Abstract

Large underground spaces are complex and huge, with problems such as fragmented data that cannot be shared, outdated management methods, and high operation and maintenance costs. The digitization of building information and the use of digital twin technology can effectively improve the efficiency of building operation and maintenance. Using information technology to build a digital-twin-based operation and maintenance management system, the huge and discrete data and equipment system information are effectively integrated and explored for application. First, we analyze the shortcomings of the traditional delivery and operation and maintenance methods and introduce the necessity of a new method of operation and maintenance management based on digital twin; then, we divide the operation and maintenance information of the construction project into four major categories of spatial information and eight major categories of equipment information and complete the coding work, and the categorized data serve as the data basis for operation and maintenance; second, we develop a digital twin operation and maintenance management platform based on the operation and maintenance data of BIM; finally, we carry out case validation for the three major constructions. Finally, case validation is carried out for three major buildings and a large underground space and the practical application shows that the operation and maintenance management system based on digital twin technology provides technical guarantee for decentralized information and system integration management and the information management quality and efficiency of the operation and maintenance process are effectively improved. Through the practice of summarizing the experience, which is worth learning, we aim to create a large underground space operation and maintenance management method to provide a reference.

1. Introduction

With the rapid development of the economy and the rapid increase in the urban population, the planning and construction of large-scale underground space has become one of the key areas of modern urban development [1]. Underground space can be flexibly used for various different purposes, including transport systems, municipal systems, commercial and recreational venues, etc. [2], and its construction and management process is bound to have a huge amount of complex building information [3]. However, the carrier of building information is mainly paper-based information, with electronic information as a supplement, limited by the fact that paper-based information is not conducive to the nature of the information transfer defects, which causes late building operation and maintenance, linking to the plight of inefficiency, but also makes it difficult to effectively use the building information and data [4], and traditional building operation and maintenance is no longer applicable to the urgent need to incorporate new intelligent technology to enhance the level of operation and maintenance.

Although BIM and digital twin technology have been studied in the field of building O&M management, there is still a lack of exploration of large underground spaces as the objects of research, and there are still the following shortcomings in the process of building O&M management: (1) O&M information is mainly paper-based, and the utilization efficiency is low; (2) management personnel are constantly moving, and O&M information is lost along with the mobility of the management personnel, which leads to difficulties in tracing the relevant O&M information; (3) there is a lack of appropriate building O&M information classification and coding standards from the perspective of building physical entities; and (4) there is a lack of effective O&M theories as guides, causing low efficiency in entity O&M management.

This paper proposes a digital-twin-based digital O&M management method for large underground spaces, aiming to solve the problems of fragmented data, obsolete management methods, and high O&M costs in traditional O&M methods. By dividing the operation and maintenance information of construction projects into four categories of spatial information and eight categories of equipment information, and completing the coding work, a digital twin operation and maintenance management platform based on BIM is developed, and case validation is carried out for large underground spaces of three major buildings. The practical application shows that the method effectively improves the information management quality and efficiency of the operation and maintenance process.

This paper is structured as follows: Section 2 introduces the research progress, including Building Information Modeling (BIM) and digital twin technology in the field of building O&M; Section 3 introduces the research methodology, including the research framework, the classification method for building O&M information, the data collection and processing methodology, and the digital twin building O&M management methodology based on BIM; Section 4 verifies the validity of the proposed methodology through an engineering case; Section 5 discusses the effectiveness, limitations, and future perspectives of the methodology; and Section 6 summarizes the full paper and presents conclusions.

2. Research Progress

In recent years, Building Information Modeling (BIM) has been widely used in the construction industry as an effective method to improve the quality of operation and maintenance of green buildings [5]. BIM is widely used to automate O&M workflows, including building information visualization, multi-departmental communication and coordination, and O&M log document management [6]. Although the field of BIM-based intelligent O&M is still in its infancy, many projects have already established BIM-based automated office platforms.

Building Information Modeling (BIM) has the potential to drive and transform facility O&M by providing facility managers with a platform to retrieve, analyze, and manipulate building information in a digital 3D environment [7]. Project O&M based on BIM technology is limited by the barriers of insufficient techniques and lack of policies and has not yet been widely promoted [8]. Wei et al. [9] outlined an intelligent building operation system (IBMS + BIM + FM) guided by “decentralised control and centralised management” to improve the sharing and management of information resources. Wang et al. [10] established a method to quantify the fire risk index of a building applied in BIM technology to quickly and reliably assess the fire risk of the target building model and improve the building’s fire operation and maintenance capability. Liu et al. [11] developed an integrated method for equipment operation and maintenance based on BIM for railway signal equipment operation and maintenance challenges so that the railway signal equipment has the functions of equipment positioning and spatial analysis information query, which will improve the efficiency of equipment operation and maintenance and the level of scientific decision making.

Digital twin technology enables the real-time mapping of information between physical entities and virtual models, thus shifting the focus of research from complex physical entities to information-integrated virtual models and improving research efficiency. There is often confusion between DT modeling and BIM, so it is important to clarify that BIM models are static representations of geometrical and parametric information whereas DTs are dynamic systems, connected to real-time information, designed to simulate the systems they represent [12]. Building Information Modeling (BIM) is the basis for the development and application of Smart Cities and digital twins [13]. These datasets are also considered to be valuable information for the efficient management and reconstruction of buildings during the operation and maintenance phases. Therefore, it can be considered that digital twin technology is an enhancement and deepening of BIM technology in the dynamic application of information.

Digital twin technology has been investigated in conjunction with BIM technology for building O&M processes. Rodríguez-Alonso et al. [14] investigated a framework for a digital twin platform for wastewater treatment plant O&M processes that can optimize the operation and maintenance processes of a wastewater treatment plant system. Wang et al. [15] proposed a DT-based framework for a sustainable building maintenance system, GBMS (DT-GBMS), to help operations teams address the lack of information and automation in sustainable building maintenance. Lu et al. [16] developed a DT system architecture designed for building and city levels that supports both effective data querying and analysis as well as a decision-making process in operation management. Jiao et al. [17] proposed a sustainable digital twin (DT) model for building infrastructure operation and maintenance, called SDTOM-BI. The proposed method is able to identify the key factors during the in-service phase to achieve sustainable operation and maintenance of building infrastructure. Finally, it is illustrated and validated by an application in a real gymnasium. Li et al. [18] constructed an energy framework for buildings using intelligent monitoring based on digital twin technology. The framework function is achieved through Building Information Modeling (BIM) and intelligent sensors with Internet of Things (IoT) technology, and it has been proven in practice that 30% of building energy saving can be achieved through the framework. Yu, G et al. [19] proposed a digital twin conceptual framework for proactive maintenance that integrates knowledge-driven, combinatorial reasoning methods to automatically generate maintenance solutions and proved the effectiveness of fault prediction and condition prediction in tunnel engineering practice. The strengths and gaps in the current state of research by relevant scholars are shown in Table 1. Table 1 illustrates that although the current state of research by relevant scholars possesses the advantages of optimizing the O&M process and the basic theory of O&M, there are gaps in the classification and coding standards of building O&M information and in the digitization of O&M information, and this paper aims to provide a reference for the solution of these two gaps.

Table 1.

Strengths and gaps in the current state of research by relevant scholars.

3. Methods

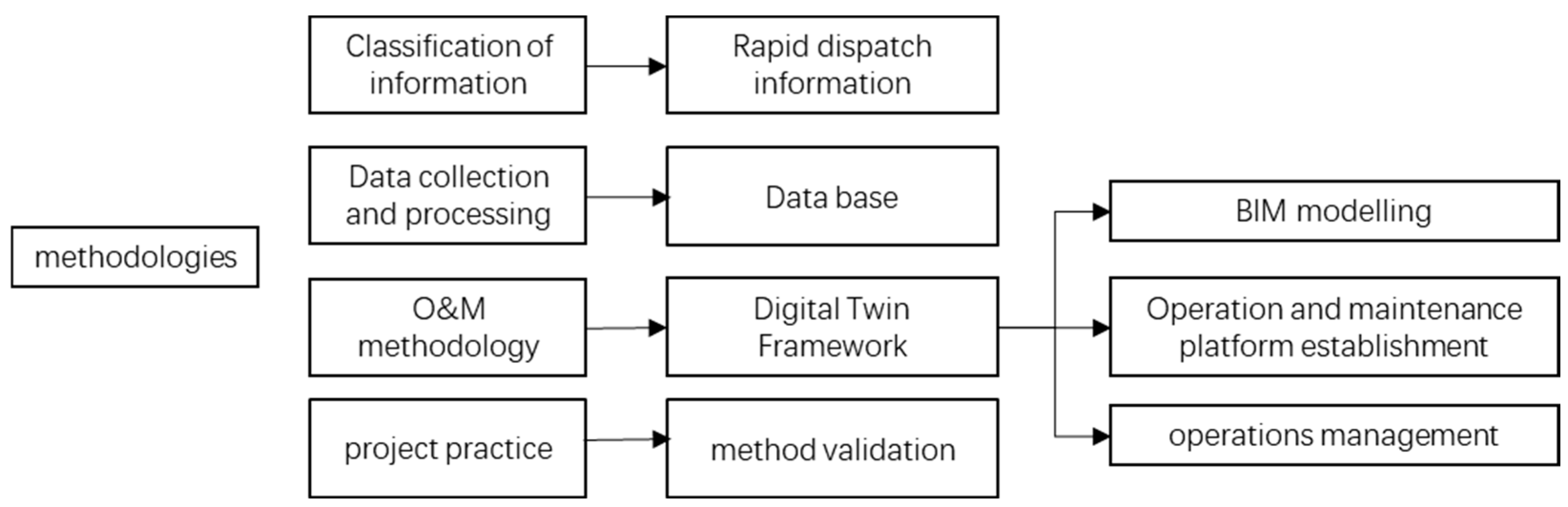

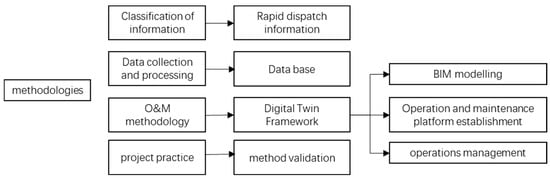

Firstly, information classification and coding are carried out to prepare for the effective classification of O&M data. Second, the O&M data are collected and analyzed and a corresponding O&M database is established as the data basis for O&M management. Next, the digital twin five-dimensional model of building O&M is proposed as a guide for the O&M method.

3.1. Research Framework

The research framework of this paper is illustrated in Figure 1. Initially, the classification method for building O&M information is introduced, providing a foundation for the digital twin O&M platform to efficiently retrieve information at a later stage. Subsequently, the methods for collecting and processing building O&M data are detailed, with the processed data being imported into an SQL database, forming the data basis for the digital twin O&M platform. Following this, the paper elaborates on the digital twin building O&M management method based on Building Information Modeling (BIM). The framework of the digital twin model is first constructed as a methodological guide for practical O&M activities. Subsequently, the BIM model is developed in accordance with this guide, structuring the functions of the O&M platform, describing the O&M process, and enabling users to view O&M information on the platform. This O&M information serves as the foundation for O&M decision making and execution. Finally, the proposed O&M method is applied and validated for a large underground space project at the Beijing Urban Vice Center.

Figure 1.

Research framework.

3.2. Building Operation and Maintenance Information Classification and Coding Methods

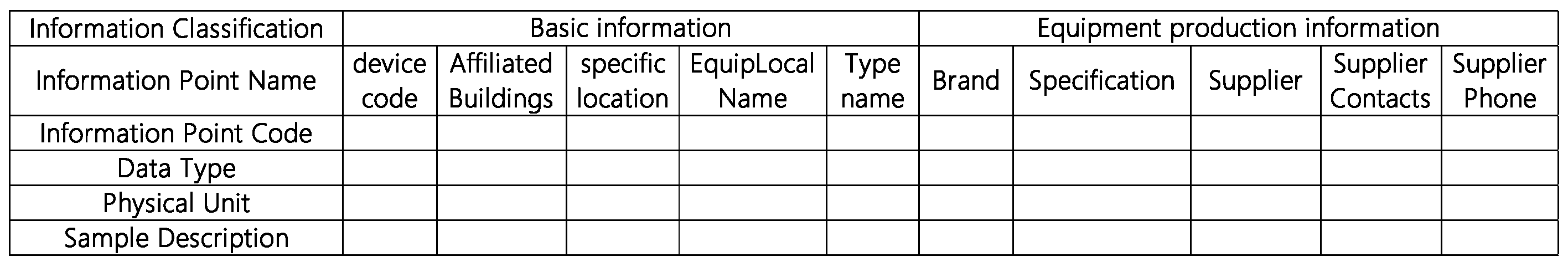

The information to be collected and utilized is categorized into two primary components: building and spatial information and O&M equipment information. Spatial information encompasses four major categories while O&M information comprises eight major categories. These categories serve as the foundation for developing a data collection template, which acts as a source of basic data. The detailed categorization of O&M information is presented in Table 2.

Table 2.

Operations and maintenance information collection.

The project implements a systematic coding and classification approach for the collected O&M data to facilitate digital delivery and support subsequent O&M activities. Equipment production information is recorded based on relevant incoming material data. On-site installation information requires contributions from on-site technical personnel, including videos, photos, and other relevant information, all of which are stored systematically.

Building and spatial information encompasses both basic and detailed room data. Basic information includes room name, number, and partition while detailed information covers net, height, area, volume, functional use, and decoration status.

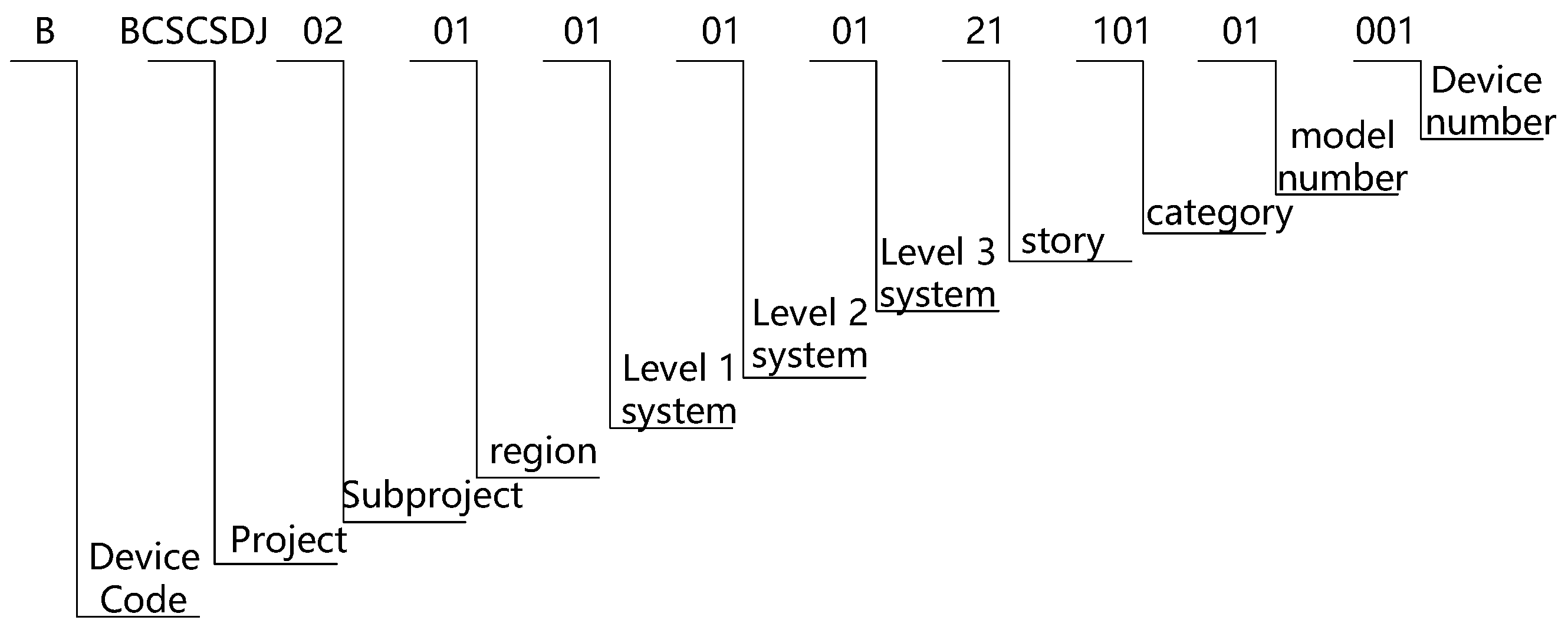

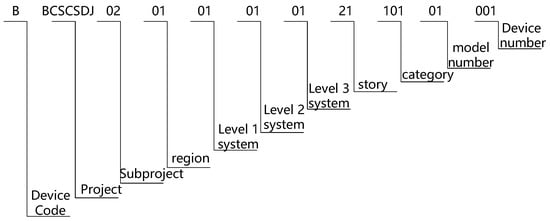

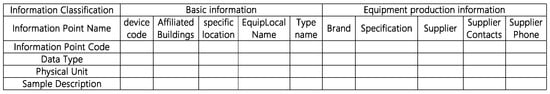

The O&M equipment information is organized using a coding classification system. According to the design drawings of professional equipment components, a 20-digit code across 11 layers has been established. This coding structure is used for entering professional equipment information. The equipment code format is as follows: equipment code (B) + item (BCSCSDJ) + number (20 digits), totaling 11 layers. The coding structure for O&M information is illustrated in Figure 2 while the detailed contents of O&M equipment information are depicted in Figure 3.

Figure 2.

O&M information coding structure.

Figure 3.

O&M equipment inclusion information.

3.3. Data Collection and Processing

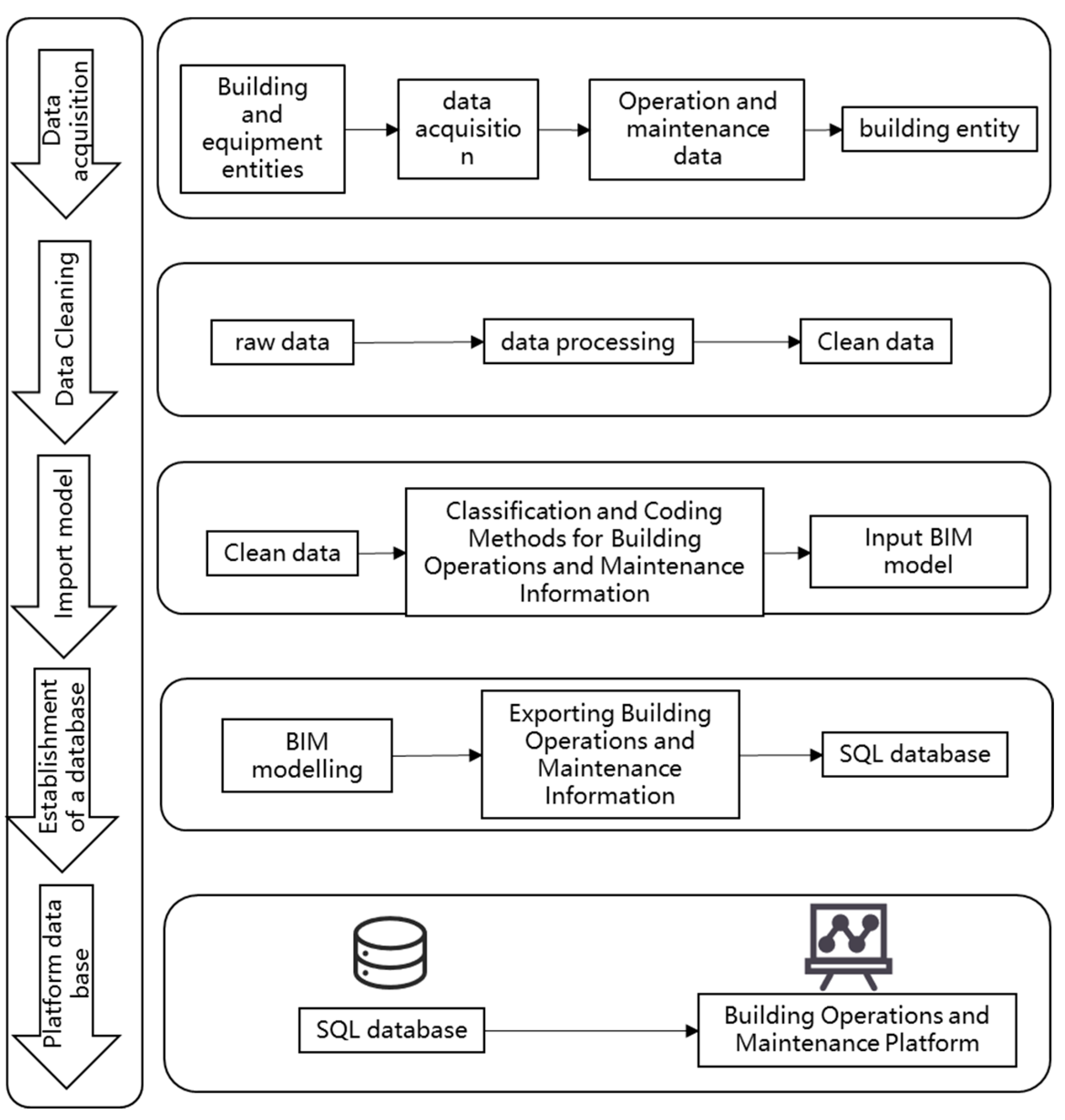

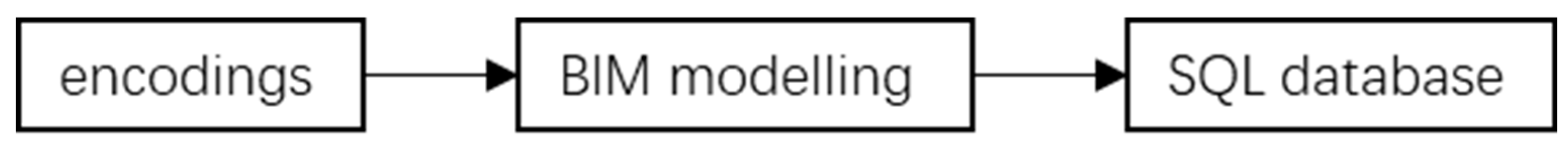

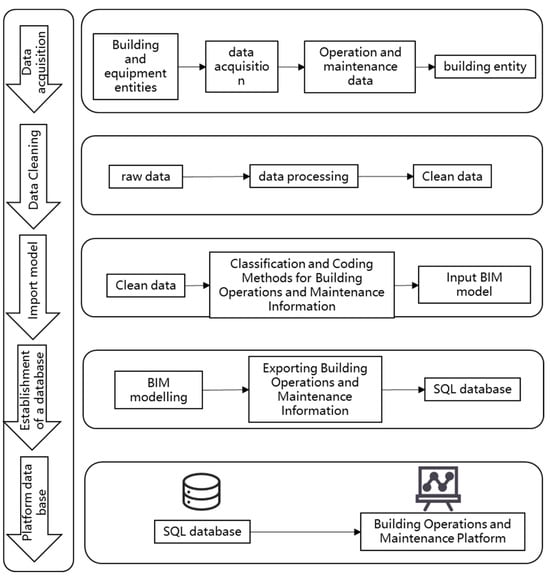

The primary objective is to collect, preprocess, mine, merge, classify, and manage the delivery data for the platform. Initially, data collection is conducted according to the classification and coding method for building O&M information. Following this, the collected data are preprocessed to remove invalid entries and merge duplicate data of the same type, ensuring the validity and stability of the delivery data. Data mining algorithms are then applied to label the delivery data with multiple tags based on the classification and coding method for building O&M information. Finally, an SQL database is created, into which the tagged building O&M data are imported. This SQL database serves as the primary source for data scheduling within the O&M platform. The data processing process is shown in Figure 4.

Figure 4.

Data processing steps.

3.4. Digital Twin Building O&M Management Method Based on BIM

Firstly, the digital twin building O&M management framework is established, then the virtual–real interaction and control method for O&M information is described, and this is jointly used as the guiding method for building O&M. Under the guiding method, the establishment process of BIM model, the functional architecture of digital twin building O&M management platform, and the O&M process are described in detail.

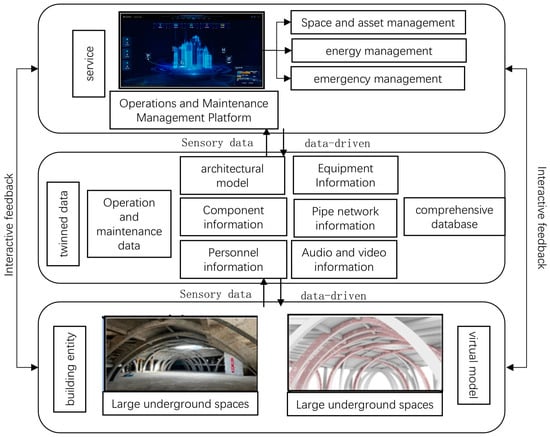

Referring to the digital twin five-dimensional model proposed by Tao Fei [20] and the intelligent construction and intelligent operation and maintenance method proposed by Liu Zhansheng based on the digital twin technology of [21], the digital-twin-based building-operation five-dimensional model framework is proposed, and this is expressed in mathematical language as (1).

MBDT = (DPE, DVE, DSs, DDD, DCN)

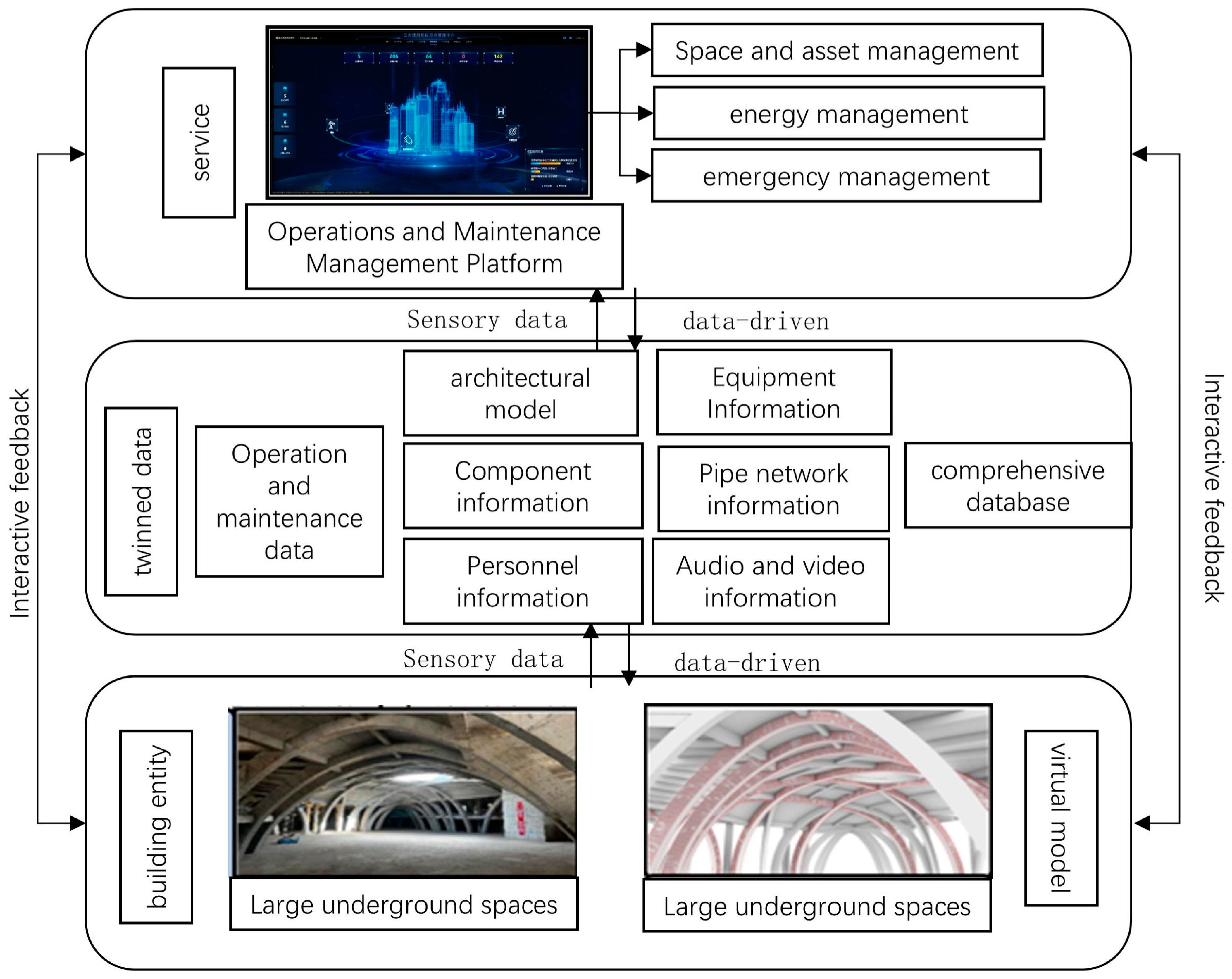

In this framework, DPE denotes the building physical entity, DVE denotes the building’s virtual model, DSs represents O&M services, DDD indicates O&M data, and DCN signifies data connectivity through the O&M platform. The building physical entity includes building physical space, component physical attributes, and building equipment information, encompassing real state information on these components throughout the building’s lifecycle and serving as the foundational data source for the building’s virtual model. The building’s virtual model has been designed for the operation and maintenance phase, covering O&M management information on the virtual entity’s components, equipment, personnel, and materials [22]. Specific components of this model include, but are not limited to, the BIM model, the 3D scanned point cloud model, and as-built delivery data in electronic format. Through iterative updates and corrections, this delivery information will ultimately form a comprehensive database of various categories for future reference. The O&M service aims to facilitate comprehensive O&M management by leveraging a multi-disciplinary collaboration platform with robust data processing capabilities. This platform is underpinned by industry standards, expert knowledge, and cutting-edge technologies such as artificial intelligence, 5G, deep learning, data fusion, and cloud computing, all of which enhance the functionality and efficiency of the O&M platform. The digital twin O&M platform acts as the central hub, ensuring connectivity between modules through data collection and transfer. Data collection is achieved via manual input, sensor reception, and network data calls. Data transfer requires a unified data collection interface, network protocols, and standardized data formats to ensure effective integration between the physical and virtual entities. The five-dimensional model framework for building O&M management based on the digital twin is illustrated in Figure 5.

Figure 5.

Five-dimensional model framework for building O&M management based on digital twin.

The detailed building O&M digital twin model establishment and O&M process includes three parts: BIM model establishment, digital twin O&M platform establishment, and virtual-reality-mapping O&M management.

(1) BIM model establishment: Information data are added in the as-built model, which is the data basis of the digital twin operation and maintenance platform and also the basis for later operation and maintenance [23]. The software used for BIM model establishment can be seen in Table 3. And modeling is carried out in accordance with the Building Information Model Design and Delivery Standard and the GB/T51301-2018 national standard. Meanwhile, to ensure consistency between the building entity and the model, the operation and maintenance managers regularly inspect the site to check potential problems and update the model to achieve the digital twin.

Table 3.

Software required for BIM model building.

(2) The digital twin platform is established with three functional modules: space and asset management, emergency management, and energy consumption management. Space management includes space planning, space allocation, human flow management, and setting up leasing and other space information according to the functional planning of shared facilities, which facilitates the expected assessment and formulation of space planning to meet future development needs. Asset management establishes and maintains an asset database associated with the model, providing an intuitively understandable source of asset management information and generating relevant asset reports in real time. The platform visualizes the location of events in the BIM model and activates the corresponding emergency plan to control the situation’s development, thereby reducing direct and indirect losses from emergencies. Combined with the energy management system, energy prepayment management system, and building-related operation data, energy consumption is categorized by areas, floors, and rooms to generate data, analyze energy consumption patterns, identify high energy consumption locations and causes, and assist in creating targeted energy management solutions.

(3) Virtual mapping operation and maintenance management: Through the virtual model of building operation and maintenance information, enabled by effective coding and classification, real-time state parameters of space and asset management, emergency management, and energy consumption management in the physical building can be quickly understood. The twin O&M management platform facilitates the identification of real-time O&M issues, allowing managers to be dispatched promptly to address building problems. Maintenance personnel can refer to pre-equipped maintenance videos on the platform to correct building components or equipment, subsequently synchronizing the data with the twin O&M management platform. This process ensures virtual and real synchronization and effective O&M management of the twin platform.

4. Case Verification

4.1. Project Case

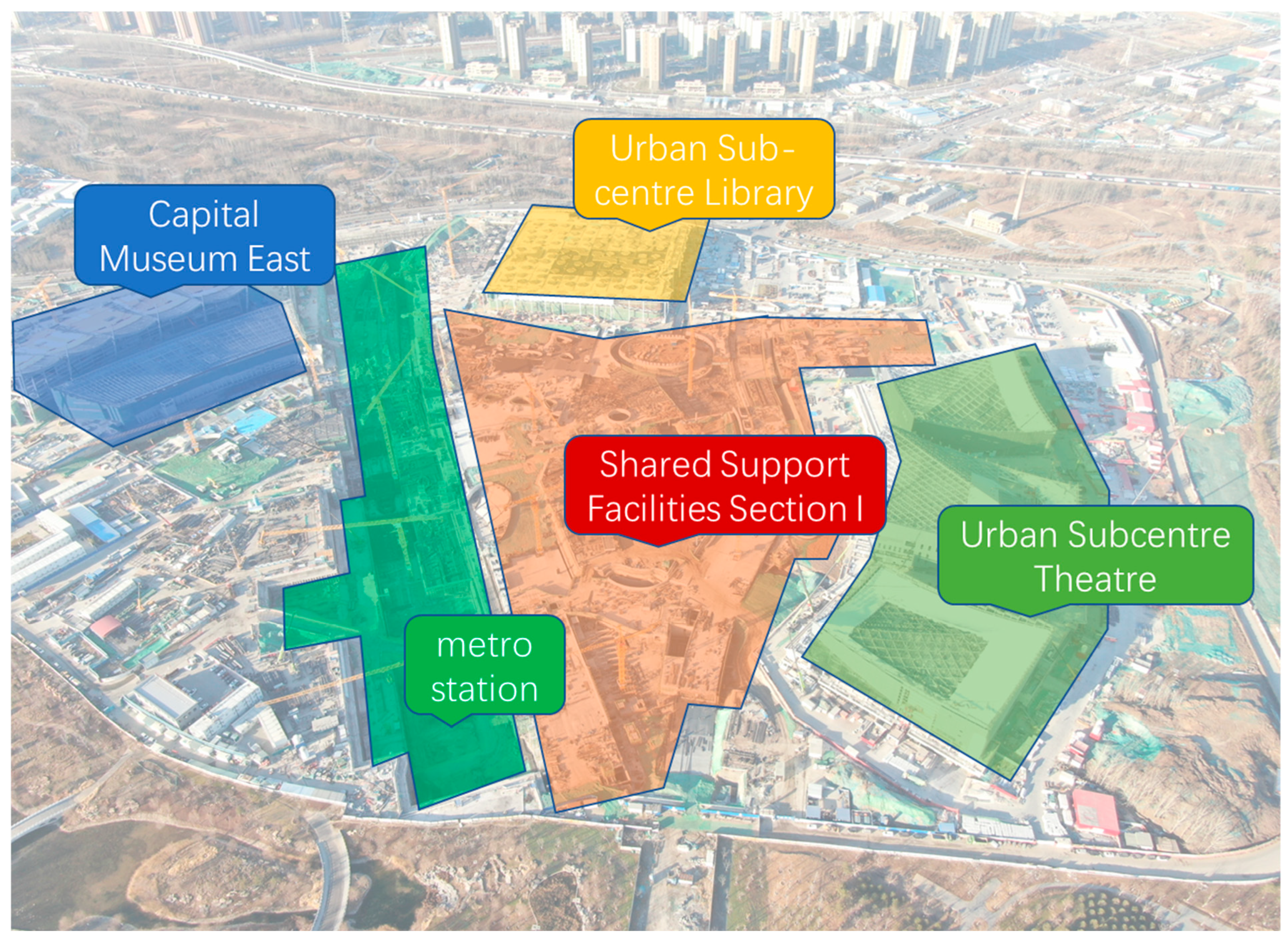

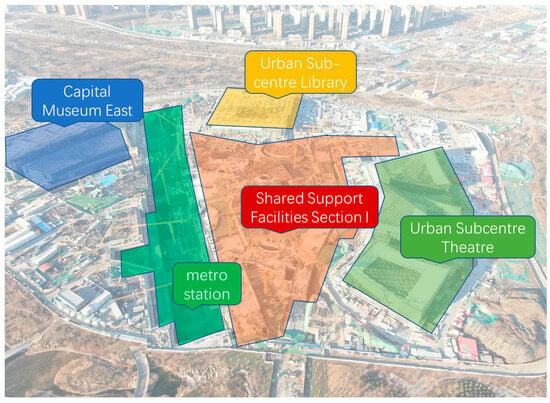

The Urban Green Centre is located at the intersection of “one axis and one belt” at Beijing’s urban sub-center. The shared facilities project is positioned as a supporting service function for the start-up area, realizing the functional linkage between the three major public buildings and the rail transit facilities and serving the three major buildings. The project’s shared supporting facilities are mainly located on the first and second underground levels, covering an area of about 154,000 square meters, with a total building scale of about 255,000 square meters. The main functions are to provide a garage, underground commercial catering, a cinema, and other comprehensive supporting service facilities. The project realizes the functional linkage between the three major public buildings and the rail transit facilities and is an important service facility for the three major buildings. The engineering plan of the shared supporting facilities of the three major buildings is shown in Figure 6.

Figure 6.

Schematic plan of the project with three major buildings sharing supporting facilities.

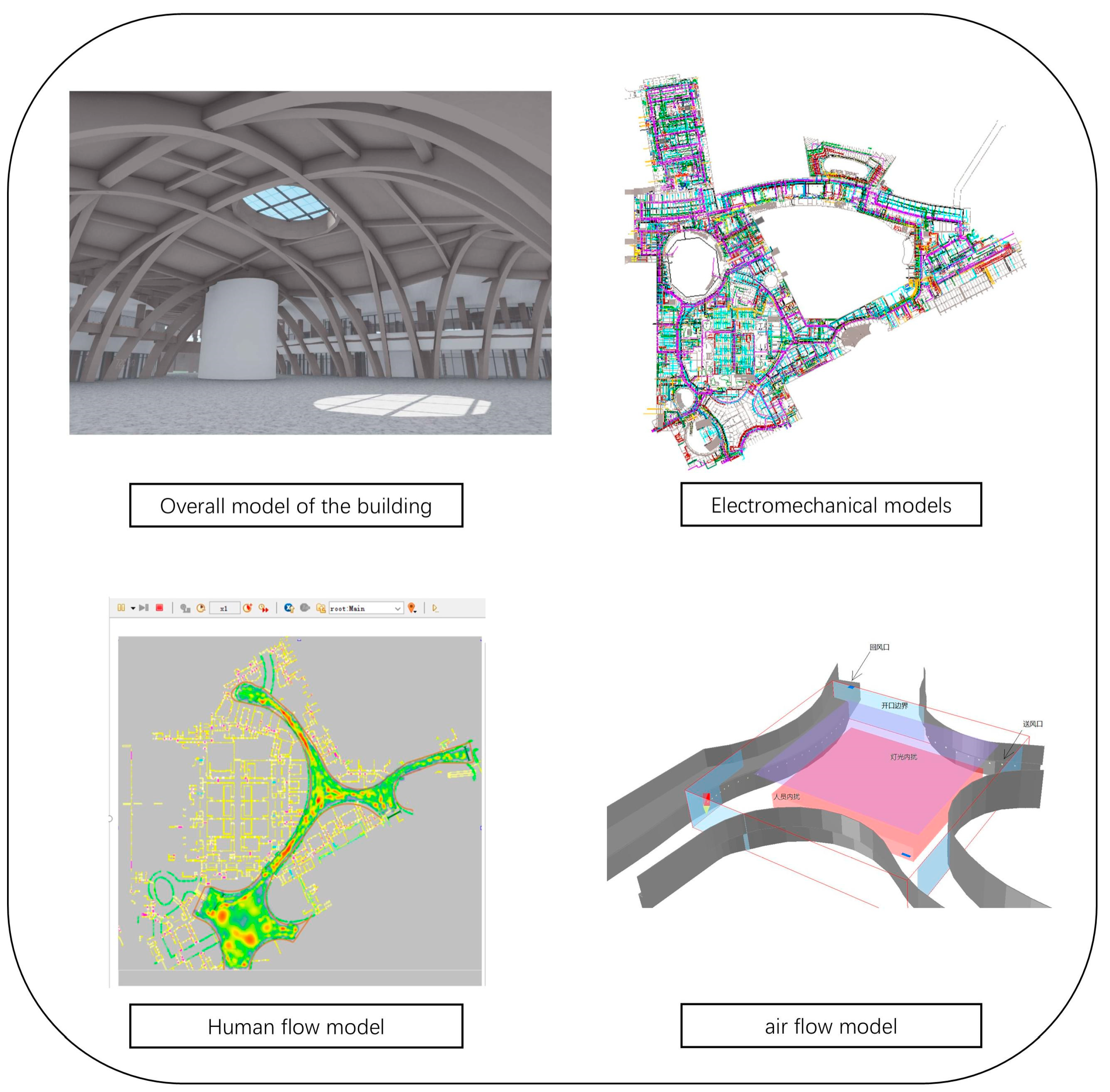

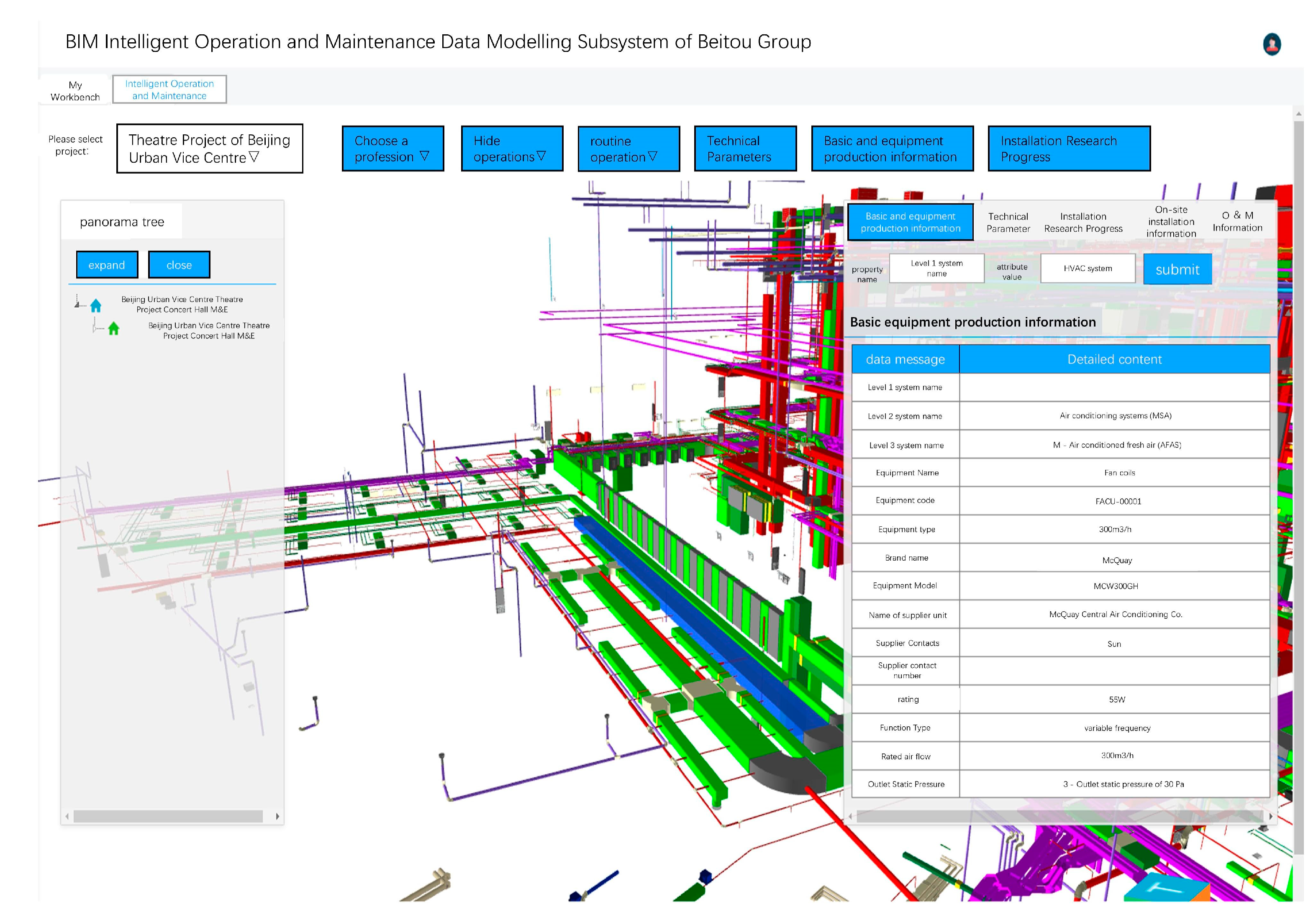

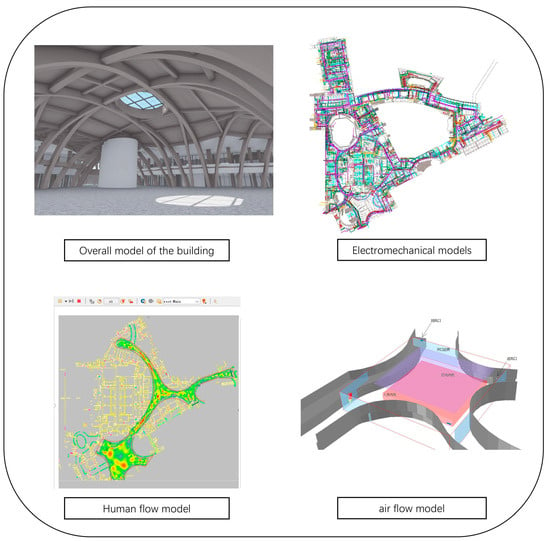

4.2. BIM Model Creation

First, one must establish a high-precision geometric model. In view of the importance of public buildings, in order to achieve digital operation and maintenance management, the completeness of the basic building and equipment information puts forward high requirements, in accordance with both the high precision of LOD500 as well as the specification requirements for the establishment of the BIM model. The BIM model covers human defense, power supply and distribution, heat, gas, heating, pipelines, and intelligent equipment; the effect of the establishment of the BIM model is shown in Figure 7.

Figure 7.

Flowchart of BIM model establishment.

Next, the BIM model data are coded, classified, and imported into the database. To facilitate digital delivery with the BIM model as the core and support subsequent operation and O&M data, four major categories of spatial information and eight major categories of equipment information are classified according to the building O&M information classification and coding method. Based on the design drawings, 376 types of professional equipment components are identified. These components are coded using an 11-layer, 20-digit code system to ensure consistency between field-collected data and the BIM model of the building and equipment information. The process employs area division to determine the same sub-item information for equipment in the same area. Finally, the encoded data from the BIM model are imported into the SQL database, forming the foundational data for the digital twin O&M management platform. The O&M data processing flowchart is illustrated in Figure 8.

Figure 8.

O&M data processing flowchart.

4.3. Digital Twin Operation and Maintenance Platform Functions and Application

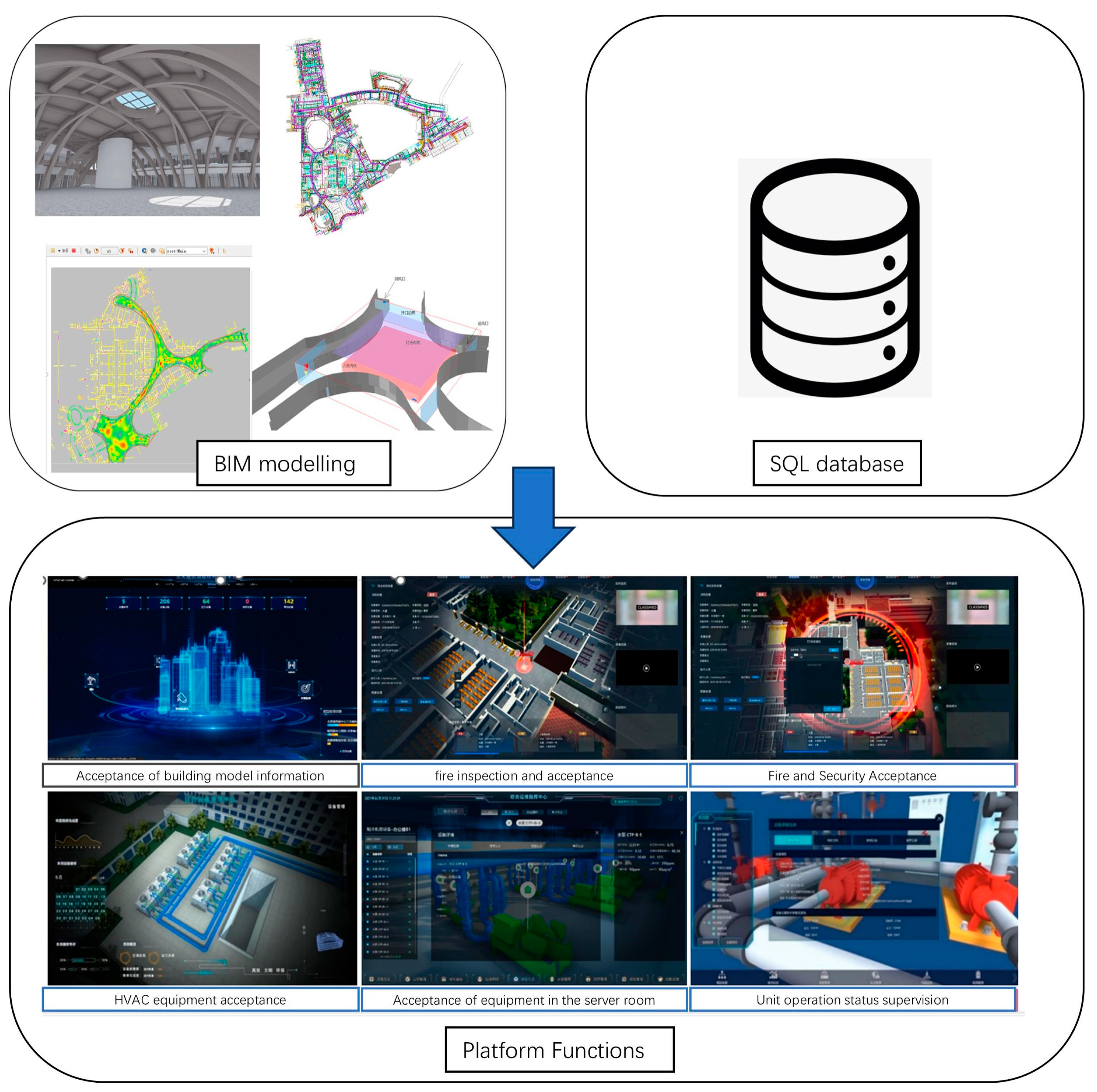

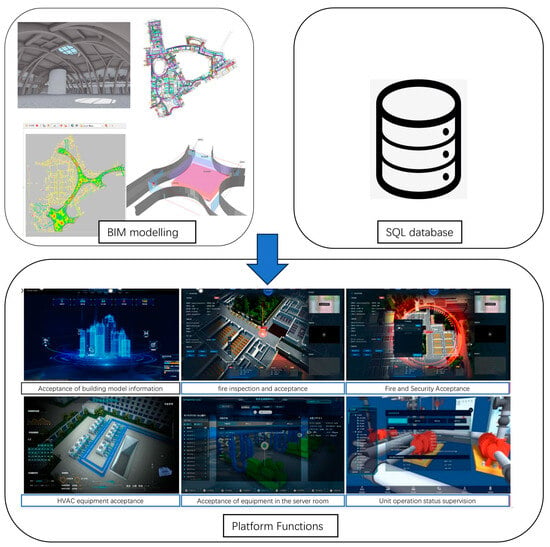

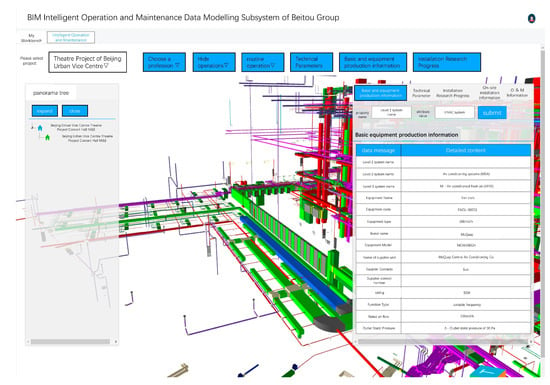

Aiming at the large underground space scenario, taking the five-dimensional model of building operation and maintenance based on digital twin technology as the guiding theory, combining the BIM model with the SQL database, a digital operation and maintenance management platform is constructed, and this has six major functions. The construction process of the digital twin O&M management platform is shown in Figure 9. The Chinese character terminology in the diagrams is due to the fact that the software used is Chinese.

Figure 9.

Digital twin operation and maintenance management platform: construction process.

The platform application in the operation and maintenance stage undertakes all the management tasks of operation and maintenance and its purpose is to provide users (including managers and users) with a safe, reliable, convenient, and healthy building environment [41]. (1) Real-time transmission of data: Considering the dynamics and continuity of the O&M process, the sensors arranged in the field are linked with IoT technology, and the data are transmitted to the twin platform via a 5G network to achieve automatic collection and the real-time transmission of monitoring data. (2) O&M process: The first interface of the platform can see the overall situation of the project, and through various types of sensors to transmit data signals, the platform can implement the detection of fire protection, HVAC, and various types of equipment in the server room. The overall steps of the operation and maintenance process are to view the data, to find problems, to rectify the problems, and to synchronize and update the real and virtual steps. The detailed functions of the digital twin O&M platform include space and asset management, emergency management, and energy consumption management.

(1) Space and asset management: This includes space planning, space allocation, human flow management, setting up leasing, and other spatial information according to the functional planning of shared facilities to facilitate the expected assessment and formulation of spatial planning to meet future development needs [42]. The physical world is closely linked to the digital world through digital twin technology, and the establishment of maintenance and model-associated asset databases can form an intuitively understandable source of asset management information, provide real-time reports on assets, and also provide a decision support and execution basis for optimizing the physical space. At the same time, the platform can provide real-time feedback on the status of assets, helping operation and maintenance personnel quickly identify problems and take measures. In practice, through the digital screen, operation and maintenance personnel can intuitively view the statuses, locations, and maintenance requirements of assets. The application of the digital twin O&M platform in space and asset management can improve asset management efficiency and reduce O&M costs. The twin platform operation and maintenance process’s space and asset management is shown in Figure 10.

Figure 10.

Twin platform operation and maintenance process: space and asset management.

(2) Emergency management: Using the twin management platform, on the one hand, one can formulate emergency plans and carry out simulation drills [42], and on the other hand, one can locate the equipment failure areas and provide maintenance personnel with maintenance assistance information. In terms of equipment maintenance, the platform integrates the attribute information and maintenance methods of the equipment, which can effectively assist the maintenance personnel carry out maintenance work, reduce the difficulty of understanding the complex electromechanical pipeline system, avoid looking up a large number of drawings and related documents, and improve the accuracy and efficiency of the daily maintenance and emergency repair; in terms of the disaster preview, the digital twin operation and maintenance management platform can use Internet of Things (IoT) technology to collect real-time temperature, humidity, human flow, and other environmental data, providing information for timely evacuation and processing. When an emergency occurs, the platform can intuitively display the location and environmental information of the event and activate the corresponding emergency plan to control the development of the situation and reduce the direct and indirect losses of the emergency [5]. The twin platform operation and maintenance process’s emergency management function is shown in Figure 11.The Chinese character terminology in the diagrams is due to the fact that the software used is Chinese.

Figure 11.

Twin platform operation and maintenance process: emergency management.

(3) Energy consumption management: The digital twin O&M management platform incorporates operational data on actual equipment, such as on energy consumption, temperature, and pressure, and generates data by dividing energy consumption by areas, floors, and rooms in a large underground space using various sensors and monitoring systems [43]. These collected data are analyzed to determine the operational status and performance of the equipment. By examining the data, the reasons for high energy consumption can be identified, allowing for optimization by adjusting operating parameters or improving the equipment design [44]. For example, if a device shows particularly high energy consumption at a certain temperature, reducing the operating temperature can lower its energy use. Additionally, digital twin technology can predict future energy consumption and equipment performance by analyzing historical data. This enables forecasting a device’s energy consumption under specific conditions. If abnormal changes in equipment parameters are detected, preemptive measures can be taken to prevent failures, thus avoiding increased energy consumption due to malfunctions. The digital twin O&M platform must continuously monitor the actual equipment’s operating status, updating and optimizing the model with new data to ensure it accurately reflects the equipment’s actual status, thereby achieving effective energy consumption management. The process of energy consumption management within the twin platform’s operation and maintenance is illustrated in Figure 12. The Chinese character terminology in the diagrams is due to the fact that the software used is Chinese.

Figure 12.

Twin platform operation and maintenance process: energy consumption management.

5. Discussion

- (1)

- Effectiveness

The digital operation and maintenance management method for large underground spaces based on digital twin technology demonstrates its significant advantages in improving information retrieval efficiency, operation and maintenance efficiency, and overall management quality. By constructing a digital twin model, the efficient classification and coding of building information can be realized and dispersed data can be effectively integrated and utilized. In practical application, the method not only improves the intelligent level of building O&M but also shows good results in specific O&M scenarios such as energy consumption management, equipment maintenance, and emergency management. For example, by analyzing the actual equipment operation data, the platform is able to optimize energy consumption management, reduce energy costs, and achieve accurate equipment maintenance. In addition, the application of digital twin technology in emergency management can quickly locate fault areas and provide effective emergency plans, improving the efficiency and accuracy of emergency responses.

- (2)

- Limitations

Although digital twin technology has significant advantages in improving O&M efficiency and management quality, there are still some limitations in its practical application. First, the digital transformation of O&M information requires a large initial investment, including hardware facilities, software development, and human resource allocation, which may constitute a large financial burden for some small- and medium-sized enterprises. Second, the current digital twin technology mainly focuses on the application of a single building or local space and has not yet formed a large-scale application system covering a whole city or a large region, which limits its application scope and effect to some extent. In addition, the classification and coding standards of building operation and maintenance information have not been fully unified, and the data compatibility and interoperability between different projects need to be improved. Finally, the ability of managers to adapt and apply new technologies also affects the promotion and application of digital twin technology and relevant training and technical support need to be strengthened.

- (3)

- Prospects

In the future, with the continuous development of digital twin technology and BIM (Building Information Modeling) technology, their application in the O&M management of large underground spaces has a bright future. Firstly, by further improving and standardizing the classification and coding methods of building O&M information, the data compatibility and sharing between different projects can be improved. Second, by combining the Internet of Things (IoT) and Artificial Intelligence (AI) technologies, a more intelligent and automated O&M management can be realized, such as via real-time data analysis and predictive maintenance, which can improve the scientificity and accuracy of O&M decisions. In addition, the application of digital twin technology on a wider scale, such as in city-level underground space management, can be explored in the future to achieve wider resource optimization and management efficiency improvement. The application of digital twin technology in the field of building O&M management will continue to deepen, providing strong technical support for the development of intelligent buildings and Smart Cities.

With the digital transformation of engineering projects, the delivered electronic data not only record all the key parameters and technical details during the construction process but also become indispensable and valuable resources in the subsequent operation and maintenance phase. The systematic preservation and effective management of these data can provide accurate technical support for future operations, helping O&M teams gain a deeper understanding of the actual state of the underground space and its historical changes, optimize maintenance strategies, prevent potential risks, improve O&M efficiency, and extend the service lives of the facilities. At the same time, these data can also provide a scientific basis for improvement and upgrading and promote the continuous improvement and innovation of large underground spaces. Therefore, the establishment of a sound electronic data management system for project delivery is a key initiative to ensure the long-term safe and reliable operation of large underground spaces.

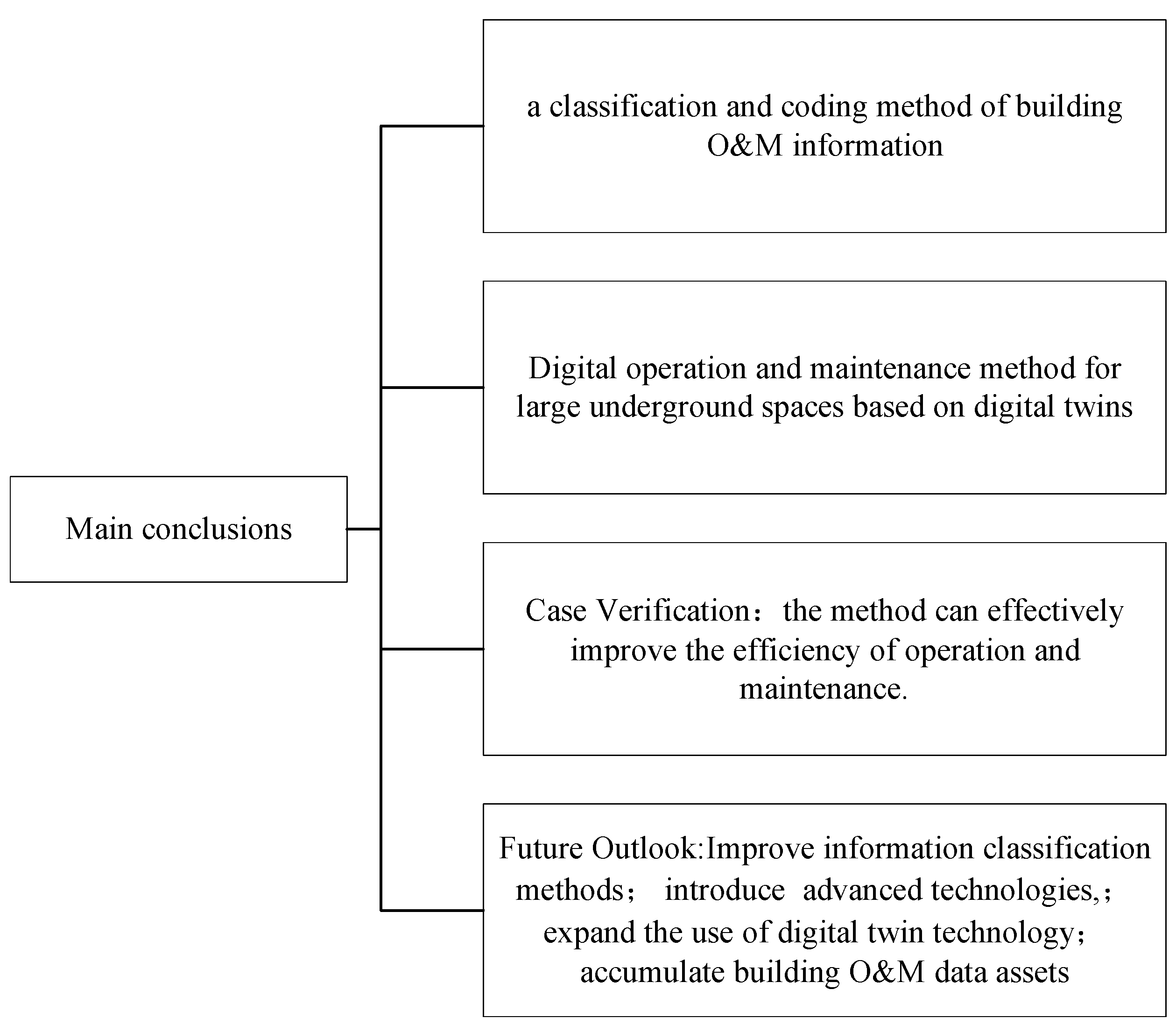

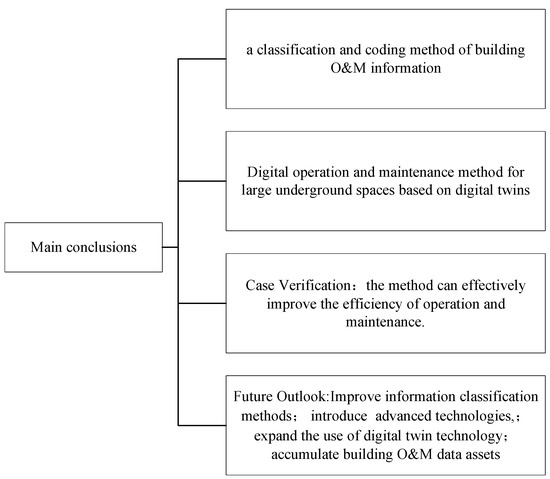

6. Conclusions

Aiming at the difficulty of operation and maintenance caused by the large volume of large underground space projects, the proposed building operation and maintenance digital twin five-dimensional model method provides a new idea for the digital operation and maintenance of large underground space projects. The main conclusions are shown in Figure 13. The following main conclusions are obtained:

Figure 13.

Main conclusions.

- (1)

- In order to achieve the effective classification of building information, a classification and coding method for building O&M information is proposed;

- (2)

- In order to improve the deficiencies of traditional building operation and maintenance, a twin model for a set of theoretical methods of digital operation and maintenance is established by using digital twin model with a large underground space as the object, and it is used as the theoretical guidance for the operation and maintenance of large underground spaces;

- (3)

- Under the guidance of the theoretical method for the twin model of digital operation and maintenance, a detailed study on the application scenarios of the operation and maintenance of large underground spaces has been carried out, combining the proposed digital delivery method with engineering cases, detailing the platform functions and application processes, and demonstrating that the method can effectively improve the efficiency of operation and maintenance;

- (4)

- In the future, the classification and coding methods of building O&M information can be further improved and standardized while the O&M process can integrate cutting-edge Internet and AI technologies and apply digital twin technology to a wider scope, with the final accumulated O&M data serving as a data asset for future continuous operation.

Author Contributions

Conceptualization, H.W.; methodology, H.W.; software, H.W.; validation, H.W., C.Y., J.Z., Y.J., Z.L. and K.Y.; writing—original draft preparation, H.W.; writing—review and editing, Z.L.; project administration, H.W.; funding acquisition, H.W. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Beijing Science and Technology plan project (Z211100004321010).

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to confidentiality concerns.

Acknowledgments

The authors would like to thank Shanghai Baoye Group Corp., Ltd. and the China University of Mining and Technology (Beijing) for their support throughout the research project.

Conflicts of Interest

Authors Wang Haitao, Yu Caizhao, Jia Yihong, and Yang Kai were employed by the company Shanghai Baoye Group Corp., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Pankratova, N.; Haiko, H.; Savchenko, I. Historical Excursion and Modern Trends of Urban Underground Development. In Modeling the Underground Infrastructure of Urban Environments: A Systematic Approach; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–23. [Google Scholar]

- Broere, W. Urban underground space: Solving the problems of today’s cities. Tunn. Undergr. Space Technol. 2016, 55, 245–248. [Google Scholar] [CrossRef]

- Schaumann, M.; Gamba, D.; Morales, H.G.; Corsini, R.; Guinchard, M.; Scislo, L.; Wenninger, J. The effect of ground motion on the LHC and HL-LHC beam orbit. Nuclear Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2023, 1055, 168495. [Google Scholar] [CrossRef]

- Artus, M.; Koch, C. Retracted: Object-Oriented Damage Information Modeling Concepts and Implementation for Bridge Inspection. J. Comput. Civ. Eng. 2022, 36, 04022029. [Google Scholar] [CrossRef]

- Cao, Y.; Kamaruzzaman, S.N.; Aziz, N.M. Building information modeling (BIM) capabilities in the operation and maintenance phase of green buildings: A systematic review. Buildings 2022, 12, 830. [Google Scholar] [CrossRef]

- Murti, C.K.; Muslim, F. Relationship between Functions, Drivers, Barriers, and Strategies of Building Information Modelling (BIM) and Sustainable Construction Criteria: Indonesia Construction Industry. Sustainability 2023, 15, 5526. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Zhao, S.; Sun, H.; Huang, Z.; Li, N.; Guo, M.; Li, X. Research on Obstacle Factors of Project Operation and Maintenance Based on BIM Technology. In Advances in Simulation and Process Modelling, Proceedings of the Second International Symposium on Simulation and Process Modelling (ISSPM 2020), Shenyang, China, 29–30 August 2020; Springer: Singapore, 2021; pp. 159–168. [Google Scholar]

- Wei, D.; Li, B.; Wang, C.; Wei, L.; Zhang, L.; Yang, J. IBMS+ BIM+ FM technology based intelligent building operation and maintenance management system design solution. In Proceedings of the 5th International Conference on Computer Information Science and Application Technology (CISAT 2022), Chongqing, China, 29–31 July 2022; SPIE: Bellingham, WA, USA, 2022; Volume 12451, pp. 1195–1204. [Google Scholar]

- Wang, L.; Li, W.; Feng, W.; Yang, R. Fire risk assessment for building operation and maintenance based on BIM technology. Build. Environ. 2021, 205, 108188. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, H.; Zhao, Z.; Bai, W.; Hu, N. Research on the Visualization of Railway Signal Operation and Maintenance Based on BIM+ GIS. Sensors 2023, 23, 5984. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Imran, A.; Cardenas-Cartagena, J.; Svennevig, P.R.; Svidt, K.; Nielsen, H.K. A Review of the Digital Twin Technology in the AEC--FM Industry. Adv. Civ. Eng. 2022, 2022, 2185170. [Google Scholar] [CrossRef]

- Mahmoud, M.; Chen, W.; Yang, Y.; Li, Y. Automated BIM generation for large-scale indoor complex environments based on deep learning. Autom. Constr. 2024, 162, 105376. [Google Scholar] [CrossRef]

- Rodríguez-Alonso, C.; Pena-Regueiro, I.; García, Ó. Digital Twin Platform for Water Treatment Plants Using Microservices Architecture. Sensors 2024, 24, 1568. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Heaton, J.; Parlikad, A.K. From BIM towards digital twin: Strategy and future development for smart asset management. In Service Oriented, Holonic and Multi-agent Manufacturing Systems for Industry of the Future; Springer: Berlin/Heidelberg, Germany, 2020; pp. 392–404. [Google Scholar]

- Jiao, Z.; Du, X.; Liu, Z.; Liu, L.; Sun, Z.; Shi, G. Sustainable Operation and Maintenance Modeling and Application of Building Infrastructures Combined with Digital Twin Framework. Sensors 2023, 23, 4182. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Lu, P.; Zhu, W.; Zhu, H.; Zhang, X. Intelligent Monitoring Platform and Application for Building Energy Using Information Based on Digital Twin. Energies 2023, 16, 6839. [Google Scholar] [CrossRef]

- Yu, G.; Lin, D.; Wang, Y.; Hu, M.; Sugumaran, V.; Chen, J. Digital Twin-enabled and Knowledge-driven decision support for tunnel electromechanical equipment maintenance. Tunn. Undergr. Space Technol. 2023, 140, 105318. [Google Scholar] [CrossRef]

- Tao, F.; Li, W.; Zhang, M. Digital Twin Five G dimensional Model and Ten Domain Applications. Comput. Integr. Manuf. Syst. 2019, 25, 1G18. [Google Scholar]

- Liu, Z.; Shi, G.; Du, X.; Jiao, Z. Intelligent operation and maintenance theory system and realisation method based on digital twin. J. Civ. Environ. Eng. 2024, 46, 46–57. [Google Scholar]

- Liu, Z.; Sun, X.; Sun, Z.; Liu, L.; Meng, X. The Digital Twin Modeling Method of the National Sliding Center for Intelligent Security. Sustainability 2023, 15, 7409. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward smart-building digital twins: BIM and IoT data integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Jacobson, C.E. Using AutoCAD for Descriptive Geometry Exercises in Undergraduate Structural Geology. Comput. Geosci. 2001, 27, 9–15. [Google Scholar] [CrossRef]

- Jadid, M.N.; Idrees, M.M. Cost estimation of structural skeleton using an interactive automation algorithm: A conceptual approach. Autom. Constr. 2007, 16, 797–805. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, X. Automatic drawing technique for horizontal projection diagrams of exploration borehole deviations. Multimed. Tools Appl. 2019, 78, 1201–1218. [Google Scholar] [CrossRef]

- Zheng, Y.; Shen, H.; Sun, C. Leveraging single-user AutoCAD for collaboration by transparent adaptation. In Proceedings of the IEEE 2009 13th International Conference on Computer Supported Cooperative Work in Design, Santiago, Chile, 22–24 April 2009; pp. 78–83. [Google Scholar]

- Yang, X.; Koehl, M.; Grussenmeyer, P. Parametric modelling of as-built beam framed structure in BIM environment. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2017, 42, 651–657. [Google Scholar] [CrossRef]

- Yang, X.G.; Wang, J. Collaborative application of computer technology in interior design. Appl. Mech. Mater. 2014, 651, 2067–2070. [Google Scholar] [CrossRef]

- Wang, D.; Lu, H. Development of a BIM Platform for the Design of Single-Story Steel Structure Factories. Buildings 2024, 14, 747. [Google Scholar] [CrossRef]

- Oti, A.H.; Tah JH, M.; Abanda, F.H. Integration of lessons learned knowledge in building information modeling. J. Constr. Eng. Manag. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Li, M.; Xiong, X.; Yin, Q. Smart City Construction Visual Simulation Application Based on Intelligent BIM Technology. Int. J. Pattern Recognit. Artif. Intell. 2021, 35, 2155014. [Google Scholar] [CrossRef]

- Cho, Y.H.; Yoo, B.H. A Study on the BasicDesign Education by the Structure Variables of Digital Modeling–Centered on Rhino 3D & CREO in the Design Education Course of Product Design. J. Digit. Des. 2014, 14, 591–604. [Google Scholar]

- Li, H. Visualizing Architectural Lighting: Creating and Reviewing Workflows Based on Virtual Reality Platforms. Ph.D. Thesis, University of Southern California, Los Angeles, CA, USA, 2017. [Google Scholar]

- Ramdhaniati, M.; Mulyanti, B. Lumion animation for digital learning: Is it applicable in both Industrial and educational contexts? IOP Conf. Ser. Mater. Sci. Eng. 2021, 1098, 022113. [Google Scholar] [CrossRef]

- Staritcyna, A.; Pollock, E.; Sokolova, E.; Martynenko, E. Energy efficiency in multi-story buildings. MATEC Web Conf. 2016, 73, 02009. [Google Scholar] [CrossRef]

- Luo, Y.; Ren, A.Z. Integration and Conversion of 3D Models from 3DS to OpenFlight. Appl. Mech. Mater. 2011, 88, 559–563. [Google Scholar] [CrossRef]

- Yang, S.; Meng, J.F.; Shi, Z.X. Pro/ENGINEER and 3DS Max Combined with Virtools for Virtual Reality Application. Adv. Mater. Res. 2014, 852, 639–643. [Google Scholar] [CrossRef]

- Amini, F.; Riche, N.H.; Lee, B.; Monroy-Hernandez, A.; Irani, P. Authoring data-driven videos with dataclips. IEEE Trans. Vis. Comput. Graph. 2016, 23, 501–510. [Google Scholar] [CrossRef] [PubMed]

- Schrimpf, B.; Dalby, M.; Mülhaupt, M.; Michel, F.; Holschbach, A.; Schiefer, U.; Ungewiss, J. Interactive training using a smartphone video retinoscope: Video article. Ophthalmologe 2020, 117, 384–388. [Google Scholar] [CrossRef] [PubMed]

- Qu, C.; Wang, D.; Liu, W.; Zhao, P. Design and Implementation of an Intelligent Operation and Maintenance Management Cloud Platform for Green Buildings Group. IOP Conf. Ser. Mater. Sci. Eng. 2019, 533, 012049. [Google Scholar]

- Yu, G.; Shi, L.; Wang, Y.; Xiong, J.; Jin, Y. A Collaborative Emergency Drill System for Urban Tunnels Using BIM and an Agent-Based Model. Sustainability 2023, 15, 13533. [Google Scholar] [CrossRef]

- Hsieh, P.C.; Hsieh, H.N.; Ho, M.C.; Lin, C.H.; Shiau, Y.C. Building Facility Management System Using Sensors and Digital Technologies. Sens. Mater. 2024, 36, 1251. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, N.; Liu, Z.; Mu, E. Construction theory for a building intelligent operation and maintenance system based on digital twins and machine learning. Buildings 2022, 12, 87. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).