Systems Engineering in the Business Case Phase to Reduce Risk in Megaprojects

Abstract

:1. Introduction

1.1. Built Environment and Physical Infrastructure Risks and Issues

1.2. Systems Engineering

1.3. Research Proposal

1.4. Research Structure

2. Research Background

2.1. Systems Definition

2.2. Systems Thinking

2.3. Systems of Systems

2.4. Systems Engineering in Megaprojects

2.5. Model-Based Systems Engineering

2.6. Information Systems Engineering

2.7. Service Systems Engineering

2.8. Systems Engineering in Artificial Intelligence

2.9. Digital Twins for Systems Engineering

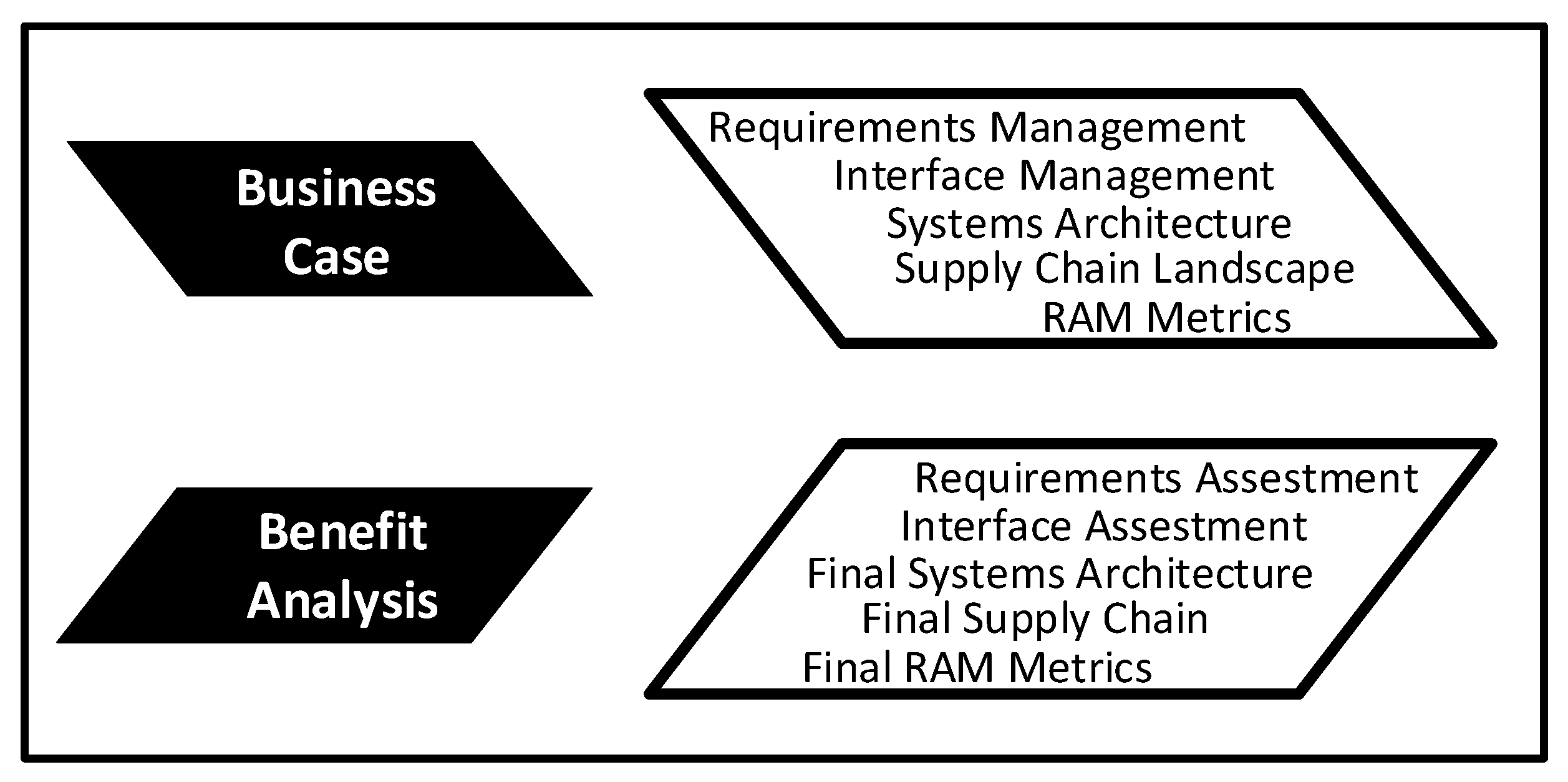

3. Systems Engineering Model in the Business Case Phase

3.1. The Business Case with Systems Engineering

3.1.1. Requirements Management

3.1.2. Interface Management

3.1.3. Systems Architecture

3.1.4. Supply Chain Landscape

3.1.5. Reliability, Availability, Maintainability, and Safety (RAMS) Targets

3.2. Outcomes of the Business Case with Systems Engineering

3.2.1. Target Operational Models

3.2.2. Design Stage

3.3. The Risks of Systems Engineering in the Business Case

3.3.1. Cost versus Quality

3.3.2. Bias versus Impartiality

3.3.3. Qualitative versus Quantitative

3.3.4. Too Much versus Too Little

3.3.5. Human versus Machine

4. Qualitative Analysis of Systems Engineering in the Business Case Phase

4.1. Canary Wharf Development

4.2. Channel Tunnel or High Speed 1

4.3. Heathrow Terminal 5

4.4. Wembley Stadium

4.5. London Olympics 2012 Games

4.6. CrossRail 1

4.7. Battersea Power Station Development

4.8. High Speed 2

4.9. Thames Tideway Tunnel

4.10. Hinkley Point C

4.11. CrossRail 2

5. Discussion

5.1. Systems Engineering for the Physical Built Environment: The Systems Architect

5.2. Systems Engineering for the Digital Built Environment: The Master Systems Integrator

5.3. Systems Engineering in Environmental, Social, and Governance (ESG)

5.4. Building Information Model/Digital Twin in Systems Engineering

5.5. Systems Engineering in Artifical Intelligence

5.6. Artifical Intelligence in Systems Engineering

5.7. Blockchain in Systems Engineering

6. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Aeronautics and Space Administration. Systems Engineering Handbook; NASA SP-2016-6105 Rev2; National Aeronautics and Space Administration: Washington, DC, USA, 2019; pp. 1–297. [Google Scholar]

- ISO/IEC/IEEE 15288:2023; Systems and Software Engineering—System Life Cycle Processes. International Organization for Standardization: Geneva, Switzerland, 2023; pp. 1–116.

- International Council on Systems Engineering. Systems Engineering Handbook: A Guide for System Life Cycle Processes and Activities—Version 4.0; International Council on Systems Engineering: San Diego, CA, USA, 2015; pp. 1–304. ISBN 978-1-118-99940-0. [Google Scholar]

- Project Management Institute. A Guide to Project Management Book of Knowledge—PMBOK Guide, 7th ed.; Project Management Institute: Newtown Square, PA, USA, 2021; pp. 1–370. [Google Scholar]

- ISO 21500:2021; Project, Programme and Portfolio Management—Context and Concepts. International Organization for Standardization: Geneva, Switzerland, 2021; pp. 1–12.

- Forsberg, K.; Mooz, H. The Relationship of System Engineering to the Project Cycle. In Proceedings of the INCOSE International Symposium, Chattanooga, TN, USA, 21–23 October 1991; pp. 57–65. [Google Scholar]

- Sheard, S. Three types of systems engineering implementation. In Proceedings of the Symposium of the International Council on Systems Engineering, Minneapolis, MN, USA, 16–20 July 2000; pp. 1–9. [Google Scholar]

- Aslaksen, E.; Delamare, M.; Fehon, K.; Godau, R.; Knott, A.; Kouassi, A.; Liefde, J. Guide for the Application of Systems Engineering in Large Infrastructure Projects; INCOSE Infrastructure Working Group: San Diego, CA, USA, 2012; pp. 1–55. [Google Scholar]

- Bahill, A.; Gissing, B. Re-evaluating Systems Engineering Concepts Using Systems Thinking. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 1998, 28, 516–527. [Google Scholar] [CrossRef]

- Davidz, H.; Nightingale, D. Enabling Systems Thinking to Accelerate the Development of Senior Systems Engineers. Syst. Eng. 2008, 11, 1–14. [Google Scholar] [CrossRef]

- Godfrey, P. Using systems thinking to learn to deliver sustainable built environments. Civ. Eng. Environ. Syst. 2010, 27, 219–230. [Google Scholar] [CrossRef]

- Adams, K.; Hester, P.; Bradley, J.; Meyers, T. Keating. Systems Theory as the Foundation for Understanding Systems. Syst. Eng. 2014, 17, 112–123. [Google Scholar] [CrossRef]

- Keating, C.; Rogers, R.; Unal, R.; Dryer, D.; Sousa, A.; Safford, R.; Peterson, W. Rabadi. System of Systems Engineering. Eng. Manag. J. 2003, 15, 36–45. [Google Scholar]

- Gorod, A.; Sauser, B.; Boardman, J. System-of-Systems Engineering Management: A Review of Modern History and a Path Forward. IEEE Syst. J. 2008, 2, 484–499. [Google Scholar] [CrossRef]

- Cloutier, R.; Griego, R. Applying Object Oriented Systems Engineering to Complex Systems. In Proceedings of the IEEE Systems Conference, Montreal, QC, Canada, 7–10 April 2008; pp. 1–6. [Google Scholar]

- Moffatt, S.; Kohler, N. Conceptualizing the built environment as a social–ecological system. Build. Res. Inf. 2008, 36, 248–268. [Google Scholar] [CrossRef]

- Davies, A.; Mackenzie, I. Project complexity and systems integration: Constructing the London 2012 Olympics and Paralympics Games. Int. J. Proj. Manag. 2014, 32, 773–790. [Google Scholar] [CrossRef]

- Geyer, P.; Stopper, J.; Lang, W.; Thumfart, M. A Systems Engineering Methodology for Designing and Planning the Built Environment—Results from the Urban Research Laboratory Nuremberg and Their Integration in Education. Systems 2014, 2, 137–158. [Google Scholar] [CrossRef]

- Nielsen, C.B.; Larsen, P.G.; Fitzgerald, J.; Woodcock, J.; Peleska, J. Systems of Systems Engineering: Basic Concepts, Model-Based Techniques, and Research Directions. ACM Comput. Surv. 2015, 48, 1–41. [Google Scholar] [CrossRef]

- Lester, H.; Smith, R. Infrastructure System Interdependencies and Built Environment Disaster Resiliency. In Proceedings of the Industrial and Systems Engineering Conference, Orlando, FL, USA, 19–22 May 2018; pp. 1486–1491. [Google Scholar]

- Davies, A.; Gann, D.; Douglas, T. Innovation in Megaprojects: Systems Integration at London Heathrow Terminal 5. Calif. Manag. Rev. 2009, 51, 101–125. [Google Scholar] [CrossRef]

- Brockmann, C. Requirements for Firms Designing Megaprojects. In Proceedings of the International Council for Research and Innovation in Building and Construction World Building Congress, Brisbane, QN, Australia, 5–9 May 2013; pp. 1–12. [Google Scholar]

- Locatelli, G.; Mancini, M.; Ishimwe, A. How Can System Engineering Improve Supplier Management in Megaprojects? Procedia Soc. Behav. Sci. 2014, 119, 510–518. [Google Scholar] [CrossRef]

- Locatelli, G.; Mancini, M.; Romano, E. Systems Engineering to improve the governance in complex project environments. Int. J. Proj. Manag. 2014, 32, 1395–1410. [Google Scholar] [CrossRef]

- Daniel, E.; Daniel, P. Megaprojects as complex adaptive systems: The Hinkley point C case. Int. J. Proj. Manag. 2019, 37, 1017–1033. [Google Scholar] [CrossRef]

- Lehtinen, J.; Peltokorpi, A.; Artto, K. Megaprojects as organizational platforms and technology platforms for value creation. Int. J. Proj. Manag. 2019, 37, 43–58. [Google Scholar] [CrossRef]

- Ninan, J.; Phillips, I.; Sankaran, S.; Natarajan, S. Systems Thinking Using SSM and TRIZ for Stakeholder Engagement in Infrastructure Megaprojects. Systems 2019, 7, 48. [Google Scholar] [CrossRef]

- Whitmore, D.; Papadonikolaki, E.; Krystallis, I.; Locatelli, G. Are megaprojects ready for the Fourth Industrial Revolution? Proc. Inst. Civ. Eng. Manag. Procure. Law 2020, 174, 49–58. [Google Scholar] [CrossRef]

- Zhu, X.-W.; Pei, A.-H.; Peng, F.; Xue, N.-N.; Zhang, W. Comprehensive Framework of Major Power Project Management Based on System Thinking. Adv. Civ. Eng. 2022, 2351779, 1–13. [Google Scholar] [CrossRef]

- Jia, F.; Xiang, P.; Chen, D. Prioritizing the Operation and Maintenance Complexity of Mega Transportation Projects Based on Systems Thinking. Journal Construction, Engineering and Management. Am. Soc. Civ. Eng. 2022, 148, 05021014. [Google Scholar]

- Ramos, A.; Ferreira, J.; Barcelo, J. Model-Based Systems Engineering: An Emerging Approach for Modern Systems. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2012, 42, 101–111. [Google Scholar] [CrossRef]

- Gräßler, I.; Wiechel, D.; Pottebaum, J. Role model of model-based systems engineering application. IOP Conf. Ser. Mater. Sci. Eng. Drive Train Technol. Conf. 2021, 1097, 012003. [Google Scholar] [CrossRef]

- Moritz, J.; Spütz, K.; Jacobs, G.; Kowalski, J.; Zerwas, T.; Berroth, J. Konrad. Automated Identification of Valid Model Networks Using Model-Based Systems Engineering. Systems 2022, 10, 250. [Google Scholar]

- Pottebaum, J.; Ebel, M.; Graessler, I. Uncovering Impact of Innovation: Continuous Stakeholder Engagement through Scenario-based Systems Engineering. In Proceedings of the Information Systems for Crisis Response and Management Conference, Münster, Germany, 25–29 May 2024; pp. 1–12. [Google Scholar]

- Deloach, S.; Wood, M.; Sparkman, C. Multiagent Systems Engineering. Int. J. Softw. Eng. Knowl. Eng. 2001, 11, 231–258. [Google Scholar] [CrossRef]

- Carlock, P.; Fenton, R. System of Systems (SoS) enterprise systems engineering for information-intensive organizations. Syst. Eng. 2001, 4, 242–261. [Google Scholar] [CrossRef]

- Castroa, J.; Kolpb, M.; Mylopoulos, J. Towards requirements-driven information systems engineering: The Tropos project. Inf. Syst. 2002, 27, 365–389. [Google Scholar] [CrossRef]

- Baxter, G.; Sommerville, I. Socio-technical systems: From design methods to systems engineering. Interact. Comput. 2011, 23, 4–17. [Google Scholar] [CrossRef]

- Tien, J.; Berg, D. A case for service systems engineering. J. Syst. Sci. Syst. Eng. 2003, 12, 13–38. [Google Scholar] [CrossRef]

- Tsai, W. Service-Oriented System Engineering: A New Paradigm. In Proceedings of the IEEE International Workshop on Service-Oriented System Engineering, Beijing, China, 20–21 October 2005; pp. 1–4. [Google Scholar]

- Böhmann, T.; Leimeister, J.; Möslein, K. Service Systems Engineering a Field for Future Information Systems Research. Bus. Inf. Syst. Eng. 2014, 6, 73–79. [Google Scholar] [CrossRef]

- Ozkaya, I. What Is Really Different in Engineering AI-Enabled Systems? IEEE Softw. 2020, 37, 3–6. [Google Scholar] [CrossRef]

- Katzung, S.; Cinkaya, H.; Kizgin, U.; Savinov, A.; Baschin, J.; Vietor, T. AI-based analysis and linking of technical and organisational data using graph models as a basis for decision-making in systems engineering. Proc. Des. Soc. 2024, 4, 2625–2634. [Google Scholar] [CrossRef]

- Campean, F.; Yildirim, U.; Korsunovs, A.; Doikin, A. Extending the function failure modes taxonomy for intelligent systems with embedded AI components. Proc. Des. Soc. 2024, 4, 1949–1958. [Google Scholar] [CrossRef]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable Digital Twins Streamlining Simulation-Based Systems Engineering for Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- Madni, A.; Madni, C.; Lucero, S. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Bolshakov, N.; Badenko, V.; Yadykin, V.; Celani, A.; Fedotov, A. Digital twins of complex technical systems for management of built environment. IOP Conf. Ser. Mater. Sci. Eng. 2020, 869, 1–8. [Google Scholar] [CrossRef]

- Loaiza, J.; Cloutier, R.; Lippert, K. Proposing a Small-Scale Digital Twin Implementation Framework for Manufacturing from a Systems Perspective. Systems 2023, 11, 41. [Google Scholar] [CrossRef]

- Flyvbjerg, B.; Skamris, M.; Buhl, S. Underestimating Costs in Public Works Projects. Error or Lie? J. Am. Plan. Assoc. 2002, 68, 279–295. [Google Scholar] [CrossRef]

- Flyvbjerg, B.; Skamris, M.; Buhl, S. What Causes Cost Overrun in Transport Infrastructure Projects? Transp. Rev. 2004, 24, 3–18. [Google Scholar] [CrossRef]

- Flyvbjerg, B.; Bruzelius, N.; Rothengatter, W. Megaprojects and Risk, An Anatomy of Ambition; Cambridge University Press: Cambridge, UK, 2003; pp. 1–207. [Google Scholar]

- Flyvbjerg, B. What You Should Know About Megaprojects and Why: An Overview. Proj. Manag. J. 2014, 45, 6–19. [Google Scholar] [CrossRef]

- Flyvbjerg, B.; Gardner, D. How Frank Gehry Delivers on Time and on Budget: Lessons from the Master Architect in Managing Big Projects. Harv. Bus. Rev. 2023, 1–13. Available online: https://hbr.org/2023/01/how-frank-gehry-delivers-on-time-and-on-budget (accessed on 20 August 2024).

- Sanso, J.; Martin, D. Benefits of Systems Engineering in Large Infrastructure Projects: The much-anticipated empirical proof. In Proceedings of the INCOSE International Symposium, Detroit, MI, USA, 25–30 June 2022; Volume 32, pp. 514–528. [Google Scholar]

- Brown, J. If You Build it, They Will Come: The Role of Individuals in the Emergence of Canary Wharf, 1985–1987. Lond. J. 2017, 42, 70–92. [Google Scholar] [CrossRef]

- Goldsmith, H.; Boeuf, P. Digging beneath the iron triangle: The Chunnel with 2020 hindsight. J. Mega Infrastruct. Sustain. Dev. 2019, 1, 79–93. [Google Scholar]

- Omega Centre, Centre for Mega Projects in Transport Development. UK Channel Tunnel Rail Link Case Study; Bartlett School of Planning: London, UK, 2008; pp. 1–140. [Google Scholar]

- Judd, R.; Kelsey, D. System Integration Management on the CTRL. In World Best Metro Practice: Meilleur Metro Mondiale; 2015; pp. 1–10. Available online: https://www.icevirtuallibrary.com/doi/epdf/10.1680/wbmp.32101.0014 (accessed on 20 August 2024).

- Franklin, J. British Rail’s Channel Tunnel (1993) Project: Overview and Management. Proc. Inst. Civ. Eng. Transp. 1998, 129, 53–71. [Google Scholar] [CrossRef]

- Bourn, J. Improving Public Services through Better Construction; National Audit Office: London, UK, 2005; pp. 1–58. [Google Scholar]

- House of Commons. The Opening of Heathrow Terminal 5; House of Commons Transport Committee: Dublin, Ireland, 2008; pp. 1–74. [Google Scholar]

- Institute of Project Management. Wembley Stadium—A Badly Run Project with a Good Outcome! Institute of Project Management: Dublin, Ireland, 2020; pp. 1–10. [Google Scholar]

- Urban Land Institute. Wembley Park Case Study; Urban Land Institute: Washington, DC, USA, 2021; pp. 1–12. [Google Scholar]

- Hughes, D. The Long-Term Legacy for the UK from the Olympic and Paralympic Games; House of Lords Library Note: London, UK, 2012; pp. 1–82. [Google Scholar]

- Grant Thornton, Ecorys, Loughborough University, Oxford Economics, Future Inclusion. Meta-Evaluation of the Impacts and Legacy of the London 2012 Olympic Games and Paralympic Games; Department of Media Culture and Sport: London, UK, 2013; pp. 1–256. [Google Scholar]

- Cross London Rail Links Ltd. Strategic Rail Authority and Transport for London. The Crossrail Business Case; Cross London Rail Links Ltd.: London, UK, 2003; pp. 1–80. [Google Scholar]

- Duncombe, D.; Robins, P.; Sexton, C. CrossRail Systems Integration Management Plan; 2011; pp. 1–21. Available online: https://learninglegacy.crossrail.co.uk/wp-content/uploads/2018/08/7G-001_01-System-Integration-Management-Plan.pdf (accessed on 20 August 2024).

- Tyner, D. CrossRail Systems Integration—Lessons Learned and Good Practice in Managing Interdisciplinary Systems Integration through Each Stage of the CrossRail Programme; CrossRail Learning Legacy: London, UK, 2021; pp. 1–10. [Google Scholar]

- Department for Transport. High Speed Two Limited. The Economic Case for HS2. Cost and Risk Status Report; Department for Transport: London, UK, 2013; pp. 1–51. [Google Scholar]

- Department for Transport. Full Business Case, High Speed 2 Phase One; Department for Transport: London, UK, 2020; pp. 1–134. [Google Scholar]

- Department for Environment Food & Rural Affairs. Creating a River Thames Fit for Our Future an Updated Strategic and Economic Case for the Thames Tideway Tunnel; Department for Environment Food & Rural Affairs: London, UK, 2015; pp. 1–22. [Google Scholar]

- National Audit Office. Review of the Thames Tideway Tunnel; Department for Environment, Food & Rural Affairs: London, UK, 2017; pp. 1–48. [Google Scholar]

- Department for Business, Energy & Industrial Strategy. Hinkley Point C Wider Benefits Realisation Plan; Department for Business, Energy & Industrial Strategy: London, UK, 2018; pp. 1–26. [Google Scholar]

- National Audit Office. Hinkley Point C; Department for Business, Energy & Industrial Strategy: London, UK, 2017; pp. 1–81. [Google Scholar]

- Haylen, A. Crossrail 2; House of Commons Library: London, UK, 2019; pp. 1–28. [Google Scholar]

- Pwc. Crossrail 2 Funding and Financing Study; Pwc: London, UK, 2014; pp. 1–120. [Google Scholar]

| Project | Schedule | Cost | Systems Engineering |

|---|---|---|---|

| Canary Wharf Development | Start: 1988 End: 1991 | Initial: N/A Final: N/A | Business case: No Design and build: No |

| Channel Tunnel | Start: 1988 End: 1994 | Initial: GBP 5.5 bn Final: GBP 9.0 bn | Business case: No Design and build: Yes |

| Heathrow Terminal 5 | Start: 2002 End: 2008 | Initial: GBP 4.0 bn Final: GBP 4.3 bn | Business case: No Design and build: No |

| Wembley Stadium | Start: 2003 End: 2007 | Initial: N/A Final: GBP 789 mn | Business case: No Design and build: No |

| London 2012 Olympics Games | Start: 2005 End: 2012 | Initial: GBP 4.0 bn Final: GBP 8.9 bn | Business case: No Design and build: Yes |

| CrossRail 1 | Start: 2009 End: 2022 | Initial: GBP 6.9 bn Final: GBP 18.8 bn | Business case: No Design and build: Yes |

| Battersea Development | Start: 2013 End: 2022 | Initial: GBP 9.0 bn Final: N/A | Business case: No Design and build: No |

| High Speed 2 | Start: 2017 Expected 2033 | Initial: GBP 50.1 bn Expected: GBP 98 bn | Business case: No Design and build: Yes |

| Thames Tideway Tunnel | Start: 2016 Expected End: 2025 | Initial: GBP 3.8 bn Final: GBP 5.0 bn | Business case: No Design and build: Yes |

| Hinkley Point C | Start: 2017 Expected End: 2030 | Initial: GBP 18 bn Final: GBP 35 bn | Business case: No Design and build: No |

| CrossRail 2 | Expected Start: 2023 Expected End: 2030s | Initial: GBP 32.6 bn Expected: GBP 45 bn | Business case: No Design and build: N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano, W. Systems Engineering in the Business Case Phase to Reduce Risk in Megaprojects. Buildings 2024, 14, 2585. https://doi.org/10.3390/buildings14082585

Serrano W. Systems Engineering in the Business Case Phase to Reduce Risk in Megaprojects. Buildings. 2024; 14(8):2585. https://doi.org/10.3390/buildings14082585

Chicago/Turabian StyleSerrano, Will. 2024. "Systems Engineering in the Business Case Phase to Reduce Risk in Megaprojects" Buildings 14, no. 8: 2585. https://doi.org/10.3390/buildings14082585