −11.11% to −37.38% | Decrease as % increases |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, G.; Bansal, T.; Haq, M.; Sharma, U.; Kumar, A.; Jha, P.; Sharma, D.; Kamyab, H.; Valencia, E.A.V. Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review. Buildings 2024, 14, 2495. https://doi.org/10.3390/buildings14082495

Kumar G, Bansal T, Haq M, Sharma U, Kumar A, Jha P, Sharma D, Kamyab H, Valencia EAV. Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review. Buildings. 2024; 14(8):2495. https://doi.org/10.3390/buildings14082495

Chicago/Turabian StyleKumar, Gaurav, Tushar Bansal, Moinul Haq, Utsav Sharma, Amit Kumar, Pooja Jha, Dayanand Sharma, Hesam Kamyab, and Edison Alejandro Villacreses Valencia. 2024. "Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review" Buildings 14, no. 8: 2495. https://doi.org/10.3390/buildings14082495

APA StyleKumar, G., Bansal, T., Haq, M., Sharma, U., Kumar, A., Jha, P., Sharma, D., Kamyab, H., & Valencia, E. A. V. (2024). Utilizing E-Waste as a Sustainable Aggregate in Concrete Production: A Review. Buildings, 14(8), 2495. https://doi.org/10.3390/buildings14082495