Changing Rules in Subway Tunnel Thermal Environment and Comprehensive Utilization of Waste Heat

Abstract

1. Introduction

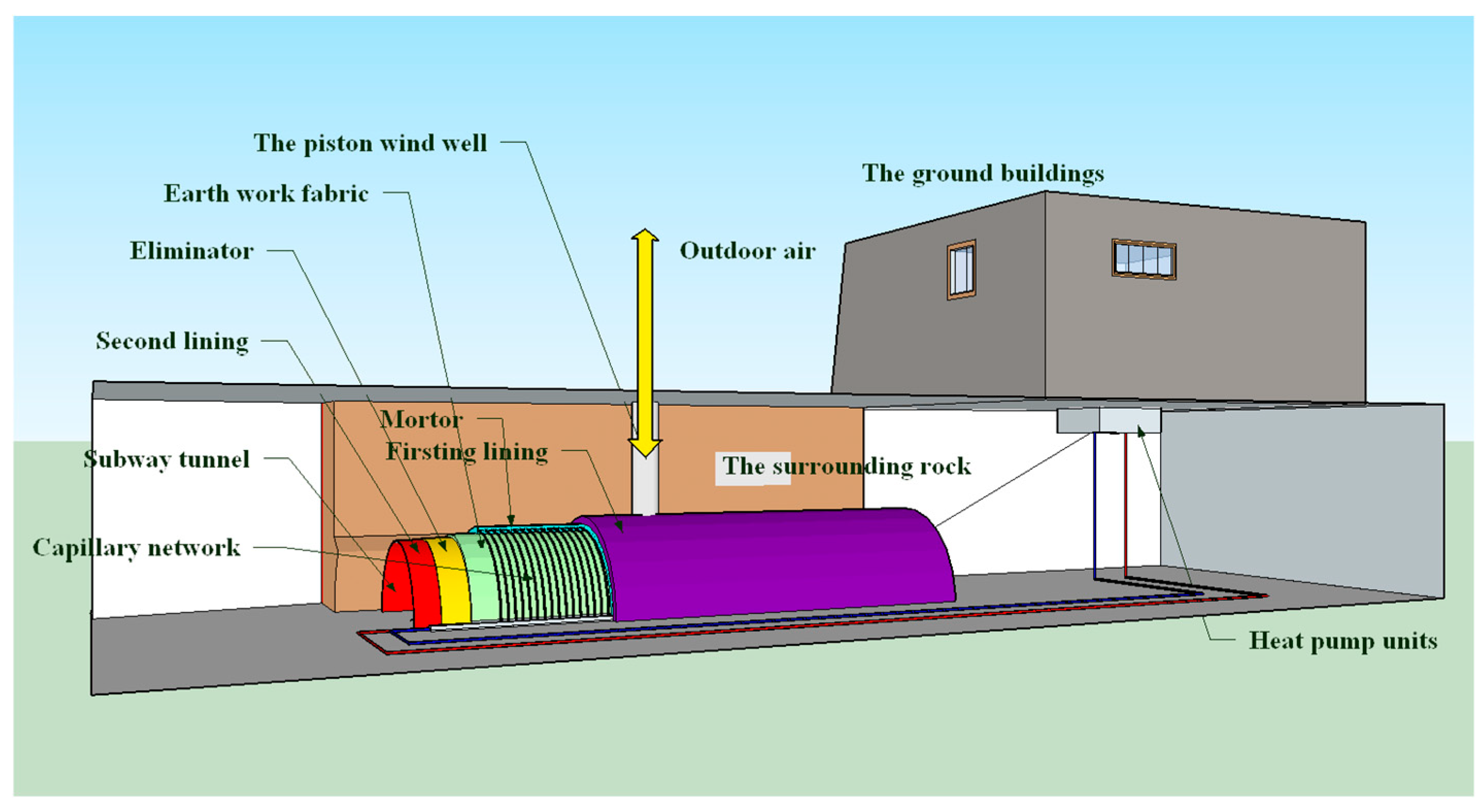

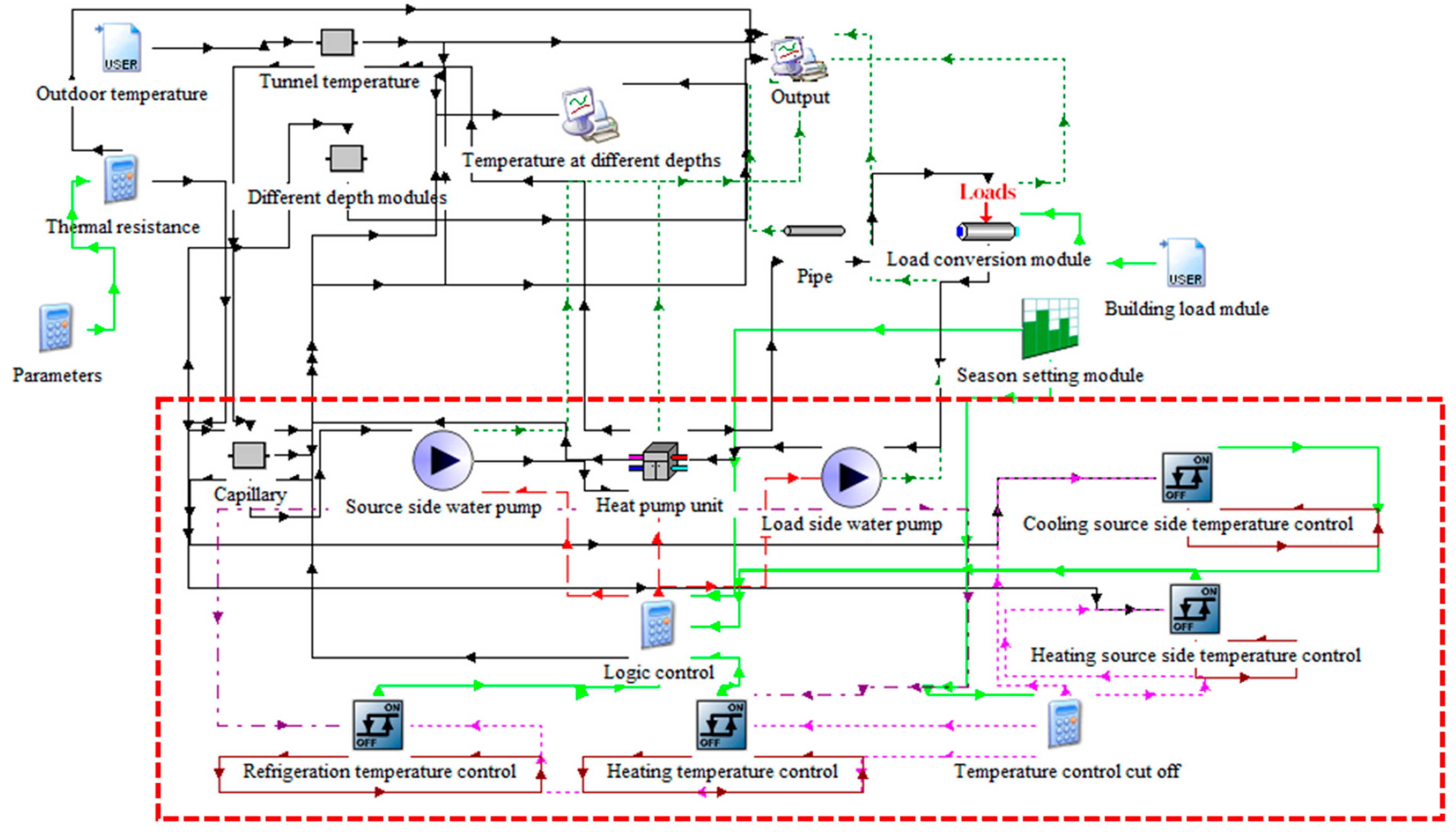

2. Method

2.1. Tunnel Air Temperature Module

- Heat generated by trains starting from rest

- 2.

- Heat generated by trains during acceleration and braking

- 3.

- Heat generated by train driving

- 4.

- Heat generated by air-conditioning units

- 5.

- Heat generated by auxiliary equipment

- 6.

- Heat generated by lighting equipment

- 7.

- Heat transfer of piston wind

2.2. Capillary Network Module

2.3. Season Setting Module

2.4. Other Modules

- Type823: Temperature module for different depths of subway tunnel surrounding rock temperature. Based on the surface temperatures of the surrounding rock obtained by the capillary module, the numerical calculation of the unsteady heat conduction is carried out using the finite difference method.

- Type668: Heat pump unit module. This is a device that converts low-grade energy to high-grade energy. Two signals are set in this module, one for heating and one for cooling; correspondingly, it can achieve both cooling and heating functions.

- Type682: Load conversion module. This is used to describe the process of fluid flow from the load to the water collector through the water divider and the system end device.

- Type114: Constant flow water pump module. The selection standard refers to the water pump connected to the heat pump unit in the project.

3. Results

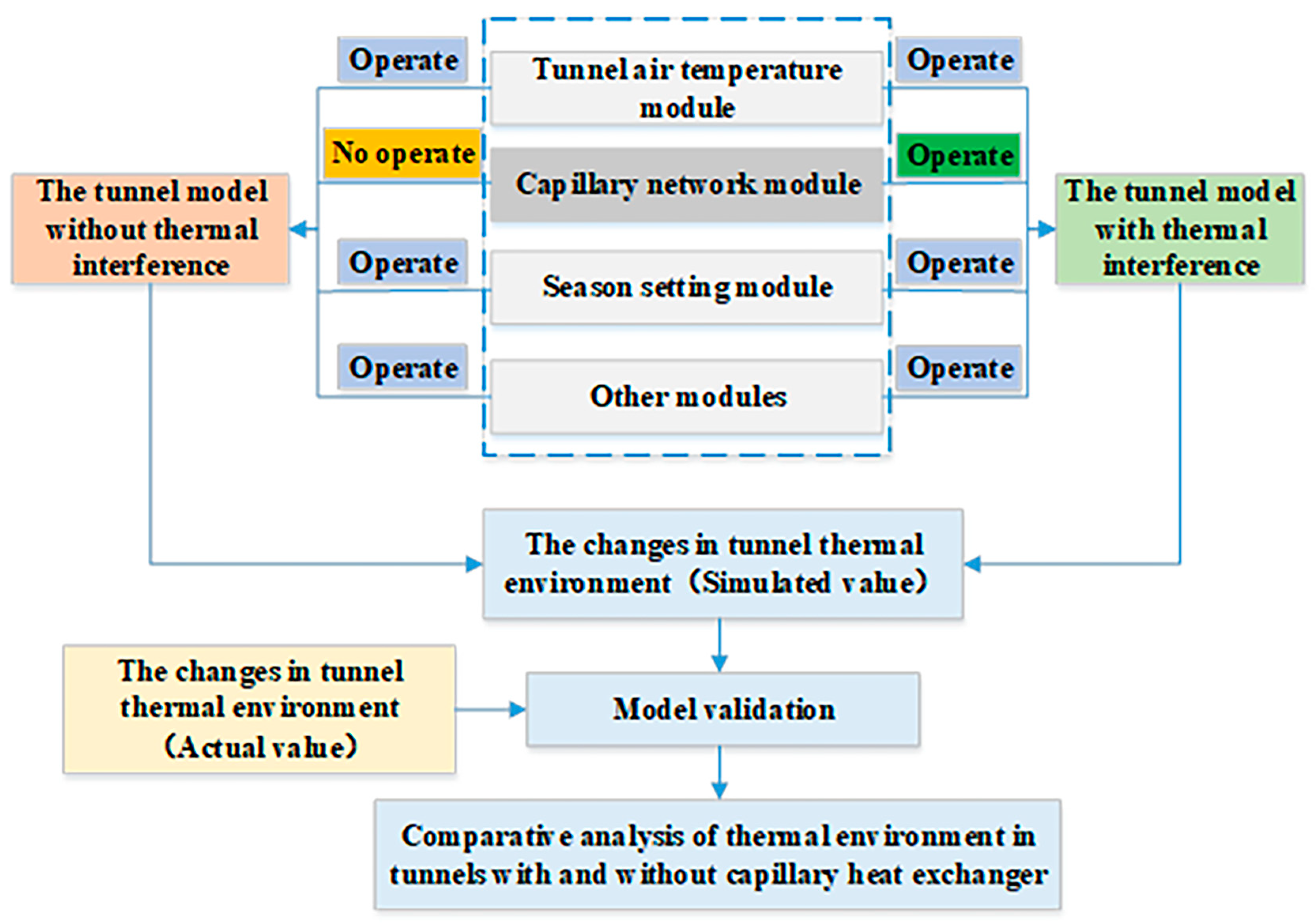

3.1. Study on the Law of the Tunnel with No Thermal Interference

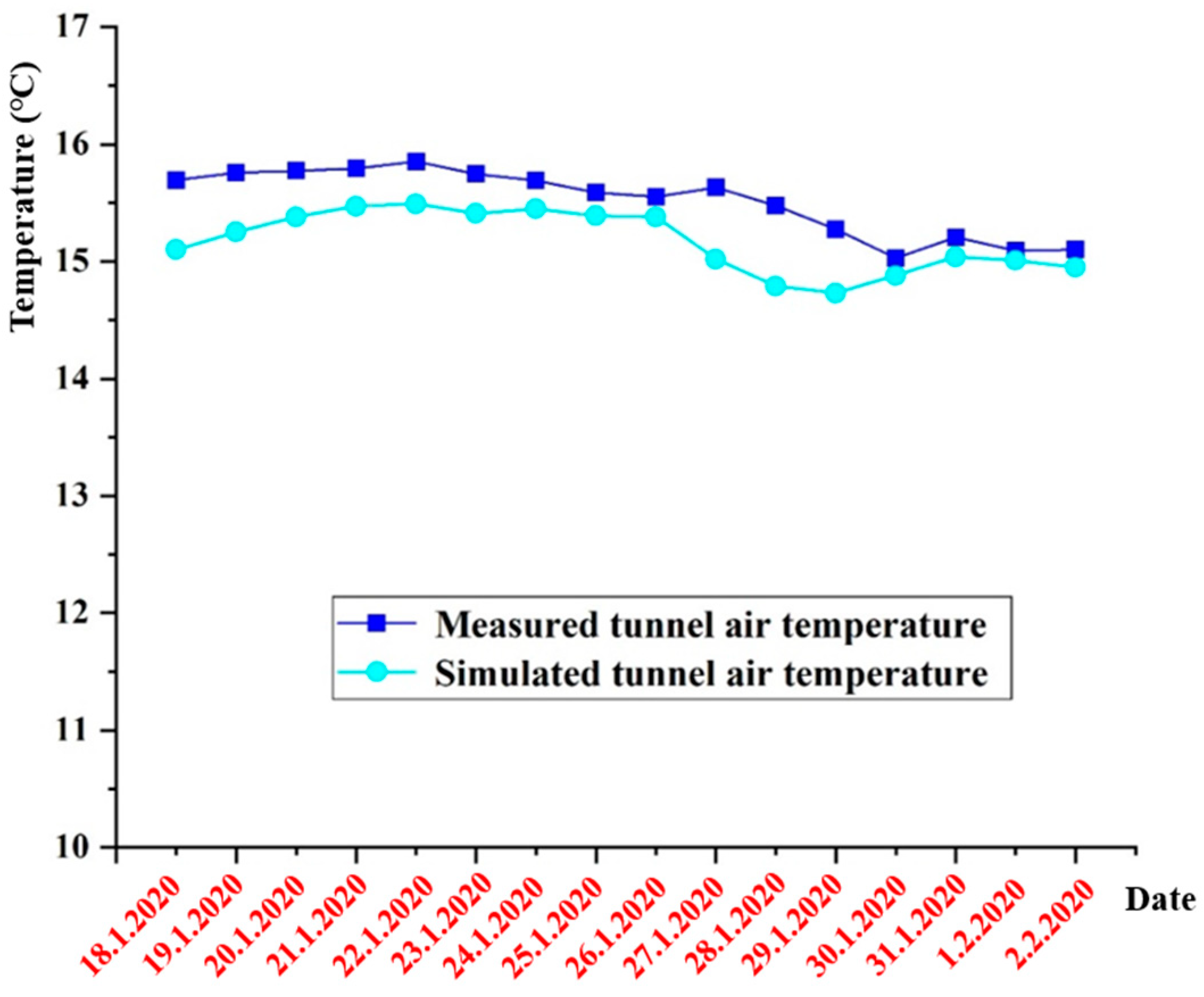

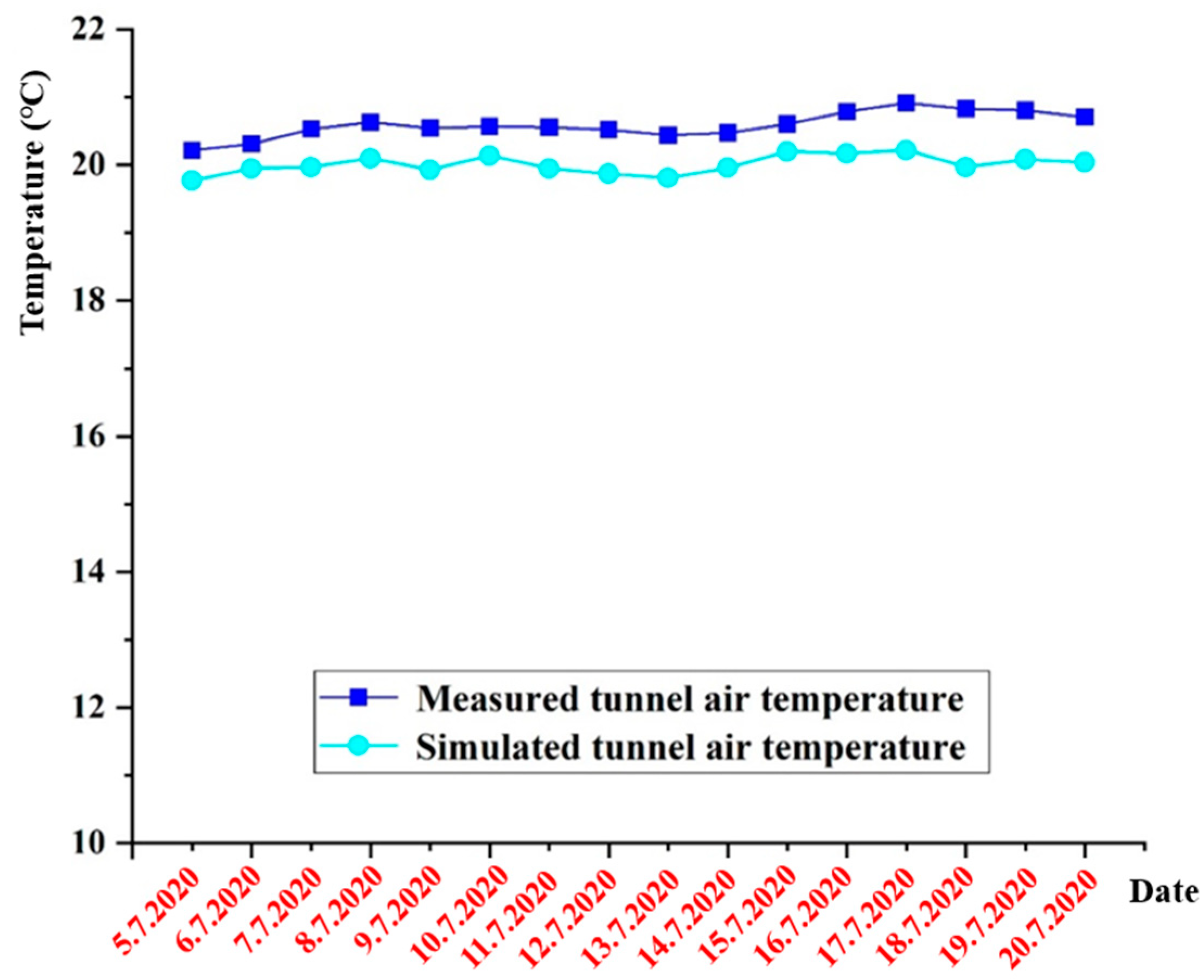

3.1.1. Validation of the Tunnel Model without Thermal Interference

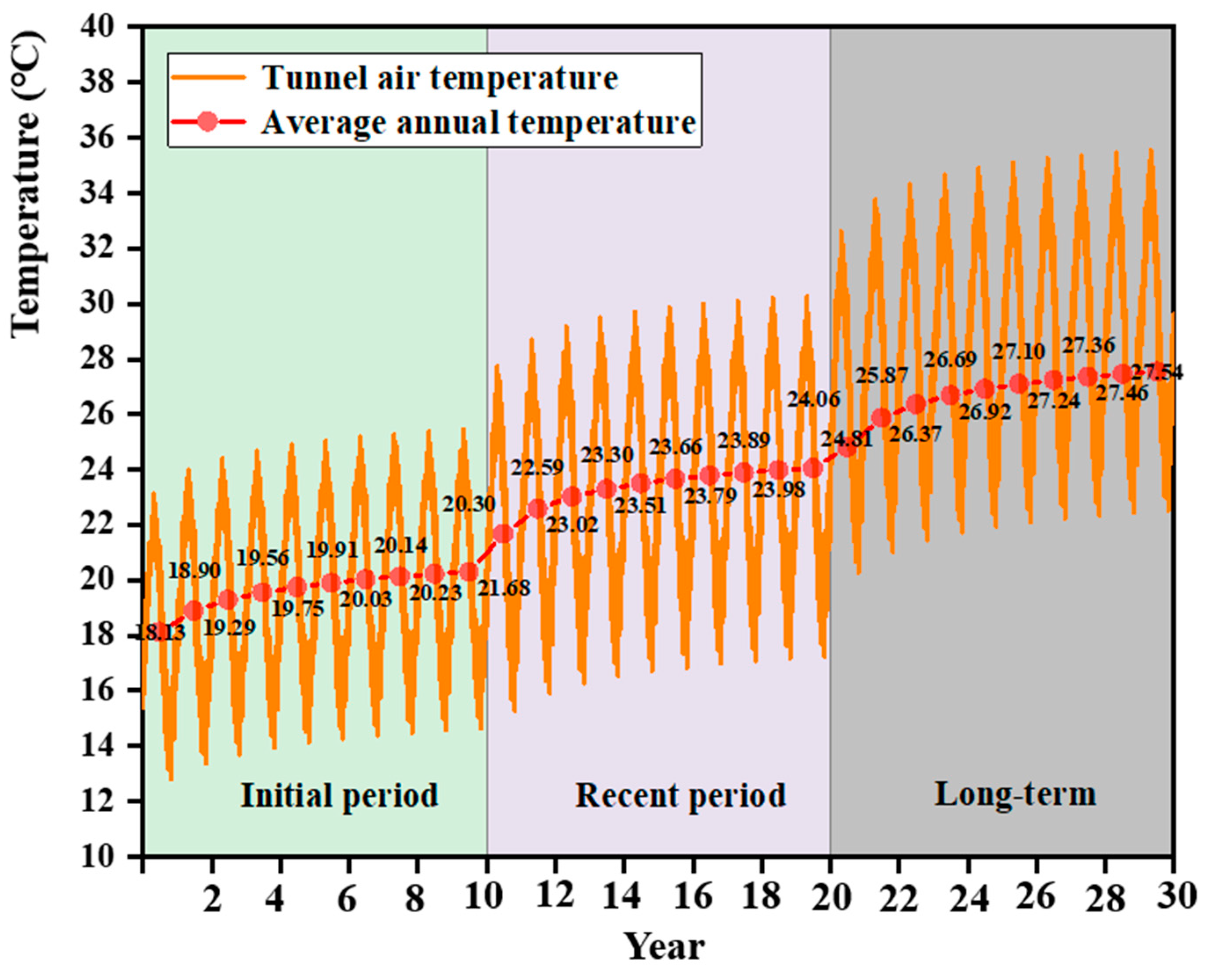

3.1.2. Analysis of Long-Term Laws of Tunnel Air Temperature (No Thermal Interference)

3.2. Laws of Tunnel Temperature with Thermal Interference

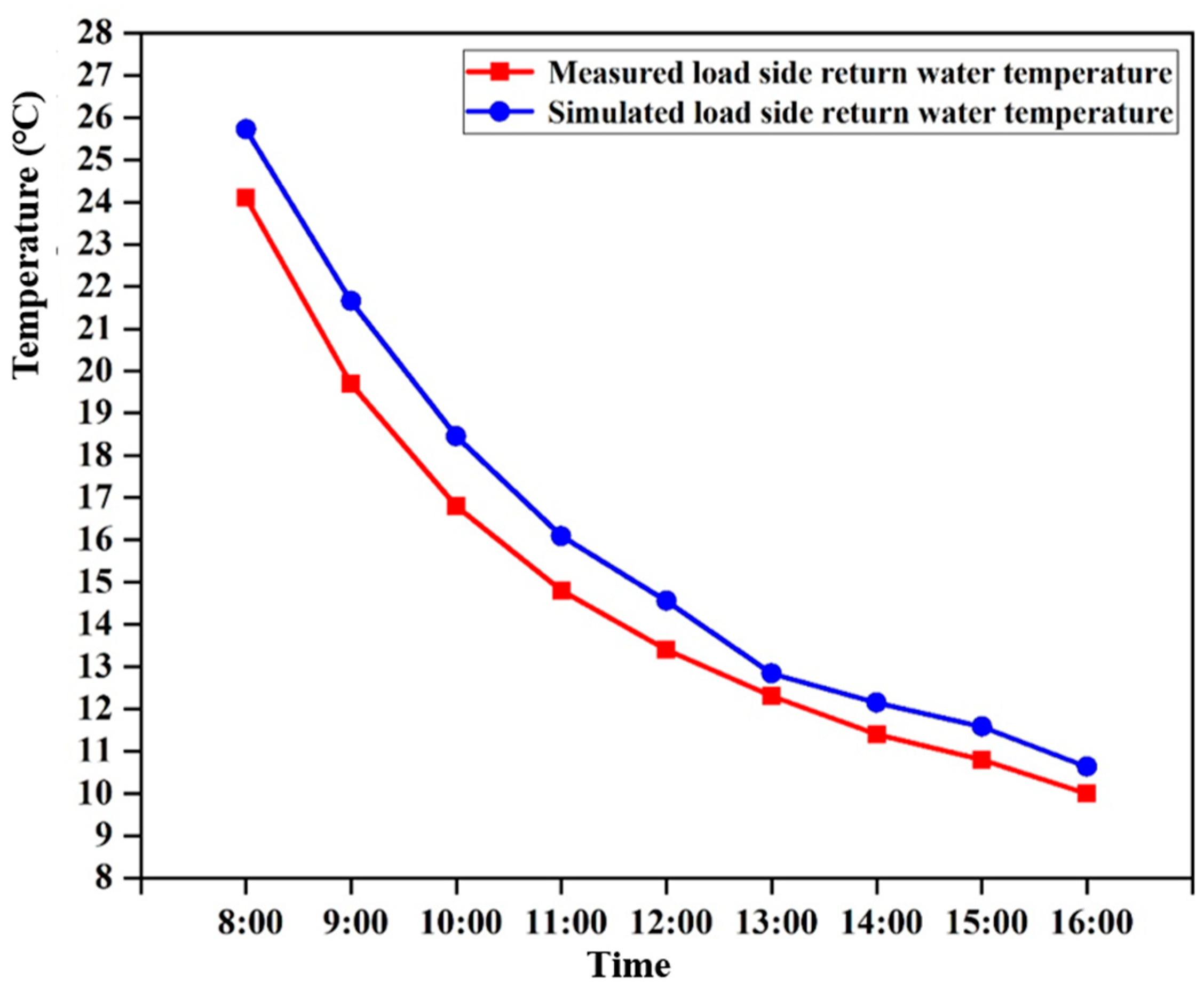

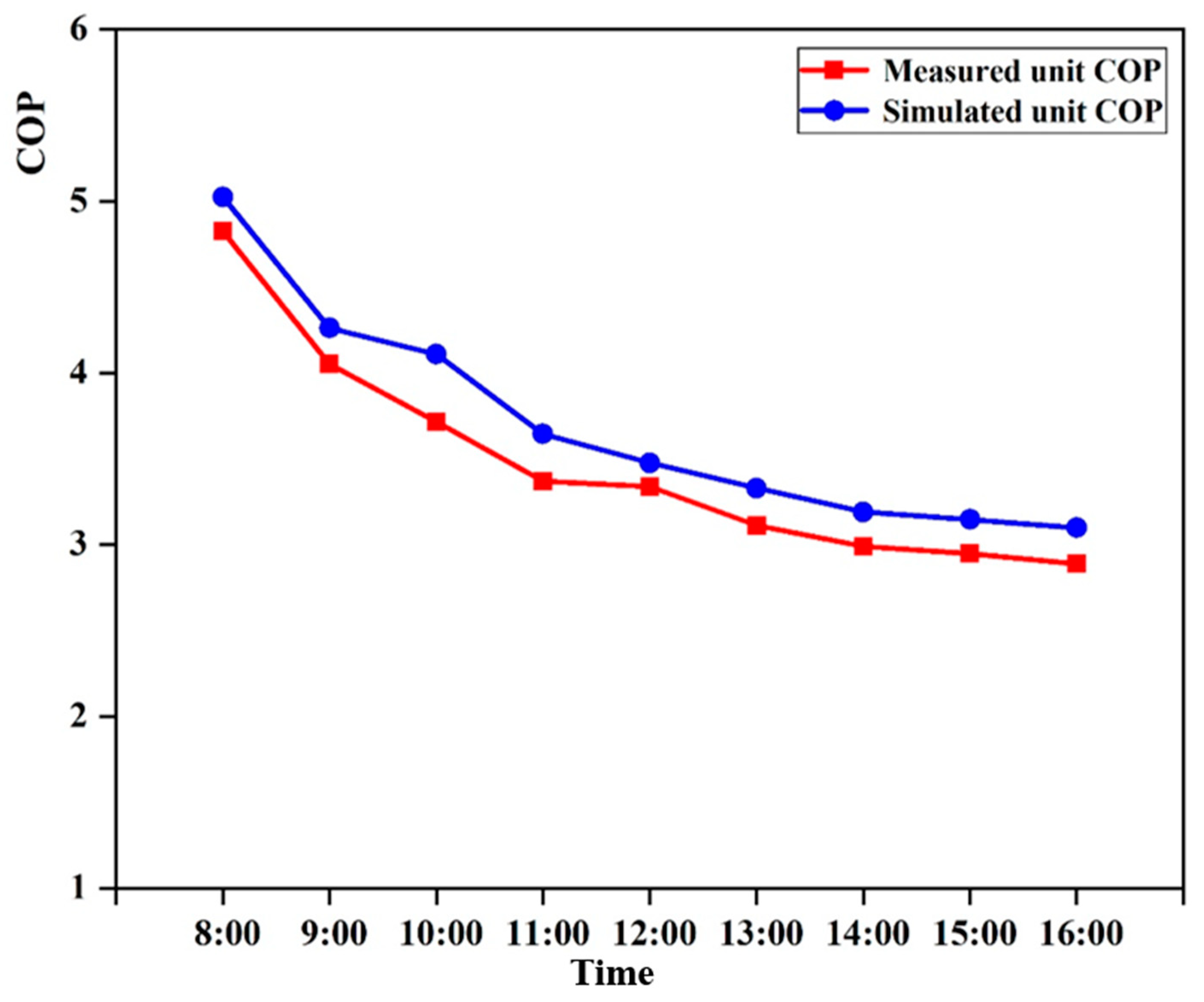

3.2.1. Validation of the Tunnel Model with Thermal Interference

3.2.2. Long-Term Analysis of Tunnel Air Temperature Changes (with Thermal Interference)

3.3. Comparative Analysis with and without a Capillary Heat Exchanger

4. Discussion

5. Conclusions

- (1)

- The validation results of the tunnel model with and without capillary heat exchangers are displayed. When there is no capillary heat exchanger, the relative error between the measured and simulated winter and summer temperatures in the tunnel is less than 5%. When there is a capillary heat exchanger, the relative error between the measured and simulated values of the user side return water temperature is less than 10%, and the average relative error between the measured and simulated values of the unit COP is 6.67%. From this, it can be concluded that the system model has high accuracy and reliability and can be applied for long-term operational analysis in the next step.

- (2)

- According to the simulation results, it was found that in the first 10 years of subway operation, the air temperature in tunnels with capillary heat exchangers was 2.18 °C lower than that in tunnels without capillary heat exchangers; in the next decade of subway operation, the air temperature in tunnels with capillary heat exchangers will be 0.29 °C lower than that in tunnels without capillary heat exchangers; during the 10 years of long-term subway operation, the air temperature in tunnels with capillary heat exchangers was 0.52 °C lower than that in tunnels without capillary heat exchangers. This result indicates that the use of capillary heat exchangers helps to reduce tunnel air temperature, thereby reducing thermal pollution.

- (3)

- When capillary heat exchangers are installed in subway tunnels, the anti-seasonal heat storage characteristics of the system lead to a significant increase in tunnel temperature in summer and a significant decrease in winter, with a slight decrease in annual average temperature. This indicates that capillary heat exchangers have significant effects on the treatment of thermal pollution in subway tunnels and the comprehensive utilization of waste heat.

- (4)

- The results of this study indicate that the use of capillary heat exchangers has significant benefits in reducing heat and thermal pollution in subway tunnels and can provide reference for improving the long-term thermal environment of subway interval tunnels. However, research on the influencing factors and design optimization of the entire system is limited. In future research, relevant parameters such as temperature changes at different depths of surrounding rock, flow velocity inside capillaries, capillary laying methods, laying lengths, and the application of capillary heat exchanger technology in engineering practice should be considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Transport for London. London Underground Environment Strategy 2008–2013; Transport for London: London, UK, 2011; Volume 9. [Google Scholar]

- Nakamura, H.; Yamana, T.; Matshushita, T.; Wakamatsu, T. Research on smoke control in underground structures. Tunn. Undergr. Space Technol. 1992, 7, 325–333. [Google Scholar] [CrossRef]

- Heffels, P. Improving fire protection in tunnels for commuter rail traffic. Tunn. Undergr. Space Technol. 1987, 2, 311–314. [Google Scholar] [CrossRef]

- Subway Environmental Design Handbook. Volume ii. Subway Environment Simulation Computer Program (ses). Part 2. Programmer’s Manual. 1975. Available online: https://trid.trb.org/View/42725 (accessed on 12 August 2024).

- Jun, K.J.; Hwang, Y.C.; Yune, C.Y. Field measurement of temperature inside tunnel in winter in Gangwon, Korea. Cold Reg. Sci. Technol. 2017, 143, 32–42. [Google Scholar] [CrossRef]

- Bidarmaghz, A.; Narsilio, G.A. Heat exchange mechanisms in energy tunnel systems. Geomech. Energy Environ. 2018, 16, 83–95. [Google Scholar] [CrossRef]

- Ninikas, K.; Hytiris, N.; Emmanuel, R.; Aaen, B.; Younger, P.L. Heat recovery from air in underground transport tunnels. Renew. Energy 2016, 96, 843–849. [Google Scholar] [CrossRef]

- Ninikas, K.; Hytiris, N.; Emmanuel, R.; Aaen, B. The Performance of an ASHP System Using Waste Air to Recover Heat Energy in a Subway System. Clean Technol. 2019, 1, 154–163. [Google Scholar] [CrossRef]

- Krasyuk, A.M.; Lugin, I.V.; Pavlov, S.A. Experimental research into air distribution in a terminal subway station. Tunn. Undergr. Space Technol. 2019, 85, 21–28. [Google Scholar] [CrossRef]

- Olander, L. Do Train Tunnels Need Ventilation Systems. Int. J. Vent. 2010, 9, 89–92. [Google Scholar] [CrossRef]

- Subway Environmental Design Handbook; Urban Mass Transportation Administration: Washington, DC, USA, 1976.

- Ninikas, K.; Hytiris, N.; Emmanuel, R.; Aaen, B. Heat energy from a shallow geothermal system in Glasgow, UK: Performance evaluation design. Environ. Geotech. 2017, 7, 274–281. [Google Scholar] [CrossRef]

- Ninikas, K.; Hytiris, N.; Emmanuel, R.; Aaen, B. Recovery and Valorisation of Energy from Wastewater Using a Water Source Heat Pump at the Glasgow Subway: Potential for Similar Underground Environments. Resources 2019, 8, 169. [Google Scholar] [CrossRef]

- Ke, M.T.; Cheng, T.C.; Wang, W.P. Numerical simulation for optimizing the design of subway environmental control system. Build. Environ. 2002, 37, 1139–1152. [Google Scholar] [CrossRef]

- Lassow, W.; Lustenader, E.L.; Schoch, K.F. A Thermal Model for the Evaluation of Subway Ventilation and Air Conditioning. IEEE Trans. Ind. Appl. 2007, IA-8, 504–513. [Google Scholar] [CrossRef]

- Zeng, Y.; Liu, K.; Zhou, X.; Fan, L. Tunnel temperature fields analysis under the couple effect of convection-conduction in cold regions. Appl. Therm. Eng. 2017, 120, 378–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X. Response-surface-model based on influencing factor analysis of subway tunnel temperature. Build. Environ. 2019, 160, 106140. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X. Monitoring and analysis of subway tunnel thermal environment: A case study in Guangzhou, China. Sustain. Cities Soc. 2020, 55, 102057. [Google Scholar] [CrossRef]

- Zhang, G.; Cao, Z.; Wang, W.; Mei, X.; Zhao, X.; Shen, S.; Na, T. Field test and numerical investigation on thermal environment of tunnel with air layer structure. Build. Environ. 2021, 203, 108105. [Google Scholar] [CrossRef]

- Yang, B.; Sun, Y.; Yao, Y.; Ni, L. Field measurement and analysis of subway tunnel thermal environment in severe cold region. Build. Environ. 2023, 243, 110629. [Google Scholar] [CrossRef]

- Teodosiu, C.I.; Ilie, V.; Dumitru, R.G.; Teodosiu, R.S. Assessment of ventilation efficiency for emergency situations in subway systems by CFD modeling. Build. Simul. 2016, 9, 319–334. [Google Scholar] [CrossRef]

- Juraeva, M.; Ryu, K.J.; Jeong, S.H.; Song, D.J. Influence of mechanical ventilation-shaft connecting location on subway tunnel ventilation performance. J. Wind. Eng. Ind. Aerodyn. 2013, 119, 114–120. [Google Scholar] [CrossRef]

- Vidmar, P.; Petelin, S.; Luin, B. Upgrade of a transverse ventilation system in a bi-directional tunnel. Therm. Sci. 2012, 16, 1067–1080. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, W.; Fan, Y.; Hu, S. Coupling effect between tunnel lining heat exchanger and subway thermal environment. Renew. Energy 2023, 217, 119165. [Google Scholar] [CrossRef]

- Brandl, H. Energy foundations and other thermo-active ground structures. J. Géotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- Liu, N. Study on the Law and Treatment Strategy of Thermal Pollution in Subway Tunnel; Qingdao University of Technology: Qingdao, China, 2018. [Google Scholar]

- Liu, G.; Li, C.; Hu, S.; Ji, Y.; Tong, Z.; Wang, Y.; Tong, L.; Mao, Z.; Lu, S. Study on heat transfer model of capillary exchanger in subway source heat pump system. Renew. Energy 2020, 150, 1074–1088. [Google Scholar] [CrossRef]

- Ren, M.; Yuan, Y.; Cao, X.; Sun, L.; Jiang, F. Numercial analysis on the thermal performance of capillary heat exchange system in metro running tunnel. Energy Built Environ. 2020, 1, 207–214. [Google Scholar] [CrossRef]

- Tong, L.; Liu, N.; Hu, S.; Ji, Y.; Lu, S.; Liu, G.; Tong, Z. Study on key design parameters of subway source heat pump system with capillary exchanger. Renew. Energy 2021, 164, 183–193. [Google Scholar] [CrossRef]

- Ji, Y.; Wu, W.; Qi, H.; Wang, W.; Hu, S. Heat transfer performance analysis of front-end capillary heat exchanger of a subway source heat pump system. Energy 2022, 246, 123424. [Google Scholar] [CrossRef]

- Tong, Z.; Guan, Y.; Cao, T.; Ji, Y.; Hu, S.; Liu, G.; Liu, N.; Fan, Y. Onsite measurement and performance analysis of capillary heat pump system used in subway tunnels. Appl. Therm. Eng. 2022, 204, 118008. [Google Scholar] [CrossRef]

- Ji, Y.; Shen, S.; Wang, X.; Zhang, H.; Qi, H.; Hu, S. Impact of groundwater seepage on thermal performance of capillary heat exchangers in subway tunnel lining. Renew. Energy 2024, 227, 120551. [Google Scholar] [CrossRef]

- Bidarmaghz, A.; Narsilio, G.A.; Buhmann, P.; Moormann, C.; Westrich, B. Thermal interaction between tunnel ground heat exchangers and borehole heat exchangers. Geomech. Energy Environ. 2017, 10, 29–41. [Google Scholar] [CrossRef]

- Zheng, C. Research on Thermal Environment and Heat Dissipation Methods of Subway Station Tunnels in Guangzhou Area; Guangzhou University: Guangzhou, China, 2020. [Google Scholar]

- Cheng, Y. Research on Prediction Model of Thermal Environment of Metro Capillary Heat Pump; Qingdao University of Technology: Qingdao, China, 2018. [Google Scholar]

- Liang, G.; Huang, L. Analysis of Energy Consumption and Renewable Energy Saving Effect of Metro B-type Train. J. Urban Mass Transit. 2016. [Google Scholar]

- Wu, W. Study on Thermal Characteristics and Ventilation System of Subway Tunnel in Severe Cold Region; Harbin Institute of Technology: Harbin, China, 2018. [Google Scholar]

- Gong, F. Subway Tunnel Temperature Characteristics and Its Impact on the Site Environment; Chongqing University: Chongqing, China, 2014. [Google Scholar]

- Qi, J.; Zhao, L.; Wang, J.; Li, D.; Guo, Y.; Deng, B. Measurement and characteristic analysis of piston wind in subway tunnels. J. Railw. Sci. Eng. 2016, 13, 740–747. [Google Scholar]

- Benz, S.A.; Bayer, P.; Menberg, K.; Jung, S.; Blum, P. Spatial resolution of anthropogenic heat fluxes into urban aquifers. J. Sci. Total Environ. 2015, 524–525, 427–439. [Google Scholar] [CrossRef] [PubMed]

- Tong, L.; Hu, S.; Lu, S.; Wang, Y. Study on heat transfer performance of metro tunnel capillary heat exchanger—ScienceDirect. Sustain. Cities Soc. 2019, 45, 683–685. [Google Scholar] [CrossRef]

| Symbol | Parameter | Value | Unit |

|---|---|---|---|

| Starting resistance coefficient | 2 | / | |

| W | Train weight | 159.6 | T |

| Train travel distance during the starting phase | 10 | m | |

| Train speed at the beginning of braking | 22.8 | m/s | |

| Train speed at the end of braking | 0 | m/s | |

| Train travel distance | 2250 | m | |

| Train speed at a constant speed | 19.44 | m/s | |

| n | The number of train formations | 4 | / |

| Air conditioner condensation heat generation | 35 | kJ | |

| t | Train operation hours | 138 | s |

| Motor output power | 37.5 | t | |

| Load factor | 0.85 | / | |

| Motor efficiency | 0.921 | / | |

| Interval tunnel lighting heat generation | 6000 | W/km | |

| Outdoor air density | 1.29 | kg/m3 | |

| A | Piston air shaft area | 20 | m2 |

| v | Tunnel wind speed | 3 | m/s |

| Meaning | Value | Unit |

|---|---|---|

| Thickness of second lining | 0.29 | m |

| Thickness of manger plate | 0.01 | m |

| Thickness of geotextile | 0.002 | m |

| Thickness of motar | 0.1 | m |

| Thickness of pipe wall | 0.00085 | m |

| Thickness of first lining | 0.22 | m |

| Thickness of the water layer | 0.0026 | m |

| Thermal conductivity of 2nd and 1st lining | 3.2 | W/(m·K) |

| Thermal conductivity of manger plate | 1.5 | W/(m·K) |

| Thermal conductivity of geotextie | 0.5 | W/(m·K) |

| Thermal conductivity of motar | 0.97 | W/(m·K) |

| Thermal conductivity of capillary pipe wall | 0.24 | W/(m·K) |

| Thermal conductivity of the water | 0.62 | W/(m·K) |

| Date | Season | Hours | Output Signal |

|---|---|---|---|

| 5.1–6.15 | Transition season | 1–1080 | 4 |

| 6.16–9.30 | Cooling season | 1080–3672 | 3 |

| 9.30–11.15 | Transition season | 3672–4776 | 4 |

| 11.16–4.5 | Heating season | 4776–8160 | 2 |

| 4.6–4.30 | Transition season | 8160–8760 | 4 |

| Time | Water Supply Temperature On Load Side | Water Return Temperature On Load Side | ||||

|---|---|---|---|---|---|---|

| Measured Value/°C | Simulated Value/°C | Relative Error % | Measured Value/°C | Simulated Value/°C | Relative Error % | |

| 8:00 | 18.8 | 19.85 | 5.56 | 24.1 | 25.72 | 6.72 |

| 9:00 | 14.9 | 15.95 | 7.07 | 19.7 | 21.65 | 9.92 |

| 10:00 | 12.4 | 13.47 | 8.63 | 16.8 | 18.45 | 9.2 |

| 11:00 | 10.8 | 11.41 | 5.63 | 14.8 | 16.09 | 8.72 |

| 12:00 | 9.5 | 10.28 | 8.20 | 13.4 | 14.56 | 8.66 |

| 13:00 | 8.6 | 9.31 | 8.26 | 12.3 | 12.84 | 4.39 |

| 14:00 | 7.9 | 8.54 | 8.08 | 11.4 | 12.15 | 6.58 |

| 15:00 | 7.3 | 7.99 | 9.45 | 10.8 | 11.58 | 7.22 |

| 16:00 | 6.8 | 7.17 | 5.39 | 10 | 10.63 | 6.30 |

| Species | With Capillary Heat Exchanger | Without Capillary Heat Exchanger | |

|---|---|---|---|

| Temperature (°C) | |||

| Maximum | 23.68 | 21.71 | |

| Minimum | 9.15 | 12.57 | |

| Average | 15.81 | 17.06 | |

| Species | With Capillary Heat Exchanger | Without Capillary Heat Exchanger | |

|---|---|---|---|

| Temperature(°C) | |||

| Maximum | 30.95 | 32.24 | |

| Minimum | 15.09 | 22.97 | |

| Average | 22.54 | 27.54 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, L.; Zhang, M.; Hu, S.; Ji, Y. Changing Rules in Subway Tunnel Thermal Environment and Comprehensive Utilization of Waste Heat. Buildings 2024, 14, 2524. https://doi.org/10.3390/buildings14082524

Tong L, Zhang M, Hu S, Ji Y. Changing Rules in Subway Tunnel Thermal Environment and Comprehensive Utilization of Waste Heat. Buildings. 2024; 14(8):2524. https://doi.org/10.3390/buildings14082524

Chicago/Turabian StyleTong, Li, Mingzhi Zhang, Songtao Hu, and Yongming Ji. 2024. "Changing Rules in Subway Tunnel Thermal Environment and Comprehensive Utilization of Waste Heat" Buildings 14, no. 8: 2524. https://doi.org/10.3390/buildings14082524

APA StyleTong, L., Zhang, M., Hu, S., & Ji, Y. (2024). Changing Rules in Subway Tunnel Thermal Environment and Comprehensive Utilization of Waste Heat. Buildings, 14(8), 2524. https://doi.org/10.3390/buildings14082524